Method and system for preparing nitrogen-vanadium alloy

A nitrogen-vanadium alloy and nitrogen synthesis technology, which is applied in the system field of preparing nitrogen-vanadium alloy, can solve the problems of low yield, expensive, unstable, etc., and achieve the effects of low impurity content, low production cost, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

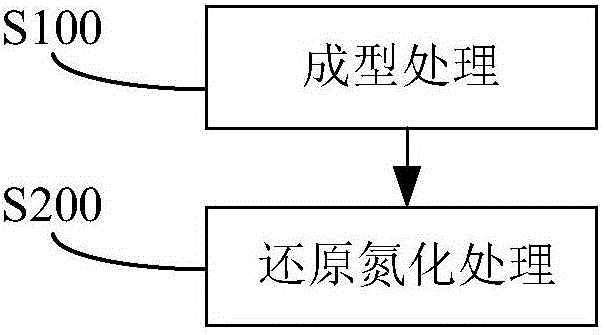

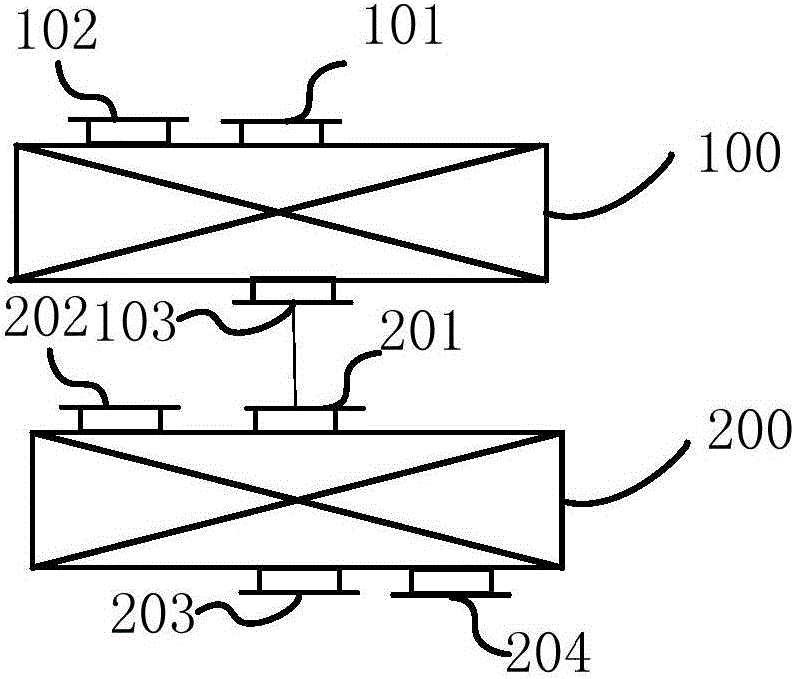

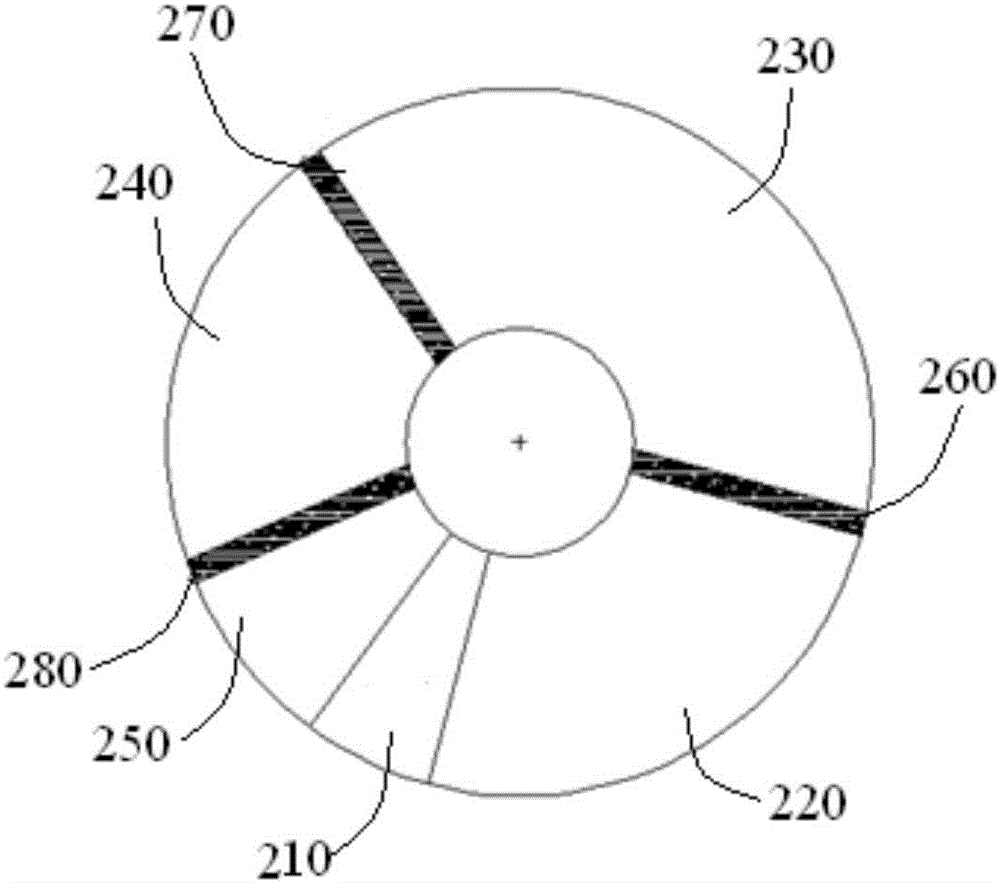

Method used

Image

Examples

Embodiment 1

[0065] Utilize the method for the embodiment of the present invention to prepare nitrogen vanadium alloy, concrete method is as follows:

[0066] (1) Put V 2 o 3 1. Graphite powder and water are mixed according to the mass ratio of 100:45:8 for pelletizing to obtain mixed pellets;

[0067] (2) drying the mixed pellets to obtain dried pellets;

[0068] (3) Put the dried pellets into the rotary hearth furnace. The temperature of the carbonization reaction zone of the rotary hearth furnace is set at 1210°C±10°C, the reaction time is 0.8h, and the temperature of the nitriding reaction zone is set at 1300±10°C. The reaction time is 1 hour, the nitriding reaction is finished, the vanadium-nitrogen alloy enters the cooling zone, is cooled to below 200° C., and is released from the furnace to obtain a nitrogen-vanadium alloy product. The obtained nitrogen-vanadium alloy product has a nitrogen content of 13% and a vanadium content of 73%.

Embodiment 2

[0070] Utilize the method for the embodiment of the present invention to prepare nitrogen vanadium alloy, concrete method is as follows:

[0071] (1) Put V 2 o 3 1. Graphite powder and water are mixed according to the mass ratio of 100:50:10 for pelletizing to obtain mixed pellets;

[0072] (2) drying the mixed pellets to obtain dried pellets;

[0073] (3) Put the dried pellets into the rotary hearth furnace. The temperature of the carbonization reaction zone of the rotary hearth furnace is set at 1210°C±10°C, the reaction time is 1h, and the temperature of the nitriding reaction zone is set at 1350±10°C. After 1.5 hours, the nitriding reaction ends, the vanadium-nitrogen alloy enters the cooling zone, and is cooled to below 200° C. to be released from the furnace to obtain a nitrogen-vanadium alloy product. The obtained nitrogen-vanadium alloy product has a nitrogen content of 14.5% and a vanadium content of 76%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com