Bone repair stent material and preparation method thereof

A scaffold material and bone repair technology, applied in medical science, prosthesis, etc., can solve the problem of difficulty in obtaining raw materials, and achieve the effects of simple preparation and processing methods, strong controllability, and promotion of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

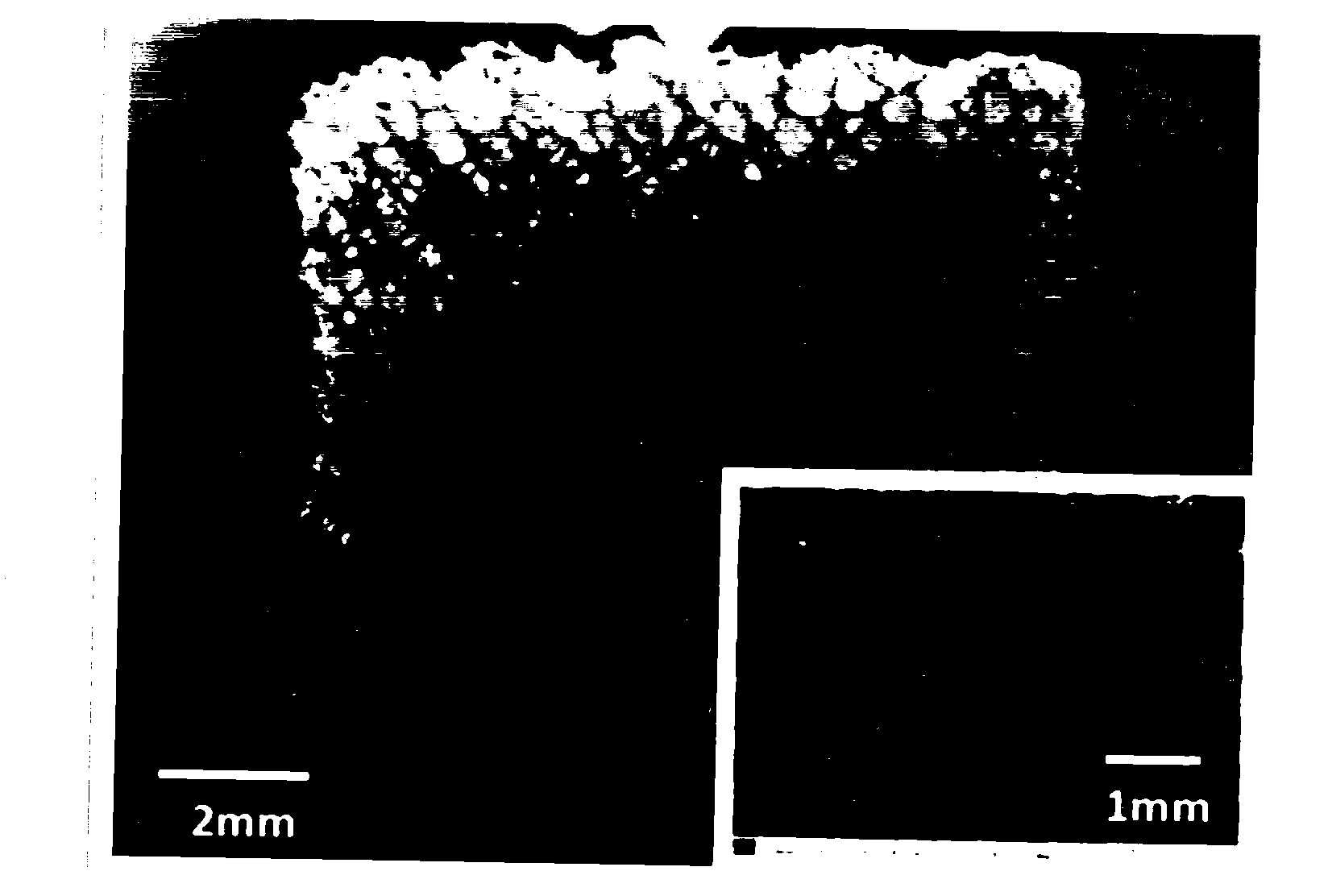

[0022] (1) Fresh sika deer antler bones were taken, and the cortical bone around the core cancellous bone structure of the antler trunk was excised with a mechanical cutter to obtain a 10×10×10 mm antler cancellous bone block.

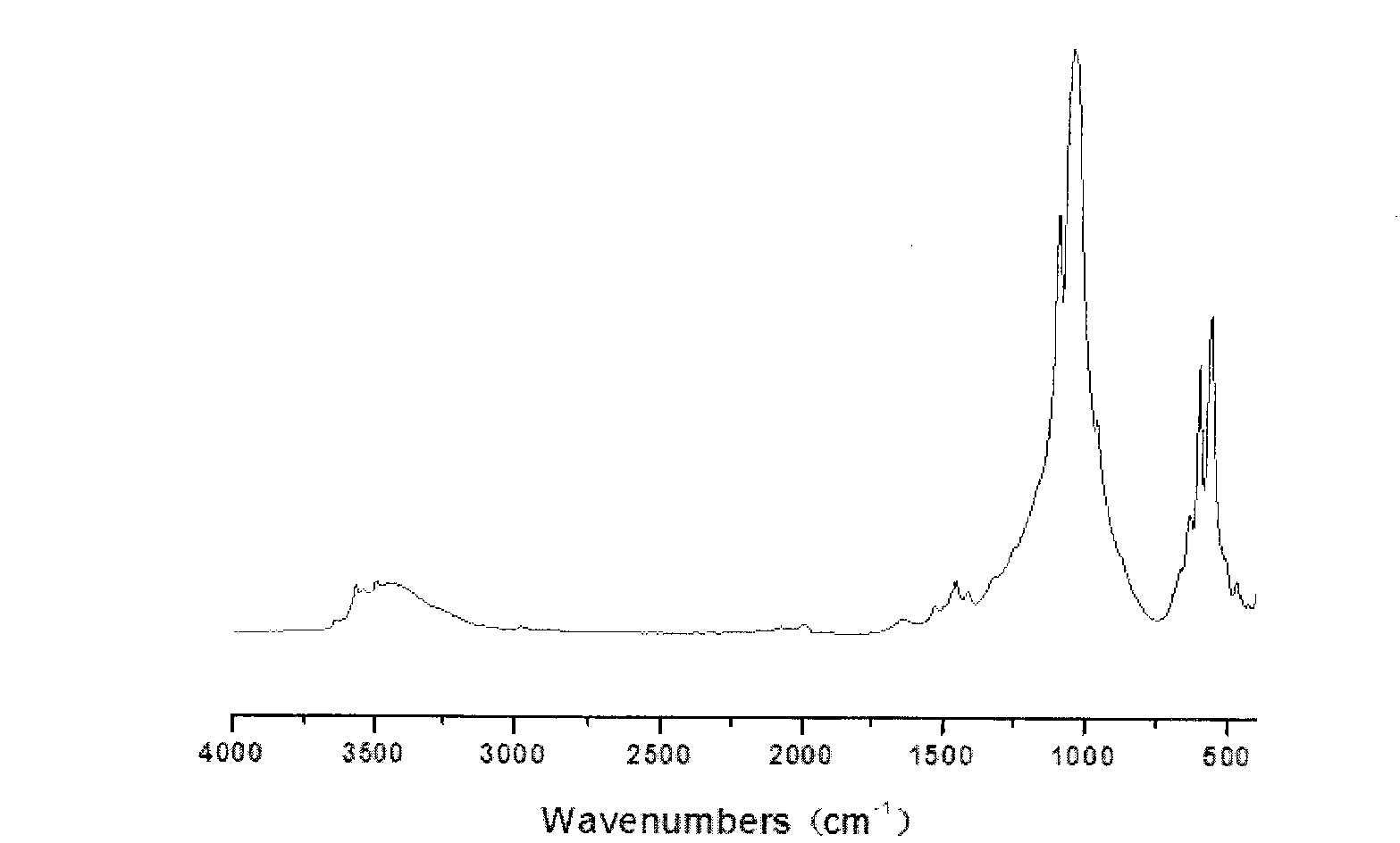

[0023] (2) The antler cancellous bone obtained in step (1) was soaked in 0.6mol / L NaOH for 2 hours, chloroform for 2 hours, 30% hydrogen peroxide for 12 hours, 2mol / L calcium chloride for 3 hours, and 10mol / L calcium chloride for 2 hours. Soak in L lithium chloride for 6 hours, wash with deionized water 5 times between each step, and dry at a constant temperature of 80° C. for 1 day.

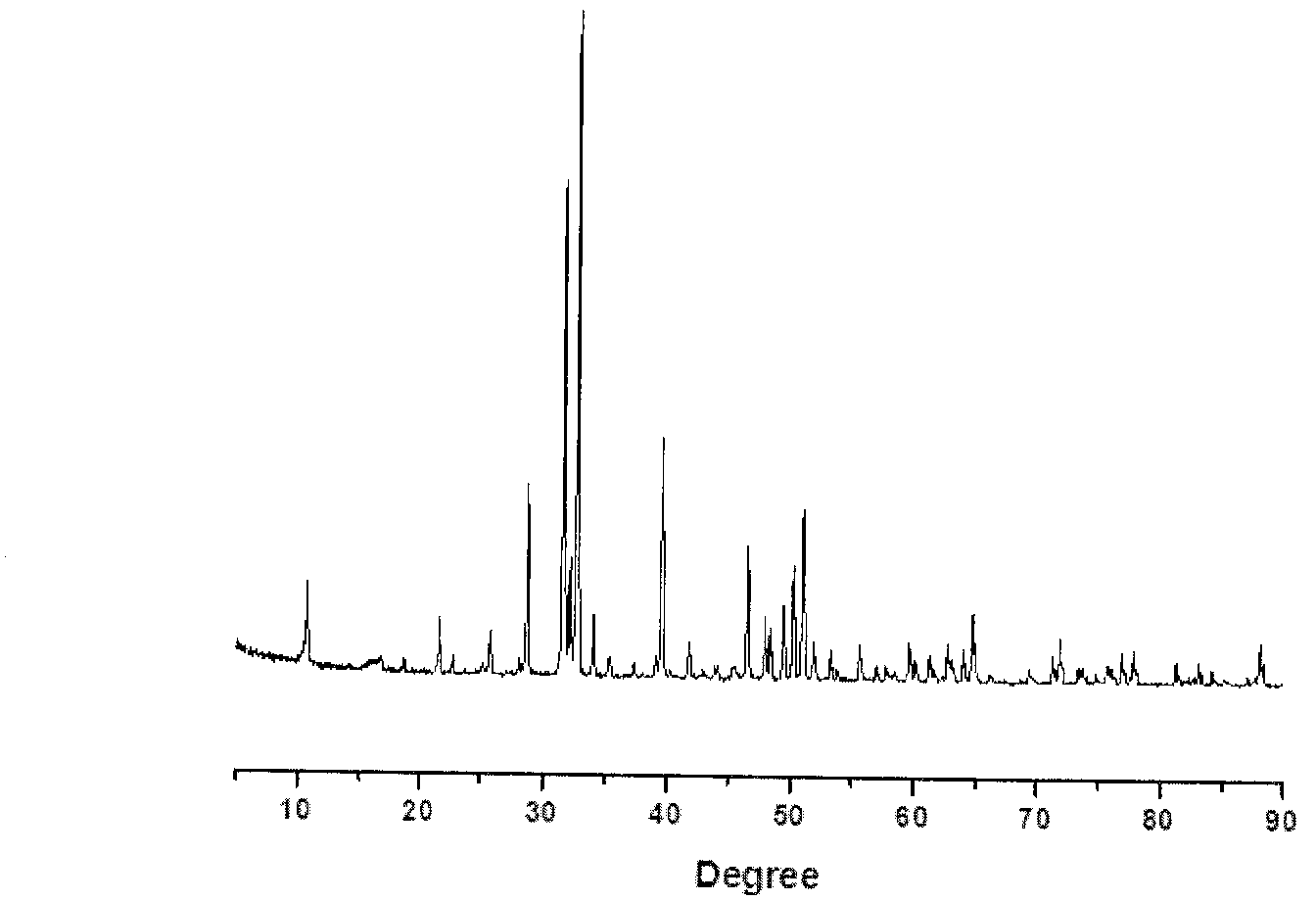

[0024] (3) Put the dried product obtained in step (2) into a high-temperature sintering furnace for calcination under air atmosphere, the sintering temperature is 1000°C, the heating rate is 5°C / min, the sintering time is 6h, and the cooling rate is 5°C / min .

[0025] The bone repair scaffold material obtained through the above steps contains hydroxyapatite, which is a ...

Embodiment 2

[0027] (1) Fresh red deer antler bones were taken, and the cortical bone around the core cancellous bone structure of the antler trunk was excised with a wire cutting machine to obtain an antler cancellous slider body of 10×20×10 mm.

[0028] (2) The antler cancellous bone obtained in step (1) was soaked in 0.1mol / L NaOH for 20 hours, chloroform for 5 hours, 30% hydrogen peroxide for 48 hours, 1mol / L calcium chloride for 8 hours, and 3mol / L calcium chloride for 8 hours. Soak in L lithium chloride for 8 hours, wash 3 times with deionized water between each step, and dry at a constant temperature of 50° C. for 3 days.

[0029] (3) Put the dried product obtained in step (2) into a high-temperature sintering furnace for calcination under air atmosphere, the sintering temperature is 600°C, the heating rate is 1°C / min, the sintering time is 48h, and the cooling rate is 10°C / min .

[0030] The natural bone repair scaffold material obtained through the above steps has a porous interp...

Embodiment 3

[0032] (1) Fresh sambar antler bones were taken, and the cortical bone around the core cancellous bone structure of the antler trunk was excised with a wire cutting machine to obtain a 10×15×10 mm antler cancellous bone block.

[0033] (2) The antler cancellous bone obtained in step (1) was soaked in 0.5mol / L NaOH for 12 hours, chloroform for 1 hour, 30% hydrogen peroxide for 24 hours, 2mol / L calcium chloride for 2 hours, and 10mol / L calcium chloride for 2 hours. Soak in L lithium chloride for 24 hours, wash with deionized water 4 times between each step, and dry at a constant temperature of 55° C. for 2 days.

[0034] (3) Place the dried product obtained in step (2) into a high-temperature sintering furnace for calcination under air atmosphere, the sintering temperature is 800°C, the heating rate is 2°C / min, the sintering time is 24h, and the cooling rate is 1°C / min .

[0035] The natural bone repair scaffold material obtained through the above steps has a porous interpenetr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com