Patents

Literature

34results about How to "Control microscopic morphology" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

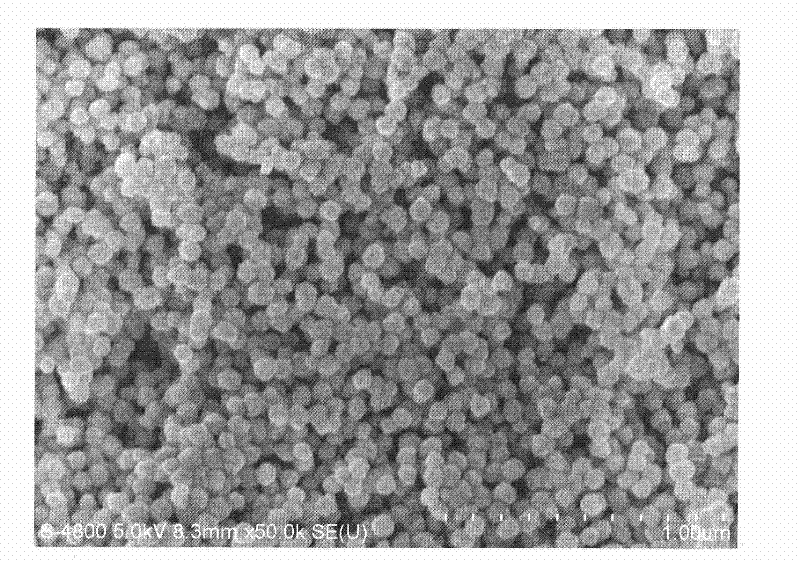

Method for preparing nano complex particle for highly conductive and magnetic electro-magnetic screen

InactiveCN101462173AExcellent magnetic and conductive propertiesControl microscopic morphologyNickel saltPolyethylene glycol

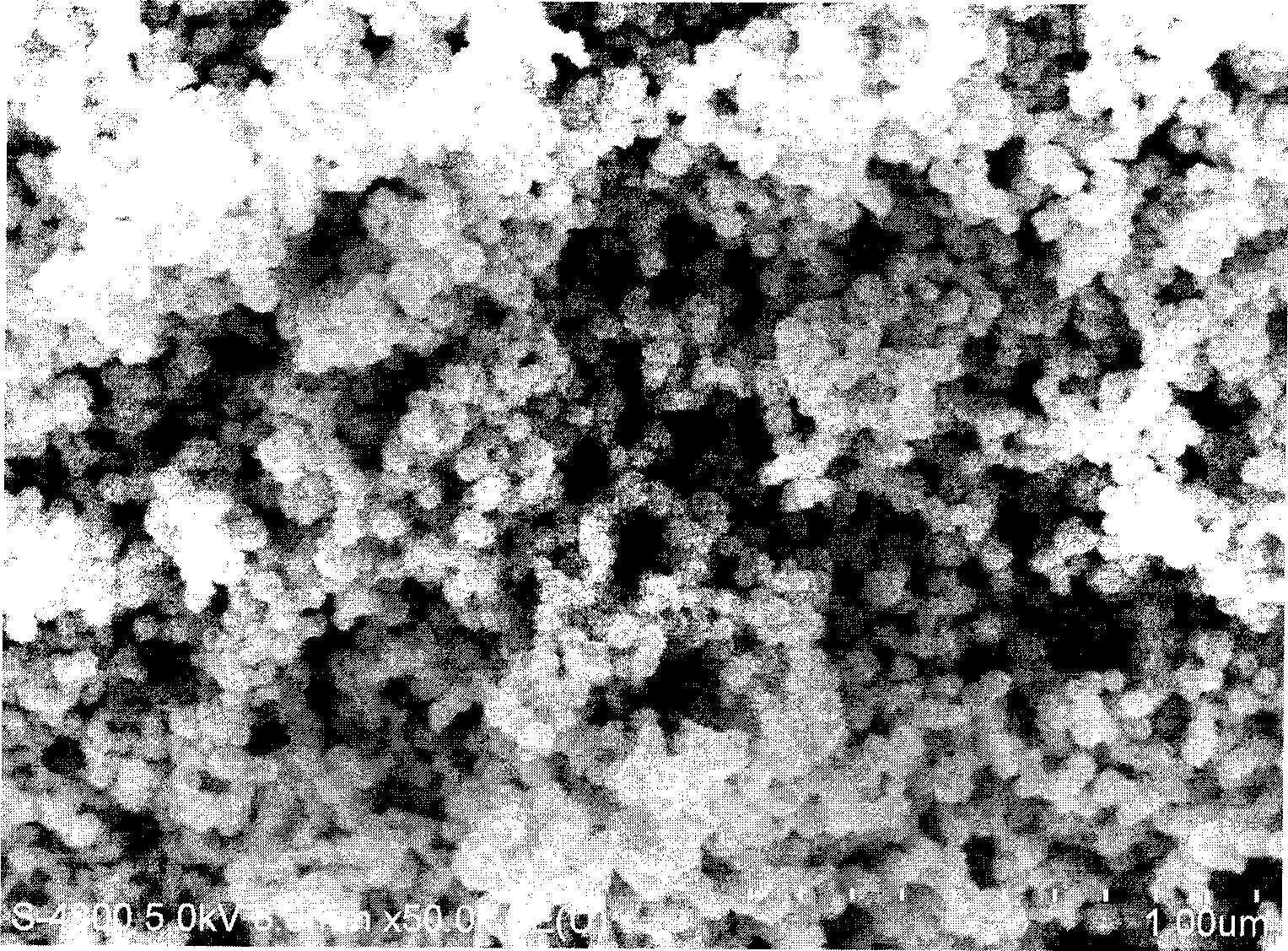

The invention relates to a method for preparing a nanometer composite particle for electromagnetic shielding. The method for preparing the high electric and magnetic conduction nanometer composite particle for electromagnetic shielding is characterized in that the method comprises the following steps: 1) material selection; 2) ferrite and nickel salt are mixed, added with polyethylene glycol and cyclohexane, then added with water and are stirred and dispersed to obtain a mixed solution; 3) the mixed solution is added with a strong reducer at a temperature of between 25 and 90 DEG C, reacts for 5 to 60 minutes under alkali condition with PH value of between 9 and 13, is cooled to normal temperature, and is washed and dried to obtain FeNi alloy nanometer particles; and 4) the FeNi alloy nanometer particles are added into anhydrous ethyl ethanol, added with a weak reducer, subjected to ultrasonic dispersion for 30 to 60 minutes, then added with a silver ammonia solution, stirred at a temperature of between 25 and 90 DEG C, react for 0.5 to 2 hours, cooled to normal temperature and are washed and dried to obtain the high electric and magnetic conduction nanometer composite particle for electromagnetic shielding. The method has the advantages of simple process, environmental protection, low production cost and high yield; and the product has excellent magnetic and electric conduction performances.

Owner:WUHAN UNIV OF TECH

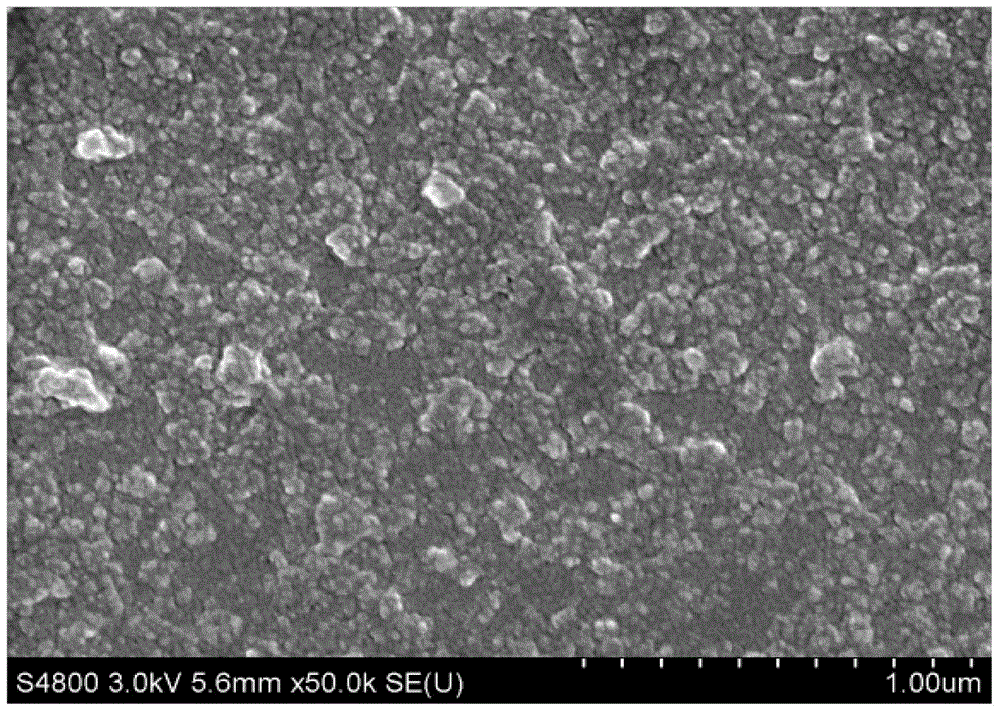

Preparation method of graphene/manganese dioxide composite material

ActiveCN103588198ASolve reunionHigh specific surface areaGrapheneManganese oxides/hydroxidesElectrophoresesOrganic solvent

The invention discloses a preparation method of a graphene / manganese dioxide composite material. The preparation method comprises the following steps: graphite is ultrasonically stripped directly in an organic solvent to obtain a graphene dispersion liquid; a manganese ion salt is added in the obtained graphene dispersion liquid; graphene adsorbs added manganese ions to carry with positive charges; and an electrophoretic deposition method is adopted to prepare the graphene / manganese dioxide composite material. The graphene of the method is prepared by adopting the liquid-phase ultrasonic stripping method, and the oxidizing treatment is not implemented, so that the defects are fewer, and the complete structure of the graphene is retained; the electrophoretic deposition method can be adopted to evenly and controllably deposit the graphene / manganese dioxide composite material on the surface of any three-dimensional conducting matrix. The method has the advantages such as easiness in operation, low production cost, high product uniformity and easiness in control.

Owner:SHANGHAI INST OF TECH

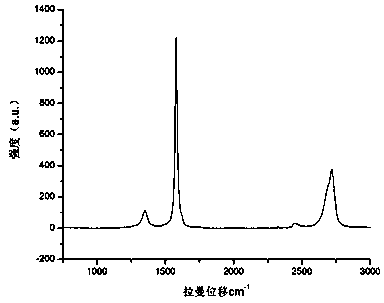

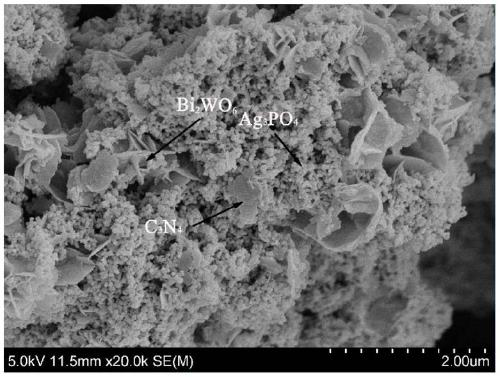

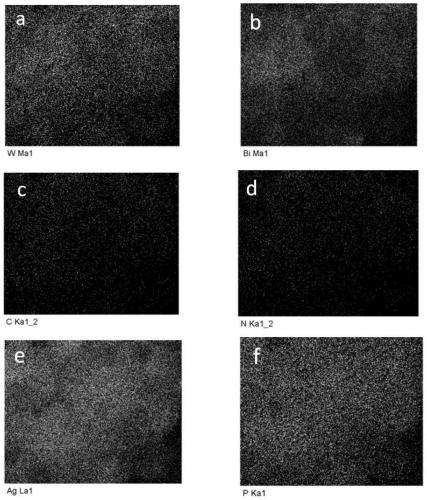

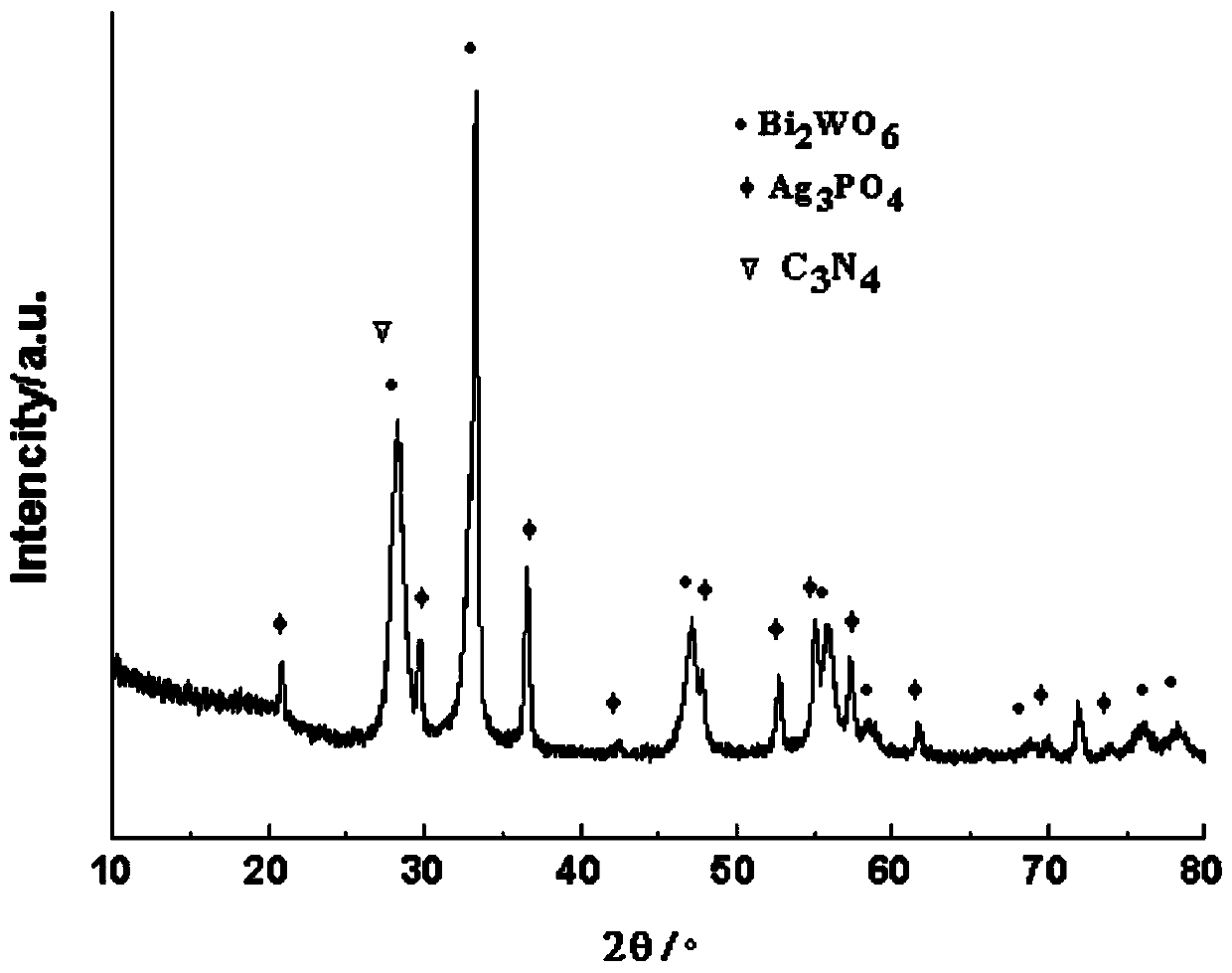

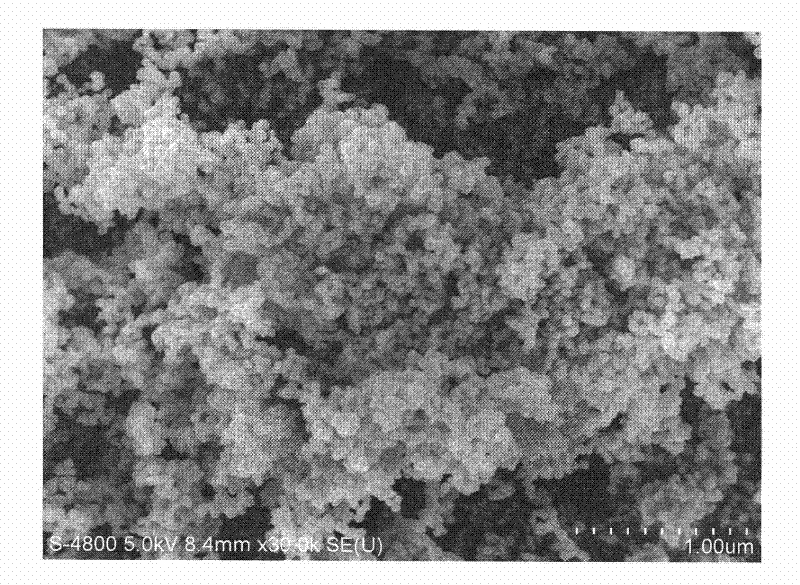

Bismuth tungstate-carbon nitride-silver phosphate ternary efficient visible-light catalyst and preparation method therefor

InactiveCN109847771AEfficient degradationControl microscopic morphologyPhysical/chemical process catalystsWater/sewage treatment by irradiationTungstateCarbon nitride

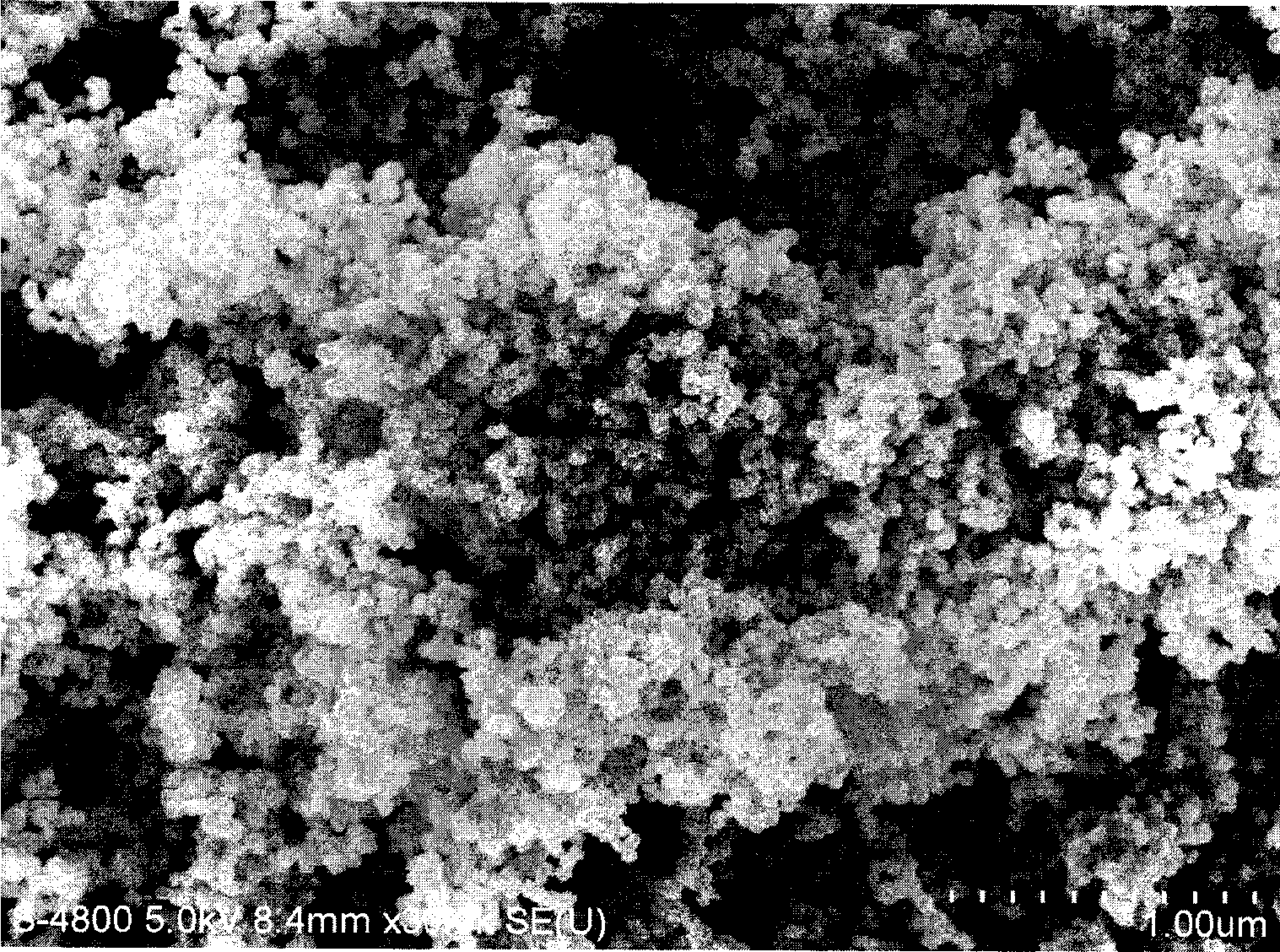

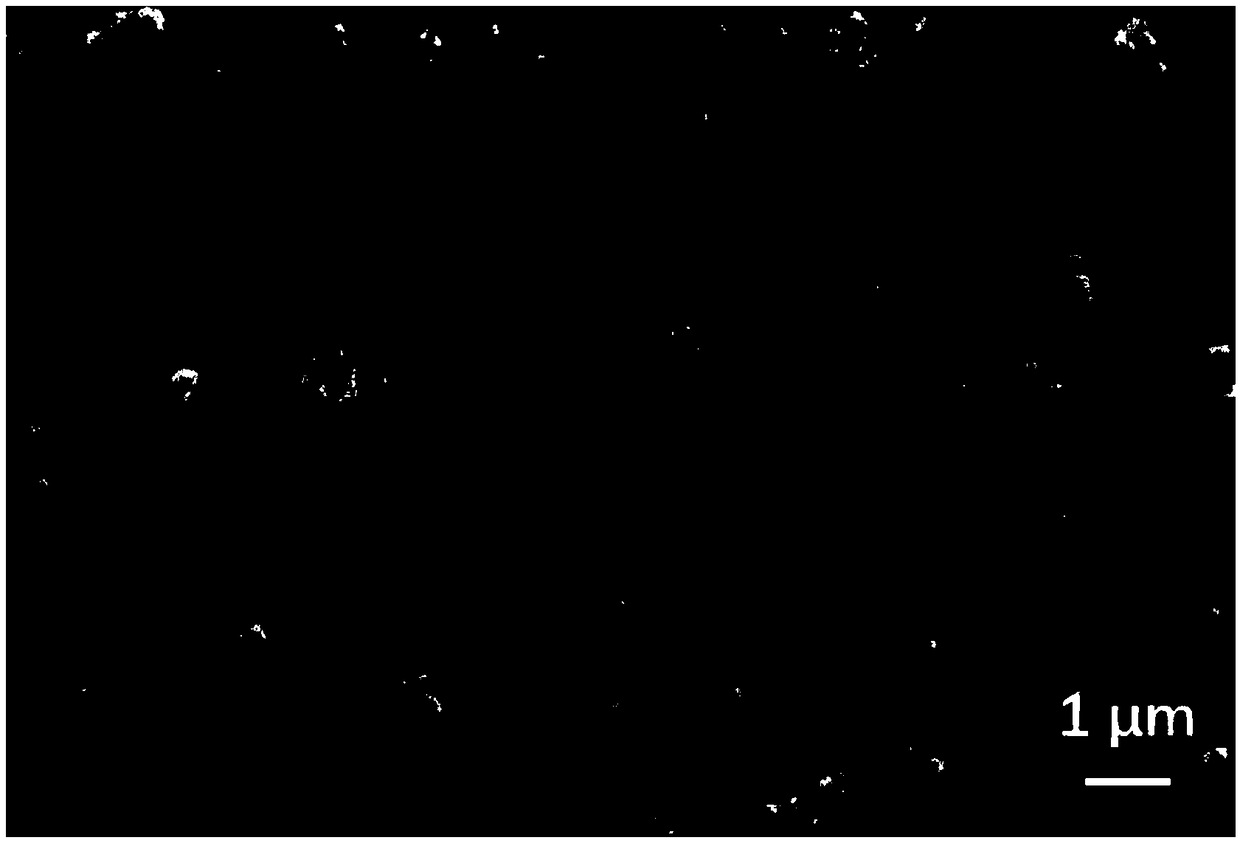

The invention provides a bismuth tungstate-carbon nitride-silver phosphate ternary efficient visible-light catalyst and a preparation method therefor. The ternary efficient visible-light catalyst andthe preparation method therefor are used for solving the difficult problem that photocatalytic performance of bismuth tungstate is not excellent enough. The ternary composite photocatalyst is preparedfrom bismuth tungstate nanosheets, carbon nitride nanosheets and nano silver phosphate which are stacked, wherein the bismuth tungstate nanosheets have the length of 0.8 to 1 micron and the width of0.4 to 0.6 micron, the carbon nitride nanosheets have the length of 0.6 to 0.8 micron and the width of 0.2 to 0.4 micron, and silver phosphate particles have the size of 50 to 100 nanometers. According to the ternary efficient visible-light catalyst and the preparation method therefor, a hydrothermal-precipitation method is applied to preparation of the bismuth tungstate-carbon nitride-silver phosphate ternary composite photocatalyst, and a powdery bismuth tungstate-carbon nitride-silver phosphate complex with excellent visible-light catalysis performance is obtained through firstly synthesizing a bismuth tungstate-carbon nitride complex by adopting a hydrothermal method, compounding silver phosphate into bismuth tungstate-carbon nitride by applying a precipitation method, carrying out filtering so as to obtain precipitates, and carrying out washing and drying. The preparation method provided by the invention is simple, is easy in operation and is beneficial to extensive use of productive practice.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

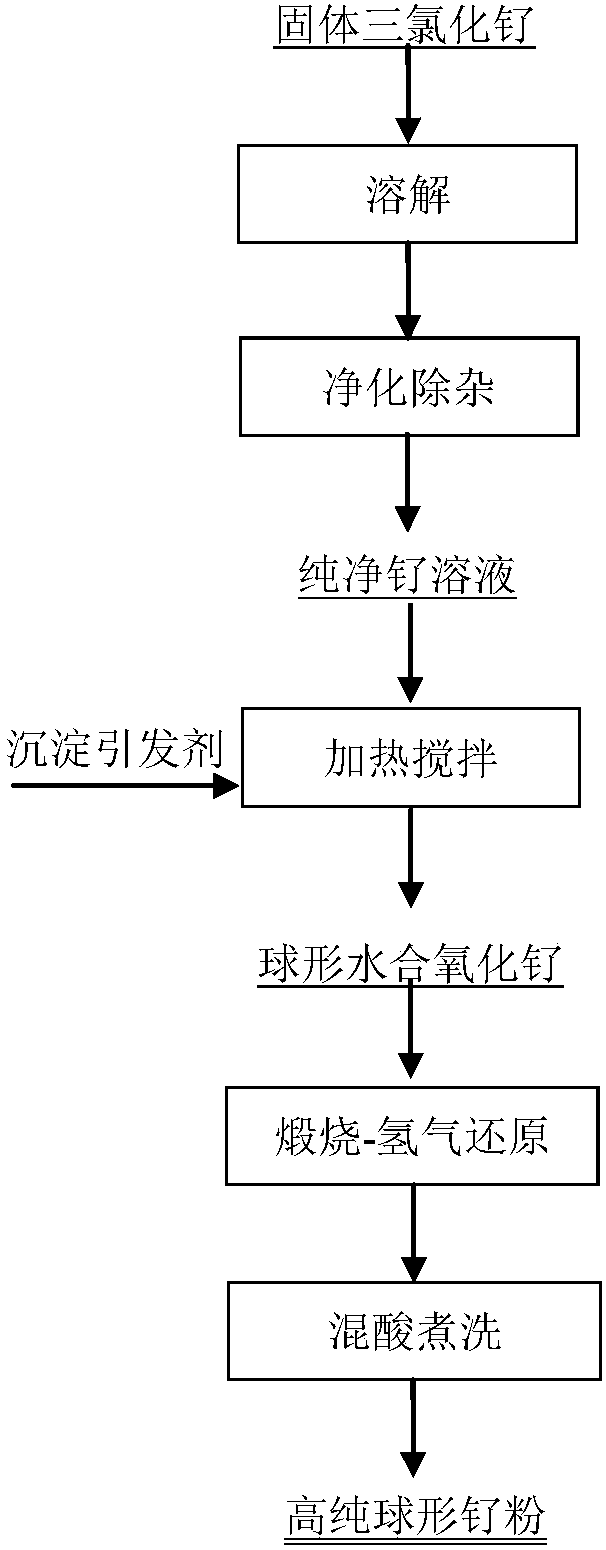

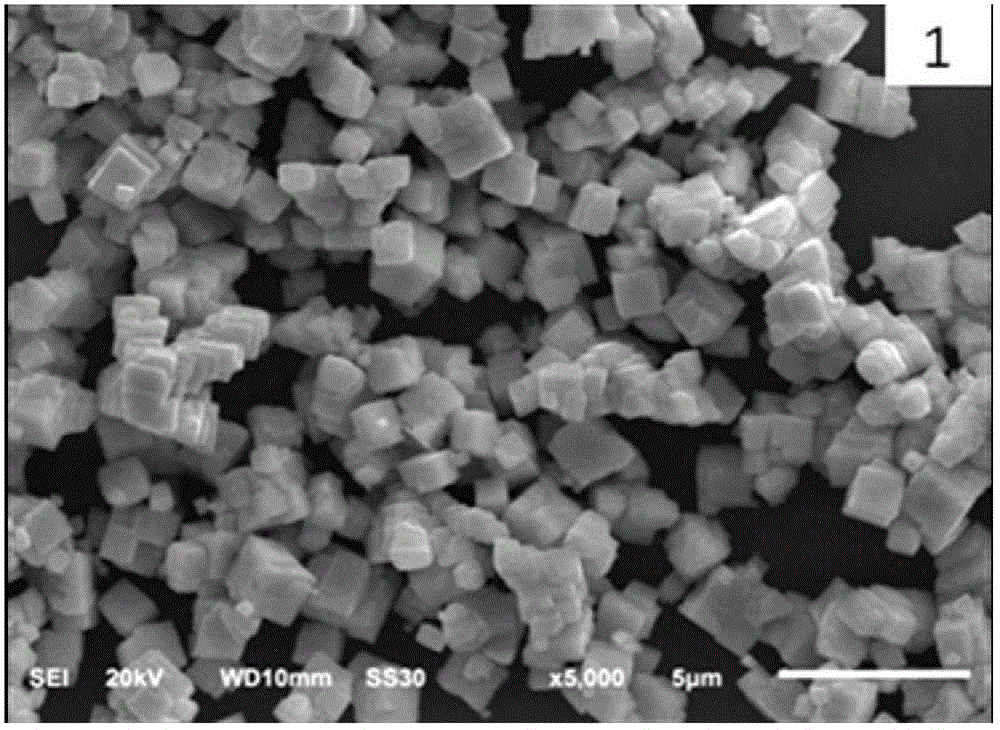

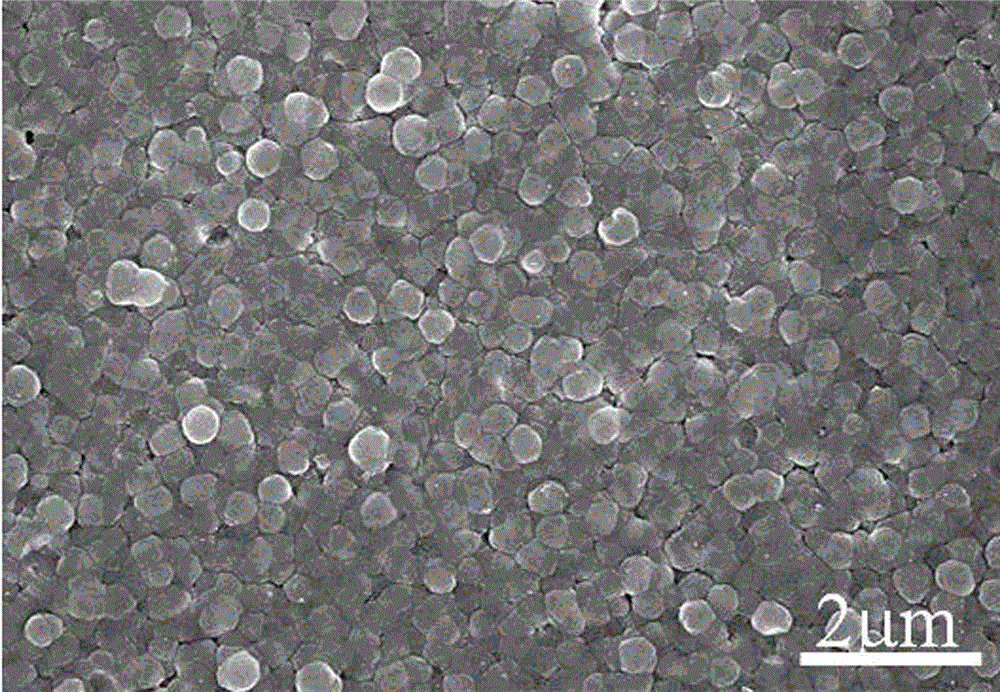

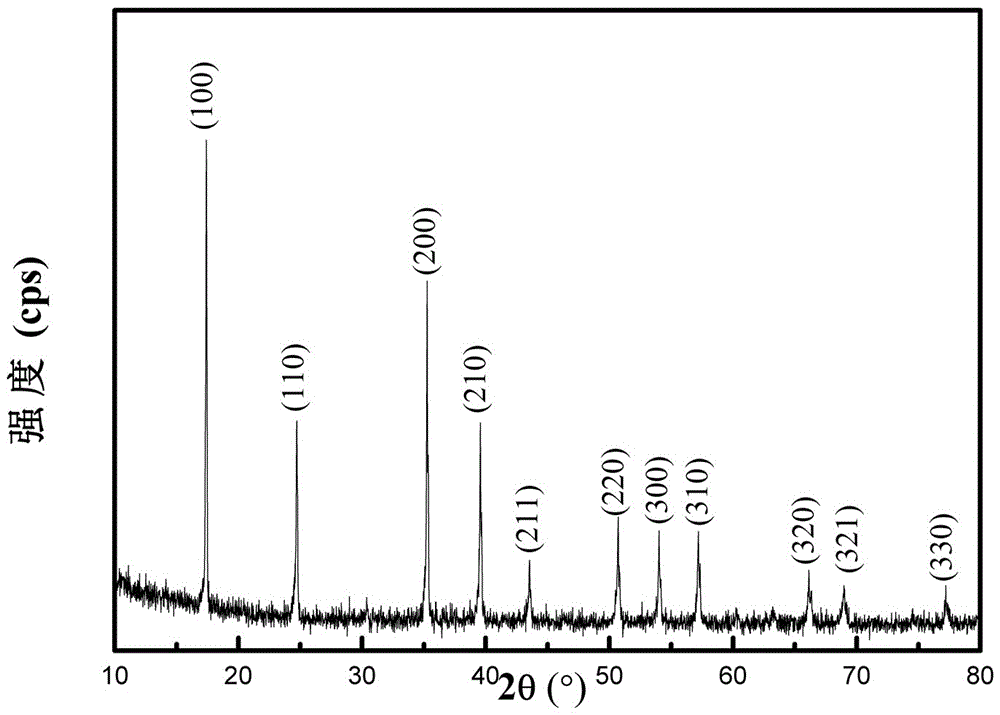

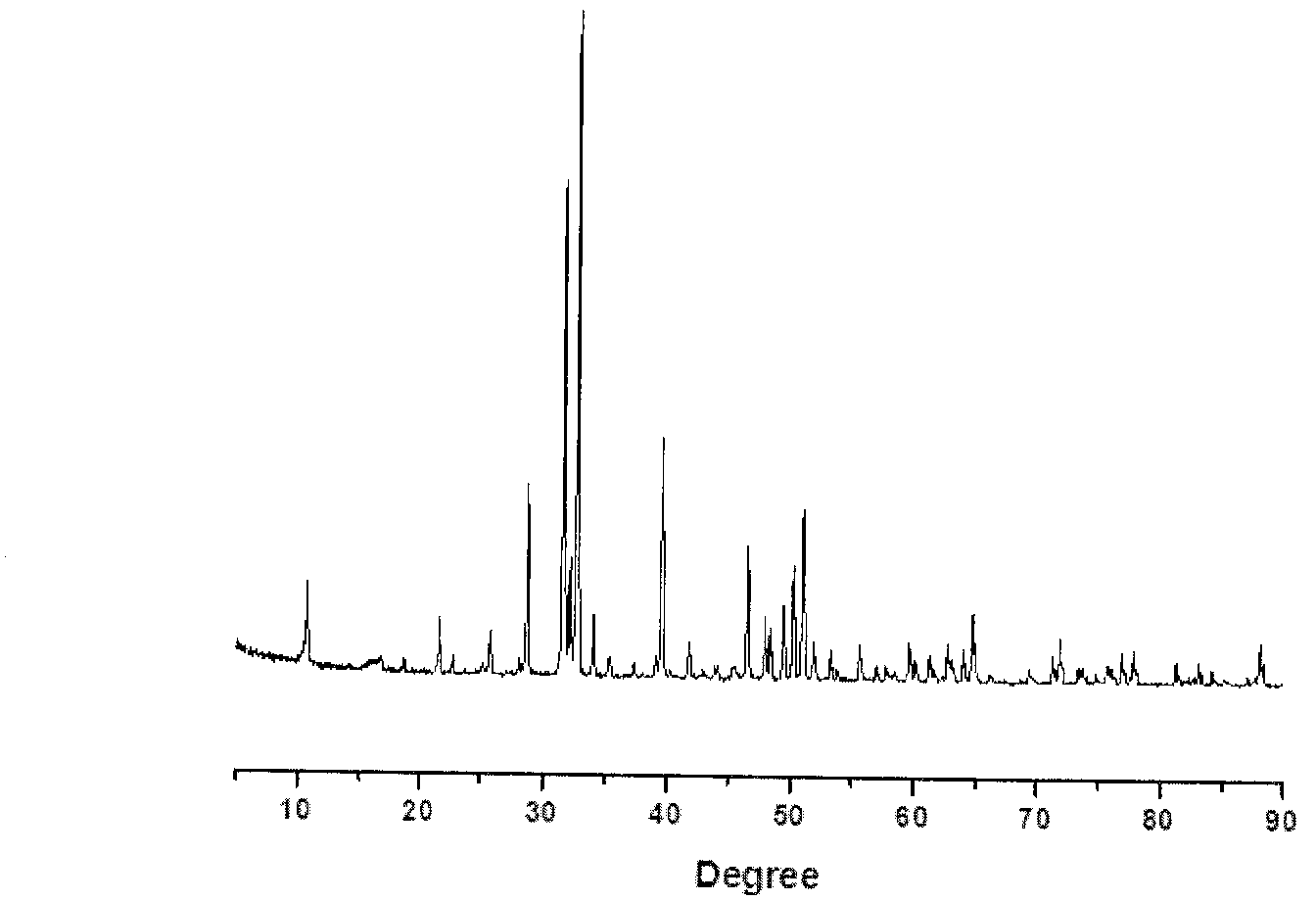

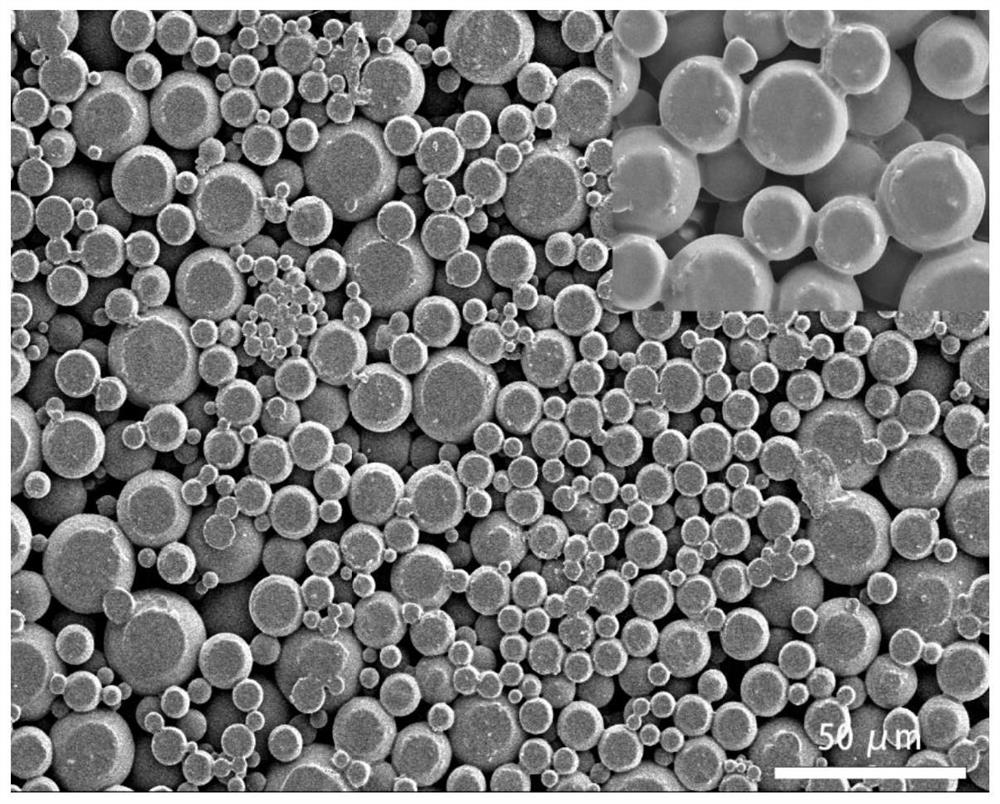

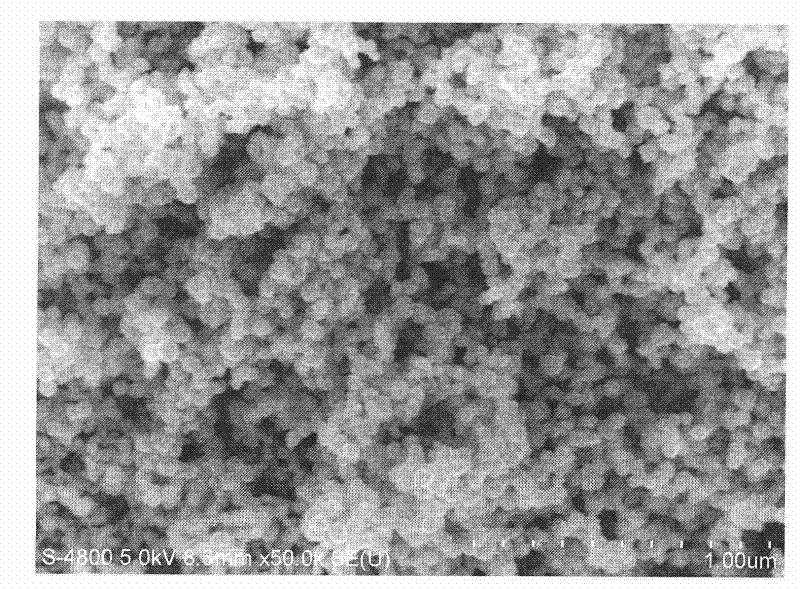

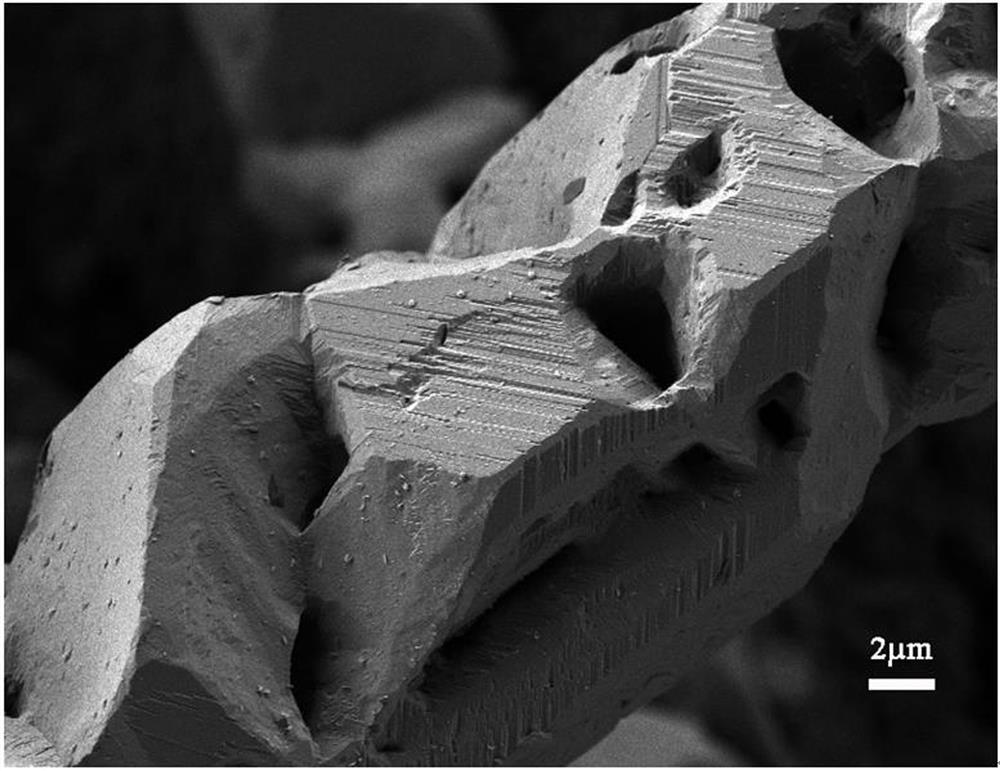

Method for preparing high-purity spherical ruthenium powder

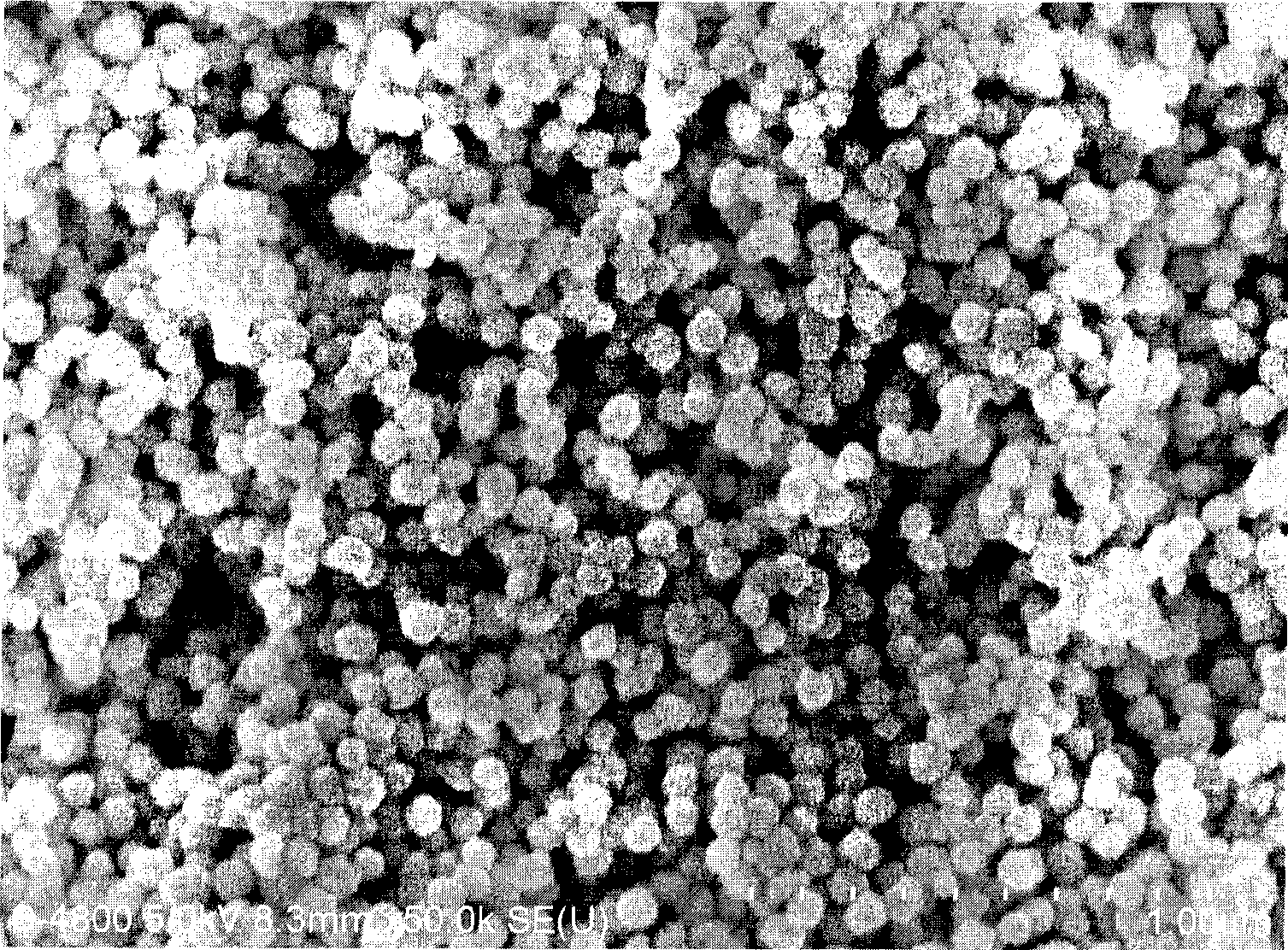

InactiveCN108405881AControl growth rateReduce contentTransportation and packagingMetal-working apparatusIon exchangeVacuum drying

The invention discloses a method for preparing high-purity spherical ruthenium powder. The method includes the steps that (1) dissolving is conducted, and hydrochloric acid is used for dissolving to obtain a ruthenium hydrochloride solution; (2) ion exchange purification impurity removing is carried out so that a pure ruthenium solution can be obtained; (3) a precursor is prepared, the initial pHvalue of the ruthenium solution obtained in the step (2) is adjusted, a sediment initiator is added, and ageing, heating and stirring are performed to generate the ruthenium powder precursor-sphericalruthenium oxide hydrate; (4) calcination dehydration-hydrogen reduction is carried out, the precursor obtained in the step (3) is put into a tube furnace to be subjected to calcination dehydration atfirst, then nitrogen is connected in for high-temperature reduction, and accordingly spherical metal ruthenium powder is obtained; and (5) mixed acid boiling washing and filtering separation are carried out, deionized water is used for sufficient washing, and the high-purity spherical ruthenium powder can be obtained after vacuum drying. By adoption of the method, the technology is simple, the impurity content in the prepared ruthenium powder is smaller than 10ppm, the microstructure of the ruthenium powder is spherical, the granularity is smaller than 5 microns, and the high-purity sphericalruthenium powder can be used as a raw material for a ruthenium-system sputtering target material.

Owner:SINO PLATINUM METALS CO LTD

Preparation method of FeCoNiCuMo high-entropy alloy film

The invention discloses a preparation method of a FeCoNiCuMo high-entropy alloy film. Deionized water serves as solvent to be prepared into electroplate liquid, and the electroplate liquid is preparedby an electrochemical deposition method. The method comprises the steps that S1, three parts of deionized water is fetched, triethanolamine, ammonium molybdate tetrahydrate and copper salt are dissolved in the first part of deionized water, and a solution A is obtained; S2, glycocoll, ethanediol, antioxidant and additional salt are dissolved in the second part of deionized water, and a solution Bis obtained; S3, trisodium citrate, bivalent iron salt, cobalt salt and nickel salt are dissolved in the third part of deionized water, and a solution C is obtained; S4, the solution A, the solutionB and the solution C are mixed evenly and aged, the pH value of the mixture is adjusted to be 7-8, the mixture is heated to 30 DEG C, oxygen is removed by leading in nitrogen, and the electroplate liquid is obtained; and S5, a graphite plate serves as an anode and a copper base serves as a cathode for electroplating, and the FeCoNiCuMo high-entropy alloy film is obtained. The method has the characteristics of being simple in equipment and process, high in production efficiency, low in production cost, high in safety and reliability, and the like, and is suitable for industrial production of the high-entropy alloy film.

Owner:SOUTHWEST PETROLEUM UNIV

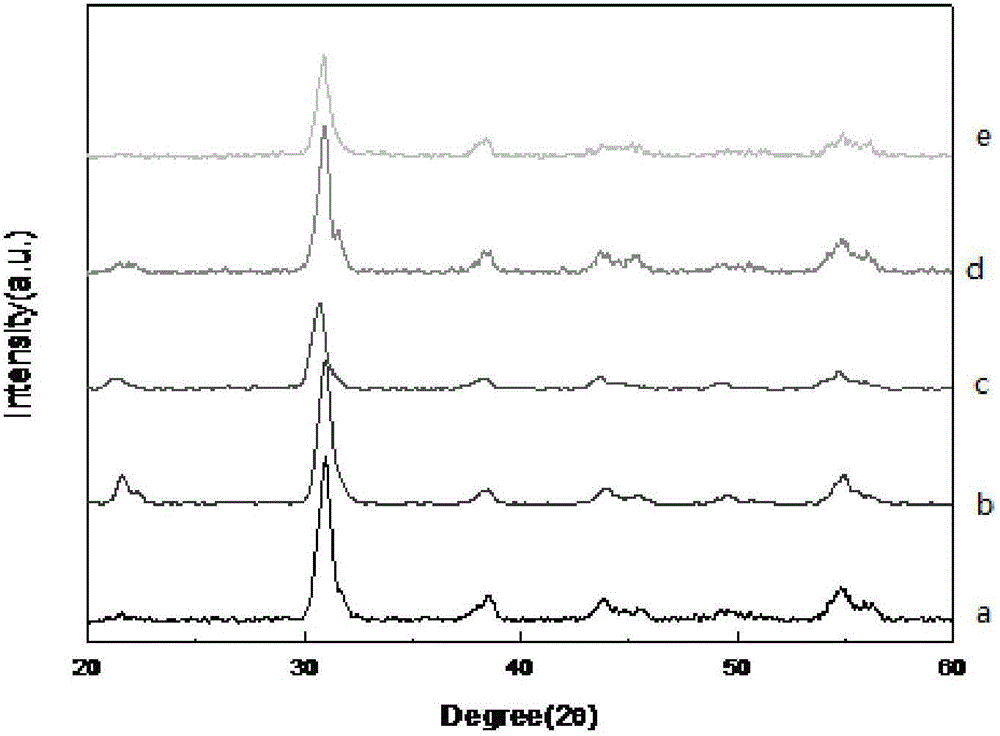

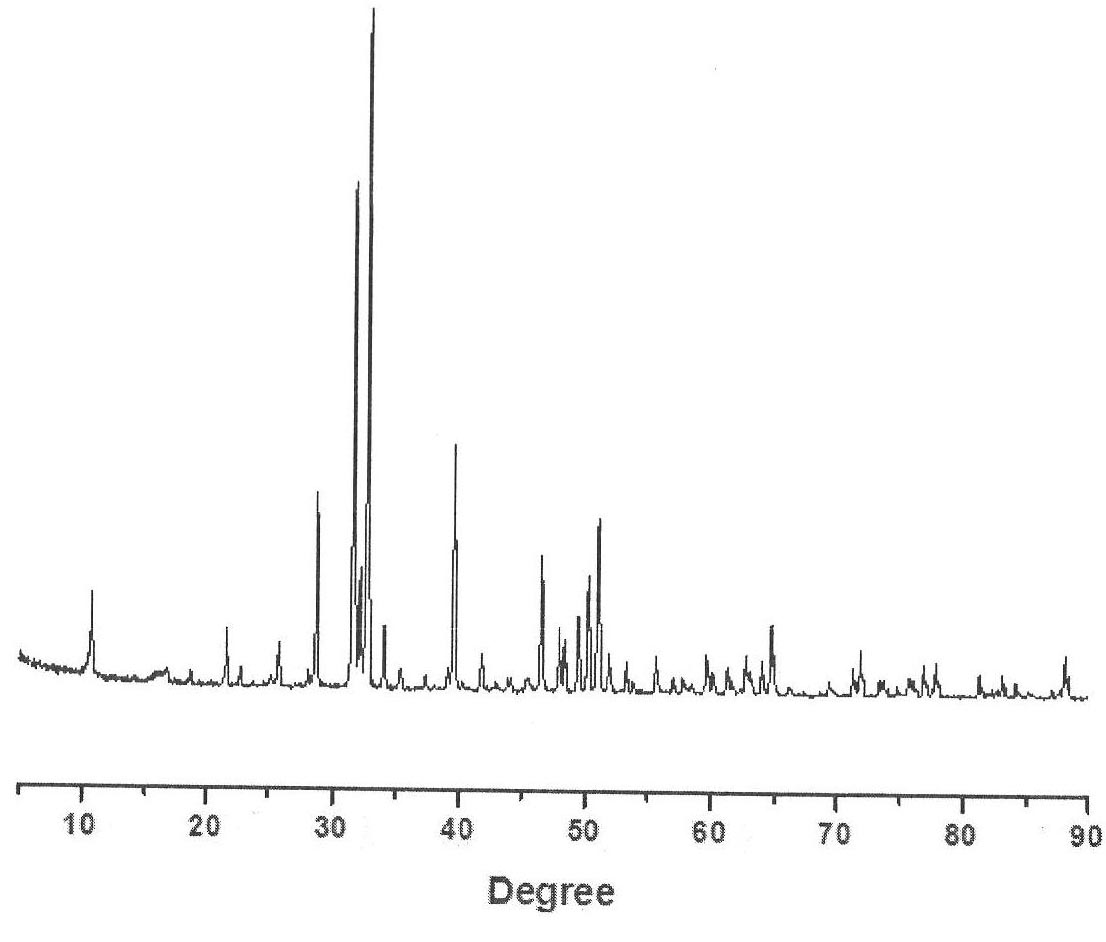

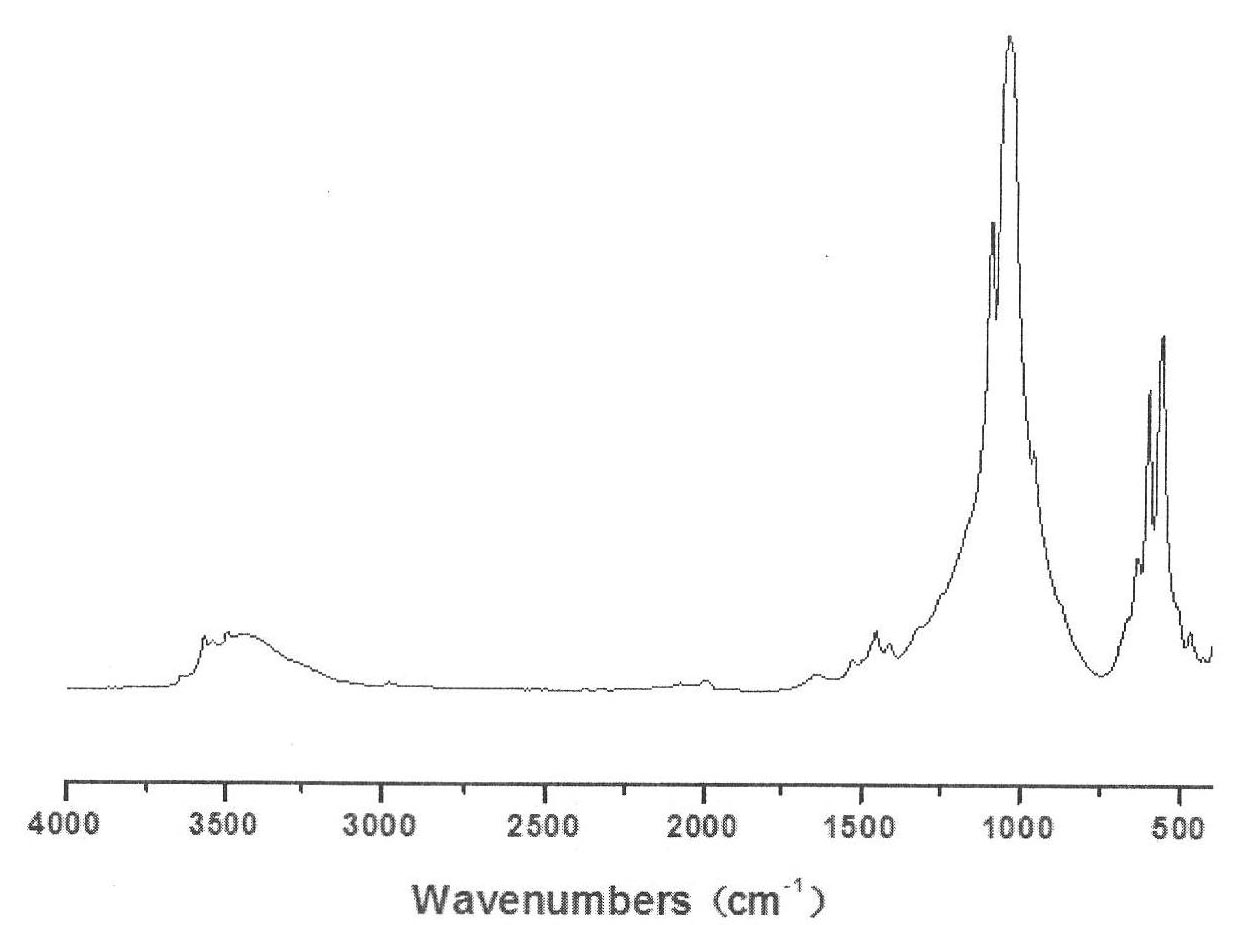

Preparation method of lead zirconate titanate piezoelectric ceramics

InactiveCN102718484AControl microscopic morphologyImprove powder sintering activitySolid phasesAdhesive

The invention discloses a preparation method of lead zirconate titanate piezoelectric ceramics, which comprises the following steps of: (1) taking tetra-n-butyl titanate and zirconium oxychloride as main raw materials to prepare and obtain aqueous solution in which a zirconium titanium hydroxide coprecipitate is suspended, taking prepared lead nitrate solution and a mineralizing agent, uniformly mixing and carrying out magnetic stirring; (2) carrying out hydro-thermal treatment on the agitated mixed solution, cooling to a room temperature after reaction, taking a reactant, cleaning and drying to obtain solid powder; and (3) grinding the solid powder, adding an adhesive to prepare a ceramic blank sheet, sintering the ceramic blank sheet and carrying out silver electrode polarization on the sintered ceramic blank sheet to prepare the lead zirconate titanate ceramics with high voltage electrical property. The preparation method has the beneficial effects that the process is simple, the lead zirconate titanate piezoelectric ceramics have uniform powder grain size, good dispersibility and high sintering activity, and the comprehensive piezoelectric and dielectric property of the lead zirconate titanate piezoelectric ceramics is remarkably superior to that of PZT ceramics sintered by a traditional solid-phase sintering method.

Owner:MORNSUN GUANGZHOU SCI & TECH +1

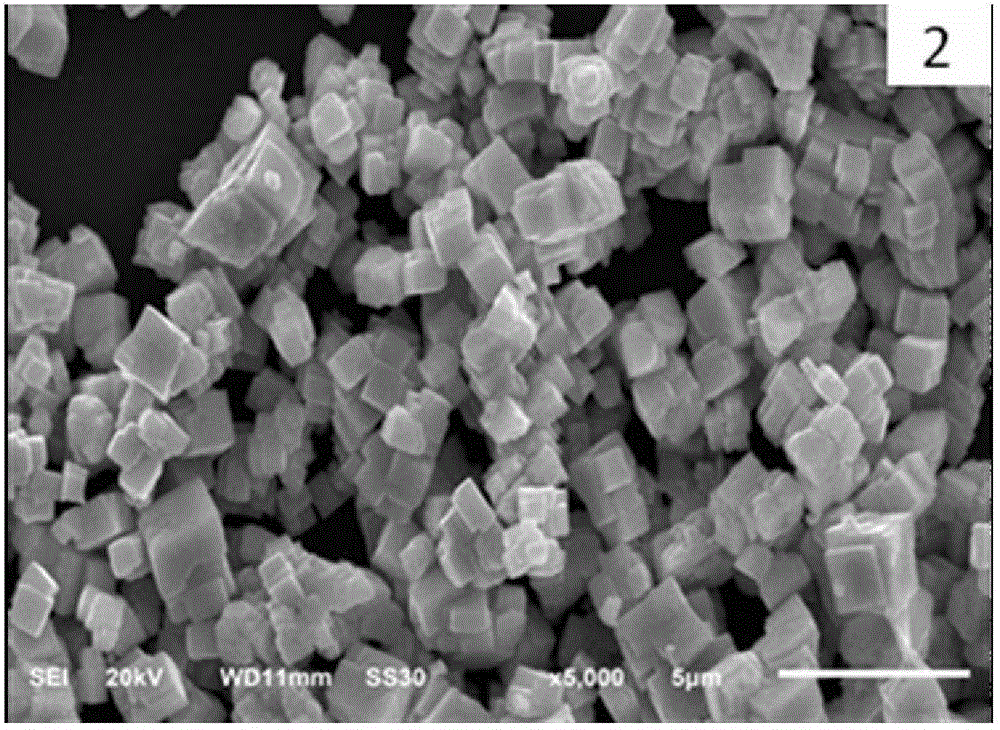

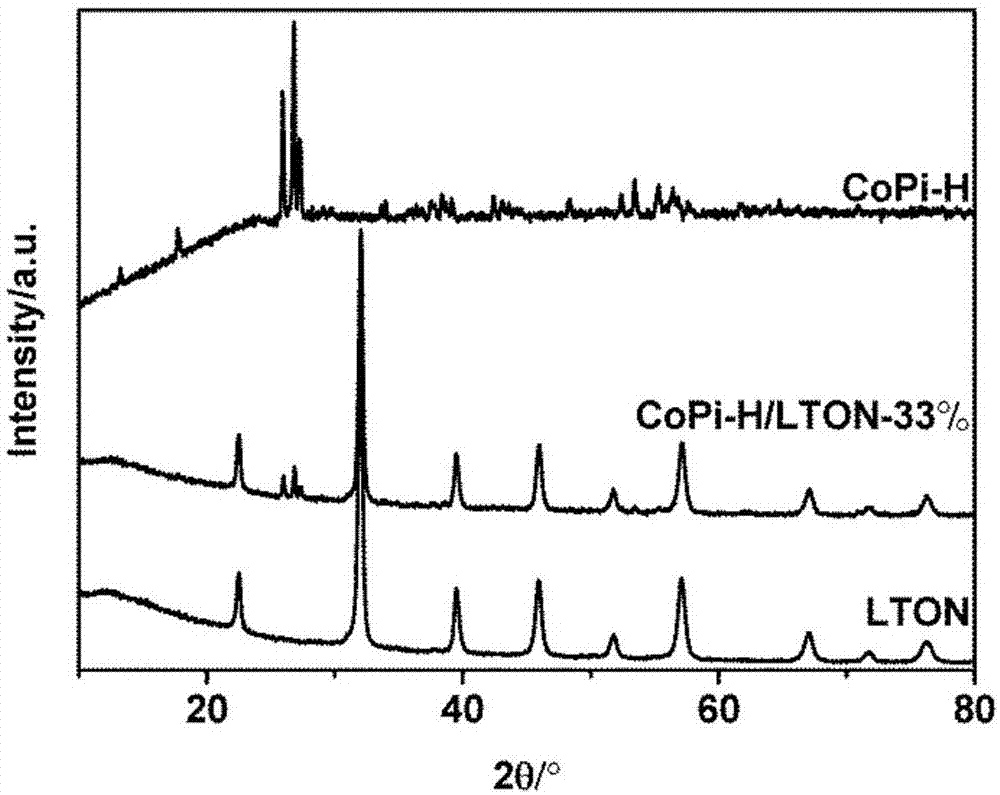

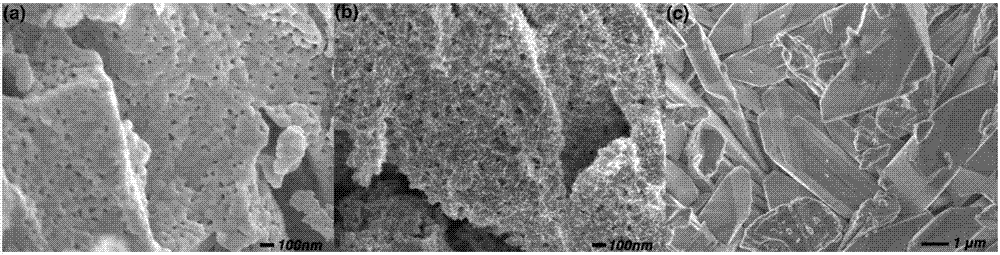

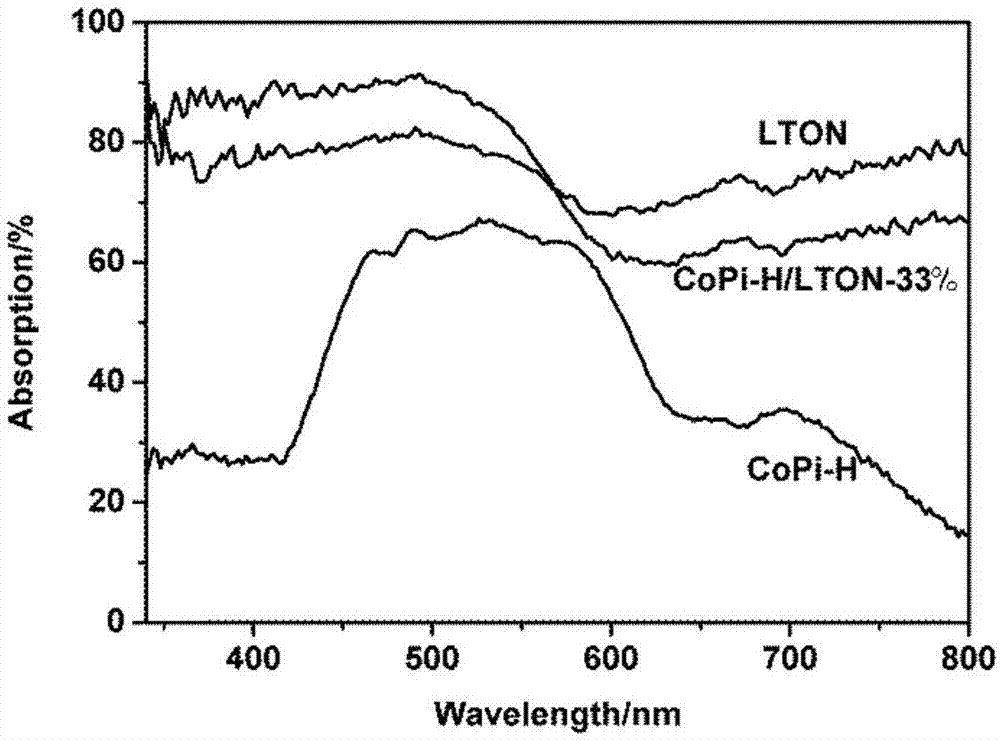

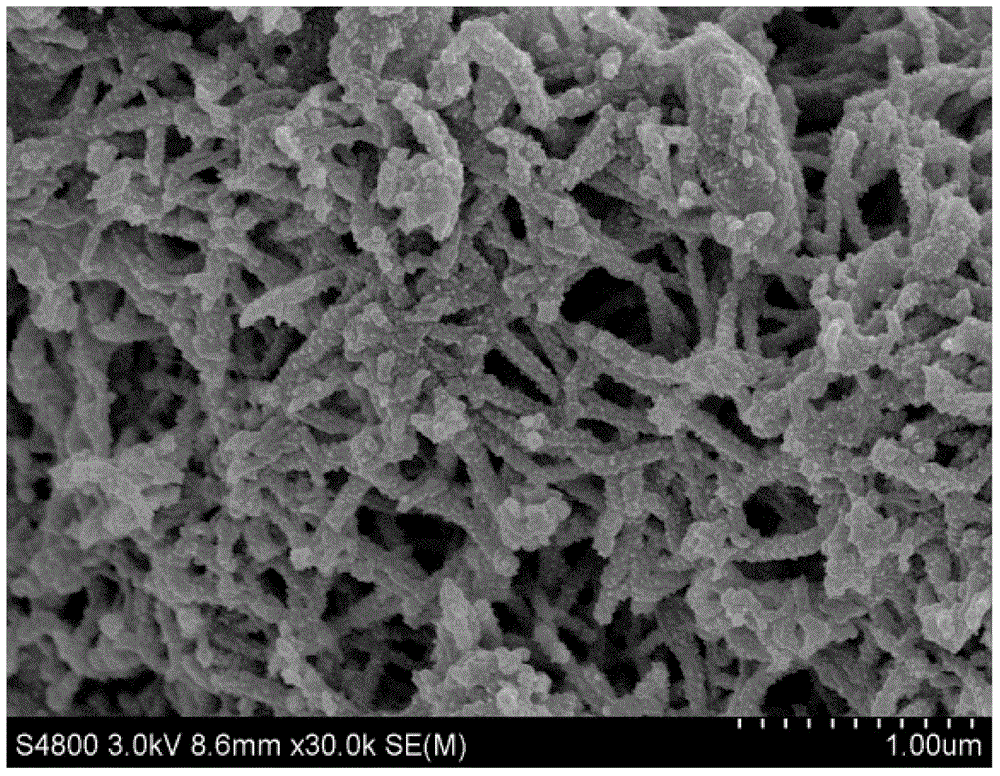

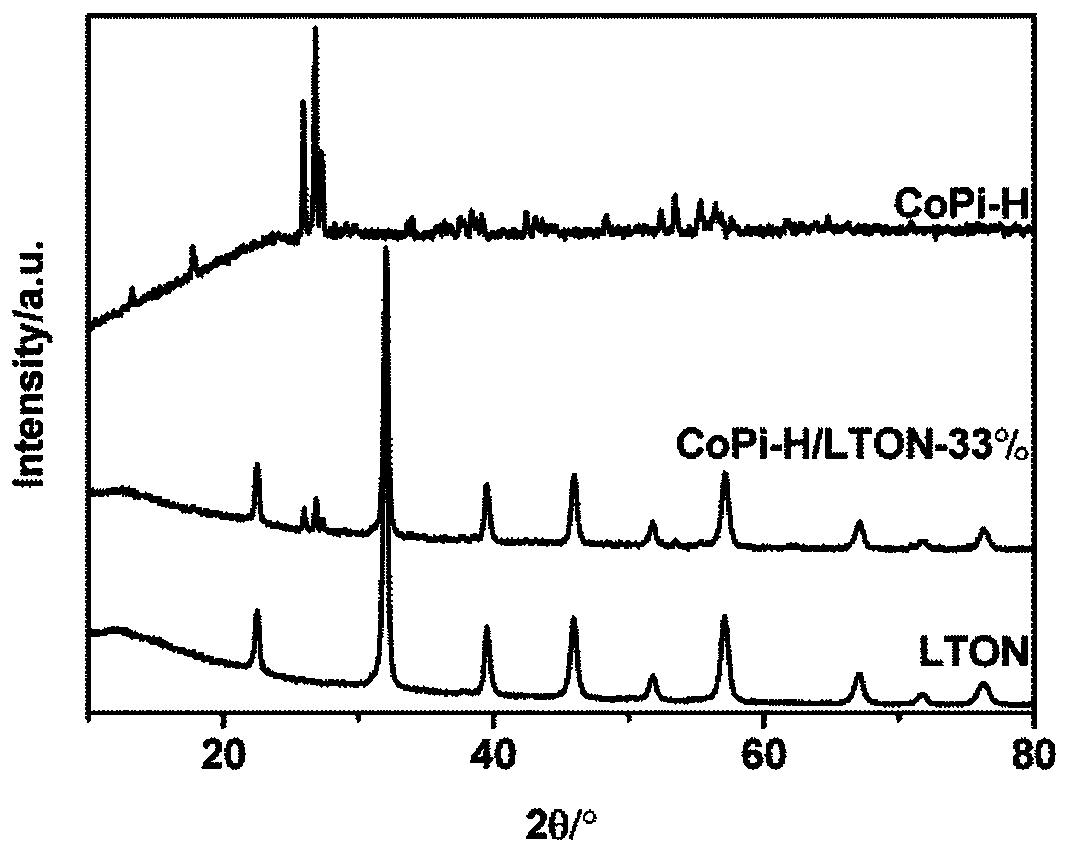

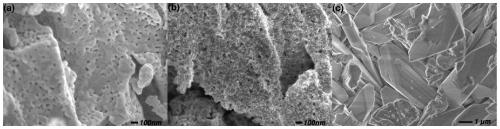

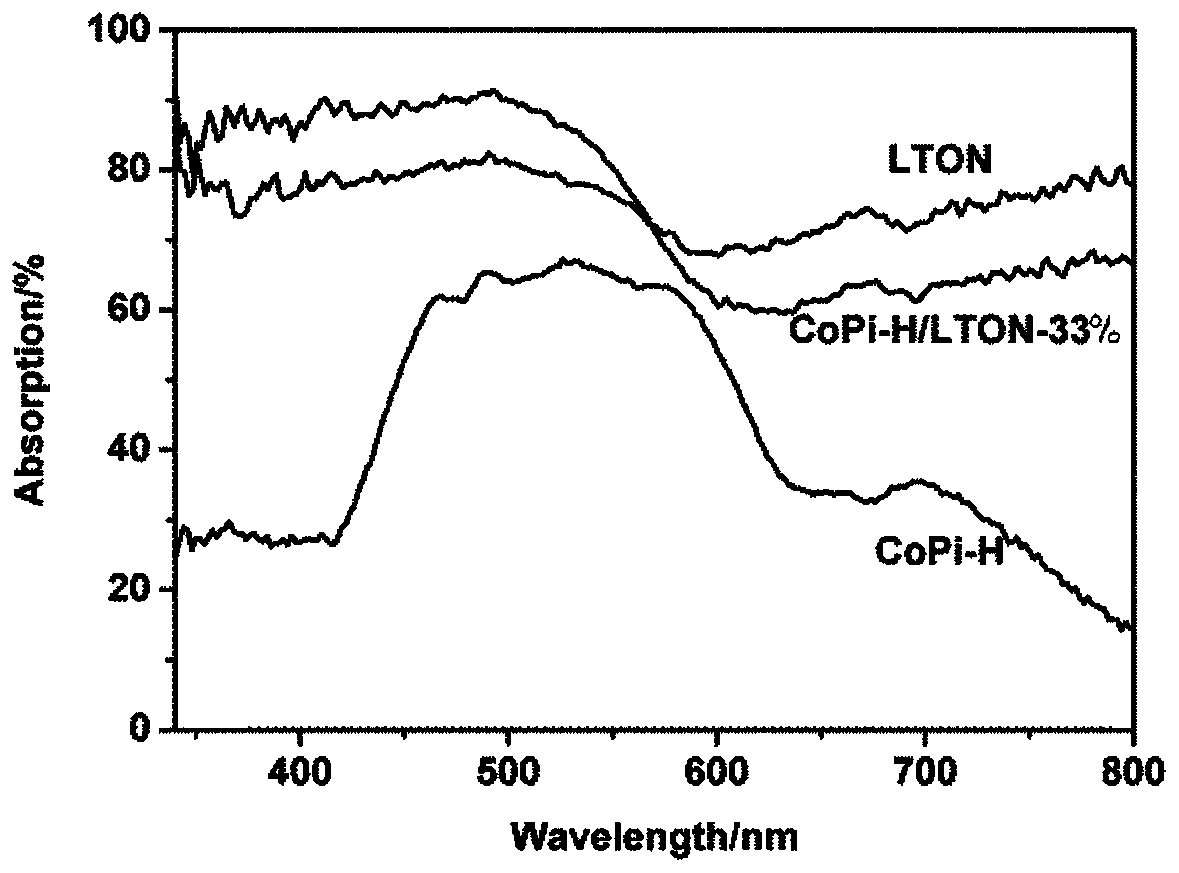

Alkali cobalt phosphate nanoneedle-containing composite LTON photocatalyst and preparation method and application thereof

ActiveCN107308973AEffective combinationControl microscopic morphologyCatalyst activation/preparationOxygen preparationHeterojunctionOxygen

The invention provides an alkali cobalt phosphate nanoneedle-containing composite LTON photocatalyst and a preparation method and application thereof. The preparation method comprises the following steps: firstly, synthesizing LaTiO2N by a polymerization complexation method and a high-temperature ammonia gas posttreatment means; then, growing Co3(OH)2(HPO4)2 nanoneedles on the LaTiO2N in situ by a hydrothermal method to obtain a target product. The alkali cobalt phosphate nanoneedle-containing composite LTON photocatalyst prepared by the preparation method provided by the invention has special morphology, and special heterojunctions are established between the LaTiO2N and the Co3(OH)2(HPO4)2 nanoneedles, so that compared with pure LaTiO2N, the LaTiO2N photocatalyst compounded with the Co3(OH)2(HPO4)2 nanoneedles has better catalytic oxygen production performance under visible light, and improvement on the catalytic oxygen production performance of the pure LaTiO2N under visible light is achieved.

Owner:XI AN JIAOTONG UNIV

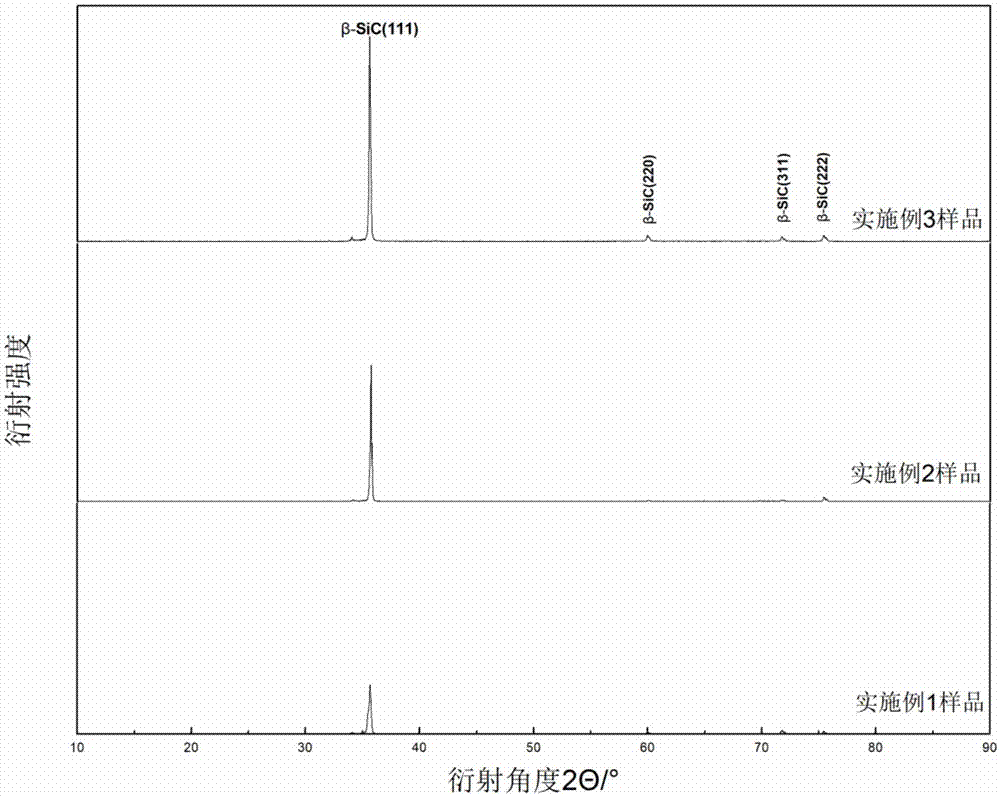

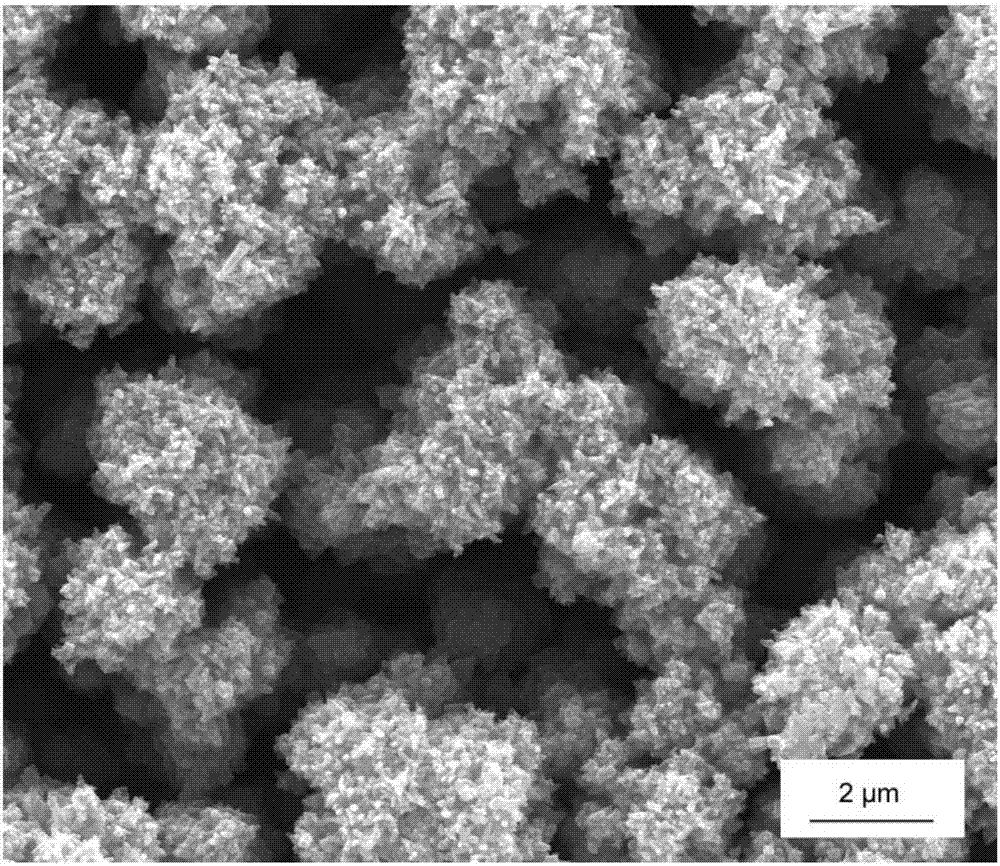

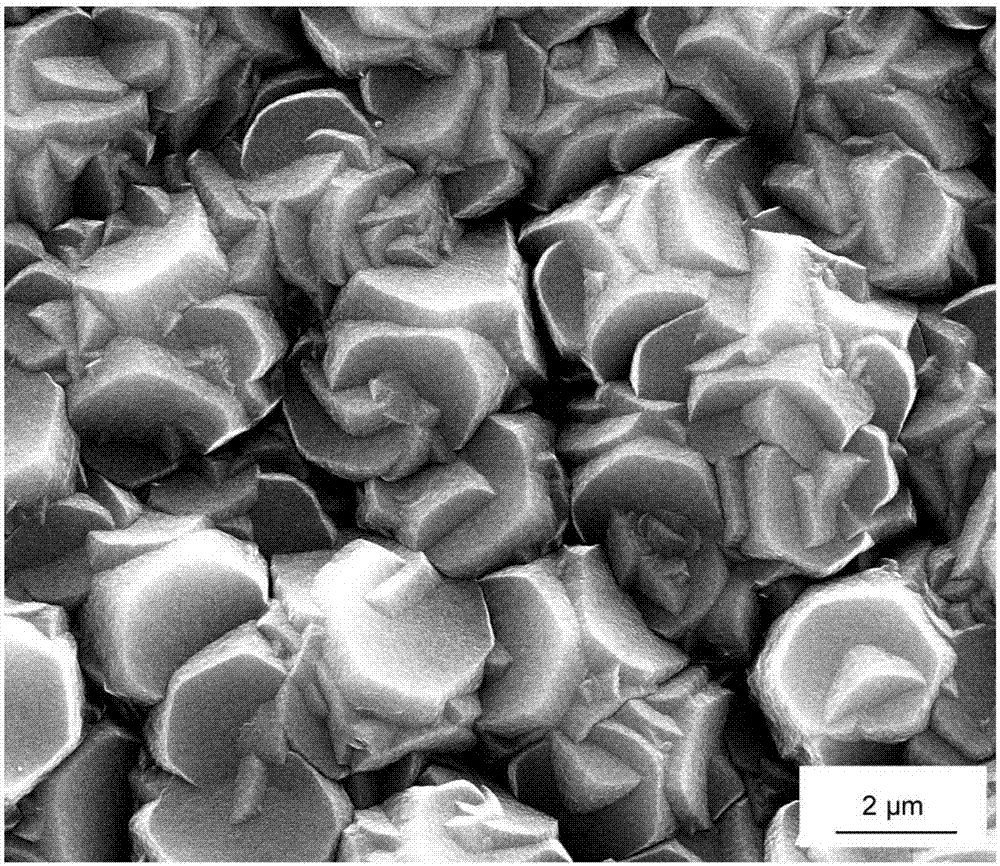

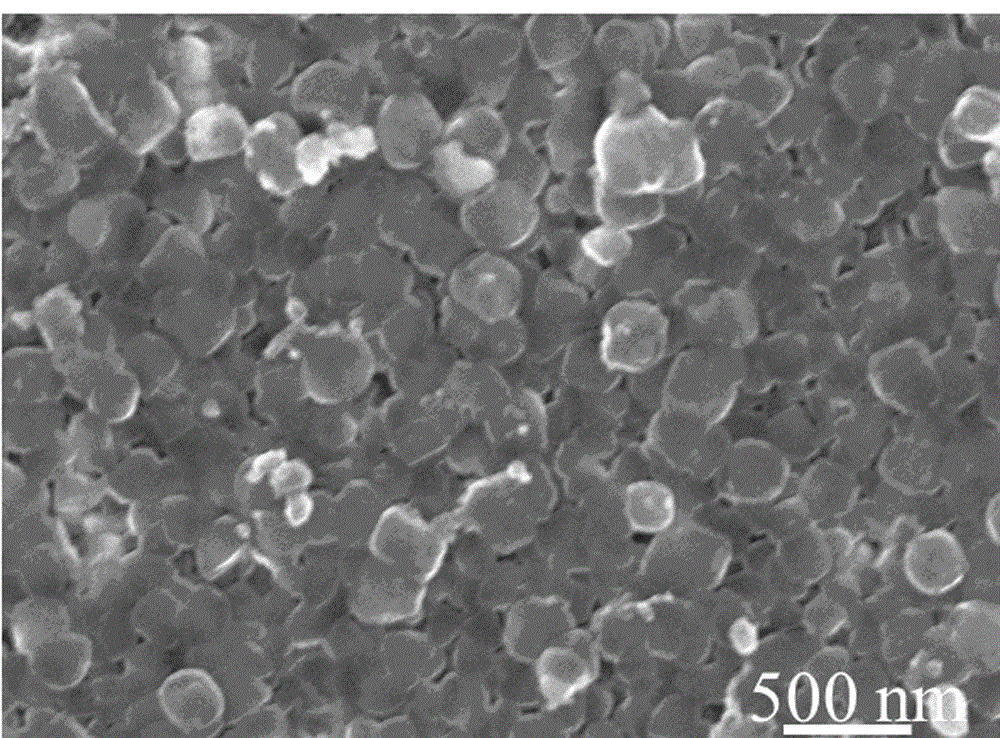

Method for preparing cube silicon carbide coating

ActiveCN107513698ACorrosion resistant structureAvoid etchingChemical vapor deposition coatingCubic silicon carbideGraphite substrate

The invention discloses a method for preparing a cube silicon carbide coating. The method includes the following steps that (1) a graphite substrate is put into a substrate base of a cold-wall-type laser chemical vapor deposition device, vacuum pumping is conducted, and the intensity of pressure is dropped to 10Pa or below; (2) H2 is connected in to serve as diluent gas; (3) lasers are started to irradiate the surface of the graphite substrate, and the temperature of graphite can be raised quickly by adjusting the laser power; (4) current-carrying gas containing precursor HMDS is connected in, the vacuum degree of a reaction chamber is adjusted to 2500-4500Pa, and the process is kept for 10-30min; and (5) the lasers, the HMDS and the diluent gas are shut down, vacuum pumping is performed and natural cooling is conducted to an indoor temperature. According to the method, the thin film obtained through deposition refers to a cube silicon carbide (beta-SiC) thin film; and under the different deposition conditions, the beta-SiC thin films of different microstructures can be formed, the surface wettability of graphite materials can be controlled and adjusted, and the method is suitable for being applied and popularized.

Owner:WUHAN UNIV OF TECH

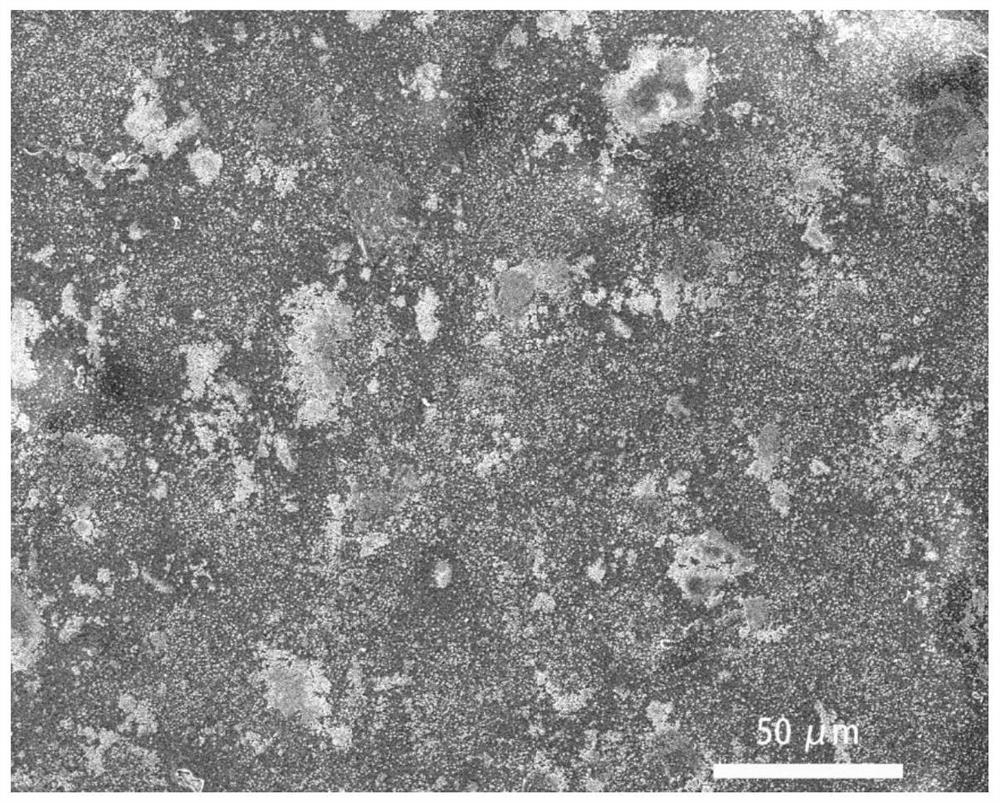

Method for directly growing Prussian-blue film on FTO conductive glass

The invention discloses a method for directly growing a Prussian-blue film on FTO conductive glass. The method includes: mixing potassium ferricyanide, reducing agent, concentrated hydrochloric acid and deionized water, transferring into a hydrothermal reaction kettle, placing a piece of FTO conductive glass into the hydrothermal reaction kettle, allowing the conductive face of the conductive glass to face downwardly, performing constant-temperature hydrothermal reaction at 100-120 DEG C for a certain period of time, and naturally cooling to room temperature after the reaction, wherein the reducing agent is optionally selected from glucose, oxalic acid or polyvinyl pyrrolidone; taking out the FTO conductive glass in the reaction kettle, washing with the deionized water, and blowing with a blower for drying to obtain the Prussian-blue film. The Prussian-blue film prepared by the method is good in electrochromic effect.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

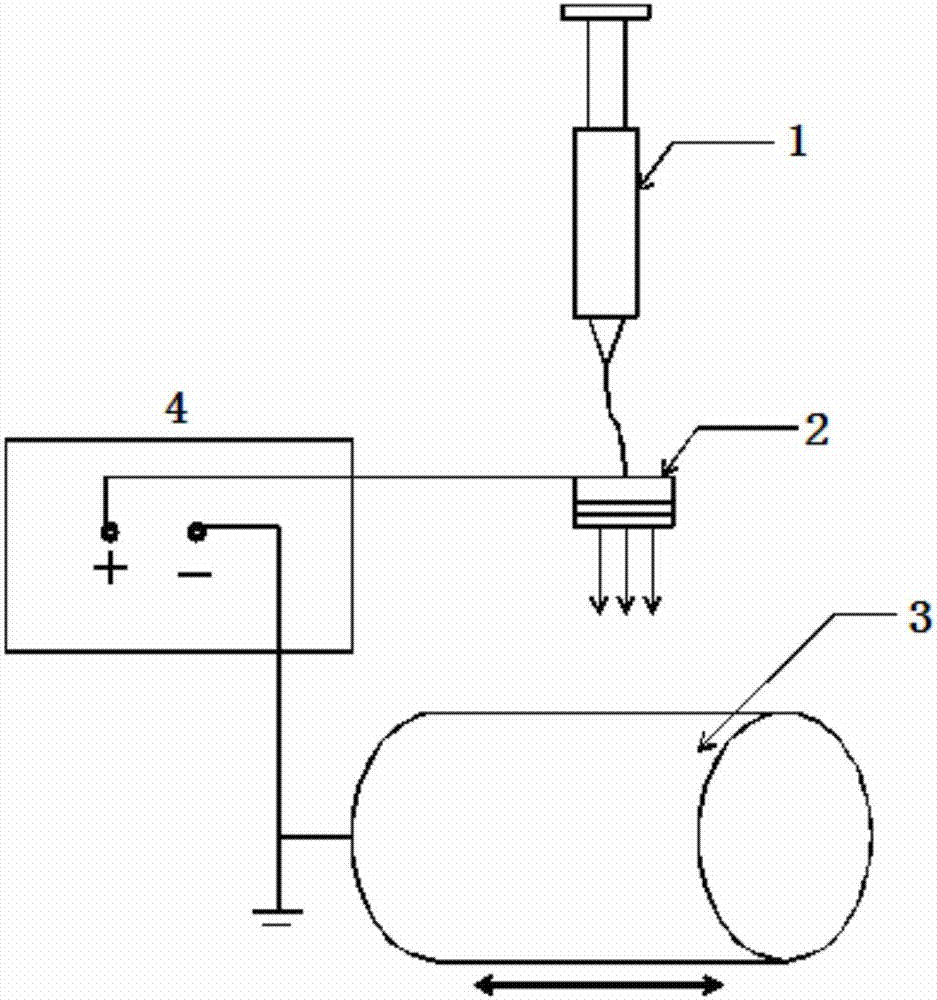

Preparation method for all-vanadium redox flow battery electrode material

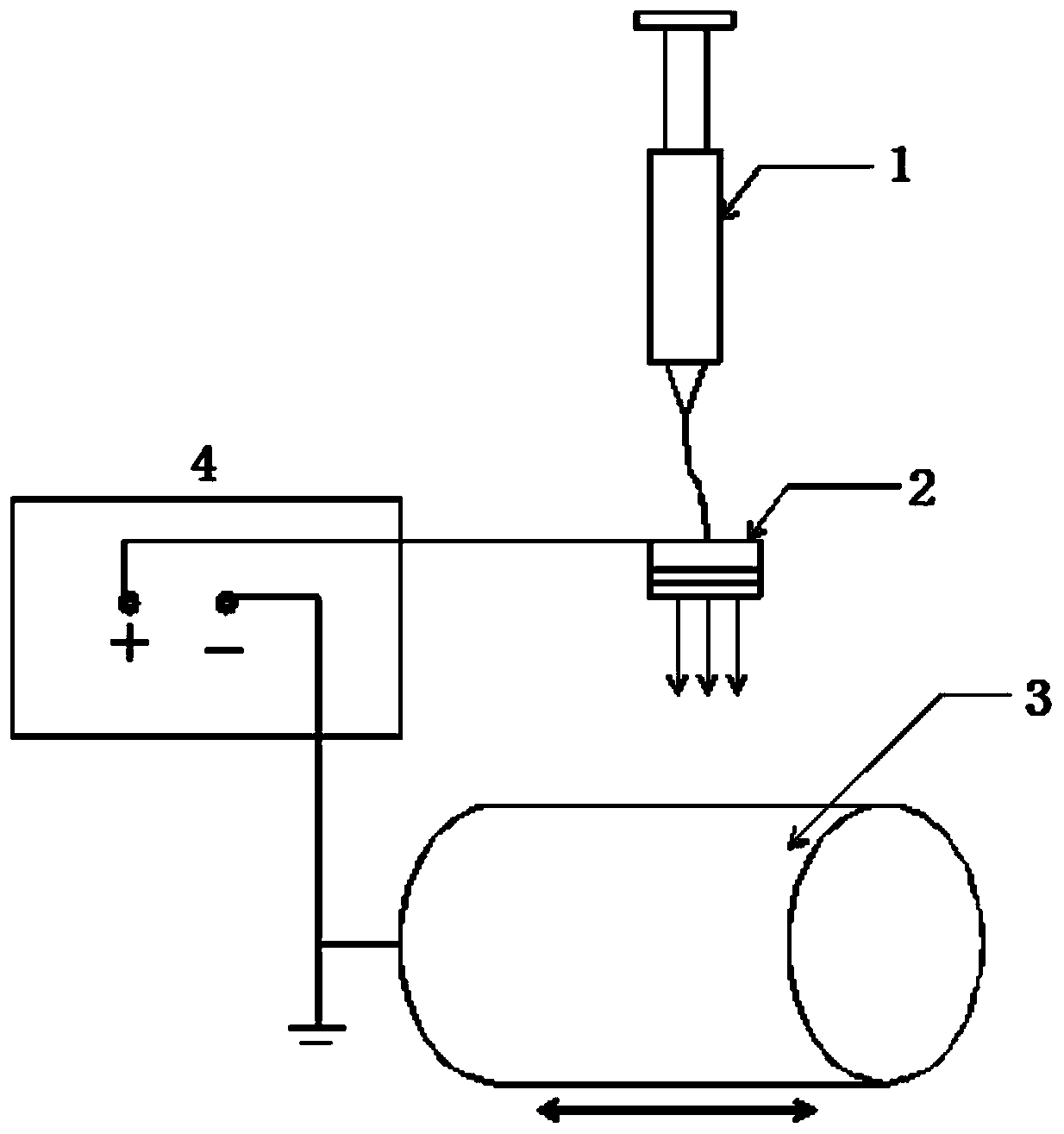

InactiveCN107039659ALow costImprove carbonization yieldMaterial nanotechnologyCell electrodesCarbon fibersCarbonization

The invention relates to the field of battery manufacturing and energy storage, in particular to a preparation method for an all-vanadium redox flow battery electrode material. The preparation method comprises the steps of taking alkaline lignin as a test material, partially substituting the hydroxymethylation alkaline lignin by a phenolic hydroxyl active functional group in an alkaline lignin structure, synthesizing organic gel from resorcinol and formaldehyde under the effect of a catalyst, preparing a precursor spinning liquid required for an experiment by taking the gel as a precursor, preparing a fiber precursor electrode material by an electrostatic spinning method, pre-oxidizing the electrode material precursor by a vacuum / atmosphere furnace, and performing carbonization in an inertia atmosphere to obtain the carbon fiber electrode material. In the vanadium battery carbon fiber electrode material prepared by the method, the fiber diameter is in nanoscale, and the specific area is greatly expanded compared with a traditional carbon felt electrode material; and due to pre-oxidization processing in post period, the oxygen content of the fiber surface is also greatly improved, and the method can be used for preparing the vanadium battery carbon fiber electrode material.

Owner:SHENYANG AGRI UNIV

Preparation method of anisotropic particles with variable morphology

The invention relates to a preparation method of anisotropic particles with variable morphology. The method comprises the following steps: firstly utilizing silanol hydrophilic groups produced by hydrolysis of a silane coupling agent to prepare a series of seeds with different hydrophilicities, then enabling the seeds to be swollen by monomers incompatible to the hydrophilic groups, and controlling the phase separation degree according to different phase separation degrees of polymers, which are induced by different interfacial tensions and incompatible to the hydrophilic groups so as to obtain the composite particles with the variable morphology. The composite particles contain organic-inorganic-organic phase non-spherical composite particles, which have an important significance for developing novel multi-component materials. The composite particles prepared by the preparation method disclosed by the invention are amphipathic, and can be used as compatibilizers, emulsifiers and the like for modifying mixtures of the incompatible polymers. The synthesis process is simple and easy to operate, clean, environment-friendly and easy to realize large-scale production; furthermore, the preparation method has universality and is suitable for other polymer systems which are mutually incompatible.

Owner:天津知顺科技有限公司

Method for synthesizing isotropic silicon nitride powder adopting hollow type annular material-distribution

InactiveCN1799994AUniform fine permeabilityImprove permeabilityNitrogen compoundsCombustionMetallic materials

The invention discloses a homogeneous silicon nitride powder synthetic method of hollow ring-shaped cloth combustion in the inorganic non-metal material domain, which is characterized by the following: grinding to mix the silicon powder and silicon nitride powder at different proportions; placing the material in the combustion synthetic reaction device with poromeric hollow pipe according to the hollow ring-shaped cloth method after drying; charging 1-20 Mpa nitrogen gas in the vacuum device; inducing the combustion synthetic reaction through igniting. The invention realizes the complete nitridation of whole reactant at isothermal pattern, which improves the uniformity of silicon nitride powder.

Owner:UNIV OF SCI & TECH BEIJING

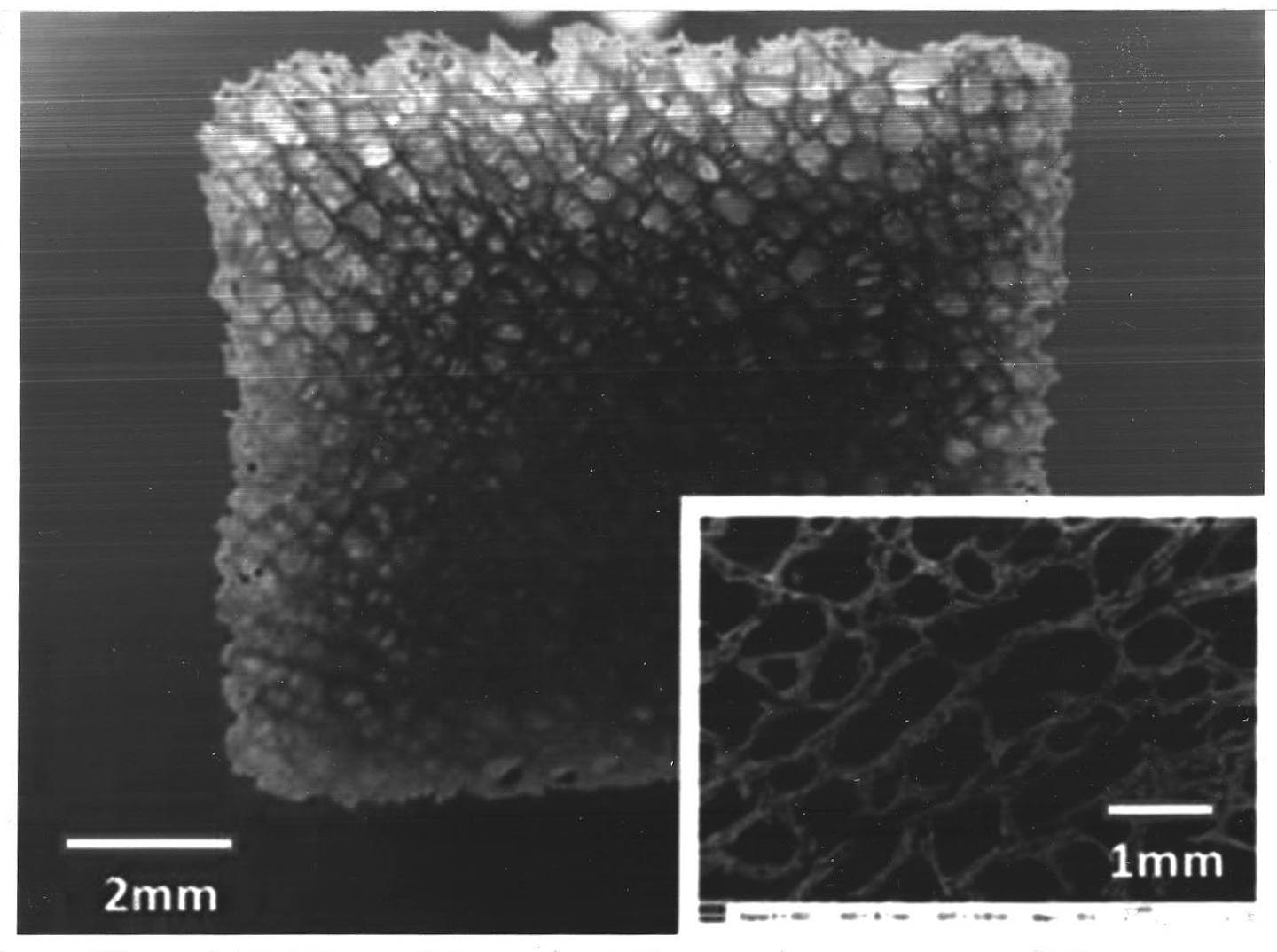

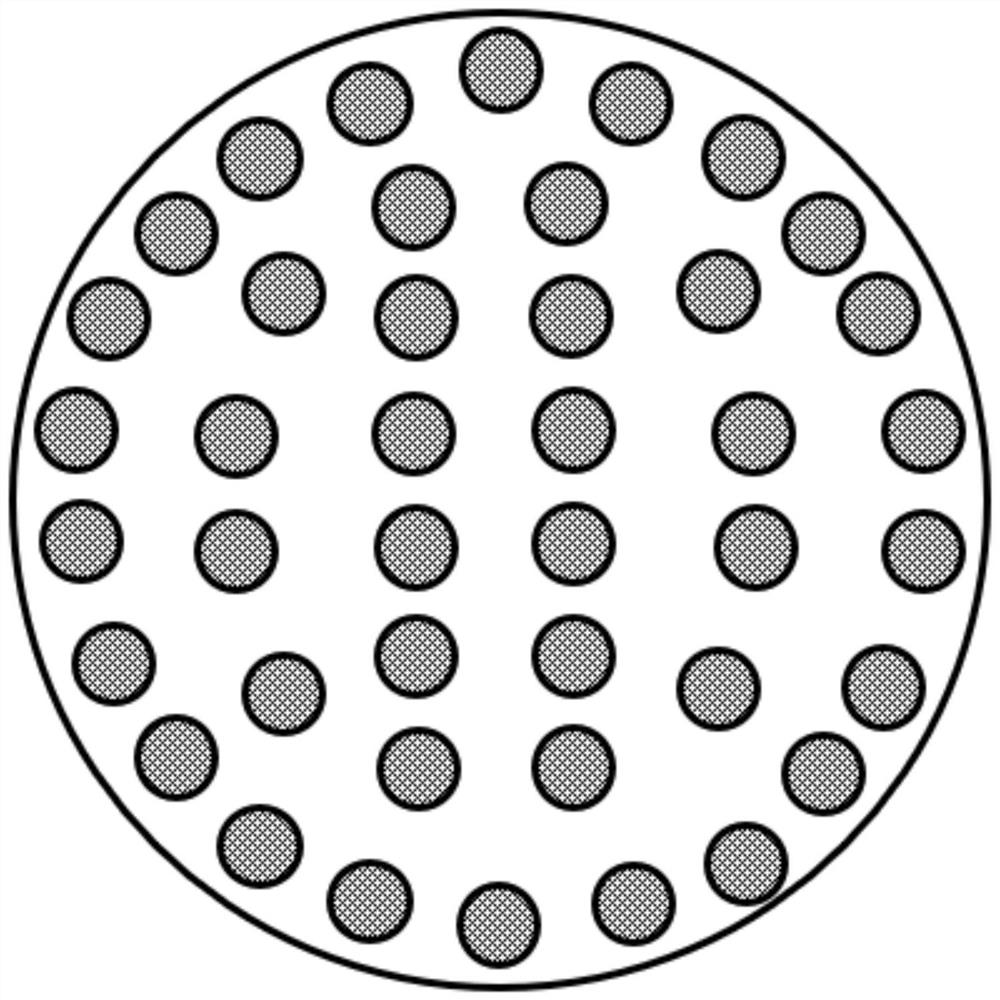

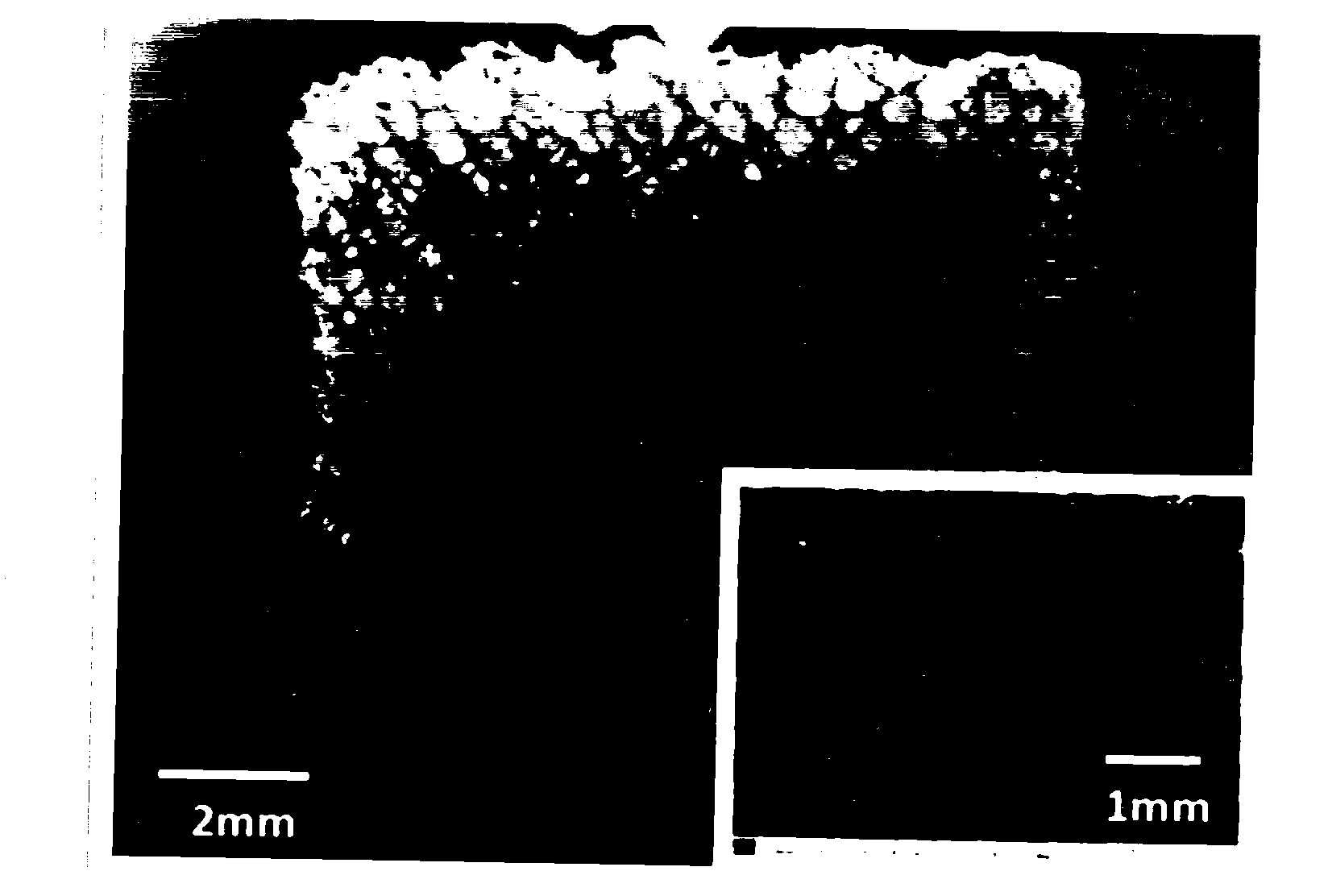

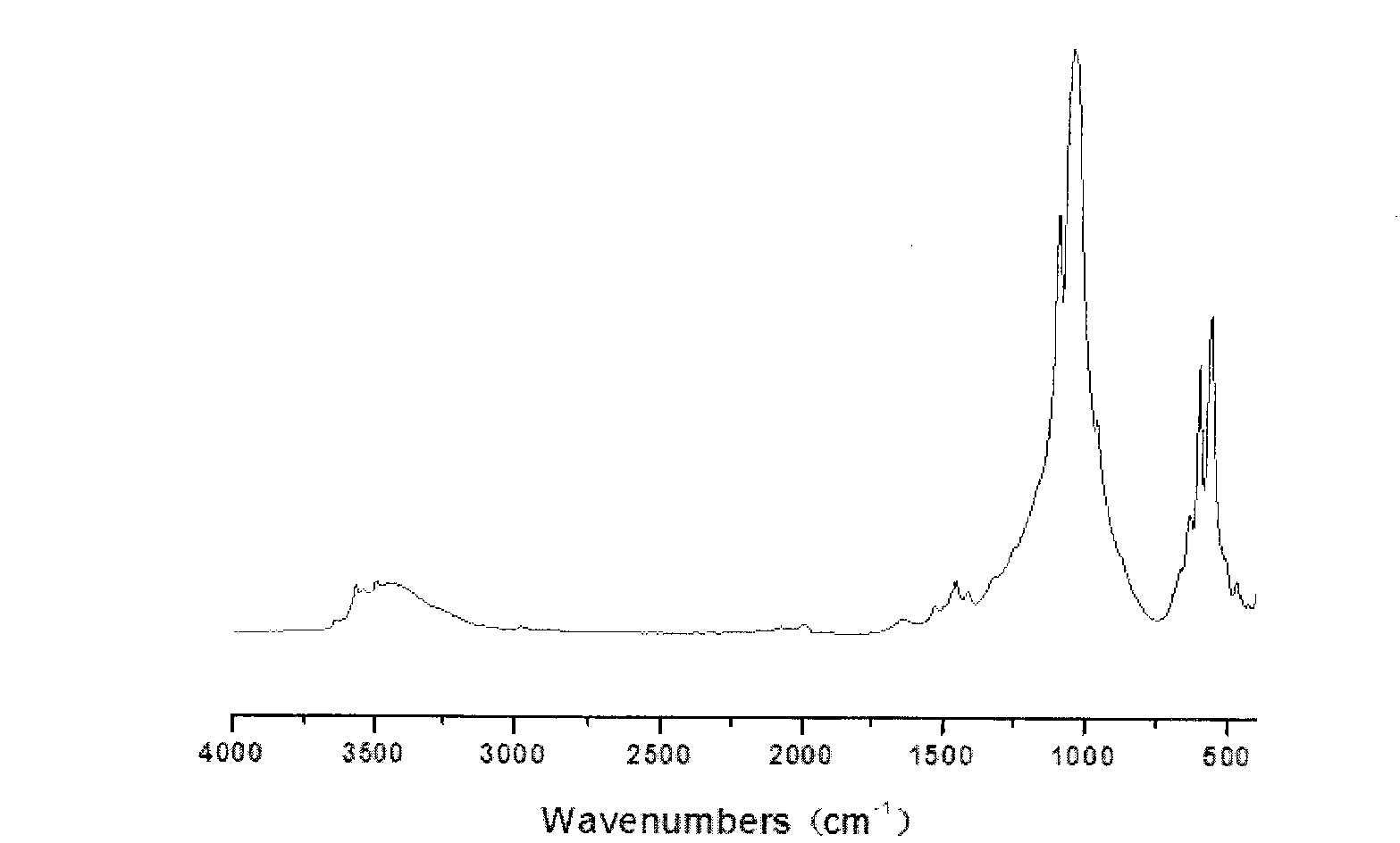

Bone repair stent material and preparation method thereof

The invention relates to a bone repair stent material and a preparation method thereof, and the bone repair stent material can be used to overcome the defects of difficult obtainment of raw materials and ethical problems in the existing practice of taking a small bovine bone as the bone repair stent material. The bone repair stent material contains hydroxyapatite, the material is in a porous interpenetrating network structure, the porosity is 30%-85%, the macropore diameter is 100-800 microns, and the micropore diameter is 10-60 microns. The stent material can be widely used in repair treatment of bone defects and bone loss caused by diseases, traffic accidents, sports injuries and the like.

Owner:邓旭亮

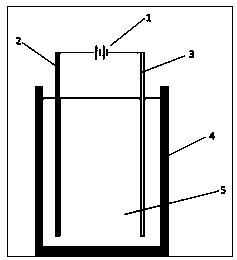

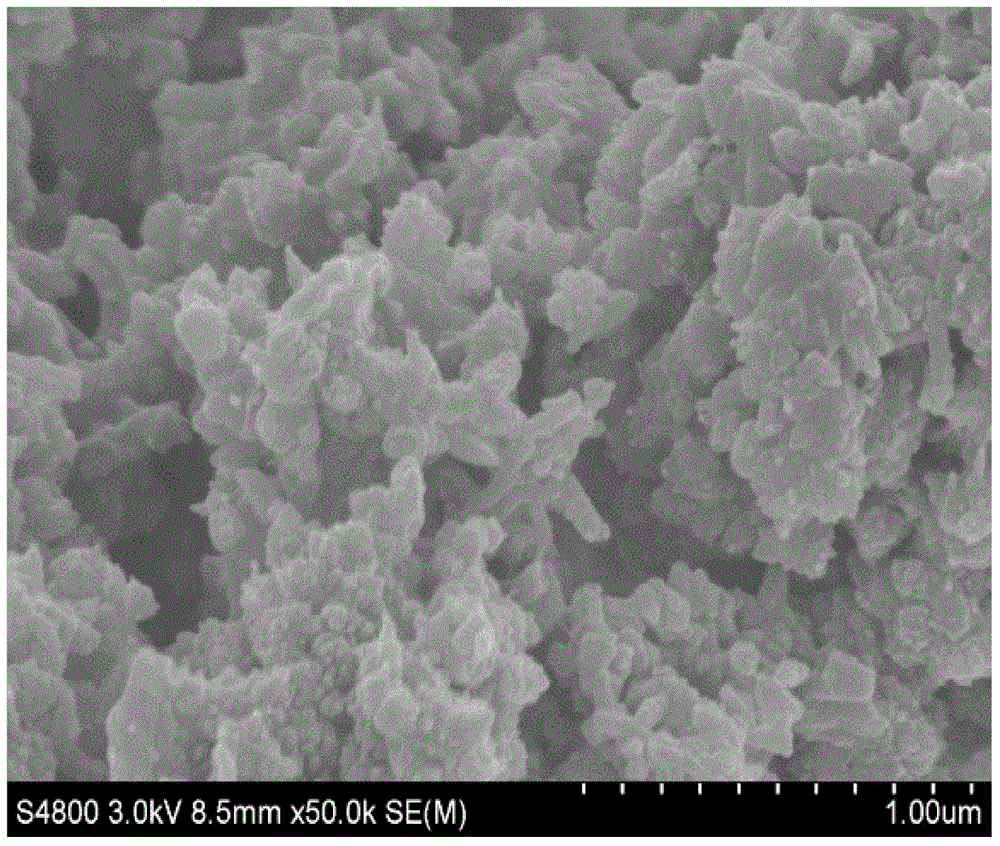

Method for preparing morphology-controlled conductive polyaniline film by using electrophoretic deposition

InactiveCN104532288AControl microscopic morphologyImprove electrochemical performanceElectrophoretic processesElectrophoretic depositionChemical synthesis

The invention discloses a method for preparing a morphology-controlled conductive polyaniline film by using electrophoretic deposition. The conductive polyaniline is considered as a conductive high polymer material with the best industrial application prospects, and the method for preparing the conductive polyaniline film is an effective processing method for promoting polyaniline industrialization. The method comprises the following steps: by taking the chemically synthetic conductive polyaniline sol as electrolyte, taking a direct current power supply as a working power supply, and taking a platinum plate electrode as a counter electrode, preparing the conductive polyaniline film with good electrochemical performance on an indium tin oxide conductive glass working electrode by adopting an electrophoretic deposition method. The micro morphology of the prepared conductive polyaniline film is consistent with the micro morphology of the chemically synthetic conductive polyaniline, and the morphology of the conductive polyaniline film can be controlled according to the morphology of the chemically synthetic polyaniline.

Owner:SHAANXI RES INST OF AGRI PRODS PROCESSING TECH +1

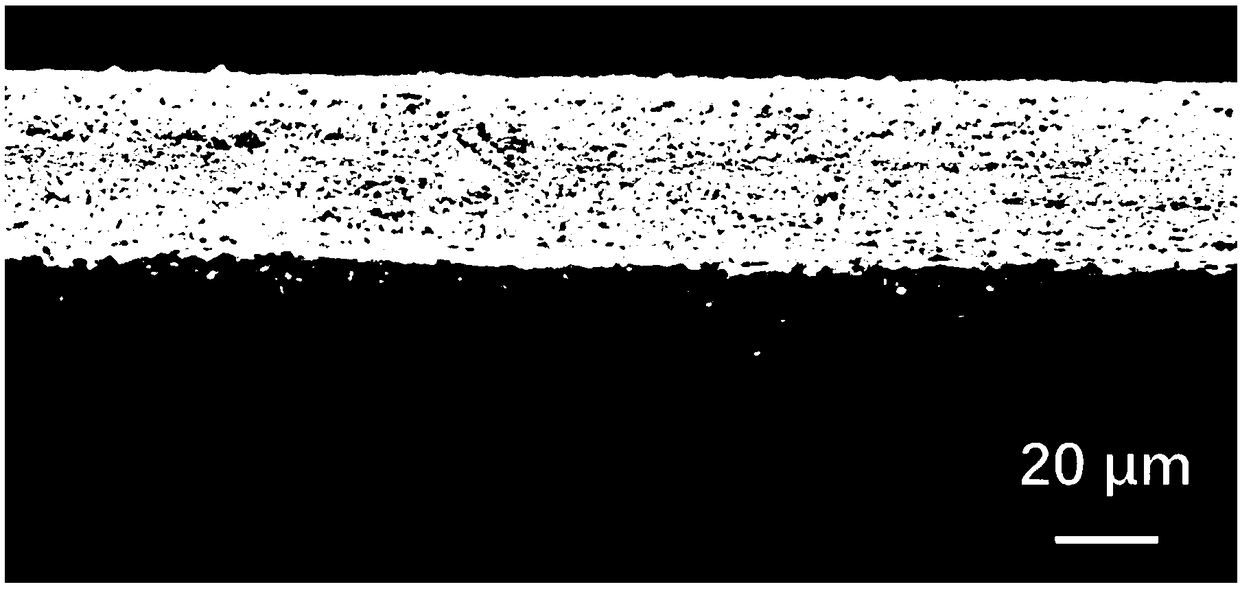

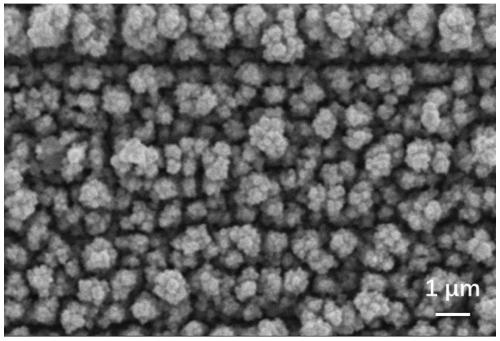

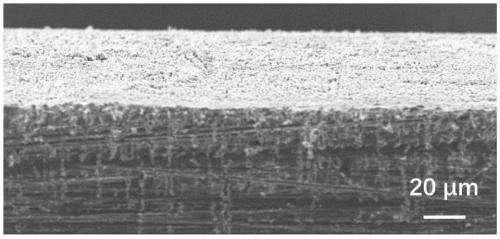

Fiber cloth-based lithium ion battery diaphragm as well as preparation method and application thereof

ActiveCN112038542AControl Mechanical PropertiesControl microscopic morphologyCell component detailsSecondary cells servicing/maintenanceYarnPolyolefin

The invention belongs to the technical field of lithium ion batteries, and discloses a fiber cloth-based lithium ion battery diaphragm as well as a preparation method and application thereof. The preparation method comprises the following steps of: preparing composite fine denier fiber yarns taking polyolefin as a core and a blended polymer as a sheath through adopting a composite fiber spinning method technology; and warping and weaving the composite fine denier fiber yarns into warp and weft fiber cloth or arranging fibers in the same direction in a biorthogonal composite laminating manner to obtain weftless cloth, and performing hot pressing by means of a smooth roll to obtain the fiber cloth-based lithium ion battery diaphragm. The preparation method is simple in step, and the batterydiaphragm with high liquid absorption rate, high ionic conductivity and high mechanical property can be prepared without coating slurry on one side or two sides of the diaphragm and stretching, orienting and pore-forming; and a gel layer is attached to polypropylene framework fibers in situ in the production process, that is to say, gel polymers attached to the framework fibers are equivalent, sothat the fiber cloth diaphragm is uniform in thickness, and the porosity and pore size distribution are kept constant.

Owner:GUANGDONG UNIV OF TECH +1

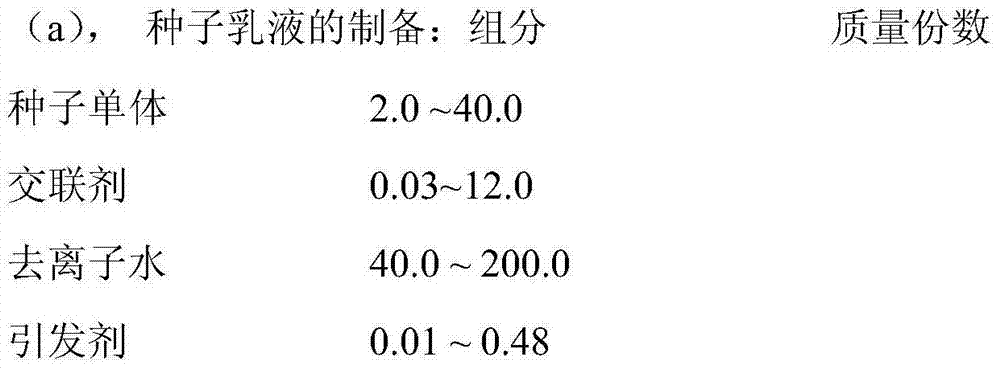

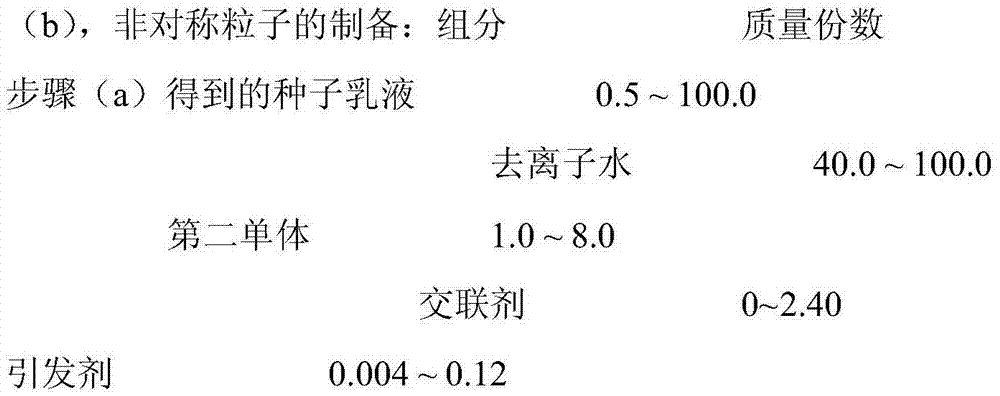

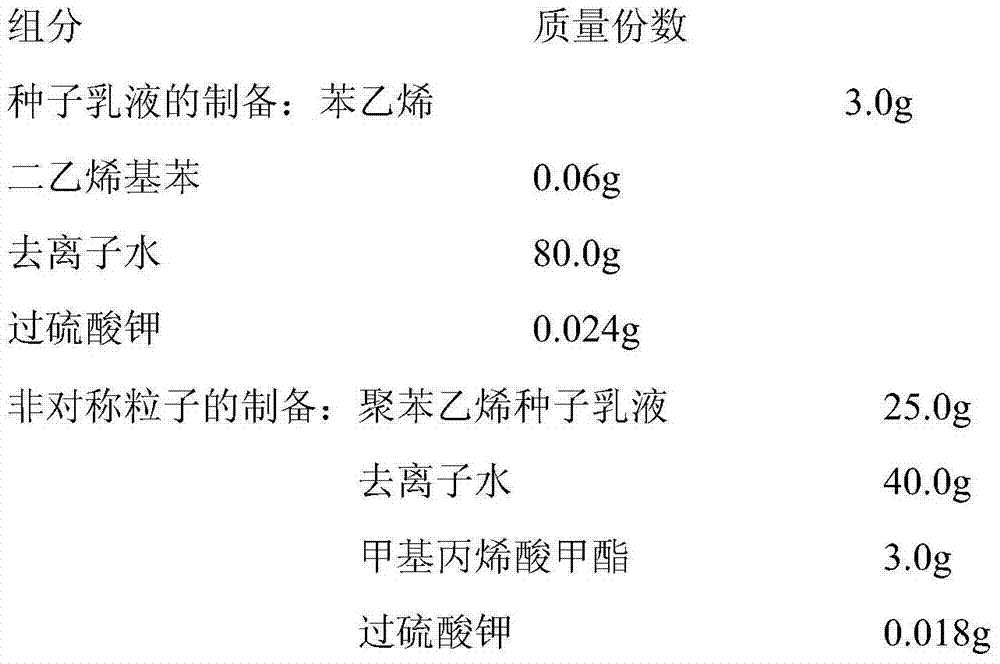

Preparation method of asymmetric particles based on swelling seed emulsion polymerization

The invention relates to a preparation method of asymmetric particles based on swelling seed emulsion polymerization. The method comprises: firstly, preparing a series of seeds with different degrees of crosslinking, and then, respectively swelling the seeds through a second monomer for polymerization. Since phase separation degrees controlled by different degrees of crosslinking are different, the feeding dosage of the second monomer is isomorphically adjusted and the reaction time is controlled to prepare asymmetric composite particles. The forms of the composite particles prepared by the method are controllable, the composite particles are easy to separate and treat, and meanwhile, the composite particles have the properties of two polymers, are capable of being used as bulking agent between incompatible polymer blends, and the like. The synthesis process is simple, convenient and feasible, and the system contains no emulsifier, thereby being clean and easy to realize large scale production, and having environmental-friendly effect.

Owner:TIANJIN QUANDA TECH

Bone repair stent material and preparation method thereof

The invention relates to a bone repair stent material and a preparation method thereof, and the bone repair stent material can be used to overcome the defects of difficult obtainment of raw materials and ethical problems in the existing practice of taking a small bovine bone as the bone repair stent material. The bone repair stent material contains hydroxyapatite, the material is in a porous interpenetrating network structure, the porosity is 30%-85%, the macropore diameter is 100-800 microns, and the micropore diameter is 10-60 microns. The stent material can be widely used in repair treatment of bone defects and bone loss caused by diseases, traffic accidents, sports injuries and the like.

Owner:邓旭亮

Cement grinding aid and preparation method thereof

The invention discloses a cement grinding aid for improving grinding efficiency in a cement production process and a preparation method thereof, and relates to the technical field of cement productionand processing. The technical scheme of the invention is: a cement grinding aid is characterized in that the cement grinding aid comprises the following raw materials (by weight): 25-47 parts of eggshell powder and 2.5-5 parts of water; wherein the eggshell powder is a undersize of a 0.85 mm sieve after grinding of the discarded eggshell. Compared with the prior art, the invention has the following outstanding substantive features and significant progress: the cement grinding aid is green and environmentally-friendly, is prepared by using eggshell powder as the main raw material, can replaceexisting cement grinding aids, and can remarkably improved the technical performance index of the cement for upgrading.

Owner:YANTAI UNIV

A kind of preparation method of electrode material of vanadium redox flow battery

InactiveCN107039659BLow costImprove carbonization yieldMaterial nanotechnologyCell electrodesCarbon fibersElectrical battery

The invention relates to the field of battery manufacturing and energy storage, in particular to a preparation method for an all-vanadium redox flow battery electrode material. The preparation method comprises the steps of taking alkaline lignin as a test material, partially substituting the hydroxymethylation alkaline lignin by a phenolic hydroxyl active functional group in an alkaline lignin structure, synthesizing organic gel from resorcinol and formaldehyde under the effect of a catalyst, preparing a precursor spinning liquid required for an experiment by taking the gel as a precursor, preparing a fiber precursor electrode material by an electrostatic spinning method, pre-oxidizing the electrode material precursor by a vacuum / atmosphere furnace, and performing carbonization in an inertia atmosphere to obtain the carbon fiber electrode material. In the vanadium battery carbon fiber electrode material prepared by the method, the fiber diameter is in nanoscale, and the specific area is greatly expanded compared with a traditional carbon felt electrode material; and due to pre-oxidization processing in post period, the oxygen content of the fiber surface is also greatly improved, and the method can be used for preparing the vanadium battery carbon fiber electrode material.

Owner:SHENYANG AGRI UNIV

A kind of basic cobalt phosphate nanoneedle composite lton photocatalyst and its preparation method and application

ActiveCN107308973BEffective combinationControl microscopic morphologyCatalyst activation/preparationOxygen preparationPhosphoric acidPhoto catalysis

The invention provides a basic cobalt phosphate nanoneedle composite LTON photocatalyst and its preparation method and application. The method first uses a polymerization complexation method and a high-temperature ammonia gas post-treatment method to synthesize LaTiO 2 N; then in LaTiO by hydrothermal method 2 In situ growth of Co on N 3 (OH) 2 (HPO 4 ) 2 Nano-needles, the target product is obtained. The basic cobalt phosphate nanoneedle composite LTON photocatalyst prepared by the invention has a special morphology, and the LaTiO 2 N and Co 3 (OH) 2 (HPO 4 ) 2 A special heterojunction is constructed between the nanoneedles, making Co 3 (OH) 2 (HPO 4 ) 2 Nanoneedle composite LaTiO 2 N photocatalyst compared to pure LaTiO 2 N has better visible light catalytic oxygen production performance, achieving the best performance for pure LaTiO 2 Improvement of N visible light catalytic oxygen production performance.

Owner:XI AN JIAOTONG UNIV

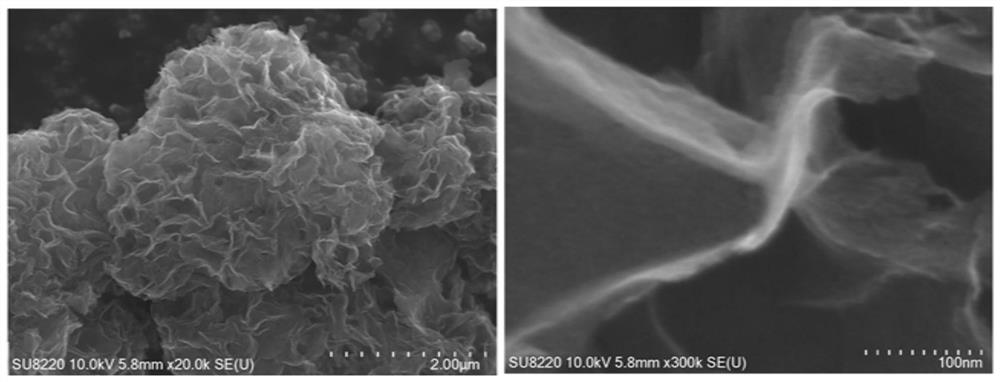

A kind of silicon carbide-graphene composite powder and preparation method thereof

ActiveCN107311177BAchieve low temperature preparationImprove the strengthening and toughening effectOther chemical processesCarbon compoundsFreeze-dryingEvaporation

The invention relates to silicon carbide-graphene composite powder and a preparation method thereof. The technical scheme adopted by the invention is that the preparation method comprises the following steps: firstly, mixing 40 to 80 parts by mass of expanded graphite with 20 to 60 parts by mass of silicon-containing raw material and then carrying out ball milling to obtain composite powder; secondly, carrying out heat treatment under the condition of 800 to 1400 DEG C and argon to obtain the silicon carbide-graphene composite powder; or adding 5 to 100 parts by mass of absolute ethyl alcohol solution of a catalyst into 100 parts by mass of composite powder, then stirring and carrying out rotary evaporation; carrying out the heat treatment under the condition of 800 to 1400 DEG C and flowing of argon for 1 to 6 hours to obtain the silicon carbide-graphene composite powder; or adding 10 to 100 parts of mixed solution of the catalyst and a protective agent into the 100 parts by mass of the composite powder, then stirring, and carrying out freeze drying; carrying out the heat treatment under the condition of 800 to 1400 DEG C and the argon to obtain the silicon carbide-graphene composite powder. The preparation method disclosed by the invention has the advantages of simple technology, short production cycle, low production cost and less pollution. The prepared product has the advantages of high specific surface area, good optical property and excellent electrical property.

Owner:WUHAN UNIV OF SCI & TECH

A kind of preparation method of feconicumo high entropy alloy film

ActiveCN108728876BUniform compositionControl microscopic morphologyHigh entropy alloysElectrochemistry

The invention discloses a preparation method of a FeCoNiCuMo high-entropy alloy film. Deionized water serves as solvent to be prepared into electroplate liquid, and the electroplate liquid is preparedby an electrochemical deposition method. The method comprises the steps that S1, three parts of deionized water is fetched, triethanolamine, ammonium molybdate tetrahydrate and copper salt are dissolved in the first part of deionized water, and a solution A is obtained; S2, glycocoll, ethanediol, antioxidant and additional salt are dissolved in the second part of deionized water, and a solution Bis obtained; S3, trisodium citrate, bivalent iron salt, cobalt salt and nickel salt are dissolved in the third part of deionized water, and a solution C is obtained; S4, the solution A, the solutionB and the solution C are mixed evenly and aged, the pH value of the mixture is adjusted to be 7-8, the mixture is heated to 30 DEG C, oxygen is removed by leading in nitrogen, and the electroplate liquid is obtained; and S5, a graphite plate serves as an anode and a copper base serves as a cathode for electroplating, and the FeCoNiCuMo high-entropy alloy film is obtained. The method has the characteristics of being simple in equipment and process, high in production efficiency, low in production cost, high in safety and reliability, and the like, and is suitable for industrial production of the high-entropy alloy film.

Owner:SOUTHWEST PETROLEUM UNIV

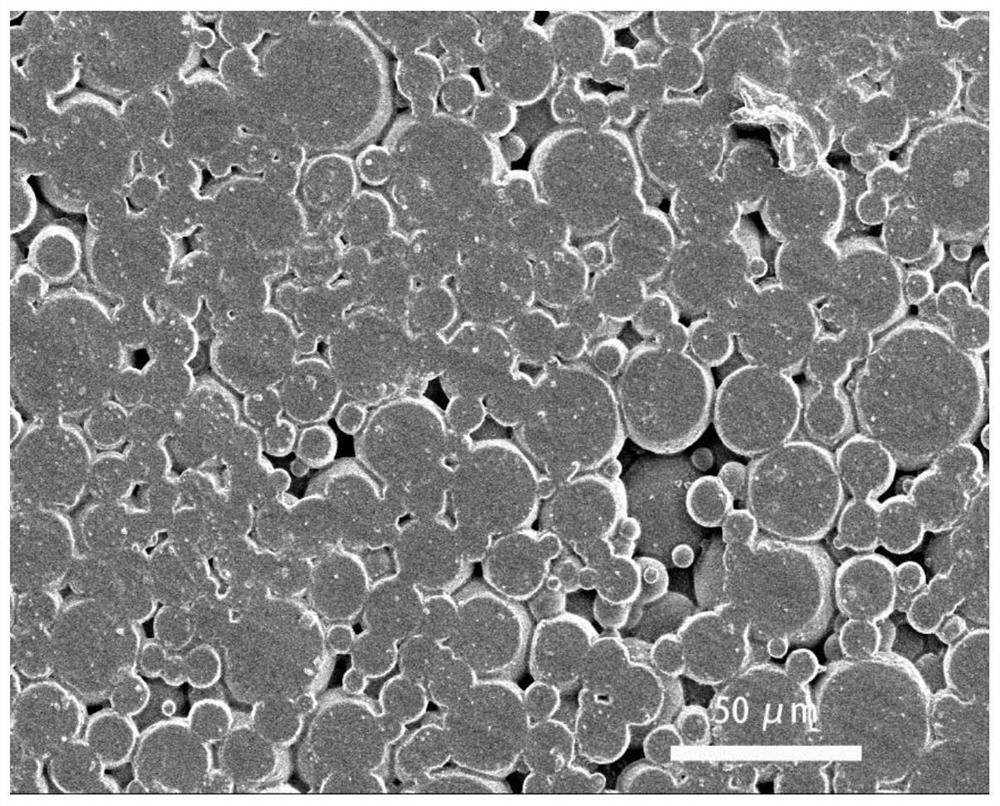

Polylactic acid/nano hydroxyapatite composite material and its preparation method and application

ActiveCN111286074BEvenly dispersedAvoid reunionPharmaceutical delivery mechanismProsthesisMicrosphereNano hydroxyapatite

The invention provides a polylactic acid / nano-hydroxyapatite composite material and its preparation method and application. In the preparation method, firstly, polylactic acid / nano-hydroxyapatite composite microspheres are prepared as a powder raw material by using an emulsion solvent volatilization method, and then , put the powder raw material in a mold, heat and press to form the polylactic acid / nano hydroxyapatite composite material. Adopting the preparation method of the present invention is conducive to the uniform dispersion of nano-hydroxyapatite in the polylactic acid matrix, thereby improving the mechanical properties and impact strength of the product, and it is easy to control the microscopic shape of the molded product. The porogen can obtain microsphere bonded porous structure and microsphere fused dense structure.

Owner:WUHAN UNIV OF TECH

Method for preparing nano complex particle for highly conductive and magnetic electro-magnetic screen

InactiveCN101462173BExcellent magnetic and conductive propertiesControl microscopic morphologyNickel saltPolyethylene glycol

The invention relates to a method for preparing a nanometer composite particle for electromagnetic shielding. The method for preparing the high electric and magnetic conduction nanometer composite particle for electromagnetic shielding is characterized in that the method comprises the following steps: 1) material selection; 2) ferrite and nickel salt are mixed, added with polyethylene glycol and cyclohexane, then added with water and are stirred and dispersed to obtain a mixed solution; 3) the mixed solution is added with a strong reducer at a temperature of between 25 and 90 DEG C, reacts for 5 to 60 minutes under alkali condition with PH value of between 9 and 13, is cooled to normal temperature, and is washed and dried to obtain FeNi alloy nanometer particles; and 4) the FeNi alloy nanometer particles are added into anhydrous ethyl ethanol, added with a weak reducer, subjected to ultrasonic dispersion for 30 to 60 minutes, then added with a silver ammonia solution, stirred at a temperature of between 25 and 90 DEG C, react for 0.5 to 2 hours, cooled to normal temperature and are washed and dried to obtain the high electric and magnetic conduction nanometer composite particle for electromagnetic shielding. The method has the advantages of simple process, environmental protection, low production cost and high yield; and the product has excellent magnetic and electric conduction performances.

Owner:WUHAN UNIV OF TECH

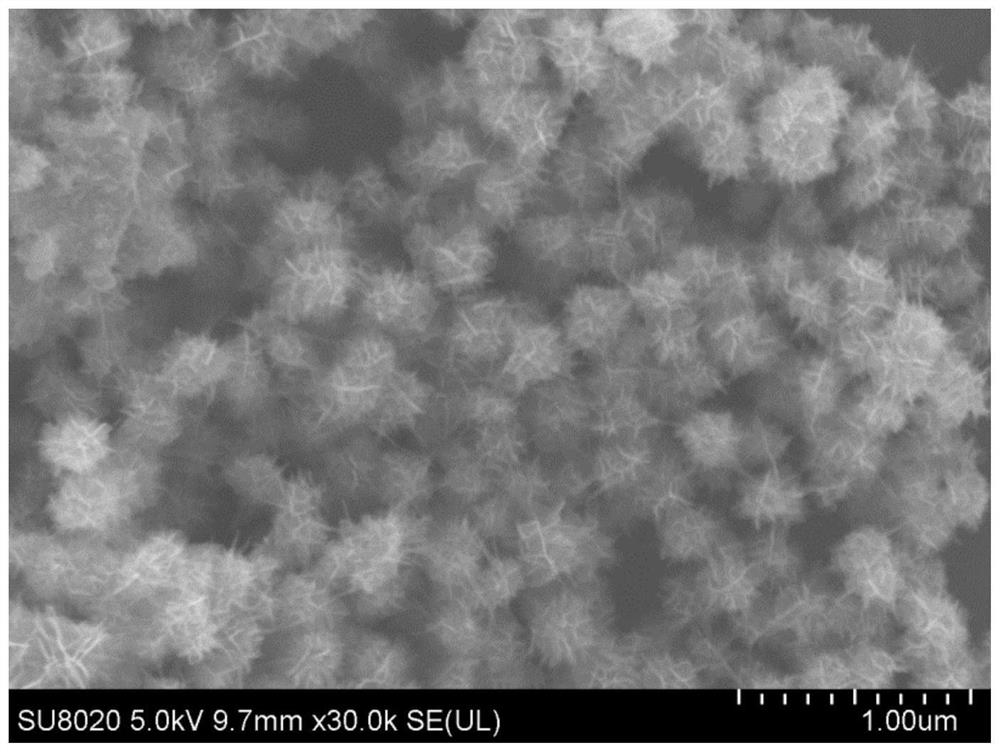

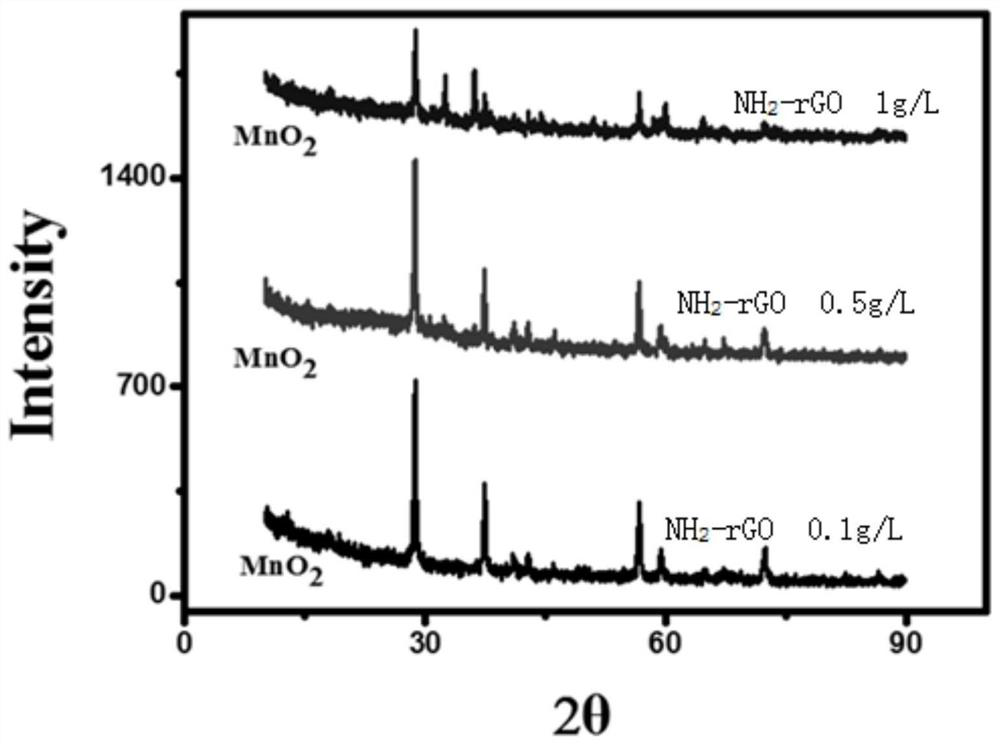

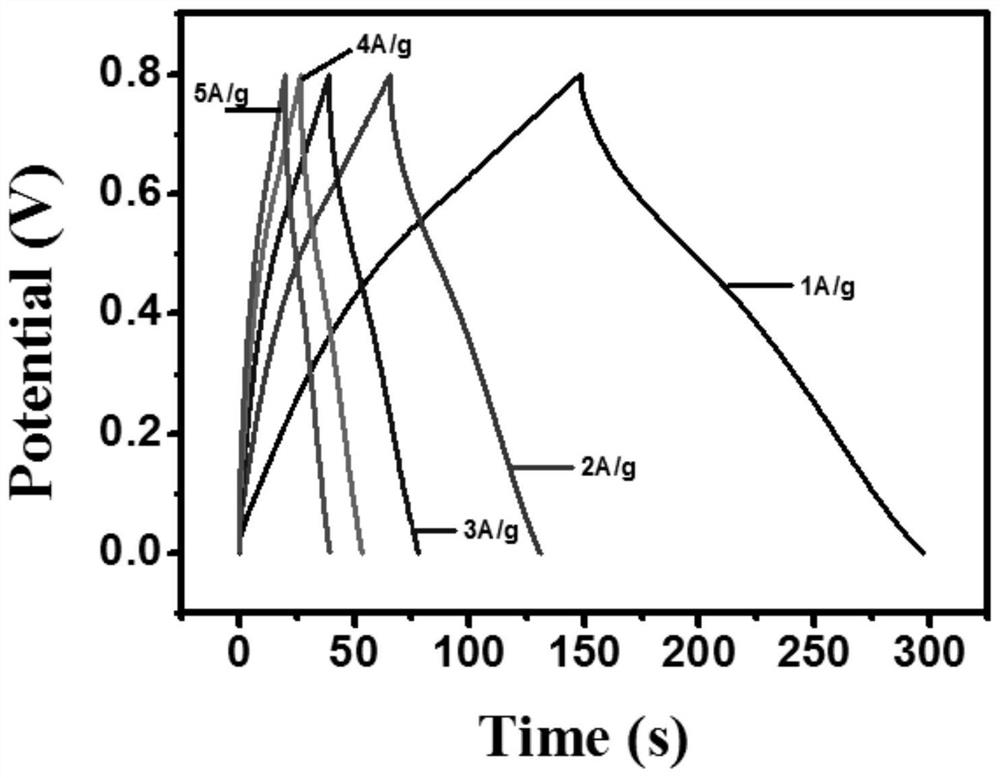

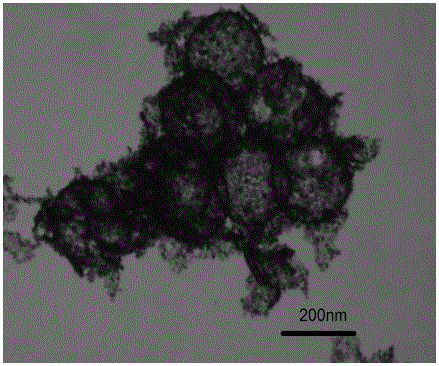

a kind of nh 2 -rgo/mno 2 Composite materials, preparation methods and applications

ActiveCN108172408BRegulatoryImprove conductivityMaterial nanotechnologyHybrid capacitor electrodesAlcoholElectrochemistry

The invention discloses an NH2-rGO / MnO2 composite material, a preparation method and an application thereof. Graphite oxide GO is prepared and the prepared graphite oxide is processed into an aqueoussolution; the aqueous graphite oxide solution and dimethyl formamide are stirred in a water-bath manner, p-phenylenediamine is added into the solution for reaction, the temperature rises, backflow stirring is carried out, an obtained reactant is washed by ethyl alcohol and deionized water until supernate becomes colorless and neutral, an obtained precipitate is dispersed into the deionized water,and then an aminated reduced graphene oxide NH2-rGO solution is obtained; and according to a hydrothermal method, potassium hypermanganate KMnO4 and the prepared NH2-rGO solution are mixed and stirredand then ultrasonic processing is carried out, the mixture is transferred to a reaction still, so that an NH2-rGO / MnO2 composite material is prepared. According to the invention, the prepared aminated graphene enables the conductivity of the manganese dioxide to be improved; because of the amino existence, the electrochemical activity of the material is enhanced and the infiltration property withthe electrolyte is improved; the microscopic appearance of the manganese dioxide can be improved; the specific surface area is increased; the dispersion of the materials is enhanced; and the performance of the super-capacitor is improved.

Owner:HEFEI UNIV OF TECH

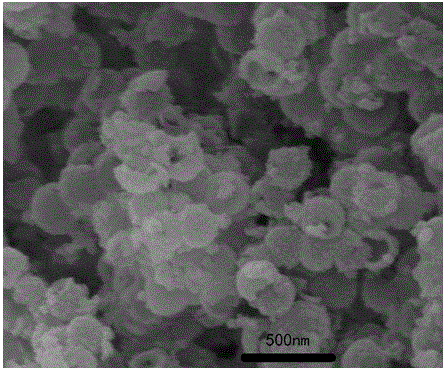

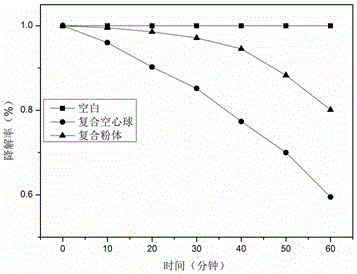

a kind of ceo 2 /tio 2 Nanocomposite hollow sphere catalyst and preparation method thereof

InactiveCN104001491BImprove thermal stabilityLarge specific surface areaMetal/metal-oxides/metal-hydroxide catalystsHydration reactionPtru catalyst

The invention discloses a CeO2 / TiO2 nanometer composite hollow sphere catalyst and a preparation method thereof. The CeO2 / TiO2 nanometer composite hollow sphere catalyst is prepared by firstly preparing CeO2 / TiO2 coated polystyrene composite microspheres by using polystyrene as a template, and using tetrabutyl titanate and cerium nitrate hexahydrate as wall materials, and through combination of a sol-gel method with a precipitation method, and then performing calcination to obtain the product, wherein the using amount ratio of polystyrene, tetrabutyl titanate and cerium nitrate hexahydrate is 0.1-0.3g:0.2-8*10<-3>mol:1-6*10<-3>mol. The CeO2 / TiO2 nanometer composite hollow sphere catalyst prepared in the invention is uniform in size, good in photocatalysis, and good in thermal stability.

Owner:SHANGHAI INST OF TECH

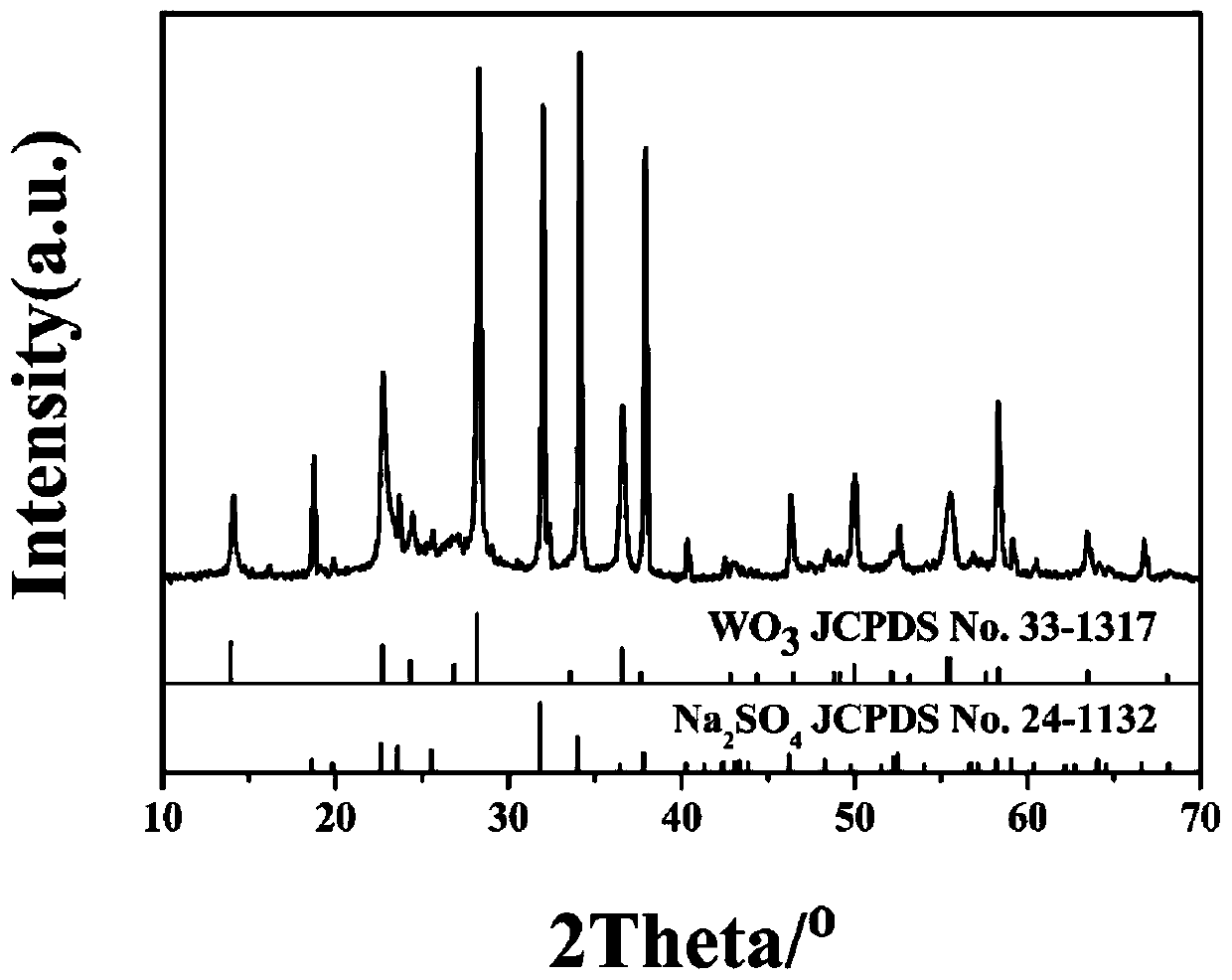

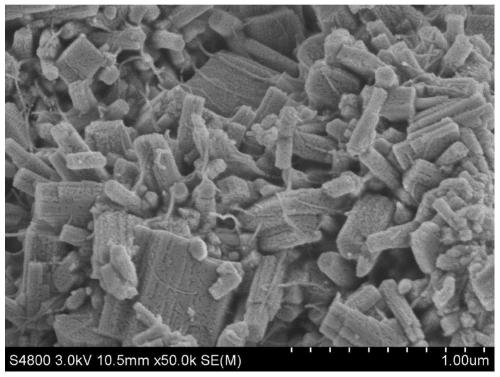

Preparation method of WO3/NaSO4 composite

InactiveCN109794267AHigh crystallinityMild reaction conditionsWater/sewage treatment by irradiationWater contaminantsAmmonium metatungstateHigh pressure

A preparation method of a WO3 / NaSO4 composite includes preparing a solution A by dissolving analytically pure ammonium metatungstate in mixed alcohols; adding analytically pure lauryl sodium sulfate in the solution A to obtain a mixed solution B; pouring the mixed solution B in a polytetrafluoroethylene-lined high-pressure reactor to perform hydrothermal reaction, cooling to the room temperature after the reaction, washing the final product with absolute ethyl alcohol, and then drying the washed product to obtain the WO3 / NaSO4 composite. By a solvothermal method of a wet synthesis process, theprecursor is dissolved in a non-aqueous solvent, reactants disperse in the solution and become much active on a liquid-phase or supercritical condition, thereby facilitating the reaction. Nanocrystalline particles prepared by the solvothermal method have small size, high degree of crystallinity and large specific surface area. The lauryl sodium sulfate surfactant is introduced so as to achieve dual functions, namely morphology adjusting and composite forming.

Owner:SHAANXI UNIV OF SCI & TECH

Method for synthesizing boron and nitrogen co-doped graphitized nano-carbon by using ion-exchange resin

InactiveCN103112845BEvenly distributedControl contentMaterial nanotechnologyNano-carbonIon-exchange resinHeat treating

The invention discloses a method for synthesizing boron and nitrogen co-doped graphitized nano-carbon by using ion-exchange resin, which relates to a synthetic method of boron and nitrogen co-doped graphite carbon. According to the method, the problem of incapability of implementing industrial production caused by complex preparation technologies, harsh reaction conditions, uncontrollable microstructures of products, uncontrollable contents of boron and nitrogen, low yield and high cost of the boron and nitrogen co-doped graphite carbon is solved. The method comprises the following steps of: (1) pre-treating the ion-exchange resin; (2) coordinating functional ions and the ion-exchange resin; (3) pre-carbonizing; (4) heat-treating; and (5) inducing acid reflux and deionized water washing, and drying to acquire the boron and nitrogen co-doped graphite carbon. The microstructure of the boron and nitrogen co-doped graphite carbon acquired by the invention is controllable, the contents of boron and nitrogen are controllable, and the conductivity is good; and meanwhile, the preparation technologies are simple, the microstructure of the product is controllable, the contents of boron and nitrogen are controllable, the yield is high, and the cost is low. The method can be applied to the field of the storage and conversion of energy.

Owner:HEILONGJIANG UNIV

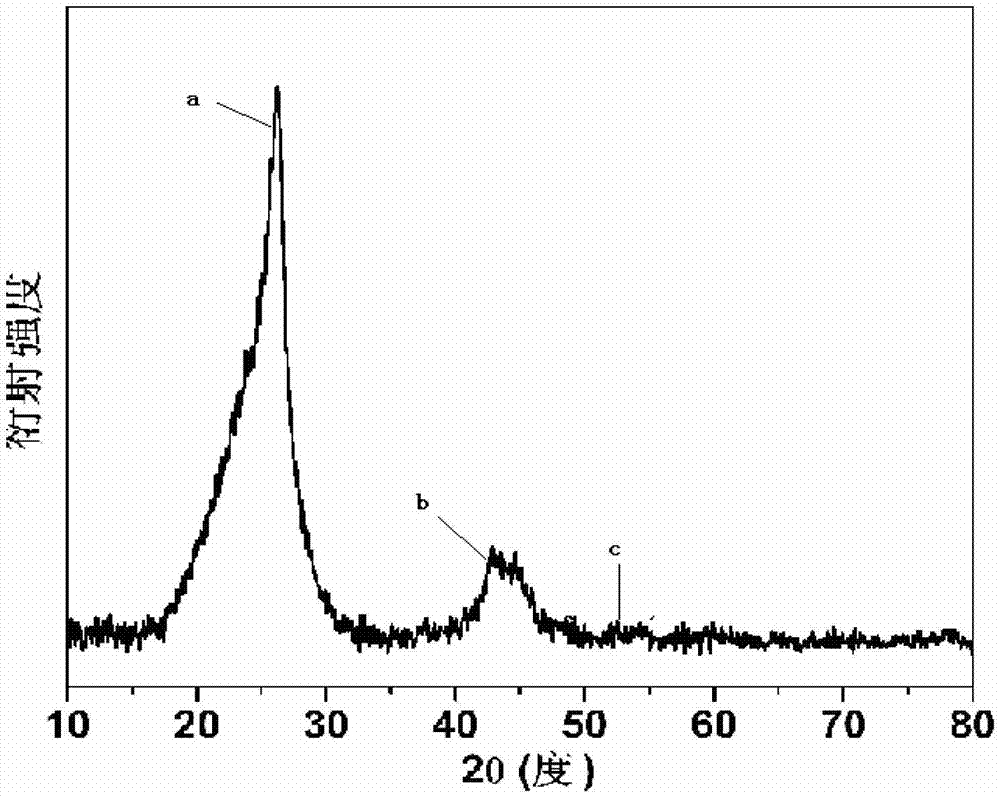

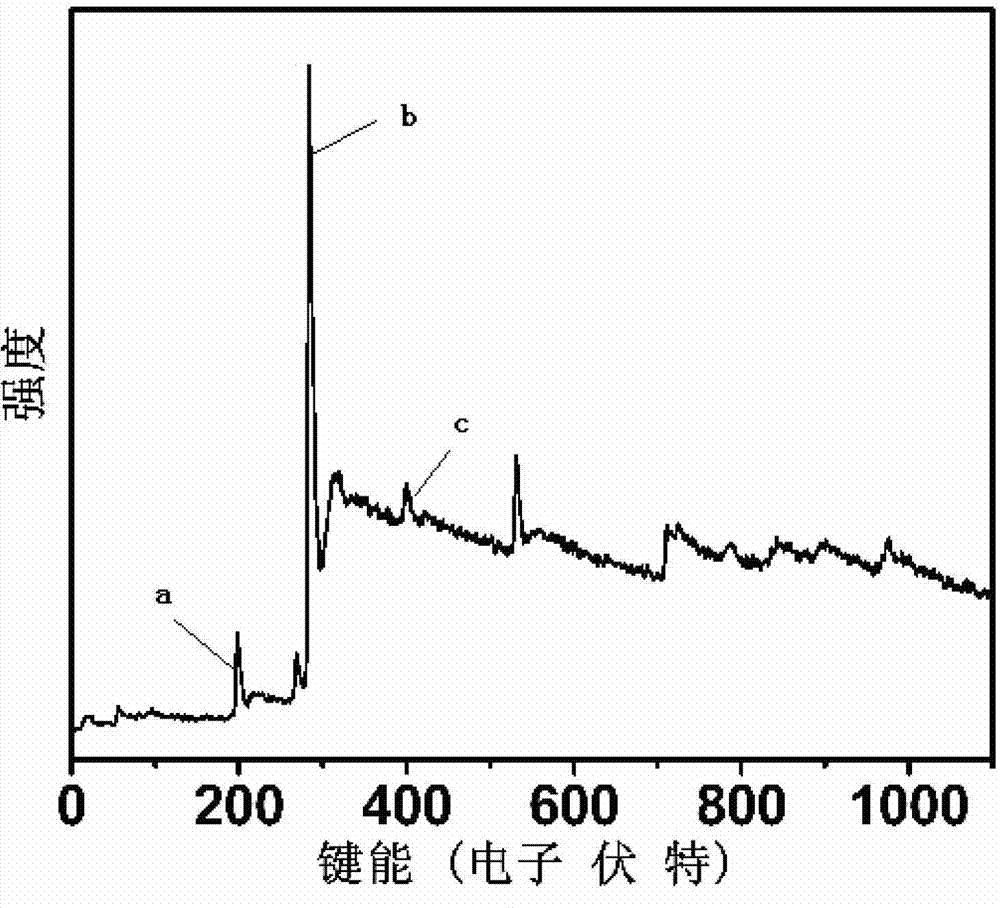

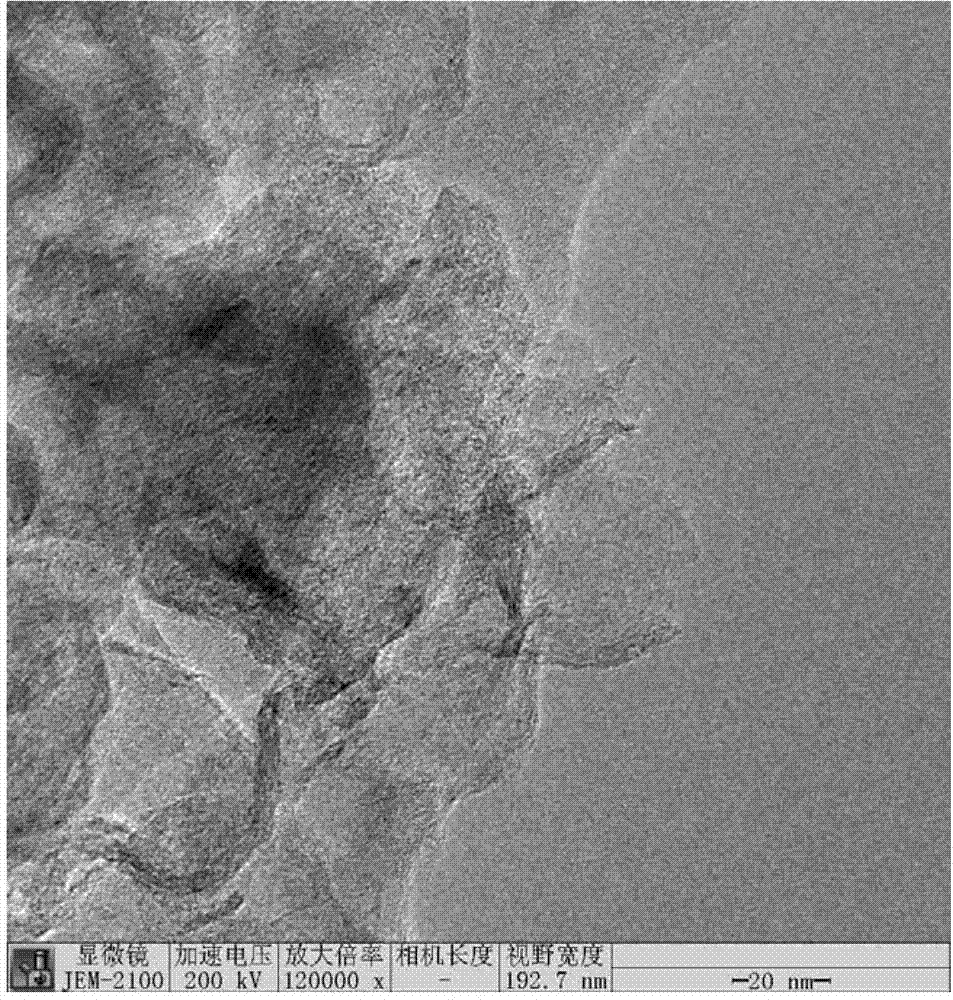

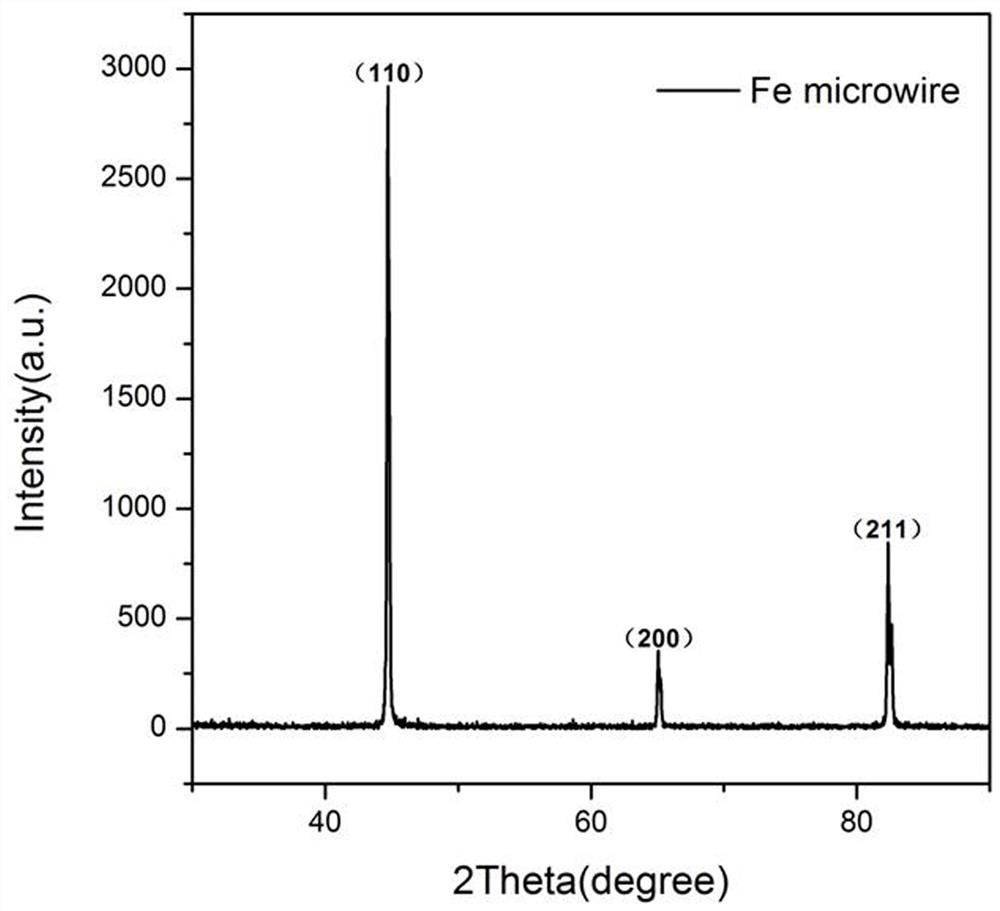

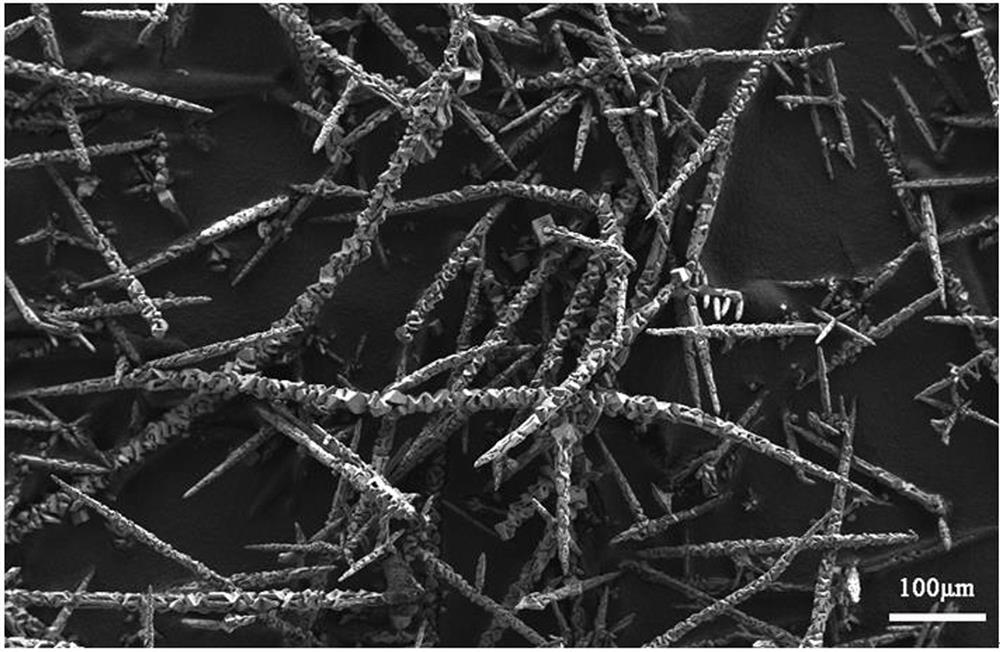

A kind of soft magnetic metal iron porous micro-wire and preparation method thereof

ActiveCN110976898BControl rateLow coercivityInorganic material magnetismInductances/transformers/magnets manufactureAnhydrous ethanolIron salts

The present invention provides a method for preparing soft magnetic metal iron porous micro-wires. The present invention adopts divalent iron salt as raw material and anhydrous ethanol, isopropanol and ethylene glycol as solvent to prepare soft magnetic wire by solvothermal reduction method. Metal iron porous microwires. The method obtains iron micro-wires with different lengths, different diameters and different pore sizes by controlling factors such as reaction temperature, reaction time, reactant concentration, ligand and solvent types. The method for synthesizing the soft magnetic metal iron porous micrometer wire in one step requires simple equipment, simple preparation process and low production cost. The invention provides a new method for preparing soft magnetic metal iron porous micro-wires.

Owner:SHENYANG POLYTECHNIC UNIV

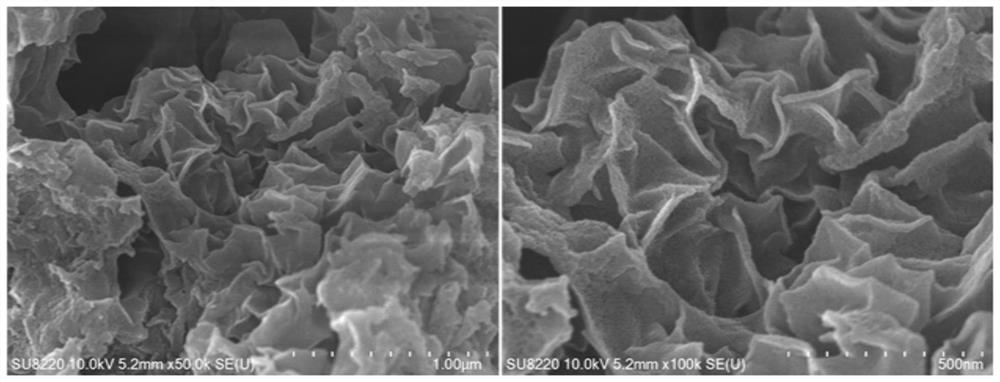

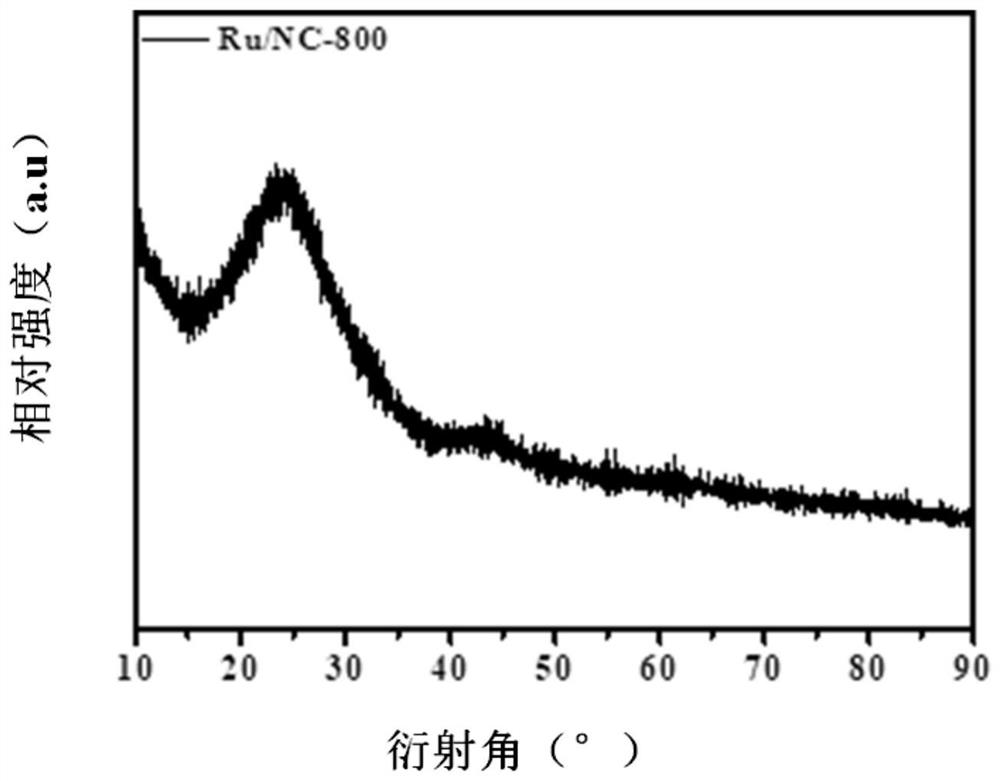

A kind of lignin-based nano-flower porous carbon carrier-loaded Ru-based catalyst and its preparation method and application in lignin depolymerization

ActiveCN109967072BEffective control of pore sizeSmall particlesMetal/metal-oxides/metal-hydroxide catalystsEther preparationPtru catalystDepolymerization

The invention belongs to the technical field of metal solid catalysts and discloses a lignin-based nanoflower porous carbon carrier-loaded Ru-based catalyst, its preparation method and its application in lignin depolymerization. The preparation method of the present invention uses lignin as a carbon source and magnesium oxide as a template agent, and uses microwave processing to process a mixed solution system containing the two to obtain a composite of lignin and magnesium oxide precursors; and then calcines at high temperature to obtain lignin-based nanometer The flower porous carbon carrier is loaded with the active component Ru through an impregnation method to prepare a lignin-based nanoflower porous carbon carrier supporting a Ru-based catalyst. The obtained catalyst has a structure composed of a large number of irregularly wrinkled nanoflowers and well-developed pores. The loaded ruthenium nanoparticles are small (1.5-6nm) and have a large specific surface area (5-180m 2 / g), high dispersion, and high stability. It can be used in lignin depolymerization, showing excellent activity, with a monophenol yield as high as 26.8%, and good cycle stability.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com