Fiber cloth-based lithium ion battery diaphragm as well as preparation method and application thereof

A lithium-ion battery and fiber technology, which is used in secondary batteries, battery pack components, and secondary battery repair/maintenance, etc. High ionic conductivity, effect of improving thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

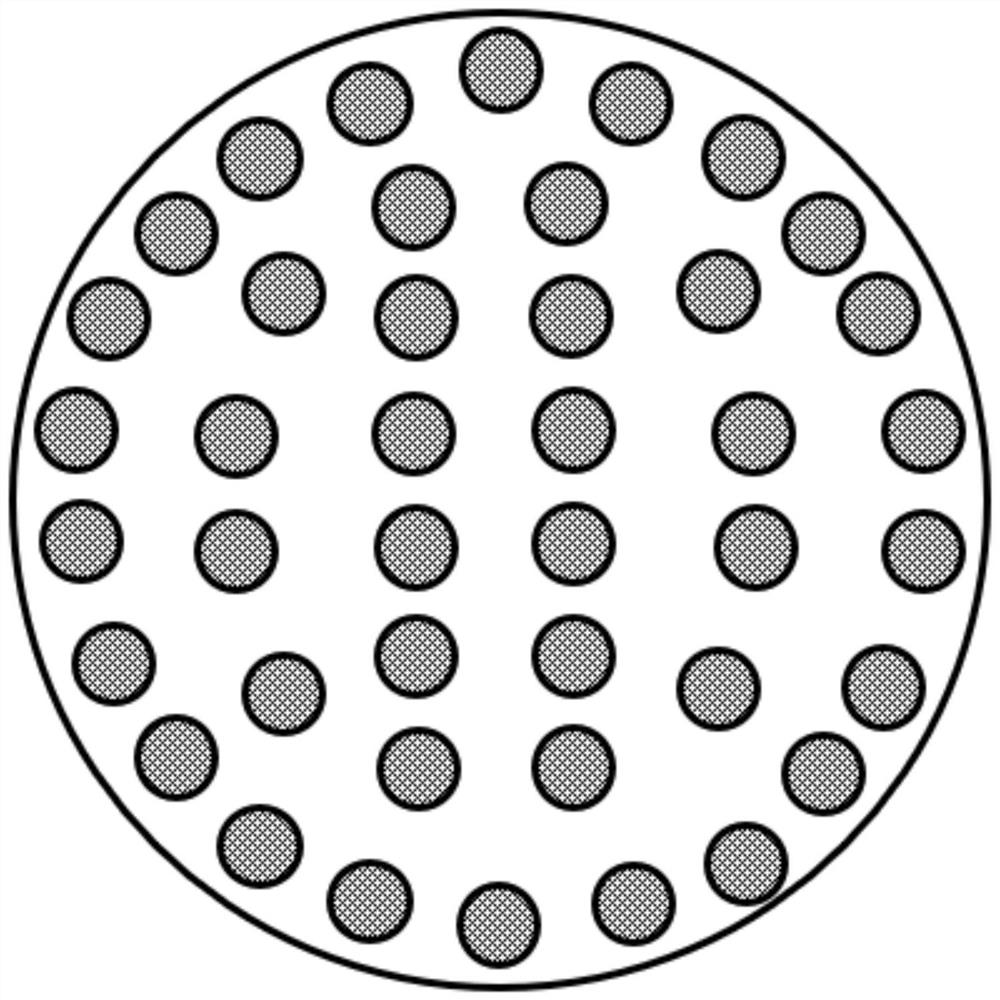

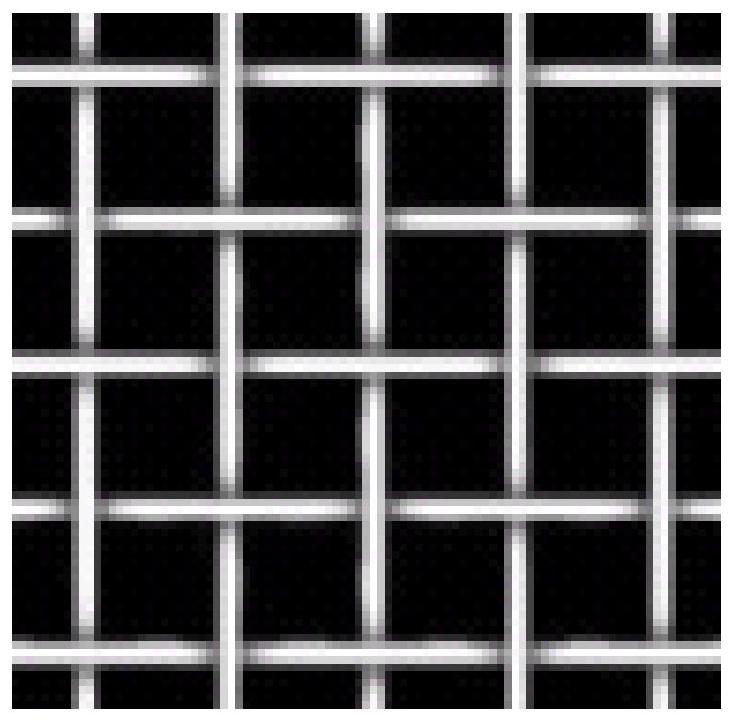

[0029] At room temperature, the raw materials are subjected to hot-melt spinning technology and then passed through a composite spinning device to produce a composite fine-denier fiber with polypropylene as the island and a blend of polyvinylidene fluoride and polymethyl methacrylate as the sea. ,Such as figure 1 Shown; the mass fraction of polypropylene is 10wt%, the mass fraction of the blend is 90wt%, and polyvinylidene fluoride accounts for 90wt% of the blend. In order to ensure that the blend is better dispersed on the entire fiber separator by subsequent smooth roller heat pressing, the polypropylene fiber is controlled below 0.5 denier according to the requirements of ultrafine denier fibers. Warp and weave the fiber cloth to obtain a warp and weft fiber cloth with a warp and weft ratio of 40:30, such as figure 2 shown. In order to extrude the excess blended polymer at the interlacing points of the warp and weft to supplement the weaving pores, and to distribute the ...

Embodiment 2

[0031] At room temperature, the raw materials are subjected to hot-melt spinning technology and then passed through a composite spinning device to produce a composite fine-denier fiber with polypropylene as the island and a blend of polyvinylidene fluoride and polymethyl methacrylate as the sea. ,Such as figure 1 Shown; the mass fraction of polypropylene is 20wt%, the mass fraction of the blend is 80wt%, and polyvinylidene fluoride accounts for 90wt% of the blend. In order to ensure that the blend is better dispersed on the entire fiber separator by subsequent smooth roller heat pressing, the polypropylene fiber is controlled below 0.5 denier according to the requirements of ultrafine denier fiber. The fiber cloth is warped and woven to obtain a warp and weft fiber cloth with a warp and weft ratio of 40:20, such as figure 2 shown. In order to extrude the excess blended polymer at the interlacing points of the warp and weft to supplement the weaving pores, and to distribute ...

Embodiment 3

[0033] At room temperature, the raw materials are subjected to hot-melt spinning technology and then passed through a composite spinning device to produce a composite fine-denier fiber with polypropylene as the island and a blend of polyvinylidene fluoride and polymethyl methacrylate as the sea. ,Such as figure 1 Shown; the mass fraction of polypropylene is 20wt%, the mass fraction of the blend is 80wt%, and polyvinylidene fluoride accounts for 80wt% of the blend. In order to ensure that the blend is better dispersed on the entire fiber separator by subsequent smooth roller heat pressing, the polypropylene fiber is controlled below 0.5 denier according to the requirements of ultrafine denier fiber. The fiber cloth is warped and woven to obtain a warp and weft fiber cloth with a warp and weft ratio of 30:20, such as figure 2 shown. In order to extrude the excess blended polymer at the interlacing points of the warp and weft to supplement the weaving pores, and to distribute ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com