Roasting technology for isostatic pressing formed graphite primary roasting

A technology of isostatic pressing and graphite, applied in the direction of inorganic chemistry, non-metallic elements, carbon compounds, etc., can solve the problems of product damage, production cost increase, etc., and achieve the effect of increasing carbonization rate and reducing sand sticking rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

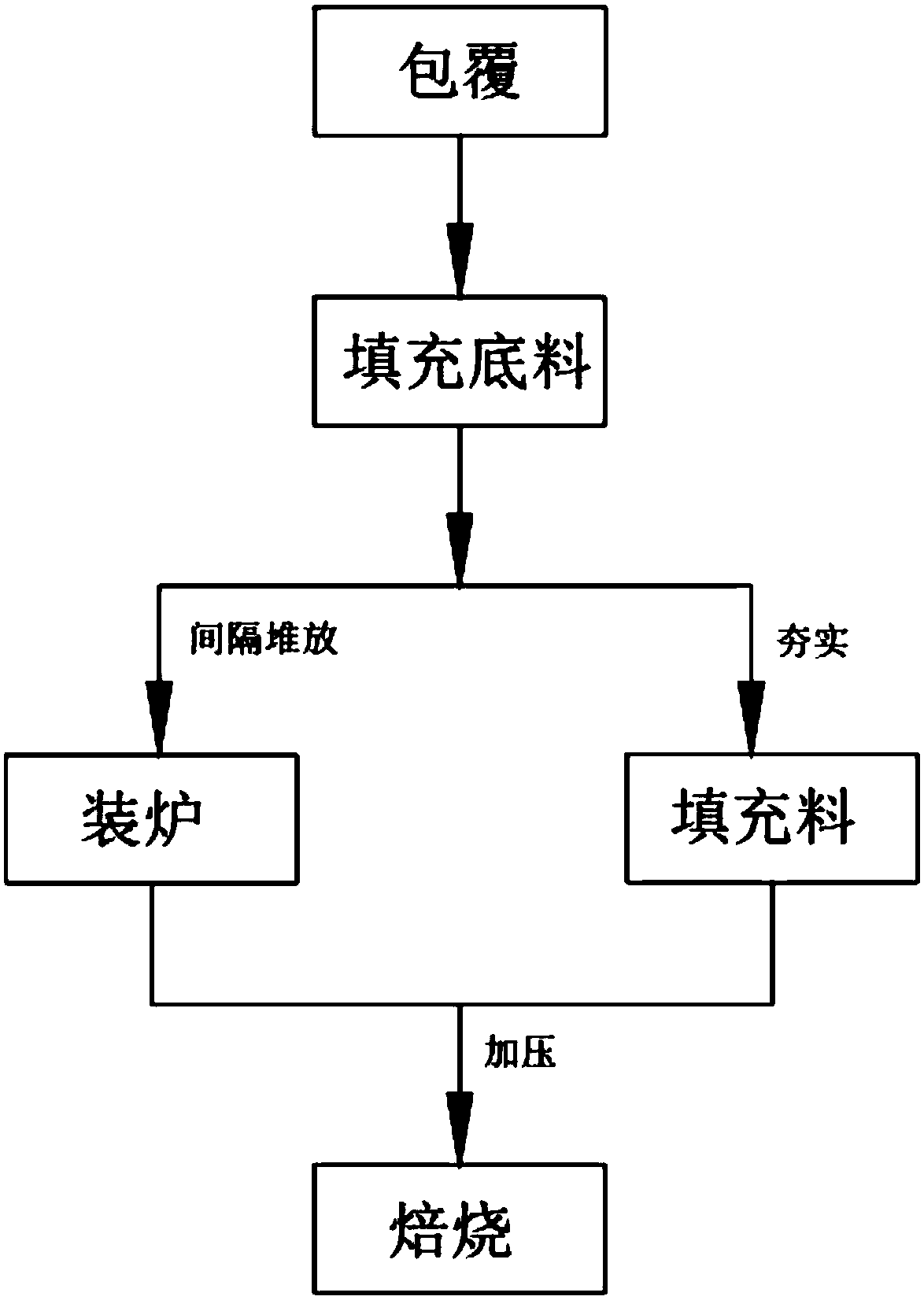

[0039] A kind of roasting process for isostatic pressing graphite, comprises the following steps:

[0040]Step 1, coating, coating the outer surface of the graphite green body after isostatic pressing with a coating film, so that the graphite green body is isolated from the external environment, wherein the coating film is an organic coating film;

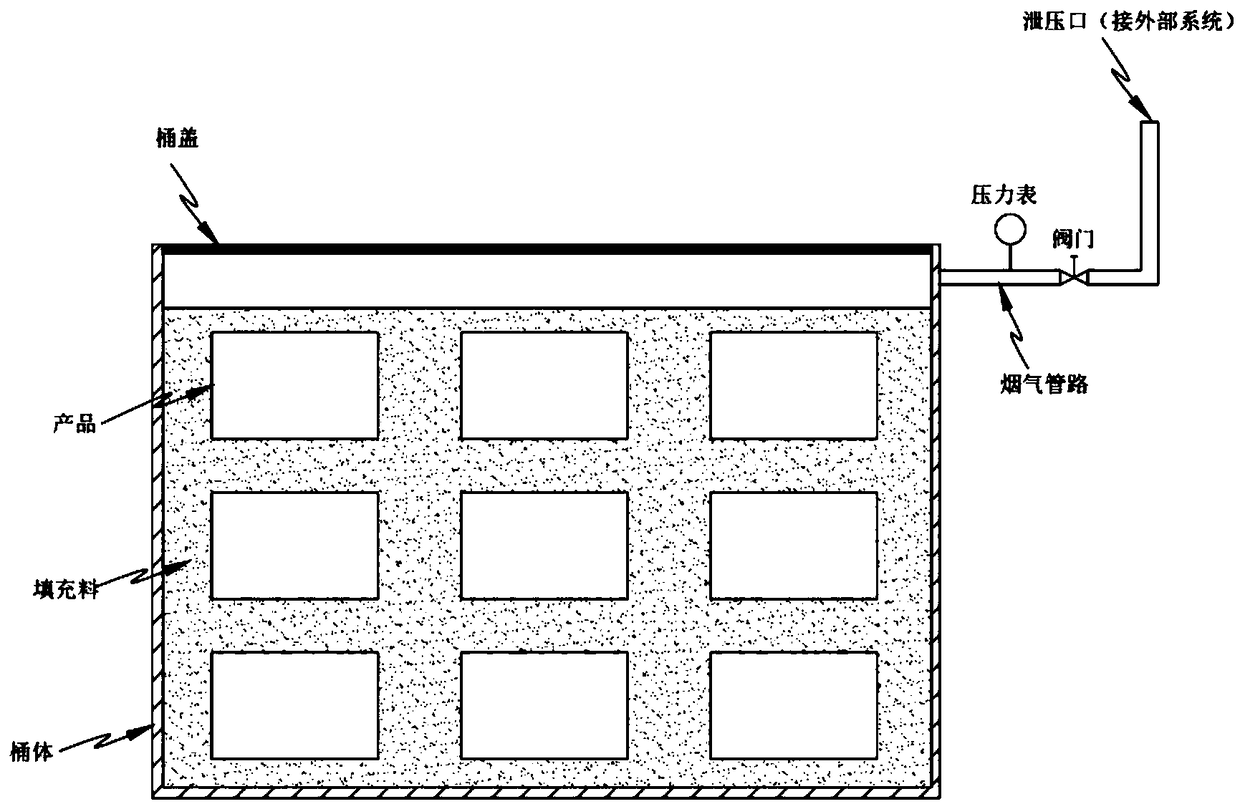

[0041] Step 2, filling the bottom material, filling the bottom of the pressure roasting device with a filler material with heat transfer properties, the thickness of the filler materi...

Embodiment 2

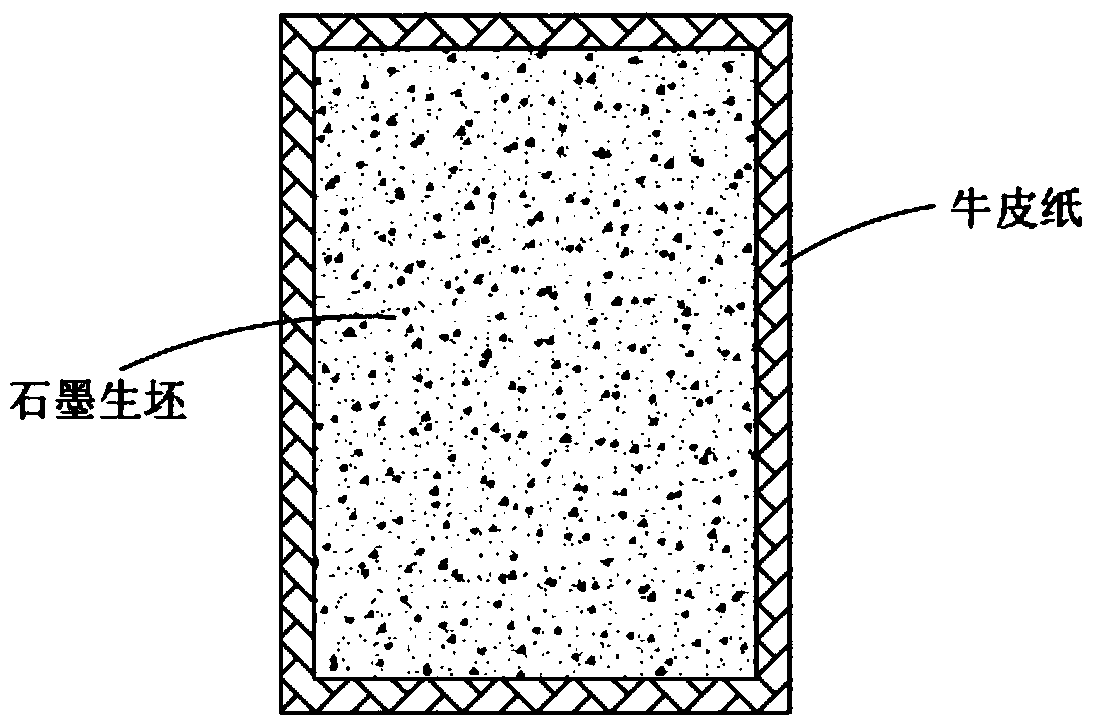

[0061] Components that are the same as or corresponding to Embodiment 1 use the corresponding reference numerals as in Embodiment 1. For the sake of simplicity, only the differences from Embodiment 1 will be described below. This embodiment two and image 3 The difference of the shown embodiment one is:

[0062] In the step 1, the organic coating film is a wood chip coating layer, and the wood chip coating layer is a wooden box whose shape is larger than the graphite green body, and the bottom of the wooden box is filled with wood chips with a thickness of 2 to 3 mm and compacted to keep the graphite green body level, and then put the graphite green body into the wooden box.

[0063] It should be noted that, in this embodiment, wood chips are selected as the organic coating layer. When the inventors carried out actual production, they found that using wood chips as the organic coating layer was more effective than using kraft paper as the graphite product produced by the orga...

Embodiment 3

[0066] Components that are the same as or corresponding to Embodiment 1 use the corresponding reference numerals as in Embodiment 1. For the sake of simplicity, only the differences from Embodiment 1 will be described below. This embodiment three and image 3 The difference of the shown embodiment one is:

[0067] Further, as Figure 5 As shown, the whole of the wooden box is a hollow frame structure, and the distance between it and the graphite green body is 1-3mm, and the wood chips with a particle size of 0.1-0.5mm are used to control the graphite green body and the wooden box. When filling the gap between the graphite green body and the wooden box with wood chips, observe and correct the angle α between the axis of the graphite green body and the axis of the wooden box at any time, so that α satisfies, 0≤α<15°, preferably 0°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com