Preparation method and application of nitrogen-containing porous carbon material based on polyaspartic acid salt

A polyaspartate and porous carbon material technology, which is applied in the preparation/purification of carbon, hybrid capacitor electrodes, etc., can solve the problems of cumbersome steps, high separation and purification difficulty, uneven distribution, etc., and achieves uniform pore size distribution, The effect of uniform distribution of nitrogen atoms and pore size and loss reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The present invention is based on the preparation method of the nitrogen-containing porous carbon material of polyaspartic acid salt, and it comprises the following steps:

[0043] Step 1: High temperature carbonization

[0044] Put the polyaspartic acid salt into a carbonization furnace and carbonize it under vacuum conditions. During the carbonization process, the protective gas is continuously introduced at a rate of 15-45mL / min, and the temperature is first raised from room temperature at a rate of 3-8°C / min to After 1.5~2.5 hours of heat preservation at 175℃~225℃, continue to heat up at a rate of 3~8℃ / min to 900±10℃ for 0.5~1.5 hours, and then slowly lower to room temperature to obtain a black nitrogen-containing carbon material;

[0045] Step 2: pickling

[0046] Soak in hydrochloric acid solution and ultrasonically clean for three times for half an hour each time to obtain a nitrogen-containing porous carbon material.

[0047] In the present invention, also inc...

Embodiment 1

[0070] Step 1: High temperature carbonization

[0071] Put potassium polyaspartate into a carbonization furnace to carbonize under vacuum conditions, and continuously feed N at a rate of 30mL / min during the carbonization process. 2 / Ar, first increase the temperature from room temperature to 200±5°C for 2 hours at a rate of 5°C / min, then continue to heat at a rate of 5°C / min to 900±5°C for 1 hour, and then slowly lower to room temperature, that is, the black Nitrogen-containing carbon materials;

[0072] Step 2: pickling

[0073] Soak in 0.1 mol / L hydrochloric acid solution and ultrasonically clean for three times for half an hour each time to obtain a nitrogen-containing porous carbon material.

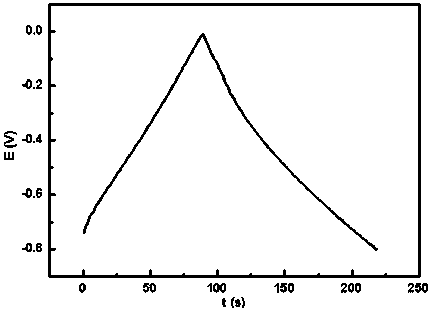

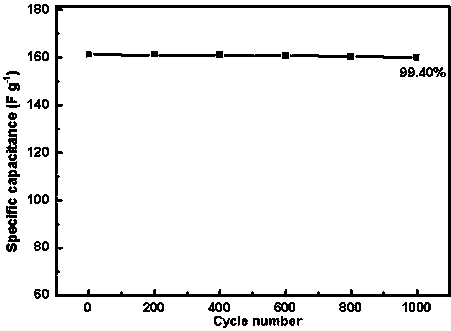

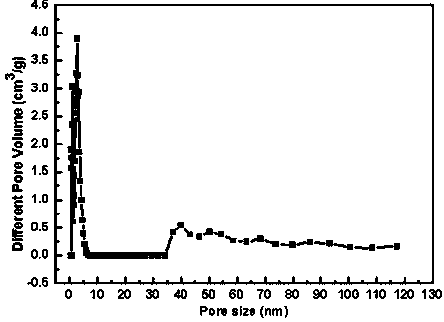

[0074] The parameters of the prepared nitrogen-containing porous carbon material are as follows: the specific surface area is 1550 m 2 / g, pore volume 1.2 cm 3 / g, the yield is 15%. When the current density is 1A / g, the specific capacitance value is 161F / g, and after 1000 cycles...

Embodiment 2

[0076] Step 1: High temperature carbonization

[0077] Put sodium polyaspartate into a carbonization furnace and carbonize under vacuum conditions, and continuously feed N at a rate of 30mL / min during the carbonization process. 2 / Ar, first increase the temperature from room temperature to 200±5°C for 2 hours at a rate of 5°C / min, then continue to heat at a rate of 5°C / min to 900±5°C for 1 hour, and then slowly lower to room temperature, that is, the black Nitrogen-containing carbon materials;

[0078] Step 2: pickling

[0079] Soak in 0.1 mol / L hydrochloric acid solution and ultrasonically clean for three times for half an hour each time to obtain a nitrogen-containing porous carbon material.

[0080] The parameters of the prepared nitrogen-containing porous carbon material are as follows: the specific surface area is 1152 m 2 / g, pore volume 0.8 cm 3 / g, the yield is 13%. When the current density is 1A / g, the specific capacitance value is 155F / g, and after 1000 cycles, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com