Preparation method of binder asphalt, binder asphalt and electrode for aluminum smelting

A technology of binder asphalt and asphalt, which is applied in the direction of processing tar asphalt/petroleum asphalt/natural asphalt, processing of tar asphalt/petroleum asphalt/natural asphalt, petroleum industry, etc. Pores, blocked surface openings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] Tar 1 and 2 are produced by different coking enterprises, and cinder and coal ash are removed by centrifugal treatment. Toluene was added to the purified coal tar in an amount of 8%, and mixed uniformly by a mixer with a stirring paddle at a mixing temperature of 70°C. The mixed tar is passed into the electrolytic reactor, the anode is lead dioxide, and the cathode is graphite. The voltage is 3V and the current is 5mA. After 6 minutes of electrochemical reaction, the processed tar on the anode plate was scraped off with a scraper, and the above reaction was repeated to collect the processed tar.

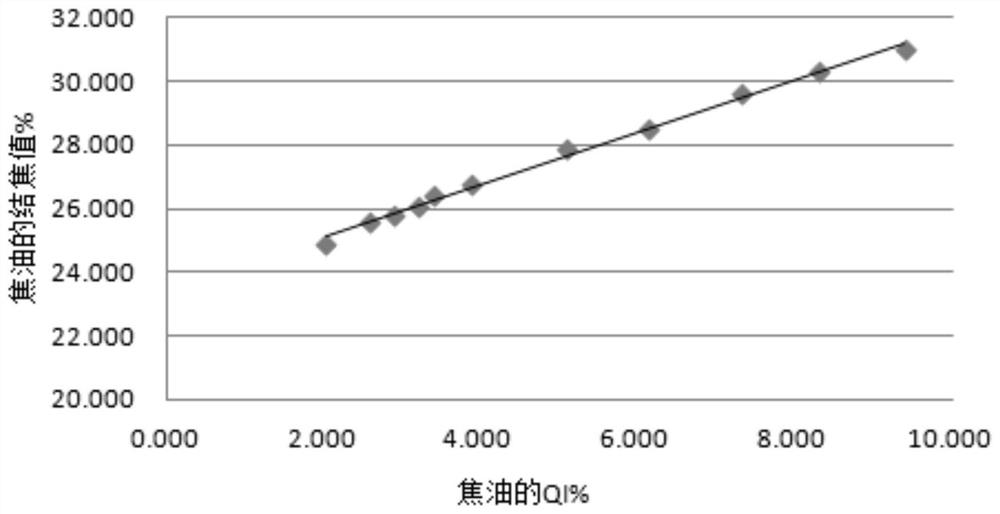

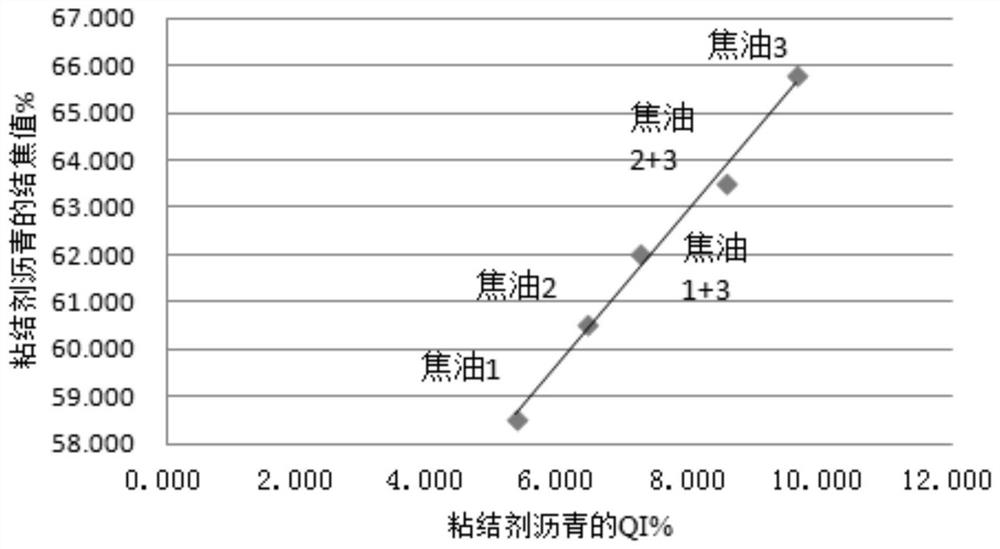

[0072] The QI1 of the processed tar 1 after the above treatment is 2.02% by mass, and the CV1 is 24.9%. The QI2 and CV2 of the processed tar 2 are 6.12% and 28.4% respectively. After mixing according to the ratio of 65:35, the mixed tar 12 is obtained and then decompressed Medium-temperature pitch 12 was obtained by distillation, which was blown into the pitch at a reforming...

Embodiment 2

[0074] Tar 1 and 2 are produced by different coking enterprises, and cinder and coal ash are removed by centrifugal treatment. Toluene was added to the purified coal tar in an amount of 8%, and mixed uniformly by a mixer with a stirring paddle at a mixing temperature of 70°C. The mixed tar is passed into the electrolytic reactor, the anode is lead dioxide, and the cathode is graphite. The voltage is 3V and the current is 5mA. After 6 minutes of electrochemical reaction, the processed tar on the anode plate was scraped off with a scraper, and the above reaction was repeated to collect the processed tar. Processed tar 2 and 3 processed above, QI2 and CV2 of processed tar 2 are 6.12%, 28.4% respectively, processed tar 3QI3 is 3.40% by mass, CV3 26.4%, mixed according to the ratio of 55:45 to obtain mixed tar 23 was further subjected to vacuum distillation to obtain medium-temperature pitch 23, which was blown into the pitch at a reforming temperature of 310°C at a steam injecti...

Embodiment 3

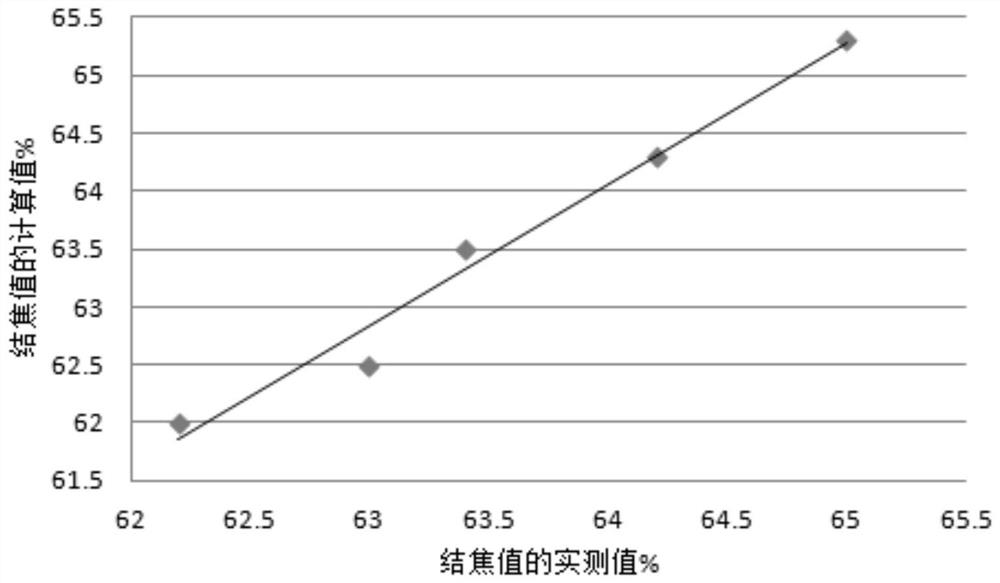

[0087] Processed tar 1 and 2 were obtained in the same manner as in Example 1. The QI1 of tar 1 was 2.02% by mass, and the CV1 was 24.9%. The QI2 and CV2 of tar 2 were 6.12% and 28.4%, respectively, and mixed according to the ratio of 65:35 to obtain mixed tar 12 Further vacuum distillation was carried out to obtain medium-temperature pitch 12, which was blown into the pitch at a reforming temperature of 300°C with a steam injection rate of 30kg steam / t pitch, and then thermally reformed for 12 hours to obtain binder pitch 12 (1) . The softening point (SP) of gained binder pitch 12 (1) is shown in the binder pitch column of table 2, quinoline insoluble matter (QI), comprises the content of primary and secondary QI, coking value (CV) , viscosity (160°C) and 360°C fraction. The binder pitch coking value is 64 through calculation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com