Homogeneous beam spot method for electron beam surface treatment

A surface treatment and electron beam technology, applied in the field of uniform beam spot and electron beam surface treatment, can solve the problems of small thermal action area and uneven heating of the material surface, and achieve good economical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

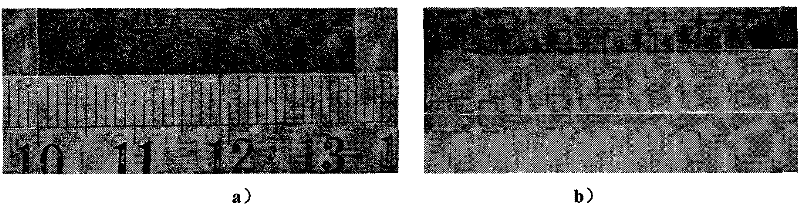

[0028] Example 1 TC4 titanium plate test

[0029] Step 1: Large-area uniform beam spot waveform design

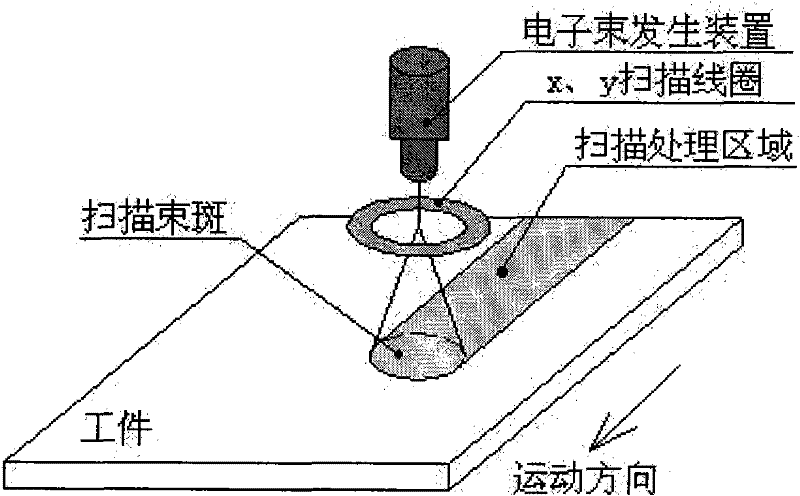

[0030] The scanning system of the electron beam is composed of two mutually perpendicular electromagnetic coils at the bottom of the electron gun. Under the action of the two-dimensional magnetic field, the electron beam can realize non-contact deflection and produce any two-dimensional plane graphics; With different magnetic field signals, the electron beam can produce various patterns of electron beam trajectories under the action of different magnetic fields, such as figure 1 shown;

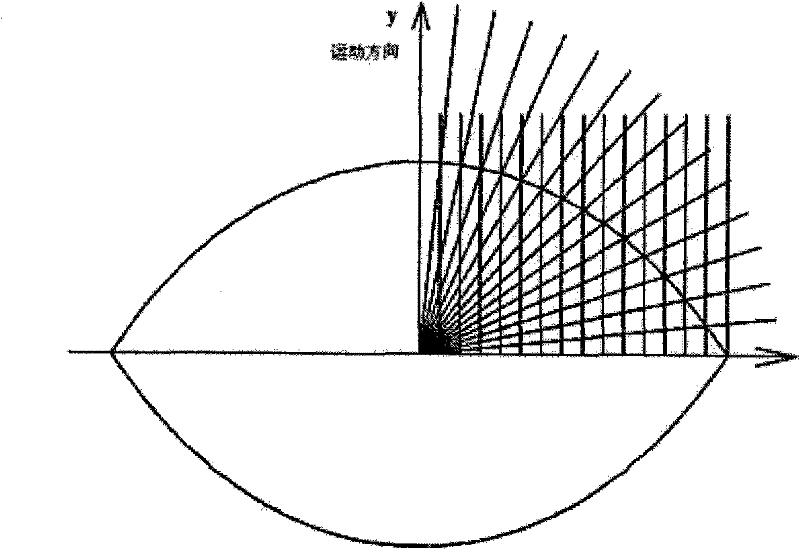

[0031] The electrons move at a very high speed. Within a certain period of time, the heating sequence caused by the two-dimensional plane graphics generated by the electron beam scanning during the heating process can be ignored; as the workpiece moves, the component of the electron beam energy perpendicular to the direction of motion is guaranteed. Equal, so that the heating of the treat...

example 2

[0045] Example 2 Silicide coating cladding treatment test

[0046] Step 1: Large-area uniform beam spot waveform design

[0047] The scanning system of the electron beam is composed of two mutually perpendicular electromagnetic coils at the bottom of the electron gun. Under the action of the two-dimensional magnetic field, the electron beam can realize non-contact deflection and produce any two-dimensional plane graphics; With different magnetic field signals, the electron beam can produce various patterns of electron beam trajectories under the action of different magnetic fields, such as figure 1 shown;

[0048] Electrons move at a very high speed. Within a certain period of time, the heating sequence caused by the two-dimensional plane graphics generated by electron beam scanning during the heating process can be ignored; The components are equal, thus ensuring the uniformity and consistency of heating in the treated area;

[0049] The specific method is: divide the x-ax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com