Preparation and application of high-performance sodium-ion battery energy storage material based on regulation and control of hard carbon structure through ion catalysis

A sodium-ion battery, high-performance technology, applied to structural parts, battery electrodes, secondary batteries, etc., to achieve high safety, high rate performance, and increased curvature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with examples, but the embodiments of the present invention are not limited thereto.

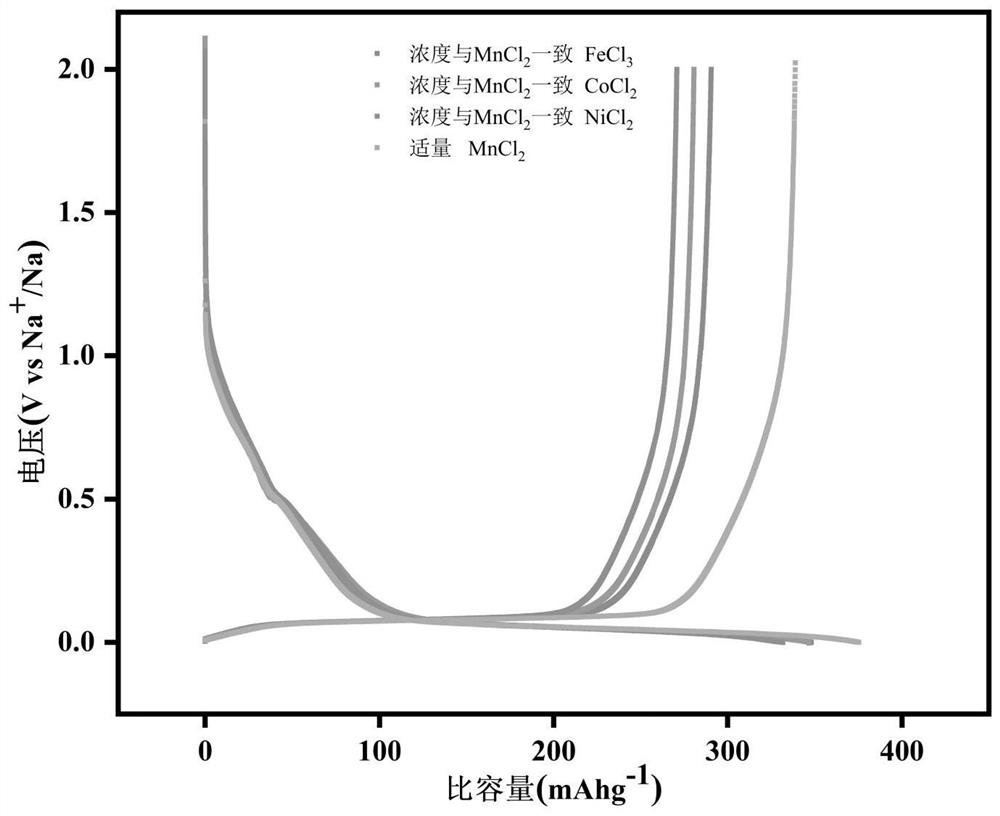

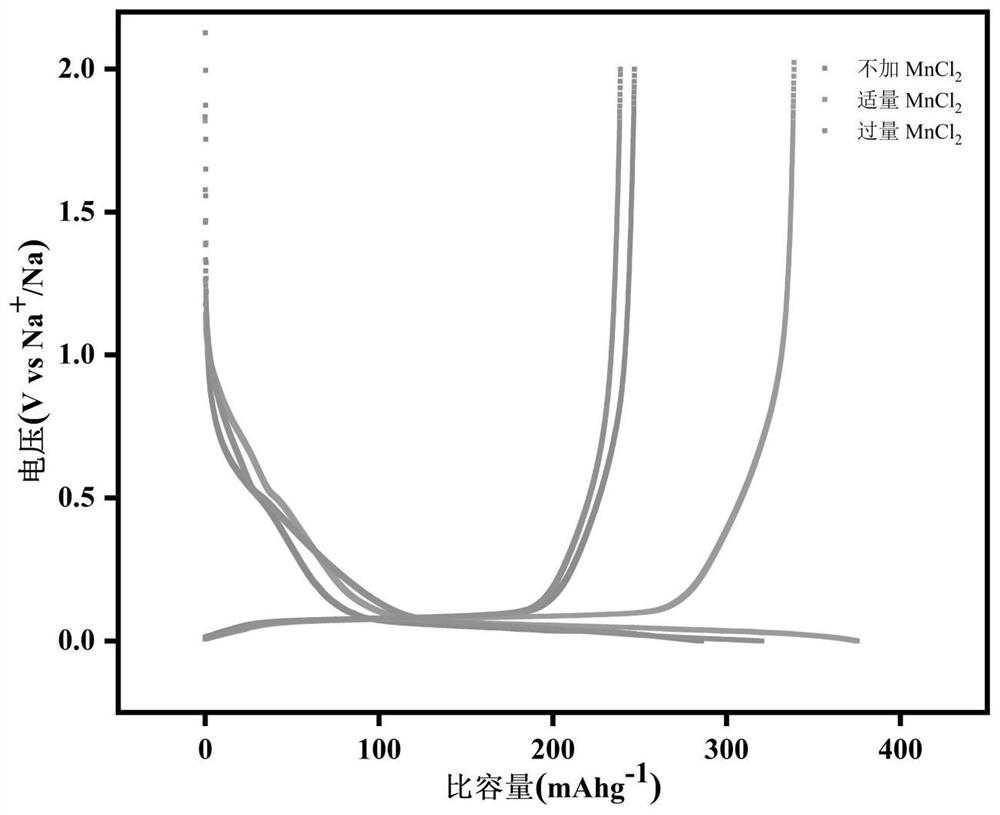

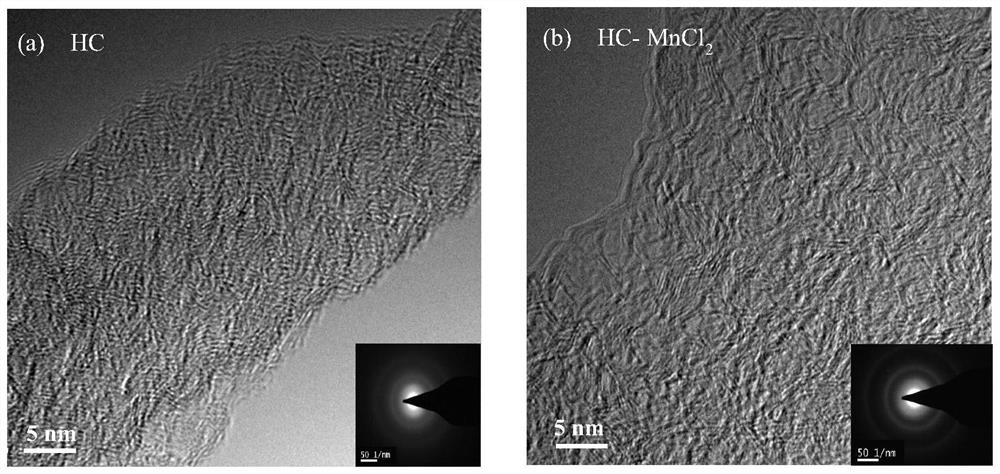

[0032] The transition metal manganese regulated hard carbon structure provided in this experiment realizes the preparation and application of high-performance sodium-ion battery energy storage materials, including the following steps:

[0033] S1: Soak the carbon source precursor in 0.04mol / L MnCl 2 Soak in the solution for 30min.

[0034] S2: The impregnated materials were stacked between graphite plates, and carbonized at 1400°C in an argon (Ar) gas atmosphere for a carbonization time of 4 hours to obtain a hard carbon material regulated by transition metals.

[0035] The hard carbon material regulated by the flexible transition metal obtained by carbonization is used to cut the pole pieces with a 10mm mold, and the cut pole pieces are stored in a vacuum oven at 90°C.

[0036] The electrochemical perfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com