A kind of preparation method of electrode material of vanadium redox flow battery

A technology of all-vanadium redox flow battery and electrode material, which is applied in the direction of battery electrode, textile material processing, nanotechnology for materials and surface science, etc., can solve the difficulty of carbon fiber surface crystallization growth, carbon fiber axial misorientation, fiber Low degree of graphitization and other problems, to achieve the effect of easy to meet the experimental conditions, improve hydrophilicity, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

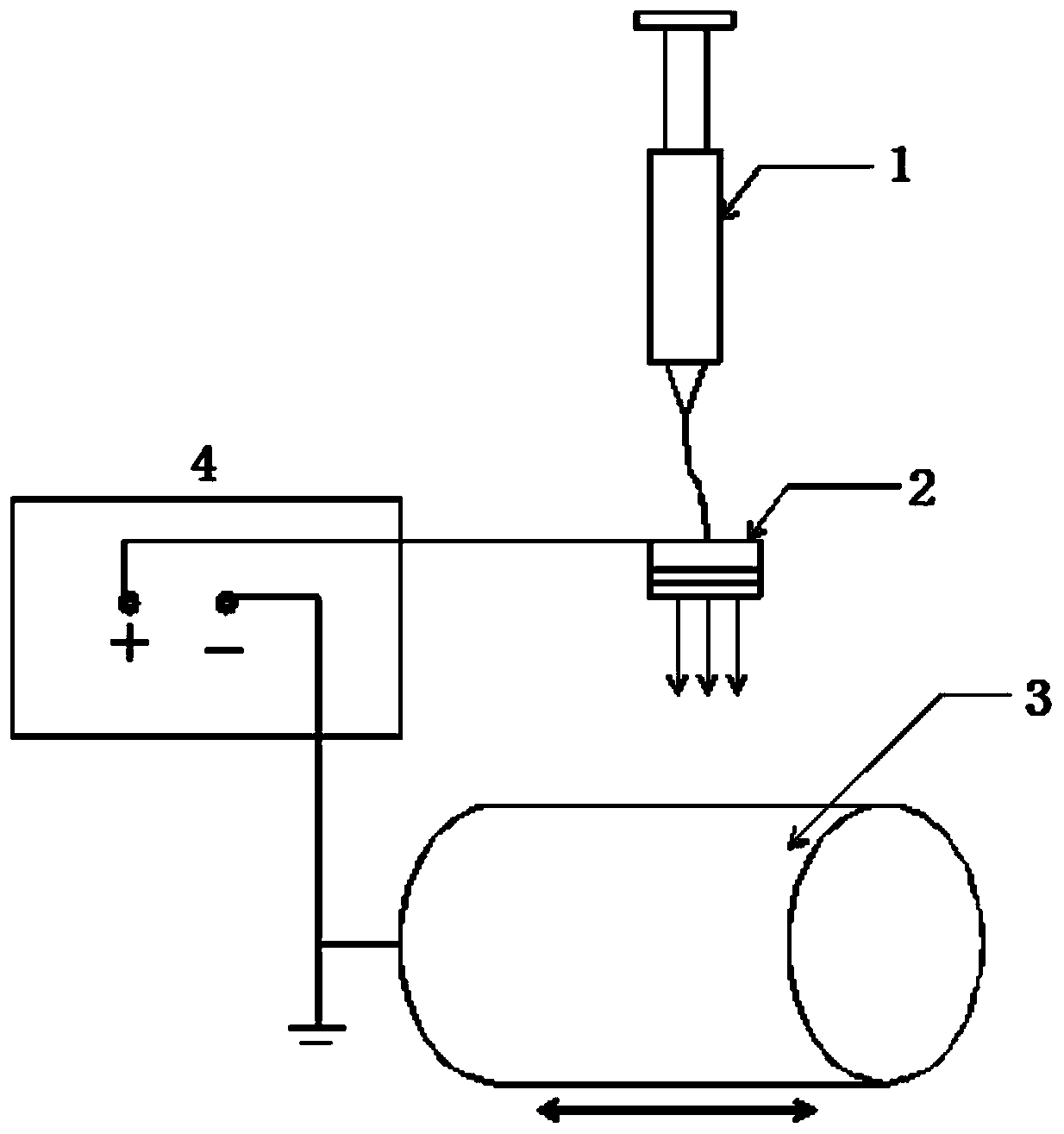

Method used

Image

Examples

Embodiment 1

[0033] In this embodiment, the preparation method of the electrode material of the all-vanadium redox flow battery is as follows:

[0034]1) Dissolve the alkaline lignin into NaOH aqueous solution with a concentration of 0.5mol / L, add formaldehyde, the molar ratio of alkaline lignin + resorcinol to formaldehyde is 1:2, stir evenly, and the stirring time is 1h, The hydroxymethylation reaction was carried out, and the pH value was adjusted to 9 with NaOH aqueous solution. Add resorcinol to the above solution, and the molar ratio of alkaline lignin to resorcinol is 2:1. Then slowly add iron acetylacetonate solution, adjust the molar ratio of alkaline lignin + resorcinol to metal salt catalyst to 20:1, keep stirring until it is completely dissolved, stir vigorously until the reaction forms a gel, and the stirring time is 1h. The gel was transferred to a vacuum drying oven to dry at 80°C, and after sealing and aging, the sample was taken out and cooled to room temperature to obtai...

Embodiment 2

[0041] The difference from Example 1 is that the preparation method of the all-vanadium redox flow battery electrode material in this example is as follows:

[0042] 1) Dissolve the alkaline lignin in NaOH aqueous solution with a concentration of 0.4mol / L, add formaldehyde, the molar ratio of alkaline lignin + resorcinol to formaldehyde is 1:3, stir evenly, and the stirring time is 2h, The hydroxymethylation reaction was carried out, and the pH value was adjusted to 9 with NaOH aqueous solution. Add resorcinol to the above solution, and the molar ratio of alkaline lignin to resorcinol is 1:5. Then slowly add cobalt nitrate solution, adjust the molar ratio of alkaline lignin + resorcinol to metal salt catalyst to 30:1, keep stirring until it is completely dissolved, stir vigorously until the reaction forms a gel, and the stirring time is 3h. The gel was transferred to a vacuum drying oven to dry at 85°C, and after sealing and aging, the sample was taken out and cooled to room ...

Embodiment 3

[0049] The difference from Example 1 is that the preparation method of the all-vanadium redox flow battery electrode material in this example is as follows:

[0050] 1) Dissolve the alkaline lignin into an ammonia solution with a concentration of 0.4mol / L, add formaldehyde, the molar ratio of alkaline lignin + resorcinol to formaldehyde is 1:4, stir evenly, and the stirring time is 3h, The hydroxymethylation reaction was carried out, and the pH value was adjusted to 9 with ammonia solution. Add resorcinol to the above solution, and the molar ratio of alkaline lignin to resorcinol is 1:4. Then slowly add cobalt nitrate solution, adjust the molar ratio of alkaline lignin + resorcinol to metal salt catalyst to 40:1, keep stirring until it is completely dissolved, stir vigorously until the reaction forms a gel, and the stirring time is 4h. The gel was transferred to a vacuum drying oven to dry at 85°C, and after sealing and aging, the sample was taken out and cooled to room tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com