Preparation method for boron-containing phenolic resin microsphere and carbon microsphere

A technology of boron phenolic resin and microspheres, which is applied in the field of preparation of boron-containing phenolic resin microspheres and carbon microspheres, can solve the problems of deformation of carbonized products, low carbonization yield of microspheres, and insufficient heat resistance of microspheres, and achieve Effects of increasing carbonization yield and increasing reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The invention provides a method for preparing boron-containing phenolic resin microspheres. Firstly, an organoboron compound and an aldehyde are subjected to a prepolymerization reaction under acidic conditions, and then a polycondensation reaction is performed with an aldehyde and a curing agent under conditions of an alkaline catalyst and a solvent. , and finally placed in a high-pressure reactor to continue polycondensation and cross-linking to obtain boron-containing phenolic resin microspheres.

[0026] From the above description, it can be seen that the beneficial effect of the present invention is that the boron-containing phenolic resin microspheres are prepared by using the organoboron compound as the phenol source through a four-step method, which effectively increases the reactivity of the organoboron compound, the dispersibility and particle size of the microspheres It is well controlled and the carbonization yield of microspheres is significantly improved. ...

Embodiment 1

[0045] 1) Add 10g of triphenyl borate, 4g of 37% aqueous formaldehyde solution and 0.05g of oxalic acid into the reaction kettle, heat up to 90°C and react for 30min;

[0046] 2) Add 15 g of ammonia water, 400 mL of water and 15 g of 37% formaldehyde solution to the reactant obtained in step 1), and stir for 3 h;

[0047] 3) Add 5 g of hexamethylenetetramine to the reactant obtained in step 2), and stir for 12 h;

[0048] 4) Put the above solution into an autoclave and react at a temperature of 100°C for 48 hours;

[0049] 5) The product is washed with water and dried in vacuum to obtain boron-containing phenolic resin microspheres.

[0050] Carbonization: Place the phenolic resin microspheres in a carbonization furnace, raise the temperature to 800°C at a rate of 5°C / min under a nitrogen atmosphere, and keep it for 3 hours. After cooling down, phenolic resin-based carbon microspheres are obtained, with a yield of 79% %.

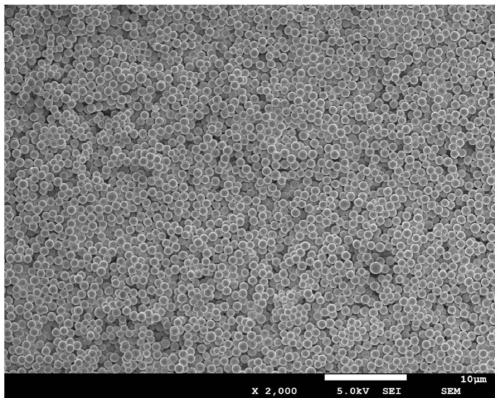

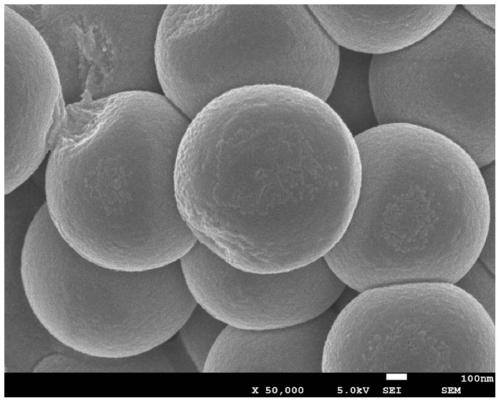

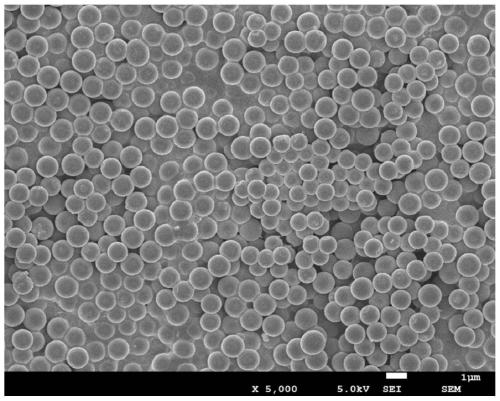

[0051] see figure 1 , is the SEM image of the prep...

Embodiment 2

[0053] 1) Add 10g of triphenyl borate, 10g of 37% formaldehyde solution and 0.06g of oxalic acid into the reaction kettle, heat up to 100°C and react for 10min;

[0054] 2) Add 15 g of ammonia water, 400 mL of water and 15 g of 37% formaldehyde solution to the reactant obtained in step 1), and stir for 3 h;

[0055] 3) Add 5 g of hexamethylenetetramine to the reactant obtained in step 2), and stir for 12 h;

[0056] 4) Put the above solution into an autoclave and react at a temperature of 100°C for 48 hours;

[0057] 5) The product is washed with water and dried in vacuum to obtain boron-containing phenolic resin microspheres.

[0058] Carbonization: Place the phenolic resin microspheres in a carbonization furnace, raise the temperature to 800°C at a rate of 5°C / min under a nitrogen atmosphere, and keep it for 3 hours. After cooling down, carbon microspheres are obtained with a yield of 78%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com