Carbonized fibers and carbonization method thereof

A carbonized fiber and carbonization rate technology, which is applied in the fields of fiber chemical characteristics, chemical instruments and methods, textiles and papermaking, etc., can solve the problems of water resistance or air permeability cannot be improved at the same time, carbonization rate cannot be guaranteed, and application prospects are limited. , to achieve the effect of superior waterproof performance, high carbonization rate and superior air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

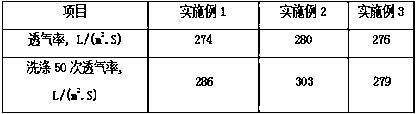

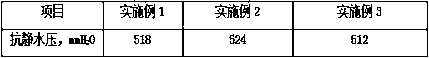

Examples

Embodiment 1

[0036] Example 1 A carbonized fiber and its carbonization method

[0037] (1) Raw material preparation

[0038] As the raw material, Lyocell fiber is selected;

[0039] The Lyocell fiber is Lyocell industrial filament, the specification is: linear density is 1900 dtex, strength is 90.5N, constant elongation is 4.6% at 66.6N, constant elongation at 73.6N is 4.6%, elongation at break is 7.5%, strength is not The uniform rate is 2.1%, the uneven rate of breaking elongation is 5.77%, and the dry heat shrinkage rate (177°C.10min.0.05CN / dtex) is 0.5%.

[0040] (2) Preparation of base cloth

[0041] The above-mentioned fibers are woven with an air-jet loom or an arrow loom according to the siro spinning process, and then undergo conventional singeing, desizing, scouring, bleaching, mercerizing, dyeing, ammonia fumigation, oxidation, washing, drying and drying. Pre-shrinking process to obtain the base cloth.

[0042] When weaving, the warp density is set at 80-85 threads / m, and th...

Embodiment 2

[0064] Example 2 A carbonized fiber and its carbonization method

[0065] (1) Raw material preparation

[0066] As the raw material, Lyocell fiber is selected;

[0067] The Lyocell fiber is Lyocell industrial filament, the specification is: linear density is 1833 dtex, strength is 88.5N, constant elongation is 3.2% at 66.6N, constant elongation at 73.6N is 4.0%, elongation at break is 6.5%, strength is not The uniform rate is 1.9%, the uneven rate of breaking elongation is 5.4%, and the dry heat shrinkage rate (177°C.10min.0.05CN / dtex) is 0.45%.

[0068] (2) Preparation of base cloth

[0069] The above-mentioned fibers are woven with an air-jet loom or an arrow loom according to the siro spinning process, and then undergo conventional singeing, desizing, scouring, bleaching, mercerizing, dyeing, ammonia fumigation, oxidation, washing, drying and drying. Pre-shrinking process to obtain the base cloth.

[0070] When weaving, the warp density is set at 85-90 threads / m, and th...

Embodiment 3

[0092] Example 3 A carbonized fiber and its carbonization method

[0093] (1) Raw material preparation

[0094] As the raw material, Lyocell fiber is selected;

[0095] The Lyocell fiber is Lyocell industrial filament, the specification is: linear density is 1889 dtex, strength is 89.6N, constant elongation is 3.6% at 66.6N, constant elongation at 73.6N is 4.45%, elongation at break is 6.68%, strength is not The uniform rate is 2.15%, the uneven rate of breaking elongation is 5.6%, and the dry heat shrinkage rate (177°C.10min.0.05CN / dtex) is 0.47%.

[0096] (2) Preparation of base cloth

[0097] The above-mentioned fibers are woven with an air-jet loom or an arrow loom according to the siro spinning process, and then undergo conventional singeing, desizing, scouring, bleaching, mercerizing, dyeing, ammonia fumigation, oxidation, washing, drying and drying. Pre-shrinking process to obtain the base cloth.

[0098] When weaving, the warp density is set at 86-90 threads / m, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage | aaaaa | aaaaa |

| carbonization coefficient | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com