Patents

Literature

62results about How to "Increase sodium storage capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

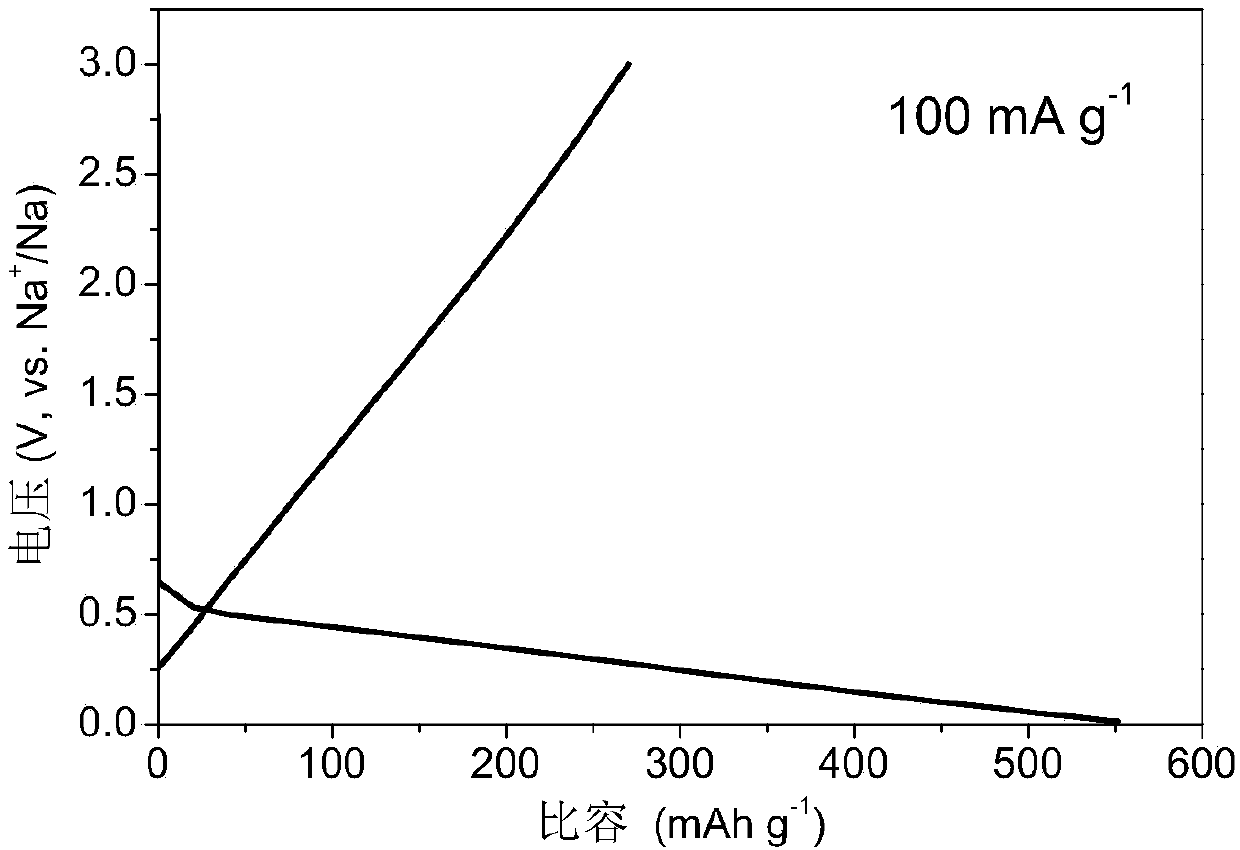

Molybdenum selenide based composite cathode material for sodium-ion battery and preparation method thereof

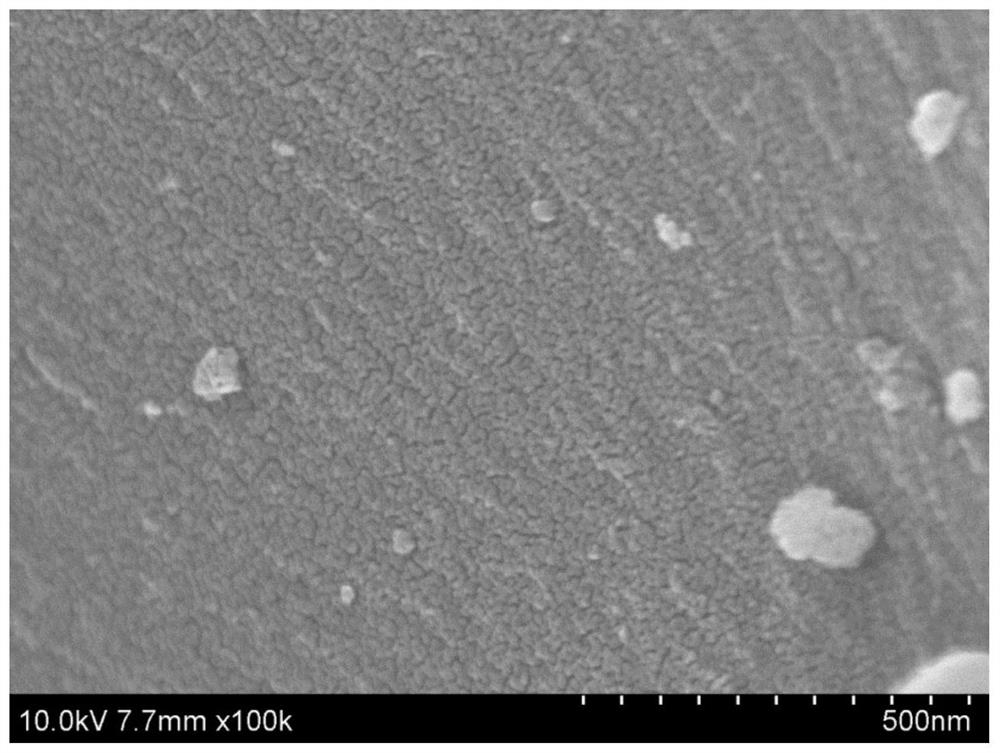

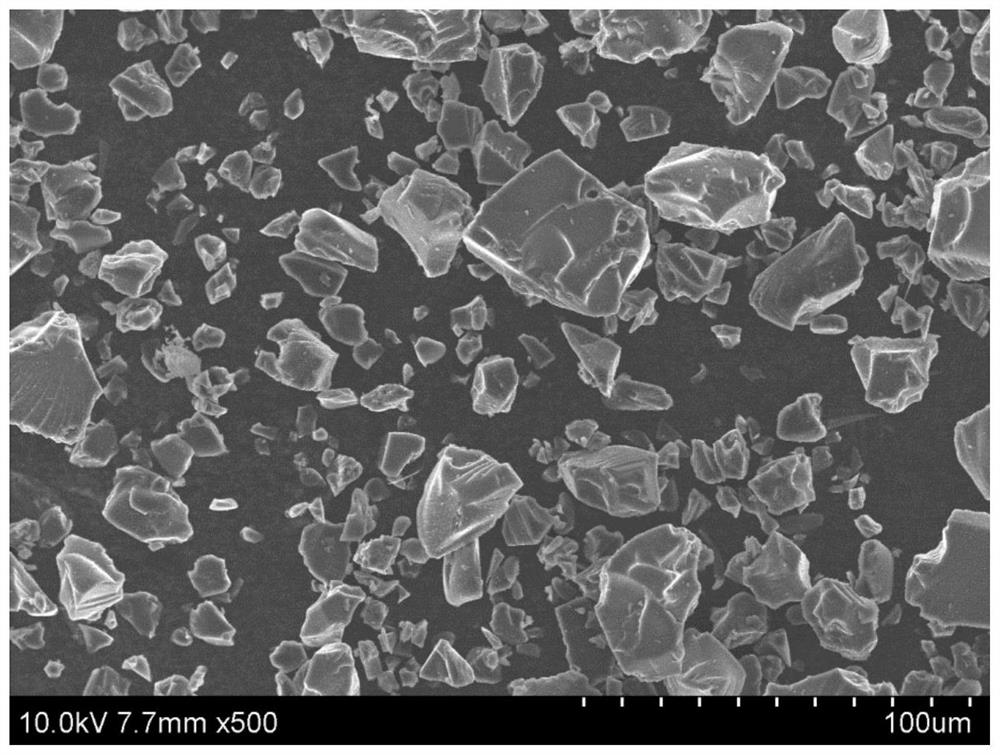

InactiveCN105006570ASmall sizeIncrease sodium storage capacityMaterial nanotechnologyCell electrodesIonCarbon source

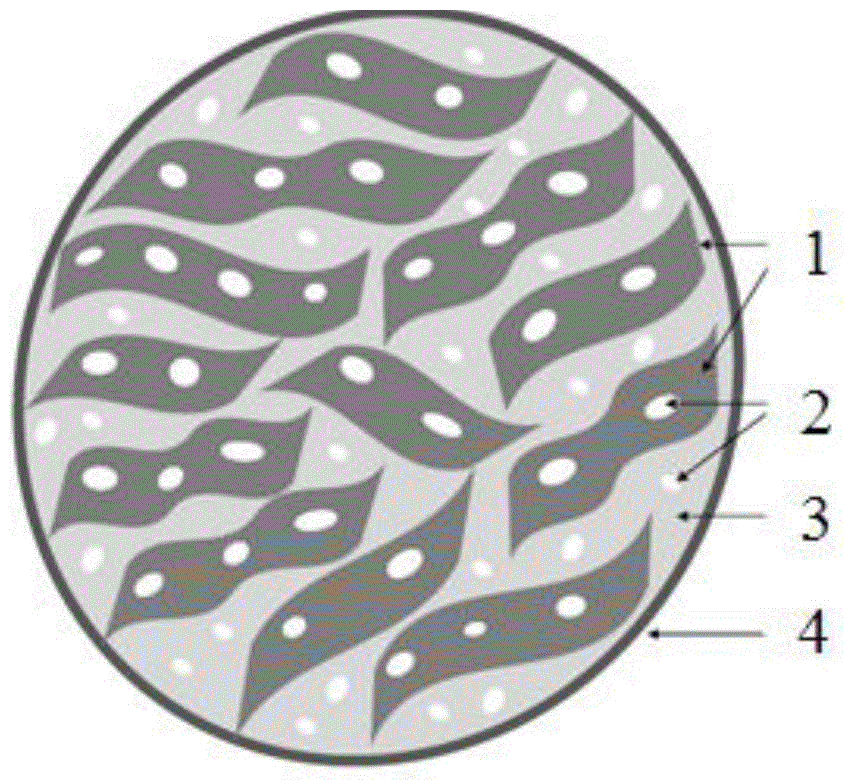

The invention discloses a molybdenum selenide based composite cathode material for a sodium-ion battery and a preparation method thereof. The cathode material is a composite material which is of a three-dimensional net structure and is formed by molybdenum selenide evenly growing on the surface of hollow carbon nanofiber. The preparation method comprises the steps of adopting a hydrothermal method to synthesize a precursor of the hollow carbon nanofiber, using the precursor of the hollow carbon nanofiber as a selenium source, a carbon source and a template, evenly dispersing the precursor in the mixed solution prepared by ethyl alcohol and water, adding a reducing agent and a molybdenum source into the mixed solution, performing hydrothermal reaction, cooling and drying a product to be at the room temperature so as to obtain the precursor of a molybdenum selenide / hollow carbon nanofiber composite material, and performing high-temperature calcination processing to obtain the molybdenum selenide / hollow carbon nanofiber composite material. The preparation method is simple, reliable, good in process repeatability and in operability and low in cost and is suitable for industrial production. The molybdenum selenide based composite cathode material is used for the sodium-ion battery and has good electrochemical performance.

Owner:CENT SOUTH UNIV

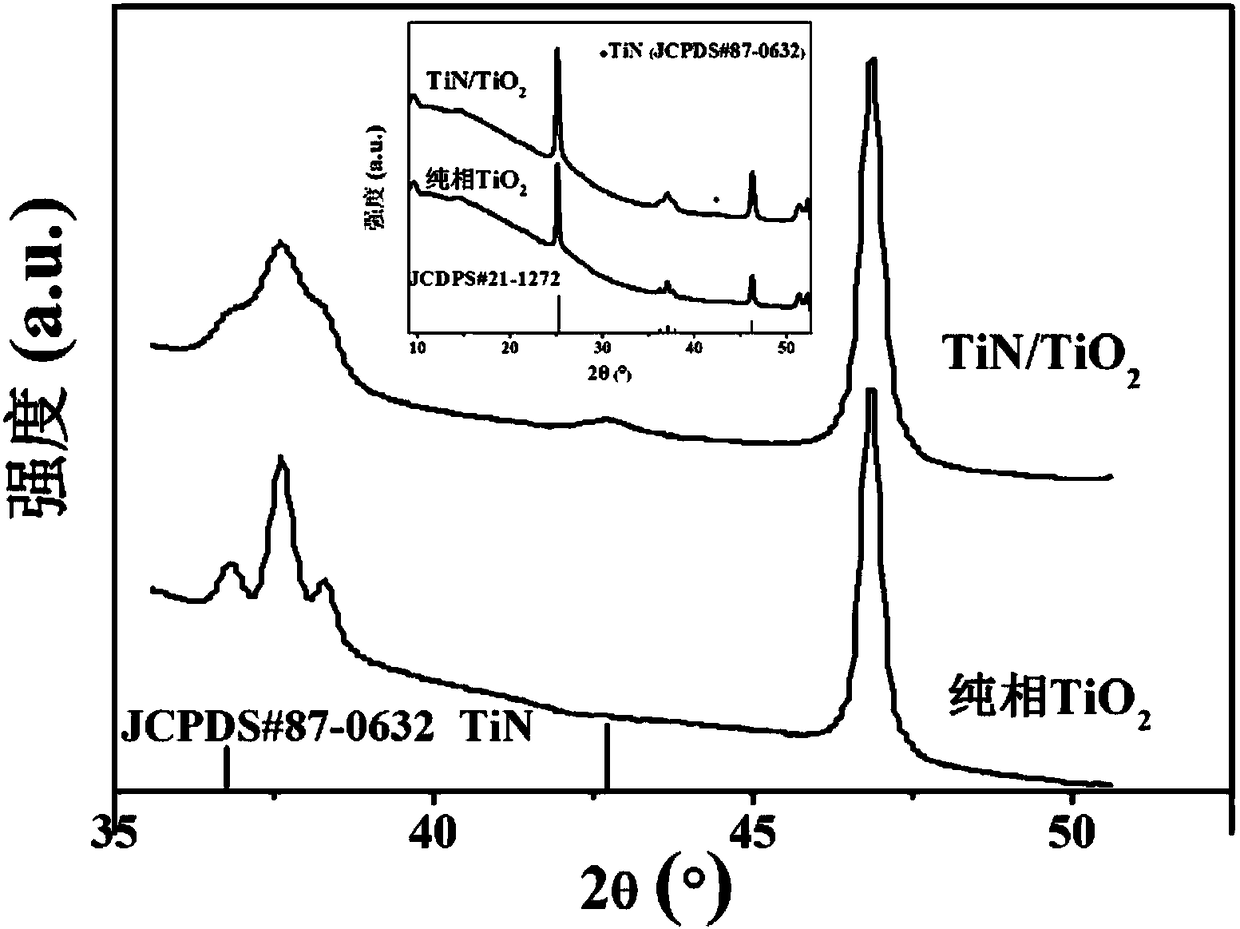

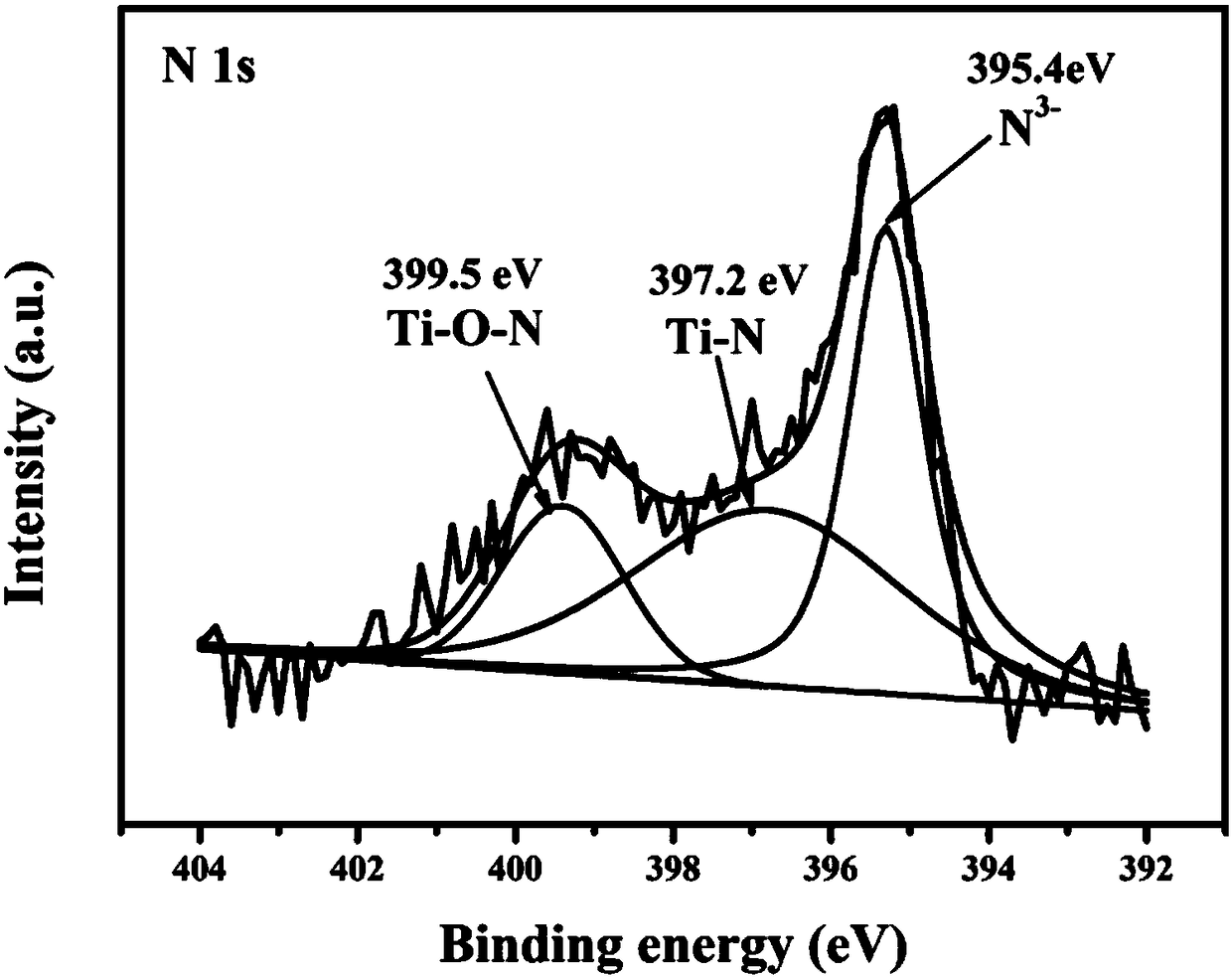

Method for modifying sodium ion battery negative electrode material titanium dioxide

ActiveCN108470903AImprove electronic conductivityImprove sodium storage capacity and rate performanceCell electrodesSolventIon

The invention provides a method for modifying a sodium ion battery negative electrode material titanium dioxide, wherein the method comprises the steps : mixing a titanium source and a structure-directing agent to form a titanium-containing solution, and carrying out a hydrothermal reaction to prepare a nano titanium dioxide precursor, wherein the molar ratio of the titanium source to the structure-directing agent is 1:(0.1-1), and the ratio relationship between the titanium source and a solvent is (0. 01-0.5) mol:1 L; and mixing the obtained nano titanium dioxide precursor with a solid nitrogen source with the mass ratio of the titanium source to the nitrogen source of 1:(0.1-10), stirring and grinding, and calcining the mixture in protective gas to obtain the sodium ion battery negativeelectrode material titanium dioxide. In the method, cladding of a titanium nitride thin film can significantly enhance the electronic conductivity, so the sodium storage capacity and the rate performance of the titanium dioxide material are improved; at the same time, with doping of the nitrogen element, the conductivity of titanium dioxide can be further effectively improved, so excellent electrochemical performance is showed.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

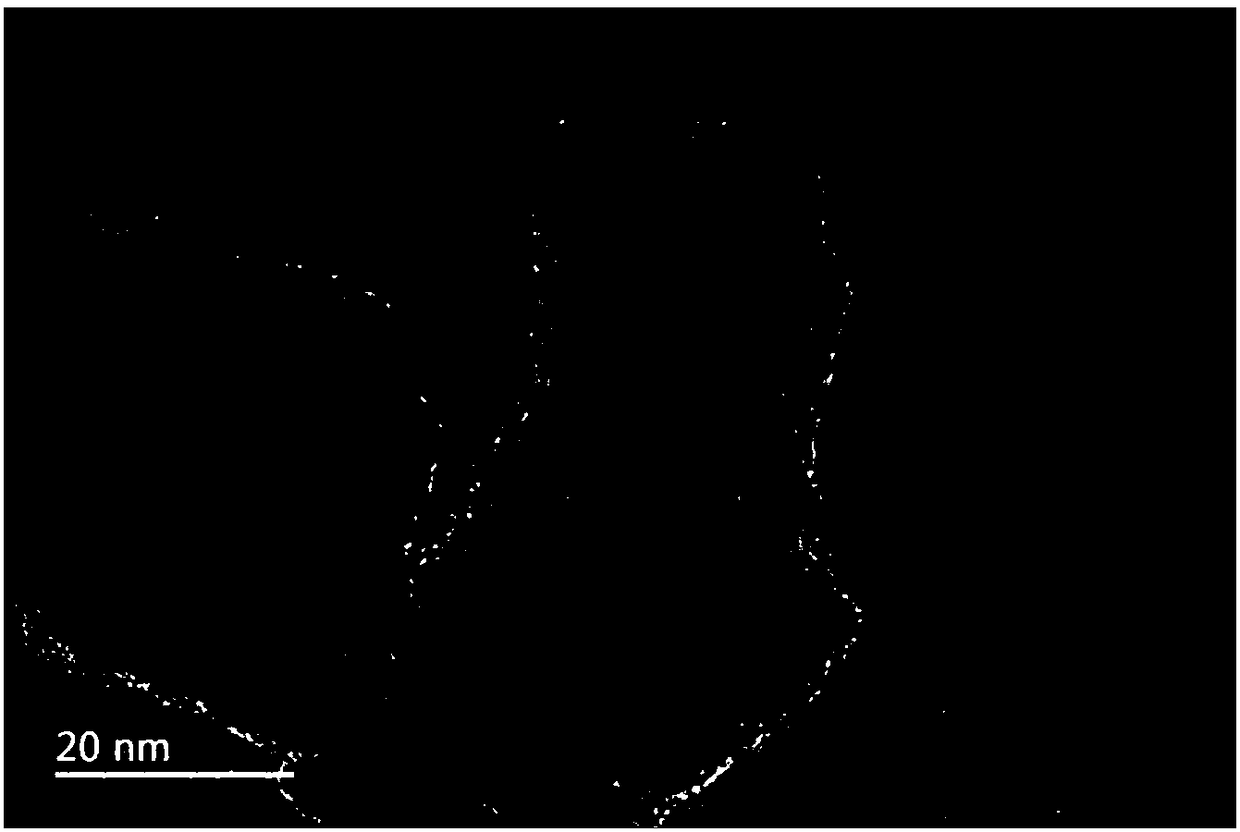

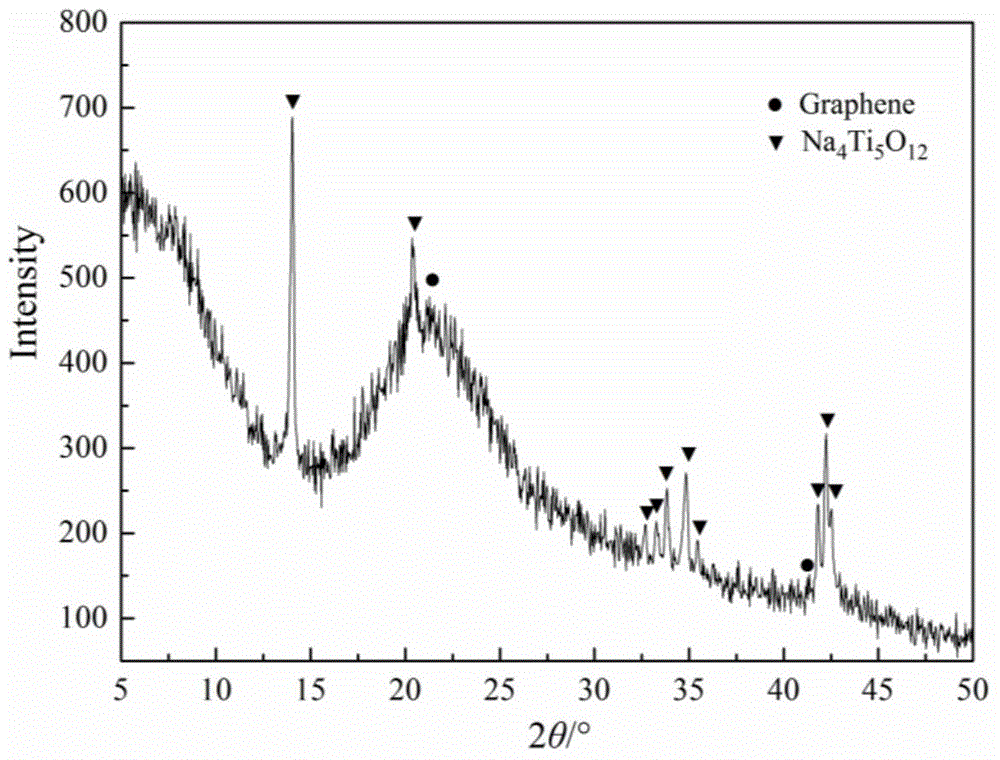

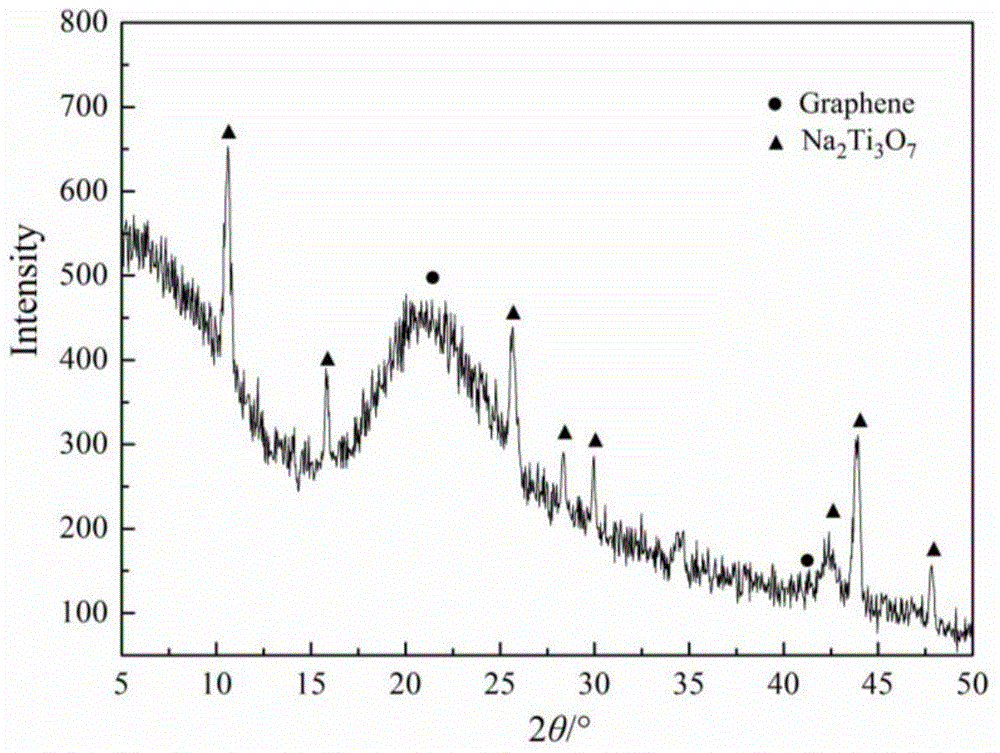

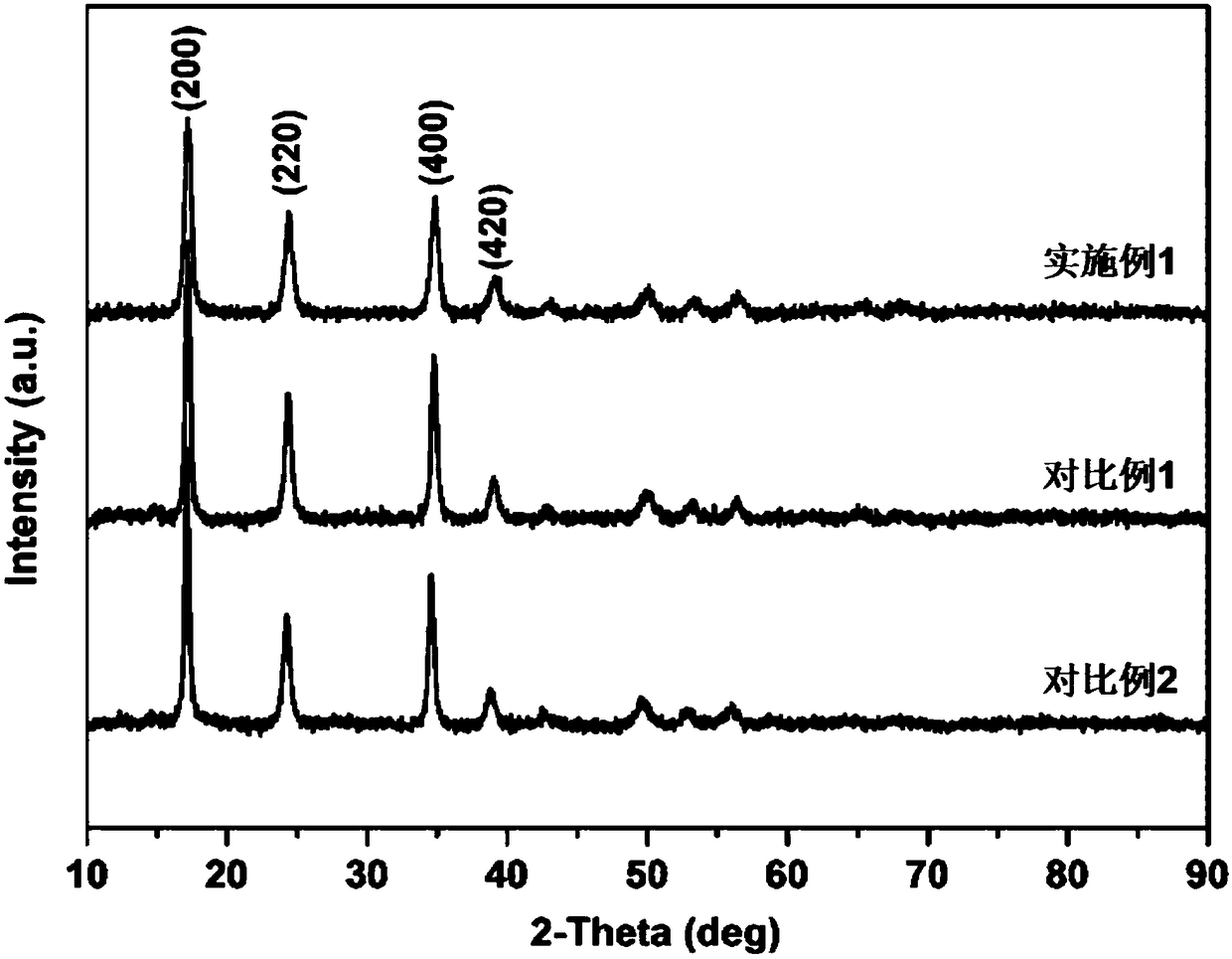

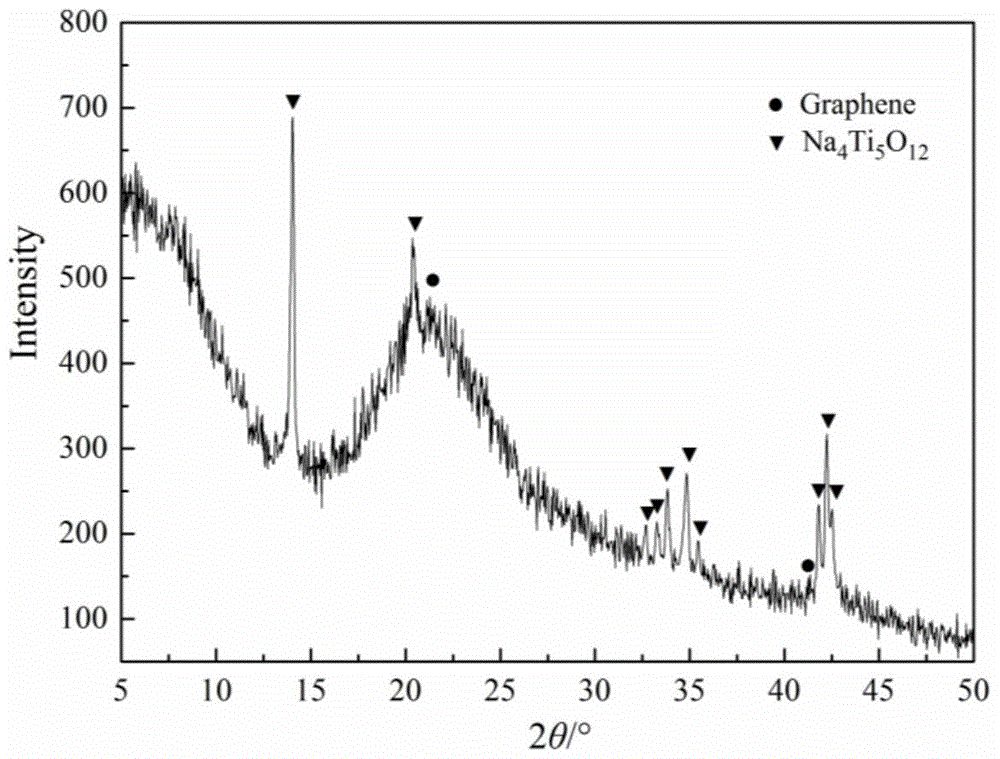

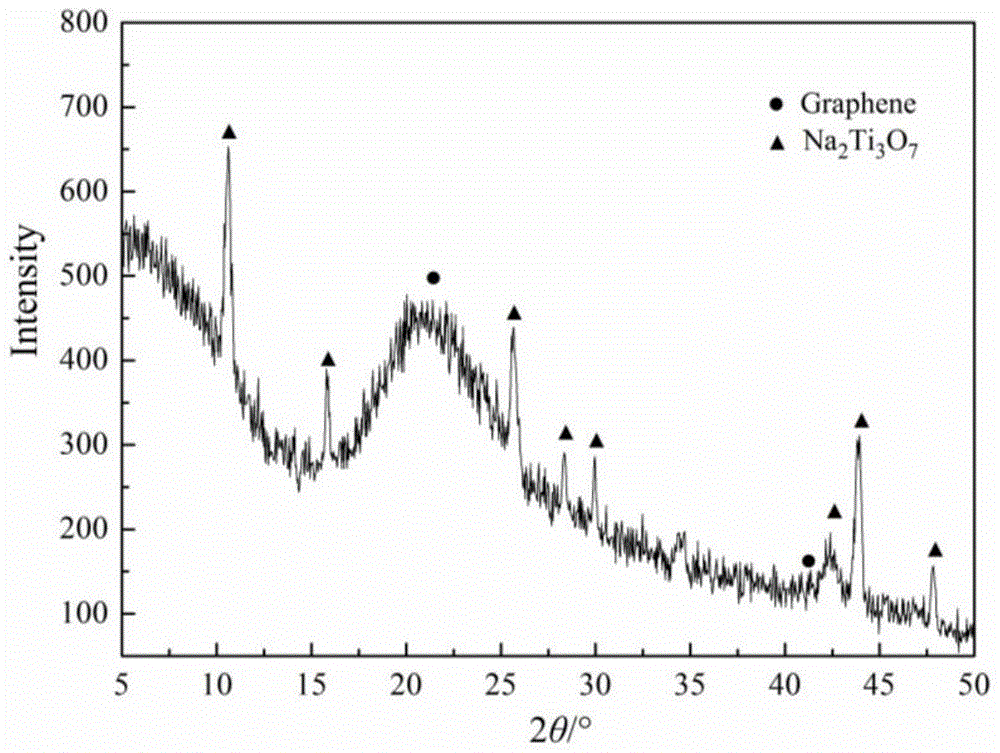

Preparation method of sodium titanate/graphene composite cathode material of sodium ion battery

ActiveCN104600271AEasy to storeFacilitated DiffusionCell electrodesSecondary cellsStrontium titanateHigh sodium

The invention provides a preparation method of a sodium titanate / graphene composite cathode material of a sodium ion battery, which is used for solving the problems in the prior art that no sodium ion battery cathode material with excellent comprehensive performance is provided, and belongs to the field of sodium ion secondary batteries. The method comprises the steps of dispersing graphene oxide to obtain a graphene oxide solution, mixing the graphene oxide solution, a sodium-containing compound and a titanium-containing compound, carrying out reaction to obtain a composite precursor, mixing the composite precursor with a binder, carrying out atomizing drying and granulating to obtain a spherical composite precursor, and finally burning the spherical composite precursor in an inert atmosphere to obtain a micro-scale spherical sodium titanate / graphene composite cathode material. The composite cathode material has the advantages of high sodium storage capacity, long cycle life, good large-current discharge property, high compaction density and the like, and the requirement of the high-performance sodium ion battery for the comprehensive performance of the cathode material can be met.

Owner:LIAONING TECHNICAL UNIVERSITY

Sodium ion battery anode material and sodium iron battery comprising anode material

InactiveCN103985851AEmbedded firmlyStable prolapseNon-aqueous electrolyte accumulatorsCell electrodesElectrical batteryHigh energy

The invention discloses a sodium ion battery anode material and a sodium iron battery comprising the anode material, and belongs to the technical field of energy source materials. The sodium ion battery anode material comprises a conductive additive and Na3-xM2LO6, wherein x is greater than or equal to 0 and smaller than 2; M is one or more of Fe, Co, Ni, Cu, Zn, Mg, V and Cr; L is one or more of Sb, Te, Nb, Bi and P. The preparation method comprises the steps of mixing sodium carbonate, M oxide and L oxide according to a stoichiometric proportion, ball-milling, calcining and ball-milling so as to obtain the sodium ion battery anode material. The sodium ion battery anode material has the advantages of high sodium storage capacity, good stability and excellent rate capability, and has extremely high energy density and power density; the assembled sodium iron battery has extremely good cycling stability, is green and clean, safe and environmentally friendly and low in cost, and is an extremely excellent electrochemical energy storage system; moreover, the preparation method of the anode material is extremely simple, and raw materials are low in price and easily available.

Owner:WUHAN UNIV

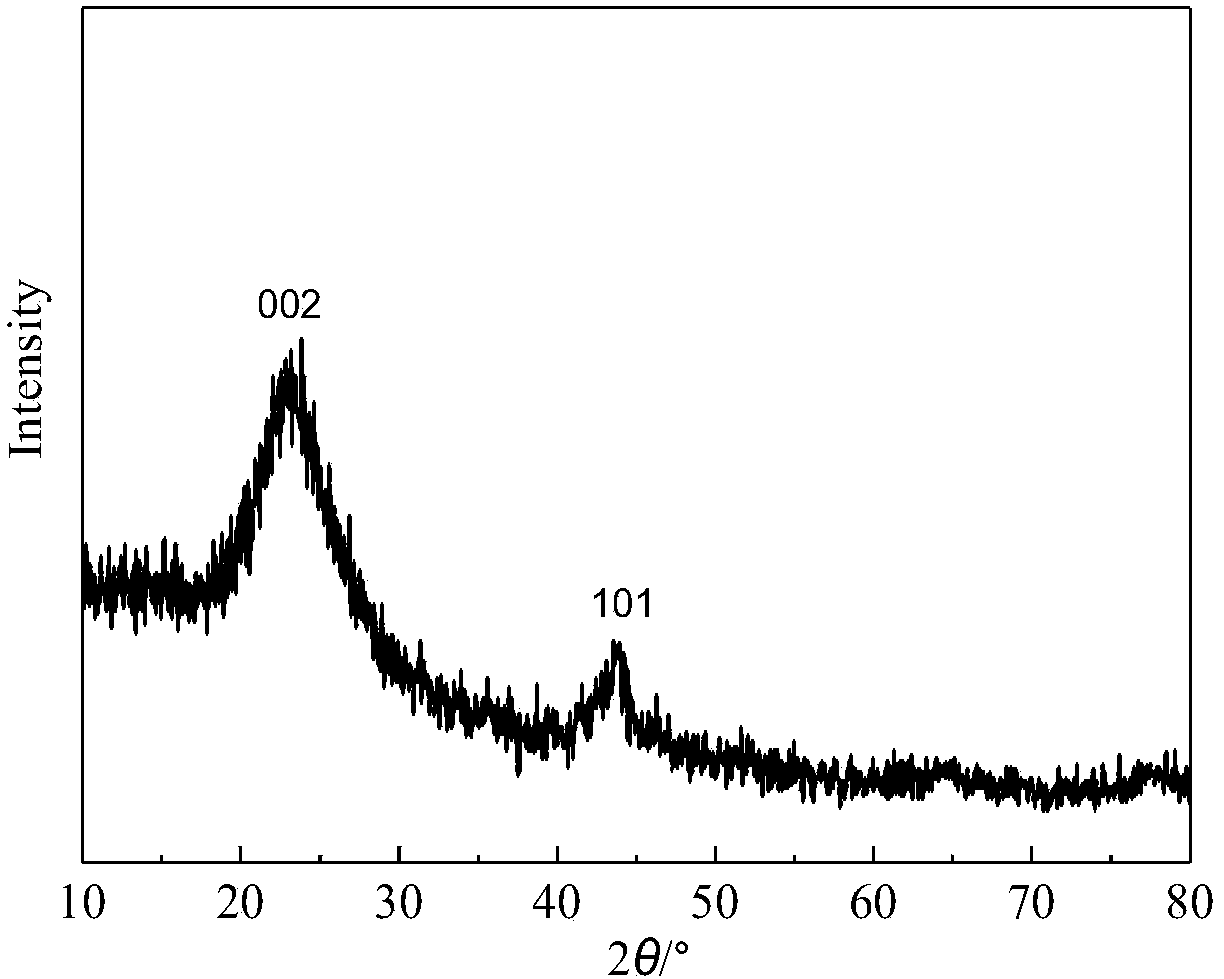

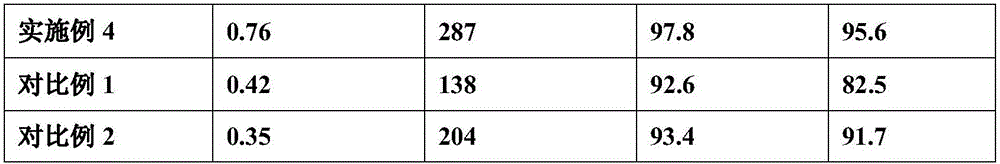

Hard carbon material, preparation method thereof, and sodium ion battery

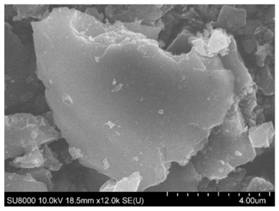

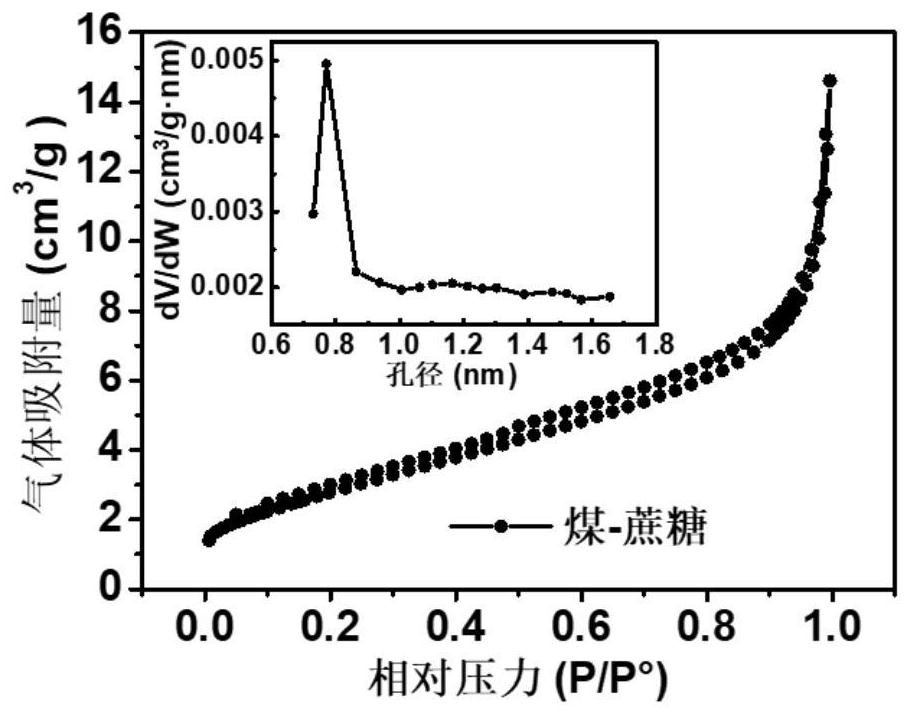

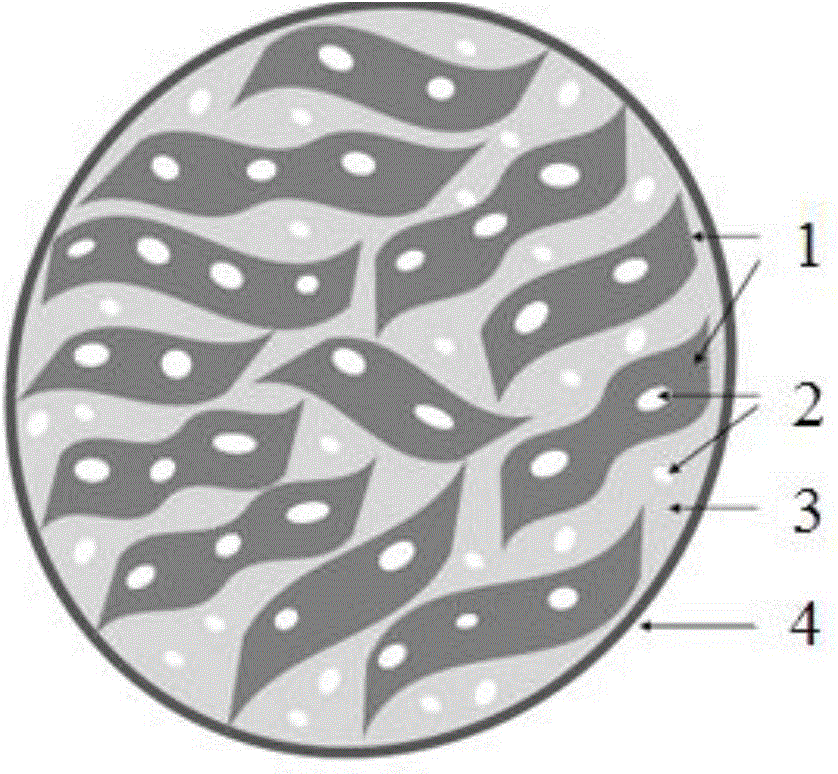

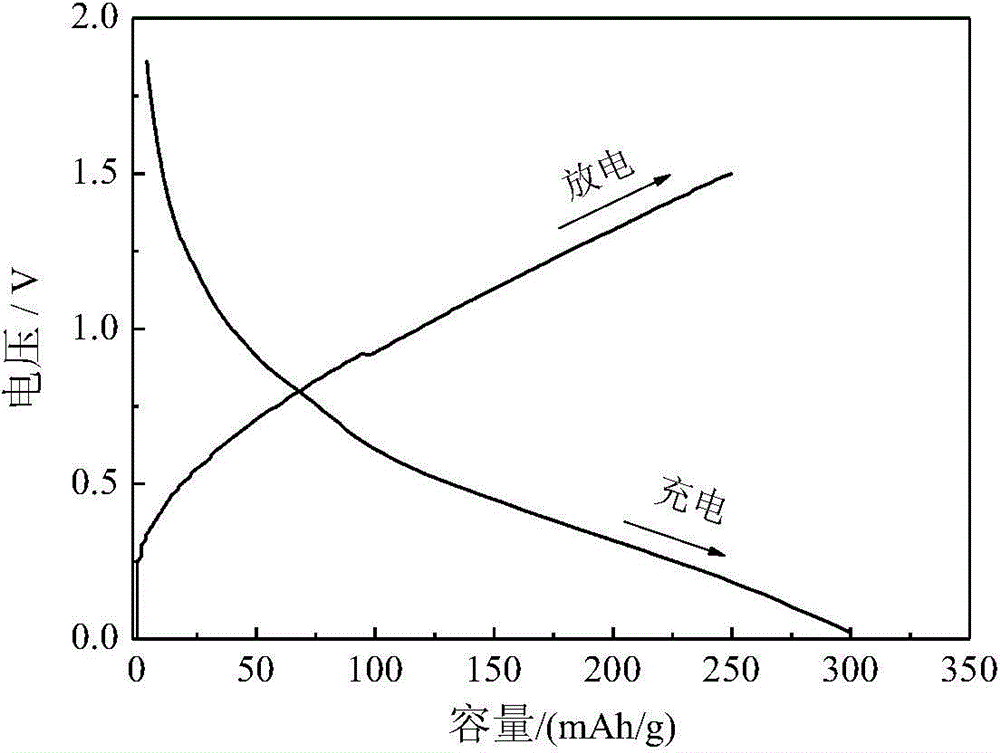

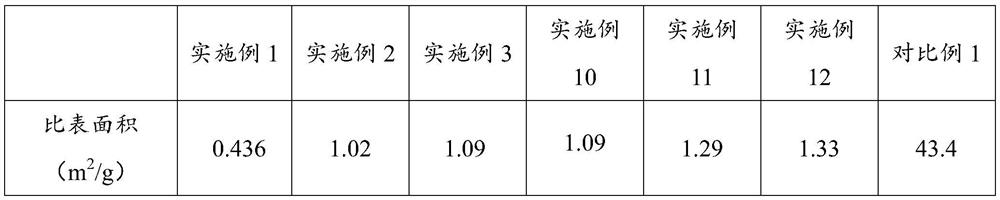

ActiveCN112397715AClose contactContact fully occursNegative electrodesSecondary cellsCarbon layerPhysical chemistry

The invention relates to the technical field of sodium ion batteries, and provides a preparation method of a hard carbon material. The preparation method comprises the following steps: mixing a coal-based material and a hard carbon precursor, and pressing to obtain a hard sheet, wherein the hard carbon precursor is carbohydrate and / or gelatin; and carrying out high-temperature carbonization on theobtained hard sheet to obtain the hard carbon material. According to the invention, the hard carbon precursor and the coal-based material are in close contact through a tabletting means, so that thereaction activity of the hard carbon precursor and the coal-based material is greatly improved, the hard carbon precursor and the coal-based material are fully subjected to a cross-linking reaction ina high-temperature carbonization treatment process, the carbonization yield is effectively improved, meanwhile, defects formed in the carbonization process are reduced, the specific surface area is reduced, and the disorder of the carbon layers and the spacing between the carbon layers in the carbonization process are increased. A sodium ion battery obtained by taking the hard carbon material obtained by the preparation method as a negative electrode material of the sodium ion battery has high sodium storage capacity and first coulombic efficiency.

Owner:BEIJING UNIV OF CHEM TECH

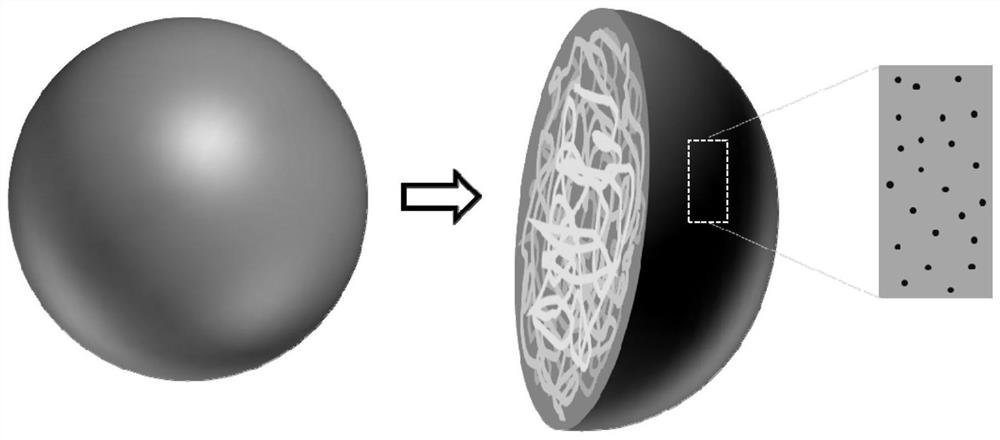

Method for preparing self-supporting three-dimensional porous graphene composite microsphere

ActiveCN104591177AOvercome the disadvantages of prone to reunionOvercome the disadvantages of reunionPorous grapheneMicrosphere

The invention aims at less current research and development on graphene-modified electrode material for energy storage devices such as a sodium ion battery, provides a method for preparing a self-supporting three-dimensional porous graphene composite microsphere and belongs to the technical field of novel carbon materials. The method comprises the following steps of mixing graphene with water, an activator and a binder and stirring to obtain a slurry, carrying out spray-drying and granulating to obtain the graphene microsphere containing the activator; dissolving petroleum pitch in kerosene, adding the graphene microsphere, uniformly mixing and drying to obtain the carbon-precursor-coated graphene microsphere; and carrying out heat treatment on the microsphere to obtain the self-supporting three-dimensional porous graphene composite microsphere. The self-supporting three-dimensional porous graphene composite microsphere obtained by using the method has the characteristics of stable structure, high gap content, high bulk density and the like. The sodium ion battery prepared from the graphene composite microsphere has the advantages of high capacity, good high-current discharge performance, excellent cycle performance, large packing density and the like.

Owner:江苏嘉明碳素新材料有限公司

Method for preparing modified graphite negative electrode material of sodium ion battery

ActiveCN104377346AIncrease sodium storage capacityImprove structural stabilityCell electrodesCarbon layerCarbonization

The invention provides a method for preparing a modified graphite negative electrode material of a sodium ion battery and aims at solving the problem of lacking of a suitable negative electrode material of the sodium ion battery at present. The method comprises the steps of preparing paste graphite oxide by using a Hummer method, cladding the graphite oxide with asphalt, phenolic resin or glucose as carbon precursors, and carrying out carbonization heat treating on the graphite oxide clad with the carbon precursors under an inert gas atmosphere. The method has the advantages of being simple, wide in raw material sources, suitable for large-scale industrial production, and the like. According to the obtained modified graphite negative electrode material, the carbon layer spacing is not less than 0.35nm, and the thickness of the carbon clad layer is 0.01-1 micron.

Owner:LIAONING TECHNICAL UNIVERSITY

A cathode material for sodium ion battery and a preparation method thereof

ActiveCN109273682AIncrease sodium storage capacityImprove cycle stabilityCell electrodesSecondary cellsDissolved ironSodium-ion battery

The invention discloses a positive electrode material of a sodium ion battery and a preparation method thereof. cathode material of the sodium ion battery, The preparation method comprises the following steps of: dissolving iron salt in a fluorinated ionic liquid, stirring the obtained mixed solution with a carbon source, a Prussian blue sodium ion cathode material, and carrying out solvothermal reaction to obtain an iron-based fluoride and carbon in-situ coating modified Prussian blue composite sodium ion battery cathode material. The invention can effectively improve the sodium storage capacity and cycle stability of the sodium ion battery composite material, and can also increase the conductivity of the sodium ion battery composite material through a simple in-situ coating process of the iron-based fluoride and the carbon source.

Owner:GUANGDONG BRUNP RECYCLING TECH +1

Hard carbon material and preparation method and application thereof

ActiveCN112225194AReduces the formation of crystals and impuritiesImprove charge and discharge capacityCell electrodesSecondary cellsCyclic stabilityMaterials science

The invention relates to a hard carbon material as well as a preparation method and application thereof. A conductive additive is introduced into the hard carbon material precursor to improve the conductivity of an obtained material, and a large number of oxygen-containing functional groups are introduced in combination with variable-speed heating pre-oxidation, so that the crosslinking degree ofa material skeleton is increased, the strength of the material is improved, and the sodium storage specific capacity, the first-circle coulombic efficiency and the rate capability are remarkably improved. The hard carbon material has the advantages of high reversible capacity, high first-circle coulombic efficiency, good cycling stability and the like when being used for the sodium ion battery. The material has the characteristics of simple preparation method and cheap and easily available raw materials, and provides more choices for the negative electrode of the sodium-ion battery.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Porous cubic ZnSO3@graphene negative electrode material used for sodium ion battery and preparation method for porous cubic ZnSO3@graphene negative electrode material

ActiveCN105449177AIncrease sodium storage capacityImprove cycle lifeCell electrodesSecondary cellsCvd grapheneIon

The invention discloses a negative electrode material used for a sodium ion battery and a preparation method for the negative electrode material. The negative electrode material is the porous cubic ZnSO3 composite material coated with graphene; the preparation method comprises the following steps: mixing and stirring a mixed solution containing zinc salt and tin salt for a certain time, and filtering, drying and calcining to obtain the porous cubic ZnSO3; performing ultrasonic dispersion on the ZnSO3 to disperse the ZnSO3 into the solution and adding a surfactant to stir, then mixing and stirring with a graphene oxide water solution, and filtering, drying and thermal processing to obtain the porous cubic ZnSO3 coated with graphene. When the composite material is used for the sodium ion battery, high specific capacity, long cycle life and excellent rate capability of the sodium ion battery are achieved; and meanwhile, the preparation method has the characteristics of simple operation, environment-friendliness, low energy consumption and low cost, and industrial large-scale production can be achieved easily.

Owner:CENT SOUTH UNIV

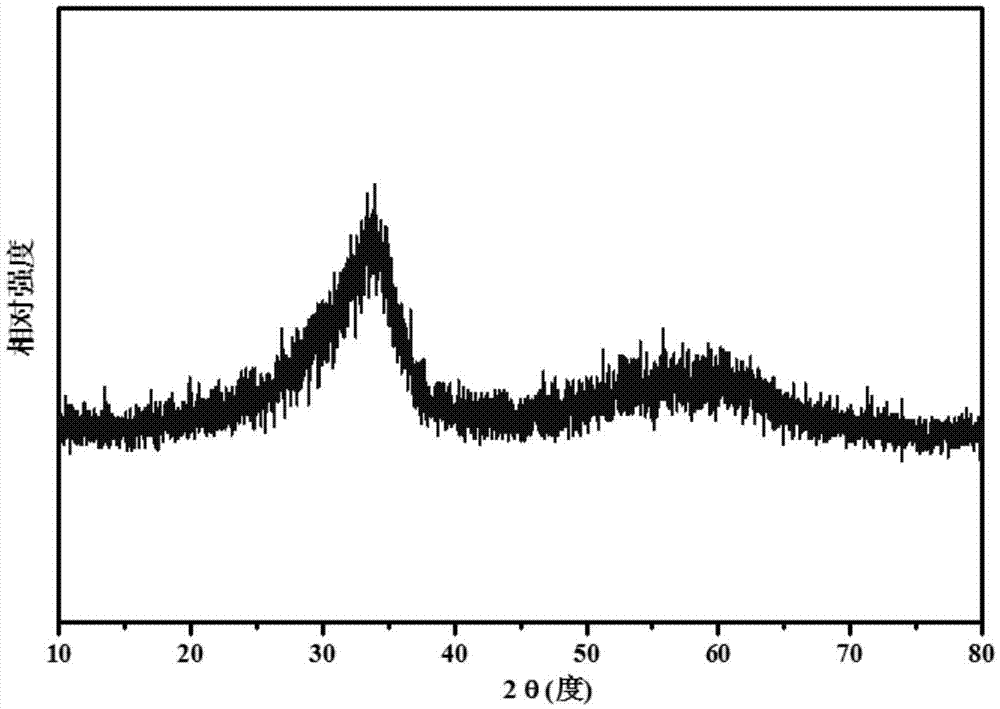

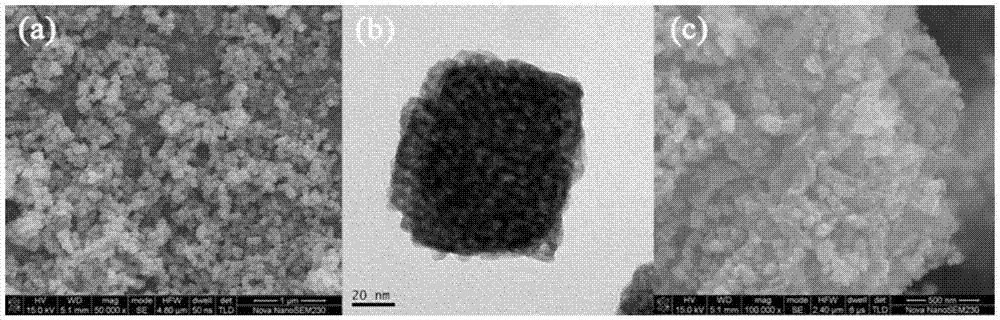

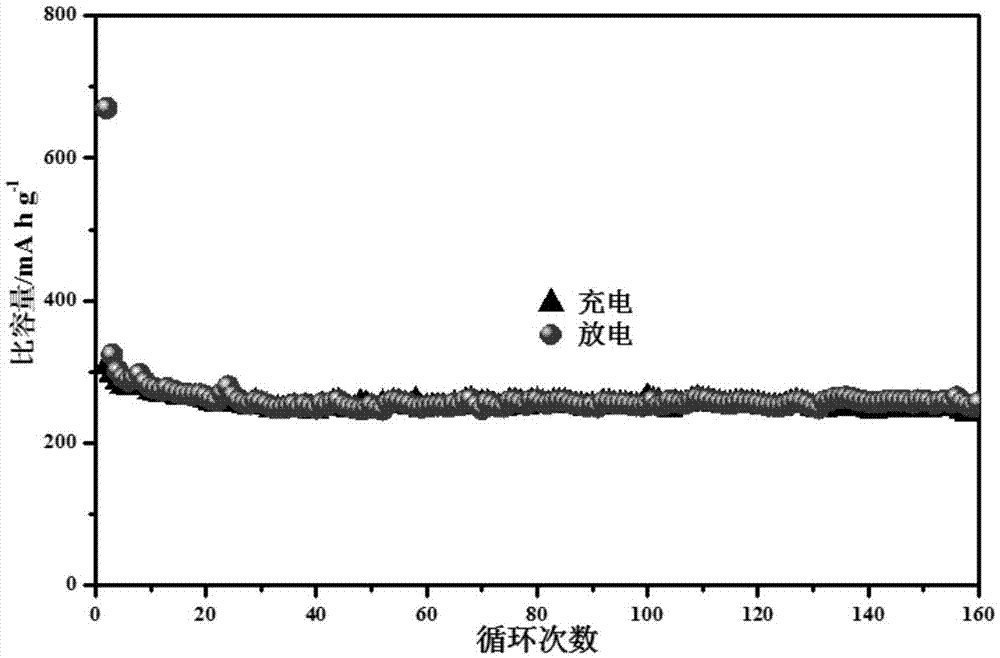

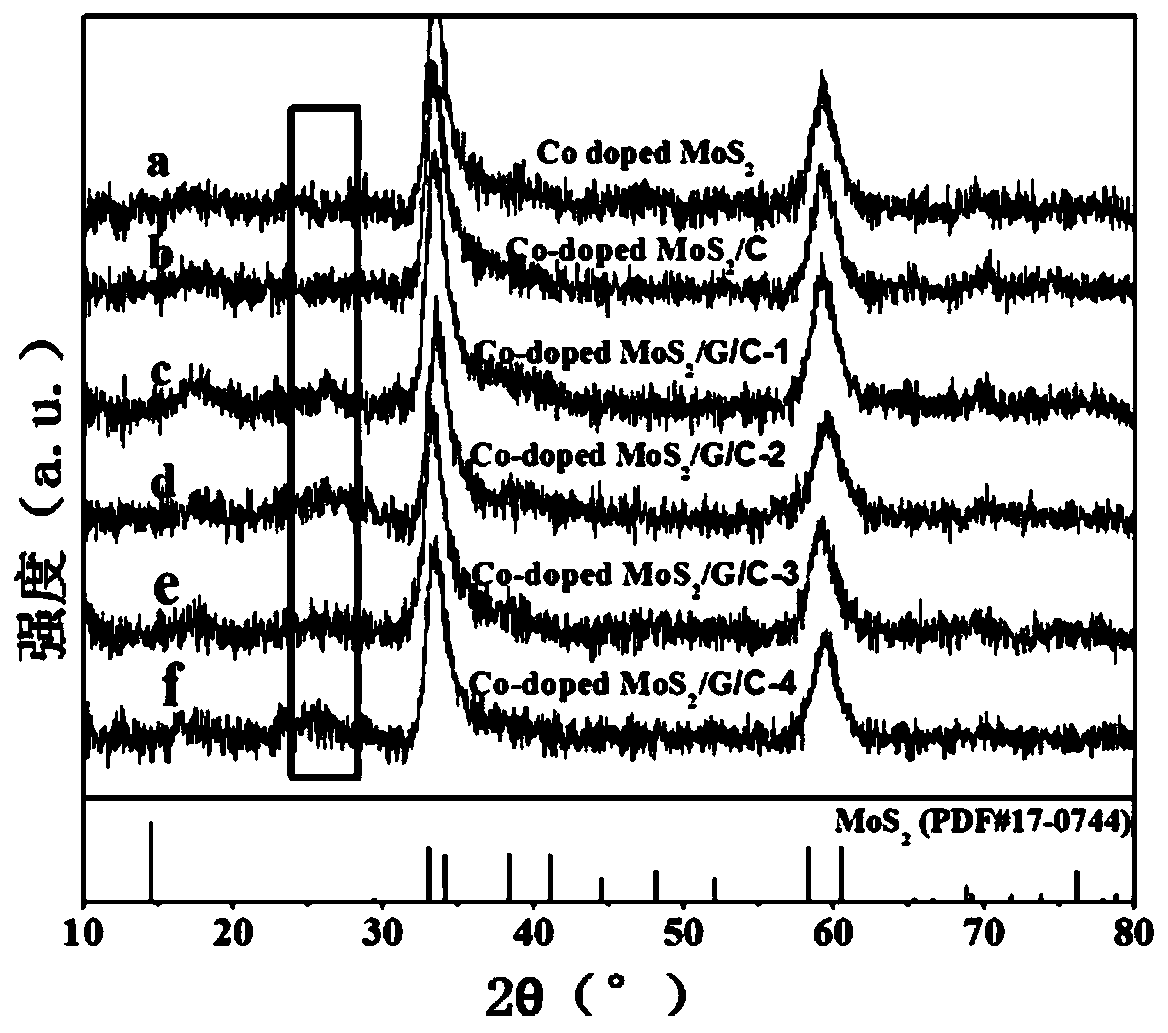

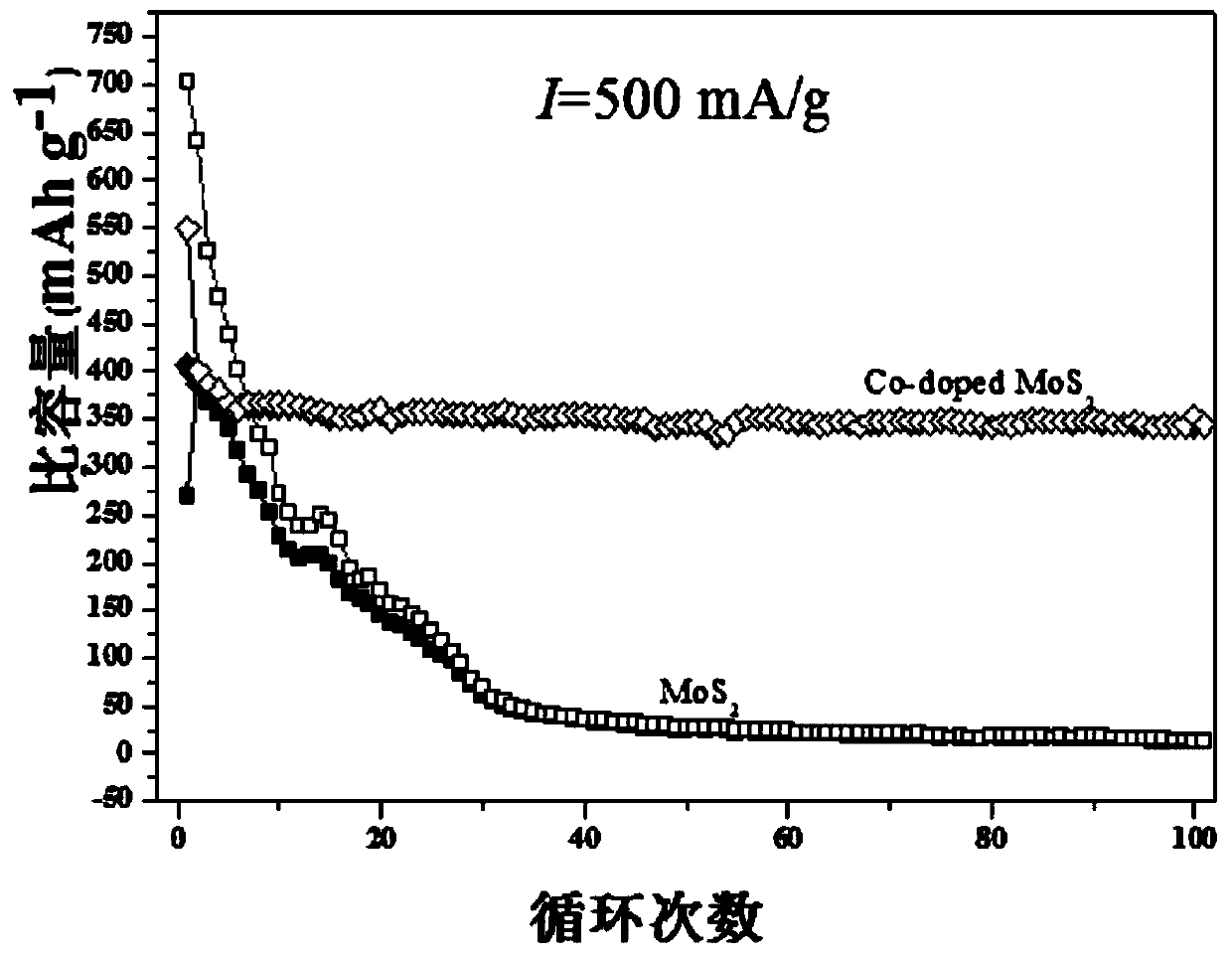

Cobalt-doped molybdenum sulfide-graphene-carbon composite material, and preparation method and application thereof

InactiveCN109713258AGood charge and discharge performanceImprove conductivityCell electrodesSecondary cellsCarbon compositesThiourea

The invention discloses a cobalt-doped molybdenum sulfide-graphene-carbon composite material, and a preparation method and application thereof. The method comprises proportionally adding cobalt salt,sodium molybdate, a graphene oxide aqueous solution and thiourea into an aqueous solution of sugar; uniformly ultrasonically mixing the mixture; transferring the mixed solution to a hydrothermal reaction kettle for a hydrothermal reaction at a fixed temperature; and obtaining the cobalt-doped molybdenum sulfide-graphene-carbon composite material by washing, drying and sintering. The invention alsodiscloses the composite material and the application thereof. The method, based on the characteristic of the molybdenum sulfide used as a sodium battery negative electrode material, uses the grapheneand carbon having excellent electrical conductivity as a composite medium, utilizes cobalt doping to greatly improve electronic conductivity and sodium storage capacity of the composite material, andprepares the molybdenum sulfide-based composite electrode material having a high specific capacity and a long cycle life in one step. The material is cheap in raw materials, simple in operation process, high in yield, excellent in charge and discharge performance, convenient for industrial production, and easy to promote.

Owner:YANCHENG INST OF TECH

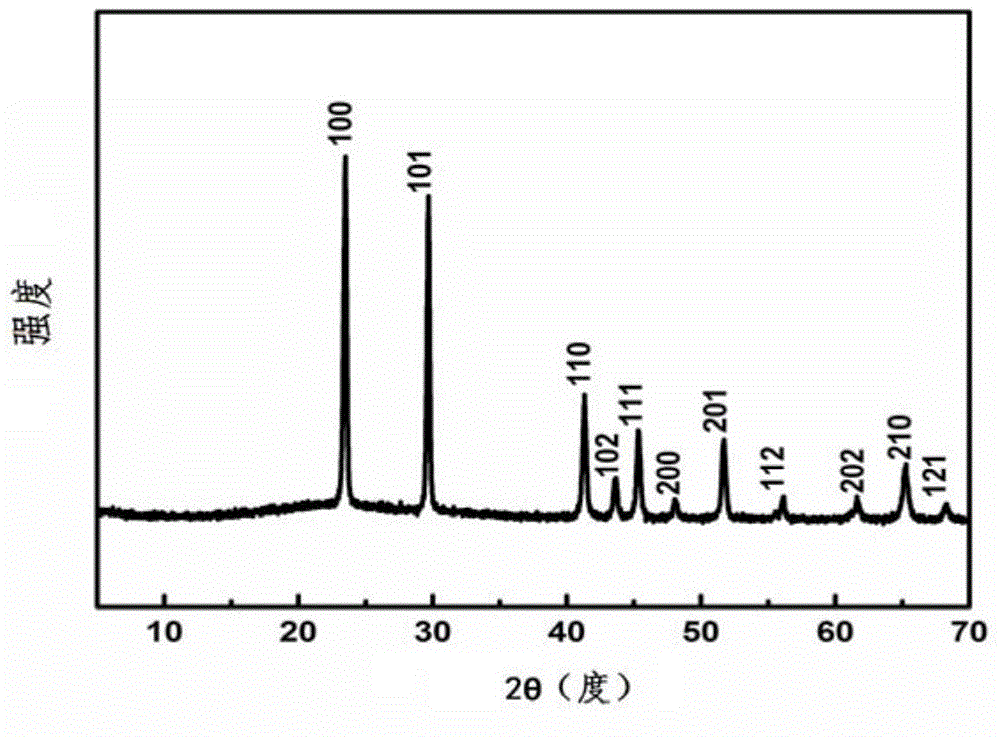

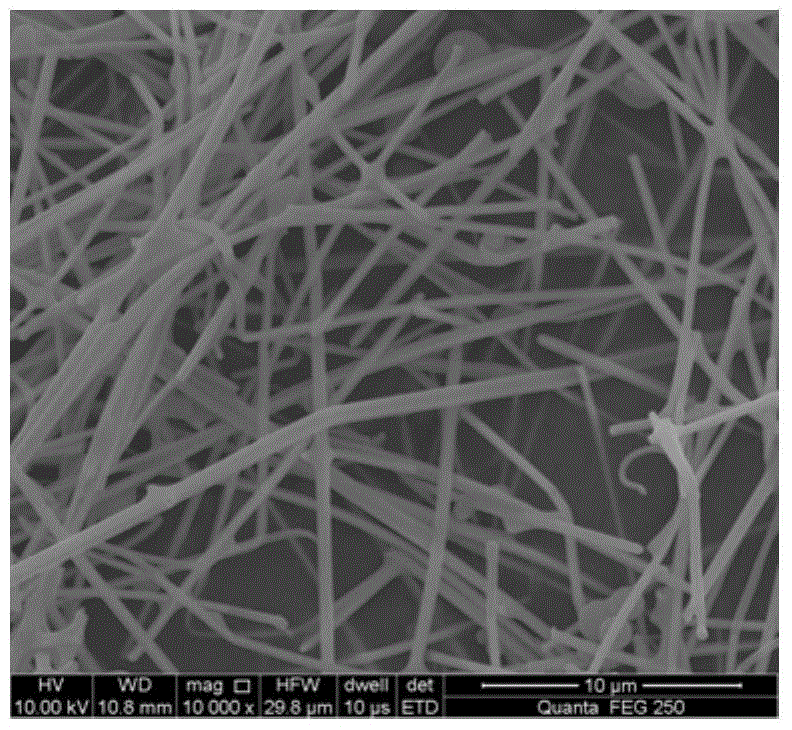

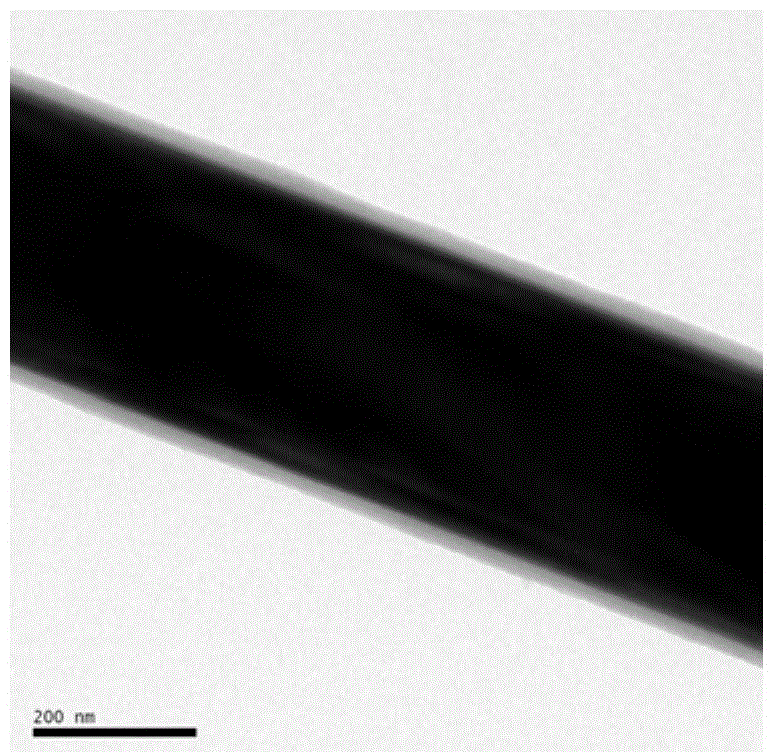

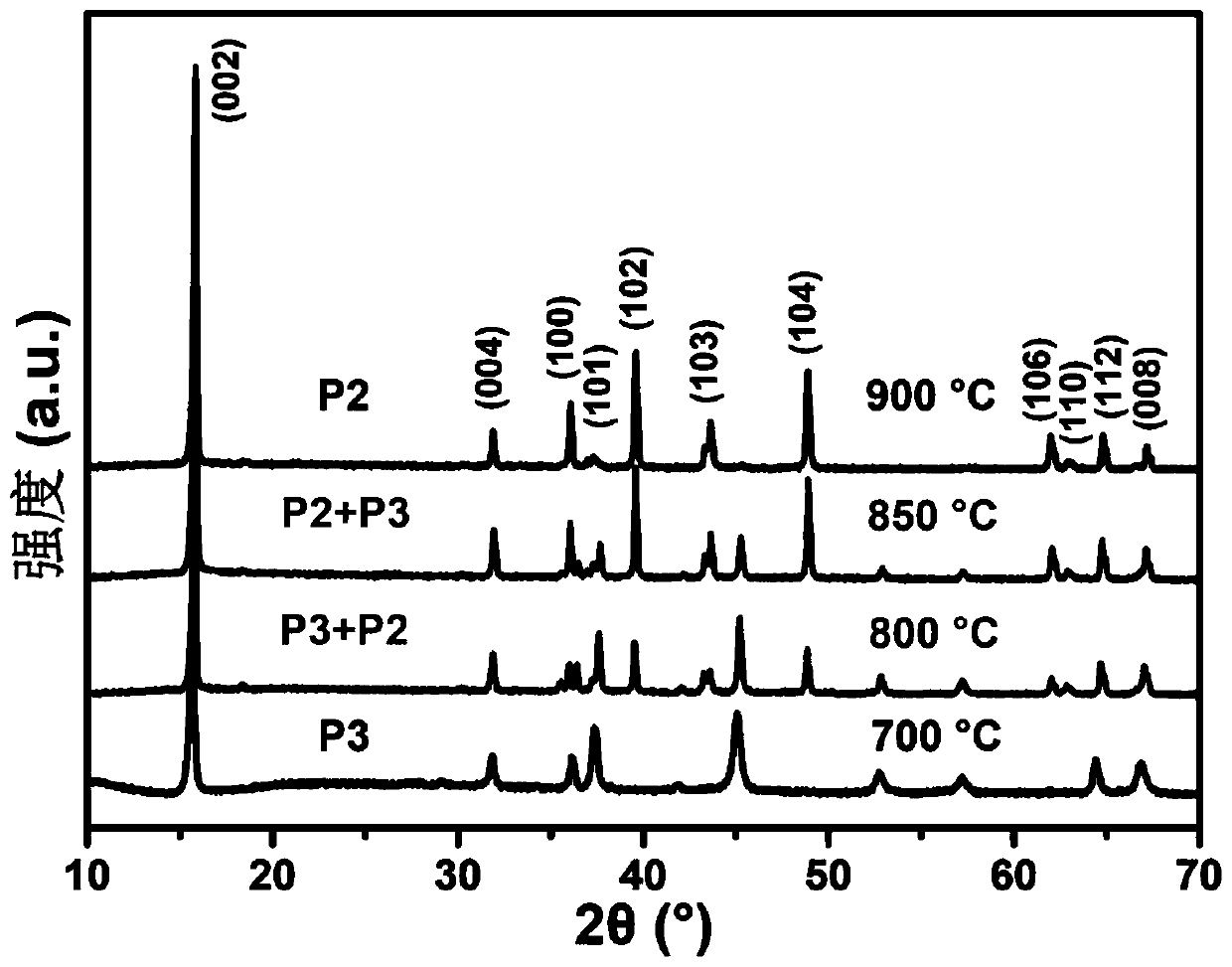

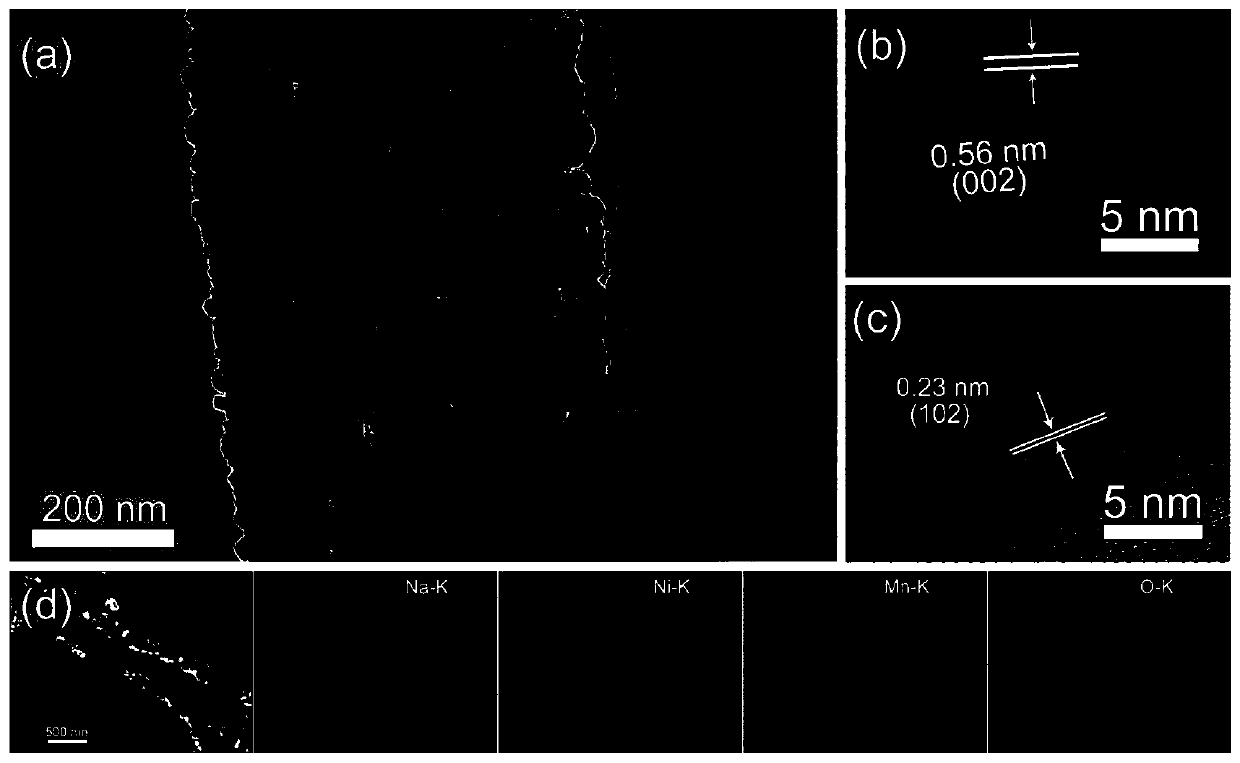

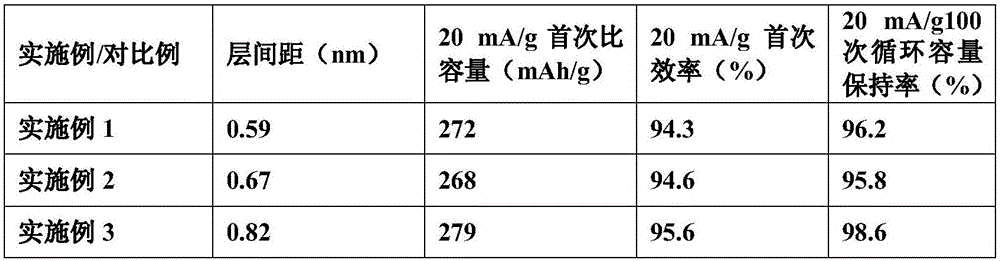

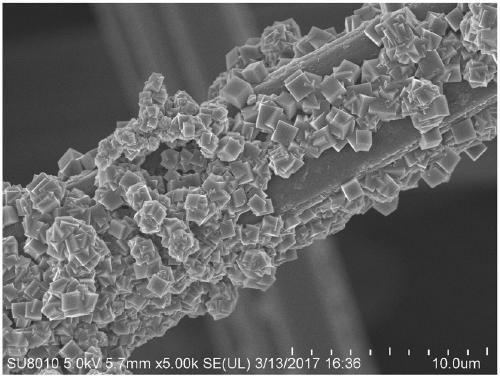

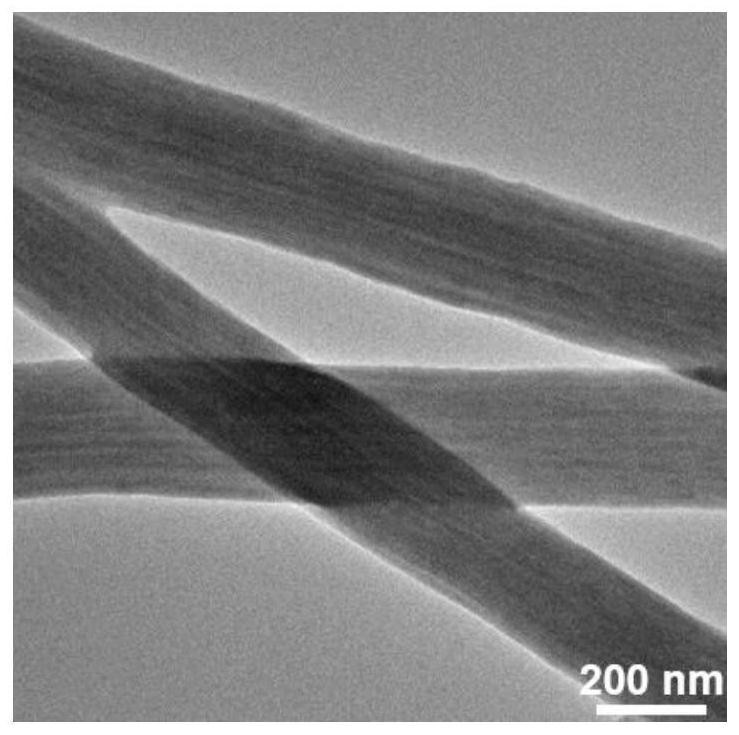

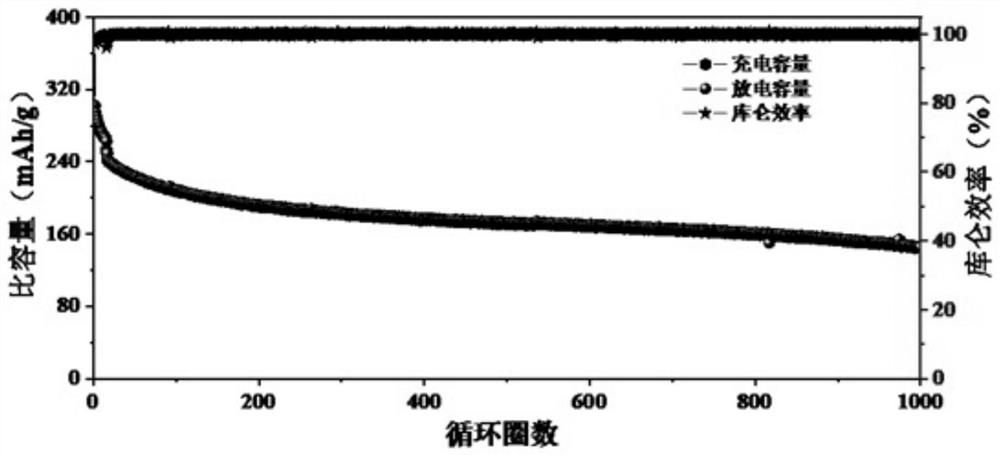

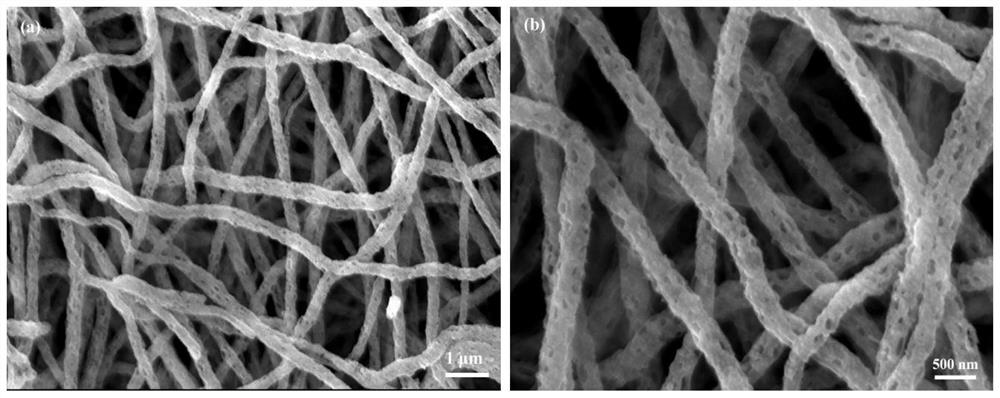

Preparation and application method of nanofiber sodium-storage positive material assembled by nanoparticles

InactiveCN110416489AImprove integrityEvenly distributedMaterial nanotechnologySecondary cellsFiberNickel salt

The invention discloses a preparation and an application method of a nanofiber sodium-storage positive material assembled by nanoparticles. The preparation method comprises the following steps: 1) dissolving polyvinylpyrrolidone (PVP) in deionized water, adding glacial acetic acid to adjust pH of the solution to form a solution A, and then successively adding a soluble sodium salt, a soluble nickel salt and a soluble manganese salt to the solution A in proportion, and conducting stirring to form a homogeneous solution B; and 2) preparing composite nanofiber from the solution by electrospinningtechnology, and conducting calcining to decompose polyvinylpyrrolidone and form a porous structure, so as to obtain the nanofiber assembled by Na<2 / 3>Ni<1 / 3>Mn<2 / 3>O<2> nanoparticles. The preparationand application method of the invention have the advantages of simple preparation process, good repeatability and easy-to-control reaction conditions. The obtained material is a the nanofiber assembled by the nanoparticles, wherein the size of the nanoparticles is 20-90 nm, and the diameter of the nanofiber is 200-600 nm. A three-dimensional network framework formed by cross-linking of the fibersenhances the structural stability of the material and promotes rapid insertion-desertion of sodium ions, significantly improves sodium storage capacity, rate performance and cycle life. The nanofibersodium-storage positive material of the invention has a good application prospect.

Owner:UNIV OF SCI & TECH BEIJING

Preparation method of large-layer-spacing graphite anode material of sodium-ion battery

ActiveCN105720269AIncrease spacingIncrease sodium storage capacitySecondary cellsNegative electrodesHigh sodiumSodium-ion battery

The invention discloses a preparation method of a large-layer-spacing graphite anode material of a sodium-ion battery. The preparation method comprises the following steps of: (1) dissolving a proper amount of carbon source into a solvent, then adding graphite oxide, and after stirring at a rotating speed of 10 to 50rpm to uniformly mix the components, drying to obtain carbon source coated graphite oxide; and (2) placing the carbon source coated graphite oxide obtained in the step 1 into a quartz glass beaker, adding liquid nitrogen, then rapidly placing the quartz glass beaker into a microwave reactor, performing a reaction for 5 to 20 minutes under the microwave power of 250 to 1,000W, and after completely volatilizing the liquid nitrogen, standing for 5 minutes and taking out the product so as to obtain the large-layer-spacing graphite anode material, wherein the quantity of the liquid nitrogen is subject to soaking on the carbon source coated graphite oxide. Compared with conventional graphite and commonly coated and reduced graphite anode, the prepared graphite anode material has the advantages of large layer spacing, high sodium storage capacity, large coulombic efficiency and long cycle life, and meets the requirements of the high-performance sodium-ion battery for comprehensive performance of the anode material.

Owner:SHENZHEN XIANGFENGHUA TECH CO LTD +1

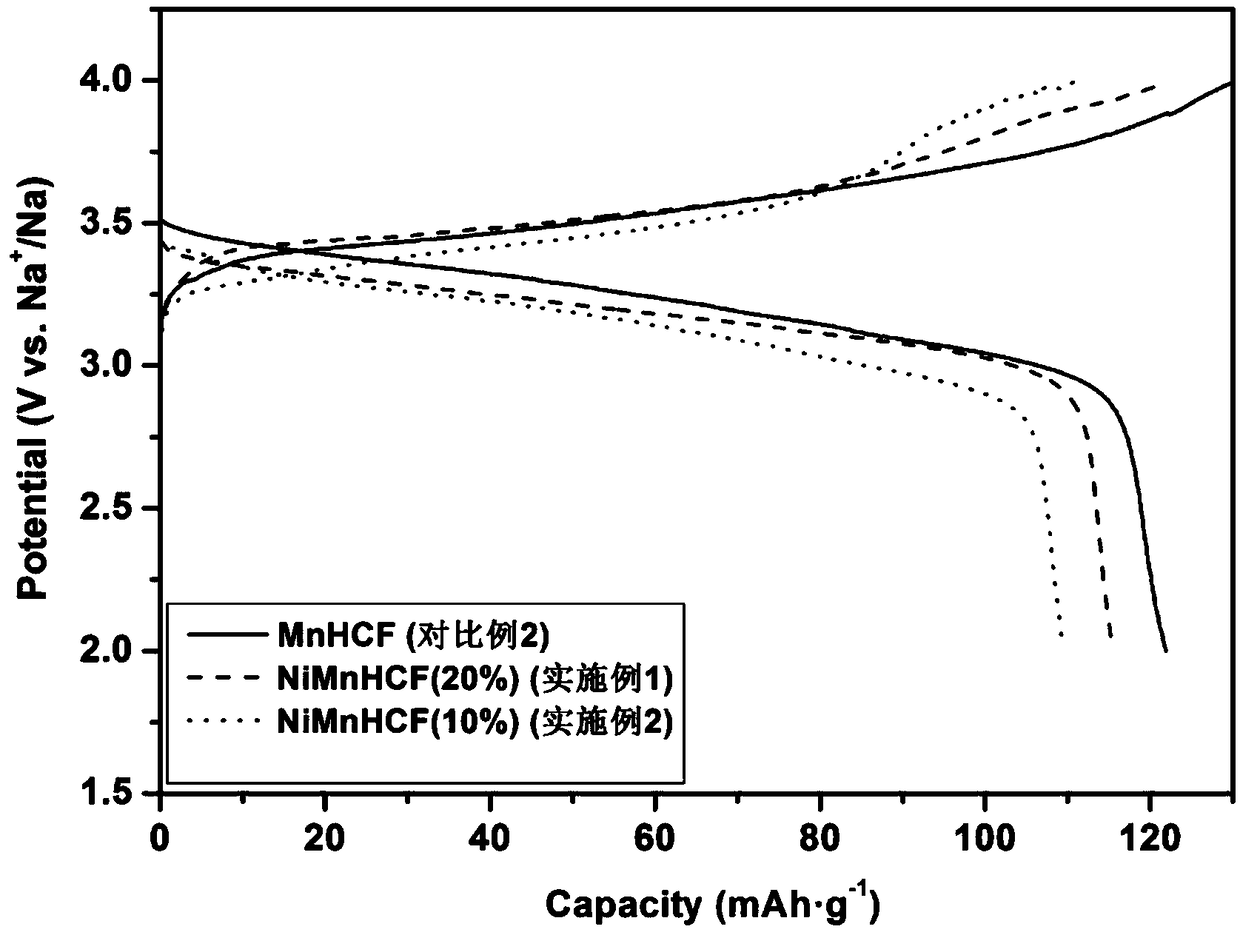

A co-doped flexible sodium ion battery cathode material and a preparation method thereof

ActiveCN109244459AIncrease capacityImprove cycle stabilityIron cyanidesCell electrodesComposite electrodePhysical chemistry

The invention discloses a co-doped flexible sodium ion battery cathode material and a preparation method thereof. The co-doped flexible sodium ion battery cathode material has the chemical formula ofNa2NimMnFe (CN) 6; Wherein M is at least one of Mn, Co, Ti, Fe, Cu, Zn and Cr; 0 <= m <= 1, 0 <= n <= 1. At that same time, the preparation method of the co-doped flexible sodium ion battery cathode material is also disclosed. The flexible composite electrode material obtained by the invention has the advantages of high capacity, high cycle stability and the like of electrochemical performance, meanwhile, has excellent flexibility and mechanical tensile strength, and the preparation process is very simple, low in cost, environmentally friendly and pollution-free, is suitable for mass preparation, and has excellent market application value.

Owner:GUANGDONG BRUNP RECYCLING TECH +1

High-circulation and high-magnification rate carbon-based negative electrode energy storage composite material and preparation method thereof

InactiveCN109065862AFull accessIncrease contact areaMaterial nanotechnologyCell electrodesNickel saltFree cooling

The invention discloses a carbon-based negative electrode energy storage composite material with high circulation and high magnification rate and a preparation method thereof. A method comprises preparing a nickel salt water gel and a nickel salt water gel precursor, then calcining, grinding, pickling and vacuum drying the nickel salt water gel precursor under the protection of inert gas, oxidizing the calcined product after pickling at high temperature and naturally cooling the same to room temperature, so as to obtain the carbon-based anode energy storage composite material with high circulation and high magnification rate which has high cycle stability, excellent charge-discharge specific capacity and good rate performance. The preparation method is simple, the cost is low and the performance is excellent, the method is suitable for the production of large-scale commercial batteries.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Bimetal selenide carbon microsphere composite material as well as preparation method and application thereof

ActiveCN113130865AImproves ion transmissionHigh activityCell electrodesSecondary cellsElectrically conductiveSelenide

The invention provides a bimetallic selenide carbon microsphere composite material as well as a preparation method and application thereof. In the bimetallic selenide carbon microsphere composite material, two kinds of metal selenide are cross-linked with each other through the carbon matrix and are uniformly combined to form microspheres; in the two kinds of metal selenide, the metal valence state of one is relatively high, and the metal valence state of the other is relatively low. By introducing the high-valence metal, the electron and ion transmission effect of the low-valence metal can be improved, and the synergistic effect of the double metals is generated, so that the activity and the sodium storage performance of the material are improved. The carbon matrix not only provides a conductive network, but also limits the volume expansion of the material.

Owner:CENT SOUTH UNIV

Sulfur vacancy nitrogen-doped carbon-coated nickel sulfide composite electrode material and preparation method thereof

ActiveCN113036097ABoost Gap DiffusionImprove conductivitySecondary cellsNegative electrodesNickel saltHexamethylenetetramine

The invention relates to a sulfur-vacancy nitrogen-doped carbon-coated nickel sulfide composite electrode material and a preparation method thereof. The preparation method sequentially comprises the following steps: S1, dissolving inorganic nickel salt and hexamethylenetetramine in a solvent according to the molar ratio of 1: (1-7), and obtaining an inorganic nickel salt solution and a hexamethylenetetramine solution; S2, uniformly mixing an inorganic nickel salt solution and a hexamethylenetetramine solution in a dropwise adding manner, and then standing and growing at 80-160 DEG C for 12-50 hours to obtain a head product containing a nickel-based metal organic framework template; and S3, carrying out centrifugal separation on the initial product containing the nickel-based metal organic framework template at a speed of 2000-4000 r / min, and respectively washing the initial product with deionized water and absolute ethyl alcohol for 3 times to obtain the clean nickel-based metal organic framework template. The prepared composite electrode material is high in energy storage specific capacity and high in cycling stability, the preparation method is simple, the cost is low, and industrial large-scale application is easy to achieve.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

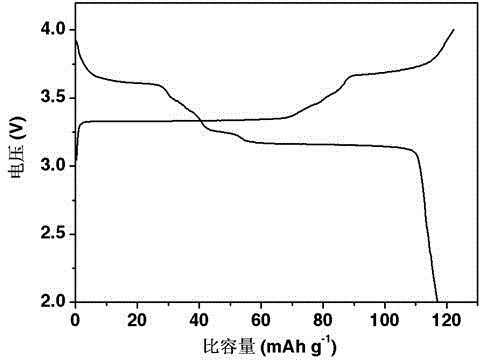

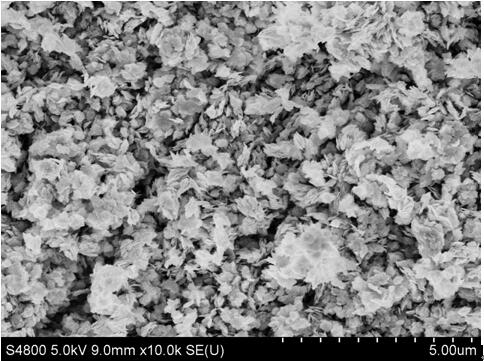

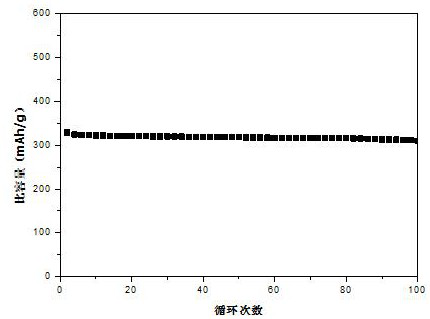

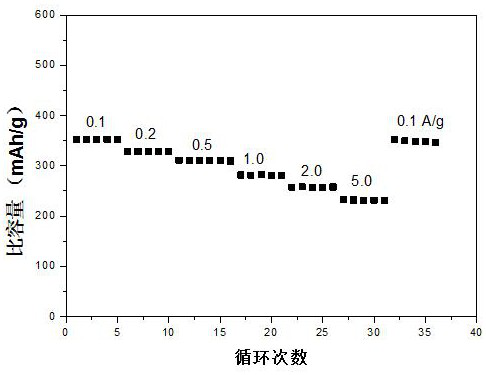

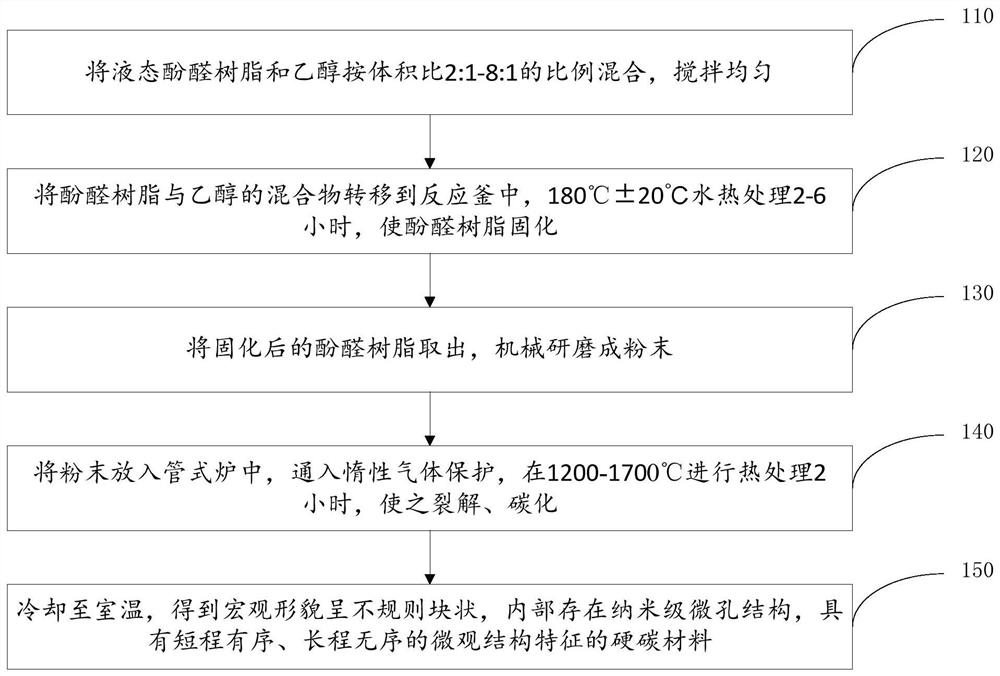

Hard carbon negative electrode material for sodium ion battery based on phenolic resin and its preparation method and application

ActiveCN109742383BIncrease energy densityHigh capacity densityCell electrodesSecondary cellsElectrical batterySodium-ion battery

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

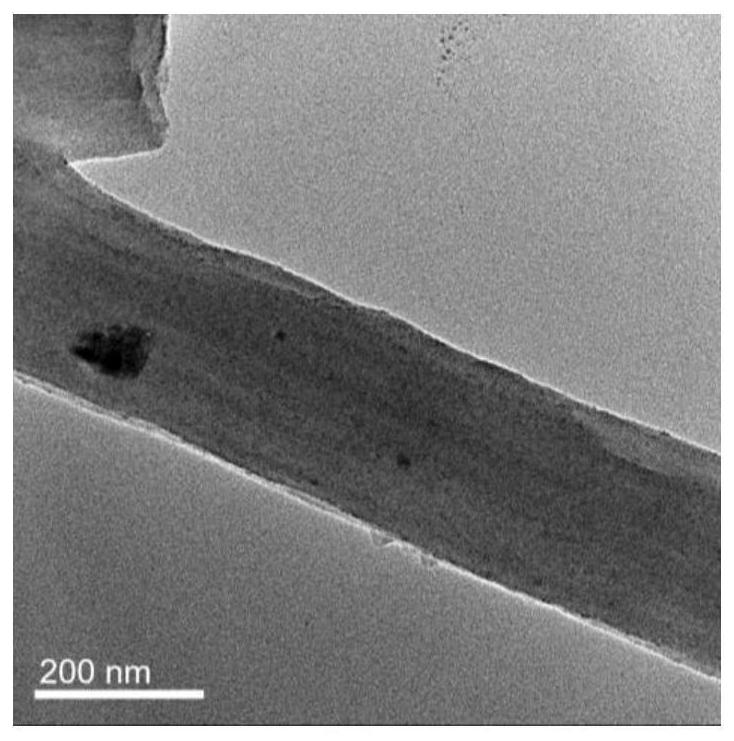

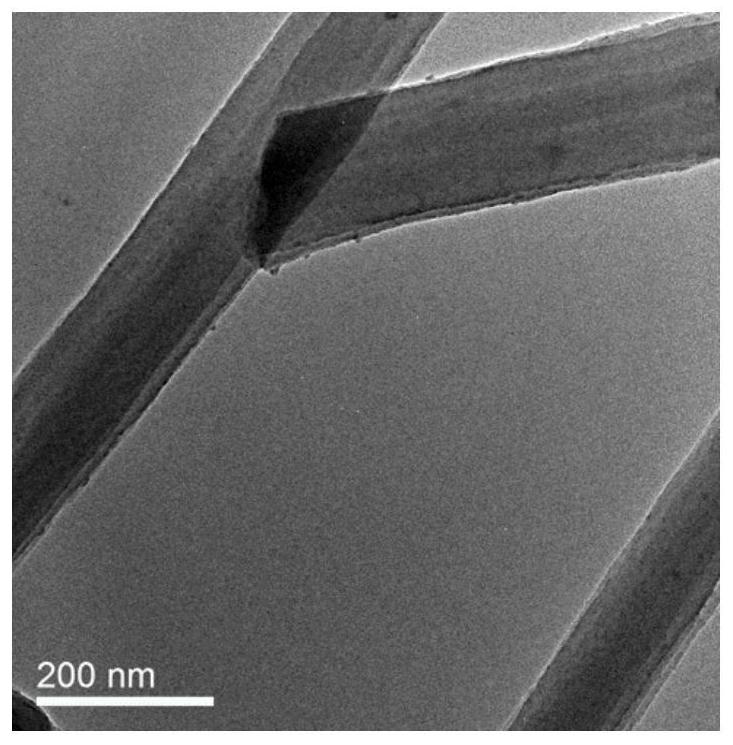

Preparation method and application of high-dispersion metal oxide/carbon nanofiber composite material

PendingCN111740099ALow costSimple processNegative electrodesSecondary cellsSpinningPolyvinyl alcohol

The invention discloses a preparation method and application of a high-dispersion metal oxide / carbon nanofiber composite material. The method is characterized by comprising the following steps: dissolving a metal precursor, a dispersing agent and polyacrylonitrile in dimethylformamide, and uniformly mixing to prepare a spinning solution; putting the spinning solution into an electrostatic spinningdevice, and preparing a fiber precursor membrane through electrostatic spinning; performing high-temperature carbonization treatment on the fiber precursor membrane in a nitrogen atmosphere to obtainthe high-dispersion metal oxide / carbon nanofiber composite material, wherein the dispersing agent is any one of malic acid, citric acid, polyvinyl alcohol, polyvinylpyrrolidone and gelatin. The high-dispersion metal oxide / carbon nanofiber composite material prepared by the invention is used as a self-supporting sodium ion battery negative electrode material; the problems that an existing composite material is large in metal oxide particle, low in dispersity, serious in agglomeration or pulverization in the charging and discharging process and the like are solved; and the composite material has the advantages of being simple in preparation process method, low in preparation cost, good in metal oxide dispersity, high in charging and discharging specific capacity, good in cycling stability and the like and has wide application prospects.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

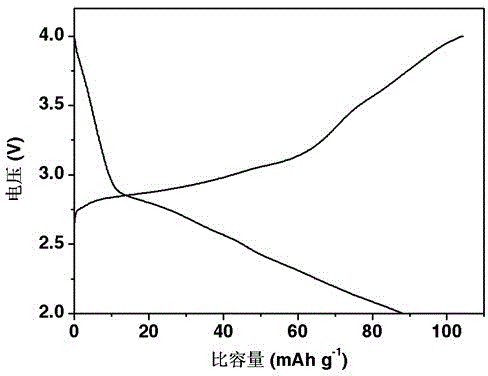

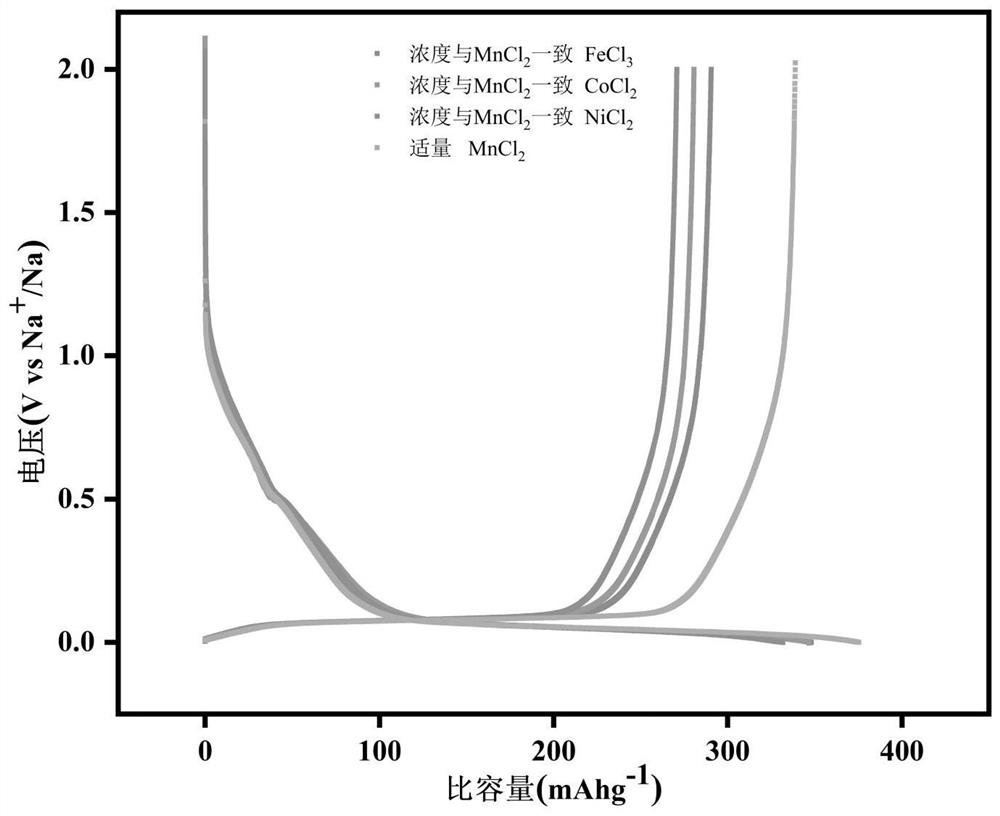

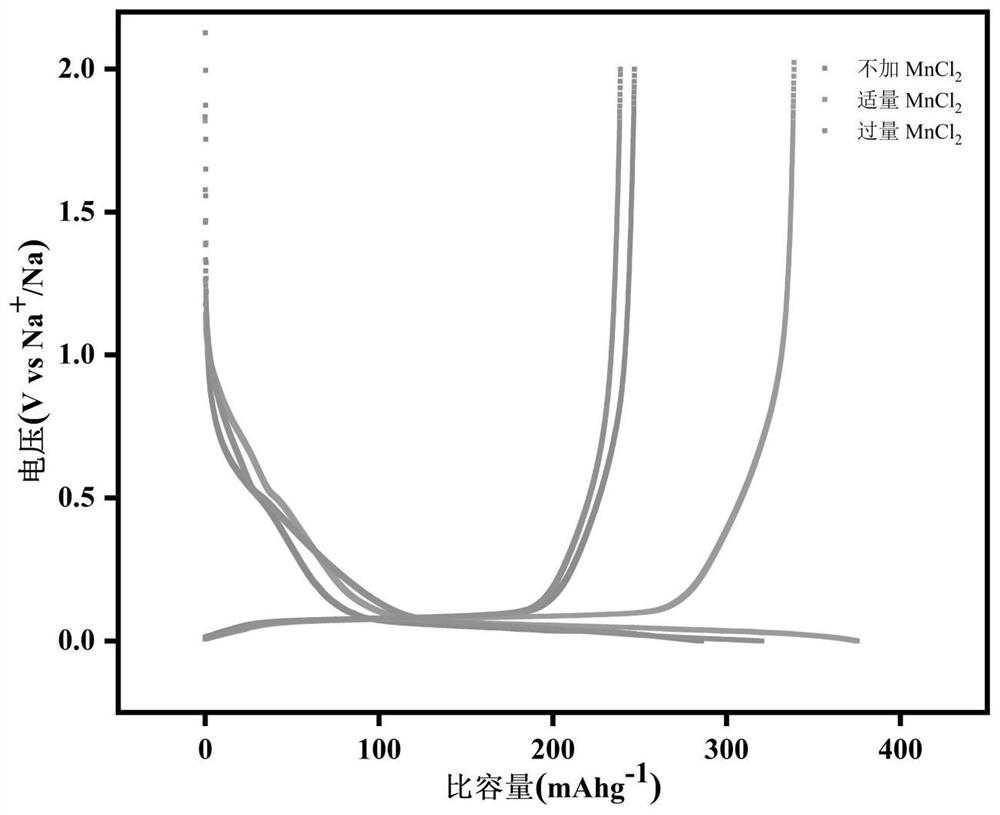

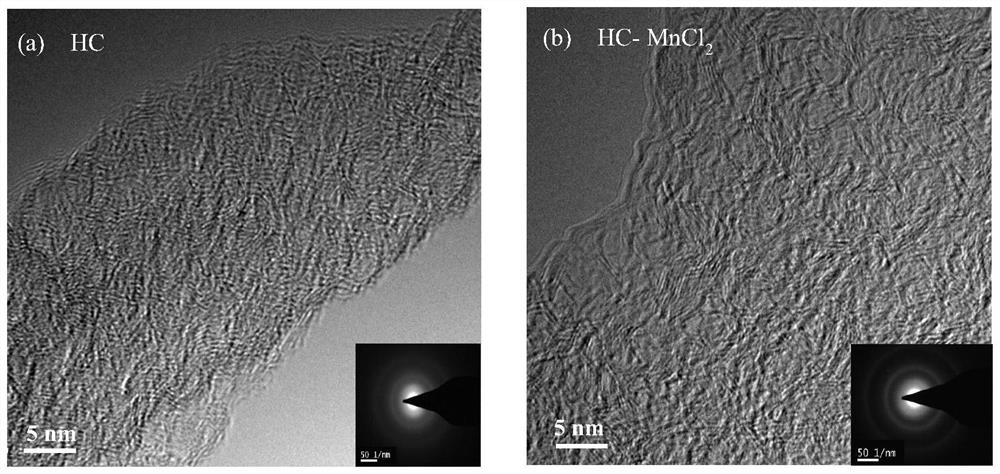

Preparation and application of high-performance sodium-ion battery energy storage material based on regulation and control of hard carbon structure through ion catalysis

ActiveCN114497543AGood repeatabilityImproved magnification performanceNegative electrodesSecondary cellsGraphene flakeManganese

The invention relates to the field of sodium ion secondary batteries, and provides a method for regulating and controlling a hard carbon structure based on transition metal manganese, which is used for a sodium ion battery negative electrode material. Cheap and easily available biomass is used as a carbon source, and manganese is ensured to be uniformly dispersed in a precursor polymer through coordination of manganese ions (Mn < 2 + >) and one-dimensional cellulose nanofibers and a coordination effect; according to the present invention, the graphene sheets are introduced into the graphene sheets, such that the conversion between the SP3 carbon and the SP2 carbon is effectively catalyzed so as to freely rearrange the graphene sheets, such that the expanded nano-graphite and the carbon micro-pores are formed, and the controllable adjustment of the carbon interlayer spacing and the micro-pores is achieved by adjusting the concentration; and finally, 92.05% of ultrahigh first efficiency and excellent circulating performance are obtained (the capacity retention ratio of 200 cycles is 95.80% under the current density of 20mA g <-1 >). The problems of low sodium ion first efficiency and poor cycling stability are solved through ion catalysis regulation and control, the first efficiency can be improved to 90% or above, the performance is improved by 30% or above, the energy density of the battery is greatly improved, and the total battery with sodium vanadium phosphate as the positive electrode has excellent electrochemical performance, has a good industrialization prospect and is suitable for industrial production. The method is very suitable for large-scale energy storage systems.

Owner:温州大学碳中和技术创新研究院

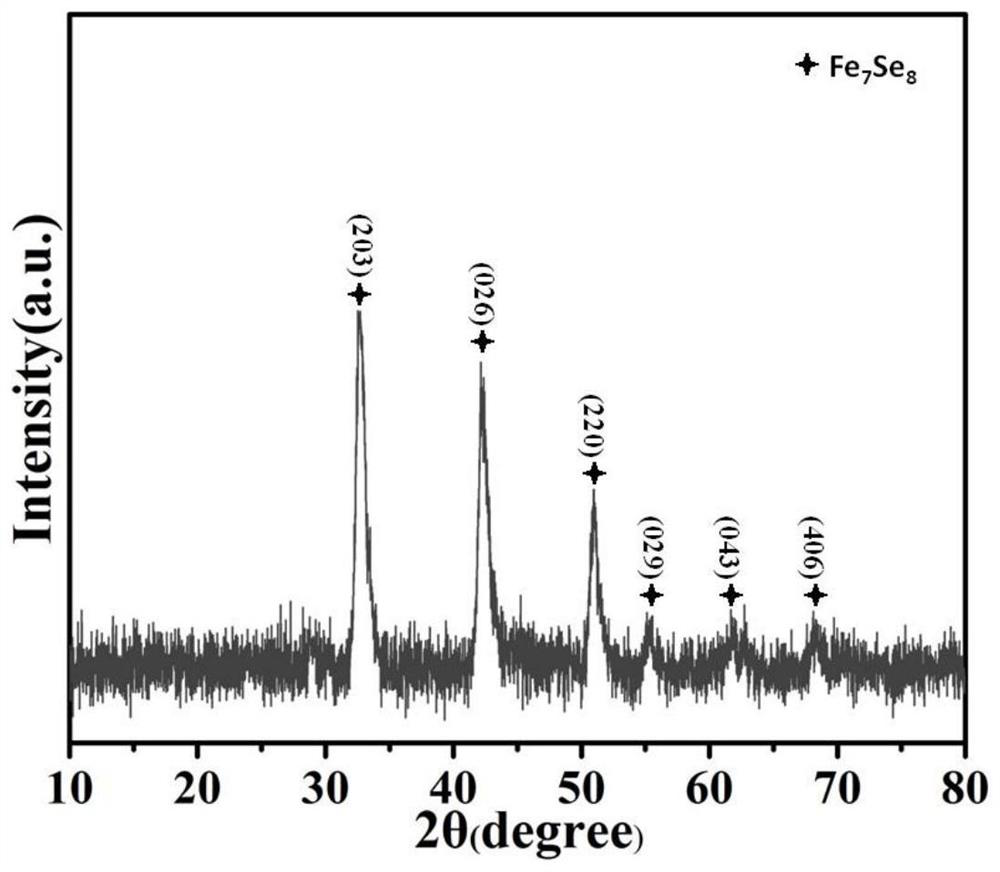

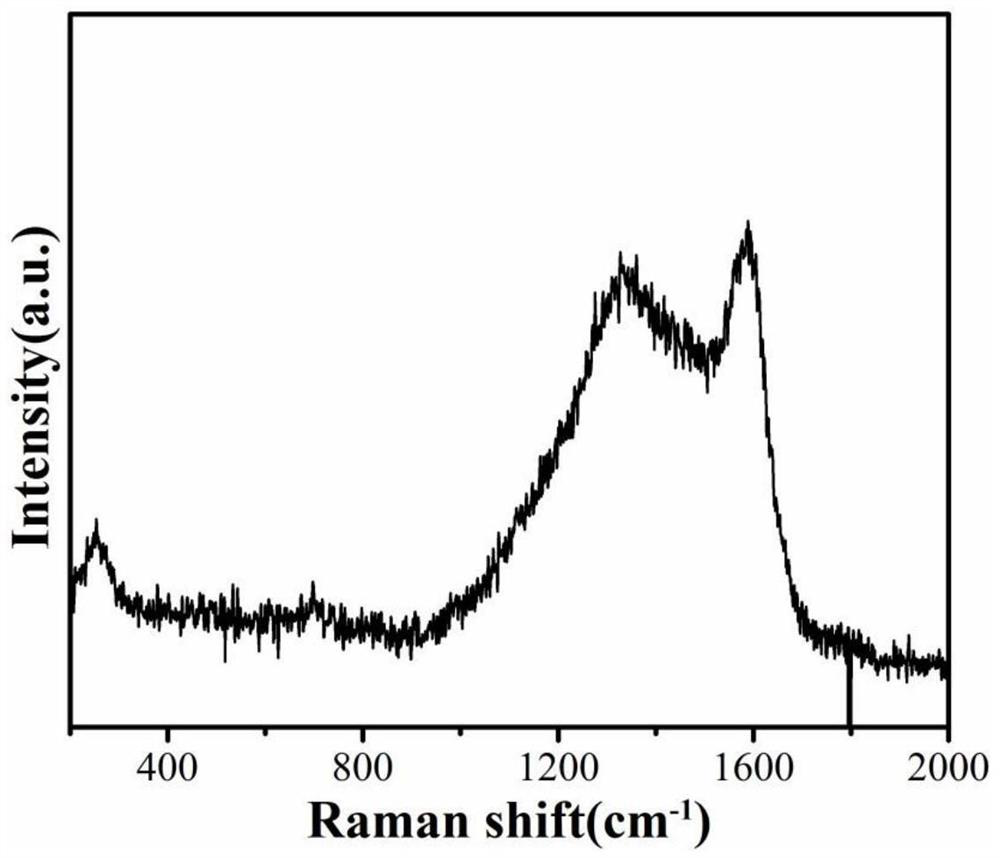

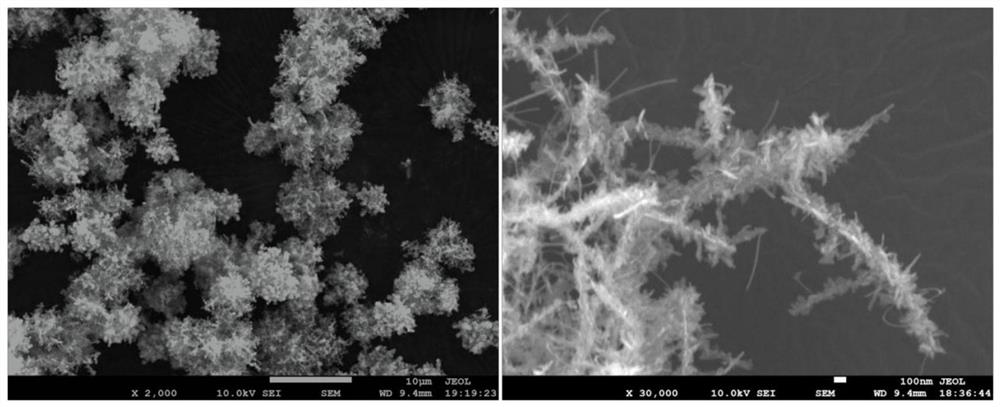

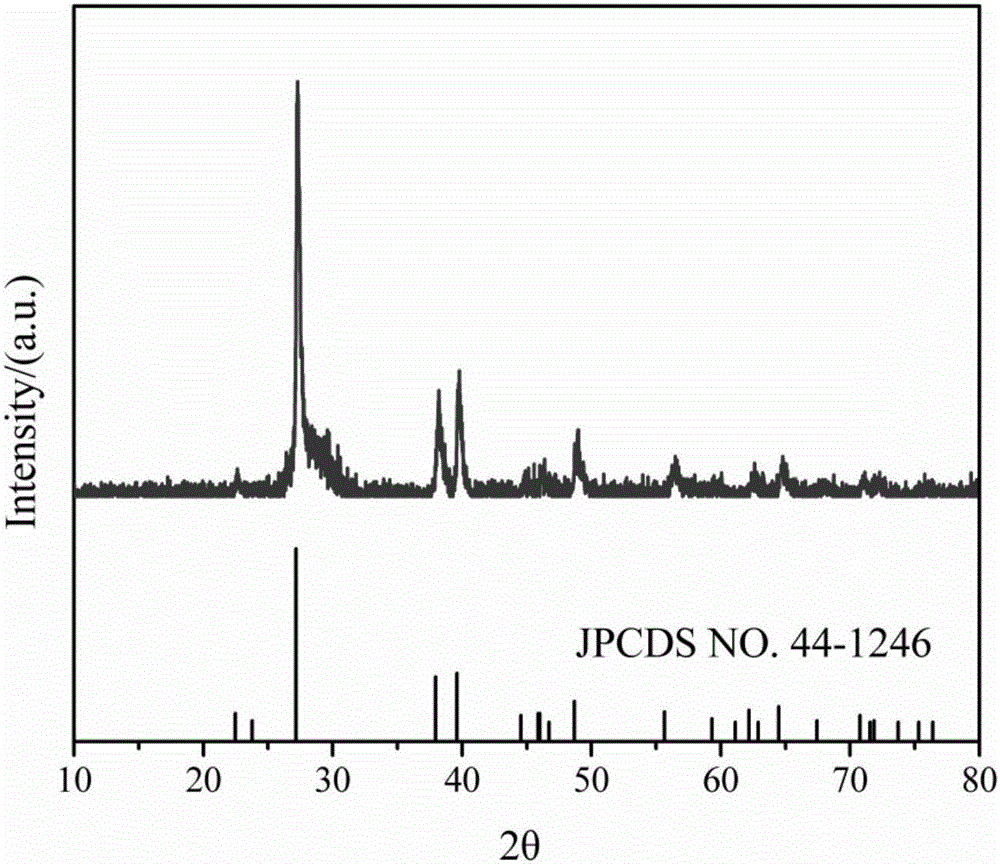

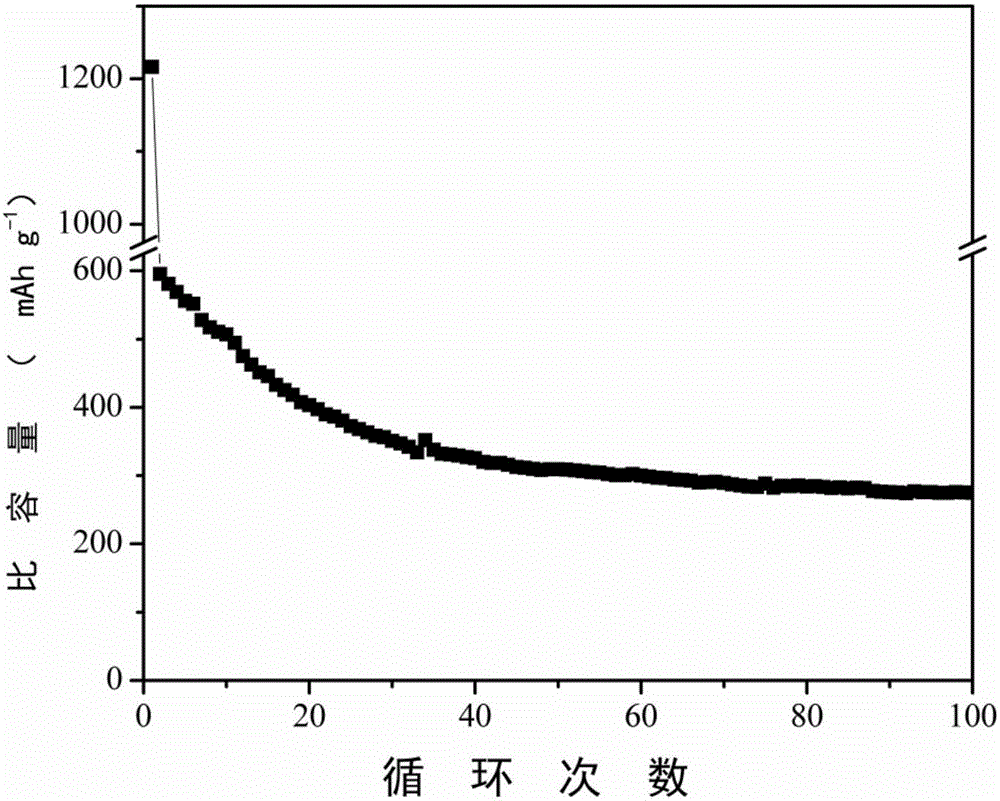

High-rate composite negative electrode material of sodium ion battery and preparation method thereof

ActiveCN112786853AUniform loadPollution-free pressureMaterial nanotechnologyNegative electrodesTube furnacePhysical chemistry

The invention belongs to the technical field of sodium-ion batteries, and particularly relates to a high-rate composite negative electrode material of a sodium-ion battery and a preparation method thereof. The method mainly comprises the following steps: uniformly mixing ferrocene and selenium powder serving as raw materials according to a proper ratio, and heating in a closed reaction kettle protected by inert atmosphere; after a heating mechanism is precisely controlled, performing natural cooling to reach the room temperature; placing the kettle bottom product in a tubular furnace, and carrying out proper heat treatment in an inert atmosphere to obtain the high-rate composite negative electrode material. The method is simple in process route, does not generate waste gas and waste water in the preparation process, and is easy for large-scale production.

Owner:SHANXI UNIV

A kind of preparation method of self-supporting three-dimensional porous graphene composite microspheres

ActiveCN104591177BOvercome the disadvantages of prone to reunionOvercome the disadvantages of reunionPorous grapheneKerosene

The invention aims at less current research and development on graphene-modified electrode material for energy storage devices such as a sodium ion battery, provides a method for preparing a self-supporting three-dimensional porous graphene composite microsphere and belongs to the technical field of novel carbon materials. The method comprises the following steps of mixing graphene with water, an activator and a binder and stirring to obtain a slurry, carrying out spray-drying and granulating to obtain the graphene microsphere containing the activator; dissolving petroleum pitch in kerosene, adding the graphene microsphere, uniformly mixing and drying to obtain the carbon-precursor-coated graphene microsphere; and carrying out heat treatment on the microsphere to obtain the self-supporting three-dimensional porous graphene composite microsphere. The self-supporting three-dimensional porous graphene composite microsphere obtained by using the method has the characteristics of stable structure, high gap content, high bulk density and the like. The sodium ion battery prepared from the graphene composite microsphere has the advantages of high capacity, good high-current discharge performance, excellent cycle performance, large packing density and the like.

Owner:江苏嘉明碳素新材料有限公司

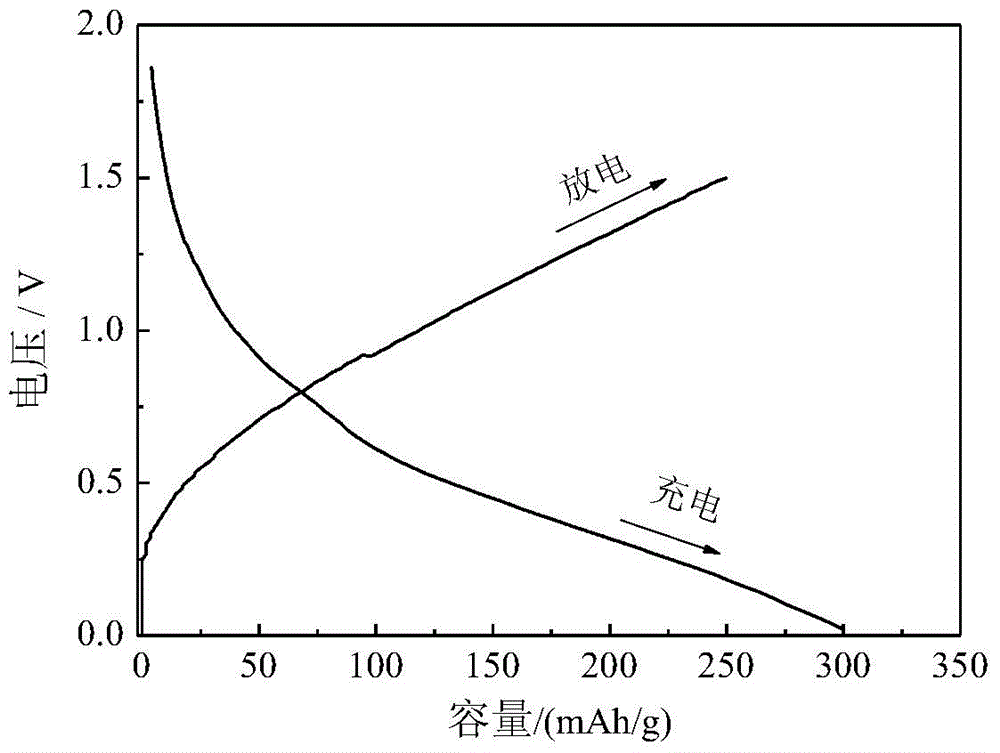

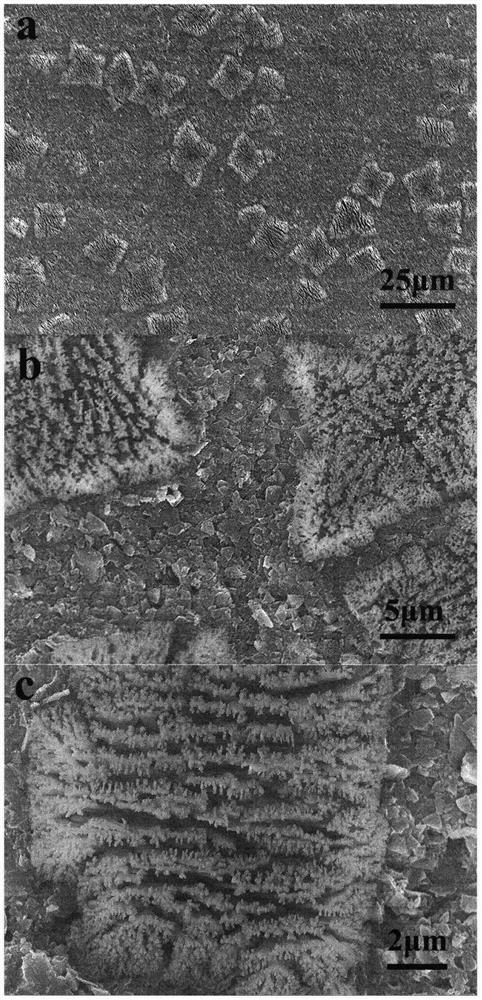

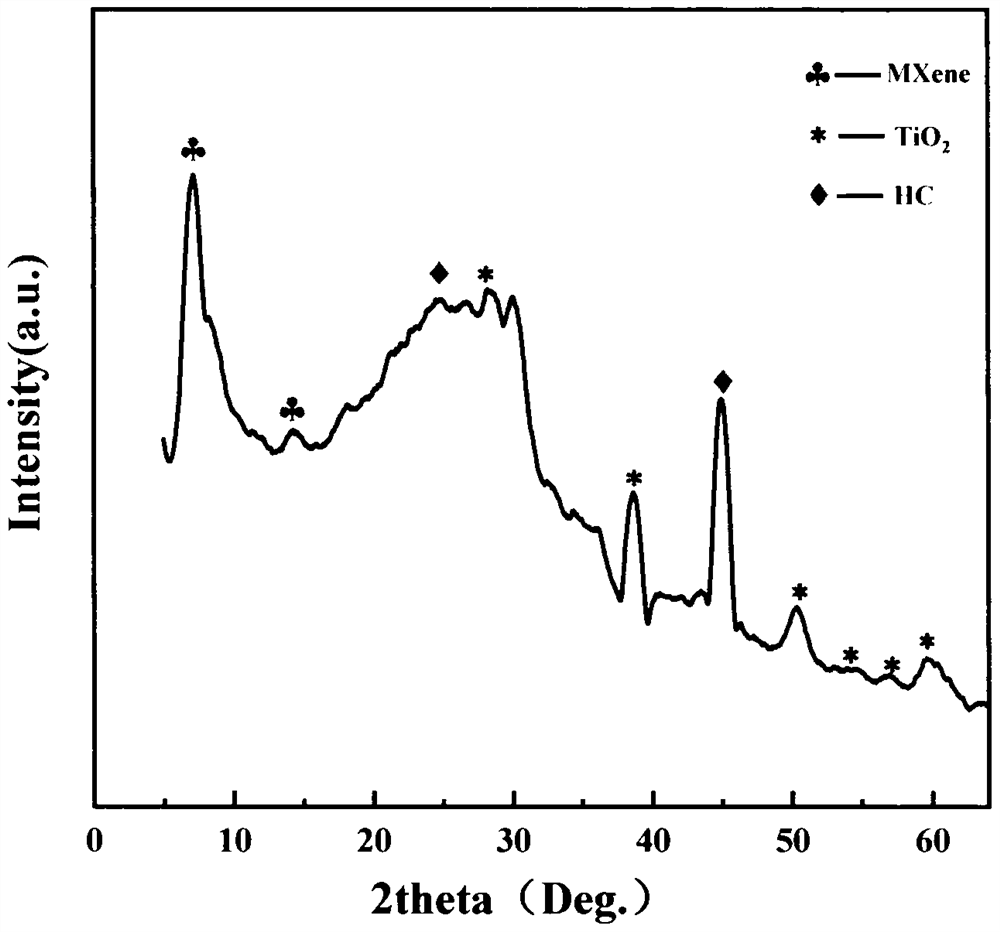

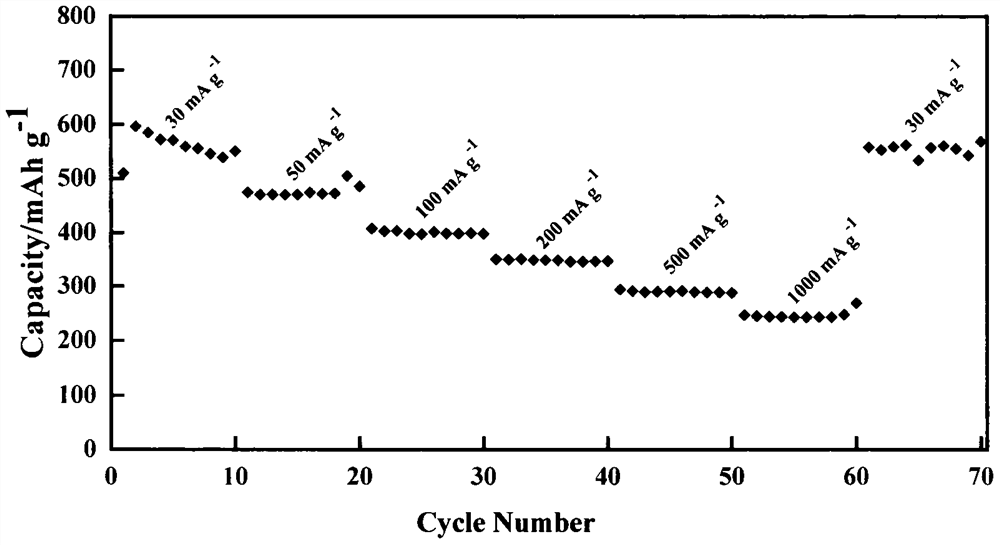

Preparation method of in-situ oxidation growth flower-like structure TiO2/MXene/hard carbon sodium ion battery negative electrode material

PendingCN113314705ALow costEasy to manufactureSecondary cellsNegative electrodesCarbon compositesElectrical battery

The invention belongs to the technical field of sodium ion batteries, and particularly relates to a preparation method of an in-situ oxidation growth flower-like structure TiO2 / MXene / hard carbon sodium ion battery negative electrode material. The method comprises the following steps: (1) in an air atmosphere, heating popcorn to 230-280 DEG C, and carrying out pre-oxidation treatment; (2) putting the pre-oxidized popcorn into an atmosphere furnace, and carbonizing at 800-1400 DEG C for 2-3 hours to obtain popcorn hard carbon; (3) grinding and sieving the popcorn hard carbon to obtain hard carbon powder with a particle size of less than 48 [mu] m; and (4) mixing the sieved hard carbon powder with multiple layers of MXene, and carrying out ball milling in an air environment by taking water as a solvent. Under the action of huge energy generated by collision of ball-milling beads, the multiple layers of MXene are stripped and react with air to generate TiO2 nanorods through in-situ oxidation at the same time, so that a TiO2 / MXene / hard carbon composite material with a flower-shaped structure, namely the sodium ion battery negative electrode material, is formed. A unique flower-shaped structure is formed through ball milling regulation and control, and the sodium storage performance of the material is improved. When the composite material is used as a negative electrode of a room-temperature sodium-ion battery, the specific capacity of the battery can be effectively improved, and the cycle performance is enhanced. Meanwhile, the method is simple and feasible to operate, pollution-free to environment and suitable for popularization and application.

Owner:TIANJIN POLYTECHNIC UNIV

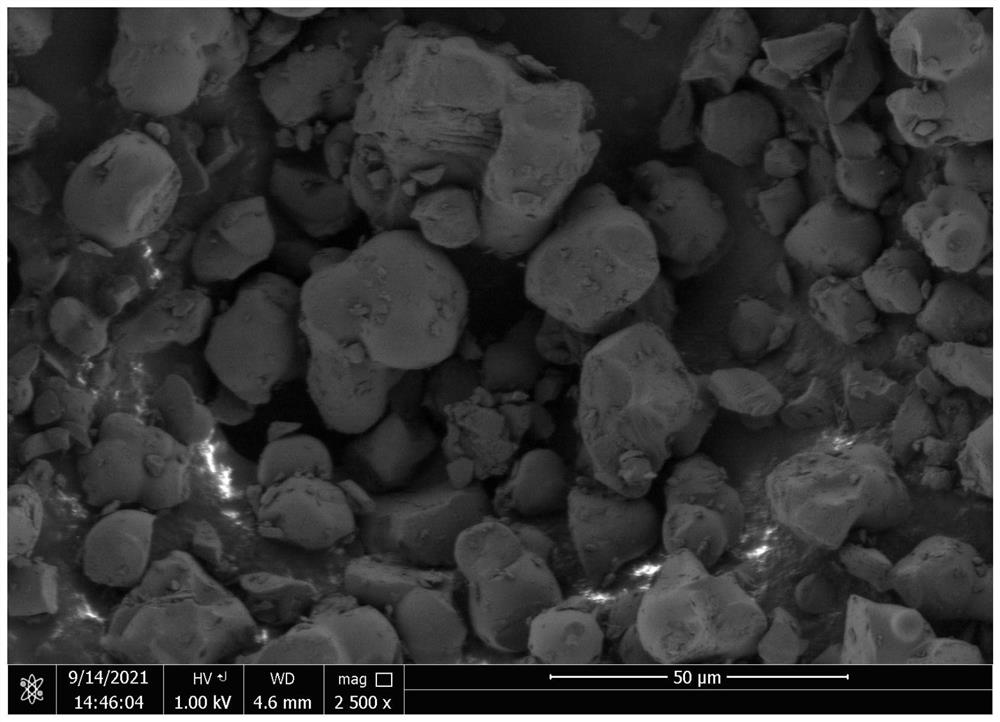

High-performance special structure monodisperse carbon sphere anode material and preparation method and application thereof

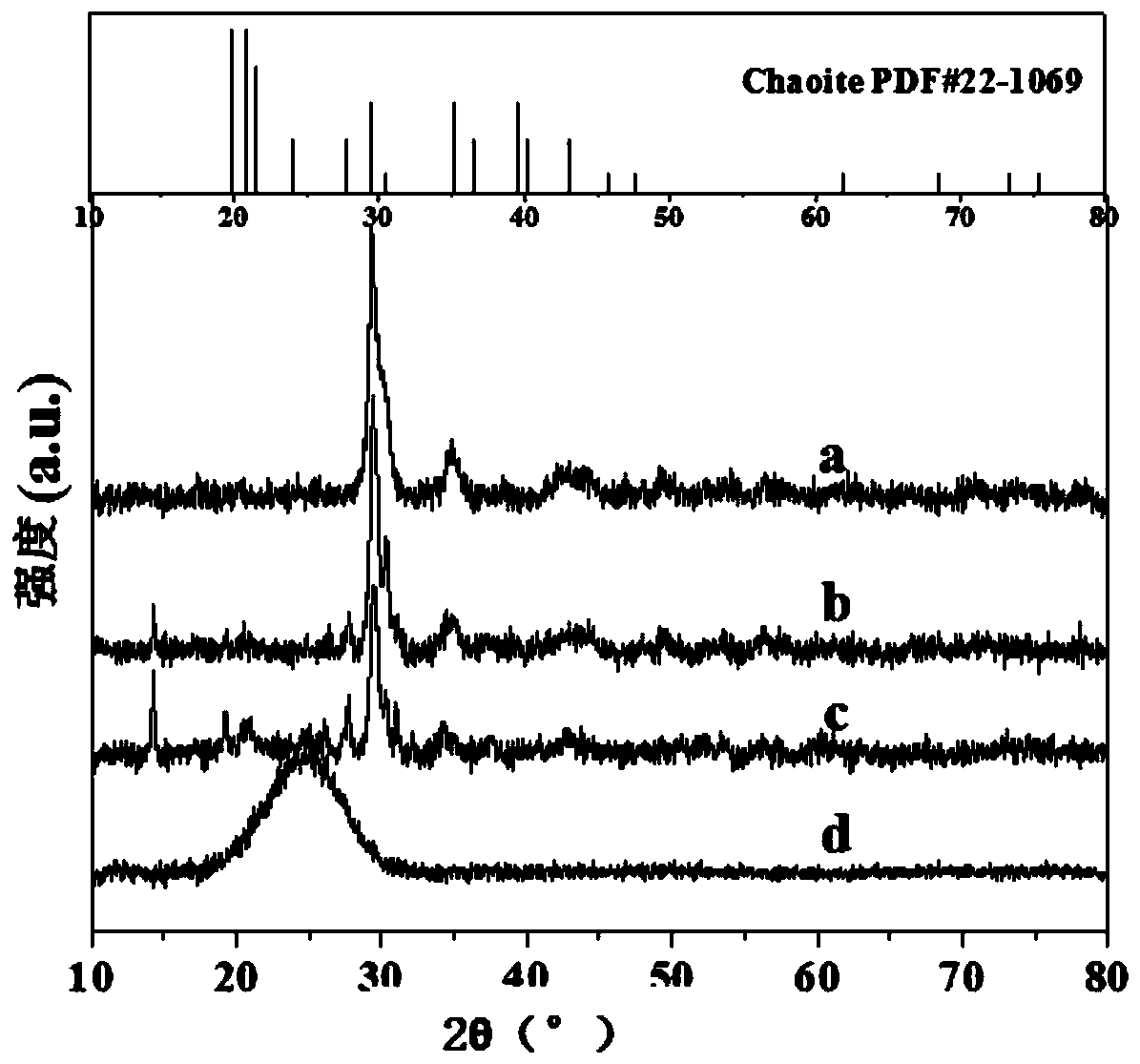

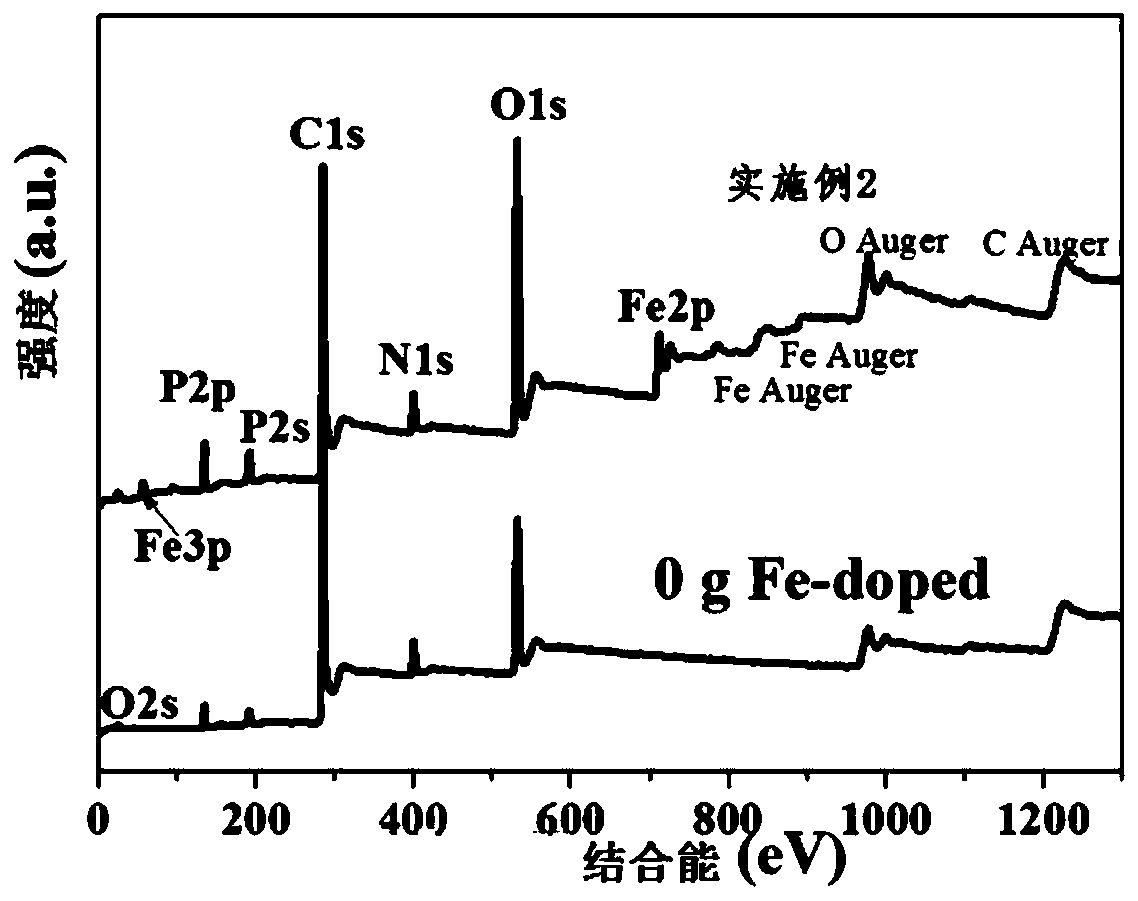

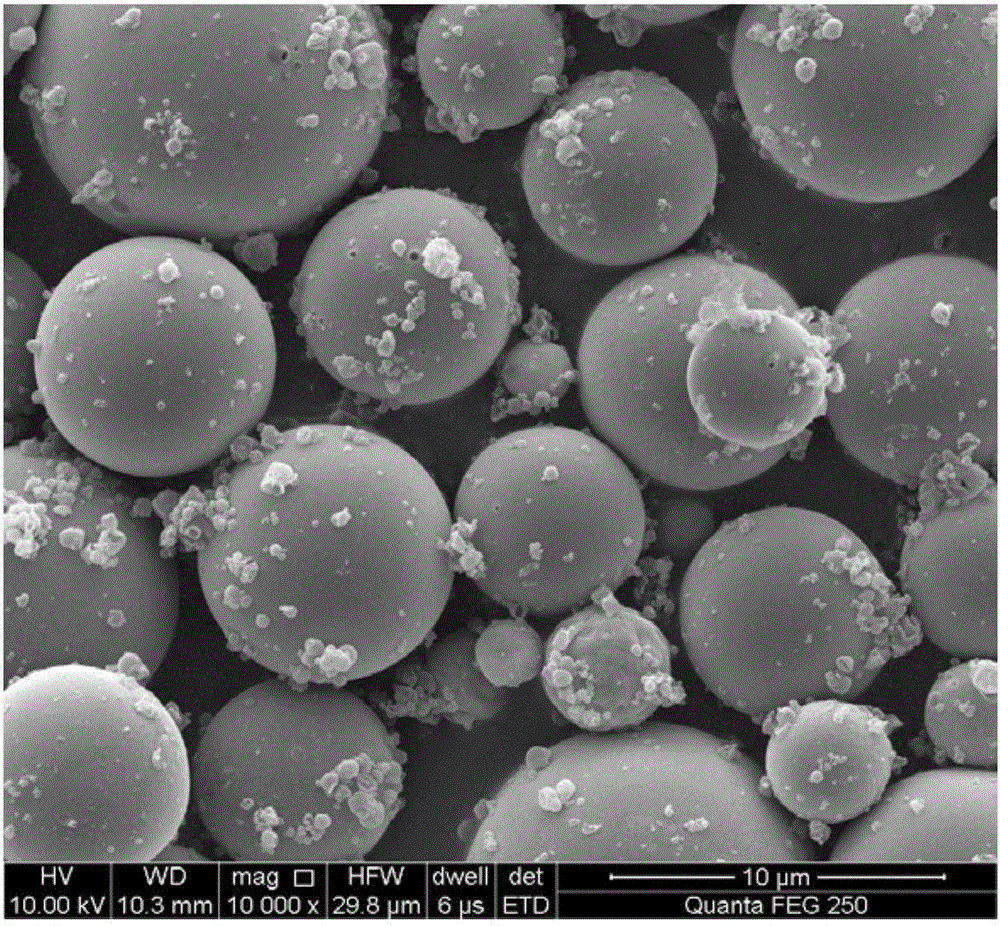

ActiveCN109713256AImprove and extend cycle performanceIncrease sodium storage capacityCell electrodesSecondary cellsIonPyrrole

The invention discloses a high-performance special structure monodisperse carbon sphere and a preparation method and application thereof. The preparation method comprises the following steps: adding phytic acid, P123 and ferric sulfate salt to a solution of pyrrole or aniline monomer; performing magnetic stirring the mixture in an ice bath; adding an ammonium persulfate aqueous solution to initiate a polymerization reaction; and finally preparing iron-doped special spherical carbon structural material with a monodisperse property by high-temperature carbonization. The iron-doped spherical carbon designed and prepared by the method according to the characteristics of charge and discharge cycle of sodium battery anode material exhibits a Chaoite structure type. The particle sizes of all materials are substantially uniform and have a monodisperse property.The material characteristic is favorable for eliminating the polarization of the electrode material, and the large lattice spacing is favorable for the storage of sodium ions, thereby improving the electrochemical performance of the electrode material. The material is cheap in raw materials, simple in operation process, high in yield, excellent in charge and discharge performance, and convenient for industrial production.

Owner:临汾袤源新材料科技有限公司

A bismuth/nitrogen-doped carbon sphere negative electrode composite material for sodium ion battery and preparation method thereof

InactiveCN105024056BImprove structural stabilityImprove conductivityCell electrodesSecondary cellsElectrical batterySodium-ion battery

The invention discloses a preparation method for bismuth / nitrogen-doped carbon-sphere composite anode material for a sodium ion battery. According to the preparation method, the bismuth / nitrogen-doped carbon-sphere composite anode material is obtained by carrying out spray pyrolysis on a mixed solution of a nitrogen-containing carbon source, a bismuth precursor, a surfactant and deionized water and then washing and drying the product. In the composite material prepared according to the method, bismuth nanoparticles are uniformly distributed in nitrogen-doped carbon spheres, and the bismuth content accounts for 50-90 percent by mass. The preparation process is simple, is low in cost, is easy to operate and is applicable for implementation in the industry and mass production, and the prepared sodium ion battery anode has the advantages of high mass specific capacity, favorable rate capability and the like.

Owner:CENT SOUTH UNIV

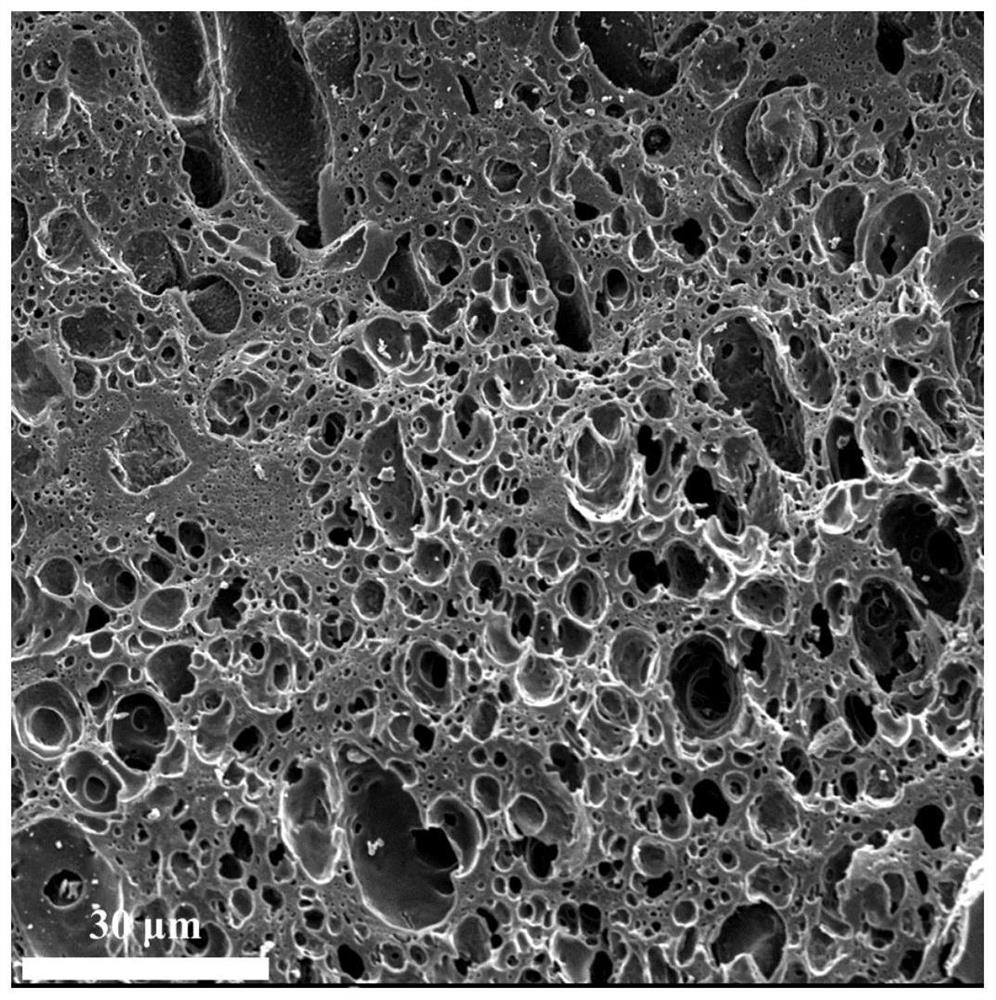

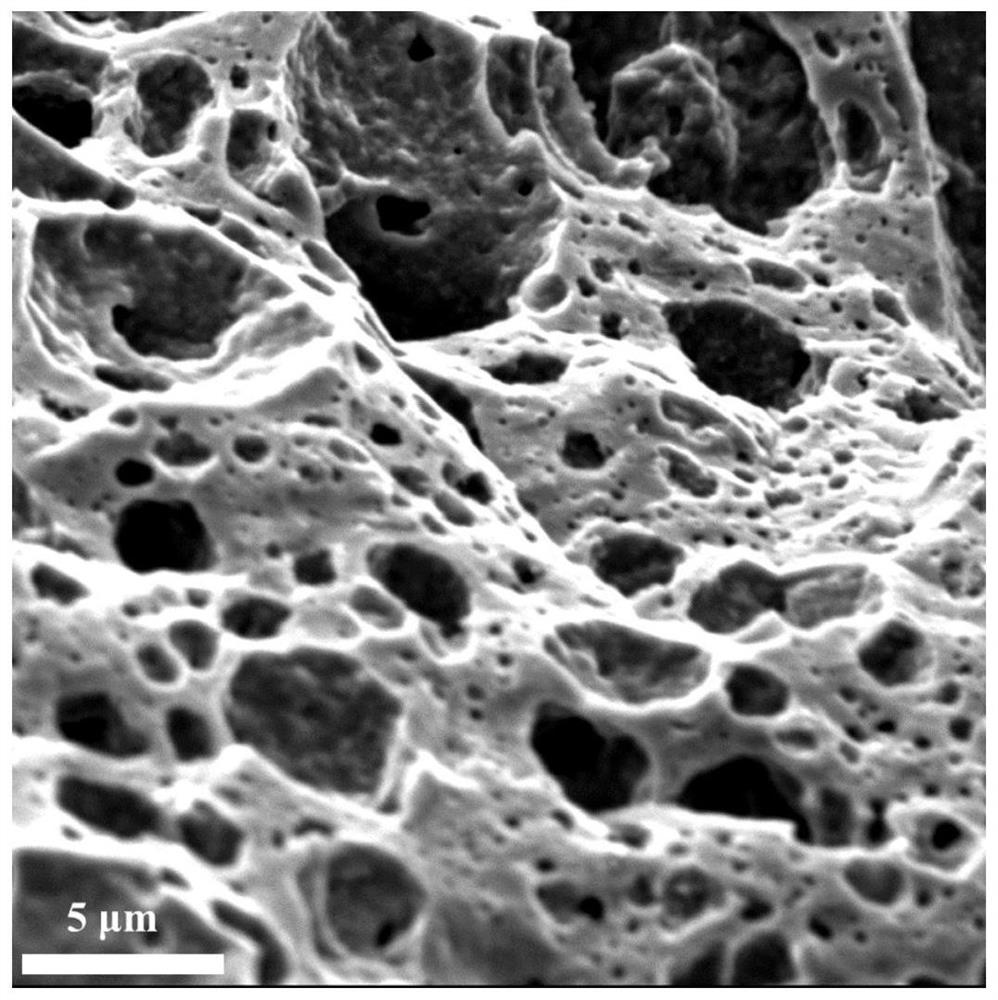

Ordered porous hard carbon for sodium ion battery

PendingCN113745510AFacilitated DiffusionIncrease usageNegative electrodesSecondary cellsElectrolytic agentElectrical battery

The invention provides an ordered porous hard carbon for a sodium ion battery. The preparation method of the ordered porous hard carbon for the sodium ion battery comprises the following steps: sequentially dissolving a polymer precursor and a phase separation accelerant in an organic solvent to form a mixed solution; heating the mixed solution in an oil bath and stirring to form a sol solution; uniformly dripping the sol solution on the surface of a mold to form a gel film; immersing the mold with the gel film formed on the surface in deionized water for phase separation; separating the obtained porous membrane from the mold and drying; and carbonizing the dried porous membrane in a protective atmosphere to form hard carbon. A sol-gel film is formed by selecting a phase separation accelerant with proper polarity and a specific precursor, ordered pore-forming can be quickly performed on the film through simple washing phase separation, and the carbonized material is similar to natural wood and has a large number of vertical and ordered macroporous channels, so that the material has a good application prospect. Therefore, the wettability and quick transmission of the electrolyte can be improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Nitrogen-doped porous carbon nanofiber sodium ion battery negative electrode material and preparation method thereof

PendingCN114361450AGood repeatabilityIncrease sodium storage capacityCell electrodesSecondary cellsElectrolytic agentCarbon fibers

The invention discloses a nitrogen-doped porous carbon nanofiber sodium ion battery negative electrode material and a preparation method thereof, and relates to the field of sodium ion secondary batteries. Polyvinylpyrrolidone (PVP) and polytetrafluoroethylene (PTFE) are used as raw materials; the nitrogen-doped porous carbon nanofiber sodium ion battery negative electrode material without the binder and the conductive agent is prepared through electrostatic spinning. Wherein the nitrogen-doped porous carbon fiber increases the conductivity, the porous structure is beneficial to infiltration of an electrolyte, and the flexible carbon nanofiber membrane is beneficial to relieving the problem of volume expansion of the electrode material caused by separation and embedding of sodium ions in the electrode material, so that the cycling stability of the material is improved. The material is stable in physicochemical property, wide in raw material source, low in cost, good in electrochemical performance and high in safety, and has relatively high rate capability and good cycling stability when being used as an electrode.

Owner:SHANGHAI UNIV

Preparation method of modified sodium alginate-derived carbon negative electrode material with high sodium storage property

InactiveCN107565133AIncrease sodium storage capacityAvoid using dissolveCell electrodesHigh sodiumCarbonization

The invention discloses a preparation method of a modified sodium alginate-derived carbon negative electrode material with high sodium storage property. The method comprises the steps of firstly, directly putting sodium alginate into an inert atmosphere for high-temperature carbonization to obtain sodium alginate-derived carbon, soaking the sodium alginate-derived carbon component into strong oxidizing acids (such as a nitric acid, a sulfuric acid or a mixed acid of the nitric acid and the sulfuric acid) for a certain period of time to remove an inorganic small molecule compound; secondly, pouring the mixed solution into a hydrothermal reactor for hydrothermal oxidation to prepare modified sodium alginate-derived carbon; and finally filtering, washing the modified sodium alginate-derived carbon to neutral, carrying out alcohol-washing and drying in sequence to obtain a final product. The prepared oxidatively modified sodium alginate-derived carbon material is taken as the negative electrode material of a sodium-ion battery, and is simple in preparation process and low in cost; a pseudocapacitance sodium storage active site can be introduced; and the sodium storage capacity of the electrode material is improved, so that the problem of relatively low sodium storage capacity of an existing carbon-based negative electrode material is overcome and the preparation method has a good application prospect.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

A kind of preparation method of sodium titanate/graphene composite negative electrode material for sodium ion battery

ActiveCN104600271BEasy to storeFacilitated DiffusionCell electrodesSecondary cellsHigh sodiumSodium-ion battery

The invention provides a preparation method of a sodium titanate / graphene composite cathode material of a sodium ion battery, which is used for solving the problems in the prior art that no sodium ion battery cathode material with excellent comprehensive performance is provided, and belongs to the field of sodium ion secondary batteries. The method comprises the steps of dispersing graphene oxide to obtain a graphene oxide solution, mixing the graphene oxide solution, a sodium-containing compound and a titanium-containing compound, carrying out reaction to obtain a composite precursor, mixing the composite precursor with a binder, carrying out atomizing drying and granulating to obtain a spherical composite precursor, and finally burning the spherical composite precursor in an inert atmosphere to obtain a micro-scale spherical sodium titanate / graphene composite cathode material. The composite cathode material has the advantages of high sodium storage capacity, long cycle life, good large-current discharge property, high compaction density and the like, and the requirement of the high-performance sodium ion battery for the comprehensive performance of the cathode material can be met.

Owner:LIAONING TECHNICAL UNIVERSITY

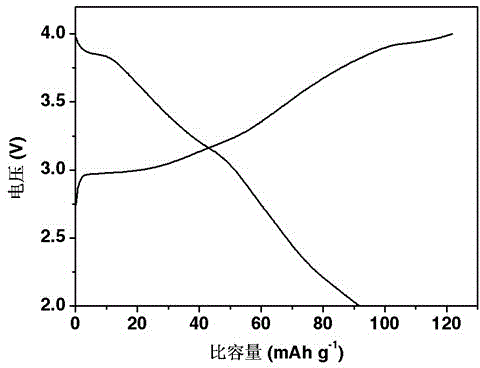

Hard carbon negative electrode material and preparation method and application thereof

PendingCN114497545AGood sodium storage environmentIncrease sodium storage capacityCell electrodesSecondary cellsPore diameterElectrode material

The invention discloses a hard carbon negative electrode material and a preparation method and application thereof. The substrate of the hard carbon negative electrode material is prepared by taking starch as a raw material; the diameter of an internal pore of the hard carbon negative electrode material is greater than that of a surface pore. The reasonable pore diameter and the large interlayer spacing of the hard carbon negative electrode material are beneficial to intercalation / deintercalation of sodium ions.

Owner:GUANGDONG BRUNP RECYCLING TECH +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com