Template-free synthesis of tannic acid-based porous polymer and derived carbon material thereof under mild condition

A technology of porous polymer and template-free method, which is applied in the preparation/purification of carbon, and can solve problems such as energy consumption, harshness, and complicated steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1 A template-free method for preparing a tannic acid-based porous polymer precursor under mild conditions

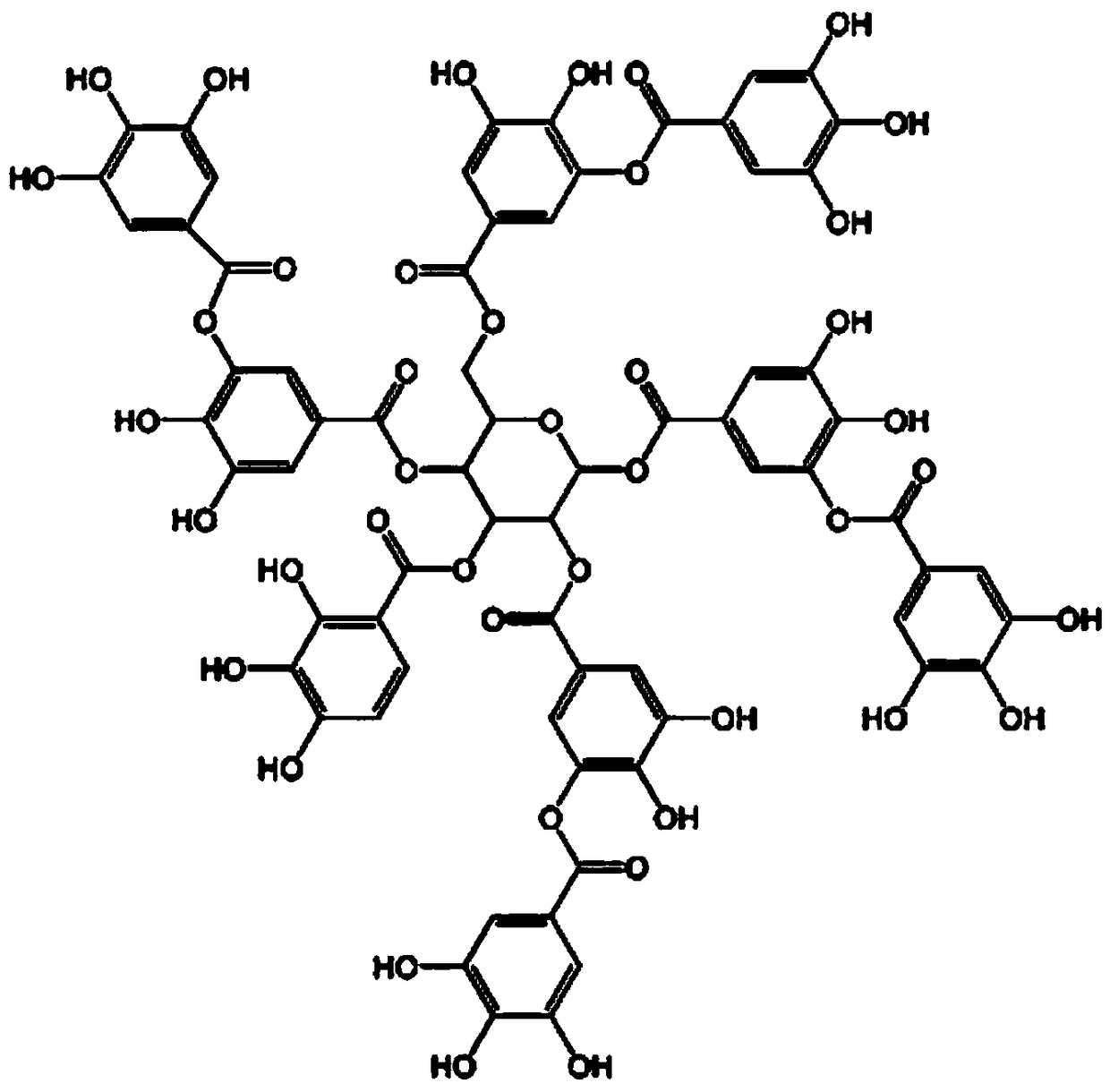

[0027] (1) The synthesis process of tannic acid-based porous polymer is shown as follows:

[0028]

[0029] (2) Synthesis method: Synthesis of tannic acid-based porous polymer precursor

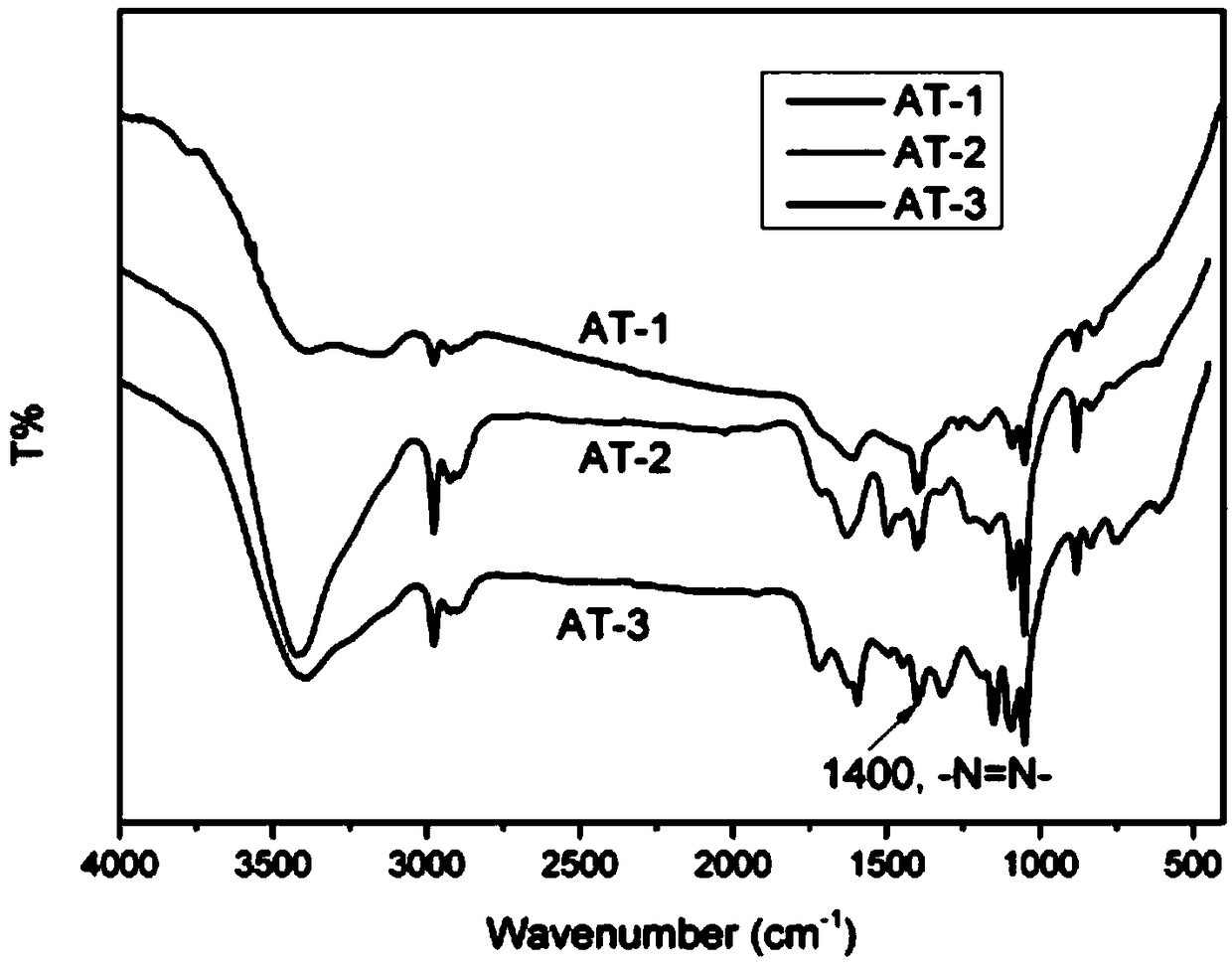

[0030] 1) Add 0.83g of 4,4'-diaminobiphenyl, 2.1mL of concentrated hydrochloric acid and 300mL of deionized water into a round-bottomed flask, and use an ice bath to control the temperature between 0 and 5°C. After stirring for 15 minutes, add 90mL An aqueous solution containing 9.3 mmol of sodium nitrite and continued stirring to completely convert the amino group into a diazonium salt.

[0031] 2) Keep the ice bath state, after neutralizing with sodium carbonate solution, add 0.78g tannic acid and 90ml 0.1M sodium carbonate aqueous solution. After 12 hours, the resulting solid precipitate was separated by filtration, washed with deionized water, methanol, tetrahydr...

Embodiment 2

[0038] The preparation of embodiment 2 porous carbon materials

[0039] (1) The tannic acid-based polymers AT-1, AT-2 and AT-3 prepared in Example 1 are calcined in a tube furnace respectively, at a heating rate of 5°C / min to 900°C, and kept After 3 hours, the temperature was naturally lowered to obtain products—tannic acid-based porous carbon materials, which were named AT-1-900, AT-2-900 and AT-3-900, respectively.

[0040] (2) The surface area and pore size distribution were measured by nitrogen adsorption and desorption at 77.3 K using a Quantachrome ASIQ-C research-grade high-performance fully automatic gas adsorption analysis system. Before analysis, the samples were vacuumed (10 -5 bar) at 200° C. for 15 hours. And using the same degassing procedure, carbon dioxide adsorption-desorption isotherms were measured at 273K.

[0041] The result is as Figure 5 , Image 6 As shown, the N of tannic acid-based porous polymer and tannic acid-based porous carbon material at 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com