Composite graphite film and preparation method and application thereof

A technology of composite graphite and composite film, applied in the field of graphite film, can solve the problems of low carbonization degree of polyimide graphite film, low fracture strength, poor electrical conductivity and thermal conductivity, etc., so as to improve the degree of carbonization and graphitization, and improve the thermal conductivity. and electrical conductivity, the effect of improving the carbonization yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

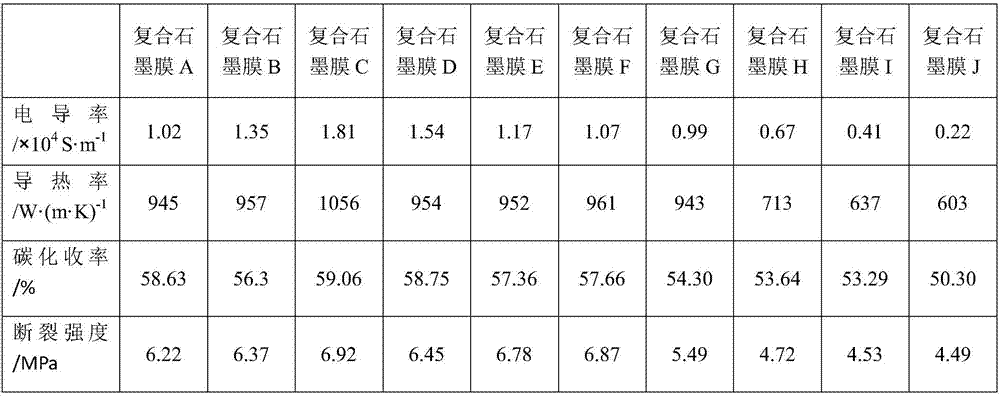

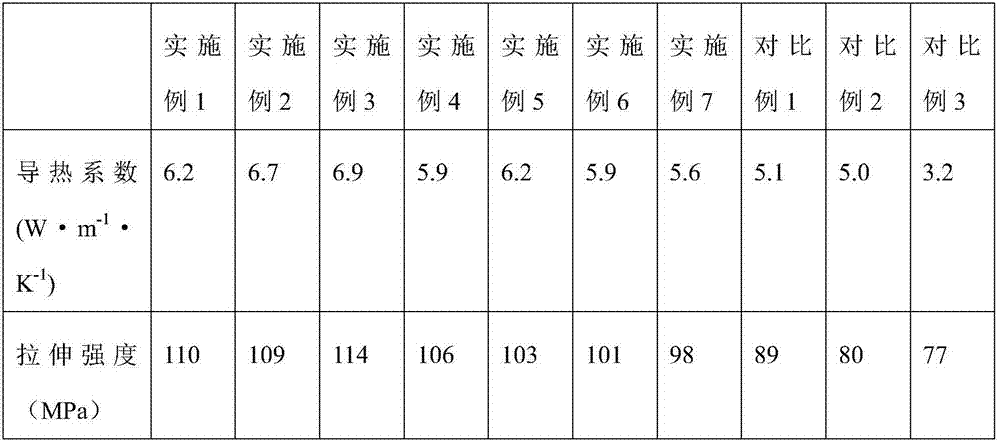

Examples

Embodiment 1

[0031] A preparation method for a composite graphite film, comprising the steps of:

[0032] (1) Select nano-diamonds with a particle diameter of 5nm, add them to N,N-dimethylacetamide (DMAc) solution, and ultrasonically disperse them until there are no obvious particles to form a nano-diamond suspension;

[0033] (2) Introduce nitrogen into the nano-diamond suspension, add 1mol 4,4'-diaminodiphenyl ether, stir until completely dissolved, then add 1mol pyromellitic anhydride three times while stirring, polyamic acid solution containing nano-diamonds, wherein the content of nano-diamonds in the polyamic acid mixed solution is 4,4'-diaminodiphenyl ether and pyromellitic acid diphenyl ether 0.1wt% of the sum of anhydride masses;

[0034] (3) Coat the polyamic acid solution on a glass plate, keep the temperature at 80°C for 2 hours, remove the film, fix the film on a shelf, place it in an oven, and adjust the heating rate of the oven to 3°C / min, First raise the temperature to 10...

Embodiment 2

[0037]A preparation method for a composite graphite film, comprising the steps of:

[0038] (1) choose the diameter to be 100nm nano-diamond, join in the DMAc solution, ultrasonically disperse to no obvious particle, form nano-diamond suspension;

[0039] (2) Pass argon into the nanodiamond suspension, add 1mol 4,4'-diaminodiphenyl ether, stir until completely dissolved, then add 1.5mol pyromellitic anhydride in five times under stirring, Under stirring, polycondensation reaction at 10°C for 2 hours at low temperature to obtain a polyamic acid solution containing nano-diamonds, wherein the content of nano-diamonds in the polyamic acid solution is 4,4'-diaminodiphenyl ether and pyromellitic acid 10wt% of the sum of dianhydride mass;

[0040] (3) Coat the polyamic acid solution on a glass plate, keep the temperature at 80°C for 2 hours, remove the film, fix the film on a shelf, place it in an oven, and control the heating rate of the oven to 5°C / min, Firstly raise the temperat...

Embodiment 3

[0043] A preparation method for a composite graphite film, comprising the steps of:

[0044] (1) choose the diameter to be 50nm nano-diamond, join in the DMAc solution, ultrasonically disperse to no obvious particle, form nano-diamond suspension;

[0045] (2) Pass argon into the nanodiamond suspension, add 1mol 4,4'-diaminodiphenyl ether, stir until completely dissolved, then add 1.02mol pyromellitic anhydride in five times under stirring, Under the stirring state, polycondensation reaction was carried out at -5°C for 6 hours at a low temperature to obtain a polyamic acid solution containing nano-diamonds, wherein the content of nano-diamonds in the polyamic acid solution was 4,4'-diaminodiphenyl ether and pyromellitic 0.5wt% of the sum of the mass of formic dianhydride;

[0046] (3) Cast the polyamic acid solution on a glass plate, keep the temperature at 80°C for 2 hours, remove the film, fix the film on a shelf, place it in an oven, and control the heating rate of the oven...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com