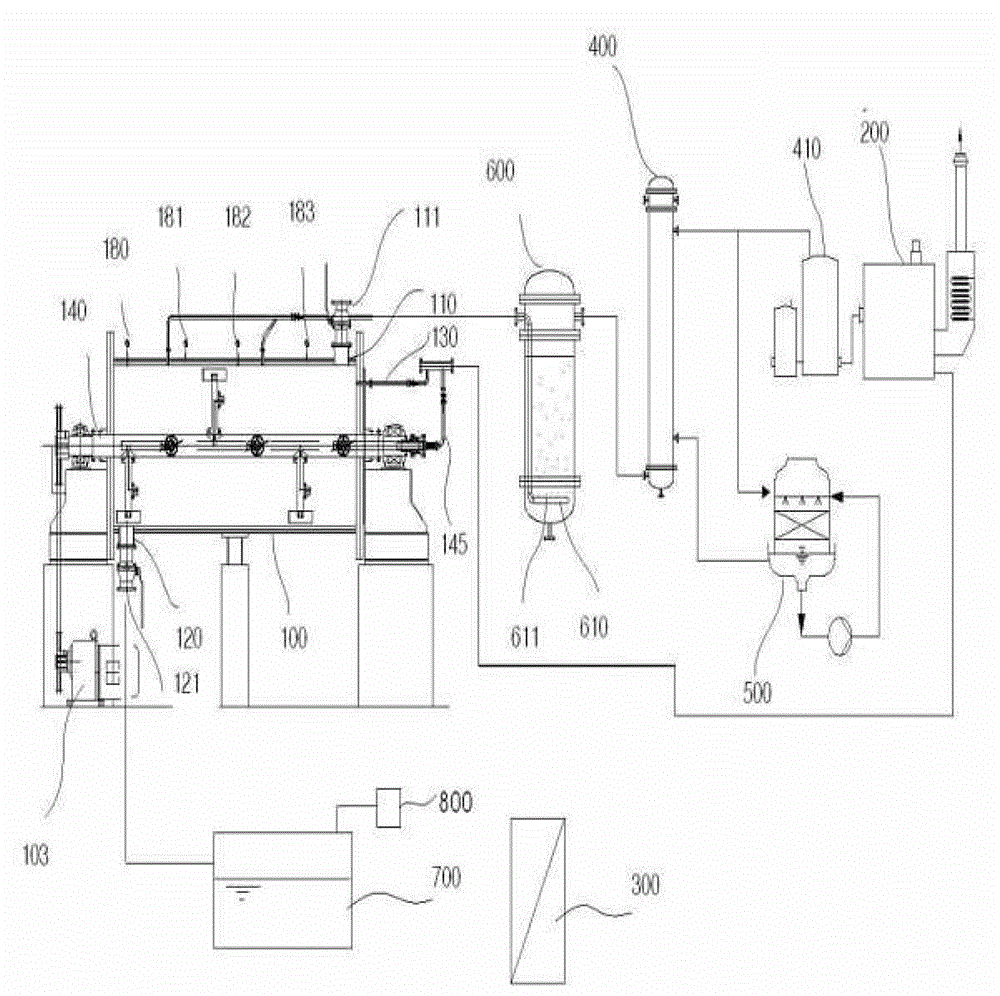

Method for production of carbonized solids and soluble liquid from food waste and device for production of same

A food waste and generation device technology, applied in the direction of solid waste removal, etc., can solve the problems of difficult moisture content, reduced heat transfer rate, pollution, etc., and achieves the reduction of food waste, convenient maintenance and high energy recovery rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

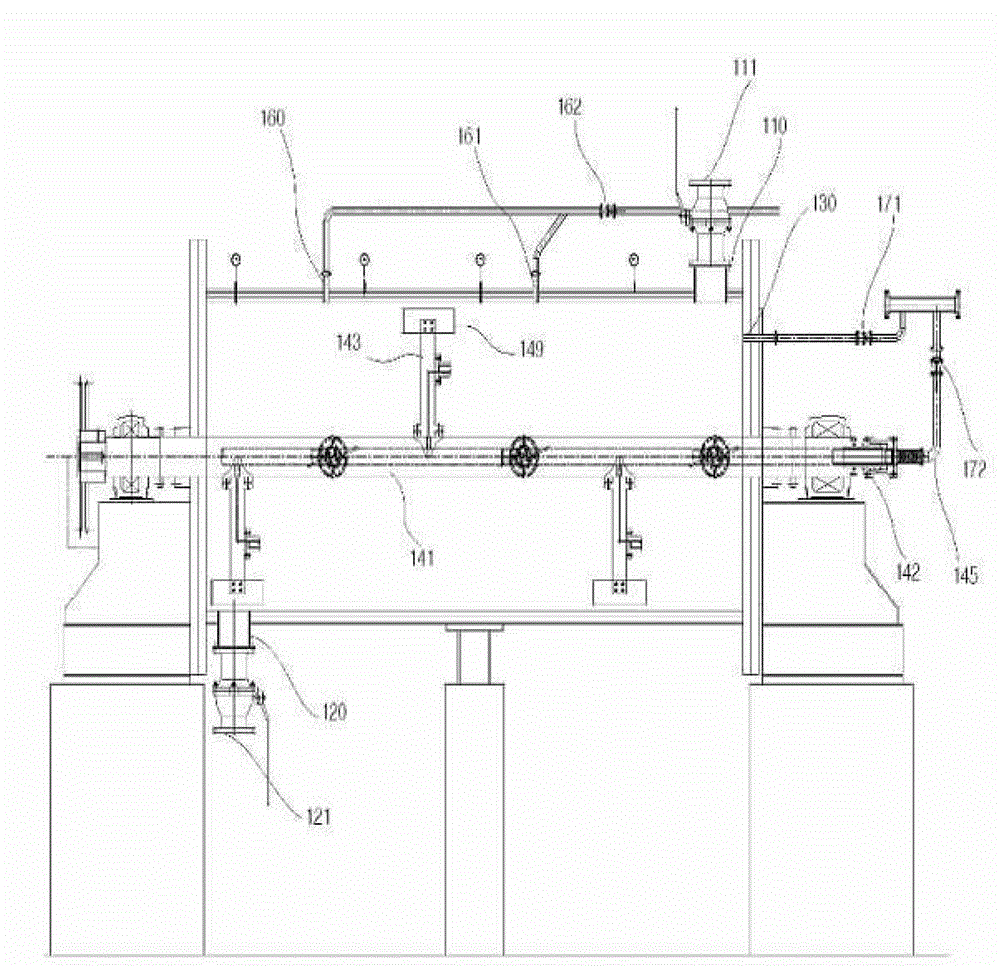

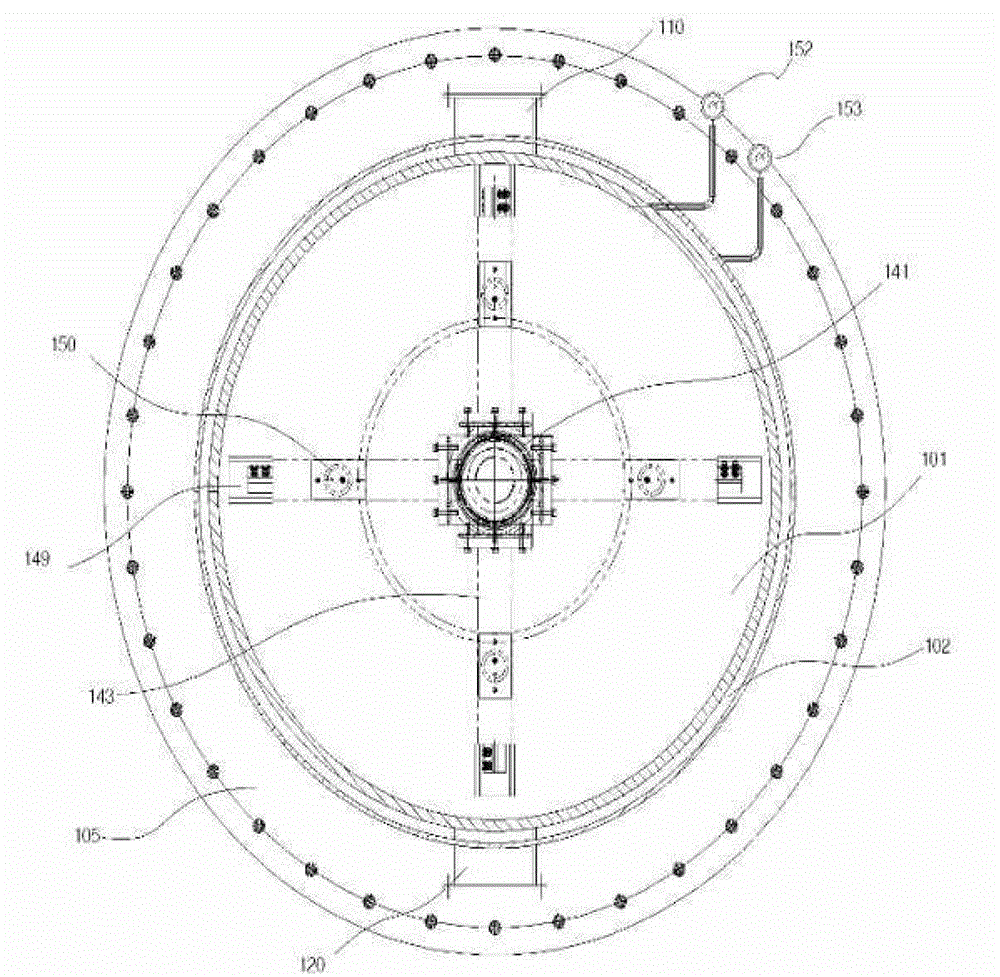

[0028] The method for producing carbonized solids and solubles from food waste according to the present invention comprises: a step of feeding food waste into a heated pressure reactor having a steam generator; and feeding the above heated pressure reactor from the steam generator The step of saturating water vapor to separate food waste into soluble and carbonized solids.

[0029] Different from the existing heated pressure reactor, the present invention adopts a non-electric heater steam generating device to heat the heated pressure reactor. As far as the electric heater adopted in the existing heating pressure reactor is concerned, what is used is the indirect heating method of heating the heating pressure reactor for thermal decomposition from the outside, and this has the following problems: resulting in heat transfer rate and because only the water in the food waste is used to maintain the pressure and temperature conditions required by the thermodynamic conditions, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com