Method for preparing polarizer

A technology for polarizers and polarizers, applied in the field of polarizers, can solve the problems of difficulty in cross-linking, difficulty in ensuring dimensional stability, difficulty in manufacturing polarizers, etc., to prevent film wrinkling, excellent durability, and improve pinning efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

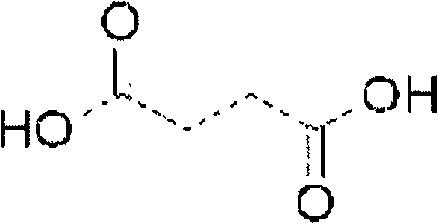

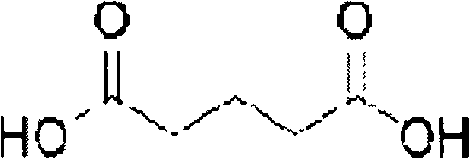

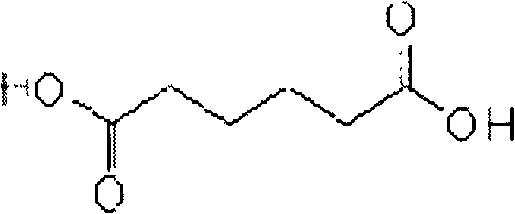

[0027] The method for preparing a polarizer according to the present invention may include the steps of: first crosslinking by dipping a polyvinyl alcohol film into a first crosslinking solution containing a boron compound; and by dipping the polyvinyl alcohol film into a first crosslinking solution containing a boron compound; The second crosslinking is carried out in a second crosslinking solution of a linear polycarboxylic acid compound containing at least two carboxyl groups.

[0028] According to the present invention, the polarizer refers to a conventional iodine polarizer comprising a polymer film and iodine adsorbed and oriented in the polymer film.

[0029] The polymer film used to prepare the polarizer may include, but is not particularly limited to, any film capable of being dyed with iodine. Specific examples of the polymer film may include: polyvinyl alcohol film and / or partially saponified polyvinyl alcohol film; hydrophilic polymer film such as polyethylene tere...

Embodiment 1

[0087] A transparent unstretched polyvinyl alcohol film (VF-PS, Kuraray Chemical Co. Ltd.) having a degree of saponification of 99.9% or more was immersed in water (deionized water) at 30°C for 2 minutes to swell. After the above immersion and swelling, the treated membrane was stained by dipping in a staining solution containing 3.5 mmol / L of iodine and 2% by weight of potassium iodide at 30° C. for 4 minutes. At this time, the membrane was stretched to 1.3 times and 1.4 times during swelling and dyeing, respectively. Next, the dyed membrane was immersed in a first cross-linking solution containing 10% by weight of potassium iodide and 3.5% by weight of boric acid at 50°C for 2 minutes (the first cross-linking step), and then, at 50°C in a solution containing 10% by weight of boric acid Potassium iodide, 3.5% by weight of boric acid and 1% by weight of glutaric acid in the second crosslinking solution for 1 minute (second crosslinking step), thereby performing a crosslinking ...

Embodiment 2

[0090] The same procedure described in Example 1 was repeated except that the second crosslinking solution contained 3% by weight of glutaric acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com