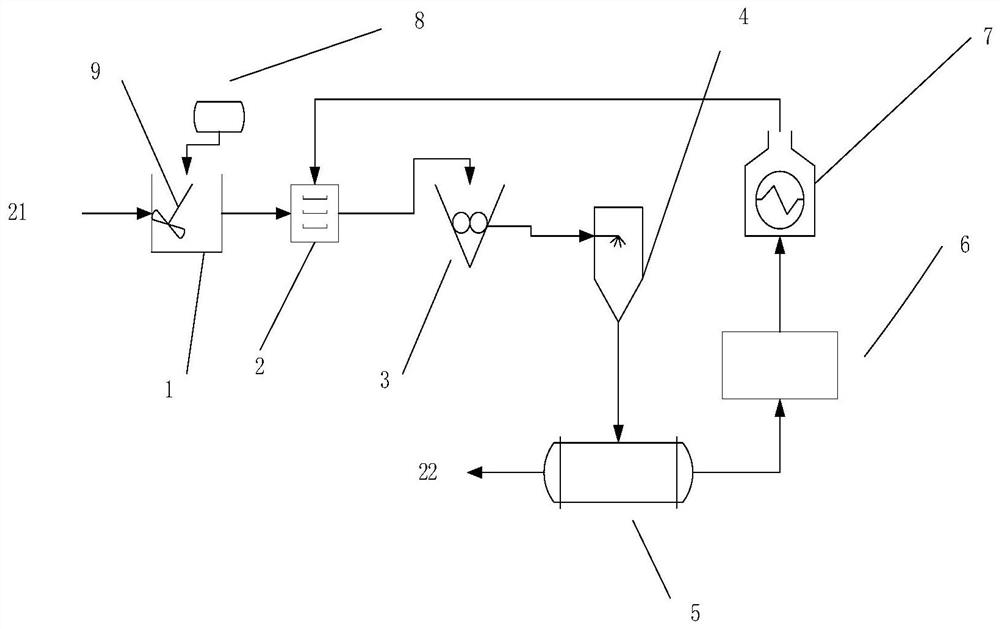

Novel biomass pyrolysis carbonization system and method

A biomass pyrolysis and biomass technology, applied in the fields of biofuels, special forms of dry distillation, petroleum industry, etc., can solve the problems of non-recovery of heat energy, incineration, pollution of the atmosphere, etc., to save costs, reduce heat loss, and save energy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The biomass 21 used is wheat straw, the wheat straw is put into the pretreatment pool 1, and the first dosing device 8 is used to add Na 2 CO 3 Solution, add medicine while spiral stirring, adjust the pH to 8.50, and then stay for 8 hours; use the conveyor belt to enter the drier 2 after soaking the wheat straw, set the drying temperature to 100 ° C, dry for 5 hours, and the moisture content of the dried wheat straw will drop to 8%; transfer the dried wheat straw to the crushing device 3, stir and crush for 30 minutes; then send the crushed wheat straw to the granulation device 4, the diameter of the granulation is 20mm; after granulation, the material is sent to the carbonization furnace 5 , the initial heating rate of the carbonization furnace 5 was 20°C / min, and after the temperature was raised to 400°C, the carbonization was carried out for 15 minutes to obtain the crude product of the carbonization product; After the combustible gas is collected, it enters the flu...

Embodiment 2

[0044] The biomass 21 used is peanut shells, the peanut shells are put into the pretreatment pool 1, and the first dosing device 8 is used to add Na 2 CO 3 Solution, add medicine while spiral stirring, adjust the pH to 9.50, and then stay for 12h; use the conveyor belt to enter the drier 2 after soaking the peanut shells, set the drying temperature to 150°C, dry for 3h, and the moisture content of the dried peanut shells will drop to 5%; send the dried peanut shells to the crushing device 3, stir and crush for 60 minutes; then send the crushed peanut shells to the granulation device 4, and the granulation diameter is 10mm; after granulation, the material is sent to the carbonization furnace 5 , the initial heating rate of the carbonization furnace 5 is 50°C / min. After the temperature is raised to 600°C, the carbonization is carried out for 30 minutes to obtain the crude product of the carbonization product; the pyrolysis gas generated during the carbonization process is mainly...

Embodiment 3

[0046]The biomass 21 used is corn stalks, the corn stalks are put into the pretreatment pool 1, and the first dosing device 8 is used to add K 2 CO 3 Solution, add medicine while spiral stirring, adjust the pH to 9.50, and then stay for 12 hours; use the conveyor belt to enter the drier 2 after soaking the corn stalks, set the drying temperature to 150 ° C, dry for 4 hours, and the moisture content of the dried corn stalks will drop to 7%; transfer the dried corn stalks to the crushing device, stir and crush them for 60 minutes; then send the crushed corn stalks to the granulation device with a granulation diameter of 20mm; after granulation, transfer the material to the carbonization furnace 5 for carbonization The initial heating rate of furnace 5 was 50°C / min. After the temperature was raised to 600°C, carbonization was carried out for 30 minutes to obtain the crude product of the carbonization product; the pyrolysis gas generated during the carbonization process was mainly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com