Method for preparing hollow carbon nanospheres through non-template method and application of hollow carbon nanospheres

A hollow nano, non-template technology, applied in the field of materials, can solve the problems of long preparation cycle, adverse environmental impact, cumbersome steps, etc., and achieve the effect of short preparation cycle, good electrical conductivity, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation method of the hollow nano-carbon spheres of the present invention comprises the following steps: using polymer vesicles as a precursor, calcining under the protection of an inert gas to obtain the hollow nano-carbon spheres.

[0028] Among them, polymersomes are self-assembled by polymer P(PMDA‐alt‐ODA). The polymer P(PMDA‐alt‐ODA) is an alternating copolymer of 4,4'‐diaminodiphenyl ether (ODA) and 1,2,4,5‐pyromellitic dianhydride (PMDA), containing a large amount of The benzene ring has a molecular weight of 5,000 to 100,000.

[0029] The preparation method of polymersomes is as follows: polymer P(PMDA-alt-ODA) is dissolved in dimethylformamide (DMF) at a concentration of 1.0-10.0mg / mL, and added dropwise under vigorous stirring Deionized water, the polymersome solution was obtained after dialysis in deionized water, and the polymersome was obtained after freeze-drying. The particle size range of the polymer vesicle is 100-800nm. In this method, the ...

Embodiment 1

[0042] This embodiment provides a method for preparing hollow carbon nanospheres, comprising the following steps:

[0043] (1), the preparation steps of polymersomes:

[0044] Dissolve 50 mg of Polymer P (PMDA‐alt‐ODA) in dimethylformamide (DMF) at a concentration of 1.0 mg / mL, and add twice the amount of deionized DMF dropwise under vigorous stirring. Water, after dialysis in deionized water to obtain a polymersome solution, freeze the polymersome solution to a solid state in a refrigerator, and then lyophilize it in a freeze dryer to obtain a polymersome (powder form);

[0045] (2), the preparation steps of hollow carbon nanospheres:

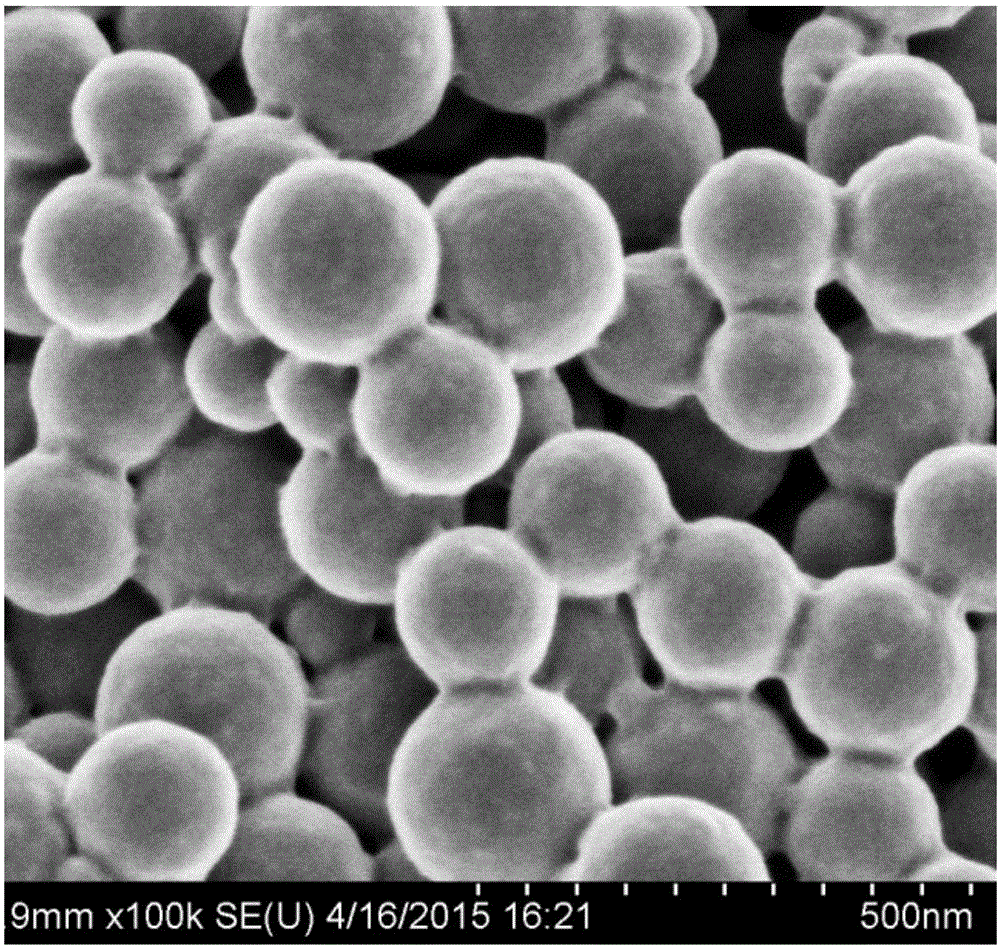

[0046] Under the protection of nitrogen, the vesicular polymer (in powder form) obtained in step (1) is calcined at 650° C. to obtain hollow carbon nanospheres with uniform dispersion and uniform particle size.

[0047] Wherein, in step (1), the molecular weight of the polymer P(PMDA-alt-ODA) used is 5000, and the particle diameter of the ob...

Embodiment 2

[0050] This embodiment provides a method for preparing hollow carbon nanospheres, comprising the following steps:

[0051] (1), the preparation steps of polymersomes:

[0052] Dissolve 50 mg of Polymer P (PMDA‐alt‐ODA) in dimethylformamide (DMF) at a concentration of 3.0 mg / mL, and add twice the volume of DMF dropwise under vigorous stirring. Water, after dialysis in deionized water to obtain a polymersome solution, the polymersome solution was frozen in a refrigerator to a solid state, and then freeze-dried in a freeze dryer to obtain a polymersome (in powder form).

[0053] (2), the preparation steps of hollow carbon nanospheres:

[0054] Under the protection of nitrogen, the vesicular polymer (in powder form) obtained in step (1) was calcined at 750° C. to obtain hollow carbon nanospheres with uniform dispersion and uniform particle size.

[0055] Wherein, in step (1), the molecular weight of the polymer P(PMDA-alt-ODA) used is 10000, and the particle diameter of the obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com