Carbon material precursor and method for producing carbon material using the same

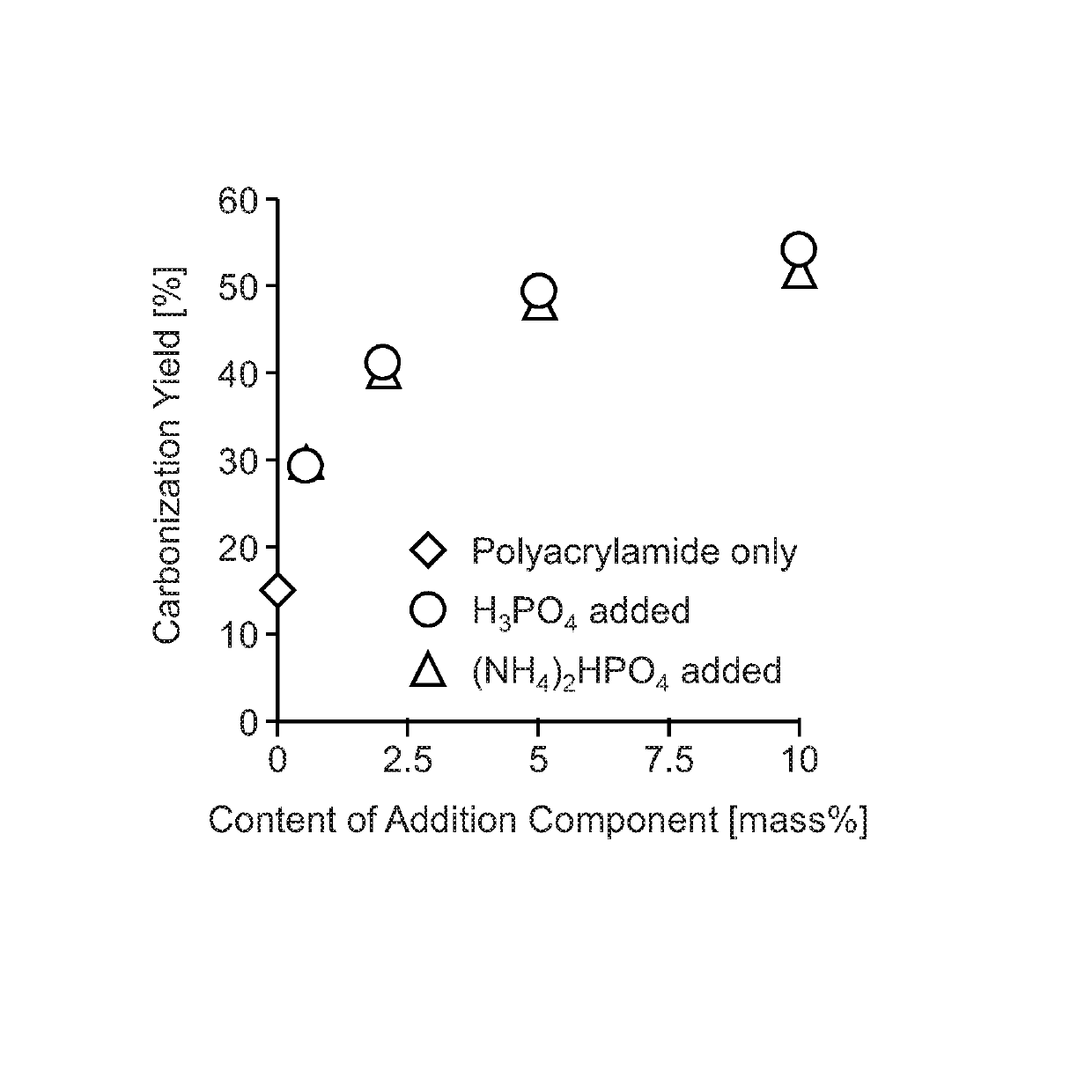

a carbon material and precursor technology, applied in the direction of carbon preparation/purification, etc., can solve the problem of low carbonization yield of carbon material precursor prepared using polyacrylamide, and achieve high carbonization yield, high carbonization yield, and enhanced carbonization yield of carbon material precursor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

synthetic example 1

[0032]Dissolved into 190 ml of water was 8.52 g (120 mmol) of acrylamide (manufactured by Wako Pure Chemical Industries, Ltd. and for electrophoresis). After that, 366 mg (1.20 mmol) of 4,4′-azobis(4-cyanovaleric acid) was added as a polymerization initiator, followed by radical polymerization for 3 hours at 70° C. The obtained aqueous solution was introduced into methanol, followed by precipitation of polyacrylamide. Polyacrylamide was collected and subjected to vacuum drying.

example 1

[0033]Polyacrylamide obtained in Synthetic Example 1 was dissolved into water so as to be a concentration of 10% by mass. Phosphoric acid was added to the obtained polyacrylamide aqueous solution so that the content of phosphoric acid was 2% by mass relative to 100% by mass of carbon material precursor. Freeze drying was performed using the obtained phosphoric acid-containing polyacrylamide aqueous solution. As a result, a carbon material precursor containing polyacrylamide and phosphoric acid was obtained.

example 2

[0034]A carbon material precursor was obtained in the same manner as that in Example 1 except that diammonium hydrogen phosphate was used instead of the phosphoric acid. Note that the content of diammonium hydrogen phosphate was 2% by mass relative to 100% by mass of carbon material precursor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| mol % | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com