Halogen-free multi-effect wood fire retardant and preparation method thereof

A fire retardant and wood technology, applied in wood treatment, wood impregnation, wood impregnation, etc., can solve the problems of shortened service life of pressure tanks, corrosion of metal components, easy migration, etc., to improve flame retardant performance and reduce static bending strength , the effect of slowing down the propagation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

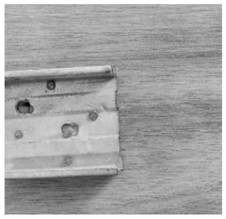

Image

Examples

preparation example Construction

[0043] The second aspect of the present invention provides a method for preparing a halogen-free multi-effect wood flame retardant, which includes the following steps: according to the proportion, adding the flame retardant component and the anti-moisture agent into the horizontal mixing tank, and adding 30 to 50 Stir at a speed of rpm for 20-40 minutes, then add anti-rust agent, anti-fungal agent, quick-drying agent, and nano-oxide, mix for 80-100 minutes, and discharge to obtain the flame retardant.

[0044] A third aspect of the present invention provides a treatment process for protecting wood with a halogen-free multi-effect wood flame retardant prepared by the present invention, comprising the following steps:

[0045] (1), dry the wood to be treated to make its moisture content ≤ 10%, and treat it with microwave for 20-30 minutes;

[0046] (2), a kind of halogen-free multi-effect wood flame retardant prepared by the present invention and organic solvent are 1: 10~1: 50 ...

Embodiment 1

[0052] Example 1 provides a halogen-free multi-effect wood flame retardant, its preparation raw materials, by weight, include 85 parts of flame retardant components, 2 parts of anti-moisture agent, 2 parts of anti-rust agent, 2 parts of anti-fungal agent , 1.5 parts of quick-drying agent, 3 parts of nano-oxide.

[0053] The flame retardant component is a mixture of ammonium polyphosphate, borax and melamine, and the weight ratio is 10:2:1.

[0054] The ammonium polyphosphate II is type II ammonium polyphosphate modified by γ-aminopropyltriethoxysilane with a degree of polymerization not less than 1000 (purchased from Shandong Changsheng Flame Retardant New Material Co., Ltd., model CS FR APP 231 ), the modification method is as follows:

[0055] S1. Put γ-aminopropyltriethoxysilane (purchased from Hangzhou Jessica Chemical Co., Ltd.), ethanol and distilled water into a three-necked flask at a volume ratio of 2:10:1, and carry out at 45°C. After reacting in a water bath for 1...

Embodiment 2

[0069] Similar to Example 1, a halogen-free multi-effect wood flame retardant and its preparation method are provided, but in the preparation raw materials, by weight, it includes 70 parts of flame retardant components and 2 parts of anti-moisture agent , 2 parts of antirust agent, 2 parts of antifungal agent, 1.5 parts of quick drying agent, 3 parts of nano oxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com