Patents

Literature

46results about How to "Improve carbonization yield" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

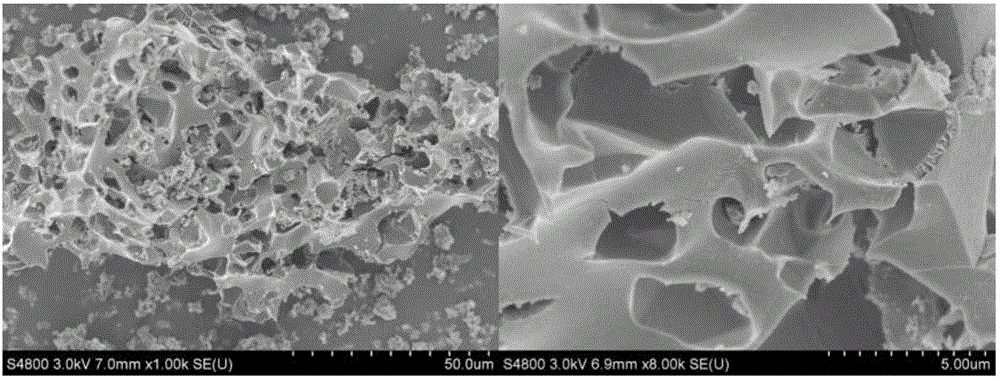

Preparation method of polyacrylonitrile/graphene composite-based carbon fiber

ActiveCN102560746AImprove thermal conductivityUniform deliveryElectroconductive/antistatic filament manufactureSynthetic polymer filament chemical after-treatmentCarbon fibersIn situ polymerization

The invention discloses a preparation method of polyacrylonitrile / graphene composite-based carbon fiber, which comprises the following steps: firstly preparing a polyacrylonitrile mixed solution uniformly dispersed with graphene through an in-situ polymerization method, and then employing the mixed solution as a spinning solution and obtaining a polyacrylonitrile / graphene composite protofilament by a wet spinning or dry-jet wet spinning process, and finally making the protofilament subject to a pre-oxidation treatment and a carbonization treatment to obtain the polyacrylonitrile / graphene composite-based carbon fiber. Compared with the existing polyacrylonitrile-based carbon fiber, the carbon fiber prepared by the method of the invention has a significantly increased mechanical property, and the carbonation yield in the preparation process is improved, therefore, the preparation method is an efficient and reliable preparation method with good application prospects.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

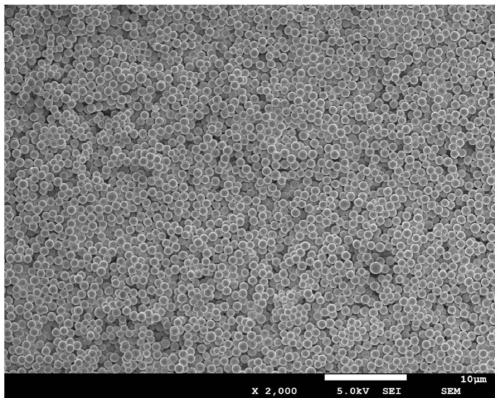

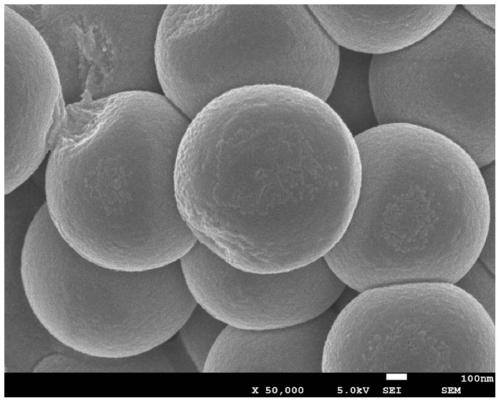

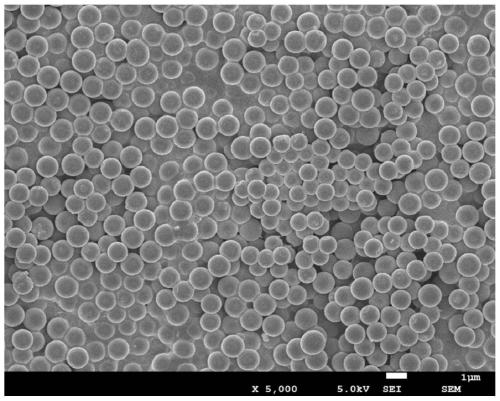

Process For Producing Spherical Carbon Material

InactiveUS20070212610A1Good yieldGood sphericityAlkali metal halidesSecondary cellsNon aqueous electrolytesElectrode material

A process for producing a spherical carbon material, comprising: subjecting a spherical vinyl resin to an oxidation treatment in an oxidizing gas atmosphere to obtain a spherical carbon precursor, and carbonizing the spherical carbon precursor at 1000-2000° C. in a non-oxidizing gas atmosphere. The thus-obtained spherical carbon material exhibits excellent performances, including high output performance and durability, when used, e.g., as a negative electrode material for non-aqueous electrolyte secondary batteries.

Owner:KUREHA KAGAKU KOGYO KK

Preparation method of phenolic resin combined honeycomb activated carbon

The invention relates to a preparation method of phenolic resin combined honeycomb activated carbon, which can be used for preparing the honeycomb activated carbon by the steps of: mixing dry powder, preparing plastic pug by mixing and kneading through a wet method, vacuum pugging, extrusion molding, drying, curing treatment and secondary heat treatment. Besides the function of bonding and improving the mechanical strength of the activated carbon, the phenolic resin also remarkably improves the heat-resisting property and water resistance of the honeycomb activated carbon; and furthermore, the honeycomb activated carbon is added with porous mineral, thus better effectively improving the mechanical strength and the specific surface area of the honeycomb activated carbon. The preparation method has lower heat treatment temperature and low production energy consumption, and effectively reduces the production cost; and the preparation technique and equipment thereof are simple, and the production investment is lower, so that the cost is further reduced.

Owner:TSINGHUA UNIV

Process for preparing precursor fiber of cellulose base carbon fiber

InactiveCN1587457AGood thermal stabilityIncreased carbonization yieldMonocomponent cellulose artificial filamentWater contentSolvent

The present invention relates to preparation process of precursor fiber of cellulose base carbon fiber in chemical fiber production. The preparation process includes mixing concentrated NMMO aqua and carbon black for carbon black water in the weight ratio of 20-10000, decomprssion distillation to obtain NMMO / carbon black solution with water content 24-28 wt%, adding the mixtue of sliced cellulose pulp and NMMO / carbon black solution in the weight ratio of 5-15 to 100 into dissolving reactor, swelling and stirring at 70-90 deg.c, raising the temperature to 90-120 deg.c, stirring and decomprssion distillation to eliminate water and form cellulose / NMMO / carbon black spinning liquid with water content of 12-14 wt%, and dry-wet spinning to obtain the precursor fiber. The present invention has high carbonizing yield, high mechanical performance of the carbon fiber, raised spinnability of the spinning liquid, non-toxic solvent, high solvent recovering rate and environment friendship.

Owner:DONGHUA UNIV

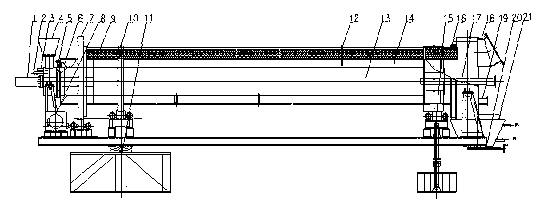

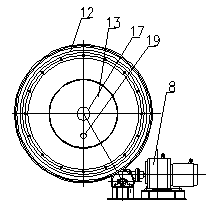

Multifunctional biomass heat conversion equipment and process

InactiveCN102839003AStrong noveltyAdvancedCarbon compoundsIndirect heating destructive distillationTemperature controlDirect combustion

The invention belongs to the technical field of biomass heat conversion, and particularly relates to equipment and a process for carbonizing, activating, pyrolysis gasification, catalytic cracking of a plurality of product roads. The equipment comprises a flue pipe, an activator (gasifying agent) inlet, an auxiliary activator (gasifying agent) inlet, a feeding hole, a feeding cover seal, a forced blanking shoveling board, a gear, a drive and transmission case, heat-insulating cotton, a riding wheel, a barrel angle adjusting bolt, a temperature measuring device, a combustion channel, a product channel, an angle adjusting screw, a discharge cover seal, a lighting-up tuyere, an explosion-proof opening, a combustion-supporting opening (viewing port), a discharge sealing valve and a discharge cooler. According to the invention, the multifunctional biomass heat conversion equipment simultaneously has the functions of carbonizing, activating, pyrolysis gasification, catalytic cracking by changing an inclination angle, a rotating speed and a sealing mode; a traditional direct combustion method is changed into a bolometric method, and the problems of low yield, serious ignition loss, non-uniform reaction, small yield, large consumption and temperature control difficulty in the biomass heat conversion process are solved from the technical aspect.

Owner:秦恒飞

Preparation method for three-dimensional hierarchical porous biomass carbon negative electrode material of lithium ion battery

ActiveCN106082158AImprove carbonization yieldStable structureCell electrodesSecondary cellsChitinLithium electrode

The invention provides a preparation method for a three-dimensional hierarchical porous biomass carbon negative electrode material of a lithium ion battery. According to the invention, edible fungus is used as a raw material for biomass carbon and three-dimensional hierarchical porous biomass carbon is prepared through a combination of a microwave hydrothermal method and a heat treatment method; the three-dimensional hierarchical porous biomass carbon has good cycle stability and rate capability when used as the negative electrode material of the lithium ion battery; the edible fungus contains rich polysaccharides, so carbonization yield of biomass is high; a cell wall contains abundant chitin, so a stable carbon skeleton can be formed and enables the negative electrode material to have a stable structure and to be not prone to collapse during charging and discharging; and the pore size of the material can be controlled by controlling alkali concentration, so the electrochemical performance of the material is improved.

Owner:SHAANXI UNIV OF SCI & TECH

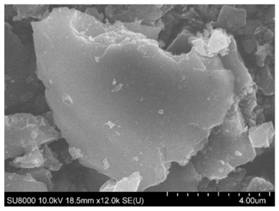

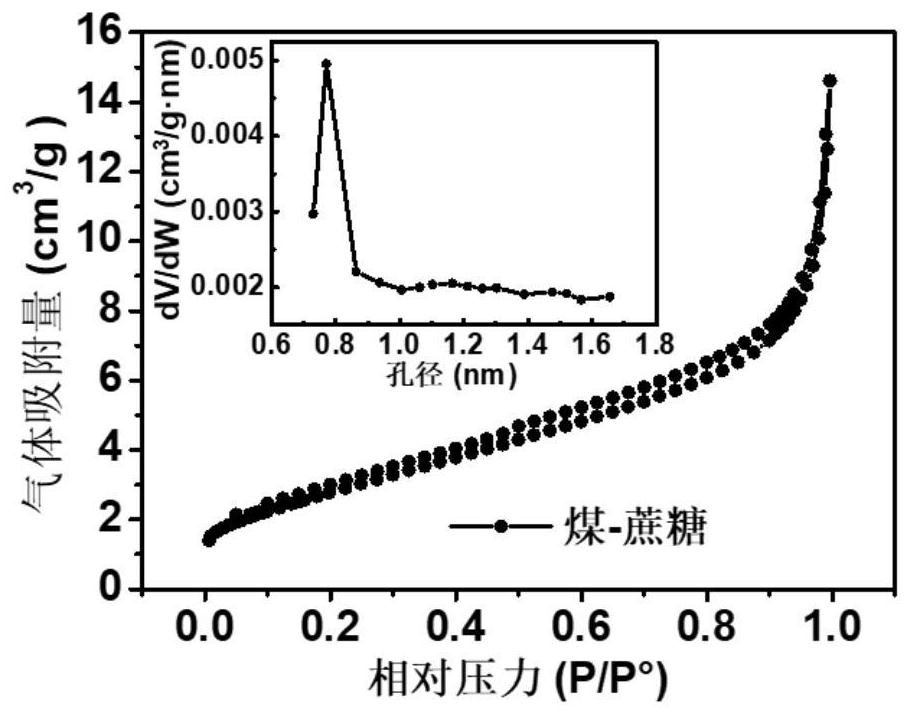

Hard carbon material, preparation method thereof, and sodium ion battery

ActiveCN112397715AClose contactContact fully occursNegative electrodesSecondary cellsCarbon layerPhysical chemistry

The invention relates to the technical field of sodium ion batteries, and provides a preparation method of a hard carbon material. The preparation method comprises the following steps: mixing a coal-based material and a hard carbon precursor, and pressing to obtain a hard sheet, wherein the hard carbon precursor is carbohydrate and / or gelatin; and carrying out high-temperature carbonization on theobtained hard sheet to obtain the hard carbon material. According to the invention, the hard carbon precursor and the coal-based material are in close contact through a tabletting means, so that thereaction activity of the hard carbon precursor and the coal-based material is greatly improved, the hard carbon precursor and the coal-based material are fully subjected to a cross-linking reaction ina high-temperature carbonization treatment process, the carbonization yield is effectively improved, meanwhile, defects formed in the carbonization process are reduced, the specific surface area is reduced, and the disorder of the carbon layers and the spacing between the carbon layers in the carbonization process are increased. A sodium ion battery obtained by taking the hard carbon material obtained by the preparation method as a negative electrode material of the sodium ion battery has high sodium storage capacity and first coulombic efficiency.

Owner:BEIJING UNIV OF CHEM TECH

Method for preparing cellulose base carbon fiber felt through low-temperature alkali urea treatment

InactiveCN106245226ASimple processLow priceArtificial filaments from cellulose solutionsHeating/cooling textile fabricsChemistryCarbon black

The invention discloses a method for preparing cellulose-based carbon fiber felt by low-temperature alkali urea method. The cellulose pulp is stirred at room temperature in a solvent composition of sodium hydroxide, urea, thiourea, water-soluble carbon black and water to prepare the felt. The cellulose suspension is obtained, and then enters the pre-frozen twin-screw extruder to obtain a black cellulose solution, which is finally filtered and defoamed and sprayed into a coagulation bath for spinning, and further washed, drawn, and oiled and drying to obtain cellulose fibers; the cellulose fibers are processed into cellulose fiber mats through a needle-punched non-woven process, and further catalyzed impregnation, pre-oxidation, and carbonization to obtain cellulose-based carbon fiber mats. The process of the invention is simple, the solvent used is green and environmentally friendly, the price is low, and the recovery rate is high. The spun cellulose fiber has a compact structure, good thermal stability, and ablation resistance. The processed cellulose-based carbon fiber felt is better than that without carbon black. Carbon fiber felt has a higher carbon yield.

Owner:DONGHUA UNIV

Preparation method of carbon fiber paper

PendingCN113584940AImprove uniformityImprove thermal conductivityNon-fibrous pulp additionSpecial paperCarbon fibersFuel cells

The invention belongs to the technical field of carbon fiber application, and discloses a preparation method of carbon fiber paper. The preparation method comprises the following steps: carrying out surface treatment on chopped carbon fibers and chopped aramid fibers; with the carbon fibers, the aramid fibers and the pulp as raw materials, conducting dispersion and papermaking to prepare carbon fiber base paper; and adding a mesophase pitch fiber layer on the surface of carbon fiber base paper by adopting a melt-blowing method, carrying out oxidation-crosslinking on mesophase pitch fibers at 200-350 DEG C by adopting air as an oxidizing agent so as to obtain composite carbon fiber base paper when a precursor is not molten, dipping the composite carbon fiber base paper in a thermosetting phenolic resin ethanol solution, and successively carrying out hot pressing, curing, carbonization and graphitization to obtain the carbon fiber paper. By adding the aramid fibers, the structural uniformity and strength of the carbon fiber paper are effectively improved; the introduction of mesophase pitch enables the carbon fiber paper to have higher electric conductivity and thermal conductivity; and the prepared carbon fiber paper can meet the preparation requirements of high-performance fuel cells, high-temperature filtration and advanced composite materials.

Owner:浙江超探碳纤维科技有限公司

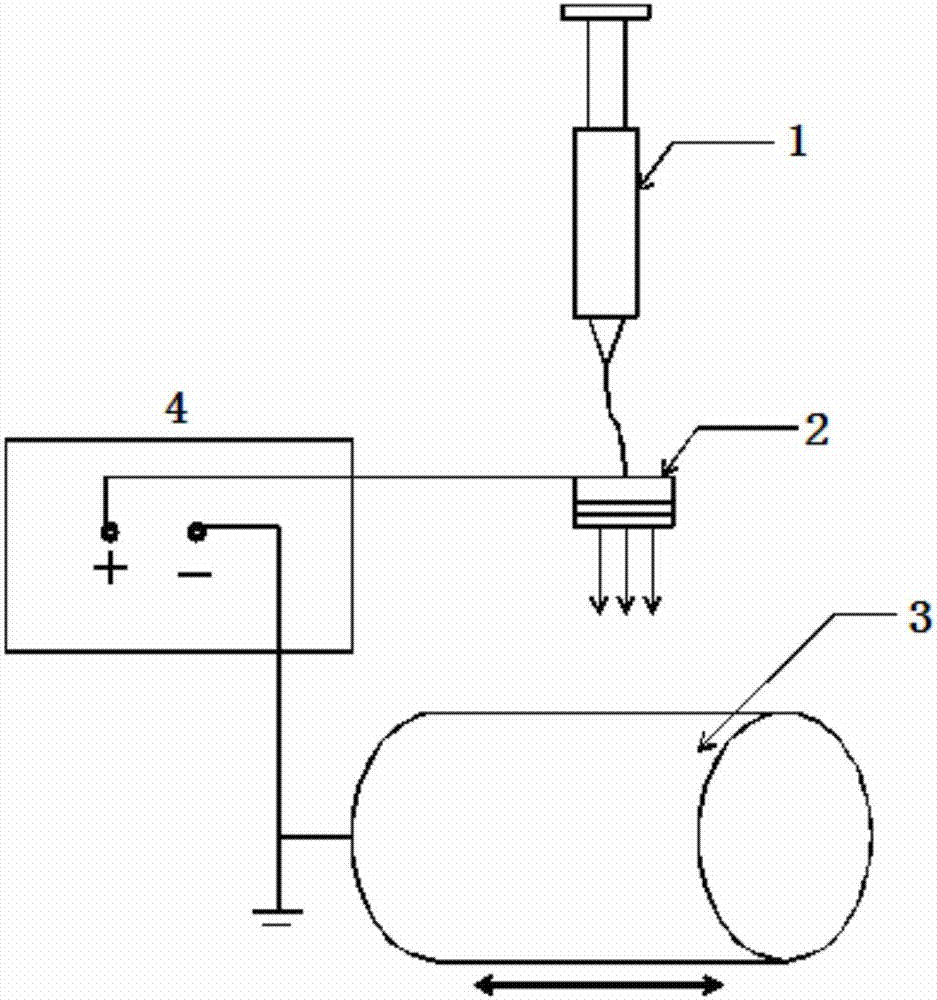

Preparation method for all-vanadium redox flow battery electrode material

InactiveCN107039659ALow costImprove carbonization yieldMaterial nanotechnologyCell electrodesCarbon fibersCarbonization

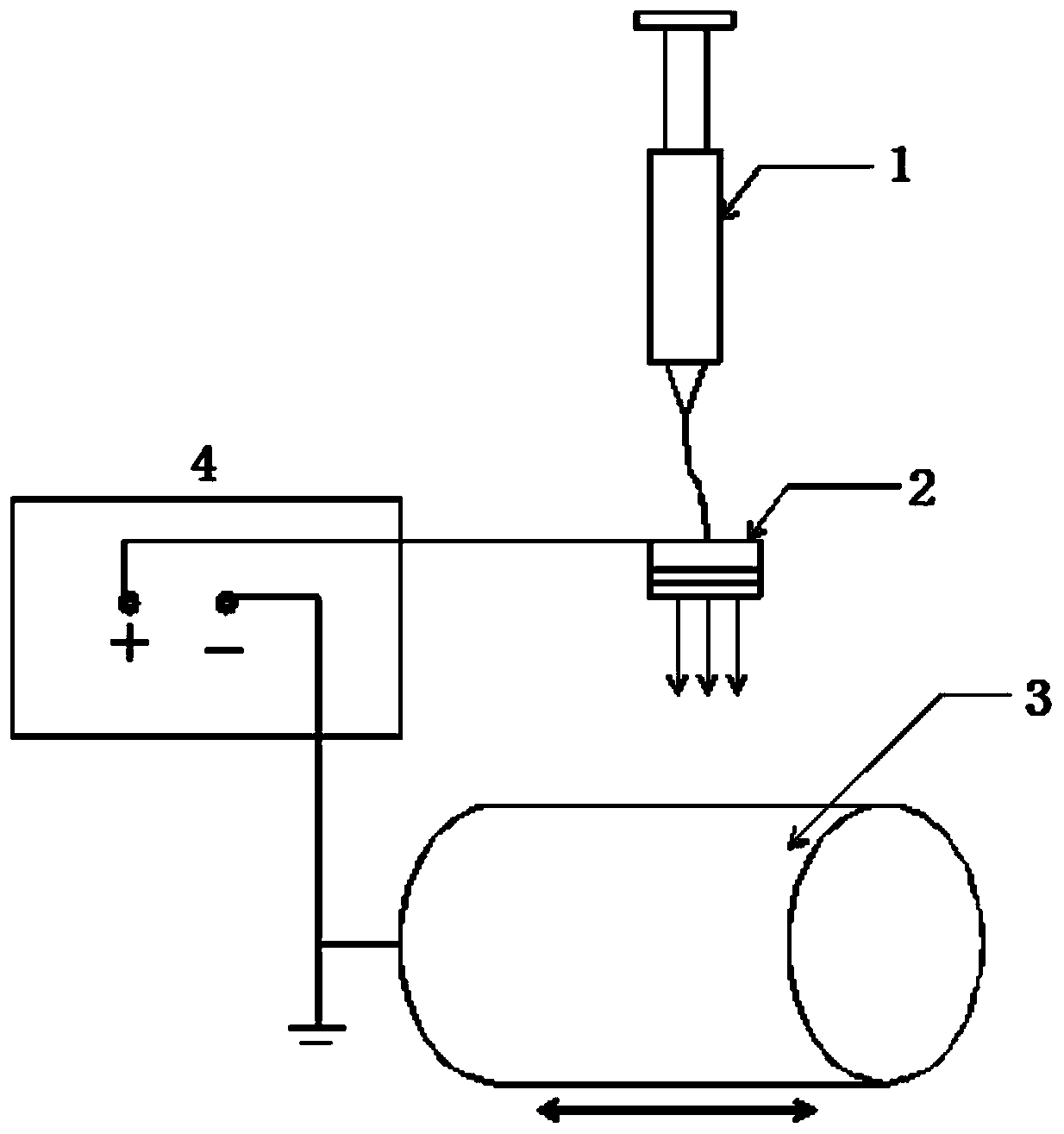

The invention relates to the field of battery manufacturing and energy storage, in particular to a preparation method for an all-vanadium redox flow battery electrode material. The preparation method comprises the steps of taking alkaline lignin as a test material, partially substituting the hydroxymethylation alkaline lignin by a phenolic hydroxyl active functional group in an alkaline lignin structure, synthesizing organic gel from resorcinol and formaldehyde under the effect of a catalyst, preparing a precursor spinning liquid required for an experiment by taking the gel as a precursor, preparing a fiber precursor electrode material by an electrostatic spinning method, pre-oxidizing the electrode material precursor by a vacuum / atmosphere furnace, and performing carbonization in an inertia atmosphere to obtain the carbon fiber electrode material. In the vanadium battery carbon fiber electrode material prepared by the method, the fiber diameter is in nanoscale, and the specific area is greatly expanded compared with a traditional carbon felt electrode material; and due to pre-oxidization processing in post period, the oxygen content of the fiber surface is also greatly improved, and the method can be used for preparing the vanadium battery carbon fiber electrode material.

Owner:SHENYANG AGRI UNIV

Preparation method for boron-containing phenolic resin microsphere and carbon microsphere

ActiveCN110144046ASmall particle sizeImprove carbonization yieldCarbon preparation/purificationResin microsphereOrganic Boron Compounds

The invention specifically relates to a preparation method for a boron-containing phenolic resin microsphere and a carbon microsphere, belonging to the field of chemical synthetic resin microspheres.The preparation method for the boron-containing phenolic resin microsphere comprises the following steps: firstly, subjecting an organoboron compound and aldehyde to prepolymerization under acidic conditions; then subjecting a product of the previous step to a polycondensation reaction with aldehyde and a curing agent under the conditions of a basic catalyst and a solvent; and finally putting a product of the previous step in an autoclave for further polycondensation and crosslinking to obtain the boron-containing phenolic resin microsphere. The invention has the beneficial effects that the preparation method for the boron-containing phenolic resin microsphere and the carbon microspheres in the invention employs the organic boron compound as a phenol source and prepares the boron-containing phenolic resin microsphere through four steps, so the reactivity of the organic boron compound is effectively increased, the dispersibility and particle size of the microsphere are well controlled,and the carbonization yield of the microspheres is significantly improved. According to testing results, the particle size of the microsphere prepared in the invention can be controlled to a range of1-1000 nm, and the yield of the carbonization product of the microsphere is 75% or more.

Owner:沙县宏盛塑料有限公司 +1

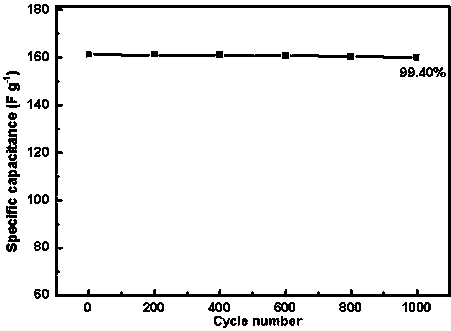

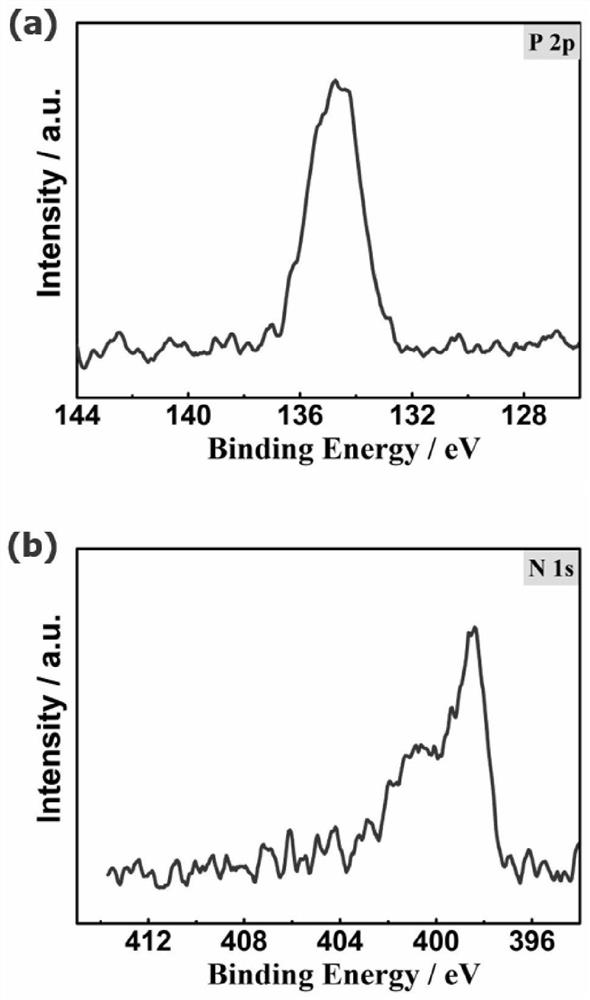

Preparation method and application of nitrogen-containing porous carbon material based on polyaspartic acid salt

ActiveCN110577206AOvercome the defect of uneven distributionUniform pore size distributionHybrid capacitor electrodesCarbon preparation/purificationPolyaspartic acidPorous carbon

The invention relates to a preparation method and application of a nitrogen-containing porous carbon material based on polyaspartic acid salt, belonging to the field of carbon materials. The polyaspartic acid salt is firstly put into a carbonization furnace to be carbonized under a vacuumizing condition to prepare a black nitrogen-containing carbon material, and the nitrogen-containing porous carbon material is obtained by pickling. The nitrogen-containing porous carbon material obtained by the method has large specific surface area, more uniform distribution of nitrogen atoms and pore diameters, and better electrical properties.

Owner:ENERGY RESOURCES INST HEBEI ACADEMY OF SCI

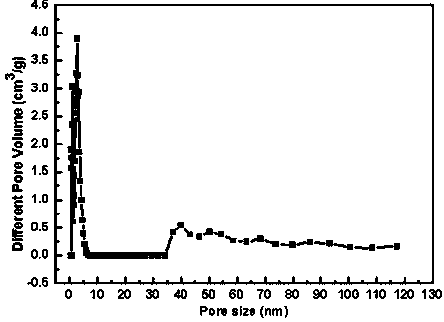

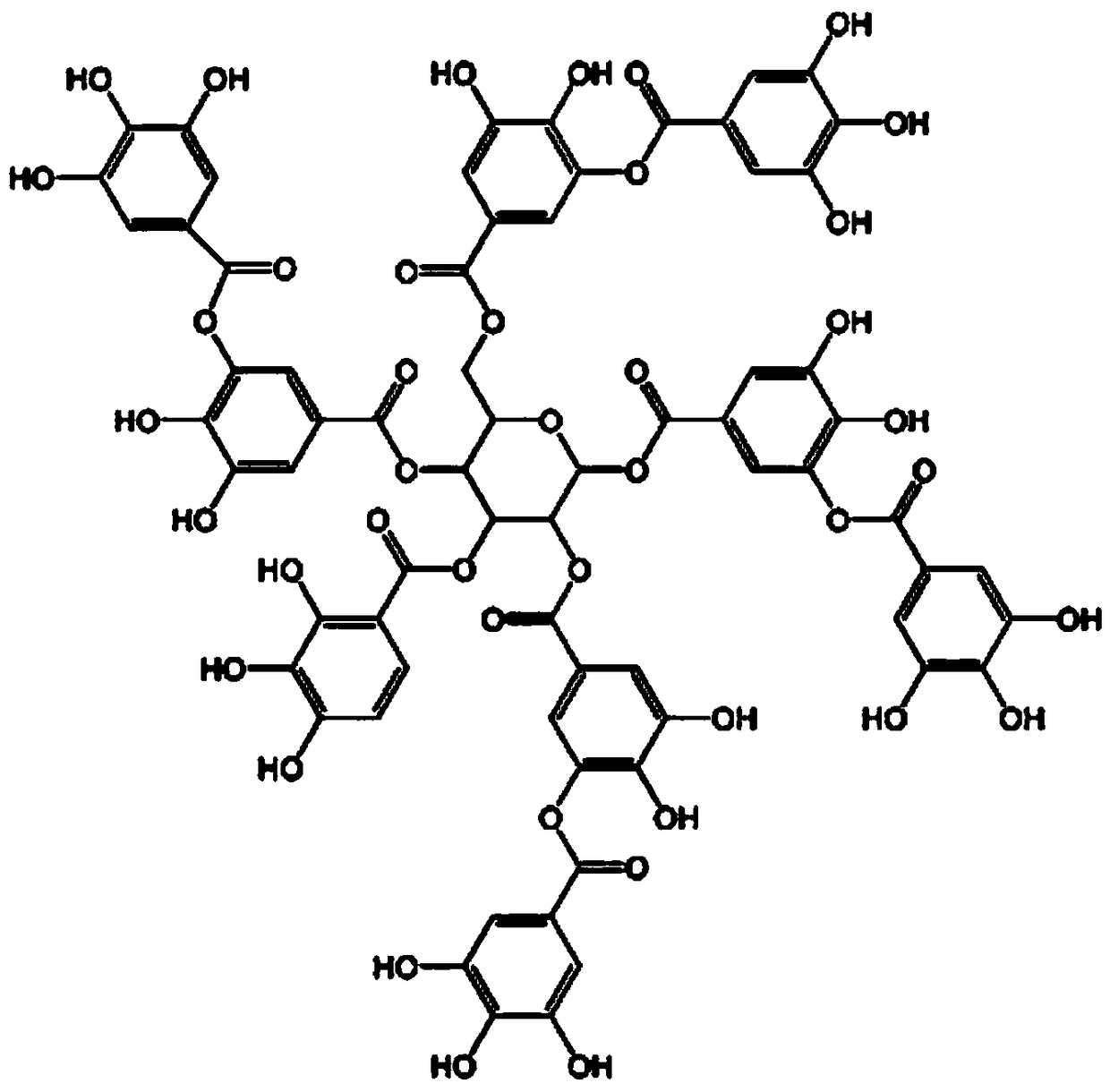

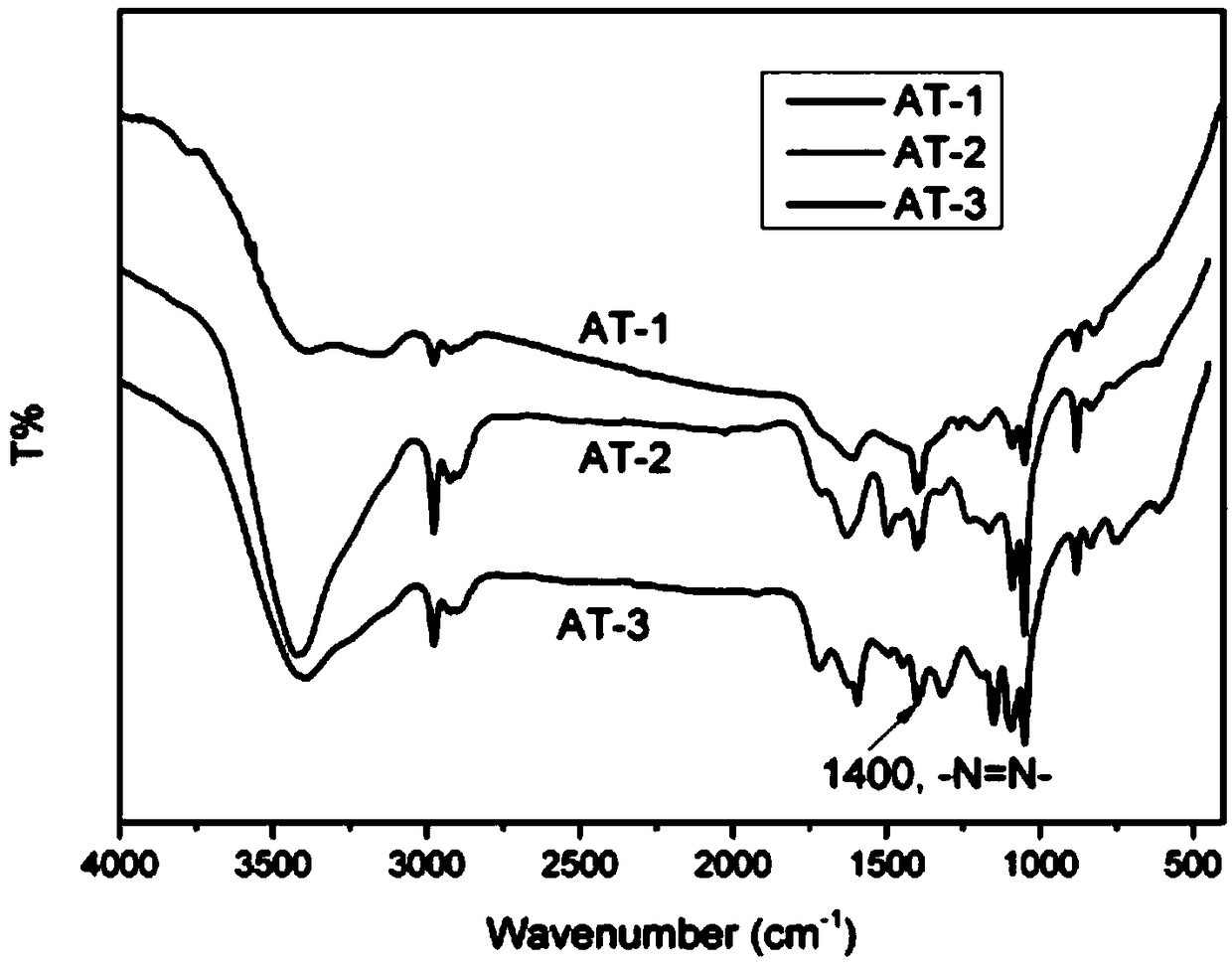

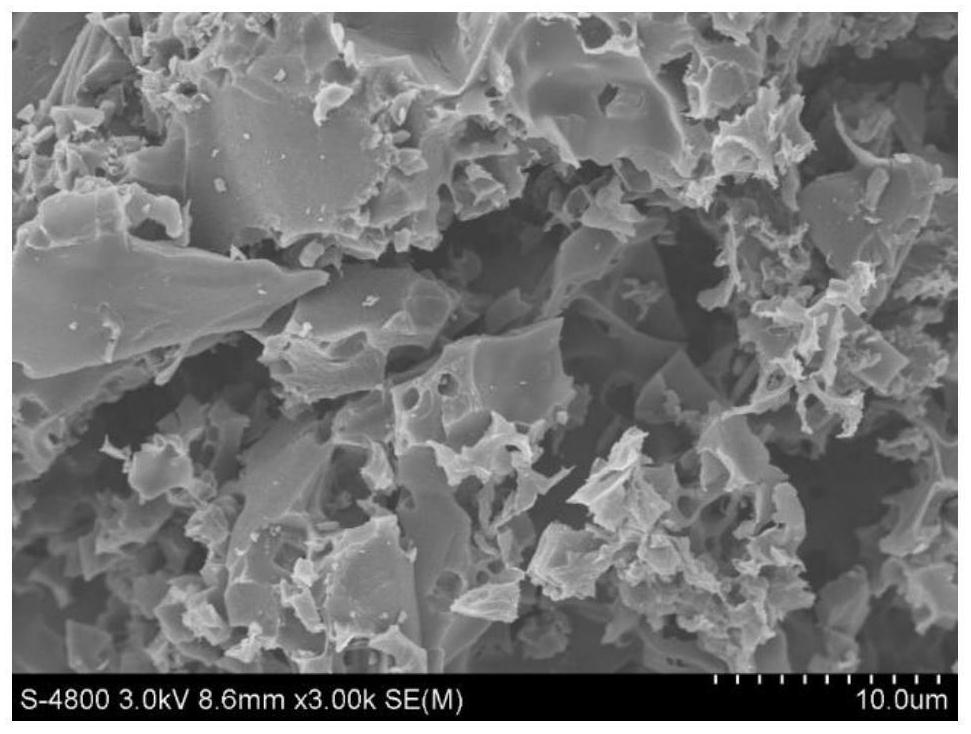

Template-free synthesis of tannic acid-based porous polymer and derived carbon material thereof under mild condition

InactiveCN108706566AImprove carbonization yieldAbility to maintain supramolecular interactionsCarbon preparation/purificationSynthesis methodsFreeze-drying

The invention discloses a template-free synthesis method of tannic acid-based porous polymers and derived carbon materials thereof under mild conditions. The template-free synthesis method of the tannic acid-based porous polymers and the derived carbon materials thereof under the mild conditions includes the steps of: (1) adding a compound containing a bisamino functional group, concentrated hydrochloric acid and deionized water to a round bottom flask, using an ice bath to control the temperature between 0-5 DEG C, and adding a sodium nitrite aqueous solution after stirring evenly and continuing stirring to completely convert amino groups into diazonium salt; (2) maintaining the ice bath state, adding a tannic acid and sodium carbonate aqueous solution after neutralizing with a sodium carbonate solution, conducting filtering separation of generated solid precipitate after 12 hours, washing with deionized water, methanol, tetrahydrofuran, methanol and water in sequence, and then conducting freeze drying to obtain the tannic acid-based porous polymers; (3) calcining the tannic acid-based porous polymers in a tube furnace at the temperature of 900 DEG C for 3 hours, and then coolingdown naturally to obtain target products. The template-free synthesis method of the tannic acid-based porous polymers and the derived carbon materials thereof under the mild conditions has the advantages of being simple, needing mild conditions and no template, and producing the final products that have excellent carbon dioxide capture capability.

Owner:LIAONING UNIVERSITY

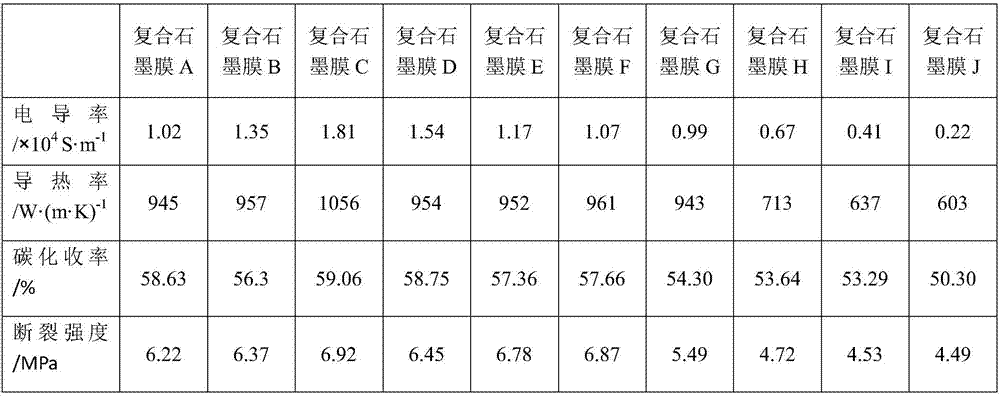

Composite graphite film and preparation method and application thereof

The invention discloses a composite graphite film and a preparation method and application thereof. The preparation method comprises the following steps: preparing a polyimide composite film formed by nano-diamond and polyimide; under the protection of an inert gas, performing carbonization and graphitization, and then removing graphite paper to obtain the composite graphite film formed by nano-diamond and polyimide. In the carbonization and graphitization process, as a crystal nucleus, nano-diamond promotes carbonization and graphitization of polyimide, so that the heat-conducting property and the electric conductivity of a composite carbon film are improved.

Owner:北京兴科迪电子技术研究院

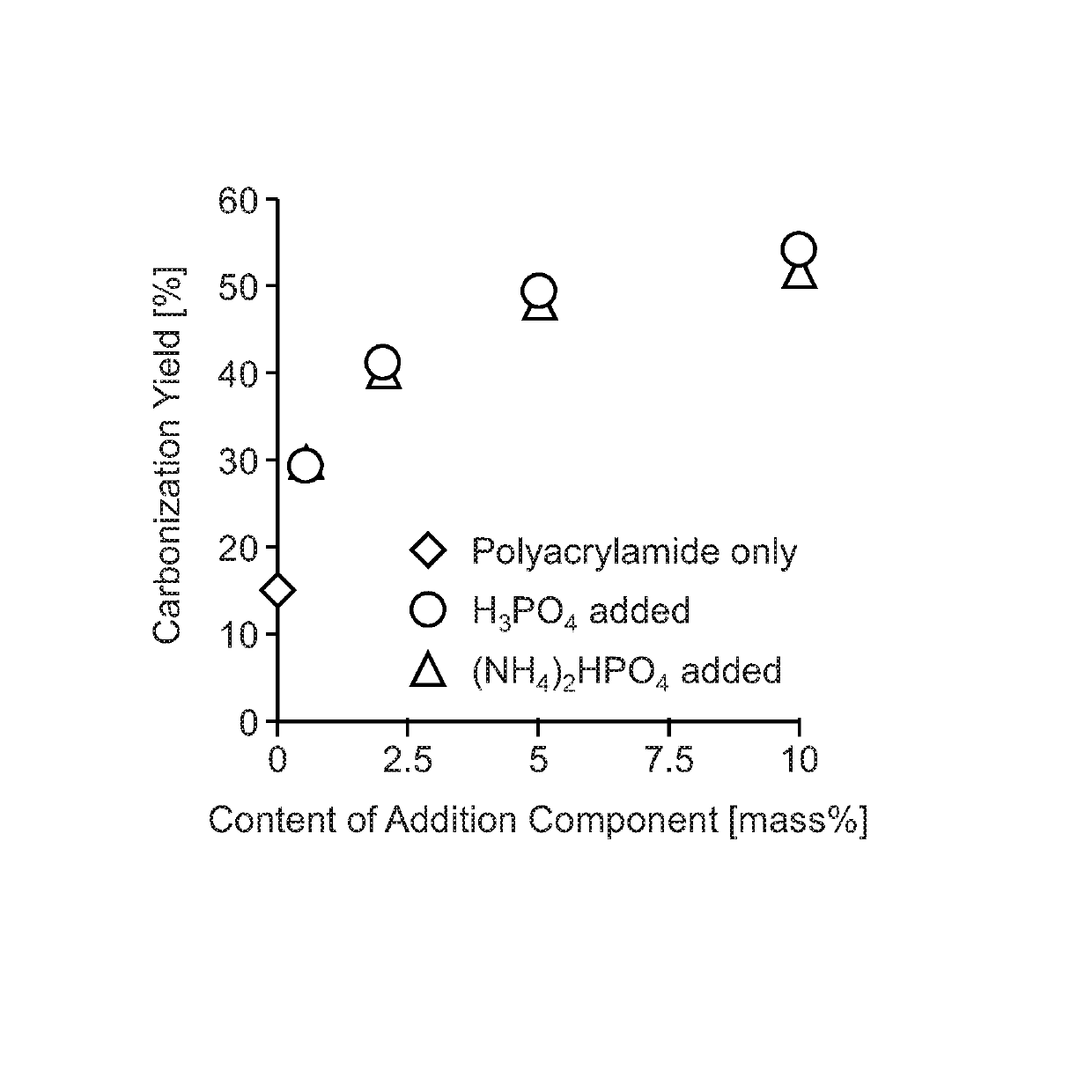

Carbon material precursor and method for producing carbon material using the same

ActiveUS10385186B2Improve carbonization yieldHigh carbonation rateCarbon preparation/purificationPolymerMaterials science

Owner:TOYOTA CENT RES & DEV LAB INC

Process for preparing precursor fiber of cellulose base carbon fiber

InactiveCN1255585CImprove thermal stabilityImprove carbonization yieldMonocomponent cellulose artificial filamentFiberCarbon fibers

The preparation method of the precursor fiber of cellulose-based carbon fiber in chemical fiber production, first stirs and mixes the concentrated NMMO aqueous solution and the carbon black contained in the carbon black water dispersion at a weight ratio of 20 to 10000:1, and distills under reduced pressure to obtain a water-containing 24-28% NMMO / carbon black solution, and then add the cellulose pulp cut into small pieces and NMMO / carbon black solution into the dissolution kettle at a weight ratio of 5-15:100, and pass through static at 70-90°C. After swelling and strong stirring, the temperature is raised to 90-120°C, and the water is removed by stirring and vacuum distillation to generate a cellulose / NMMO / carbon black spinning stock solution with a water content of 12%-14%. The filaments yield precursor fibers of cellulose-based carbon fibers. Due to the addition of carbon black in the present invention, the carbonization yield and mechanical properties of the carbon fiber prepared after oxidation and carbonization treatment are all significantly improved; the carbon black aqueous dispersion with a smaller particle size or even nano-scale is used as an additive to make spinning The silk stock solution has good spinnability; the solvent used is non-toxic, the recovery rate is high, and the spinning process is simple and environmentally friendly.

Owner:DONGHUA UNIV

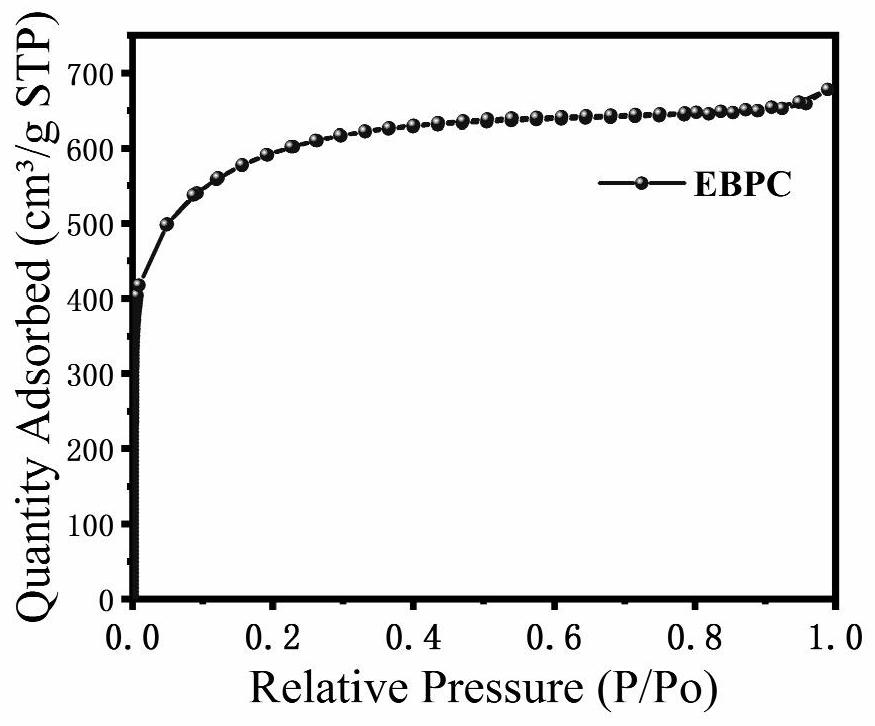

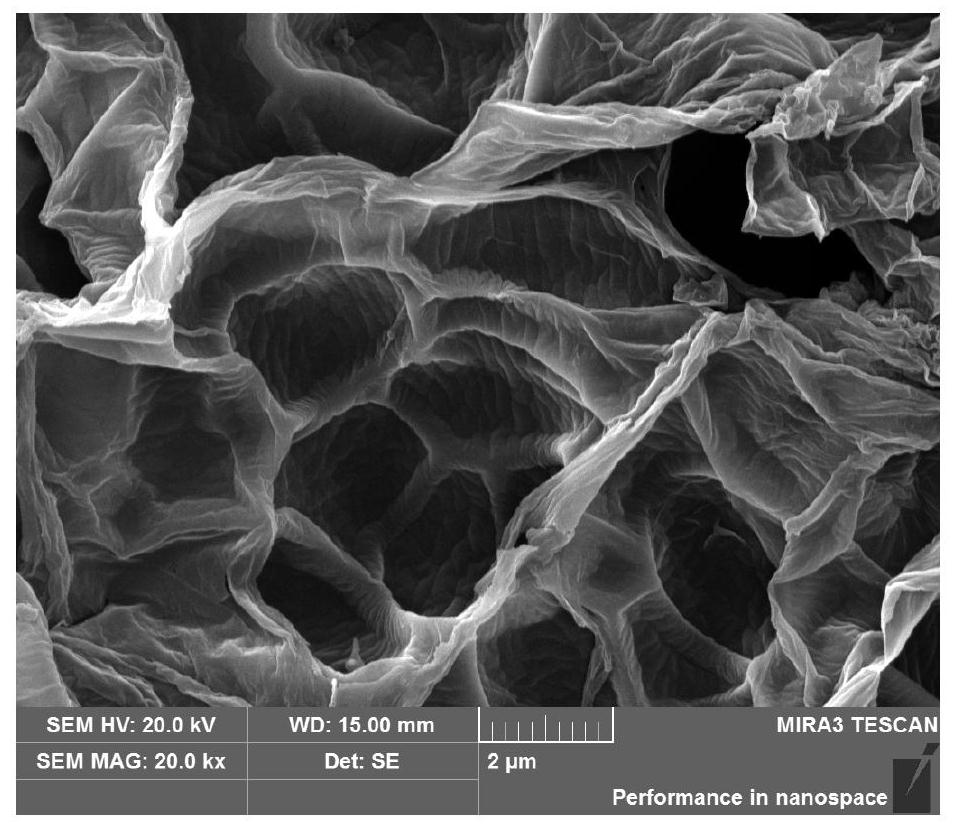

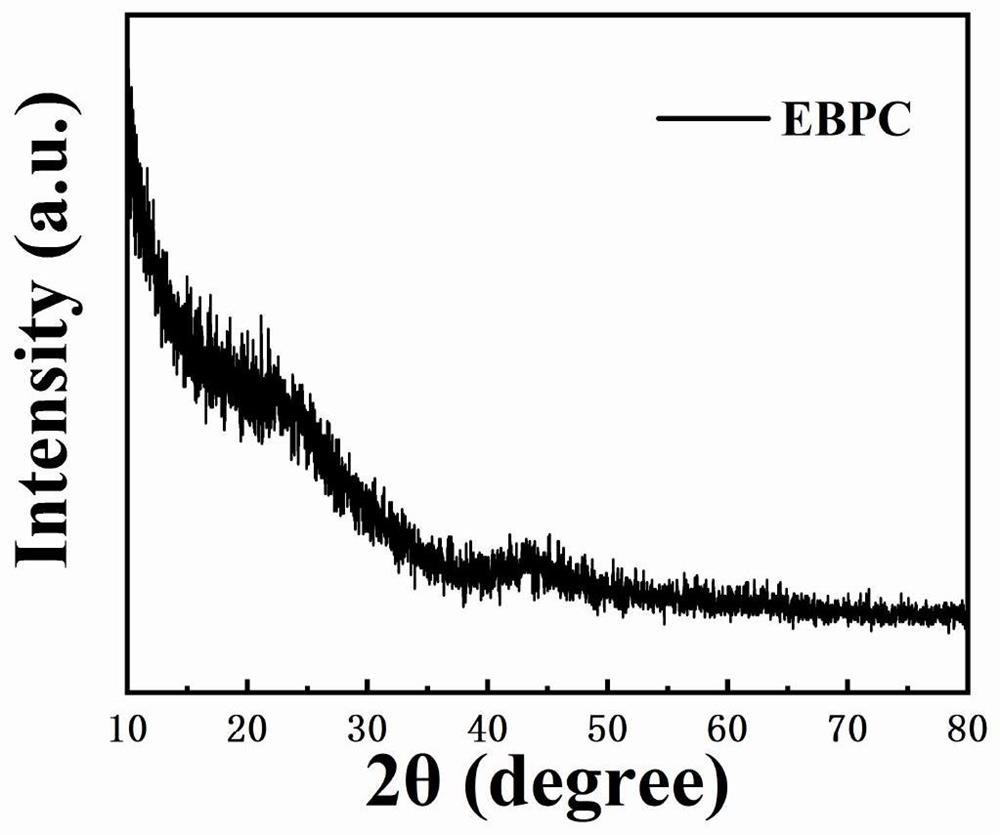

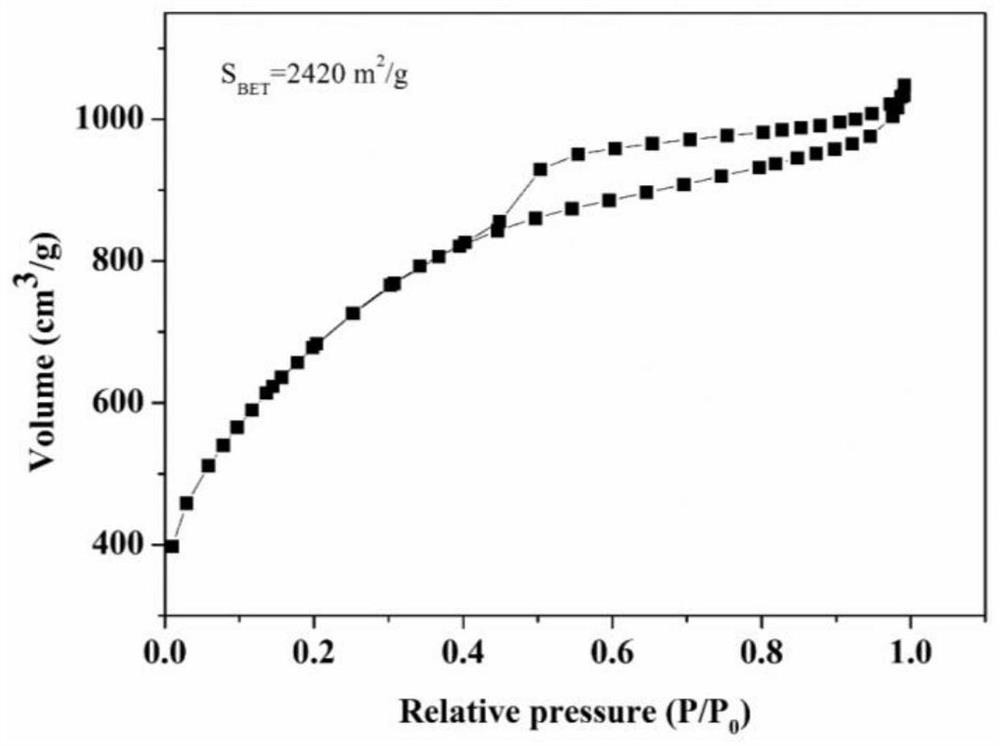

A kind of biomass porous activated carbon and its preparation method and application as electric double layer capacitor electrode material

ActiveCN109516459BWide variety of sourcesLow costCarbon compoundsHybrid capacitor electrodesFiberActivated carbon

The invention discloses biomass porous activated carbon and a preparation method thereof and application of the biomass porous activated carbon as an electrode material of a double electric layer capacitor. After a biomass raw material is pulverized by a high-energy pulverizer, the biomass raw material is placed in a furnace, protective gas is introduced into the furnace, the temperature is raisedto an activation temperature under a protective atmosphere, then activation gas is introduced into the furnace for activation treatment, protective gas is introduced into the furnace again, and the temperature is lowered to a normal temperature under a protective atmosphere to obtain the biomass porous activated carbon. The method maintains an original biological structure and ordered pore structure of wood fiber in the biomass material by high-energy pulverization combined with gas activation treatment, the prepared porous activated carbon has a large specific surface area and a high mass transfer rate and is applied as the electrode material of the electric double layer capacitor, and a capacitor with high energy density and good cycle performance can be obtained; and the porous activated carbon has a low preparation cost, simple operation and a short production cycle, and meets industrial production.

Owner:CENT SOUTH UNIV

Preparation method for high-yield needle petroleum coke

ActiveCN109022008AHigh aromaImprove carbonization yieldCoking carbonaceous materialsCross-linkCarbonization

The invention provides a preparation method of high-yield needle petroleum coke. The preparation method comprises the following steps: uniformly mixing FCC oil slurry with haloalkane (iodomethane or ethyl iodide), polyol (polyethylene glycol, polypropylene glycol and trimethylolpropane) and boron trifluoride according to catalyst-oil ratios of 0.01 to 0.07 g / g, 0.03 to 0.08 g / g and 0.001 to 0.02 g / g, respectively; carrying out coupled catalytic polycondensation-shallow alkylation for 4-6 h at a certain temperature to produce a carbene mixture with high molecular weight and high aromaticity, which enables the cross-linking and coupling degrees of fused-ring aromatic compounds to be increased; then subjecting the obtained carbene mixture to a carbonization reaction at 550-600 DEG C for 10 to14 h so as to obtain green needle coke; and finally carrying out calcination at a high temperature of 1500 DEG C so as to obtain the needle petroleum coke. The method of the invention is a combined process of coupled alkylation-carbonization reactions, has the characteristics of controllable molecular weight and aromaticity of an intermediate and easy control of carbonization reaction depth and mesophase formation; and the obtained needle coke has the advantages of high yield and low thermal expansion coefficient, and has general yield of no less than 70% and a thermal expansion coefficient as low as 0.9*10<-6> to 1.6*10<-6> / DEG C.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Process for producing spherical carbon material

InactiveUS7651817B2High yieldGood spherical shapeAlkali metal halidesSecondary cellsNon oxidativeMaterials science

A process for producing a spherical carbon material, comprising: subjecting a spherical vinyl resin to an oxidation treatment in an oxidizing gas atmosphere to obtain a spherical carbon precursor, and carbonizing the spherical carbon precursor at 1000-2000° C. in a non-oxidizing gas atmosphere. The thus-obtained spherical carbon material exhibits excellent performances, including high output performance and durability, when used, e.g., as a negative electrode material for non-aqueous electrolyte secondary batteries.

Owner:KUREHA KAGAKU KOGYO KK

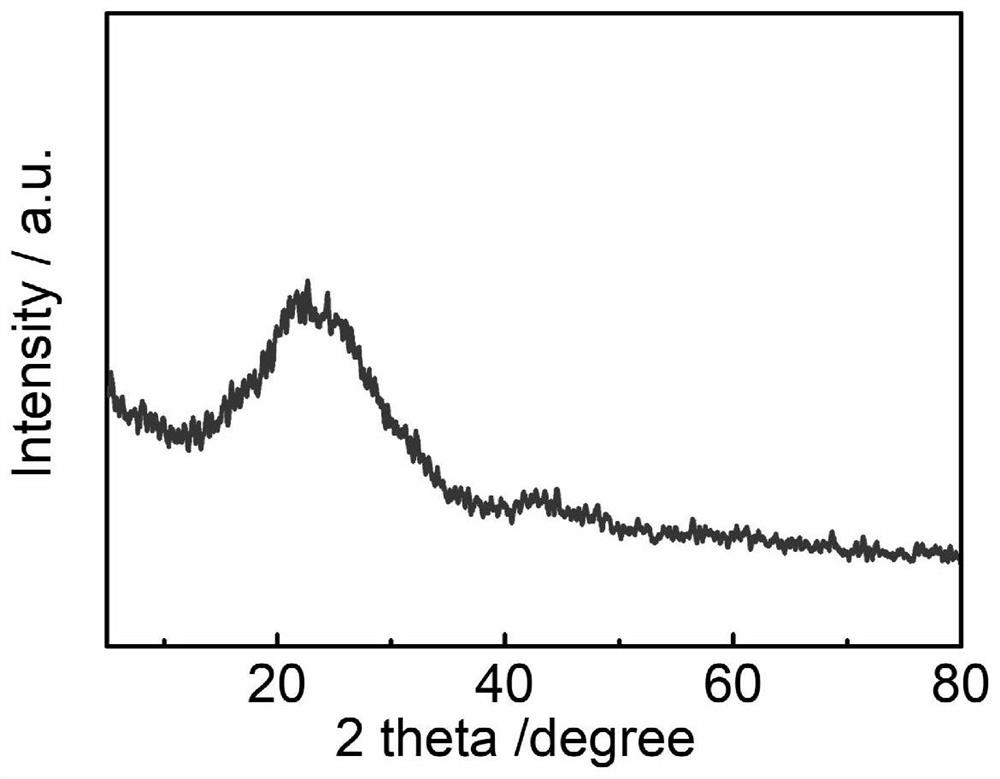

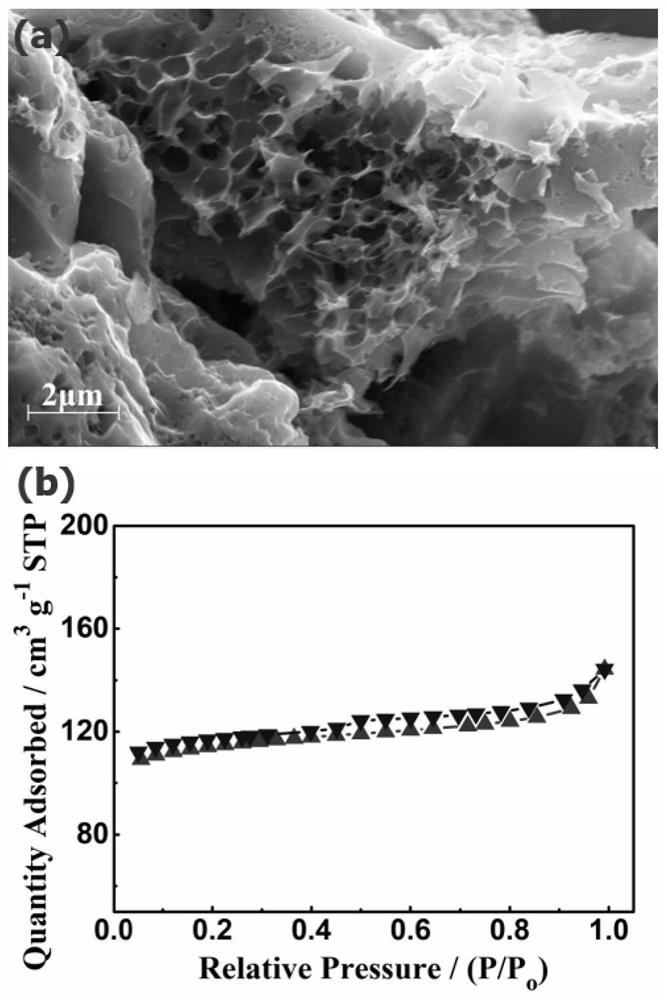

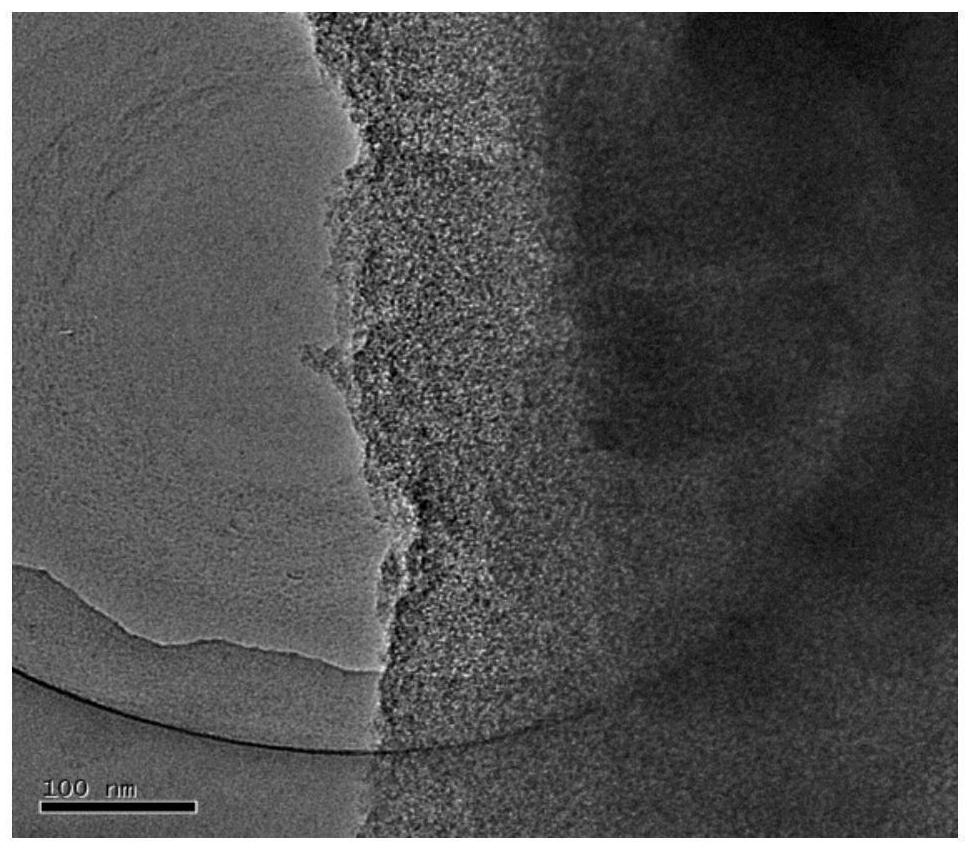

A kind of nitrogen and phosphorus co-doped porous biomass carbon material and its preparation method and application in supercapacitor

ActiveCN109019554BHigh pseudocapacitanceImprove energy storage capacityHybrid capacitor electrodesCarbon preparation/purificationMaterials scienceHeat treating

The invention discloses a nitrogen and phosphorus codoped porous biomass carbon material and a preparation method and application thereof in a supercapacitor. The preparation method comprises the following steps: grinding and mixing an oyster mushroom raw material and nitrogen and phosphorus inorganic salt, and carrying out heat treatment under protection so as to obtain the double heteroatom elements-doped porous biomass carbon material with well-developed pore structure, good conductivity and many active sites. By using the porous biomass carbon material as an electrode material of a supercapacitor, a supercapacitor with high rate performance and specific capacity can be obtained. In addition, the preparation method of the biomass carbon material is simple and low-cost, and is beneficialto industrial application.

Owner:HUNAN INSTITUTE OF SCIENCE AND TECHNOLOGY

Preparation method of nitrogen-doped porous carbon material

ActiveCN114516635AOxygen-rich functional groupsAchieve contactCarbon compoundsHybrid capacitor electrodesPorous carbonActive agent

The invention belongs to the technical field of porous carbon materials, and particularly relates to a preparation method of a nitrogen-doped porous carbon material and application of the nitrogen-doped porous carbon material in a supercapacitor. The nitrogen-doped porous carbon material is prepared by taking weathered coal humic acid as a carbon material precursor, urea as a nitrogen source and a potassium metal compound as an active agent through high-temperature reaction, and when the nitrogen-doped porous carbon material is applied to an electrode material of a supercapacitor, the supercapacitor shows excellent electrochemical performance. The initial raw materials are humic acid and urea which widely exist in nature and are low in price and rich in source, and the method only relates to a small number of procedures such as activation and cleaning, so that large-scale industrial production is easy to realize.

Owner:NINGBO CRRC NEW ENERGY TECH CO LTD

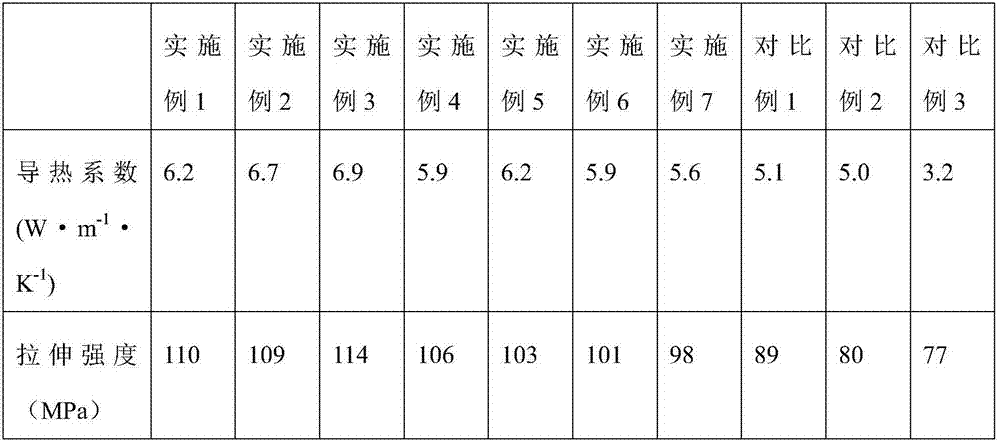

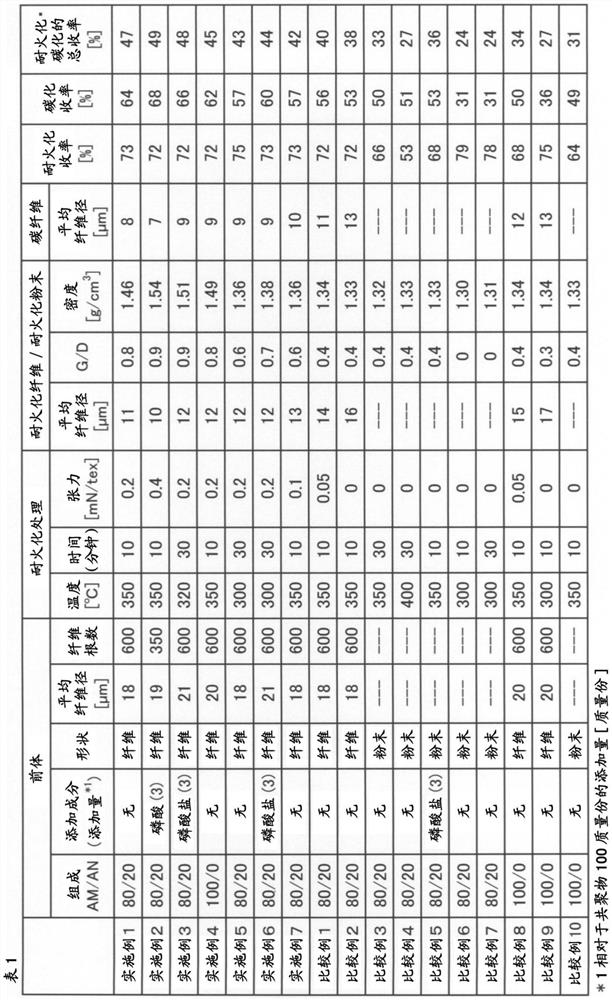

Stabilized fiber, method of producing the same, and method of producing carbon fiber

ActiveUS20210087717A1Avoid thermal decompositionDensityArtificial filament heat treatmentMonocomponent synthetic polymer artificial filamentFiberCarbon fibers

A method of producing a stabilized fiber, including performing a heat treatment on an acrylamide polymer fiber under an oxidizing atmosphere in a stabilization treatment temperature range of 200° C. to 500° C. while applying a tension of 0.07 mN / tex to 15 mN / tex.

Owner:TOYOTA JIDOSHA KK +1

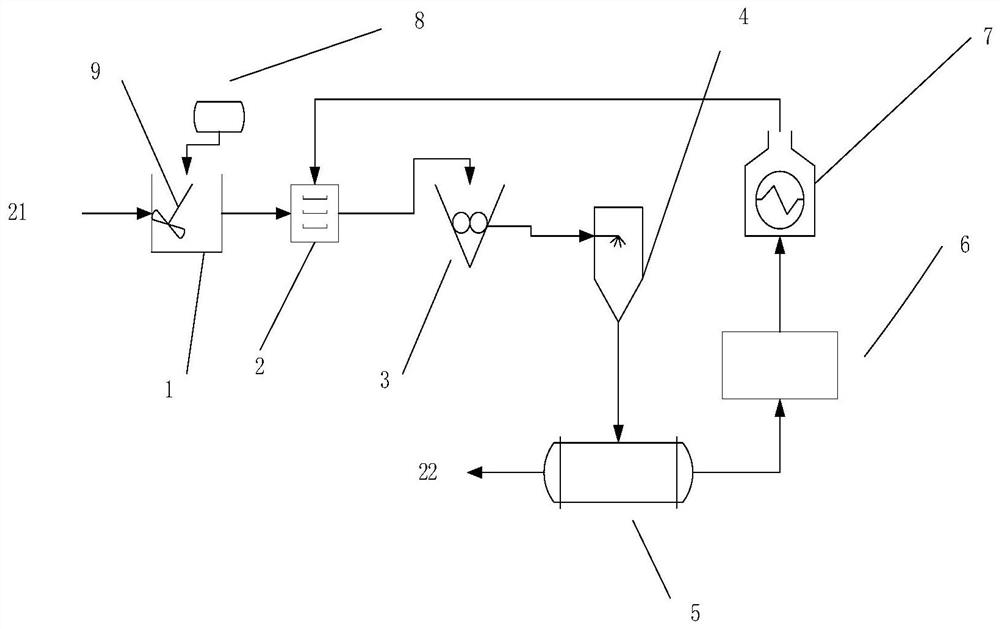

Novel biomass pyrolysis carbonization system and method

InactiveCN112159672AReduce lossesSave energyBiofuelsSpecial form destructive distillationThermodynamicsCarbonization

The invention discloses a novel biomass pyrolysis carbonization system and method, the novel biomass pyrolysis carbonization system comprises a pretreatment pool, a dryer, a crushing device, a granulation device, a carbonization device and a pyrolysis gas recovery device, the pyrolysis gas recovery device is connected with the carbonization device and a drying device. A first medicine adding device is connected to the pretreatment pool. The invention has the beneficial effects that pyrolysis gas generated in the biomass carbonization process passes through the heat energy recovery system and then is combusted again to heat the carbonization device and the drying device, the heat loss is reduced, the heat energy loss is reduced, the treatment cost is saved, and the biomass carbonization treatment system conforms to the cyclic utilization principle of resources.

Owner:TIANJIN ENEW ENVIRONMENTAL PROTECTION ENGCO LTD

Fire-resistant fiber, method for producing same, and method for producing carbon fiber

ActiveCN112522814AImprove carbonization yieldArtificial filament heat treatmentMonocomponent synthetic polymer artificial filamentFiberPolymer science

A method for producing a fire-resistant fiber, which is characterized by comprising subjecting an acrylamide polymer fiber to a heat treatment at a fire-resistant treatment temperature in the range of200-500 DEG C in an oxidizing atmosphere while imparting a tension of 0.07-15 mN / tex to the acrylamide polymer fiber.

Owner:TOYOTA JIDOSHA KK

Preparation method of a three-dimensional hierarchical porous biomass carbon lithium ion battery negative electrode material

ActiveCN106082158BImprove carbonization yieldStable structureCarbon compoundsCell electrodesCarbonizationFractionation

The invention provides a preparation method for a three-dimensional hierarchical porous biomass carbon negative electrode material of a lithium ion battery. According to the invention, edible fungus is used as a raw material for biomass carbon and three-dimensional hierarchical porous biomass carbon is prepared through a combination of a microwave hydrothermal method and a heat treatment method; the three-dimensional hierarchical porous biomass carbon has good cycle stability and rate capability when used as the negative electrode material of the lithium ion battery; the edible fungus contains rich polysaccharides, so carbonization yield of biomass is high; a cell wall contains abundant chitin, so a stable carbon skeleton can be formed and enables the negative electrode material to have a stable structure and to be not prone to collapse during charging and discharging; and the pore size of the material can be controlled by controlling alkali concentration, so the electrochemical performance of the material is improved.

Owner:SHAANXI UNIV OF SCI & TECH

A kind of preparation method of needle petroleum coke with high yield

ActiveCN109022008BHigh aromaImprove carbonization yieldCoking carbonaceous materialsThermal dilatationCarbonization

The invention provides a preparation method of high-yield needle petroleum coke. The preparation method comprises the following steps: uniformly mixing FCC oil slurry with haloalkane (iodomethane or ethyl iodide), polyol (polyethylene glycol, polypropylene glycol and trimethylolpropane) and boron trifluoride according to catalyst-oil ratios of 0.01 to 0.07 g / g, 0.03 to 0.08 g / g and 0.001 to 0.02 g / g, respectively; carrying out coupled catalytic polycondensation-shallow alkylation for 4-6 h at a certain temperature to produce a carbene mixture with high molecular weight and high aromaticity, which enables the cross-linking and coupling degrees of fused-ring aromatic compounds to be increased; then subjecting the obtained carbene mixture to a carbonization reaction at 550-600 DEG C for 10 to14 h so as to obtain green needle coke; and finally carrying out calcination at a high temperature of 1500 DEG C so as to obtain the needle petroleum coke. The method of the invention is a combined process of coupled alkylation-carbonization reactions, has the characteristics of controllable molecular weight and aromaticity of an intermediate and easy control of carbonization reaction depth and mesophase formation; and the obtained needle coke has the advantages of high yield and low thermal expansion coefficient, and has general yield of no less than 70% and a thermal expansion coefficient as low as 0.9*10<-6> to 1.6*10<-6> / DEG C.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

A kind of preparation method of electrode material of vanadium redox flow battery

InactiveCN107039659BLow costImprove carbonization yieldMaterial nanotechnologyCell electrodesCarbon fibersElectrical battery

The invention relates to the field of battery manufacturing and energy storage, in particular to a preparation method for an all-vanadium redox flow battery electrode material. The preparation method comprises the steps of taking alkaline lignin as a test material, partially substituting the hydroxymethylation alkaline lignin by a phenolic hydroxyl active functional group in an alkaline lignin structure, synthesizing organic gel from resorcinol and formaldehyde under the effect of a catalyst, preparing a precursor spinning liquid required for an experiment by taking the gel as a precursor, preparing a fiber precursor electrode material by an electrostatic spinning method, pre-oxidizing the electrode material precursor by a vacuum / atmosphere furnace, and performing carbonization in an inertia atmosphere to obtain the carbon fiber electrode material. In the vanadium battery carbon fiber electrode material prepared by the method, the fiber diameter is in nanoscale, and the specific area is greatly expanded compared with a traditional carbon felt electrode material; and due to pre-oxidization processing in post period, the oxygen content of the fiber surface is also greatly improved, and the method can be used for preparing the vanadium battery carbon fiber electrode material.

Owner:SHENYANG AGRI UNIV

Preparation method of binder asphalt, binder asphalt and electrode for aluminum smelting

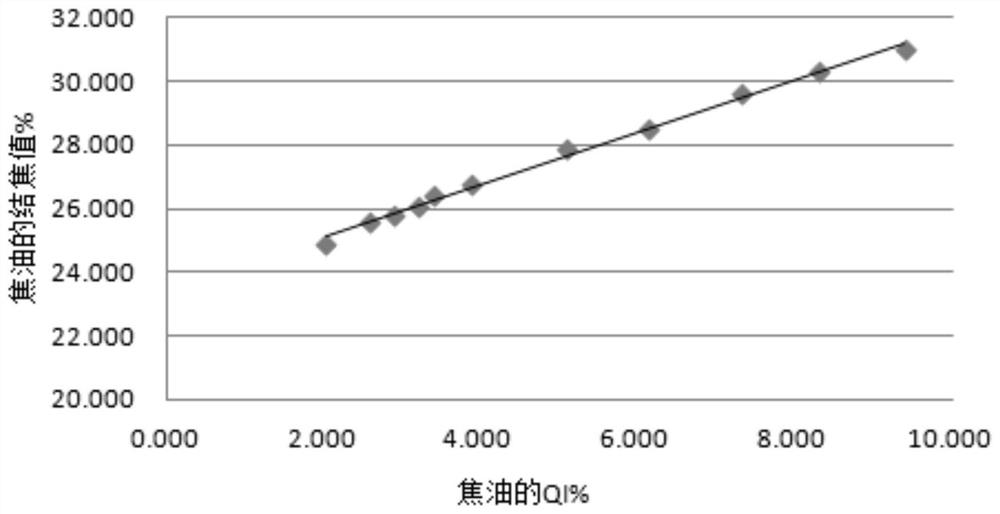

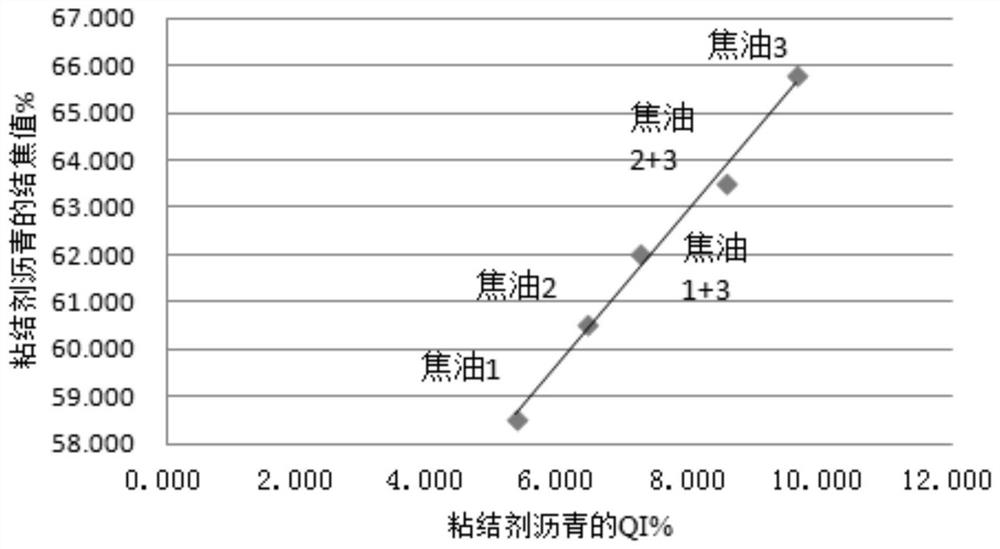

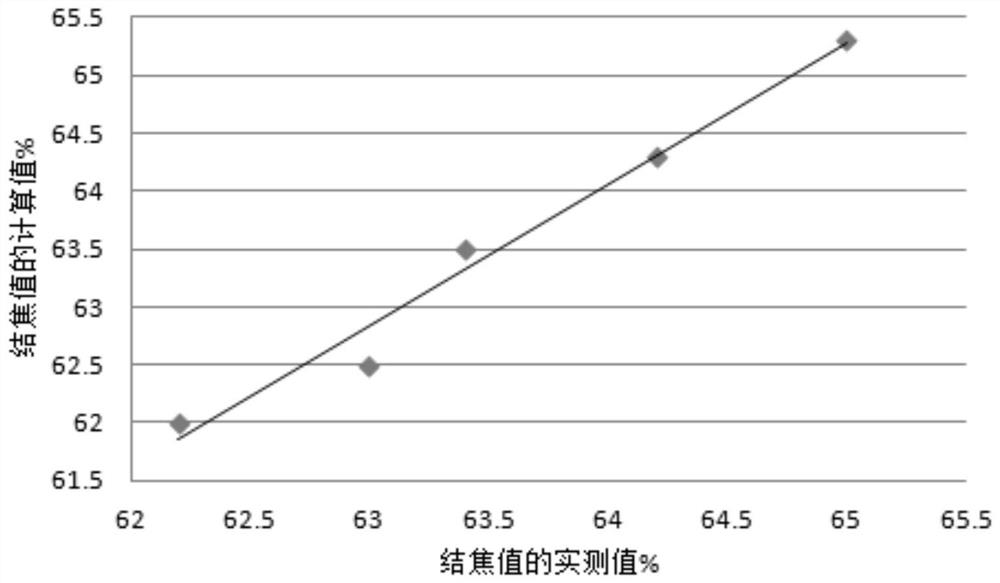

ActiveCN113046110AImprove performanceIncrease contentWorking-up pitch/asphalt/bitumen by distillationQuinolineCoke

The invention provides a preparation method of binder asphalt. The preparation method comprises the following steps: a, mixing a plurality of original tar raw materials into mixed coal tar, purifying the mixed coal tar, and carrying out an electrochemical oxidation reaction to obtain pretreated processed coal tar, wherein the quinoline insoluble content of the processed coal tar is 2% by mass or more and less than 20% by mass; b, distilling the processed coal tar to obtain medium-temperature pitch; c, carrying out thermal polymerization reaction on the medium-temperature pitch to obtain a polymer component; and d, evaporating low-molecular components in the polymer component to obtain the binder asphalt. The binder asphalt prepared by the preparation method has relatively low viscosity, and can fully wet aggregate coke when being applied to an electrode for aluminum smelting. A composite material formed by the binder asphalt and the aggregate coke is relatively high in stacking density and high in mechanical strength after being roasted. Thus, the resistivity of the electrode for aluminum smelting can be reduced, and consumption and cost in an aluminum smelting production process are reduced. The invention also relates to the binder asphalt and the aluminum smelting electrode.

Owner:BEIJING RISUN TECH CO LTD

Preparation method of phenolic resin combined honeycomb activated carbon

The invention relates to a preparation method of phenolic resin combined honeycomb activated carbon, which can be used for preparing the honeycomb activated carbon by the steps of: mixing dry powder, preparing plastic pug by mixing and kneading through a wet method, vacuum pugging, extrusion molding, drying, curing treatment and secondary heat treatment. Besides the function of bonding and improving the mechanical strength of the activated carbon, the phenolic resin also remarkably improves the heat-resisting property and water resistance of the honeycomb activated carbon; and furthermore, the honeycomb activated carbon is added with porous mineral, thus better effectively improving the mechanical strength and the specific surface area of the honeycomb activated carbon. The preparation method has lower heat treatment temperature and low production energy consumption, and effectively reduces the production cost; and the preparation technique and equipment thereof are simple, and the production investment is lower, so that the cost is further reduced.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com