Method for preparing morphology-controlled conductive polyaniline film by using electrophoretic deposition

A technology of conductive polyaniline and polyaniline film, which is applied in the direction of electrolysis process and electricity generation process, can solve the problems of inability to form and process, poor comprehensive mechanical properties, and difficulty in controlling the shape of polyaniline film, so as to achieve easy control and good electrical conductivity. The effect of chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Clean indium tin oxide conductive glass (ITO) as the working electrode, use acetone, ethanol, and distilled water in an ultrasonic cleaning machine for 20 minutes each, and dry at 40°C for 2 hours. The cleaned ITO electrode is stored in a sealed bag for later use.

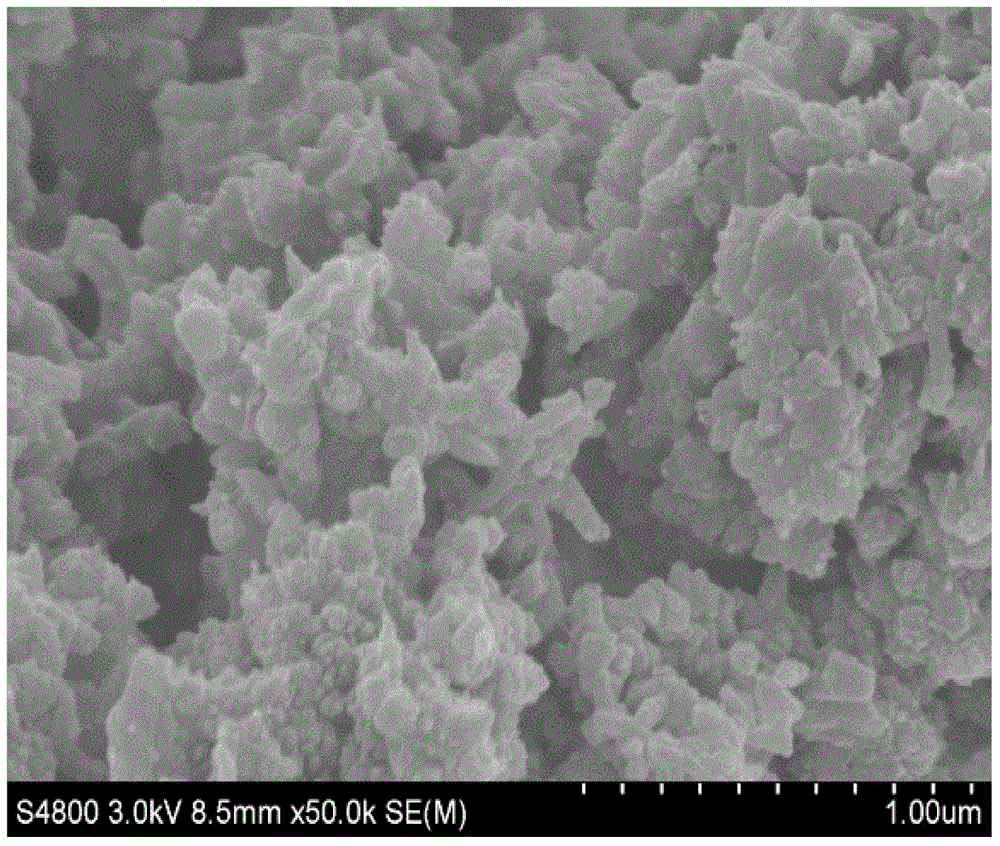

[0025] (2) Take conductive polyaniline (PANI) powder with nanofibrous morphology and dissolve it in formic acid to obtain a PANI formic acid solution with a concentration of 1 mg / mL. With PANI formic acid solution as the dispersion medium and acetonitrile as the dispersant, prepare the PANI sol with a concentration of 0.01g / L.

[0026] (3) Take the PANI sol into a beaker, fix the ITO electrode and the platinum sheet electrode (counter electrode), connect the platinum sheet electrode to the positive electrode, connect the ITO electrode to the negative electrode, connect the DC working power supply, control the deposition voltage to 50V, and the deposition time to 60s After the deposition is completed, ri...

Embodiment 2

[0028] (1) Clean indium tin oxide conductive glass (ITO) as the working electrode, use acetone, ethanol, and distilled water in an ultrasonic cleaning machine for 20 minutes each, and dry at 40°C for 2 hours. The cleaned ITO electrode is stored in a sealed bag for later use.

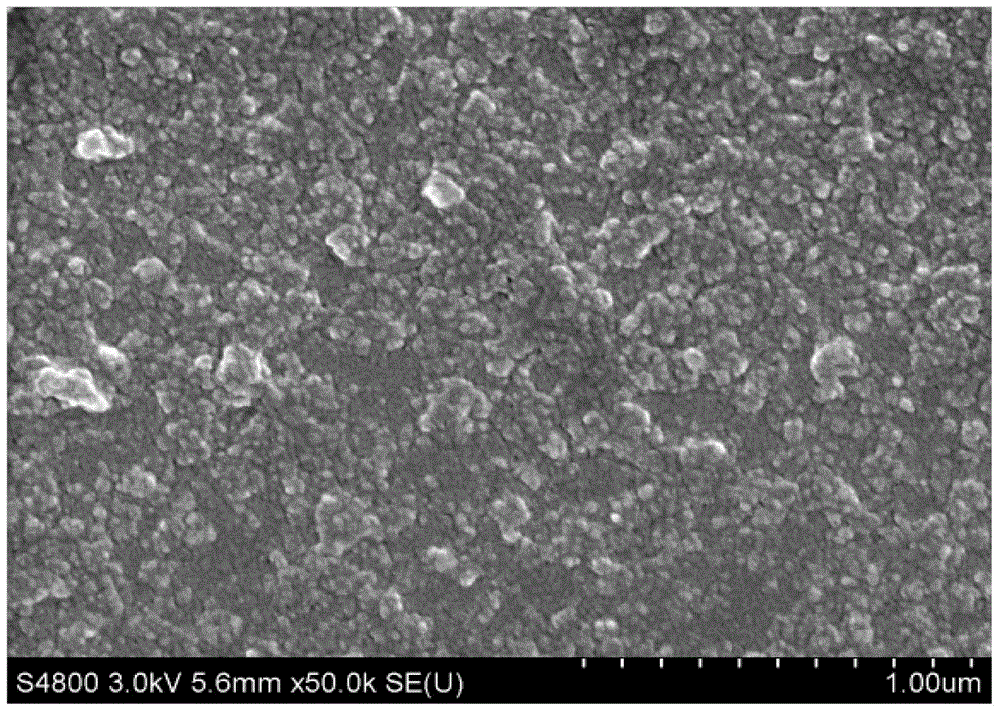

[0029] (2) Take conductive polyaniline (PANI) powder with nanofibrous morphology and dissolve it in formic acid to obtain a PANI formic acid solution with a concentration of 1 mg / mL. With PANI formic acid solution as the dispersion medium and acetonitrile as the dispersant, PANI sol with a concentration of 0.5g / L was prepared.

[0030] (3) Take PANI sol into a beaker, fix the ITO electrode and the platinum sheet electrode (counter electrode), connect the platinum sheet electrode to the positive electrode, connect the ITO electrode to the negative electrode, connect the DC working power supply, control the deposition voltage to 150V, and the deposition time to 300s After the deposition is completed, rins...

Embodiment 3

[0032] (1) Clean indium tin oxide conductive glass (ITO) as the working electrode, use acetone, ethanol, and distilled water in an ultrasonic cleaning machine for 20 minutes each, and dry at 40°C for 2 hours. The cleaned ITO electrode is stored in a sealed bag for later use.

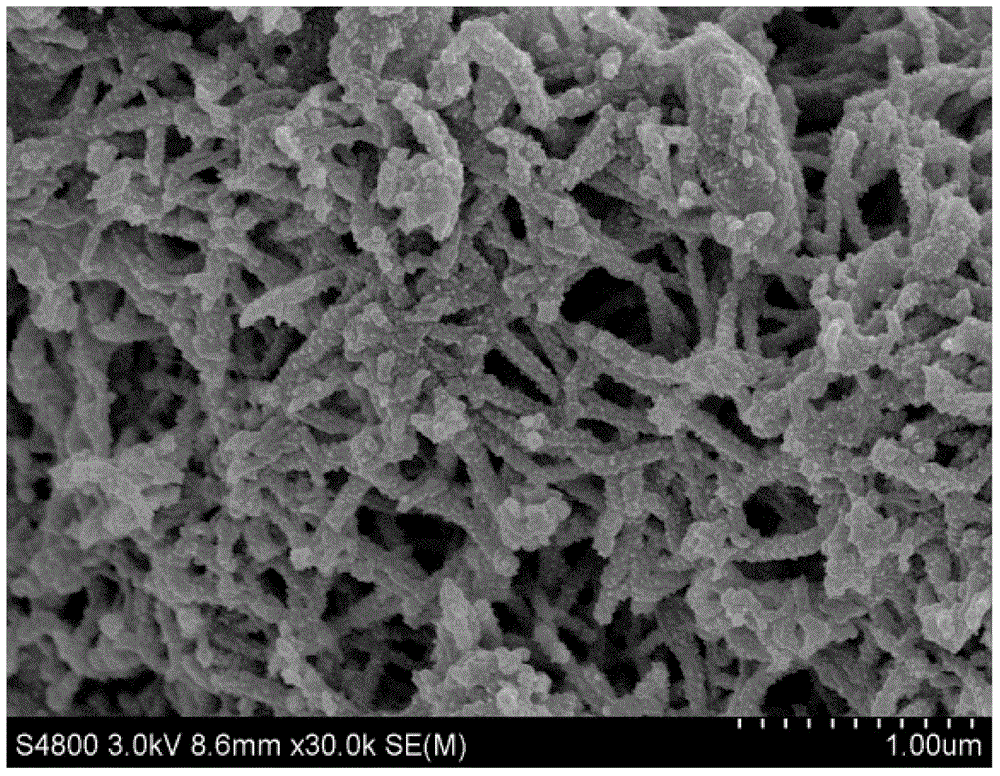

[0033] (2) Take conductive polyaniline (PANI) powder with nanotube-like morphology and dissolve it in formic acid to obtain a PANI formic acid solution with a concentration of 1 mg / mL. With PANI formic acid solution as the dispersion medium and acetonitrile as the dispersant, prepare the PANI sol with a concentration of 0.01g / L.

[0034] (3) Take the PANI sol into a beaker, fix the ITO electrode and the platinum sheet electrode (counter electrode), connect the platinum sheet electrode to the positive electrode, connect the ITO electrode to the negative electrode, connect the DC working power supply, control the deposition voltage to 50V, and the deposition time to 60s After the deposition is completed, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com