Fire-insulation flame-retardant polyester material and preparation method thereof

A flame-retardant polyester and fire-proof technology, which is applied in the field of flame-retardant polyester materials and their preparation, can solve the problems of easy deformation and burn-through, failure to block flames, and limited use, so as to improve melting strength and carbon formation The effect of density and method is simple and easy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

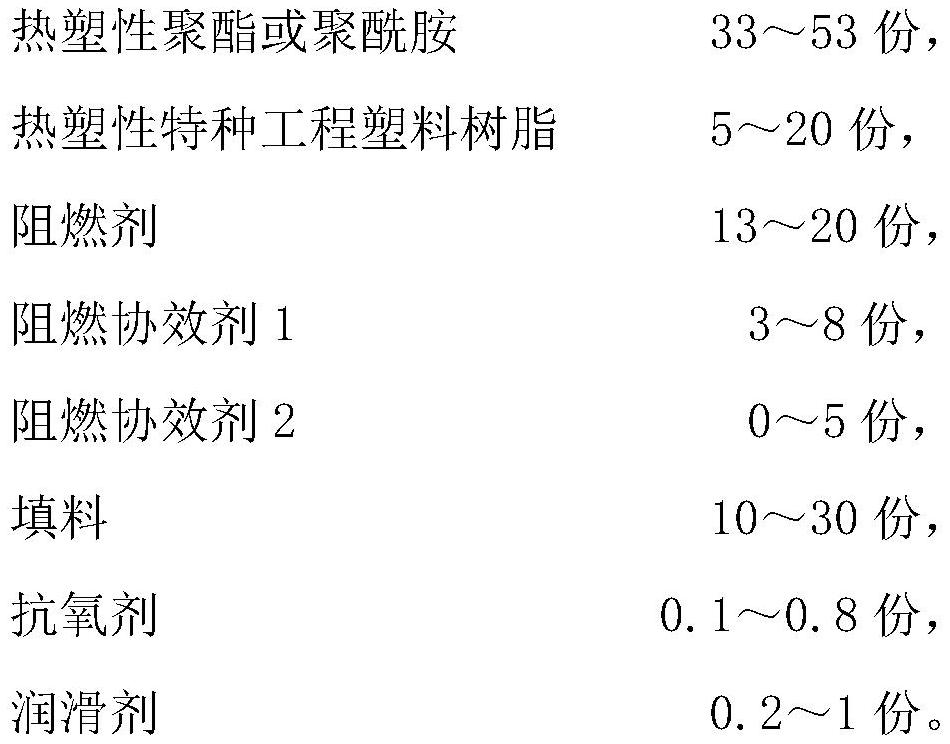

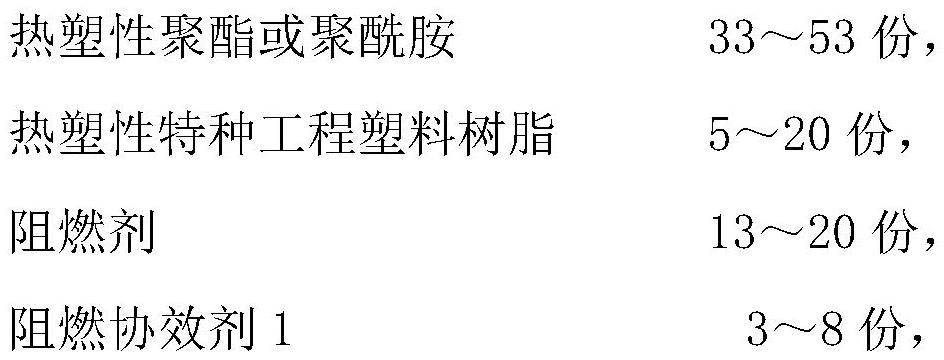

[0028] Examples 1-5 provide a kind of flame-resistant flame-retardant polyester material, and its formulation ratio is shown in Table 1 (parts by weight).

[0029] Described resin processing method is as follows:

[0030] a. Add thermoplastic polyester material, PPS resin, flame retardant, flame retardant synergist, antioxidant and lubricant into the mixing mixer for mixing

[0031] b. Add the mixture obtained in step (b) to the main feeding port, and at the same time add fillers to the side feeding ports, and blend and granulate through a twin-screw extruder to obtain a flame-resistant flame-retardant polyester material. The barrel temperature of the twin-screw extruder is 220-270° C., and the screw speed is 300 rpm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com