Preparation method of asymmetric particles based on swelling seed emulsion polymerization

An asymmetric particle and emulsion polymerization technology, which is applied in the field of synthesis of non-spherical asymmetric composite particles, can solve the problem of single shape of composite particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

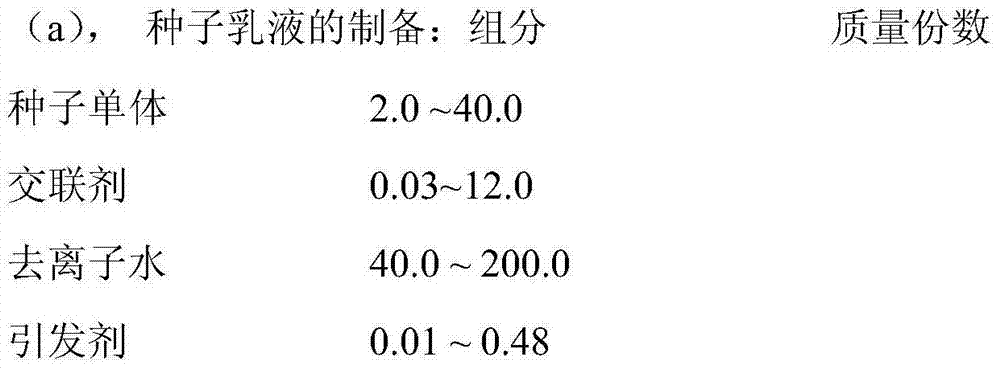

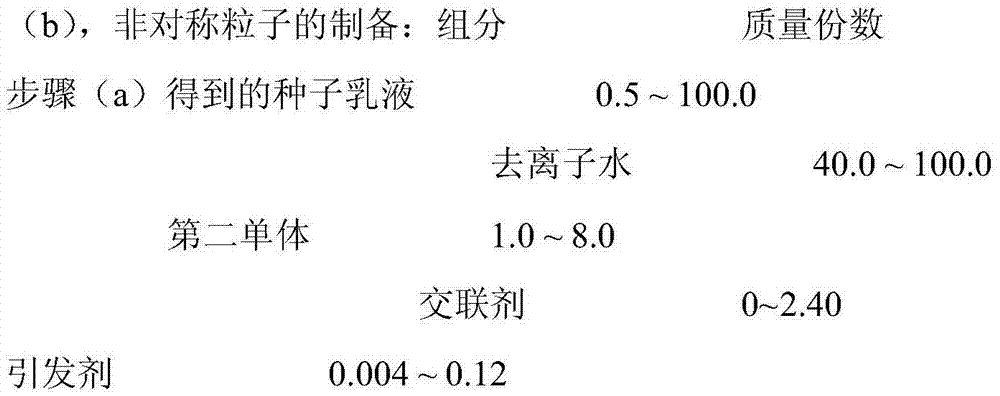

[0021]

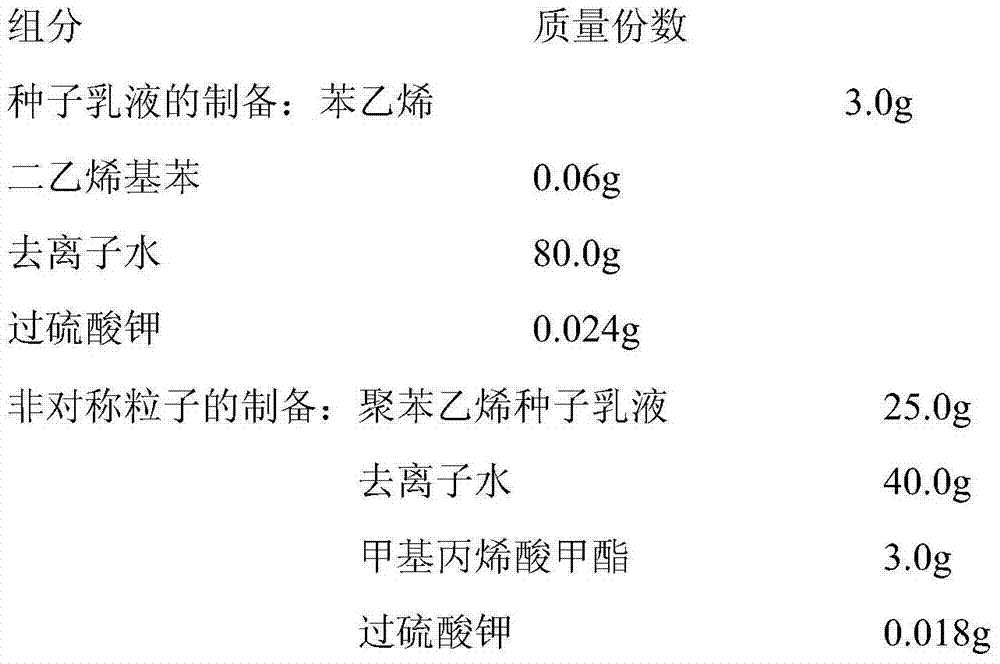

[0022] According to the above ratio, add a certain amount of seed monomer styrene (St) (3.0g), cross-linking agent divinylbenzene (DVB) (0.06g), 80.0g deionized water into the four-necked flask, start stirring In the whole process, feed nitrogen, reflux and condense. After the system reaches the reaction temperature of 70°C, add 0.024 g of initiator potassium persulfate, and polymerize for 5 hours to obtain the seed emulsion;

[0023] Add deionized water to 25.0g of seed emulsion (containing about 1.0g of PS seeds), ultrasonically disperse, add 3.0g of the second monomer methyl methacrylate (MMA) at one time, start stirring, swell at room temperature for 30min, then heat up, wait for the system After reaching the reaction temperature of 70°C, 0.018 g of initiator potassium persulfate was added. During the whole process, nitrogen gas was introduced, refluxed and condensed, and polymerized for 5 hours, and then the emulsion sample was directly taken from the reaction ...

Embodiment example 2

[0026] In the implementation case 2, the amount of the cross-linking agent DVB was changed to 0.12 g, and the rest of the implementation process was the same as the implementation case 1.

Embodiment example 3

[0028] In Embodiment 3, the amount of the cross-linking agent DVB was changed to 0.015 g, and the rest of the implementation process was the same as Embodiment 1.

[0029] Comparing the three implementation cases, it can be seen that increasing the cross-linking degree of the seeds is conducive to the occurrence of phase separation. By controlling the amount of cross-linking agent in the seeds, the morphology of the composite particles can be controlled, thereby preparing non- symmetrical particles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com