Fire-resistant fiber, method for producing same, and method for producing carbon fiber

A manufacturing method and technology of carbon fiber, which is applied in the field of refractory chemical fiber, can solve the problems of low density and G/D value of refractory chemical fiber bundles, reduced carbonization yield, low productivity, etc., and achieve the effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

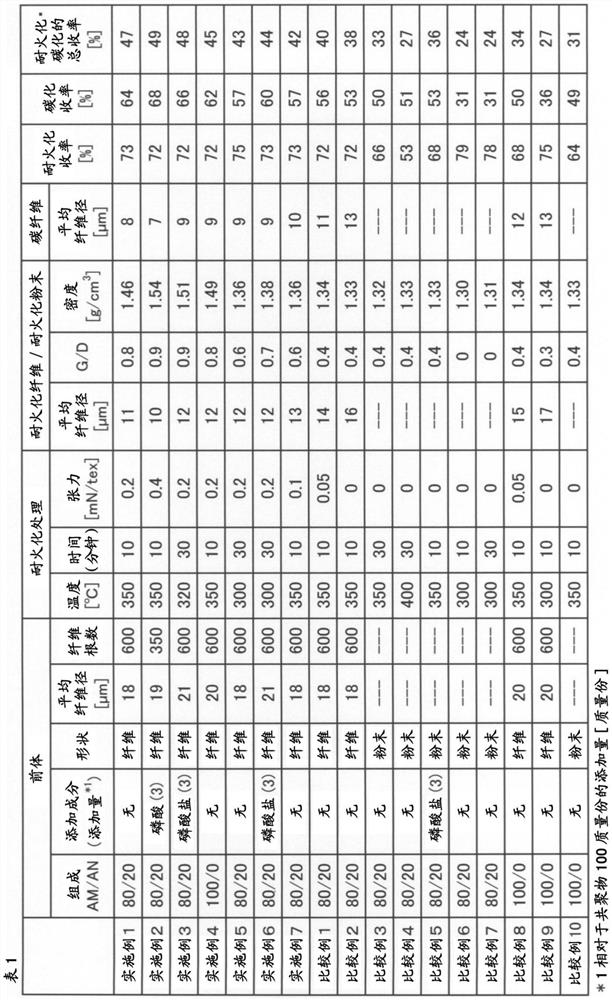

Examples

manufacture example 1

[0072] The AM / AN copolymer (AM / AN=80mol% / 20mol%) powder (p-1) obtained in Preparation Example 1 was dissolved in ion-exchanged water, and the obtained aqueous solution was used for dry spinning to produce an acrylamide-based polymer Fiber (f-1).

[0073]

[0074] 100 obtained acrylamide-based polymer fibers (f-1) were bundled to produce an acrylamide-based polymer fiber bundle, the mass of the fiber bundle was measured, and the fineness of the fiber bundle was calculated by the following formula:

[0075] Fiber bundle fineness [tex] = fiber bundle mass [g] / fiber length [m]×1000[m]

[0076] The fineness of the single fibers constituting the fiber bundle (the fineness of the acrylamide-based polymer fiber (f-1)) was determined to be 0.33 tex / fiber.

[0077]

[0078] The density of the acrylamide-based polymer fiber bundle was measured using a dry-type automatic density meter ("Akupick II1340" manufactured by Micromeritics Co., Ltd.), and the average fiber diameter of the si...

manufacture example 2

[0084]Dissolve the AM / AN copolymer (AM / AN=80mol% / 20mol%) powder (p-1) obtained in Preparation Example 1 in ion-exchanged water, and add 100 parts by mass of the AM / AN copolymer to the obtained aqueous solution 3 parts by mass of phosphoric acid to completely dissolve it. Dry spinning was performed using the obtained aqueous solution to produce acrylamide-based polymer fibers (f-2). The fineness, average fiber diameter, and density of the acrylamide-based polymer fiber (f-2) were obtained in the same manner as in Production Example 1, and the fineness was 0.38 tex / fiber, the average fiber diameter was 19 μm, and the density was 1.26 g / cm 3 .

manufacture example 3

[0086] An acrylamide-based polymer fiber (f-3) was produced in the same manner as in Production Example 2, except that 3 parts by mass of diammonium hydrogenphosphate was added instead of phosphoric acid with respect to 100 parts by mass of the AM / AN copolymer. The fineness, average fiber diameter, and density of the acrylamide-based polymer fiber (f-3) were obtained in the same manner as in Production Example 1, and the fineness was 0.46 tex / fiber, the average fiber diameter was 21 μm, and the density was 1.26 g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com