Biological full-degradable plastic film and preparation method thereof

A plastic film, fully degradable technology, applied in the field of biodegradable plastic film and its preparation, can solve the problems of slow degradation speed, poor mechanical properties, high production cost, etc., and achieve fast degradation speed, good mechanical properties, and low production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

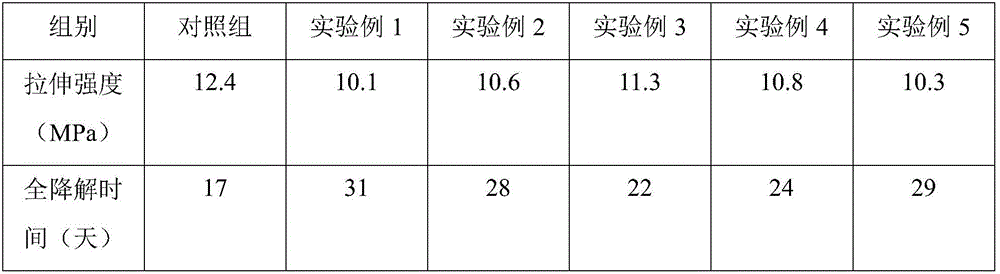

Image

Examples

Embodiment 1

[0024] A fully biodegradable plastic film is mainly made of the following raw materials in parts by weight: 48 parts of tapioca starch, 35 parts of glycerin, 35 parts of polyvinyl alcohol, and 4 parts of hydrophilic nano silicon dioxide.

[0025] The fully biodegradable plastic film also includes 0.5 parts by weight of a catalyst, and the catalyst is mainly composed of fumed white carbon black, zinc oxide and 2-mercaptobenzothiazole in a weight percentage of 10:3:2.

[0026] A method for preparing a biodegradable plastic film, comprising the steps of:

[0027] A, take the tapioca starch of above-mentioned weight portion and the hydrophilic nano-silicon dioxide of above-mentioned weight portion, put it into the ultra-high speed mixer, stir 20 minutes under 4000 rev / mins, get the first mixture;

[0028] B. Add the first mixture, the polyvinyl alcohol of the above-mentioned weight part and the glycerin of the above-mentioned weight part into the internal mixer sequentially, and r...

Embodiment 2

[0034] A fully biodegradable plastic film is mainly made of the following raw materials in parts by weight: 60 parts of tapioca starch, 40 parts of glycerin, 40 parts of polyvinyl alcohol, and 5 parts of hydrophilic nano silicon dioxide.

[0035] The fully biodegradable plastic film also includes 0.8 parts by weight of a catalyst, and the catalyst is mainly composed of fumed white carbon black, zinc oxide and 2-mercaptobenzothiazole in a weight percentage of 10:3:2.

[0036] A method for preparing a biodegradable plastic film, comprising the steps of:

[0037] A, take the tapioca starch of above-mentioned weight portion and the hydrophilic nano-silica of above-mentioned weight portion, put it into the ultra-high speed mixer, stir 18 minutes under 4200 rev / mins, get the first mixture;

[0038] B. Add the first mixture, the polyvinyl alcohol of the above-mentioned weight part and the glycerin of the above-mentioned weight part into the internal mixer sequentially, and react for ...

Embodiment 3

[0044] A fully biodegradable plastic film is mainly made of the following raw materials in parts by weight: 72 parts of tapioca starch, 45 parts of glycerin, 45 parts of polyvinyl alcohol, and 6 parts of hydrophilic nano silicon dioxide.

[0045] The fully biodegradable plastic film also includes 1 part by weight of a catalyst, and the catalyst is mainly composed of fumed white carbon black, zinc oxide and 2-mercaptobenzothiazole in a weight percentage of 10:3:2.

[0046] A method for preparing a biodegradable plastic film, comprising the steps of:

[0047] A, take the tapioca starch of above-mentioned weight portion and the hydrophilic nano silicon dioxide of above-mentioned weight portion, put it into the ultra-high speed mixer, stir 15 minutes under 4500 rev / mins, get the first mixture;

[0048]B. Add the first mixture, the above weight portion of polyvinyl alcohol and the above weight portion of glycerin into the internal mixer sequentially, and react for 30 minutes at a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com