A kind of biomass porous activated carbon and its preparation method and application as electric double layer capacitor electrode material

A technology of porous activated carbon and biomass raw materials, applied in hybrid capacitor electrodes, chemical instruments and methods, carbon compounds, etc., can solve the problems of high-cost inorganic templates, non-renewable raw materials, complicated preparation steps, etc., and achieve uniform pore size and economic value. High efficiency, uniform response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Activated carbon preparation:

[0037] (1) Carbon source preparation: choose camphor tree branches as the carbon source of the precursor, peel off the skin, take the woody main part, wash it with distilled water three times, dry it in an oven at 120°C for 24 hours, and then pass it through a pulverizer (6000r / min , the time is 5min) it is pulverized, and sieves out 325 purpose camphor tree powder.

[0038] (2) Activation: Weigh 30g of the carbon source in (1) and place it in a tube furnace, raise the temperature to 900°C at 10°C / min under an argon atmosphere, and perform high-temperature activation treatment under a water vapor atmosphere of 1L / min 2h, and then use argon gas atmosphere to lower the temperature.

[0039] (3) Washing: Wash the product in (2) once with 2mol / L HCl and twice with water to neutrality, then filter and dry in vacuum at 80°C for 8 hours. The specific surface area of the obtained activated carbon is 1387m 2 / g, the pore size is mainly concent...

Embodiment 2

[0041] Activated carbon preparation:

[0042] (1) Carbon source preparation: choose camphor tree branches as the carbon source of the precursor, peel off the skin, take the woody main part, wash it with distilled water three times, dry it in an oven at 120°C for 24 hours, and then pass it through a pulverizer (6000r / min , the time is 5min) it is pulverized, and sieves out 325 purpose camphor tree powder.

[0043] (2) Activation: Weigh 30g of the carbon source in (1) and place it in a tube furnace, raise the temperature to 900°C at 10°C / min under an argon atmosphere, and perform high-temperature activation treatment for 2 hours under a carbon dioxide atmosphere of 1L / min , and then use argon gas atmosphere to lower the temperature.

[0044] (3) Washing: The product in (2) was washed once with 2mol / L HCl and washed twice with water to neutrality, then filtered, and vacuum-dried at 80°C for 8 hours. The specific surface area of the obtained activated carbon was 990m 2 / g, the...

Embodiment 3

[0046] Activated carbon preparation:

[0047] (1) Carbon source preparation: choose camphor tree branches as the carbon source of the precursor, peel off the skin, take the woody main part, wash it with distilled water three times, dry it in an oven at 120°C for 24 hours, and then pass it through a pulverizer (6000r / min , the time is 5min) it is pulverized, and sieves out 325 purpose camphor tree powder.

[0048] (2) Activation: Weigh 30g of the carbon source in (1) and place it in a tube furnace. 1:1) for high-temperature activation treatment for 2 hours, and then use argon gas atmosphere to lower the temperature.

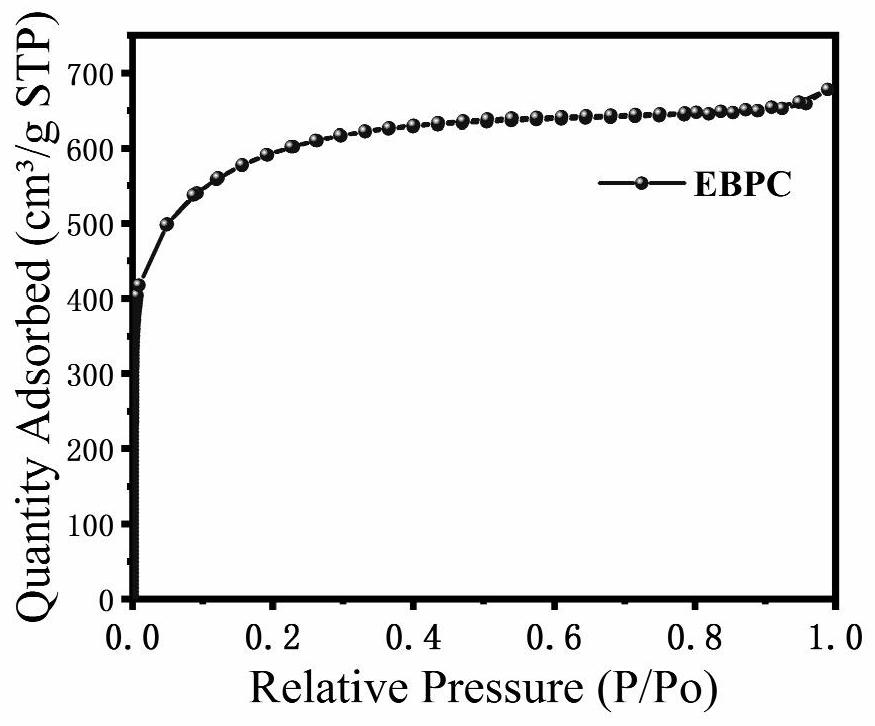

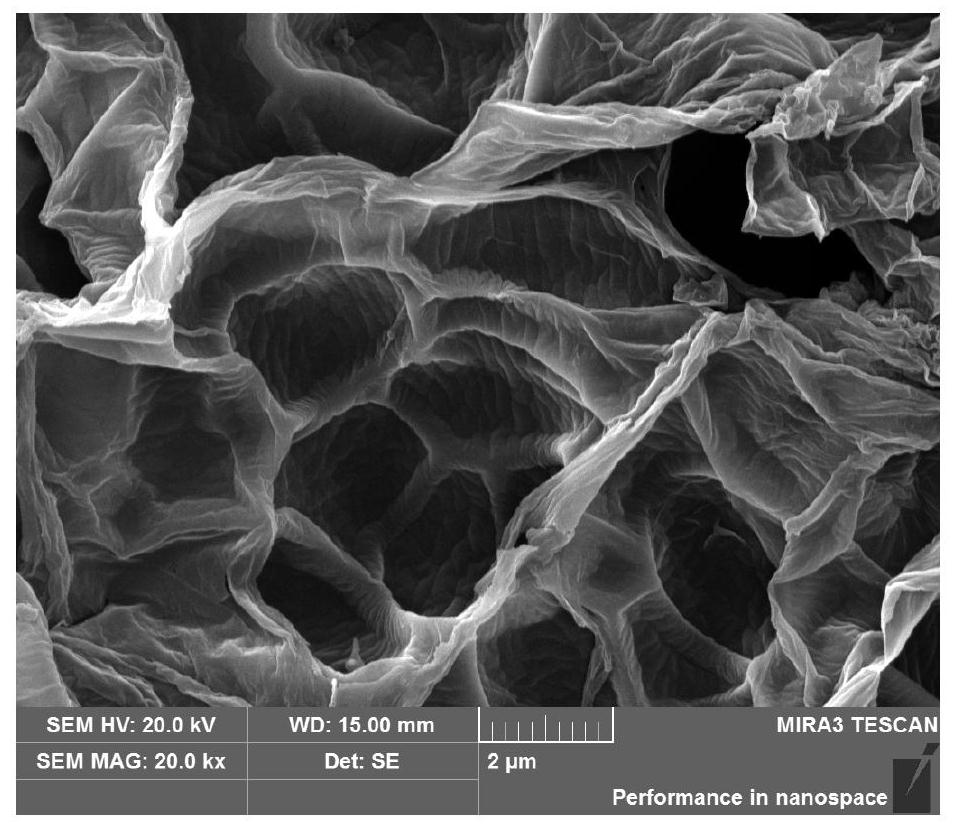

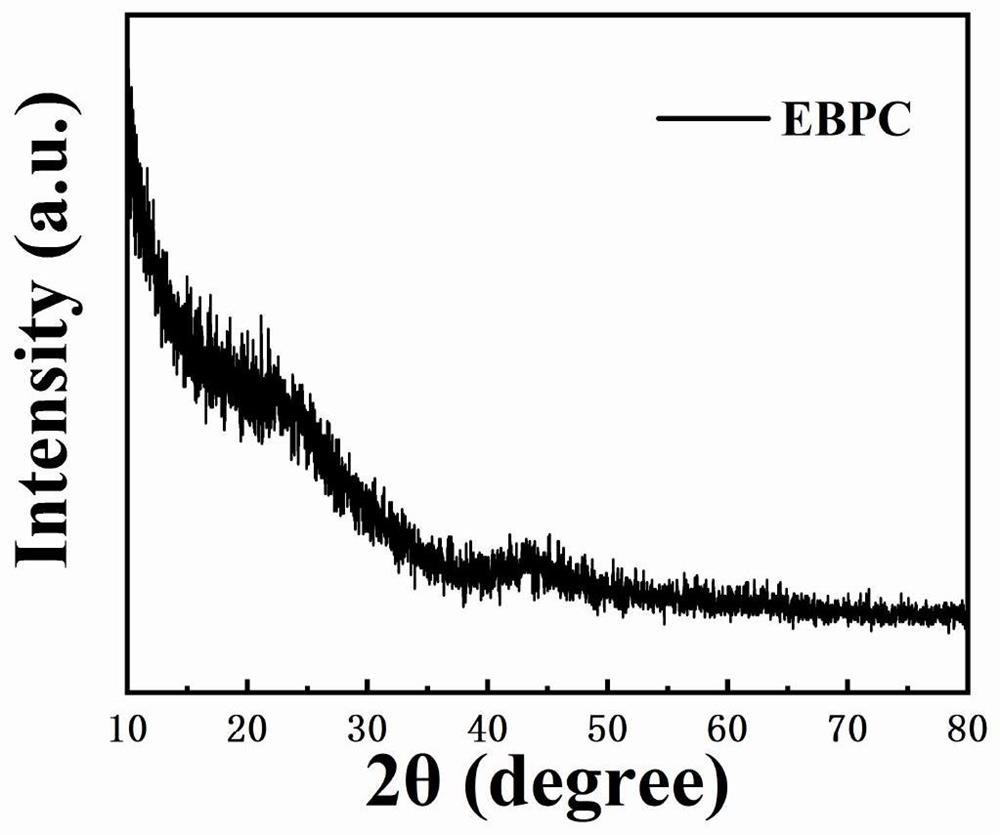

[0049] (3) Washing: Wash the product in (2) once with 2mol / L HCl and twice with water to neutrality, then filter and dry in vacuum at 80°C for 8 hours. The specific surface area of the obtained activated carbon is 1890m 2 / g, the pore size is mainly concentrated in the range of 2-4nm ( figure 1 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com