Hard carbon material, preparation method thereof, and sodium ion battery

A hard carbon, hard sheet technology, applied in battery electrodes, secondary batteries, circuits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The invention provides a kind of preparation method of hard carbon material, comprises the following steps:

[0035] (1) After mixing the coal-based material and the hard carbon precursor, press it to obtain a hard sheet;

[0036] The hard carbon precursor is carbohydrate and / or gelatin;

[0037] (2) Carrying out high-temperature carbonization of the hard sheet obtained in the step (1) to obtain a hard carbon material.

[0038] In the invention, the coal-based material and the hard carbon precursor are mixed and pressed to obtain a hard sheet.

[0039] In the present invention, the coal-based material preferably includes at least one of anthracite, bituminous coal and lignite, more preferably bituminous coal and / or lignite. In the present invention, the bituminous coal and / or lignite are cheaper among coal-based materials, and are used as raw materials for preparing hard carbon materials.

[0040] In the present invention, the hard carbon precursor is carbohydrate an...

Embodiment 1

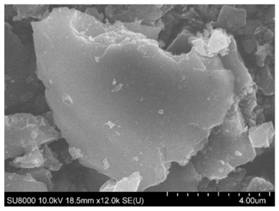

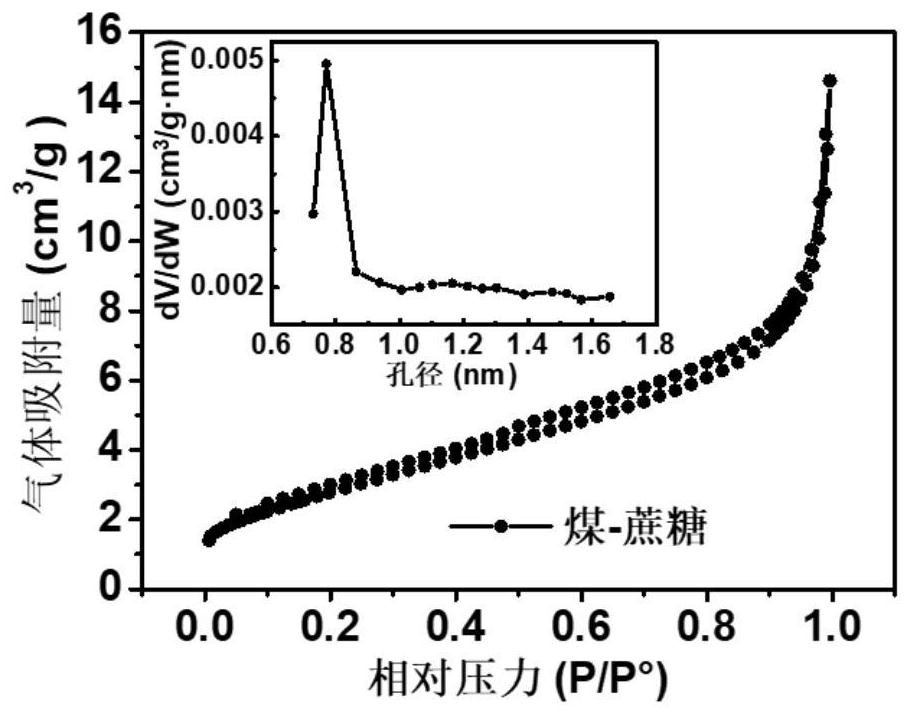

[0064] After mixing 14g lignite with 6g sucrose (the mass ratio of coal-based material and hard carbon precursor is 7:3), put it into a ball mill and mill it with the number of revolutions of 400r / min, and ball mill for 4h (at this time, the particle size of lignite and sucrose is equal to in the range of 1 to 10 μm); take out the powder, pour it into the mold of the tablet press, and keep it under a pressure of 15MPa for 5 minutes to obtain a hard tablet, which is taken out. The digital photo of the hard tablet is as follows: figure 1 As shown in Figure 1, it can be seen that the hard tablet obtained after being pressed by the step-down tablet machine is round, with a relatively smooth surface and no defects.

[0065] The hard sheet is placed in a tube furnace for high-temperature carbonization in a nitrogen atmosphere, first raised to 400°C at a rate of 2°C / min, and kept for 2 hours; then raised to 1200°C at a rate of 5°C / min, Insulate for 2 hours, and finally cool down to r...

Embodiment 2

[0088] After mixing 5g of bituminous coal and 5g of glucose, put it into a ball mill and mill at a speed of 400r / min for 3 hours (at this time, the particle sizes of bituminous coal and glucose are both in the range of 1-10μm); take out the powder and pour it into the mold of the tablet press In 20MPa pressure for 10min, a hard sheet was obtained, and the hard sheet was placed in a tube furnace for high-temperature carbonization in a nitrogen atmosphere, first raised to 500°C at a rate of 3°C / min, and kept for 0.5h. Then, the temperature was raised to 800°C at a heating rate of 4°C / min, kept for 2 hours, and finally cooled down to room temperature naturally. After the product was boiled in 3M hydrochloric acid for 4 hours, it was washed with deionized water for 4 hours until the pH was 7, and the final hard carbon material was obtained. (The mass ratio of coal-based material to hard carbon precursor is 1:1)

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Spacing | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com