A carbon material prepared by utilizing inorganic carbon to promote the carbonization of polyolefin and its preparation method

A technology of inorganic carbon material and polyolefin carbon, which is applied in inorganic chemistry, carbon preparation/purification, chemical instruments and methods, etc., can solve the problem that the structure of carbon materials is difficult to precisely control, difficult to form carbon, and lacks the controllable degree of carbonization of polyolefin. Carbonization new technology and other issues, to achieve the effect of easy promotion and large-scale application, lower carbonization temperature, and obvious carbonization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1) Weigh 1 g of linear low-density polyethylene and 0.20 g of carbon black, and stir and mix them uniformly by ball milling to obtain a polyolefin-carbon black mixture.

[0041] (2) Put the polyolefin-carbon black mixture obtained in step (1) into a crucible, and then place it in a muffle furnace for heating. Set the heating rate of the muffle furnace to 5°C / min, keep the temperature at 150°C for 1min, at 200°C, keep the temperature for 1min, set the carbonization temperature to 330°C, and keep the constant temperature at this temperature for 30min. After the crucible is naturally cooled, Carbon material is obtained. The mass of the product was weighed, and the yield of the carbon material was calculated to be 52.2 wt%.

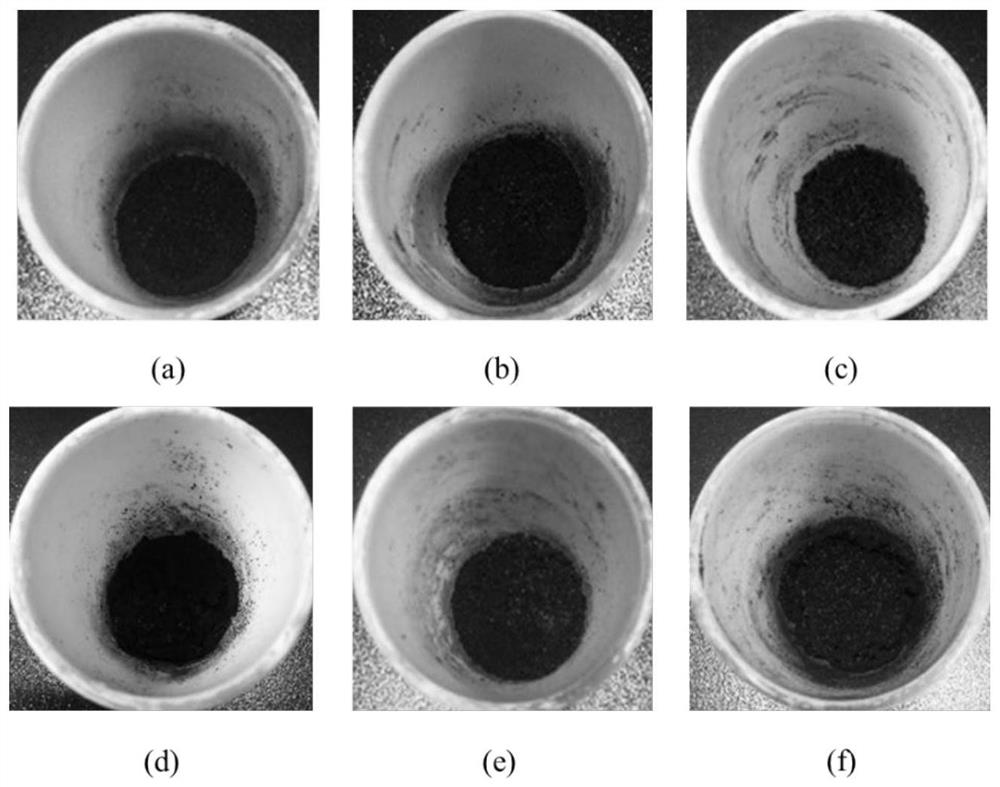

[0042] Carbonized products prepared such as figure 1 shown in (a). The product was carbon black, solid and light, indicating that the mixture of linear low density polyethylene and carbon black was fully carbonized at 330°C.

Embodiment 2

[0044] The mass of carbon black used in the above Example 1 was changed from 0.20g to 0.35g, the heating rate was changed from 5°C / min to 35°C / min, the carbonization temperature was changed from 330°C to 300°C, and the other steps remained unchanged. Carbonized product of density polyethylene and carbon black.

[0045] Carbonized products prepared such as figure 1 shown in (b). The product was carbon black, solid and light, indicating that the mixture of linear low density polyethylene and carbon black was completely carbonized under this condition, and the yield of carbon material was 54.9 wt%.

Embodiment 3

[0047] The carbon material catalyst used in the above Example 1 was changed from carbon black to carbon nanotubes, the holding time was changed from 30min to 60min, and the other steps remained unchanged to obtain a carbonized product of linear low density polyethylene and carbon nanotubes.

[0048] Carbonized products prepared such as figure 1 shown in (c). The product was carbon black, solid and light, indicating that the mixture of linear low density polyethylene and carbon nanotubes had been completely carbonized under this condition, and the yield of carbon material was 58.0 wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com