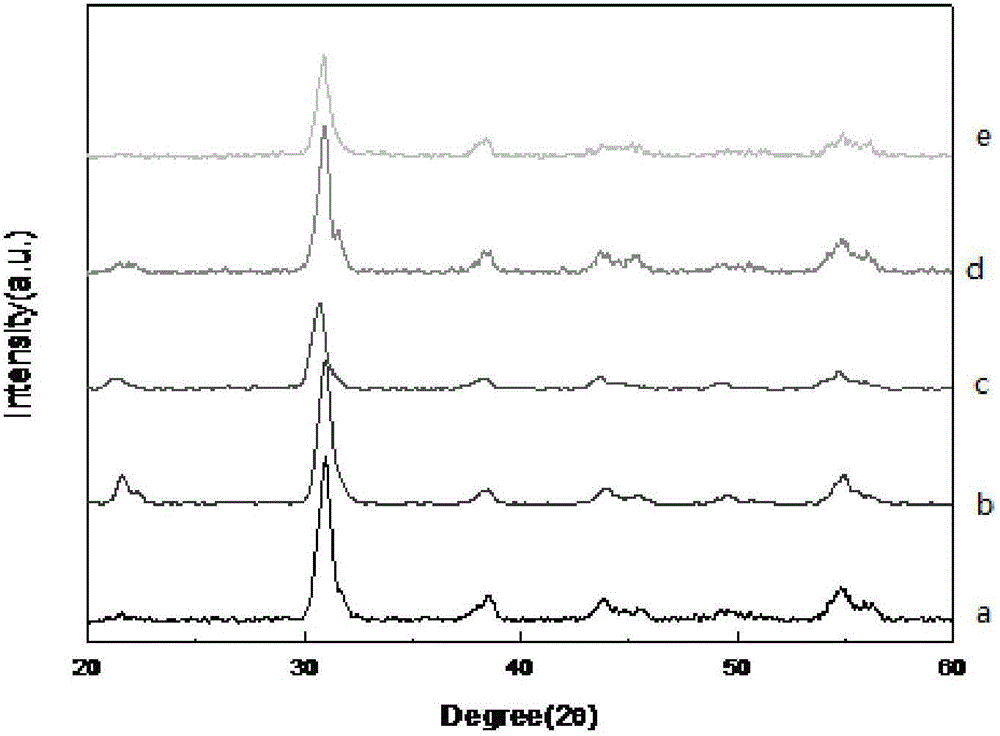

Preparation method of lead zirconate titanate piezoelectric ceramics

A technology of lead zirconate titanate and piezoelectric ceramics, which is applied in the field of preparation of lead zirconate titanate piezoelectric ceramics, to achieve the effects of easy industrial production, improved powder sintering activity, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

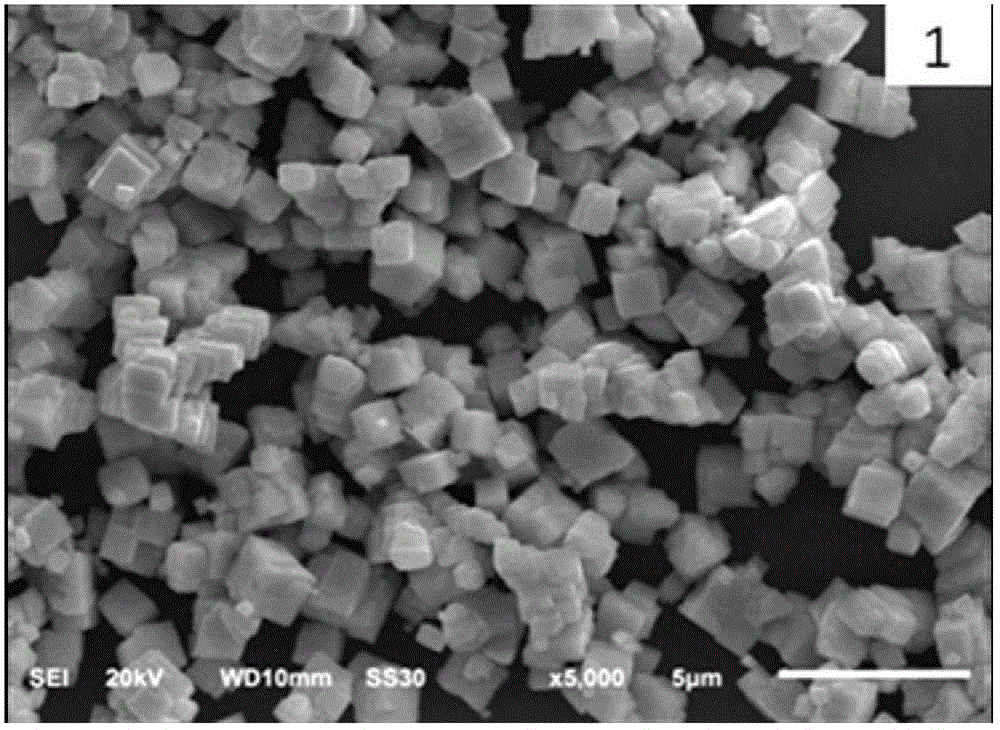

Examples

Embodiment 1

[0037] Synthesize PZT ceramic powder and burn ceramics according to the following process steps:

[0038] (1) According to the chemical formula PbZr of PZT powder to be synthesized 0.52 Ti 0.48 o 3 , measure and weigh tetra-n-butyl titanate and zirconium oxychloride, dissolve them in absolute ethanol and deionized water respectively, configure the tetrabutyl titanate absolute ethanol solution with a concentration of 0.48mol / L and the concentration of 0.52mol / L L of zirconium oxychloride aqueous solution;

[0039] (2) Under stirring, an equal volume of zirconium oxychloride aqueous solution is added to tetrabutyl titanate absolute ethanol solution to obtain a mixed solution of zirconium and titanium ions;

[0040] (3) Adding the mixed solution of zirconium and titanium ions dropwise to an excess ammonia solution with a concentration of 0.25 mol / L under stirring, settling, filtering, and washing with deionized water to obtain co-precipitation of zirconium and titanium hydroxi...

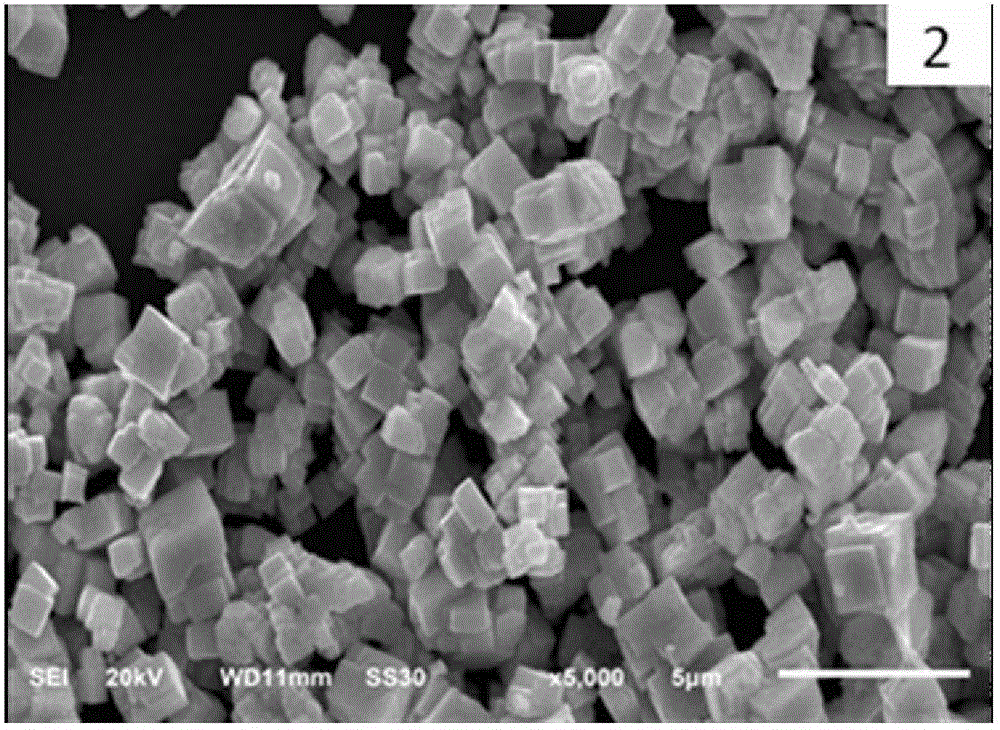

Embodiment 2

[0051] Synthesize PZT ceramic powder and burn ceramics according to the following process steps:

[0052] (1) According to the chemical formula PbZr of PZT powder to be synthesized 0.52 Ti 0.48 o 3 , measure and weigh tetra-n-butyl titanate and zirconium oxychloride, dissolve them in absolute ethanol and deionized water respectively, configure the tetrabutyl titanate absolute ethanol solution with a concentration of 0.48mol / L and the concentration of 0.52mol / L L of zirconium oxychloride aqueous solution;

[0053] (2) Add an equal volume of zirconium oxychloride aqueous solution to the tetrabutyl titanate absolute ethanol solution under stirring to obtain a mixed solution of zirconium and titanium ions;

[0054] (3) Adding the mixed solution of zirconium-titanium ions dropwise to an excess ammonia solution with a concentration of 0.25mol / L under stirring, settling, filtering, and washing with deionized water to obtain co-precipitation of zirconium-titanium hydroxide;

[005...

Embodiment 3

[0065] Synthesize high-performance PZT ceramic powder and fire ceramics according to the following process steps.

[0066] (1) According to the chemical formula PbZr of PZT powder to be synthesized 0.52 Ti 0.48 o 3 , measure and weigh tetra-n-butyl titanate and zirconium oxychloride, dissolve them in absolute ethanol and deionized water respectively, configure the tetrabutyl titanate absolute ethanol solution with a concentration of 0.48mol / L and the concentration of 0.52mol / L L of zirconium oxychloride aqueous solution;

[0067] (2) Under stirring, the zirconium oxychloride aqueous solution is added to the tetrabutyl titanate absolute ethanol solution to obtain a mixed solution of zirconium and titanium ions;

[0068] (3) Adding the mixed solution of zirconium and titanium ions dropwise to the excess ammonia solution with a concentration of 0.25 mol / L under stirring, settling, filtering, and washing with deionized water to obtain co-precipitation of zirconium and titanium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| D33 | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| D33 | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com