Patents

Literature

110results about How to "High carbonation rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process For Producing Spherical Carbon Material

InactiveUS20070212610A1Good yieldGood sphericityAlkali metal halidesSecondary cellsNon aqueous electrolytesElectrode material

A process for producing a spherical carbon material, comprising: subjecting a spherical vinyl resin to an oxidation treatment in an oxidizing gas atmosphere to obtain a spherical carbon precursor, and carbonizing the spherical carbon precursor at 1000-2000° C. in a non-oxidizing gas atmosphere. The thus-obtained spherical carbon material exhibits excellent performances, including high output performance and durability, when used, e.g., as a negative electrode material for non-aqueous electrolyte secondary batteries.

Owner:KUREHA KAGAKU KOGYO KK

Method for preparing carbide film by carbonizing graphene reinforced polyimide resin

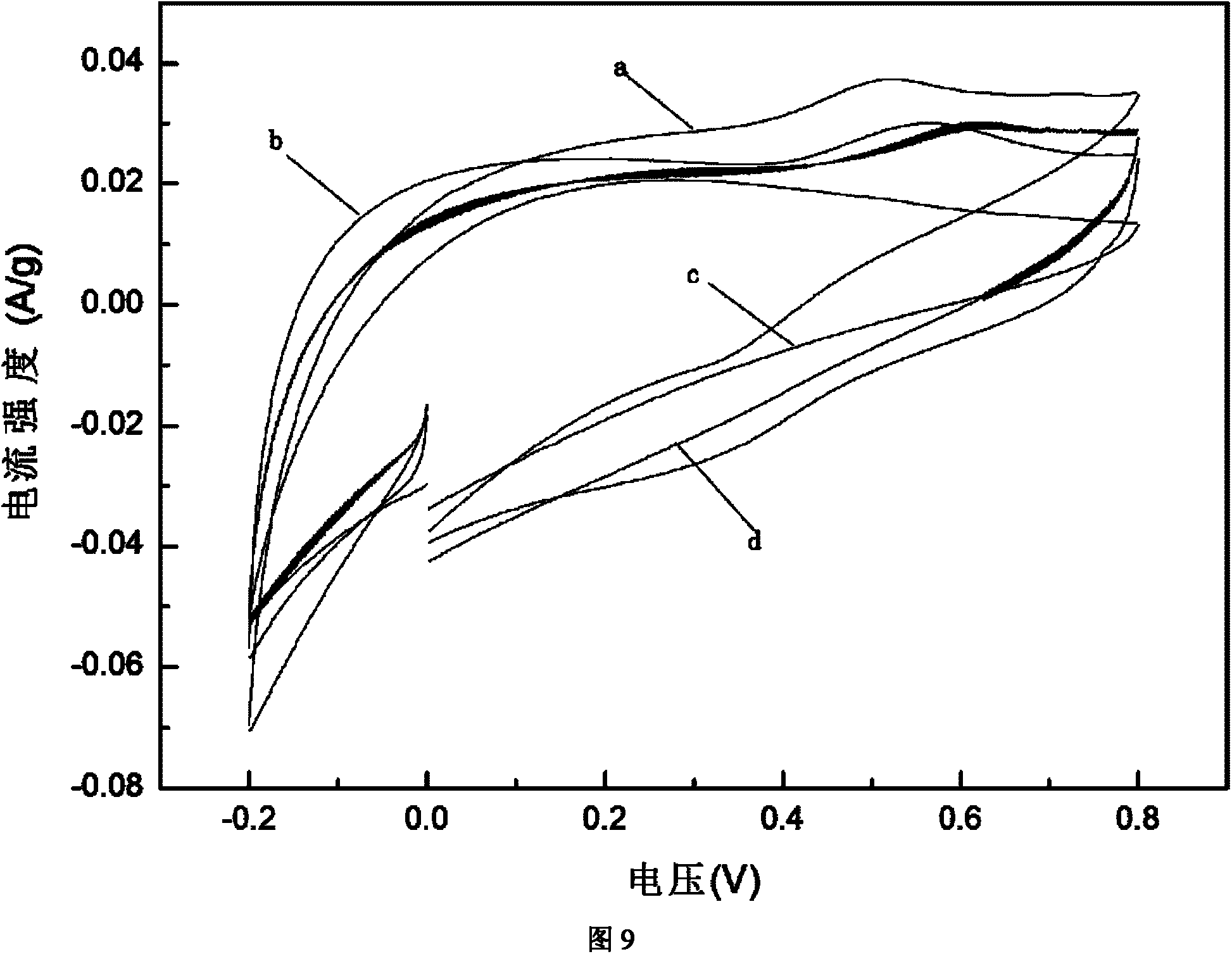

ActiveCN102560453AIncrease internal stressReduce brittlenessSolid/suspension decomposition chemical coatingCapacitancePolymer science

The invention discloses a method for preparing a carbide film by carbonizing graphene reinforced polyimide resin, and relates to a method for preparing a carbide film. The method solves the technical problems of high carbonizing temperature, high energy consumption, long carbonizing period and low carbonizing rate and low strength of the carbide film in the conventional method for preparing the carbide film. The method comprises the following steps of: 1, adding 4,4'-diamino diphenyl ether (ODA) and 3,3',4,4'-benzophenonetetracarboxylic dianhydride (BTDA) into N,N-dimethyl acetamide (DMAC), and performing mechanical stirring to obtain a polyamide acid (PAA) solution; 2, adding graphene into the PAA solution, and performing in-situ polymerization reaction to obtain a solution A; 3, spreading the solution A on a clean glass plate, heating to the temperature of 60 DEG C and preserving the heat for 2 hours, heating to the temperature of 100 DEG C and preserving the heat for 1 hour, heating to the temperature of 200 DEG C and preserving the heat for 1 hour, heating to the temperature of 300 DEG C and preserving the heat for 1 hour, and thus obtaining a composite film; and 4, carbonizing, naturally cooling to room temperature, and thus obtaining the carbide film. The carbide film has excellent mechanical properties; and because the adding proportion of the graphene is increased, the mechanical properties of the carbide film are improved, the specific capacitance of the graphene is also improved, and the carbide film is suitable to be used as an electrode material.

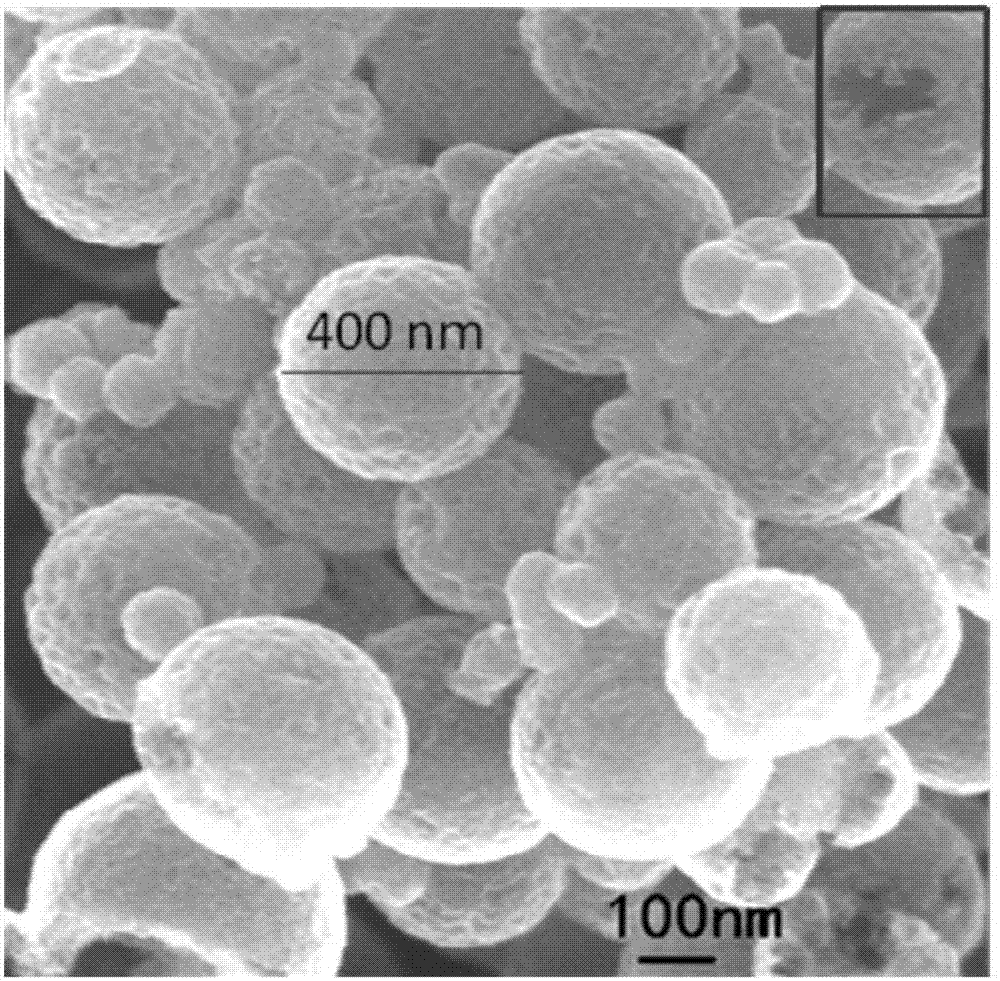

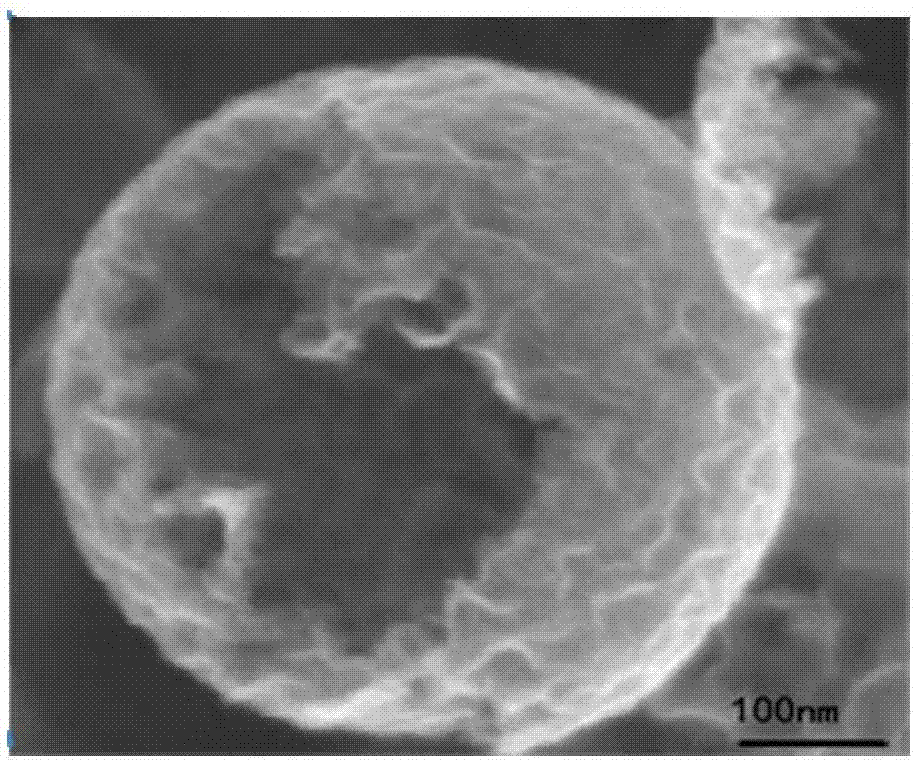

Nitrogen-doped porous hollow carbon sphere carbon dioxide adsorption material as well as preparation method and application thereof

ActiveCN106861618AWide variety of sourcesImprove biological activityOther chemical processesAlkali metal oxides/hydroxidesUltrasonic oscillationNitrogen doped

The invention relates to a nitrogen-doped porous hollow carbon sphere carbon dioxide adsorption material as well as a preparation method and application thereof. The preparation method comprises the following steps: adding SiO2 sphere flowers into mixed liquid of deionized water, absolute ethyl alcohol and ammonia water, and carrying out ultrasonic oscillation until the SiO2 sphere flowers are completely dispersed; and then adding a dopamine hydrochloride water solution, uniformly stirring at the room temperature, filtering, washing, drying, and processing at 700-900 DEG C for 2-4 hours in a N2 atmosphere so as to obtain nano-composite spheres; and finally impregnating the nano-composite spheres in hydrofluoric acid to remove the SiO2 sphere flowers, filtering, washing, and drying, so as to obtain the nitrogen-doped porous hollow carbon sphere CO2 adsorption material. The adsorption material is a porous hollow carbon sphere, the particle sizes of porous hollow nano-carbon spheres are about 400nm, the porous hollow nano-carbon spheres are uniform and regular, and the adsorption material has high nitrogen content, adsorptive property, specific surface area and pore volume and high-dispersed regular appearance, the surface of the adsorption material contains rich amino active sites, and the adsorption material can be applied to efficient adsorption of industrial CO2.

Owner:SHAANXI YUTENG IND

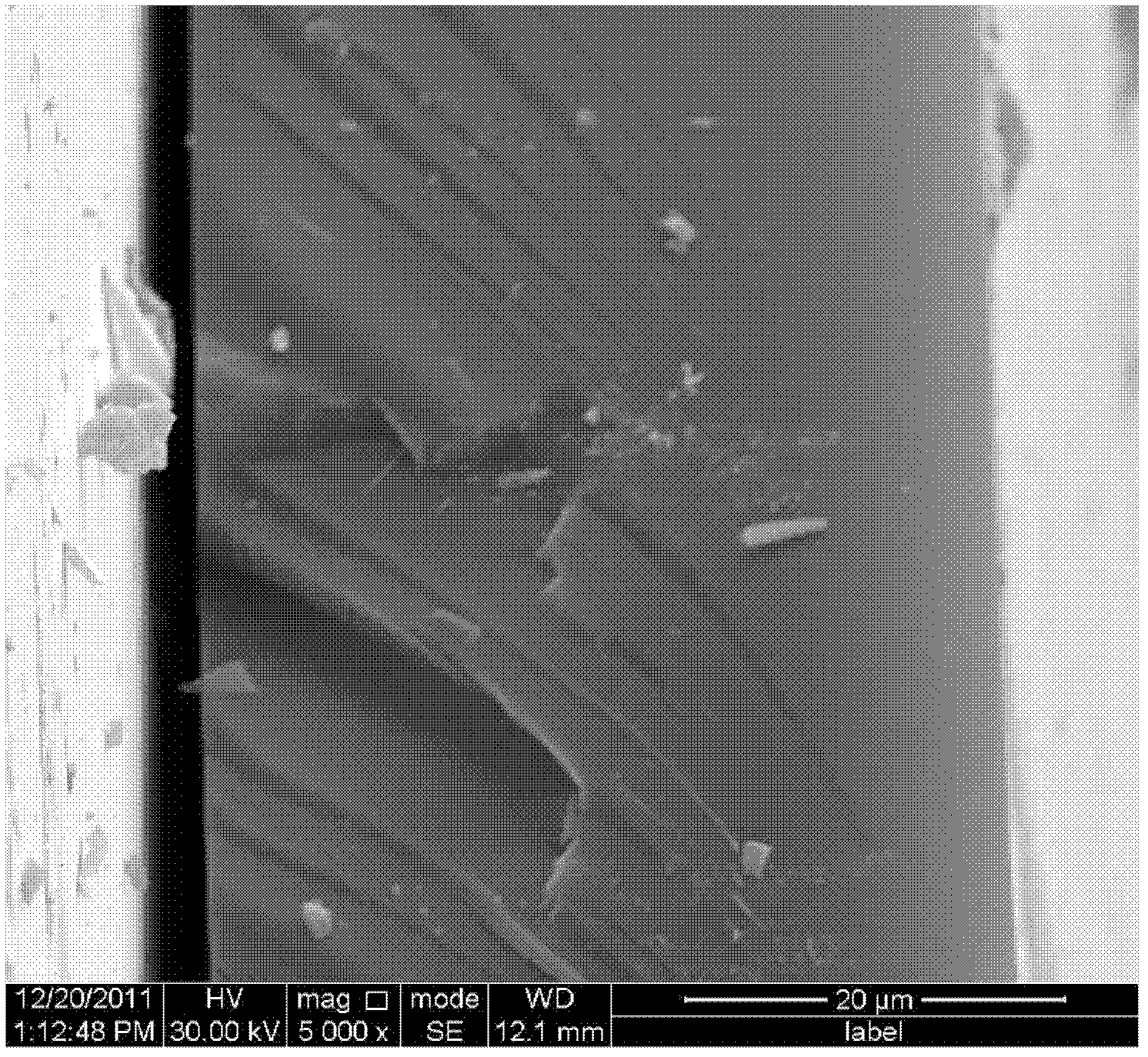

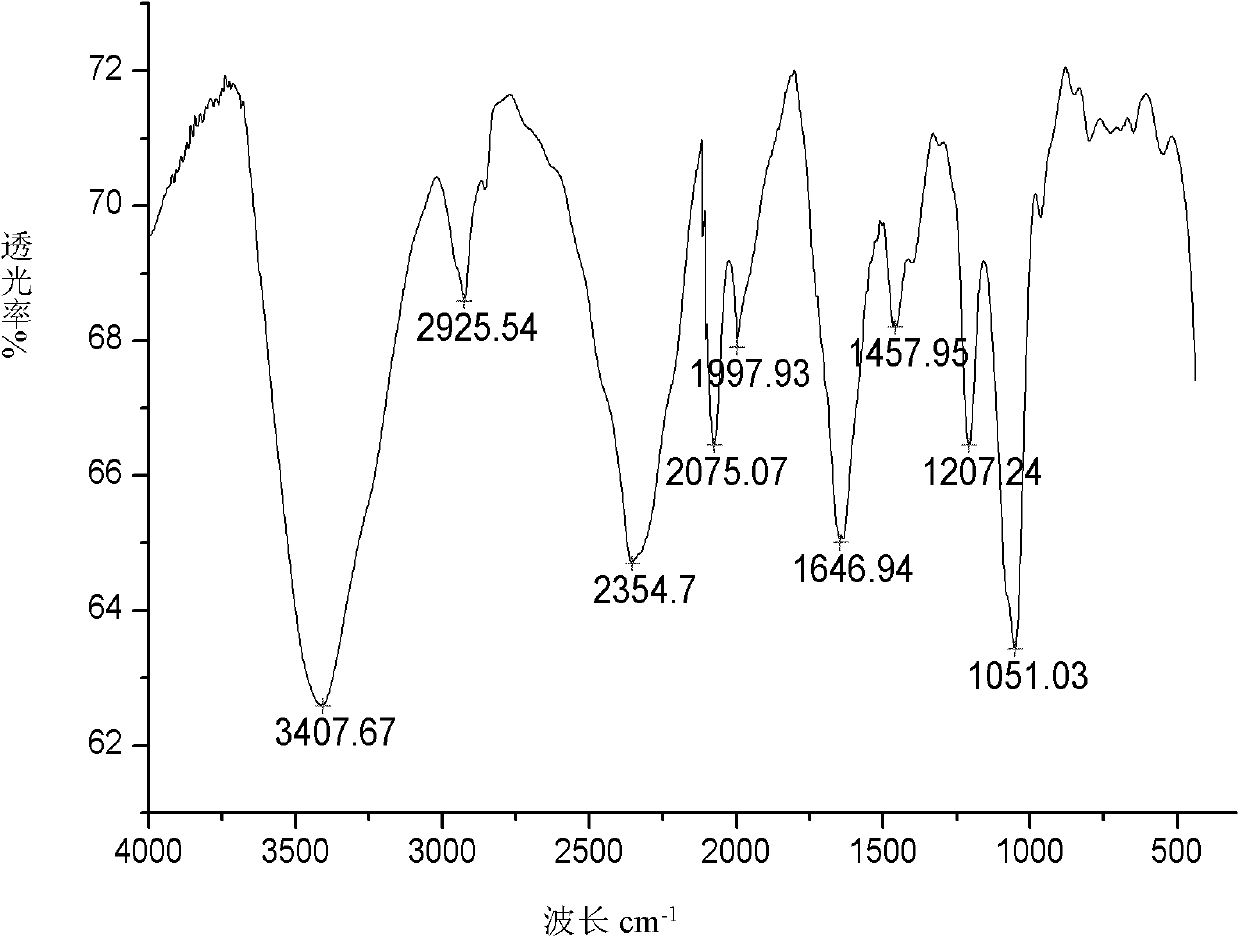

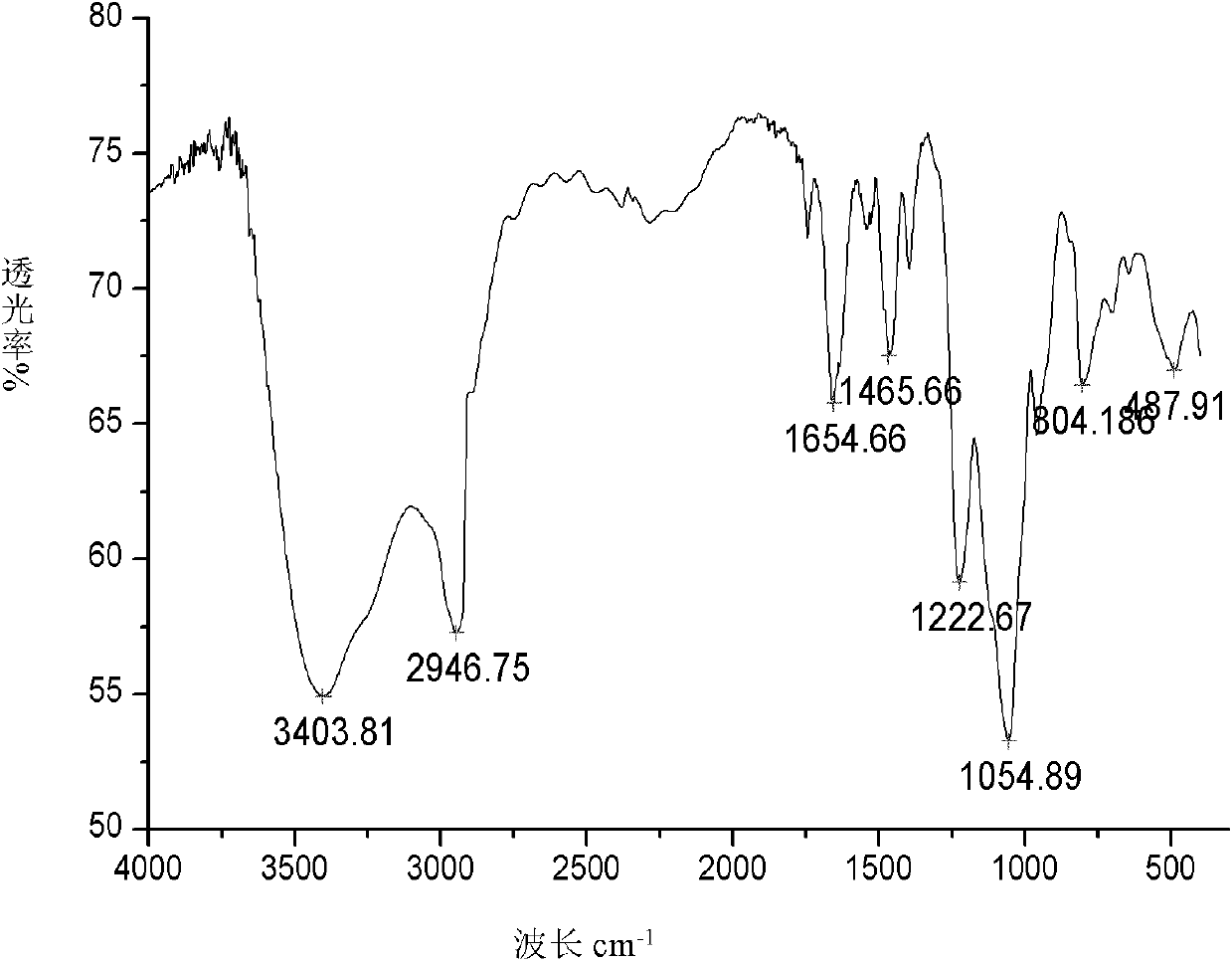

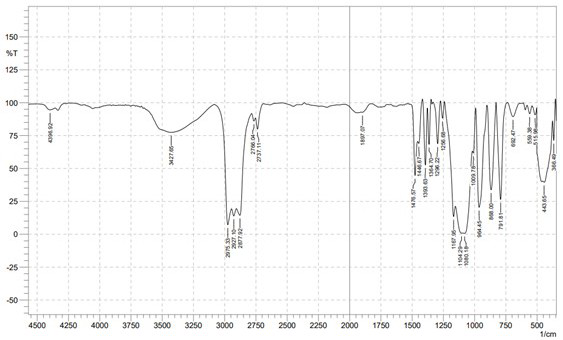

Preparation method of polyimide fibers

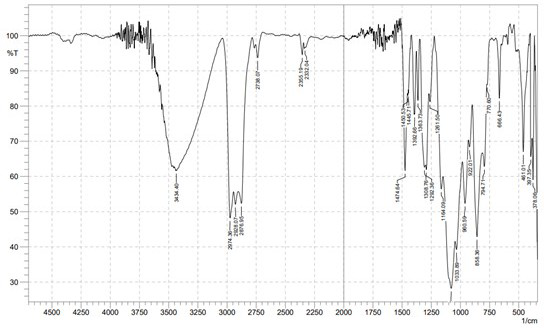

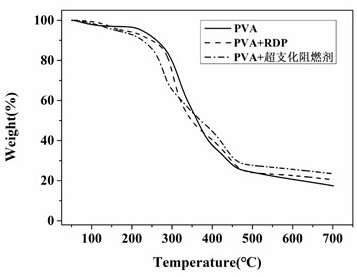

ActiveCN102766919AHigh carbonation rateInhibit the combustion chain reactionMonocomponent synthetic polymer artificial filamentGas phaseTriphenylphosphine oxide

The invention provides a preparation method of polyimide fibers. The method includes performing polymerization reaction to dianhydride and diamine in an aprotic polar solvent to obtain a polyamide acid spinning solution. The diamine comprises one or two of phenyl phosphonic acid (p-aminobenzene) diester and 3, 3'-diamine triphenylphosphine oxide; the polyamide acid spinning solution is squeezed out through a spinneret orifice and enters a coagulating bath to be coagulated to obtain polyamide acid fibers; the polyamide acid fibers are subjected to thermal amination process to obtain polyimide primary fibers; and the polyimide primary fibers are subjected to thermal draft process to obtain polyimide fibers. Phosphorus is contained in the molecular structure of the obtained polyimide fibers, so that not only the char yield of the polyamide fibers is high at a high temperature, but also the polyamide fibers can generate volatile phosphorus compounds to inhibit combustion chain mode reaction in a gas phase and have a superior flame retardant property. Experimental results show that the limit oxygen index of the polyamide fibers is 42 to 50.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

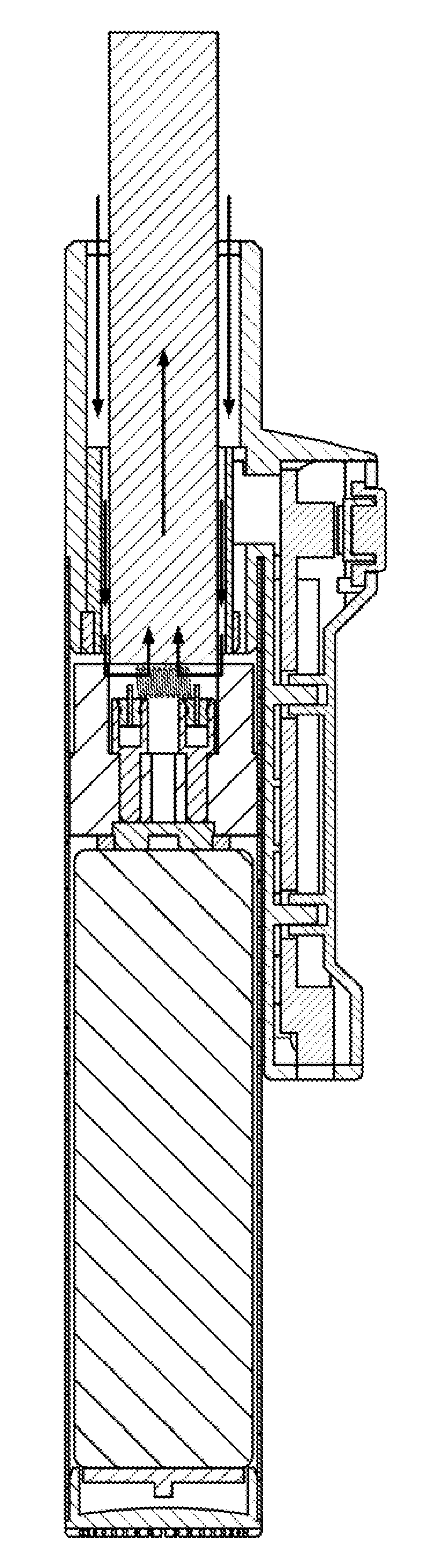

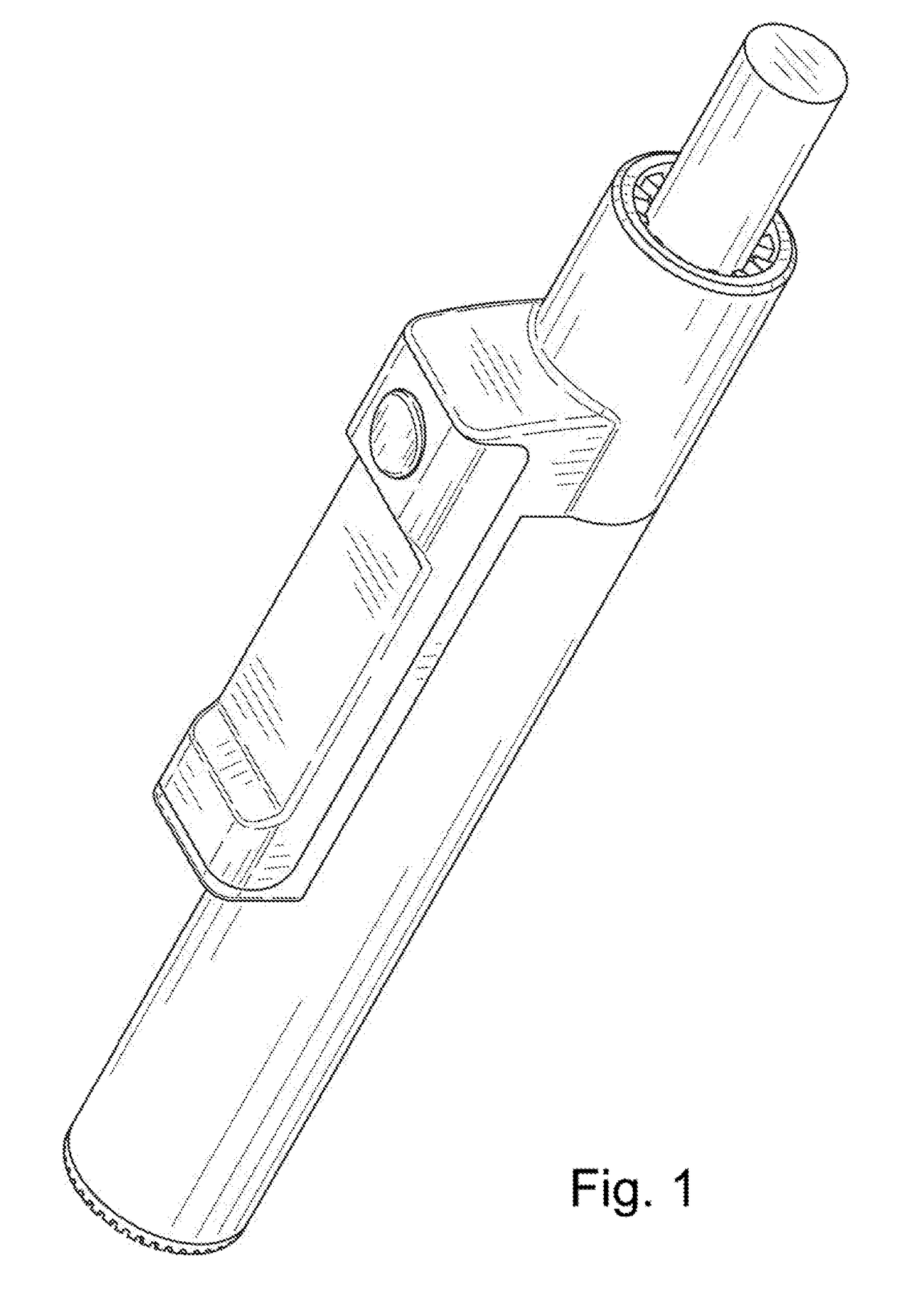

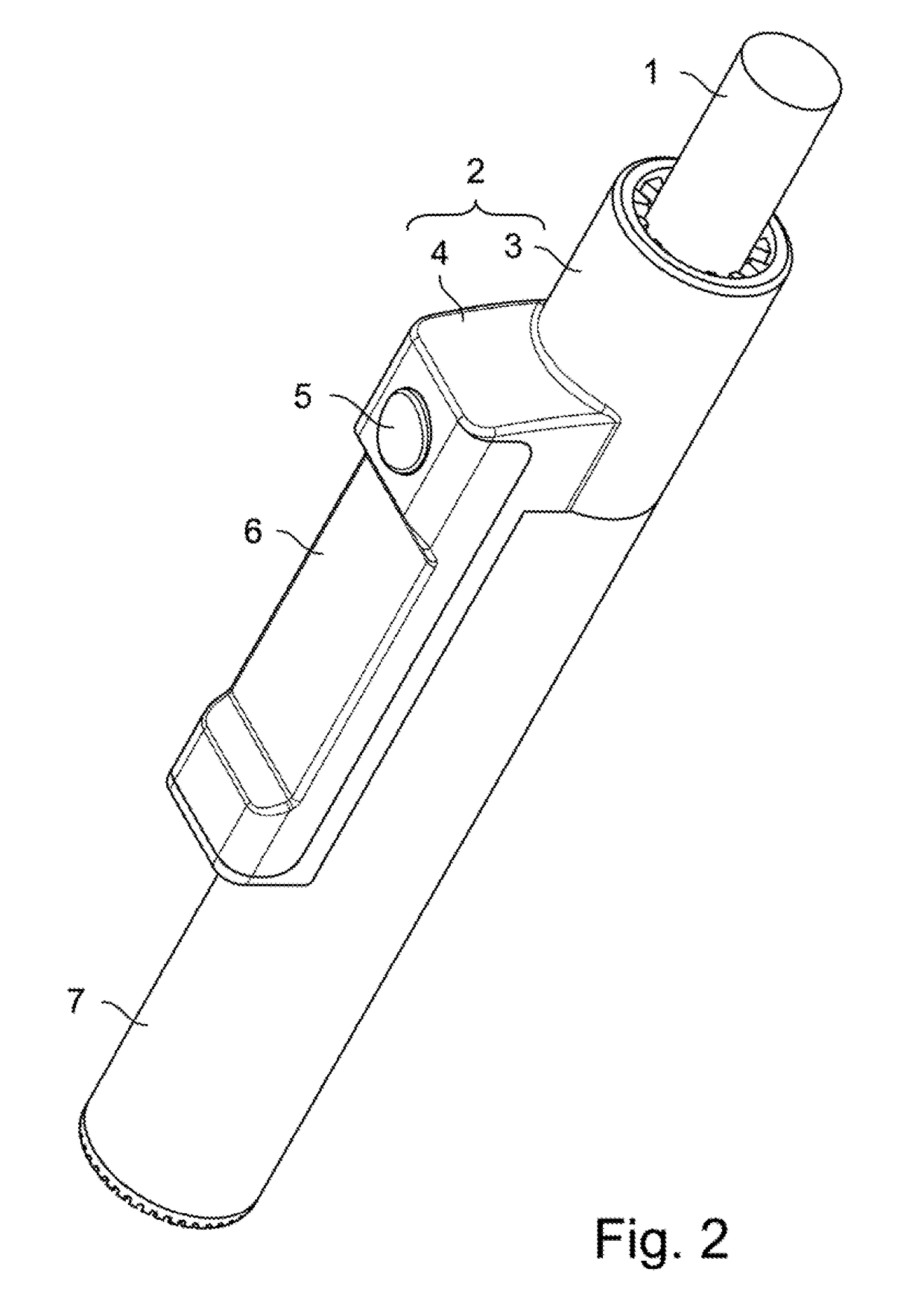

Low temperature heat not burn electronic cigarette

ActiveUS20180153216A1Significant energy lossSmall volumeTobacco devicesHeating element shapesElectrical batteryHeat not burn

The present invention relates to a low-temperature heat-not-burn electronic cigarette comprised of the first holder including a pipe and to mounting plate with the mounting plate connected to the external wall of the pipe. The mounting plate and the second holder are connected to form an inner cavity with a control plate fixed in the inner cavity and the second holder having a key linked to the buttons on the control plate with the buffer pads. The pipe has a corrugated internal wall and a moveable cigarette cartridge. The pipe is inserted into an outer pipe. The outer pipe has an insulation retaining bracket and a battery in it with the insulation retaining bracket having an installation slot facing the cigarette cartridge and the heating coil on the installation slot.

Owner:SHANGHAI GREEN VAPER TECH CO LTD

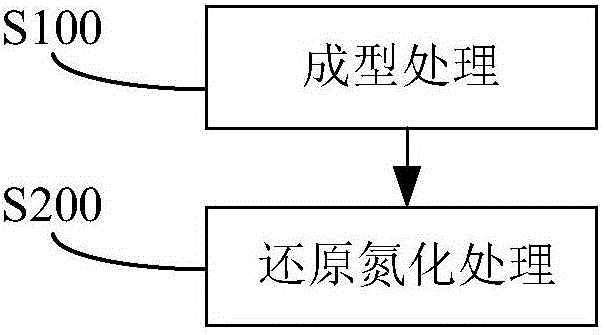

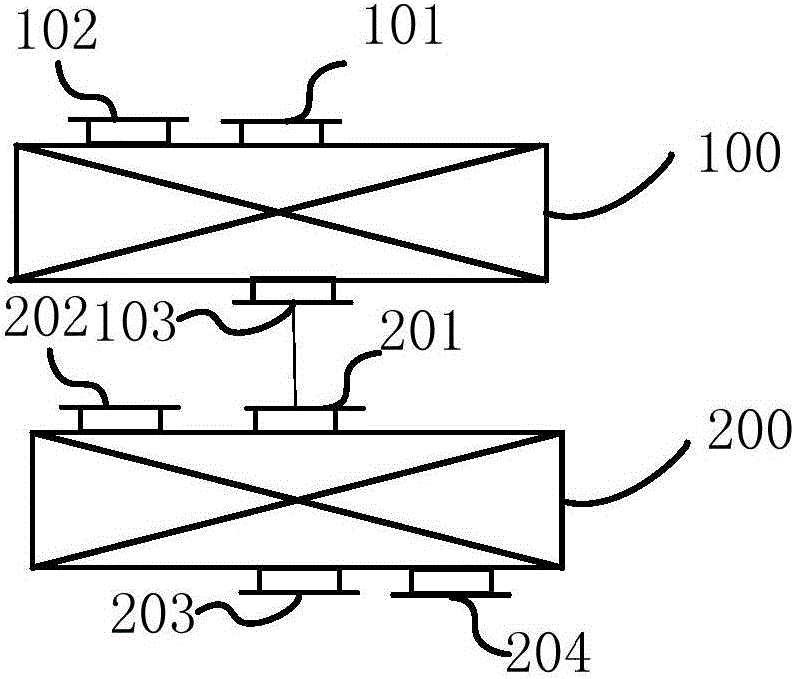

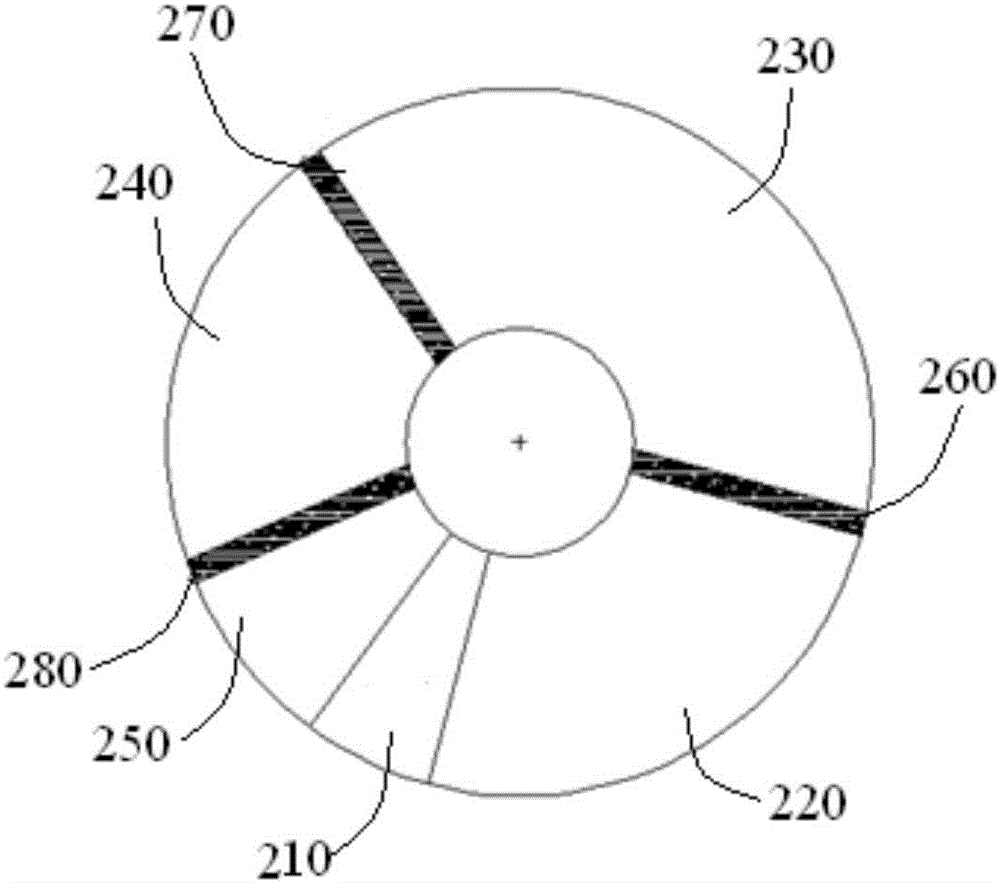

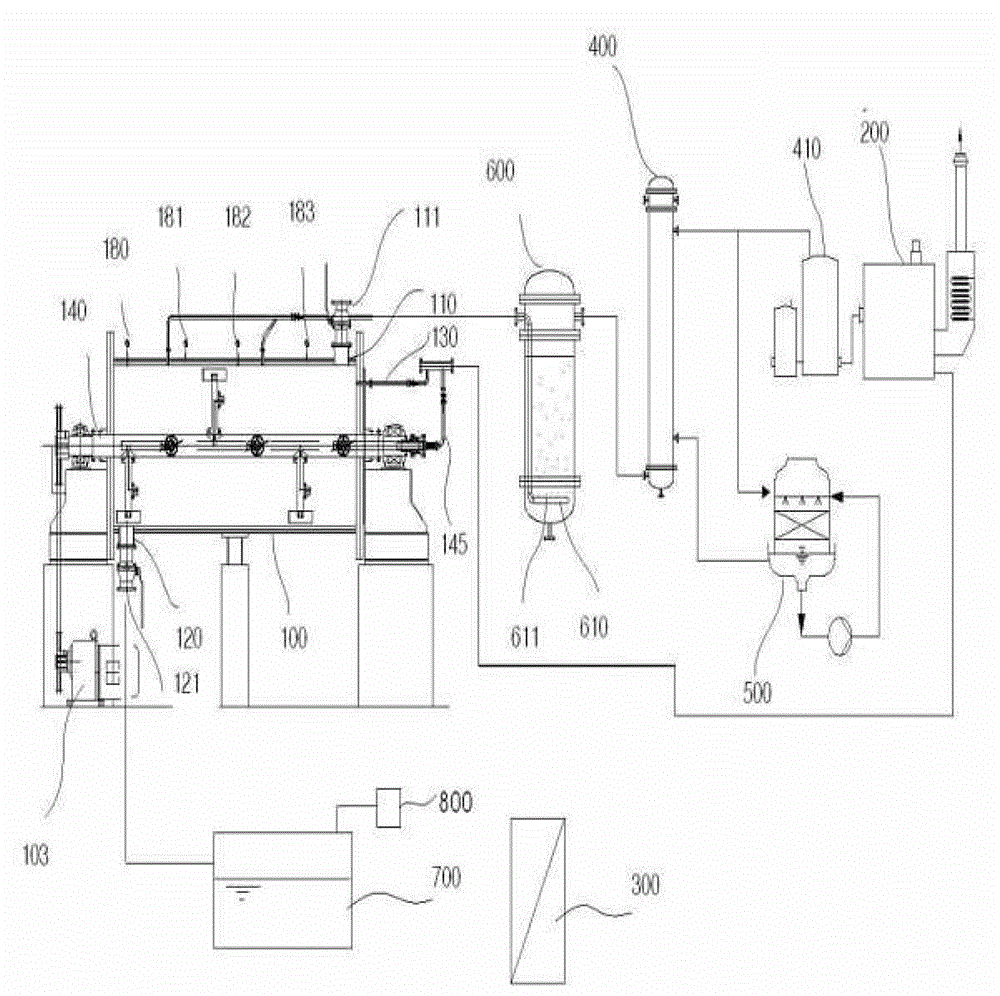

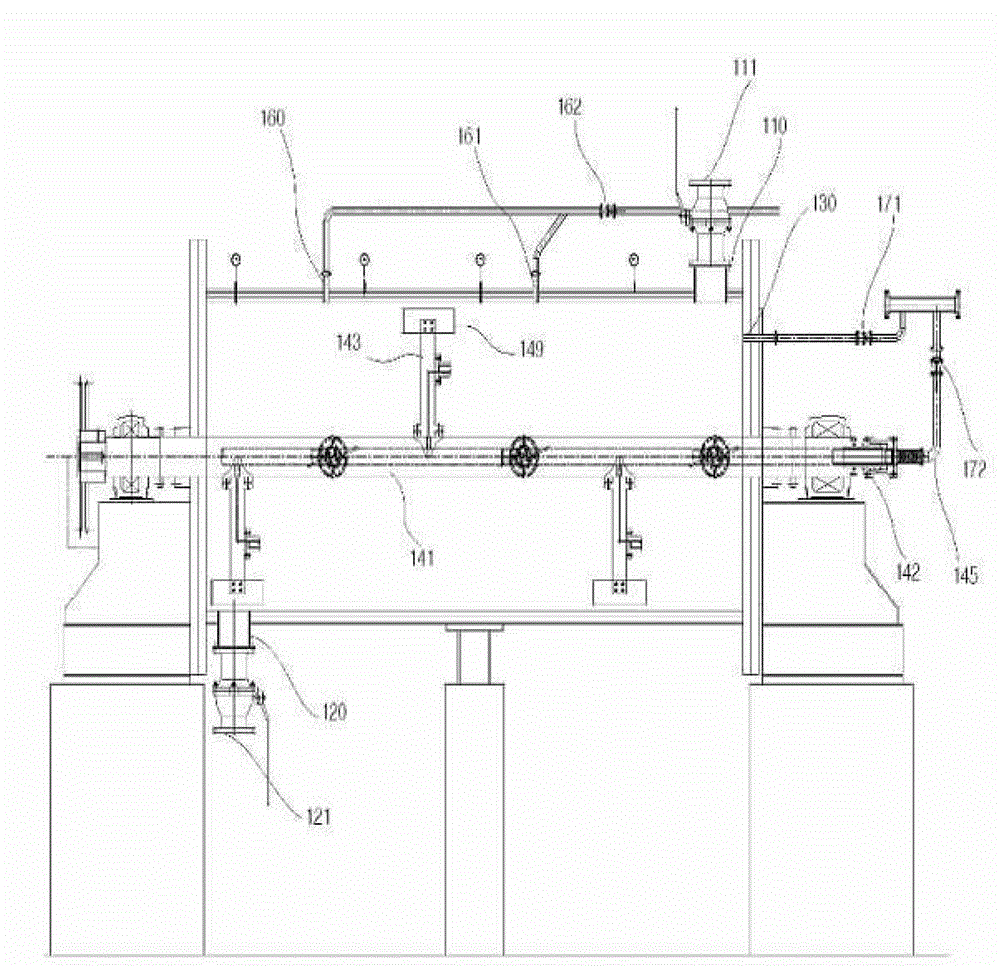

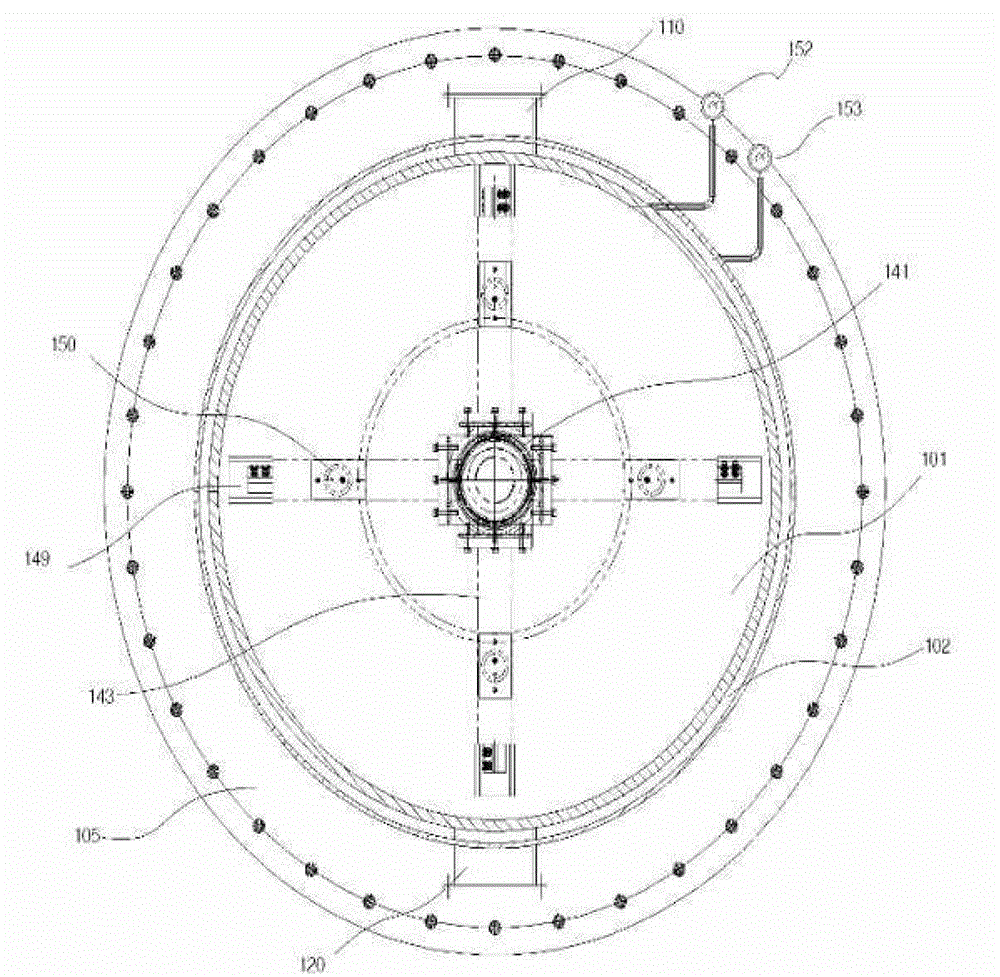

Method and system for preparing nitrogen-vanadium alloy

The invention discloses a method and a system for preparing a nitrogen-vanadium alloy. Wherein, the method for preparing the nitrogen-vanadium alloy includes: molding the vanadium trioxide powder and the graphite powder to obtain the mixed material agglomerate; transporting the mixed material agglomerate to the feeding area of the rotary hearth furnace for distribution, the The agglomerates of the mixed material pass through the carbonization reduction zone, the nitriding synthesis zone and the cooling zone in sequence, and then are discharged through the discharge zone, wherein the agglomerates of the mixed material enter the carbonization reduction zone for carbonization and reduction treatment to obtain vanadium carbide and carbon monoxide; The vanadium carbide enters the nitriding synthesis zone and undergoes nitriding treatment with nitrogen to obtain a nitrogen-vanadium alloy; the nitrogen-vanadium alloy enters the cooling zone for cooling treatment to obtain a cooled nitrogen-vanadium alloy. The method uses vanadium trioxide and graphite as raw materials to prepare mixed material agglomerates, and carries out carbonization reduction treatment and nitriding treatment step by step in a rotary hearth furnace to obtain a vanadium nitrogen alloy with high nitrogen content and low impurity content.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

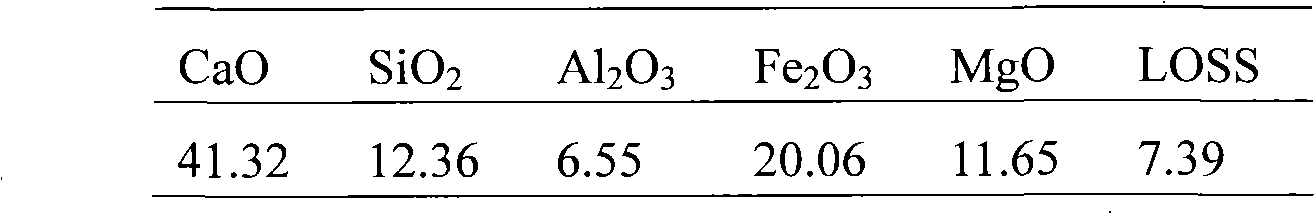

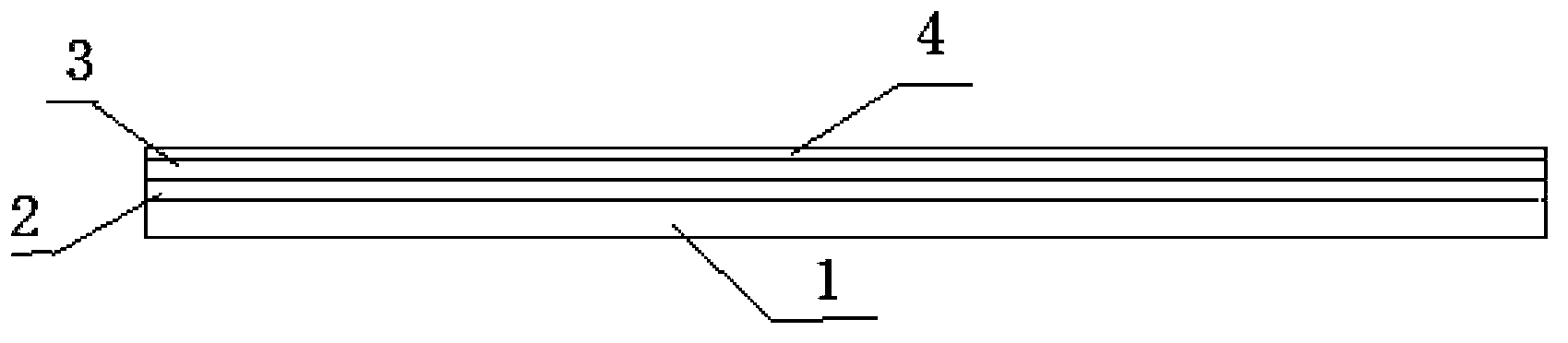

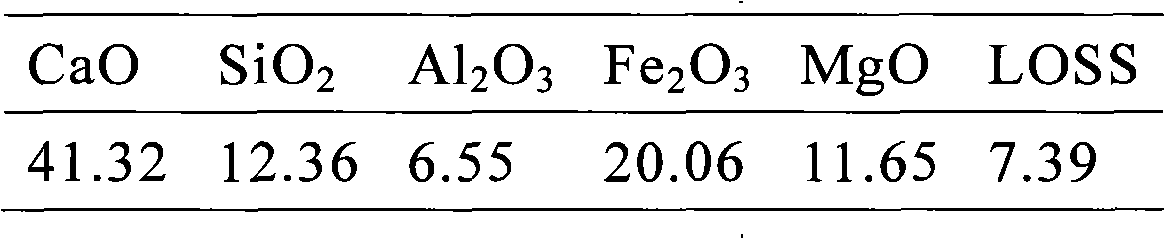

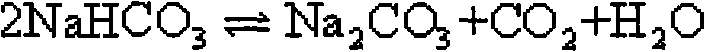

Excitant for preparing construction material by carbonized curing wastes

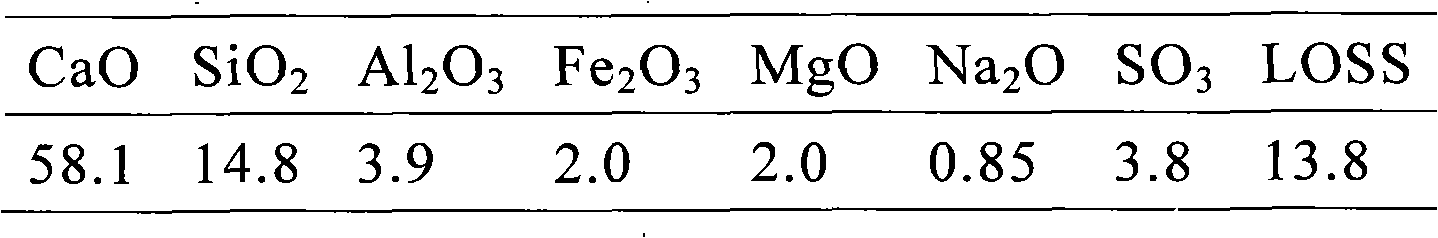

InactiveCN101337786APromote carbonizationHigh carbonation rateSolid waste managementGypsumGreenhouse gas

The invention belongs to the technical field of a constructional material, and relates to an excitant used for carbonizing and curing offal prepared constructional materials. The excitant comprises not less than 50 percent of excitable components by weight which are one or more than one of NaHCO3, soluble glass, plaster, Ca(HCO3)2, NaCl and Na2CO3. The excitant has the advantages that when offal prepared constructional materials are carbonized and cured, the excitant can promote carbonization in carbonization materials through the excitable components by adding the excitant of proper amount, thus increasing the carbonization ratio and reducing the discharged carbon dioxide as a greenhouse gas to great extent, preparing products for carbonizing and curing constructional materials having good performance, and reducing the production cycle with good economic benefit.

Owner:UNIV OF JINAN

Waste willow artwork branch recycling method

ActiveCN107142119AHigh carbonation rateQuality improvementOther chemical processesBiofuelsEnvironmental engineeringPre treatment

The invention discloses a waste willow artwork branch recycling method. The waste willow artwork branch recycling method comprises the following steps: (1) preprocessing the branch; (2) removing a surface coating; (3) processing at high temperature and high pressure; (4) processing by using an acid-base solution; (5) modifying; (6) carbonizing. The waste willow artwork branch material is processed in a targeted manner, the surface and the inner organizational structure of the branch are changed, the content and the proportion of the internal substance are regulated, the process parameters in the carbonizing are controlled, so that the overall carbonation ratio is effectively improved, the carbonation quality is improved, the carbonation ratio of the branch is finally more than 99.5%, the specific surface area of the prepared bio-carbon is not less than 3500 m<2> / g and increased by more than 20% in comparison with the prior art, the proportion of micropores in the prepared bio-carbon is more than 96.5%, a quite excellent adsorption characteristic is shown, and the use value is very high.

Owner:阜南县永盛工艺品有限公司

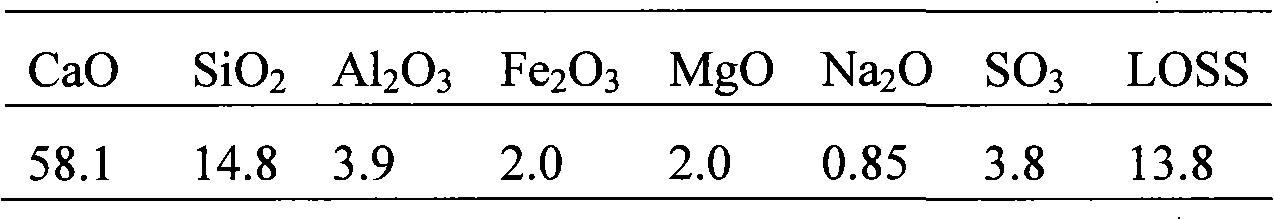

Preparation method for catalysis/adsorption material by taking kieselguhr as carrier

InactiveCN104226240AExtended stayHigh degree of oxidationOther chemical processesDispersed particle separationGlass fiberAlcohol

The invention discloses a preparation method for a catalysis / adsorption material by taking kieselguhr as a carrier. The preparation method comprises the following steps of adding 15-20 parts of absolute ethyl alcohol into 1 part of purified kieselguhr, then adding 1-3 parts of a metal compound, 0.1-0.3 part of aluminum oxide, 0.1-0.3 part of glass fibers, 0.02-0.04 part of nitric acid and 5-7 parts of deionized water in sequence under magnetic stirring for mixing and stirring; performing centrifugal washing on obtained substances by the deionized water; and drying washed ore pulp at first, and then calcining the ore pulp, thus obtaining the catalysis / adsorption material. The catalysis / adsorption material prepared by the method disclosed by the invention can prolong the retention time of organic pollutants in a reactor by using the adsorption capacity of kieselguhr, and loaded metal oxide can generate a relatively good catalytic oxidation effect in a discharging process, so that the oxidization degree of organic pollutants is increased.

Owner:杭州最清环保科技有限公司 +1

Multifunctional flame retardant as well as preparation and application thereof

InactiveCN102011309AFulfil requirementsHigh synergistic flame retardant performanceGroup 5/15 element organic compoundsVegetal fibresEnvironmental resistanceFiltration

The invention relates to a multifunctional flame retardant as well as preparation and an application thereof. The structural general formula of the flame retardant is as shown in the specification. The preparation comprises the following steps: adding phosphorus oxychloride and triethylamine into a reactor in which the air is exhausted with nitrogen, adding a solvent and sufficiently stirring under the nitrogen protection; adding alcohol or phenol in a separating funnel, and adding a solvent and mixing uniformly; dropwise adding the mixture into the reactor; after the mixture is dropwise added completely, heating and reflowing for reaction; after the reaction is over, reducing the temperature of the system to below 5 DEG C; adding aminopropyl trialkoxysilane in the separating funnel, and adding a solvent and mixing uniformly; slowly dropwise adding the mixture into the reactor, then heating and reflowing for reaction; and performing filtration, rotary evaporation, separation and purification to obtain the product. The flame retardant finishing agent provided by the invention has relatively good flame retardant effect, the finished fabric has high charring rate when being burnt and high laundry resistance, is environment-friendly and efficient, releases no formaldehyde and generates no toxic gas in the burning process. The finishing agent is applicable to purified cotton and cellulose fiber fabrics or blend fabrics thereof.

Owner:DONGHUA UNIV

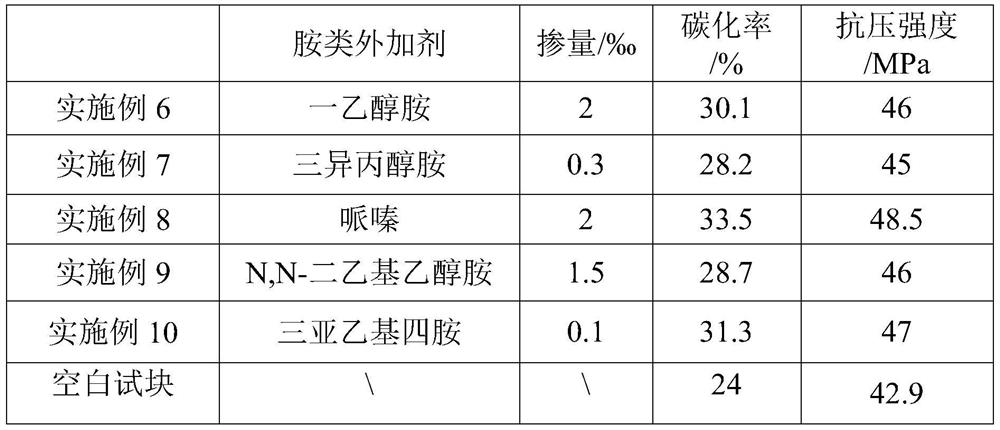

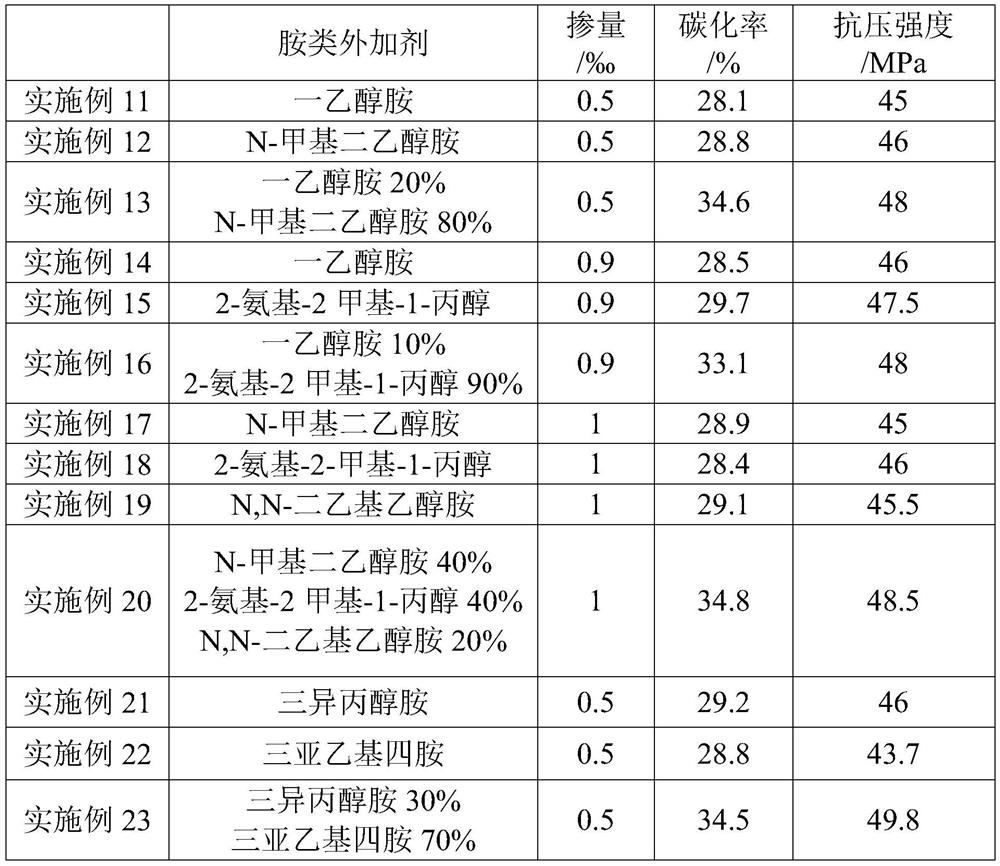

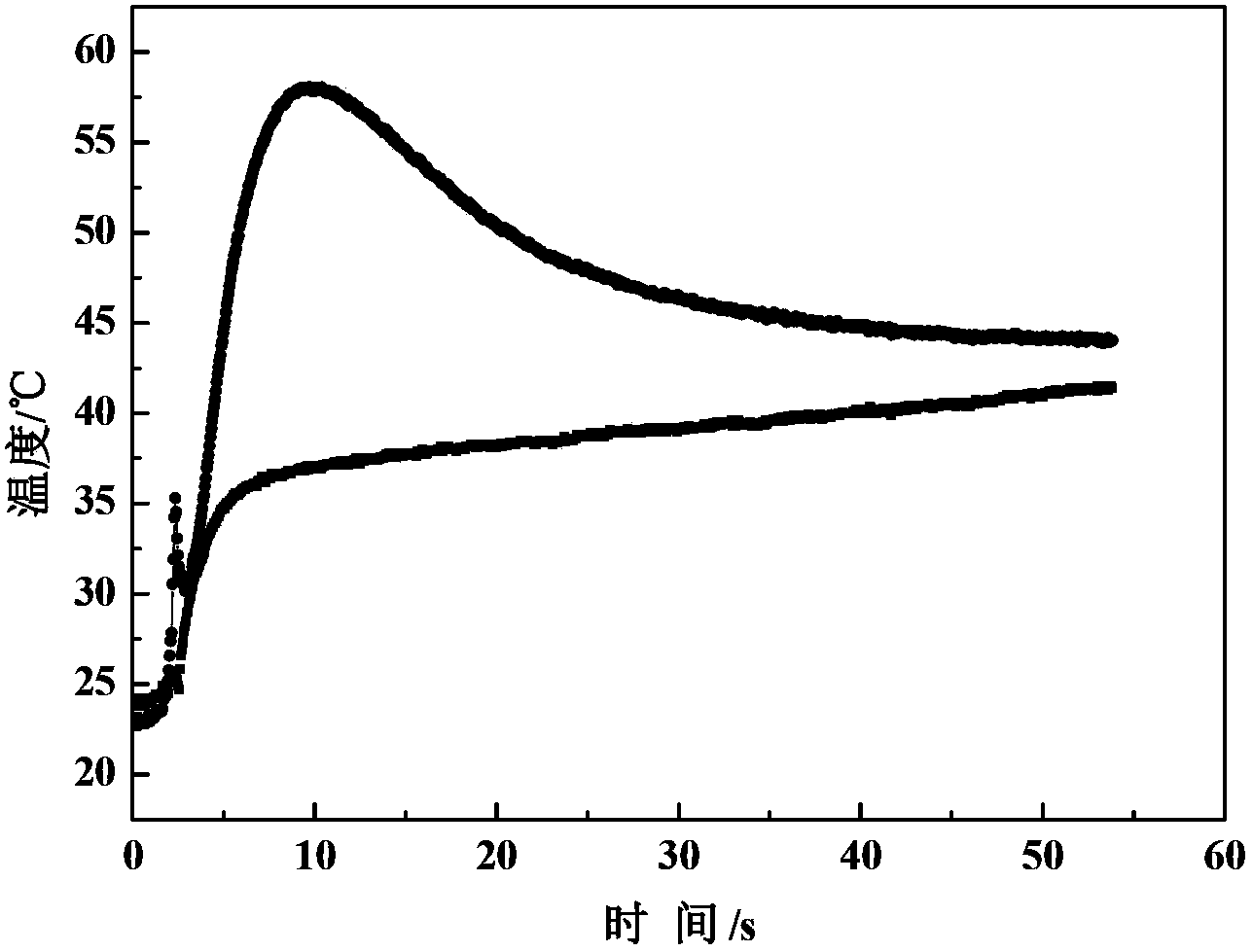

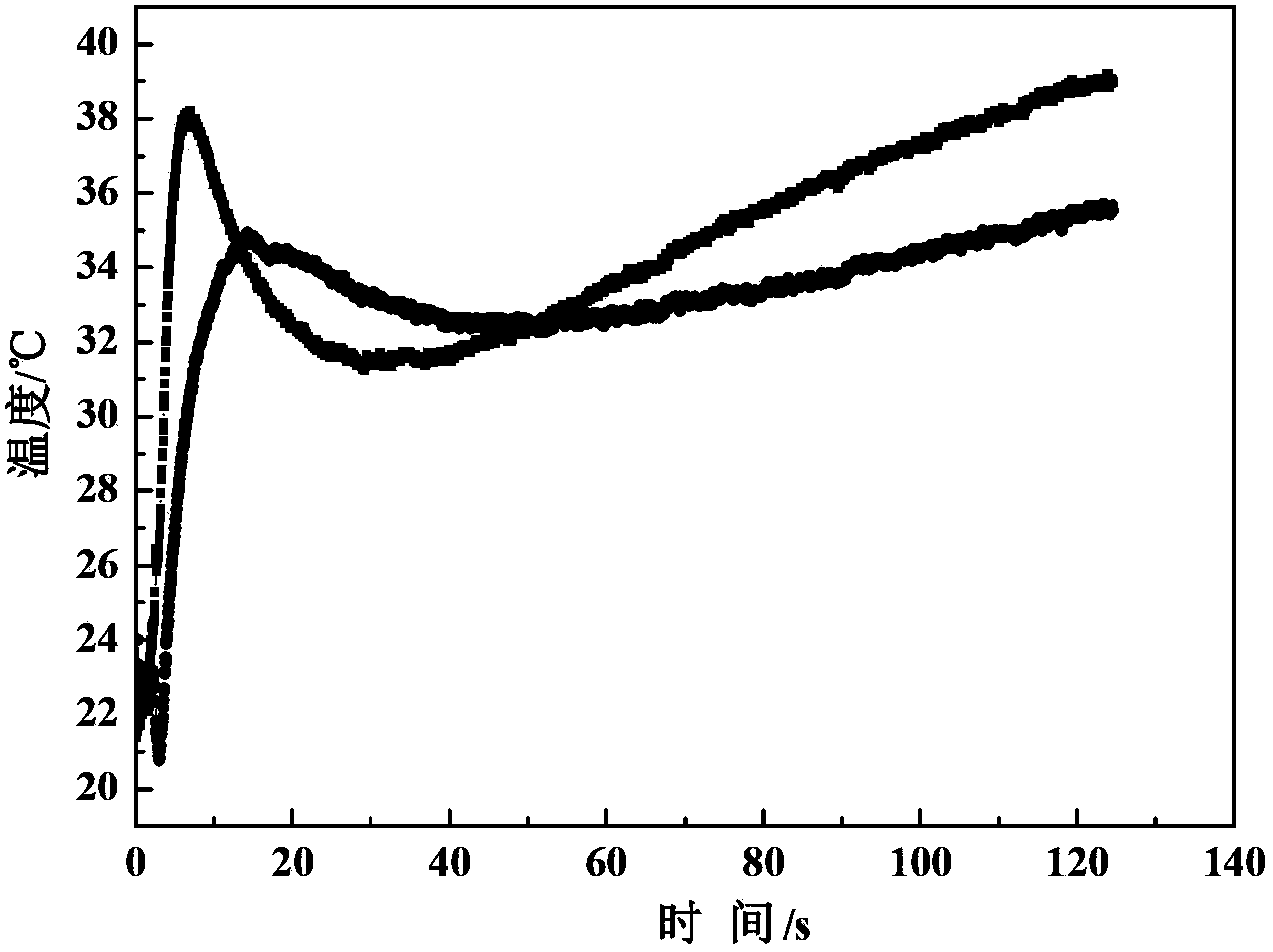

Cement-based material and preparation method thereof

PendingCN113563107AIncrease the depth of carbonization reactionImprove curing rateMaterials scienceMagnesium ion

The invention relates to a cement-based material and a preparation method thereof. The preparation method of the cement-based material comprises the following steps: mixing raw materials of the cement-based material, adding an amine admixture in the mixing process of the raw materials, adding water, conducting stirring and forming, and carrying out high-temperature pretreatment and CO2 mineralization maintenance, wherein the addition amount of the amine admixture is 0.01-0.2% of the mass of the cement in the raw materials. According to the invention, the amine admixture is added in the raw material mixing process, so the internal microporous structure of the cement-based material can be adjusted, the CO2 solubility and the calcium and magnesium ion dissolution rate of the material can be improved, the depth of CO2 carbonization reaction can be effectively improved, the CO2 carbonization rate in the cement-based material can be improved, and good energy-saving and carbon-reducing effects can be achieved. The carbonization rate of the cement-based material obtained by the method disclosed by the invention is 28-35%.

Owner:CHINA BUILDING MATERIALS ACAD

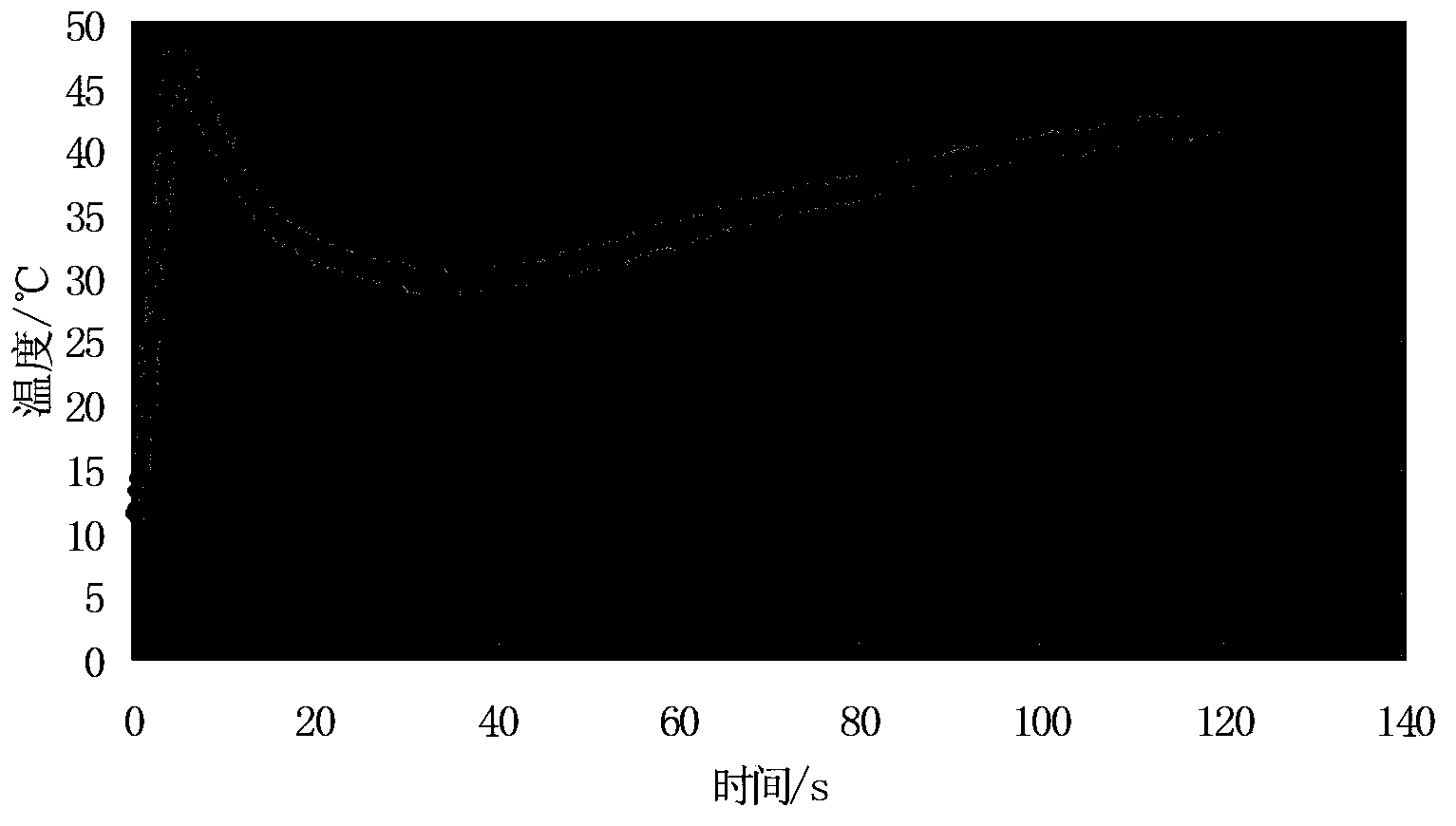

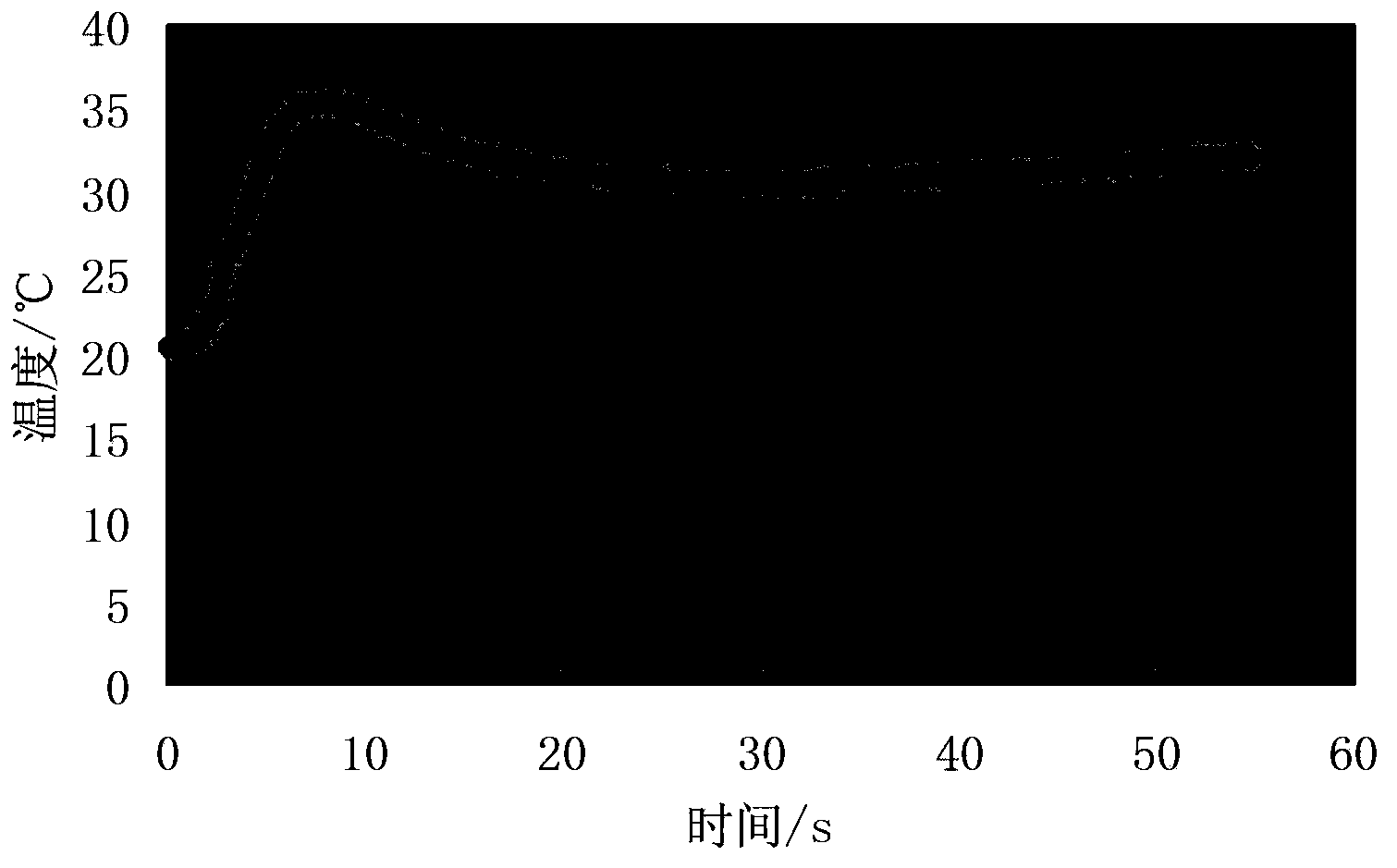

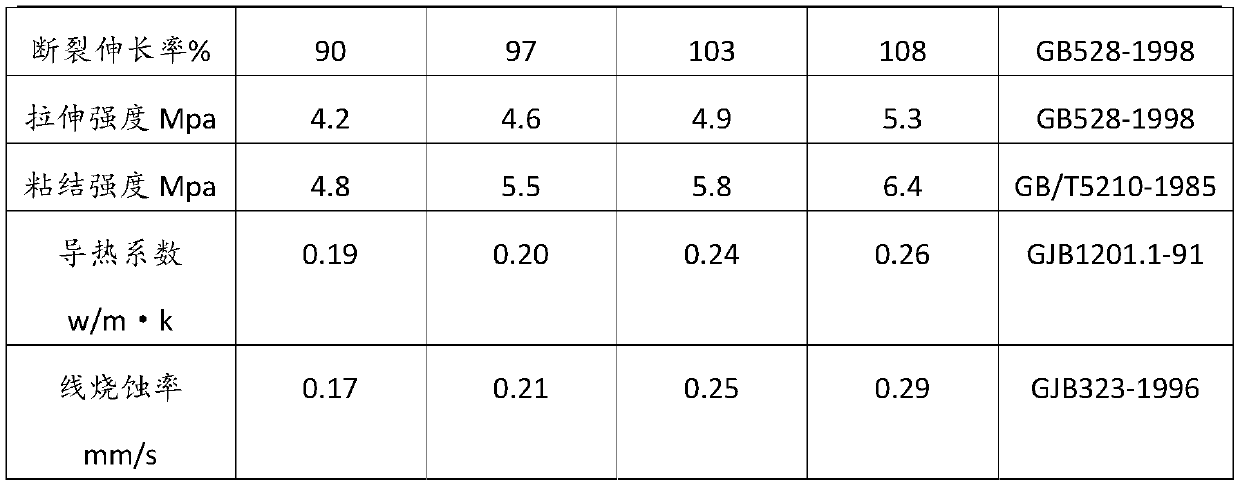

Structure of thermal protective coating for launching pad and application of structure

ActiveCN103847189AReduce thermal ablationReduce shockSynthetic resin layered productsEpoxy resin coatingsEpoxyOrganic base

The invention discloses a structure of a thermal protective coating for a launching pad and an application of the structure. The thermal protective coating material comprises an organic base layer and an organic-inorganic composite surface layer, wherein the organic base layer comprises epoxy resin, polyamide as a curing agent and liquid rubber as a toughening agent; the organic-inorganic composite surface layer comprises organic glue epoxy resin, a polyurethane curing agent, sand and cement. The thermal protective coating material can bear the simulated combustion gas flow scouring of a rocket, the temperature of a metal back surface does not exceed 200 DEG C, and the coating has excellent thermal insulation property.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Carbonization treatment method of wood plate

ActiveCN107160519APromote looseIncreasing the thicknessPressure wood treatmentWood treatment detailsSurface layerCarbonization

The invention discloses a carbonization treatment method of a wood plate. The carbonization treatment method comprises the following steps of (1) plate cleaning, (2) surface modification treatment, (3) soaking treatment, (4) carbonization treatment, and (5) cooling treatment. According to the carbonization treatment method, the carbonization effect on the wood plate can be effectively improved, the thickness of a surface carbonization layer of the wood plate is effectively increased, the carbonization rate of a surface layer material of the wood plate is also well increased, meanwhile, reasonably-added nanometer silica enhances the density and mechanical property of the surface layer, the machining defective rate is obviously decreased, and good service value is achieved.

Owner:FUNAN NATURE ARTS & CRAFTS

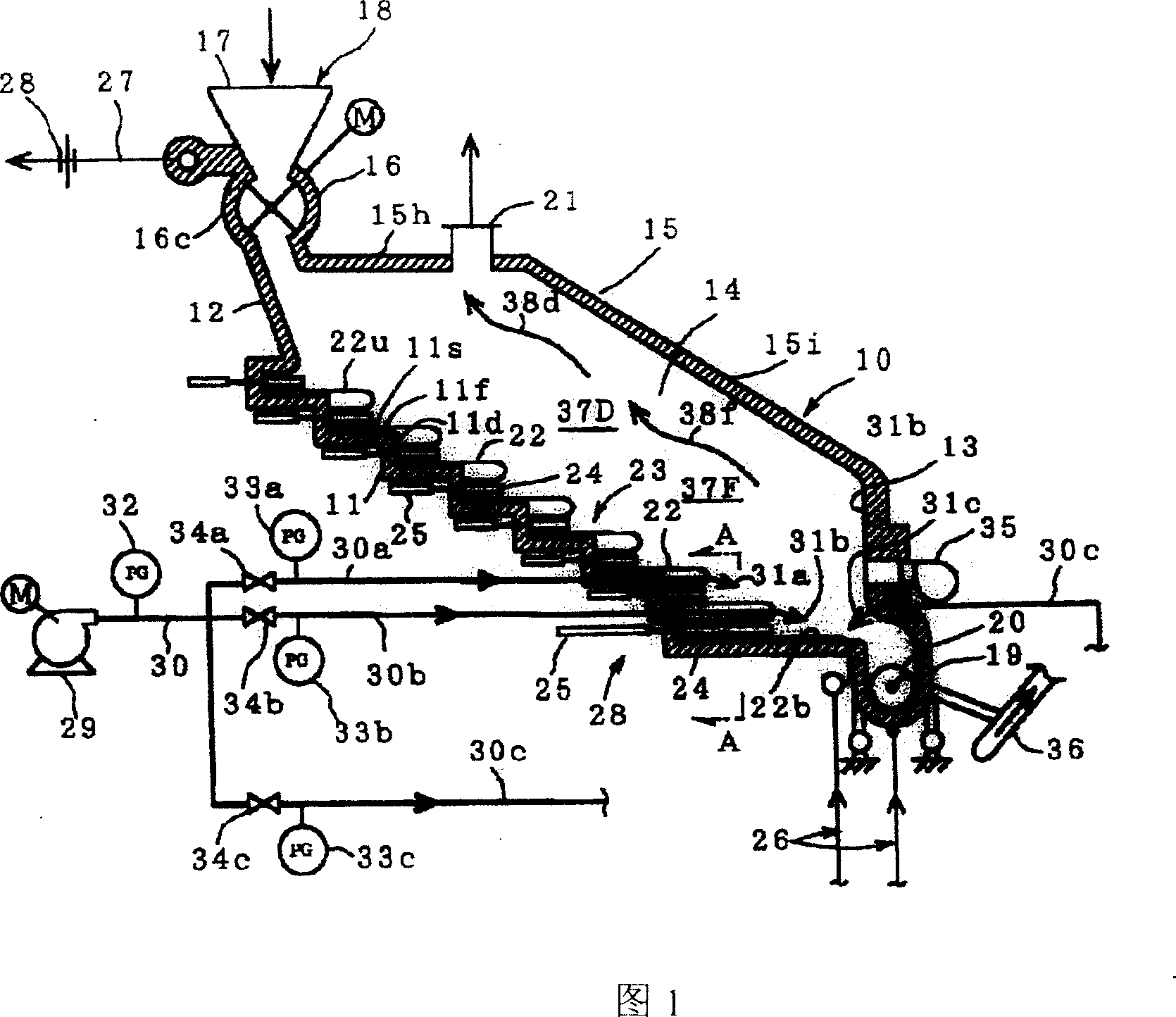

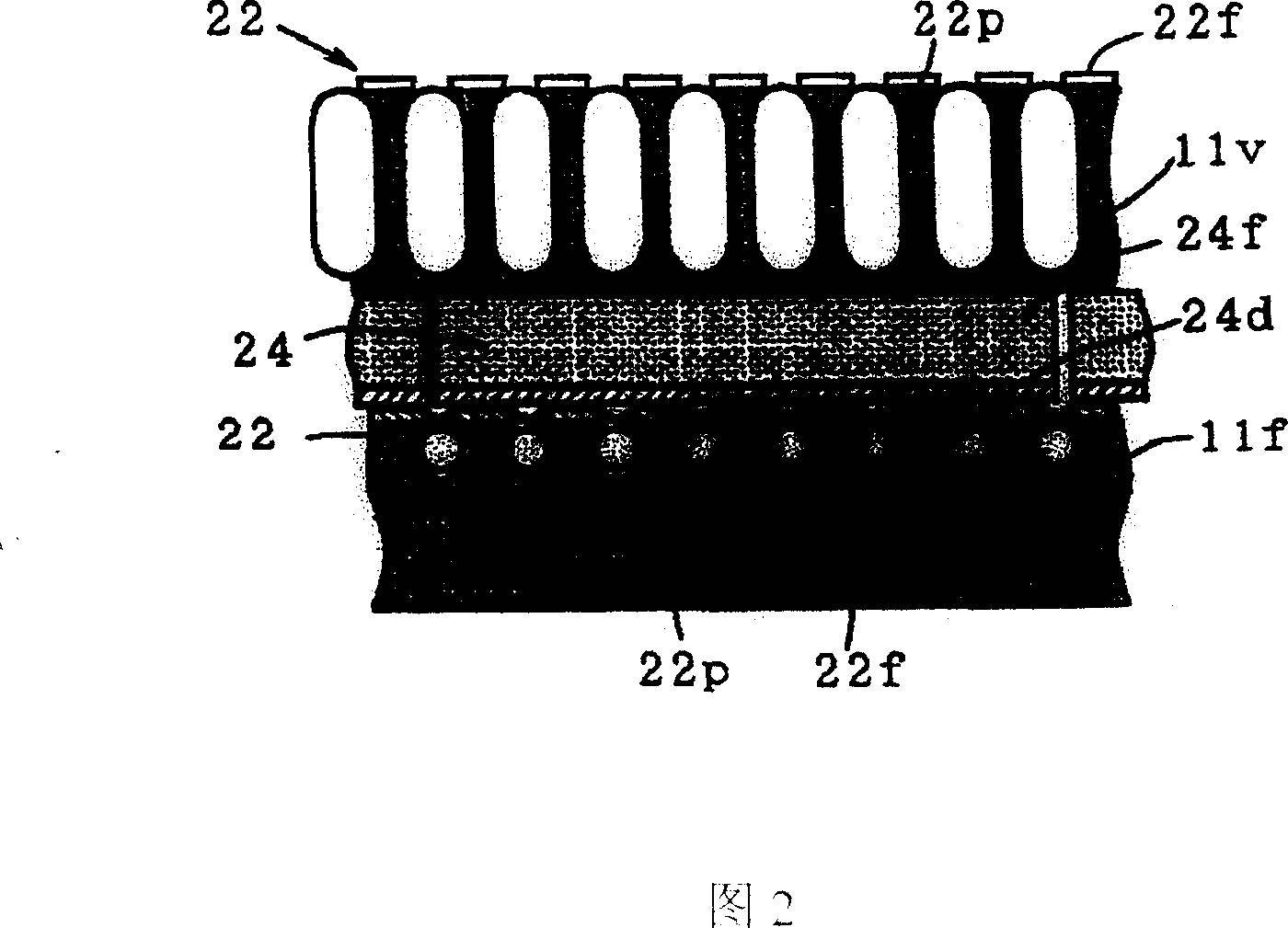

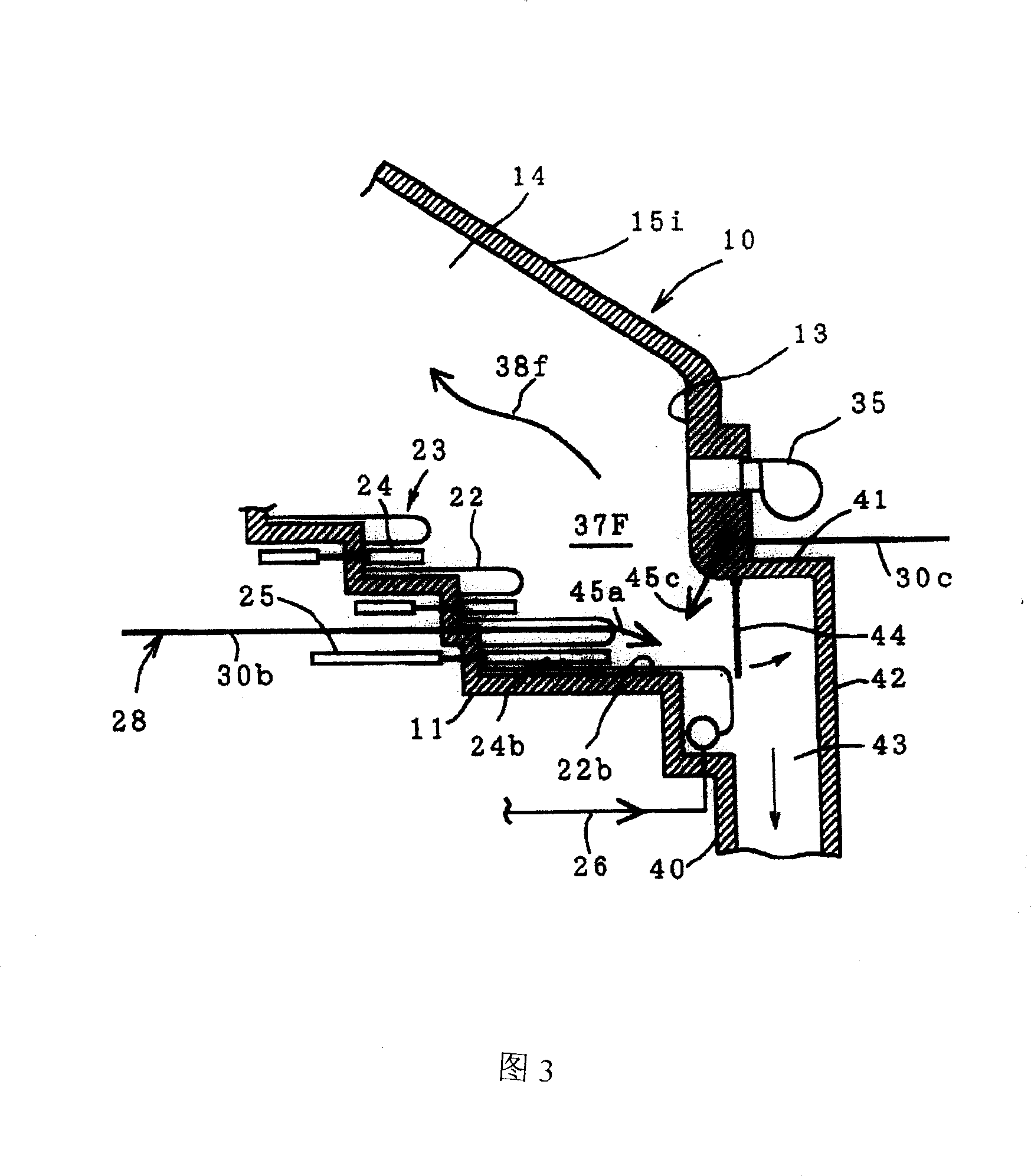

Firing machine type thermal decomposition furnace

InactiveCN101046293AReduce usageHigh carbonation rateIncinerator apparatusCarbonizationProcess engineering

The present invention provides one kind of stocker type thermal decomposing furnace to decompose garbage to generate fuel gas. The thermal decomposing furnace has a stepped grate combination, a stocker to extrude garbage downwards, a garbage feeder over the stepped grate combination, a fuel gas supply device below the stepped grate combination. The present invention can convert most of the garbage into fuel gas and decompose garbage with the combustion heat in raised carbonization rate.

Owner:高桥 贤三

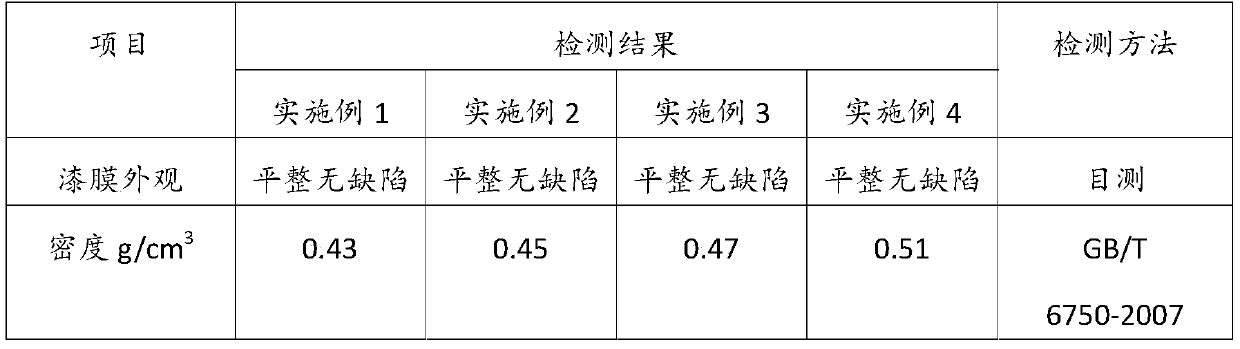

Silicone rubber composite material and preparation method thereof

The invention provides a silicone rubber composite material and a preparation method thereof and belongs to the field of silicone rubber composite materials. The silicone rubber composite material comprises, by weight, 100 parts of a silicone rubber base component A, 5 parts of a silicone rubber base component B, 5-10 parts of an anti-burning filling material, 5-10 parts of a fireproof heat-insulation filling material, 2-5 parts of a flame-retardant cooling filling material and 1-3 parts of a heat stabilizer. The silicone rubber base component A comprises silicone base resin, organosilicone oil, a binder and white carbon black. The silicone rubber base component B contains a phenolic epoxy group and through use of excellent adhesion and high carbon content of the phenolic epoxy group, burning resistance of the organosilicone resin is improved. Through use of the phenolic resin, a carbonization yield of the silicone rubber composite material is improved and a better carbonization layer is formed and has effects of isolation and heat absorption and thus a part at the back of the silicone rubber fireproofing sealing agent can be protected well.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Method for manufacturing coke biomass fuel bricks

The invention provides a method for manufacturing coke biomass fuel bricks by the following procedures: 1. raw material selecting, proportioning and fermenting; 2. drying; 3. preheating; 4. combustible gas and tar collecting and 5 pressing; through selecting, proportioning and fermenting, the compatibility and flexibility of the raw materials of the biomass are improved; the fermented raw materials of the biomass are dried to remove surplus water; the dried raw materials of the biomass are preheated to remove the volatile components; the combustible gas is recycled for drying the fuels and the tar is recycled to be used as the component of the raw materials; the preheated raw materials of the biomass are pressed so that the treated raw materials are converted into the biomass fuel bricks with the performance index similar to that of the coke. The manufactured biomass fuel bricks have the performance index of the coke and contain tar, thus having the advantages of large density, high carbonation rate, easy ignition, high heat value, long combustion time, little ash and good combustion performance and use performance. The biomass fuel bricks manufactured by the method are used as fuels.

Owner:郑文林

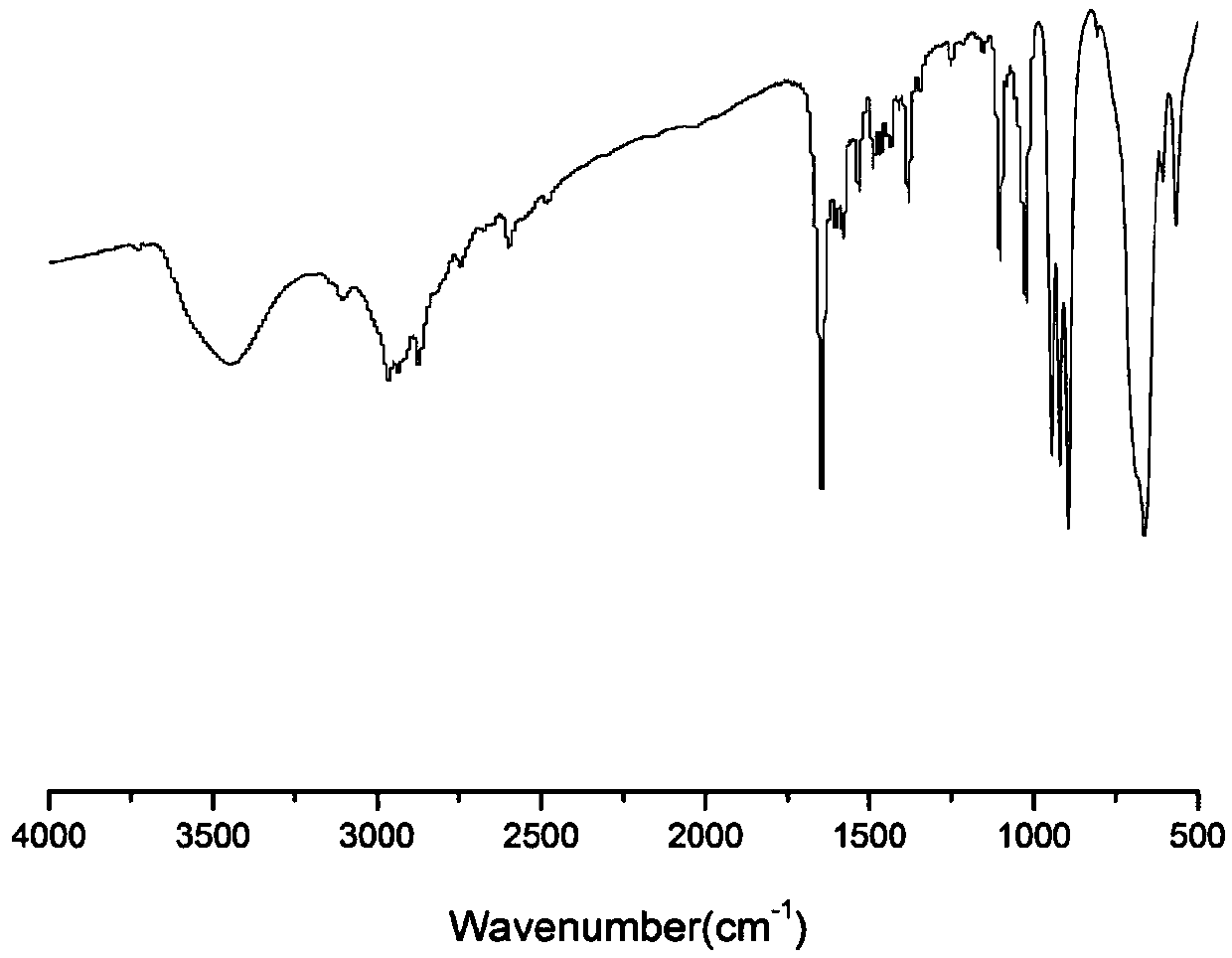

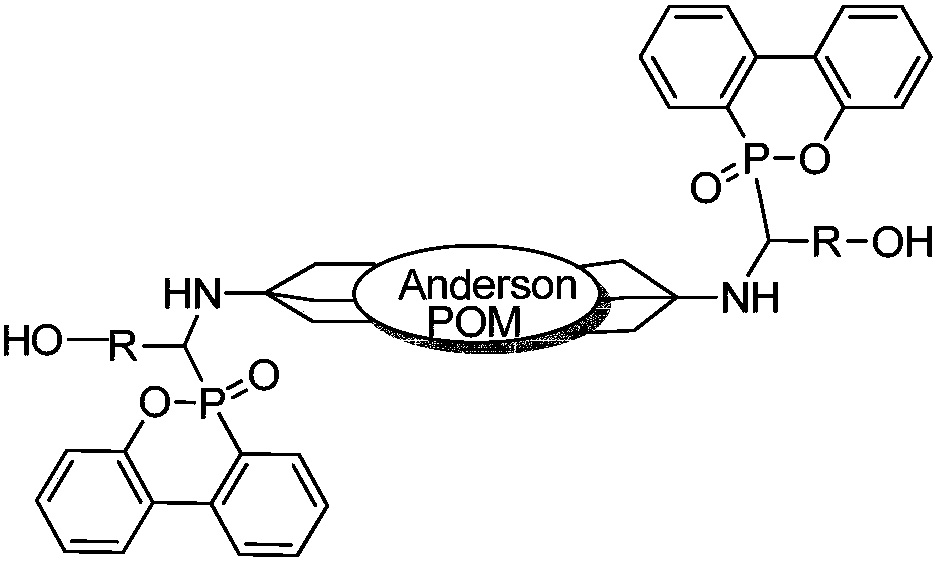

Molybdenum-containing polyoxometallate reactive flame retardant and preparation method thereof

ActiveCN109021017AHigh activityGood compatibilityGroup 5/15 element organic compoundsPolymer scienceCarbonization

The invention discloses a molybdenum-containing polyoxometallate reactive flame retardant and a preparation method thereof, and the molybdenum-containing polyoxometallate reactive flame retardant containing three elements of phosphorus, nitrogen and molybdenum is prepared from a molybdenum polyoxometallate having an Anderson structure, a hydroxyl aldehyde compound and DOPO as starting materials bya polyoxometallate organic modification method by organic covalent bond connection. The polyoxometallate and the DOPO are connected by means of a covalent bond, and a new function is given to the molybdenum-containing polyoxometallate reactive flame retardant while solving of the poor processability and the poor compatibility of the polyoxometallate with a matrix. The flame retardant contains a plurality of reactive groups, has good compatibility with the matrix, and can effectively avoid the adverse effects on the mechanical properties of the matrix when the polyoxometallate is added alone;by introducing of the molybdenum polyoxometallate into the flame retardant, the thermal stability of the flame retardant, the carbonization rate of the matrix resin, and the smoke suppression efficiency are remarkably improved; the preparation method is simple and easy.

Owner:XIAMEN UNIV

Structure for thermal protective coating of rocket launching pad and application thereof

ActiveCN103850355AReduce thermal ablationReduce shockClimate change adaptationHeat proofingEpoxyBrick

The invention discloses a structure for a thermal protective coating of a rocket launching pad and an application thereof. The thermal protective coating is composed of materials in three layers, namely, an organic bottom layer, refractory bricks and an organic-inorganic compound surface layer, wherein the organic bottom layer is composed of epoxy resin, solidifying agent polyamide and flexibilizer liquid rubber; clay refractory bricks are adopted as the refractory bricks; the organic-inorganic compound surface layer is composed of organic rubber epoxy resin, polyurethane curing agent, sand and cement. The material of the thermal protective coating provided by the invention can endure the scouring of the simulated fuel gas flow of a rocket; the temperature on a metal rear surface is not above 200 DEG C; the coating has an excellent heat-insulating property.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

Strengthening agent for construction material prepared by carbonizing curing waste

The invention belongs to the technical field of building materials and relates to an enhancer for the building materials which are prepared by taking wastes (including different types of steel slag, furnace slag, smelting slag, sludge, red sludge, incineration ash and waste cement, and the like) as main materials for absorbing CO2 waste gas, in particular to the enhancer for the building materials which are prepared by the carbonation curing wastes and using steel slag and cement as the main materials for absorbing the CO2 gas. The enhancer contains more than 50 percent by weight of easily carbonized ingredients, and the easily carbonized ingredients are one or more of calcium hydroxide, calcium oxide, portland cement or waste concrete. The enhancer of the invention plays the roles in strengthening and improving the carbonation rate, improves the strength of the building materials which are prepared by carbonation and curing and the CO2 absorption rate and shortens the production cycle.

Owner:UNIV OF JINAN

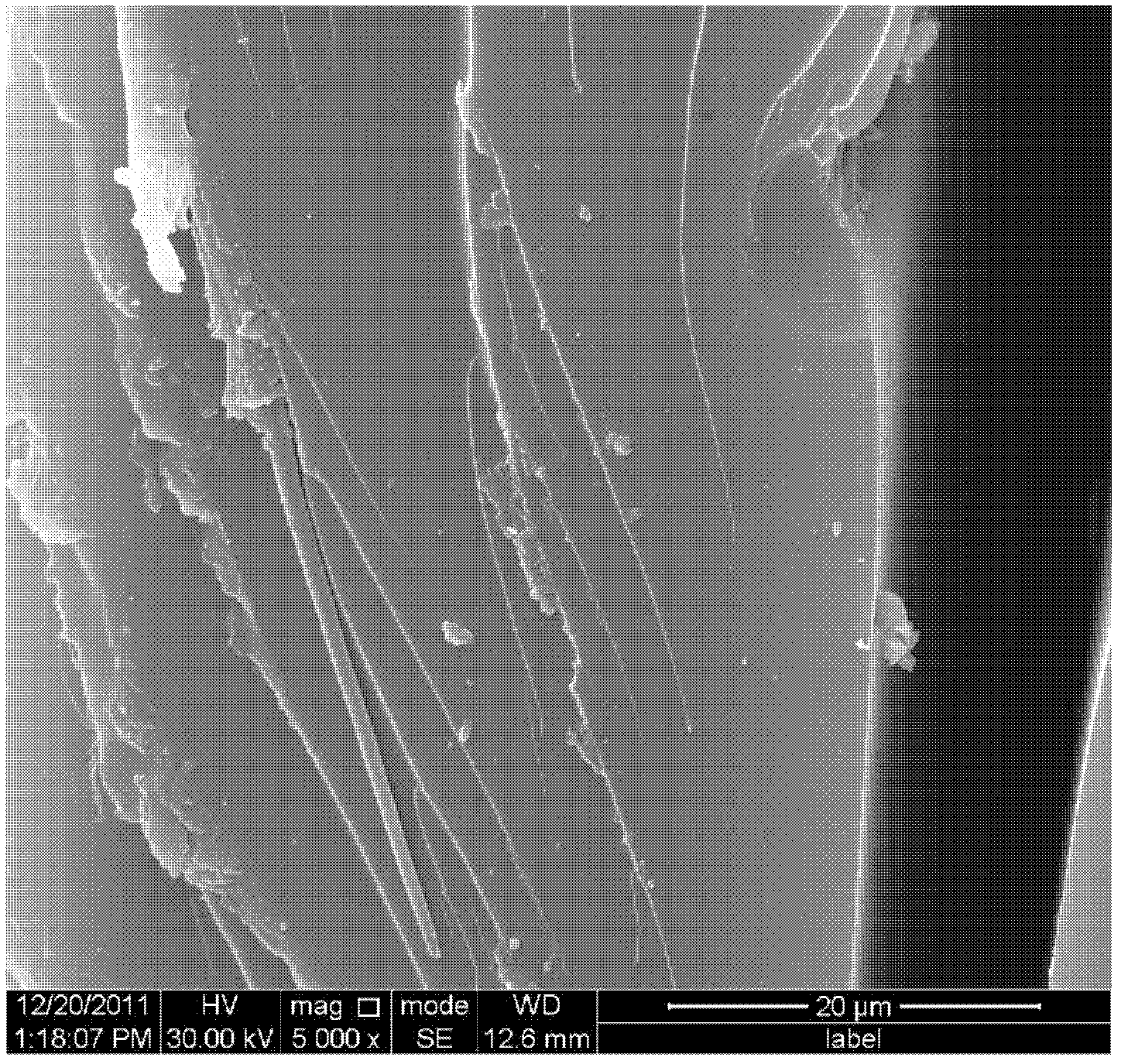

Carbonized fibers and carbonization method thereof

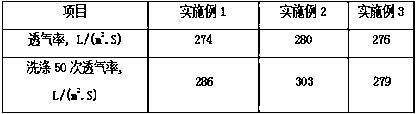

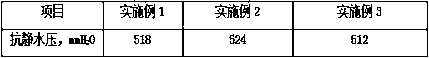

InactiveCN110172751AHigh carbonation rateLittle loss of strengthFibre chemical featuresWater/sewage treatment by sorptionMaterials preparationCarbonization

The invention provides carbonized fibers. The carbonized fibers are formed by opening a carbonized base cloth, the carbonization rate of the obtained carbonized fibers is greater than or equal to 99.996%, and the strength unevenness of the carbonized fibers is less than or equal to 0.66%; the hydrostatic pressure resistance of the carbonized base cloth is 512-524 mm / H2O; and air permeability is 274-280 L / (m2. S), and after washing, the air permeability is 279-303 L / (m2. S). The invention also provides a preparation method of the carbonized fibers. The preparation method comprises the steps ofraw material preparation, base cloth preparation and carbonization activation, in raw material preparation, Lyocell fibers are selected; the carbonized fibers are good in shape stability, not easy todeform, and low in deformation rate after washing; the flame retardant property is improved, and thus, the carbonized fibers have a wide market prospect.

Owner:孔令孝 +1

High-performance ablation-resistant coating and preparation method thereof

ActiveCN111534220AClear functional structureImprove insulation performanceFireproof paintsPolyurea/polyurethane coatingsInsulation layerHeat flow

The invention discloses a high-performance ablation-resistant coating which comprises an inner heat insulation layer and an outer temperature-resistant layer. The invention further discloses a preparation method of the high-performance ablation-resistant coating. The coating has strong bonding strength and can tolerate instantaneous high temperature above 1500 DEG C, effectively obstructs externalheat flow to protect internal devices of a base material, still has good repairable performance after multiple times of heat flow scouring, and has strong practical application value.

Owner:HUNAN AEROSPACE SANFENG SCI & TECH CO LTD

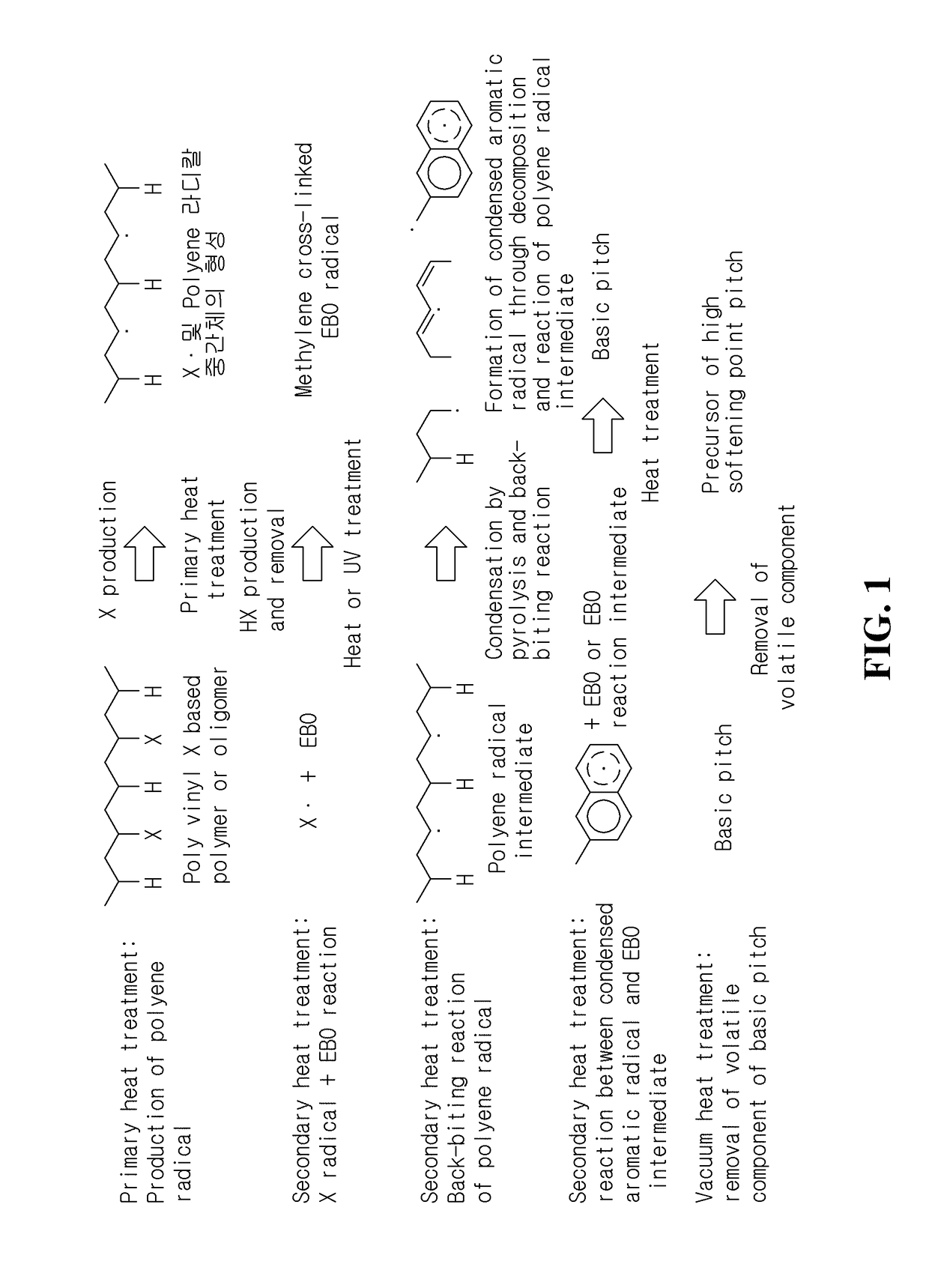

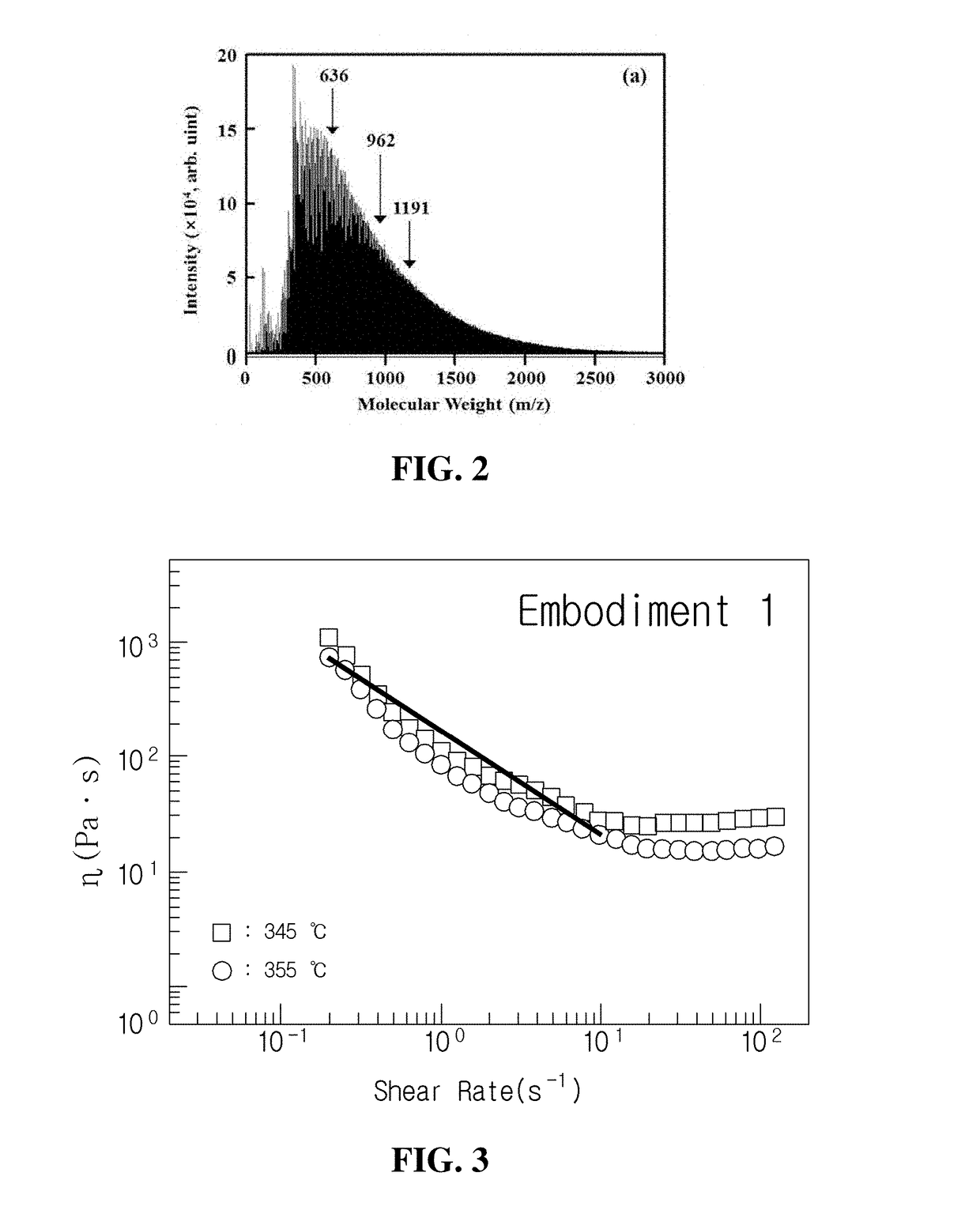

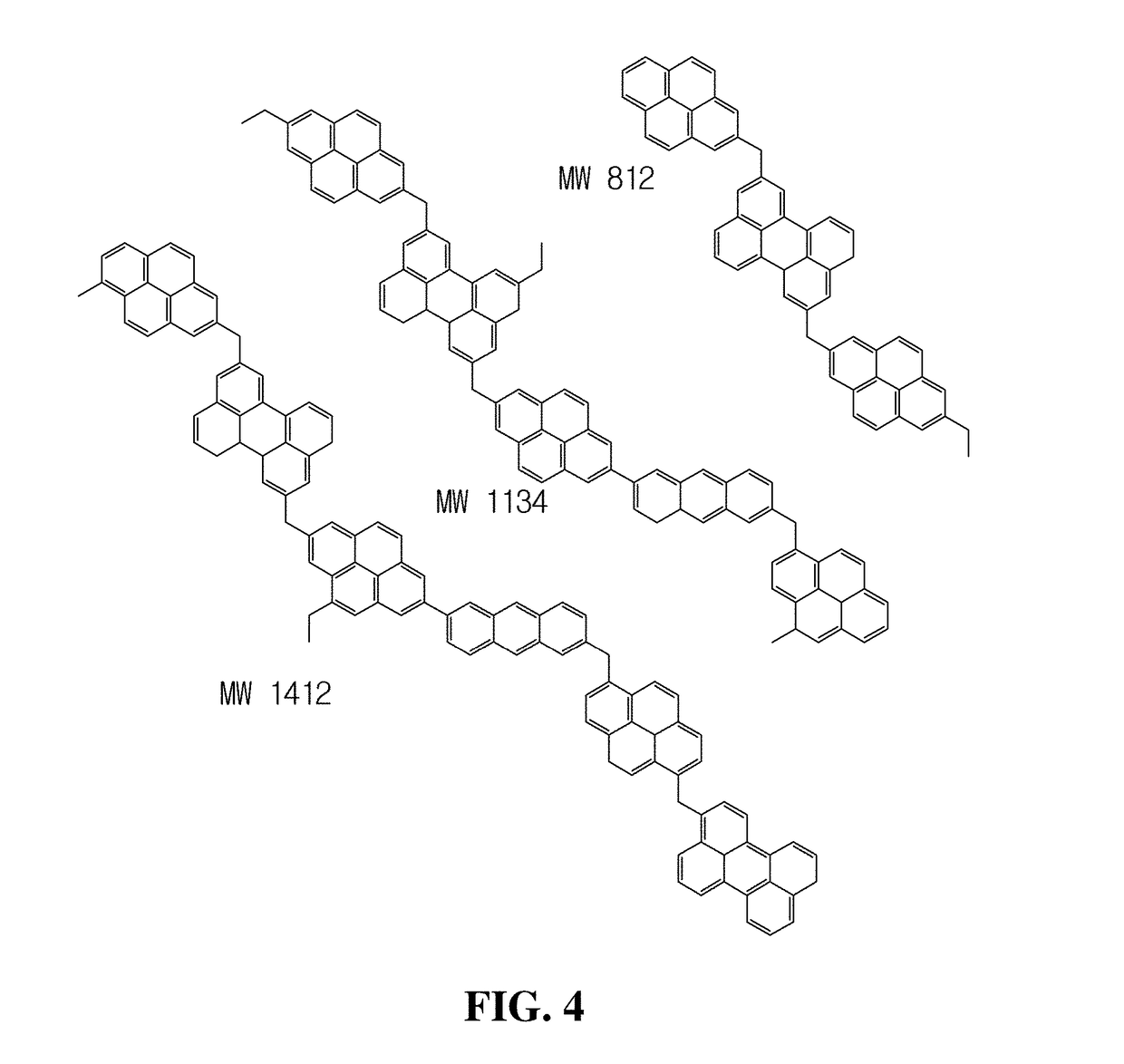

Method of preparing high softening point pitch and high softening point pitch prepared thereby

InactiveUS20170175001A1Improve yieldHigh molecular weightCell electrodesWorking-up pitch/asphalt/bitumen by chemical meansHeat treatedPhotochemistry

Provided are a method of preparing a high softening point pitch and the high softening point pitch prepared thereby, in which a polyene radical intermediate is formed, and an alkylaromatic radial material is linearly linked to the polyene radical intermediate in a benzyl or methylene form to be polymerized. The method includes performing heat treatment by adding a compound, which is able to a polyene radical intermediate, to 1- to 4-ring alkylaromatic condensates to produce a basic pitch, and performing vacuum heat treatment for the basic pitch.

Owner:YUSUNG TELECOM

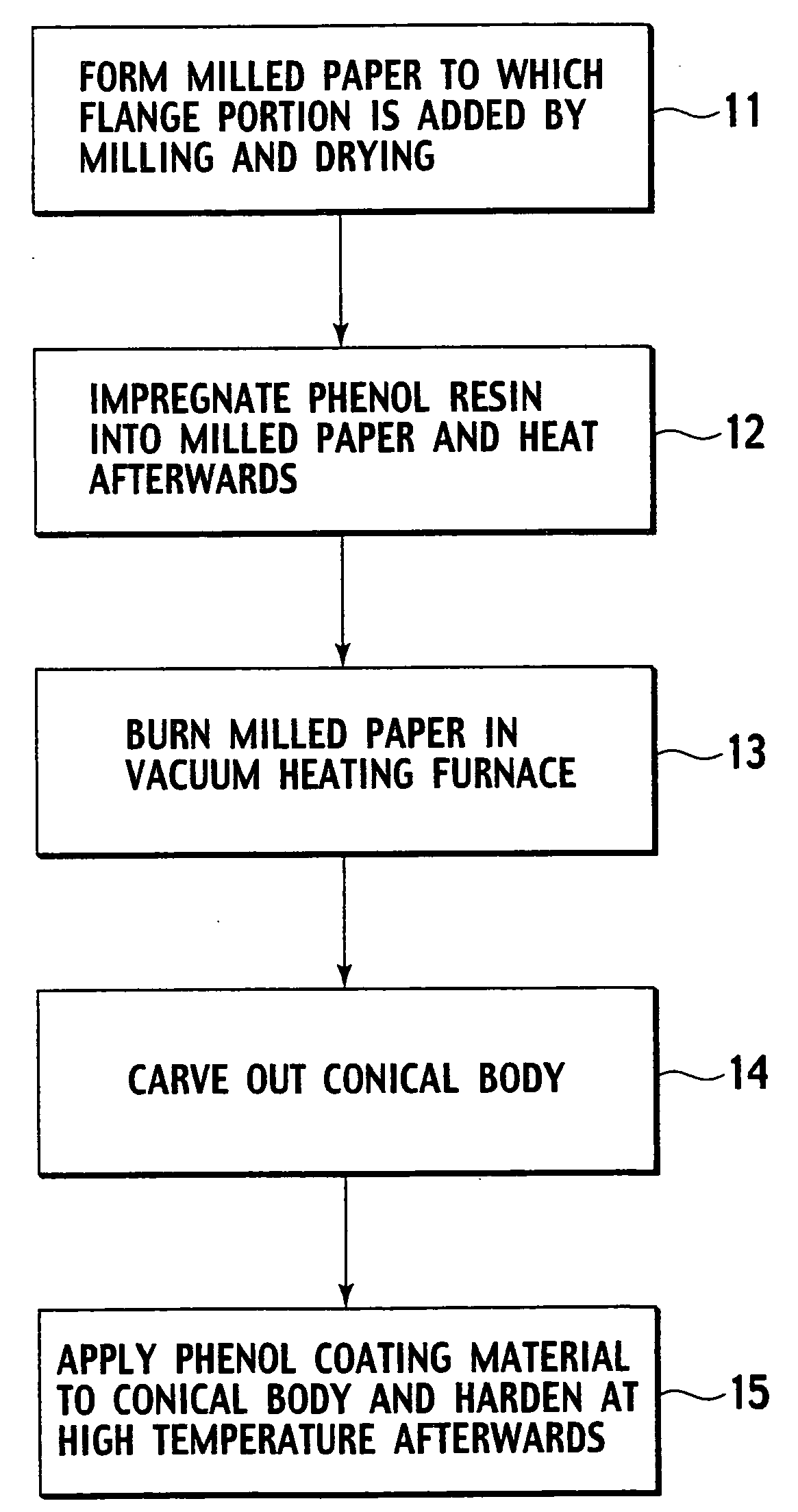

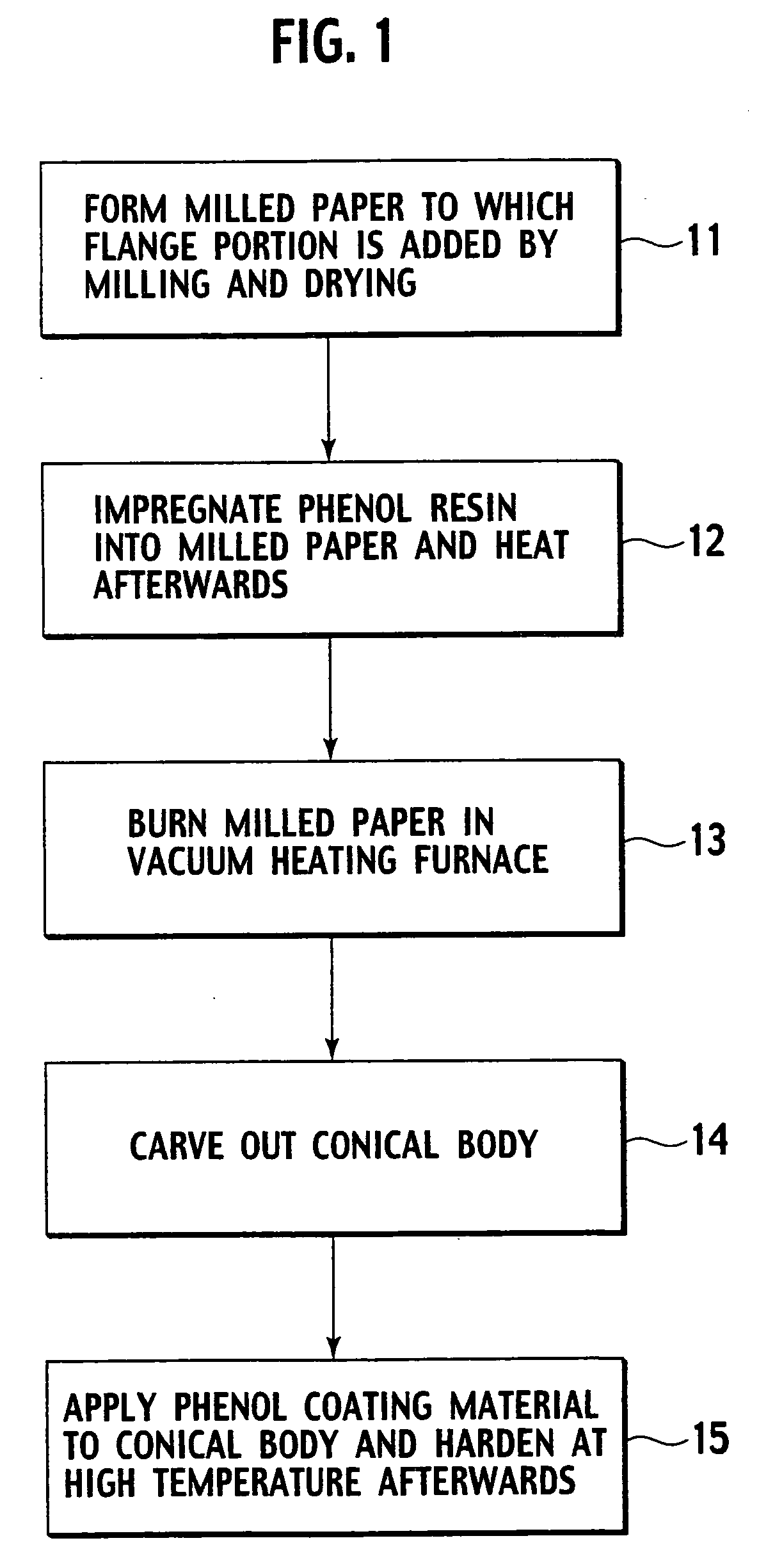

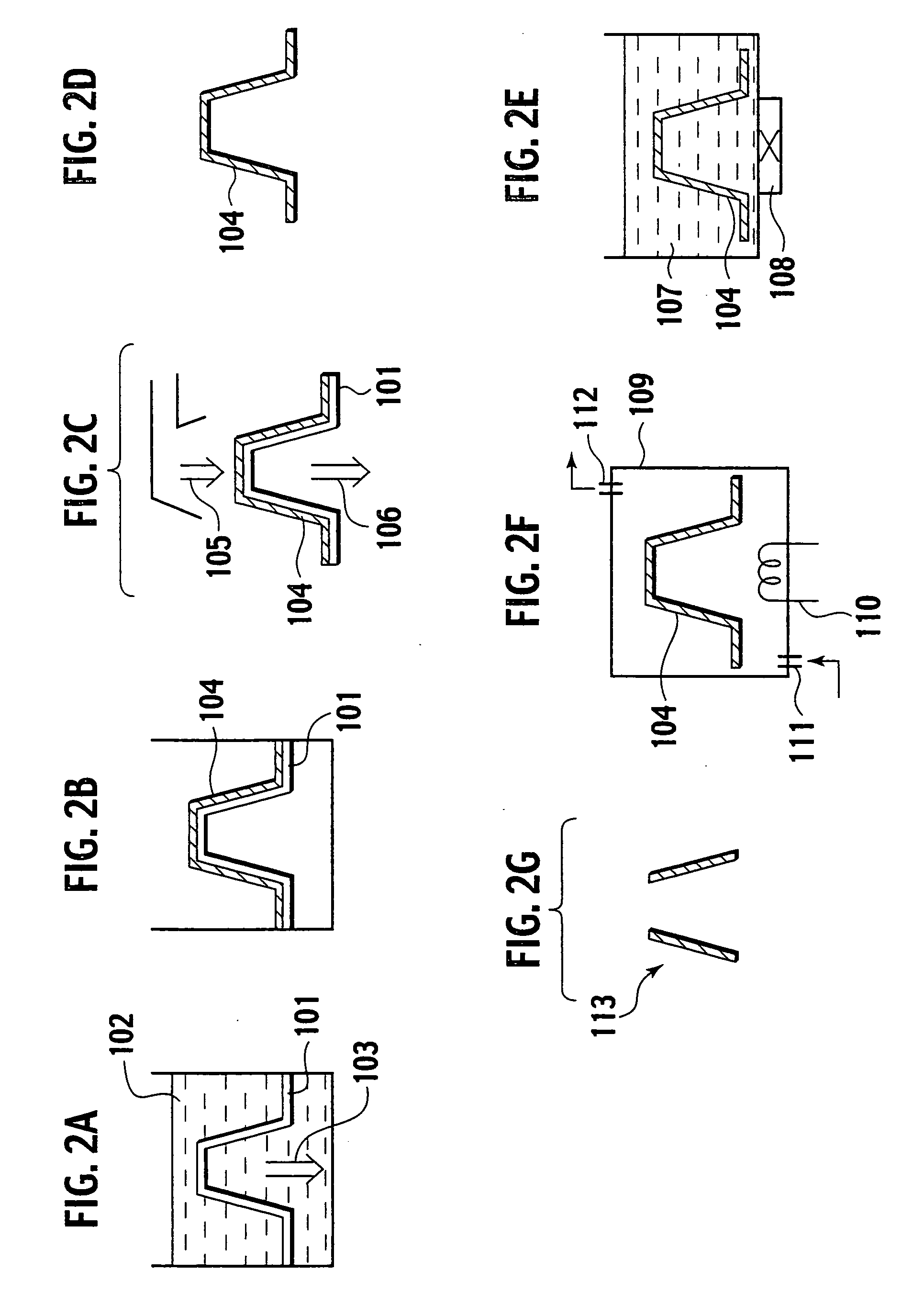

Production method of an acoustic diaphragm, acoustic diaphragm, and a speaker

InactiveUS20070187171A1Reduce hardeningLow viscosityFibre diaphragmsPolymeric diaphragmsPhenolLoudspeaker

A method of producing an acoustic diaphragm includes forming a workpiece having a shape of the acoustic diaphragm by using a natural material which can be carbonized by burning, impregnating a solution including phenol resin into the workpiece, heating the workpiece to bring the phenol resin into a high polymer state, burning the workpiece in a substantially anoxic atmosphere to carbonize the natural material after the heating step, and applying or impregnating the workpiece with a coating material of a solution including phenol resin after the burning step.

Owner:JVC KENWOOD CORP A CORP OF JAPAN

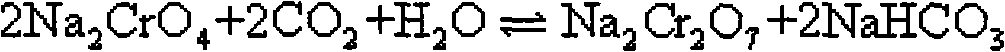

Preparation method of sodium bichromate

ActiveCN102649584AHigh carbonation rateHigh purityChromates/bichromatesChromium CompoundsSodium bicarbonate

The invention provides a preparation method of sodium bichromate. The preparation method comprises the following steps of: (1) adding 700-1,350 g.L<-1> sodium chromate neutral solution of a chromium compound in terms of Na2Cr2O7.2H2O into a carbonization reactor; (2) continuously supplying carbon dioxide into the carbonization reactor, and controlling partial pressure of carbon dioxide to be 0.01-1.5 MPa, reaction temperature to be 15-105 DEG C and reaction time to be 0.5-8.0 h; (3) separating carbonized feed liquid obtained by the step (2) to obtain carbonized liquid and sodium bicarbonate crystals, wherein the concentration of the chromium compound in the carbonized liquid is 700-1,350 g.L<-1> in terms of Na2Cr2O7.2H2O; and (4) crystallizing and dehydrating the carbonized liquid to obtain the sodium bichromate. By preparing the sodium bichromate through the preparation method, the conversation rate from the sodium chromate to the sodium dichromate can reach 95-100 percent, the quality of the sodium bichromate is high, and the sulfate content is less than 0.1 percent by weight.

Owner:SICHUAN YINHE CHEM

Halogen-free multi-effect wood fire retardant and preparation method thereof

PendingCN112223465AReduce static bending strengthReduce the speed of propagationWood treatment detailsWood impregnation detailsMildewMaterials science

The invention discloses a halogen-free multi-effect wood flame retardant and a preparation method thereof. The halogen-free multi-effect wood flame retardant comprises the following preparation raw materials in parts by weight: 70-99 parts of a flame retardant component, 1-3 parts of a moisture resistant agent, 1-3 parts of an anti-rust agent, 1-3 parts of a mildew preventive, 1-2 parts of a quickdrying agent and 1-5 parts of a nano oxide. The flame retardant provided by the invention is low in cost, halogen-free and more environment-friendly, and the flame-retardant wood prepared by the invention has excellent flame retardancy, excellent mildew resistance, excellent rust resistance and excellent quick drying capacity.

Owner:如皋市富强阻燃剂有限公司

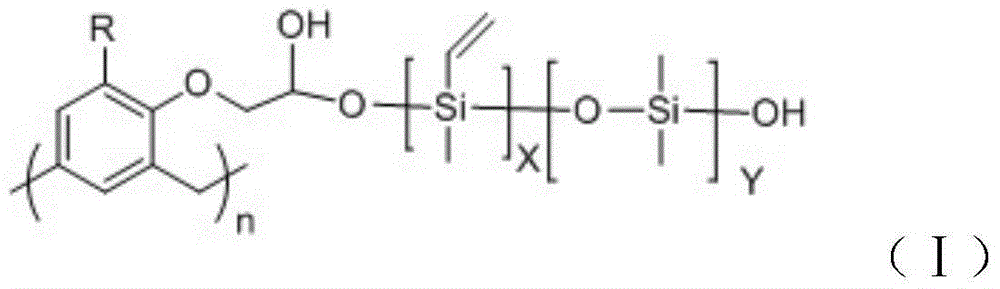

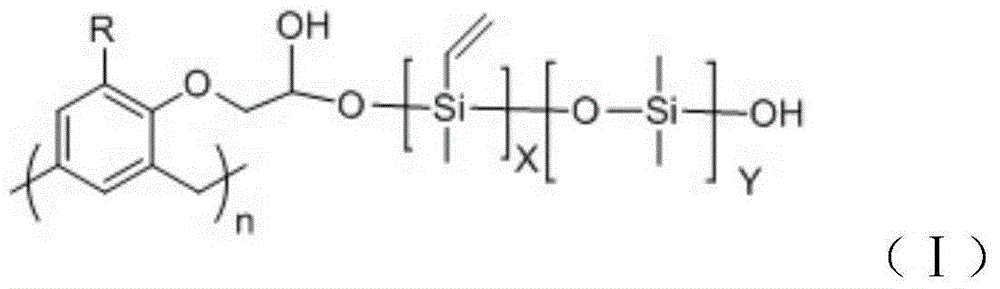

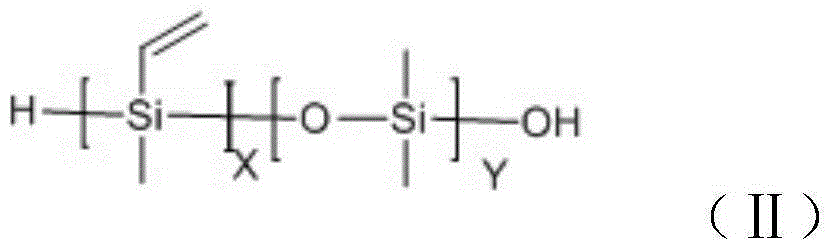

Hyperbranched phosphorus-containing oxygen group functionalized silicon-based resin flame retardant and preparation method thereof

The invention discloses a hyperbranched phosphorus-containing oxygen group functionalized silicon-based resin flame retardant, which is provided with a branched silicon atom-containing molecular skeleton and a phosphorus-containing oxygen group chemically bonded to the silicon atom of the molecular skeleton. The phosphorus-containing oxygen group functionalized silicon-based resin is obtained by (1) reacting a silane compound having three or more condensable functional groups with at least one hydroxyl group-containing compound to form a branched silicon-based resin, and (2) introducing a phosphorus-containing oxygen group to the silicon-based resin to obtain the hyperbranched phosphorus-containing oxygen group functionalized silicon-based resin flame retardant. A flame-retardant polymer composition containing the flame retardant is high in carbon forming rate, high in oxygen index and good in flame-retardant effect.

Owner:SHANDONG TIANYI CHEM

Method for production of carbonized solids and soluble liquid from food waste and device for production of same

InactiveCN104001708AImprove heat transfer efficiencyHigh carbonation rateSolid waste disposalSaturated water vaporInternal heat transfer

The invention provides a method for production of carbonized solids and soluble liquid from food waste and a device for production of the same. The method includes the steps that food waste is thrown into a heating pressure reactor with a steam generation device, and saturated steam is thrown into the heating pressure reactor from the steam generation device to enable the food waste to be separated into soluble liquid and carbonized solids. According to the method for production of carbonized solids and soluble liquid from food waste, the saturated steam supplied by the steam generation device is supplied into the reactor through a primary steam supply pipe and a secondary steam supply pipe respectively, the primary steam supply pipe and the secondary steam supply pipe can be opened and quickly meet the required thermodynamic conditions while the heating pressure reactor starts operating, in the operating process of the heating pressure reactor, the secondary steam supply pipe supplies steam into the heating pressure reactor intermittently in order to supplement heat energy in short supply and increase the saturated steam needed by internal heat transfer.

Owner:SMARTRON

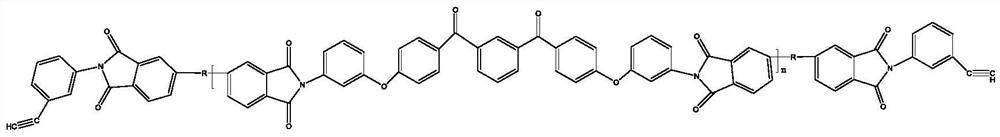

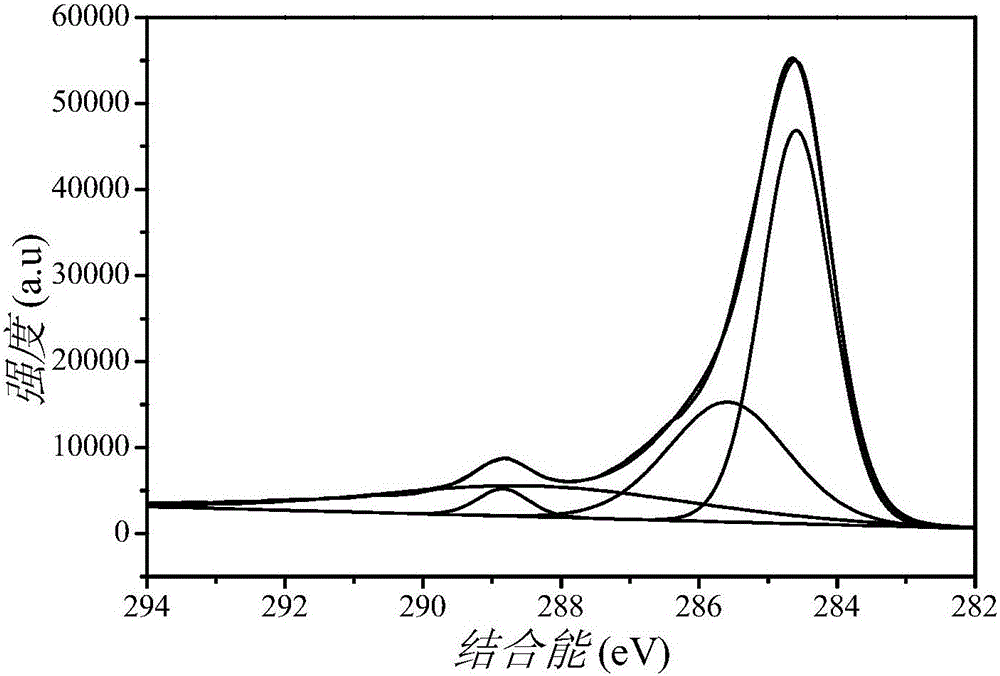

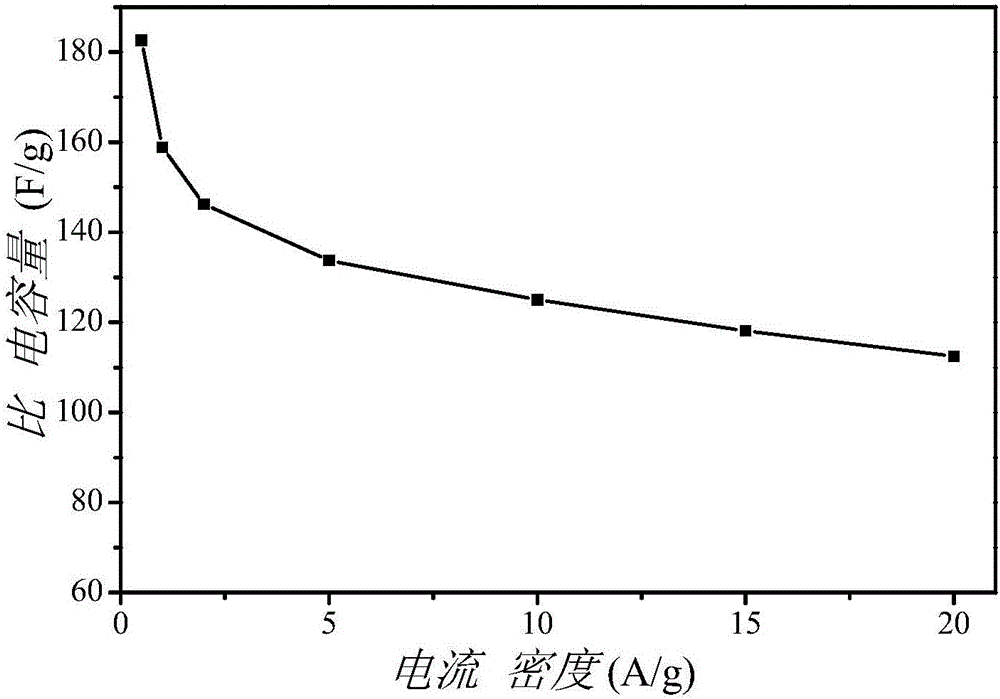

Supercapacitor electrode material and preparation method thereof

InactiveCN112374544AImprove conductivityImprove defectsCarbon compoundsHybrid capacitor electrodesPorous carbonPotassium hydroxide

The invention discloses a supercapacitor electrode material and a preparation method thereof. The preparation method comprises the following steps of: by taking potassium permanganate as a reducing agent and manganese sulfate as a manganese source, preparing sea urchin-shaped nano alpha-MnO2 by adopting a hydrothermal method, then performing hydroxylation modification, grafting polyimide resin tothe sea urchin-shaped nano alpha-MnO2 by adopting a click chemistry mode to obtain the sea urchin-shaped nano alpha-MnO2 grafted polyimide resin, and carrying out high-temperature activation treatmenton the sea urchin-shaped nanometer alpha-MnO2 grafted polyimide resin by adopting potassium hydroxide to obtain the sea urchin-shaped nanometer alpha-MnO2 in-situ modified porous carbon supercapacitor electrode material. By using the electrode material, the defects of MnO2 crystal lattices are improved, the conductivity and stability of electrons are improved, protons and the electrons can freelyflow among the crystal lattices, rapid transmission of ions and the electrons of an interface is guaranteed, the charge transfer path can be shortened, more active sites are provided for charge storage, the electron trapping and transfer capacity is enhanced, and the mechanical stability is also improved.

Owner:犀望新能源科技(昆山)有限公司

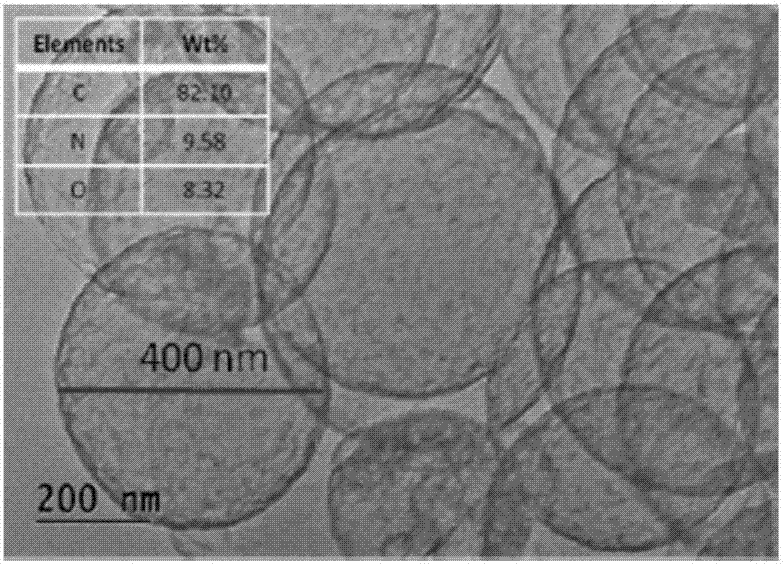

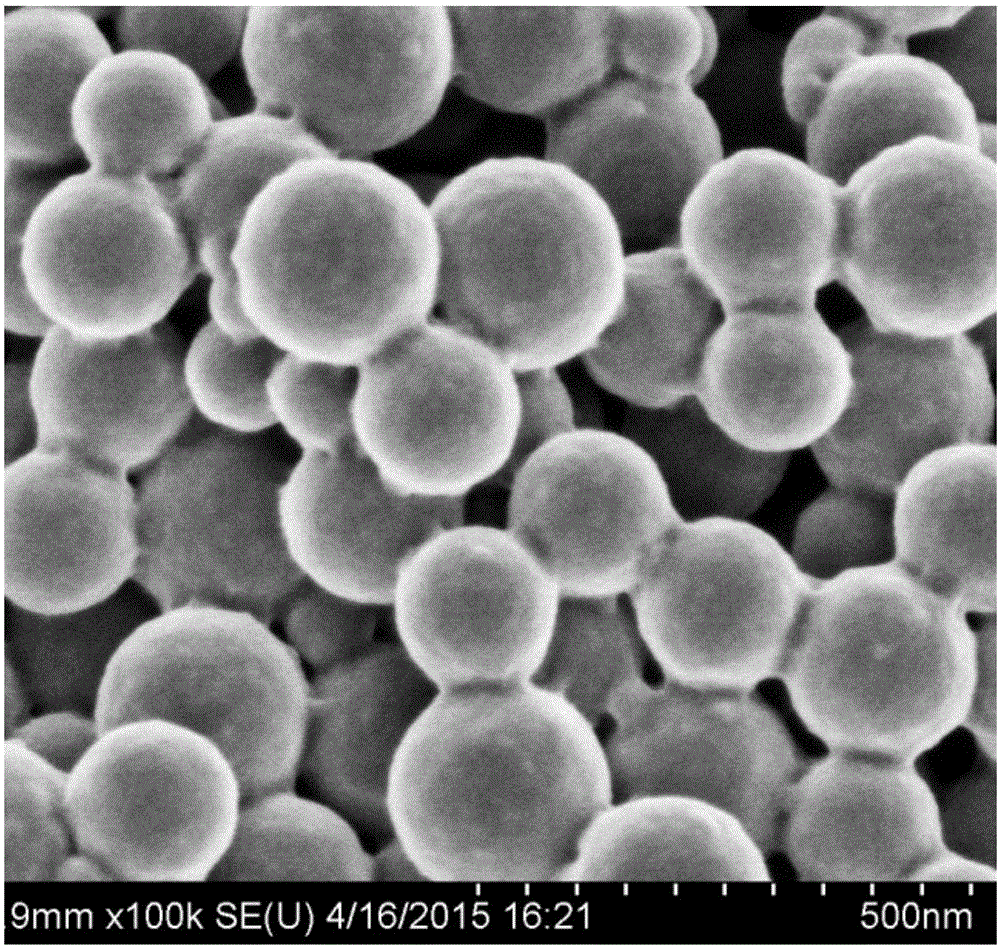

Method for preparing hollow carbon nanospheres through non-template method and application of hollow carbon nanospheres

The invention provides a method for preparing hollow carbon nanospheres through a non-template method and application of the hollow carbon nanospheres. The method includes the steps that with polymeric vesicles being precursors, calcination is performed under protection of inert gas, and the hollow carbon nanospheres are obtained; the polymeric vesicles are formed by polymers P (PMDA-alt-ODA) in a self-assembly mode. No templates are needed according to the preparing method, the preparing process is simple, the preparing period is short, and the method is environmentally friendly; the particle size of the prepared hollow carbon nanospheres is 110-820 nm; because the polymers P (PMDA-alt-ODA) contain a large number of benzene rings, the hollow carbon nanospheres are provided with graphite-like ordered structures, the carbonation rate reaches 50%, and the hollow carbon nanospheres have very good conductive capacity and electricity storage capacity and can be used as active electrode materials of conductive materials, electricity storage materials or supercapacitors.

Owner:TONGJI UNIV

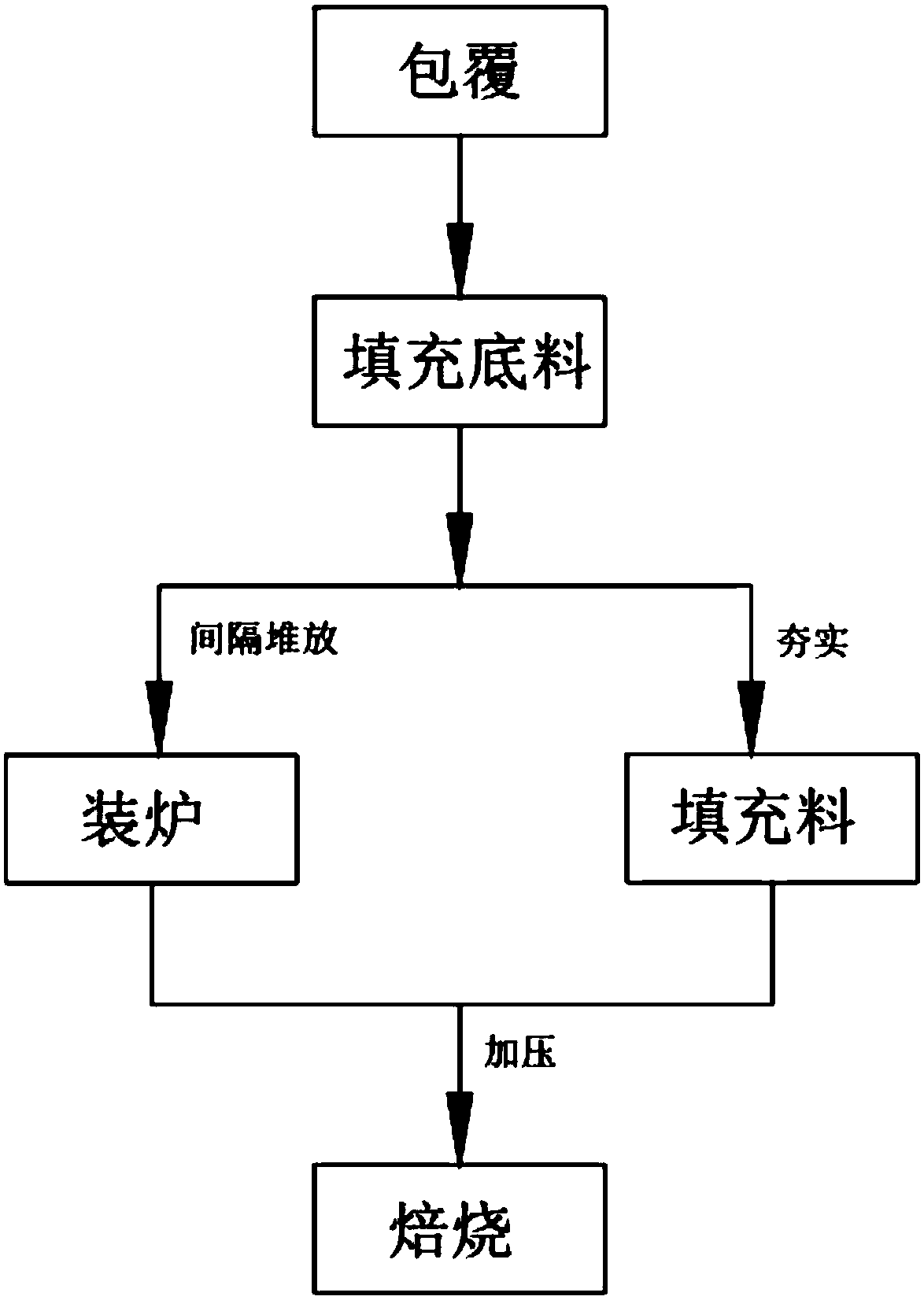

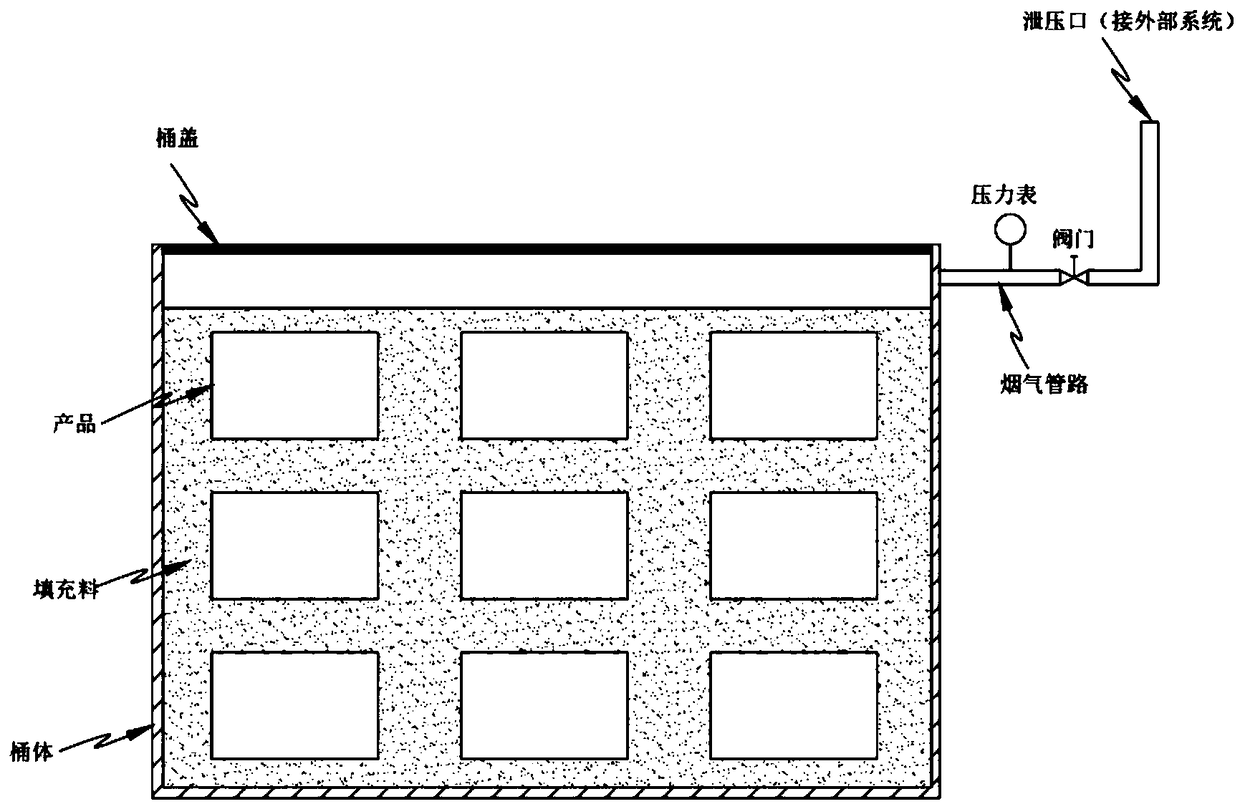

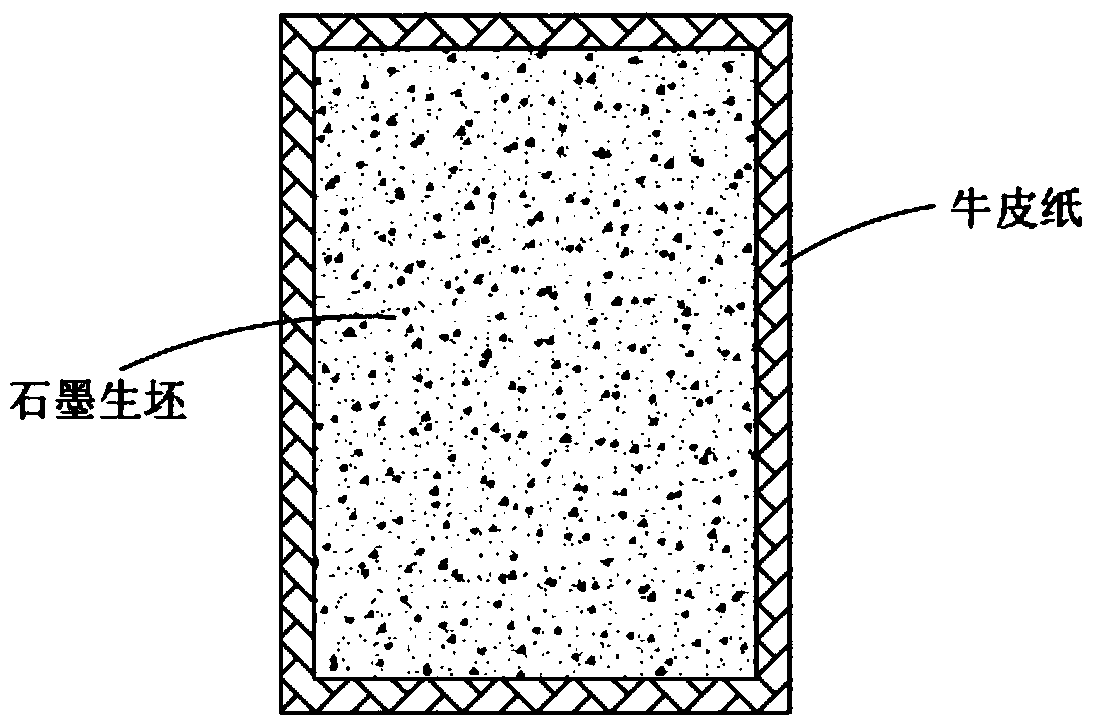

Roasting technology for isostatic pressing formed graphite primary roasting

InactiveCN108751182AReduce sand sticking rateHigh carbonation rateCarbon compoundsCarbonizationGraphite

The invention provides a roasting technology for isostatic pressing formed graphite. The roasting technology comprises the steps that the outer surface of a graphite green body is coated with a layerof organic coating film uniformly before the primary baking of the graphite green body, so that direct contact between a graphite product and sand is isolated in a roasting process, a carbonization process of the organic coating film is used for absorbing organic gas volatilized during a heating process of the graphite product, and at the same time, a purpose of pressurization is achieved by relying on the self gas expansion generated by the graphite product in the roasting process, so that a pressure roasting device is used for roasting according to a roasting pressure process curve. A technical problem that sand is liable to stick to the surface of the graphite product after roasting in the prior art is solved, and at the same time, the coke separating amount of the product is improved.

Owner:SINOSTEEL NEW MATERIAL ZHEJIANG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com