a kind of ceo 2 /tio 2 Nanocomposite hollow sphere catalyst and preparation method thereof

A nano-composite, hollow sphere technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem that ceria cannot meet high-temperature applications, etc. Effects of excellent light capture efficiency, mild reaction conditions, and excellent oxygen storage and release capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

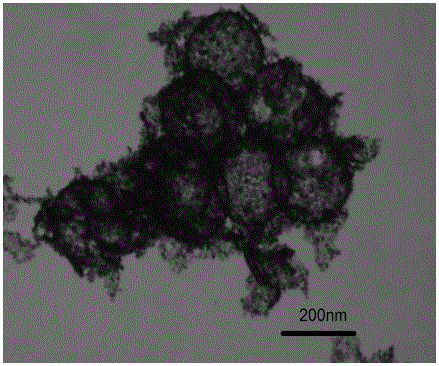

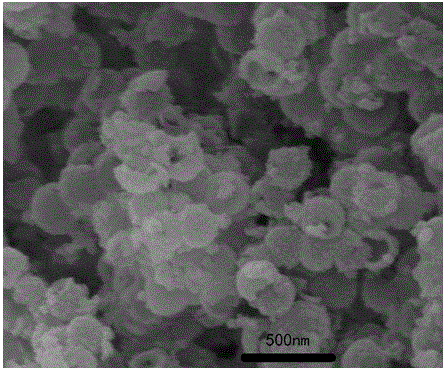

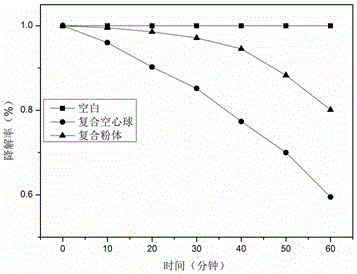

[0033] a CeO 2 / TiO 2 Nanocomposite hollow sphere catalysts, that is, first use polystyrene as a template, use tetrabutyl titanate and cerium nitrate hexahydrate as wall materials, and prepare CeO by combining sol-gel method and precipitation method 2 / TiO 2 Composite microspheres coated with polystyrene and then calcined to obtain CeO 2 / TiO 2 Nanocomposite hollow microsphere catalyst;

[0034] Among them, the amount of polystyrene, tetrabutyl titanate and cerium nitrate hexahydrate, according to polystyrene: tetrabutyl titanate: cerium nitrate hexahydrate is 0.1g: 0.2 × 10 -3 mol:1×10 -3 mol.

[0035] CeO above 2 / TiO 2 The preparation method of nanocomposite hollow sphere catalyst specifically comprises the following steps:

[0036] (1) Mix 0.1g polystyrene, 0.5g deionized water, 50μL concentrated ammonia water and 20mL absolute ethanol evenly, then control the temperature at 60°C and the rotation speed at 300r / min for 2 hours to obtain the reaction solution 1;

...

Embodiment 2

[0045] a CeO 2 / TiO 2 Nanocomposite hollow sphere catalysts, that is, first use polystyrene as a template, use tetrabutyl titanate and cerium nitrate hexahydrate as wall materials, and prepare CeO by combining sol-gel method and precipitation method 2 / TiO 2 Composite microspheres coated with polystyrene and then calcined to obtain CeO 2 / TiO 2 Nanocomposite hollow sphere catalyst;

[0046] Among them, the amount of polystyrene, tetrabutyl titanate and cerium nitrate hexahydrate, according to polystyrene: tetrabutyl titanate: cerium nitrate hexahydrate is 0.3g: 8 × 10 -3 mol:4×10 -3 mol.

[0047] CeO above 2 / TiO 2 The preparation method of nanocomposite hollow sphere catalyst specifically comprises the following steps:

[0048] (1) Mix 0.3g polystyrene, 2g deionized water, 10μL concentrated ammonia water and 20mL absolute ethanol evenly, control the temperature at 70°C, and react at a speed of 400r / min for 4 hours to obtain the reaction solution 1;

[0049] The part...

Embodiment 3

[0057] a CeO 2 / TiO 2 Nanocomposite hollow sphere catalysts, that is, first use polystyrene as a template, use tetrabutyl titanate and cerium nitrate hexahydrate as wall materials, and prepare CeO by combining sol-gel method and precipitation method 2 / TiO 2 Composite microspheres coated with polystyrene and then calcined to obtain CeO 2 / TiO 2 Nanocomposite hollow sphere catalyst;

[0058] Among them, the amount of polystyrene, tetrabutyl titanate and cerium nitrate hexahydrate is 0.2g according to polystyrene: tetrabutyl titanate: cerium nitrate hexahydrate: 4×10 -3 mol: 6×10 -3 mol.

[0059] CeO above 2 / TiO 2 The preparation method of nanocomposite hollow sphere catalyst specifically comprises the following steps:

[0060] (1) Mix 0.2g polystyrene, 1g deionized water, 30μL concentrated ammonia water and 20mL absolute ethanol evenly, control the temperature at 75°C, and react at a speed of 500r / min for 3 hours to obtain the reaction solution 1;

[0061] The partic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com