Patents

Literature

44results about How to "Facilitates insertion and extraction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

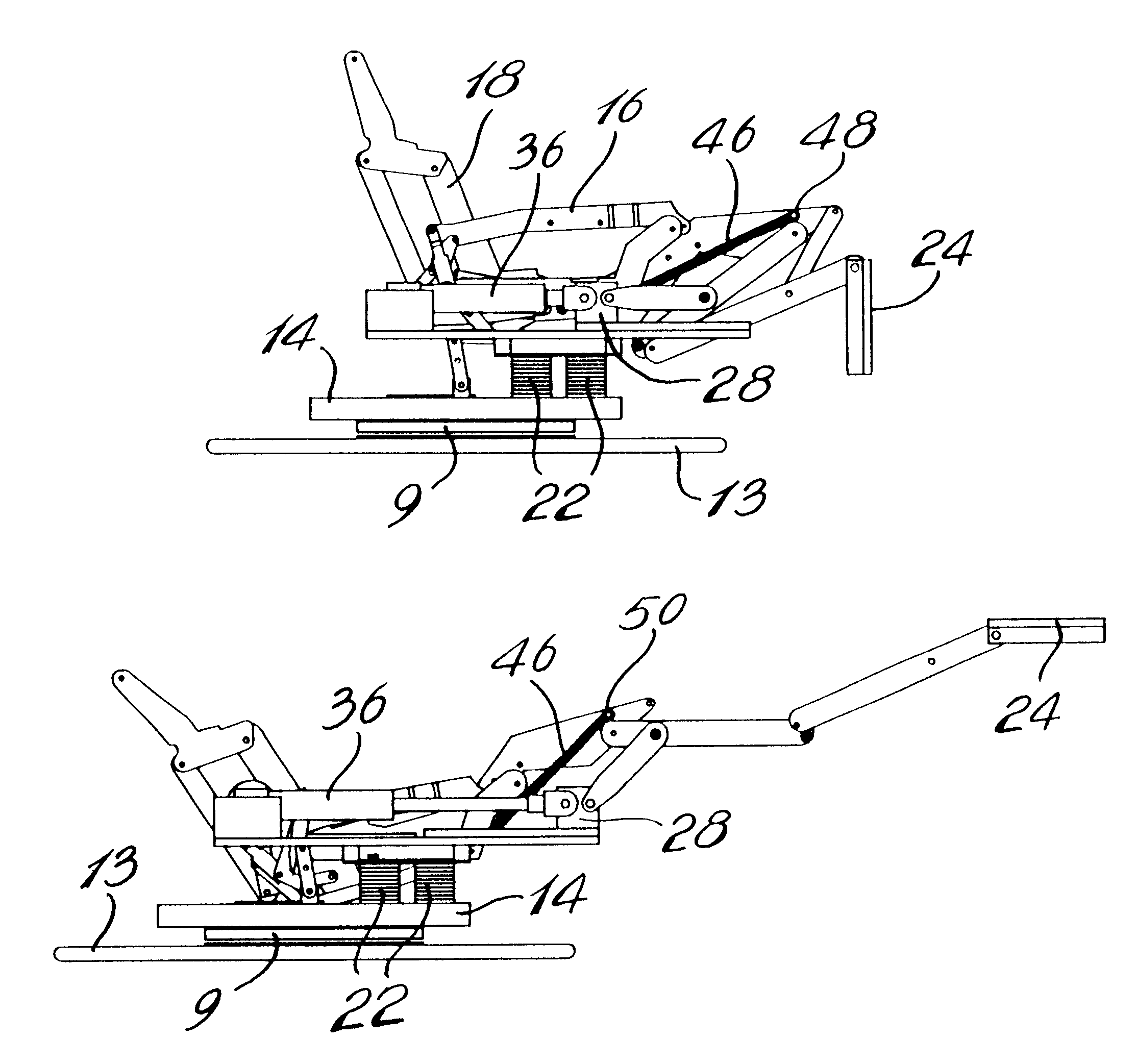

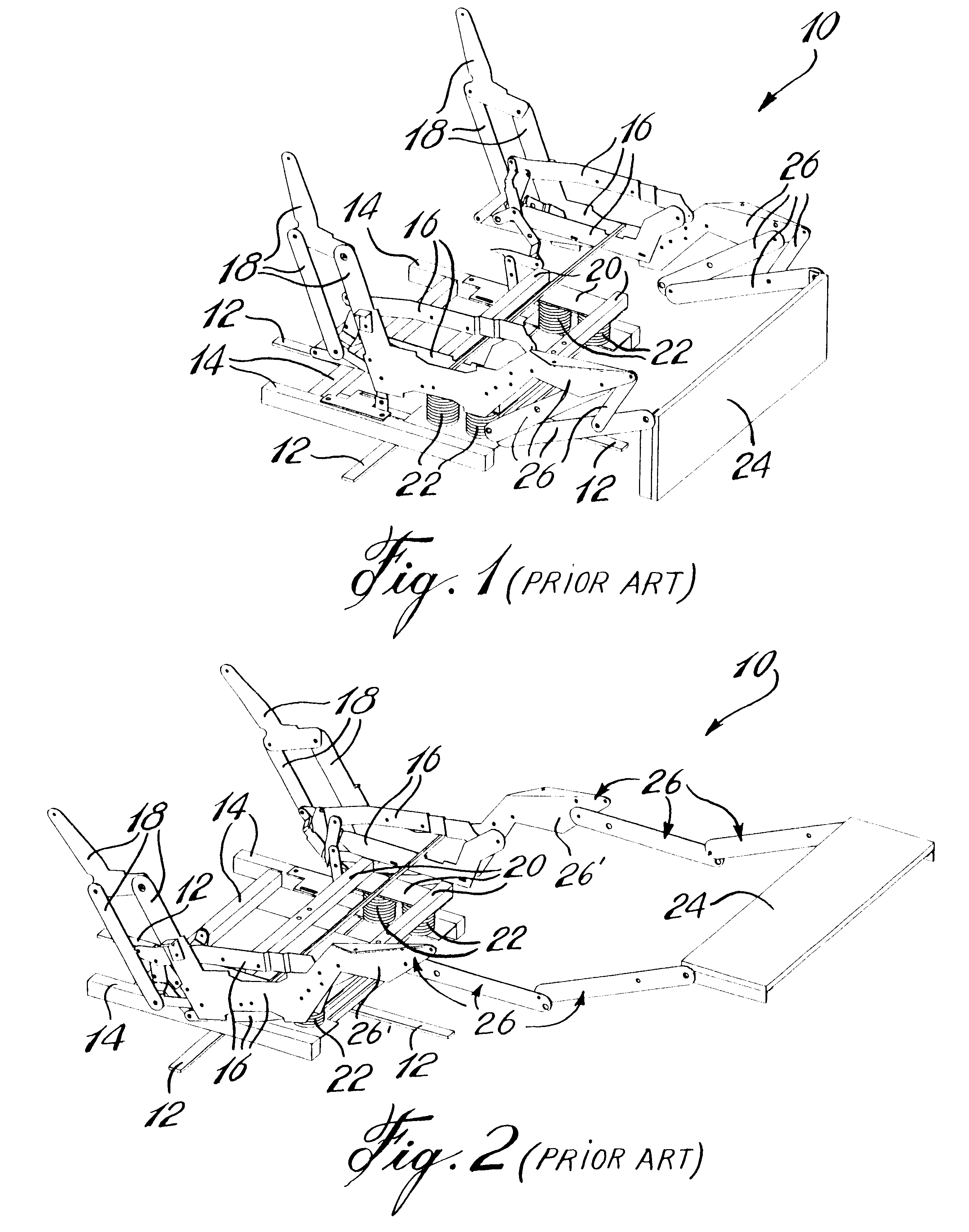

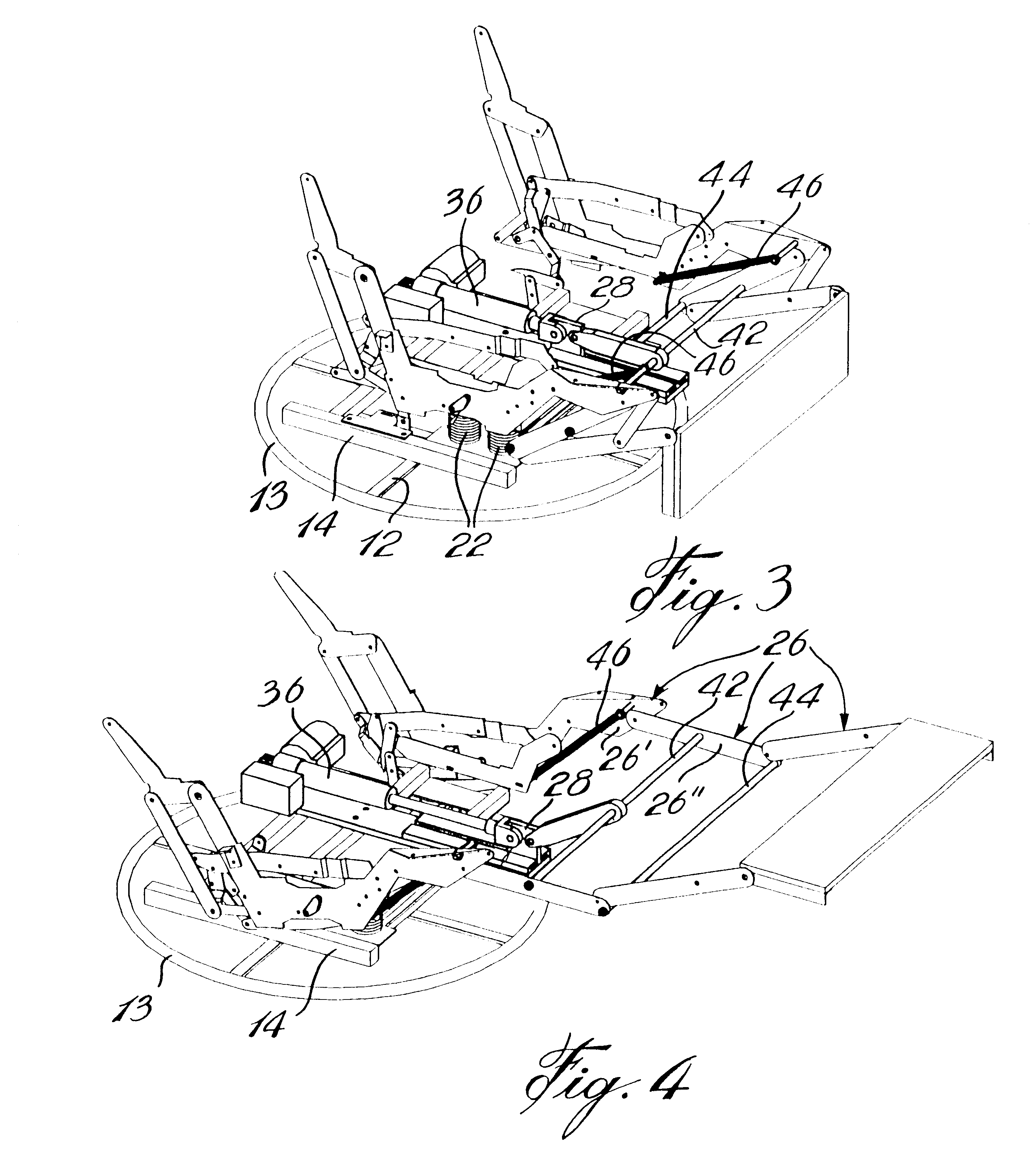

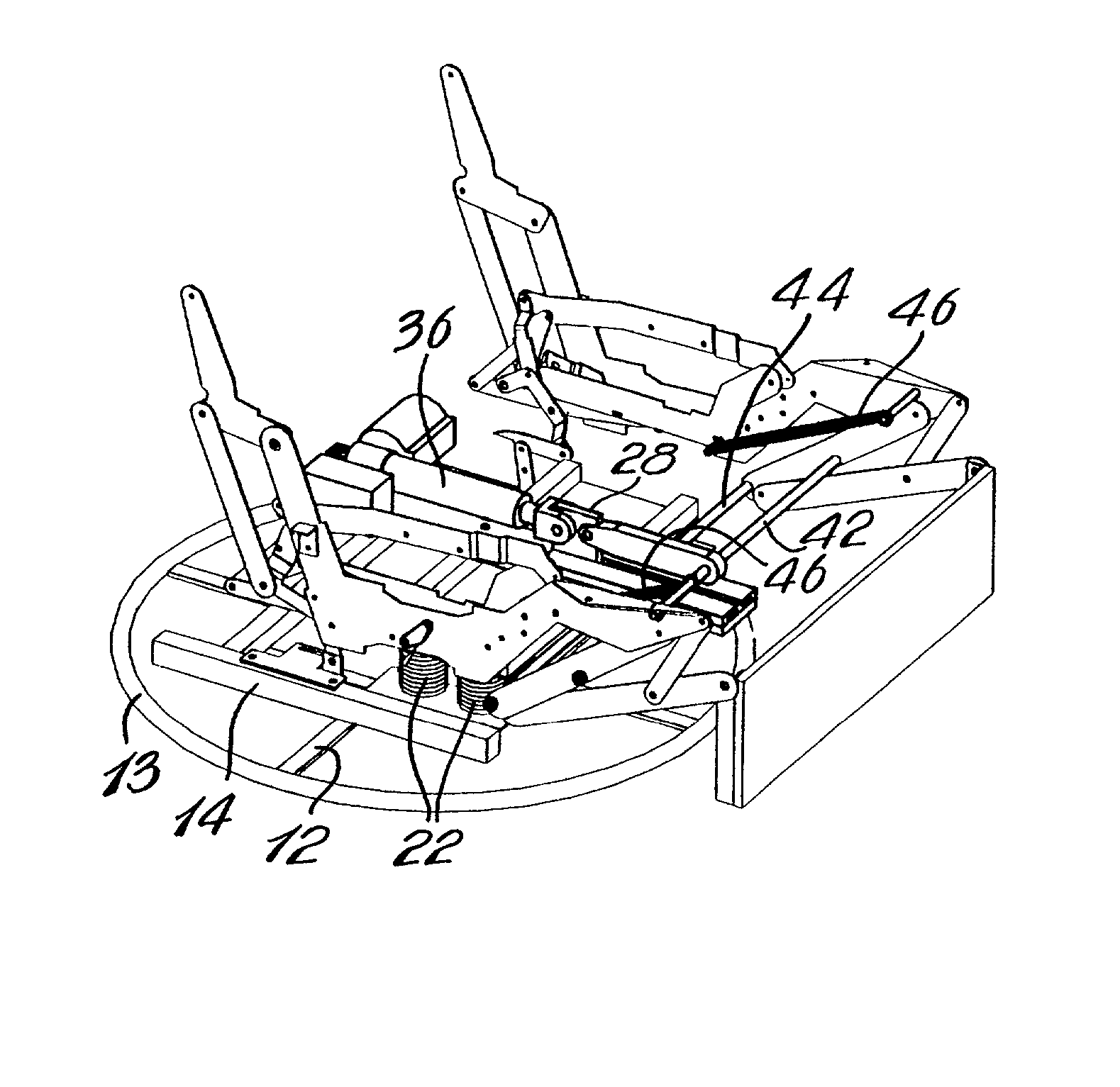

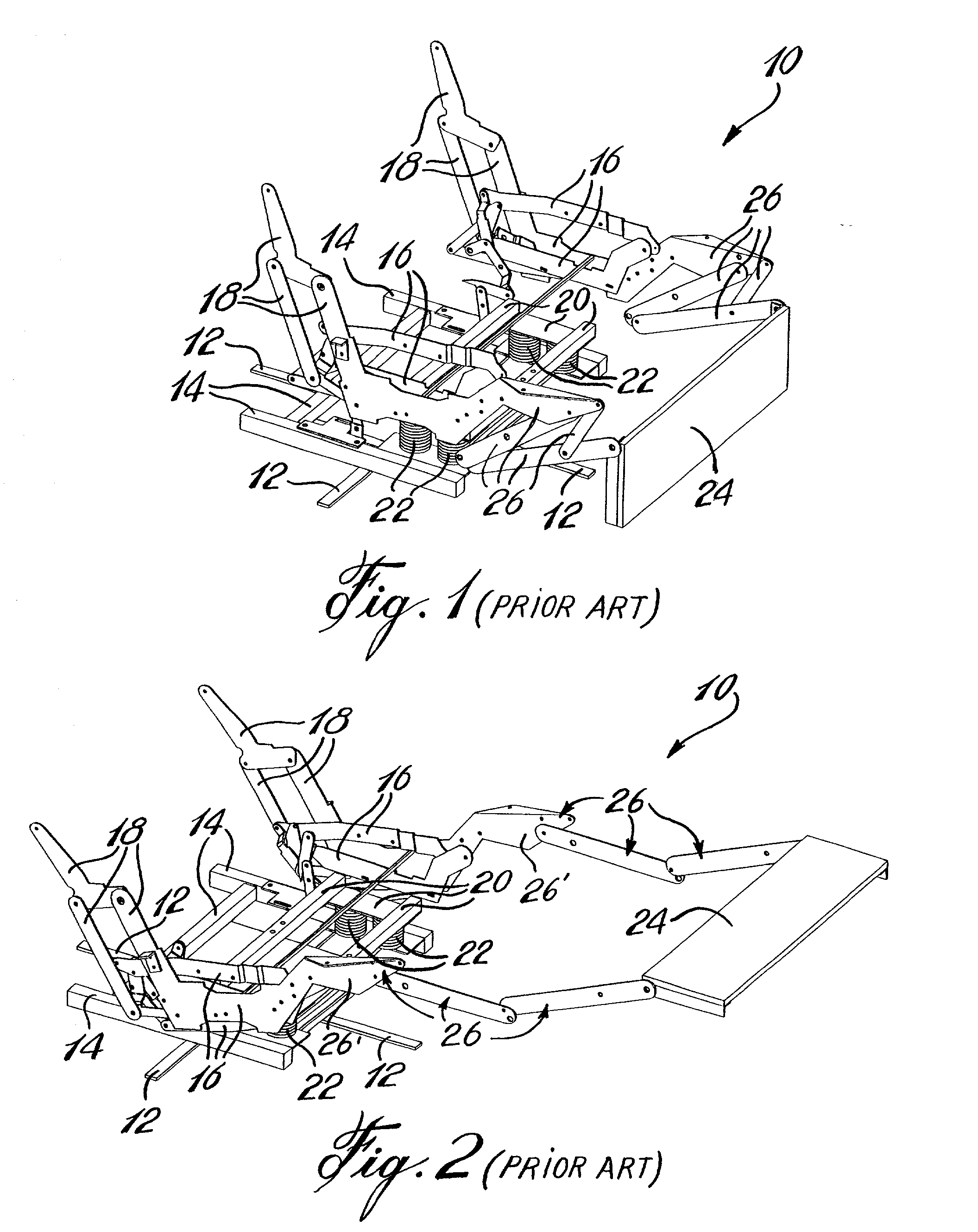

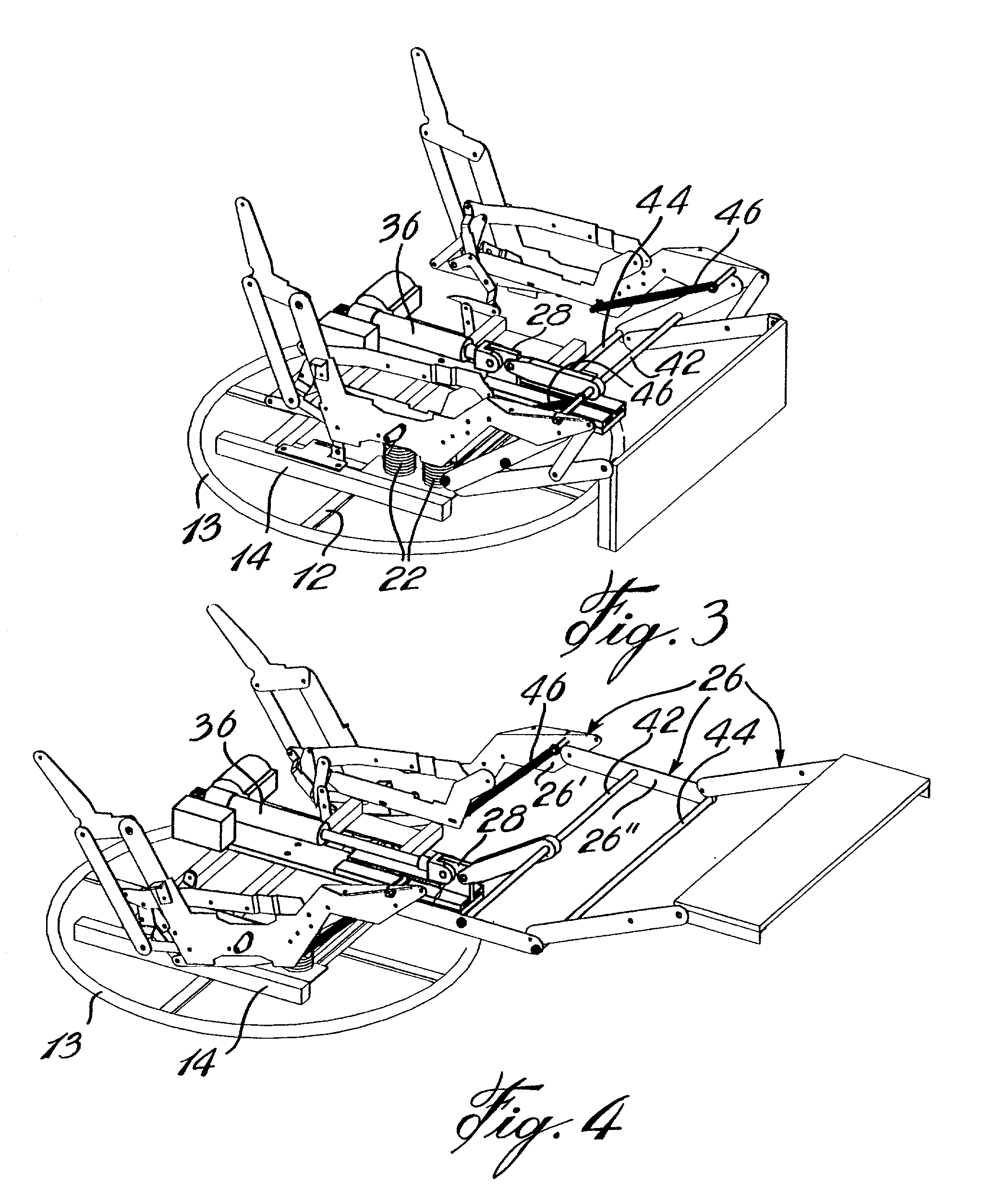

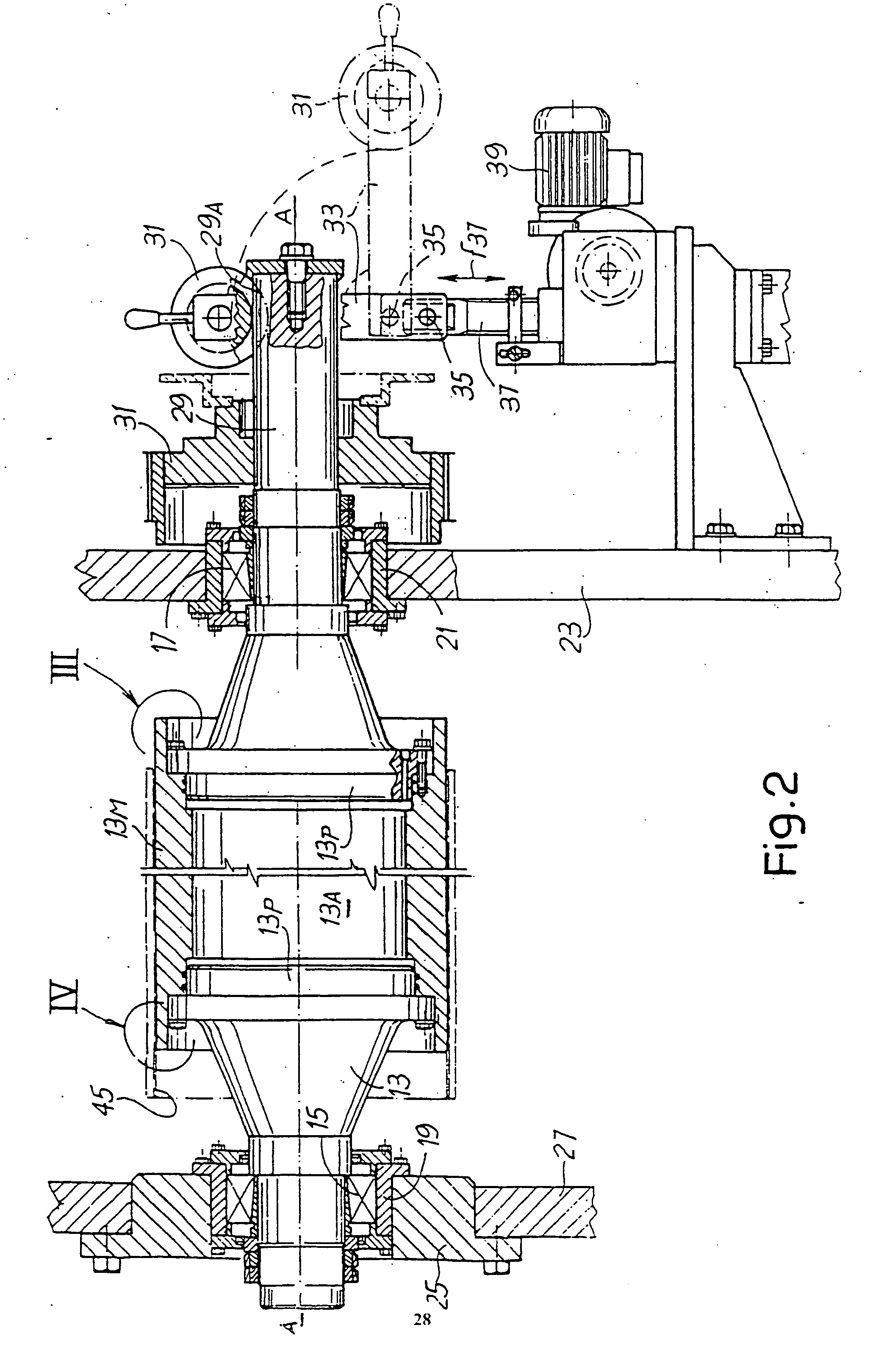

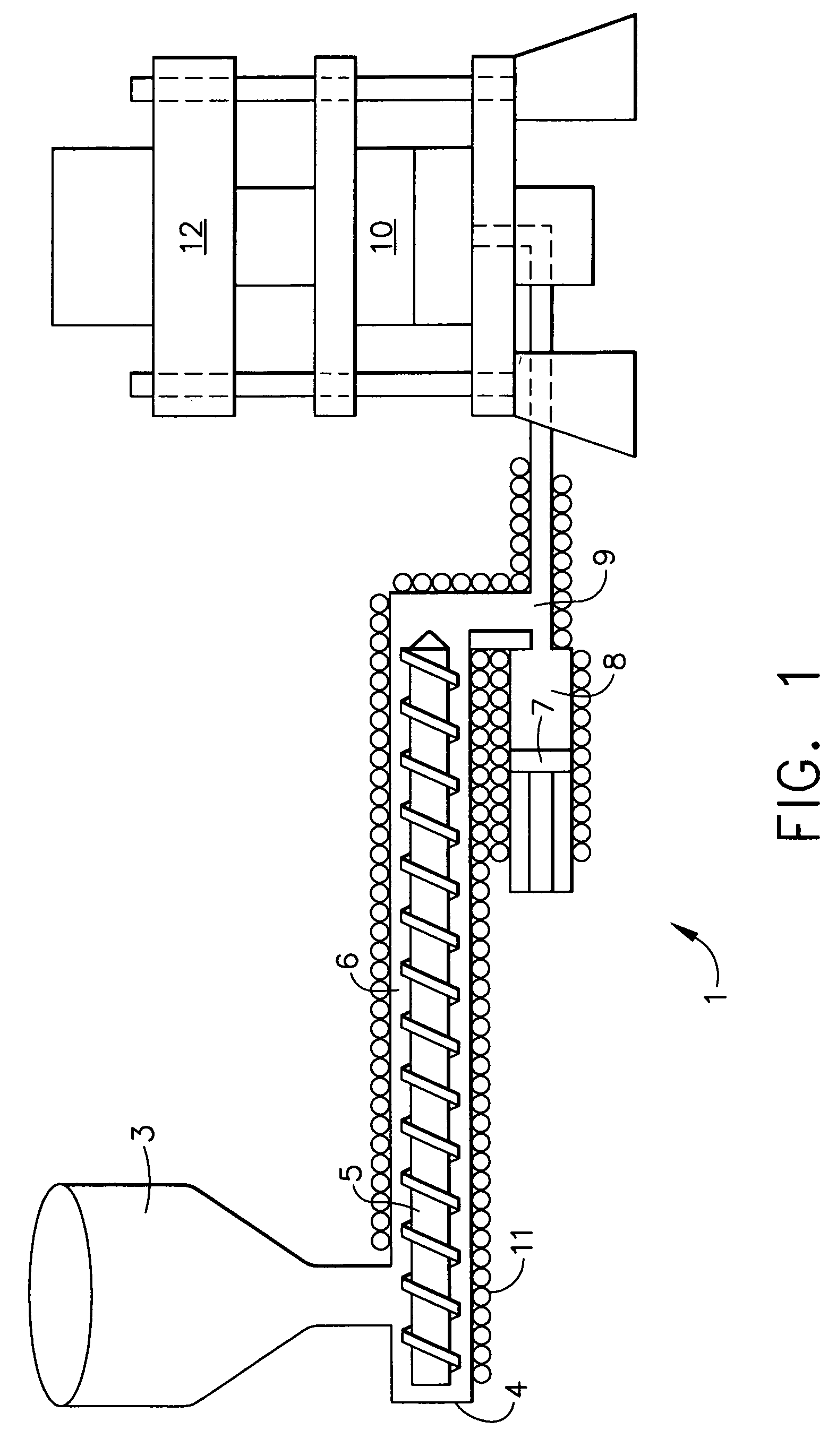

Reclining motorized multi-position chair with rocking and pivoting action

InactiveUS6659556B2Easy to modifyIncreases range of angular motionOperating chairsSofasEngineeringRestoring force

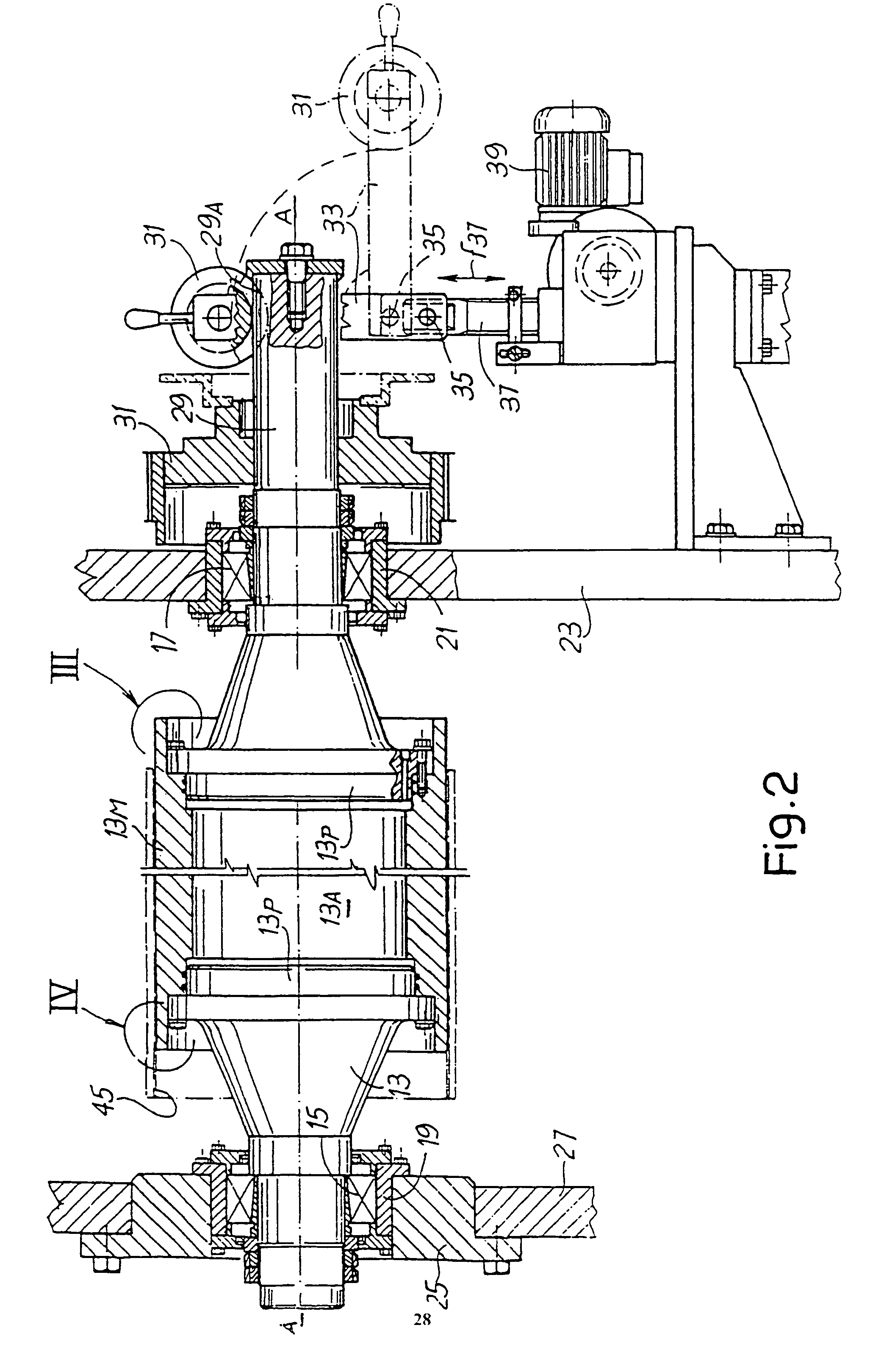

A tilt adjustment assembly for a motorized reclining chair having a base frame adapted for rest on a floor surface. A seat and a back articulated support linkage are interconnected together for displacement of a seat and back of a reclining chair. An intermediate frame is mounted on the base frame through spring attachments, whereby to impart a rocking motion to the chair. A pair of foot rest linkages interconnect each of two of the said seat articulated support linkages to a foot rest plate. The tilt adjustment assembly comprises a motor-operated actuating rod secured at a free end to a sliding member to guidingly displace that member along a straight axis in a fixed plane and to any desired position along the axis. A pivotal link arm is pivotally secured at one end of the sliding member. A transverse linkage securing rod is secured to a second end of the pivotal link arm and extends transversely thereto. The transverse securing rod has opposed ends pivotally connected to an intermediate link arm of a respective one of the pair of foot rest linkages. Tensioning springs are secured to each of the pair of foot rest linkages for applying a restoring force to the foot rest to a retracted position.

Owner:PELLERIN RENE

Reclining motorized multi-position chair with rocking and pivoting action

InactiveUS20030047973A1Simplify linkageIncrease rangeOperating chairsSofasEngineeringReclining chair

A tilt adjustment assembly for a motorized reclining chair having a base frame adapted for rest on a floor surface. A seat and a back articulated support linkage are interconnected together for displacement of a seat and back of a reclining chair. An intermediate frame is mounted on the base frame through spring attachments, whereby to impart a rocking motion to the chair. A pair of foot rest linkages interconnect each of two of the said seat articulated support linkages to a foot rest plate. The tilt adjustment assembly comprises a motor-operated actuating rod secured at a free end to a sliding member to guidingly displace that member along a straight axis in a fixed plane and to any desired position along the axis. A pivotal link arm is pivotally secured at one end of the sliding member. A transverse linkage securing rod is secured to a second end of the pivotal link arm and extends transversely thereto. The transverse securing rod has opposed ends pivotally connected to an intermediate link arm of a respective one of the pair of foot rest linkages. Tensioning springs are secured to each of the pair of foot rest linkages for applying a restoring force to the foot rest to a retracted position.

Owner:PELLERIN RENE

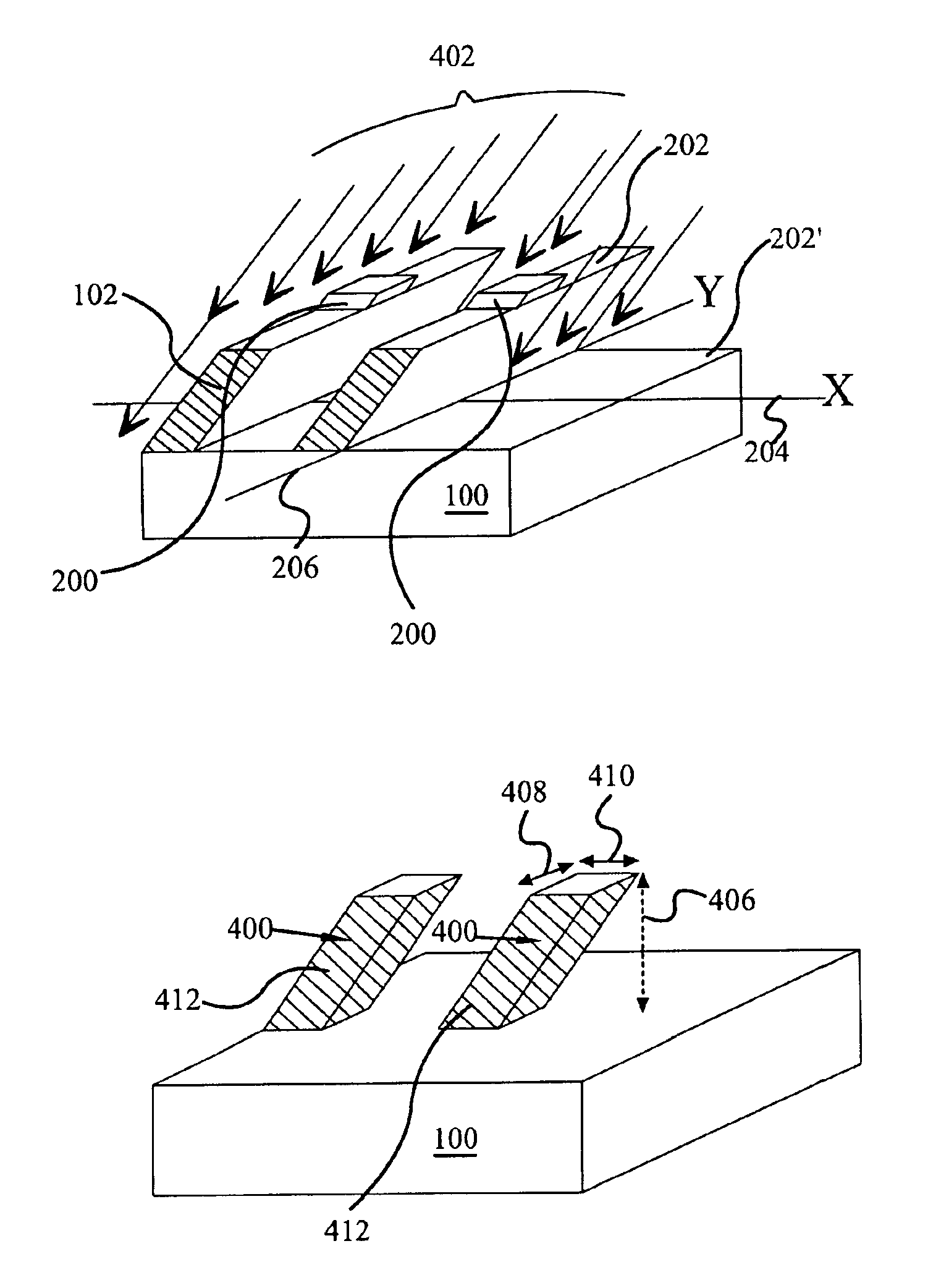

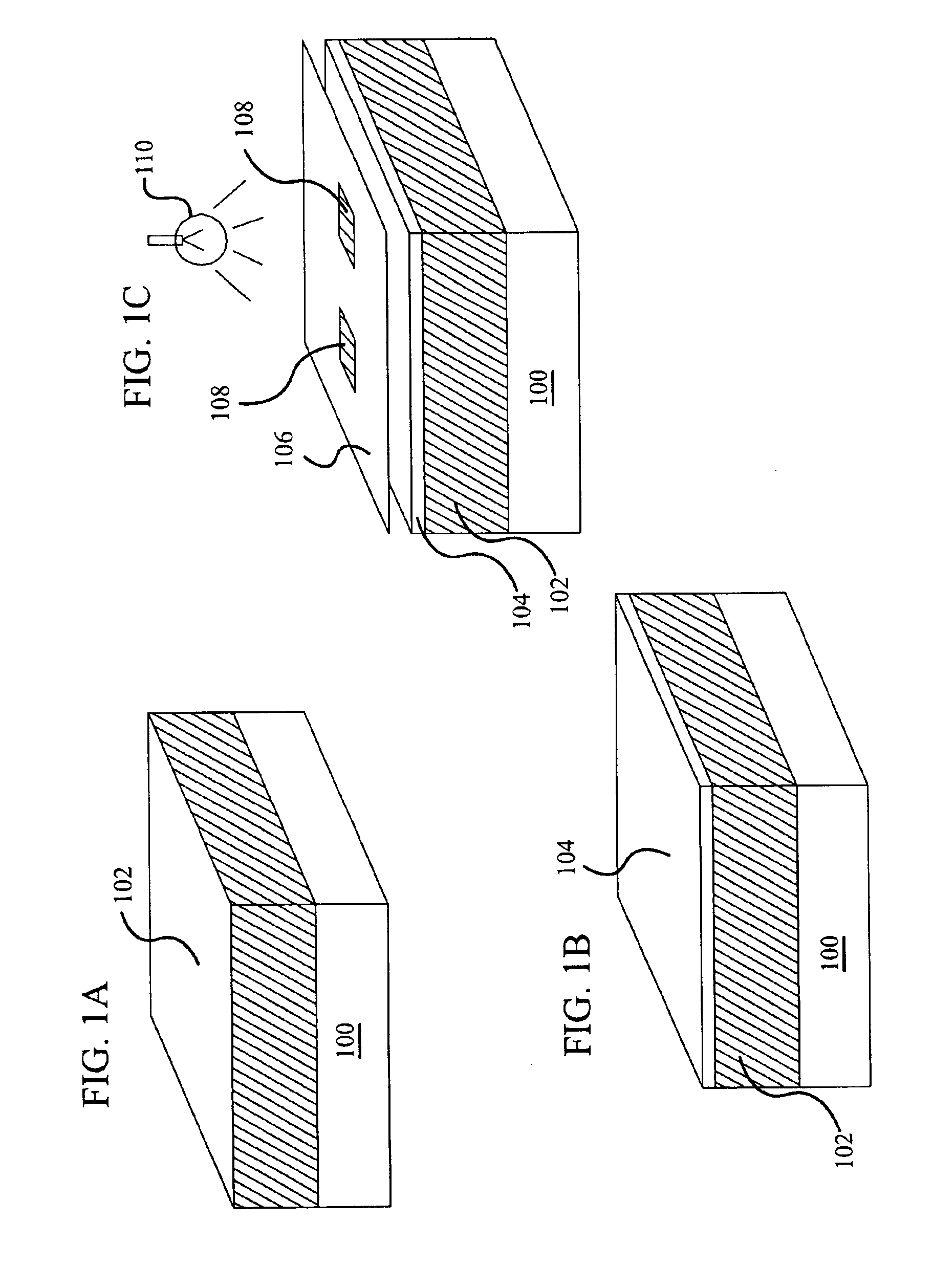

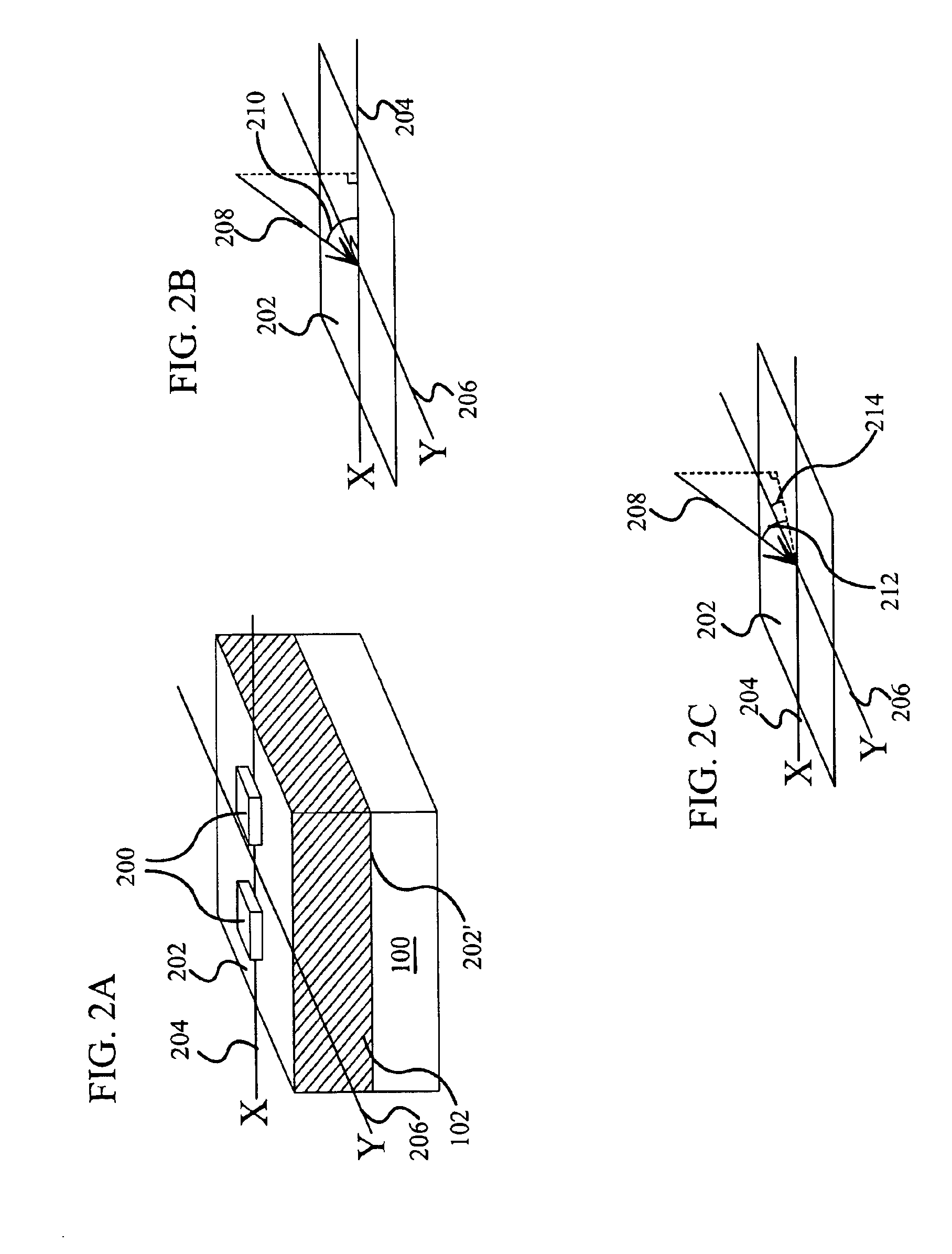

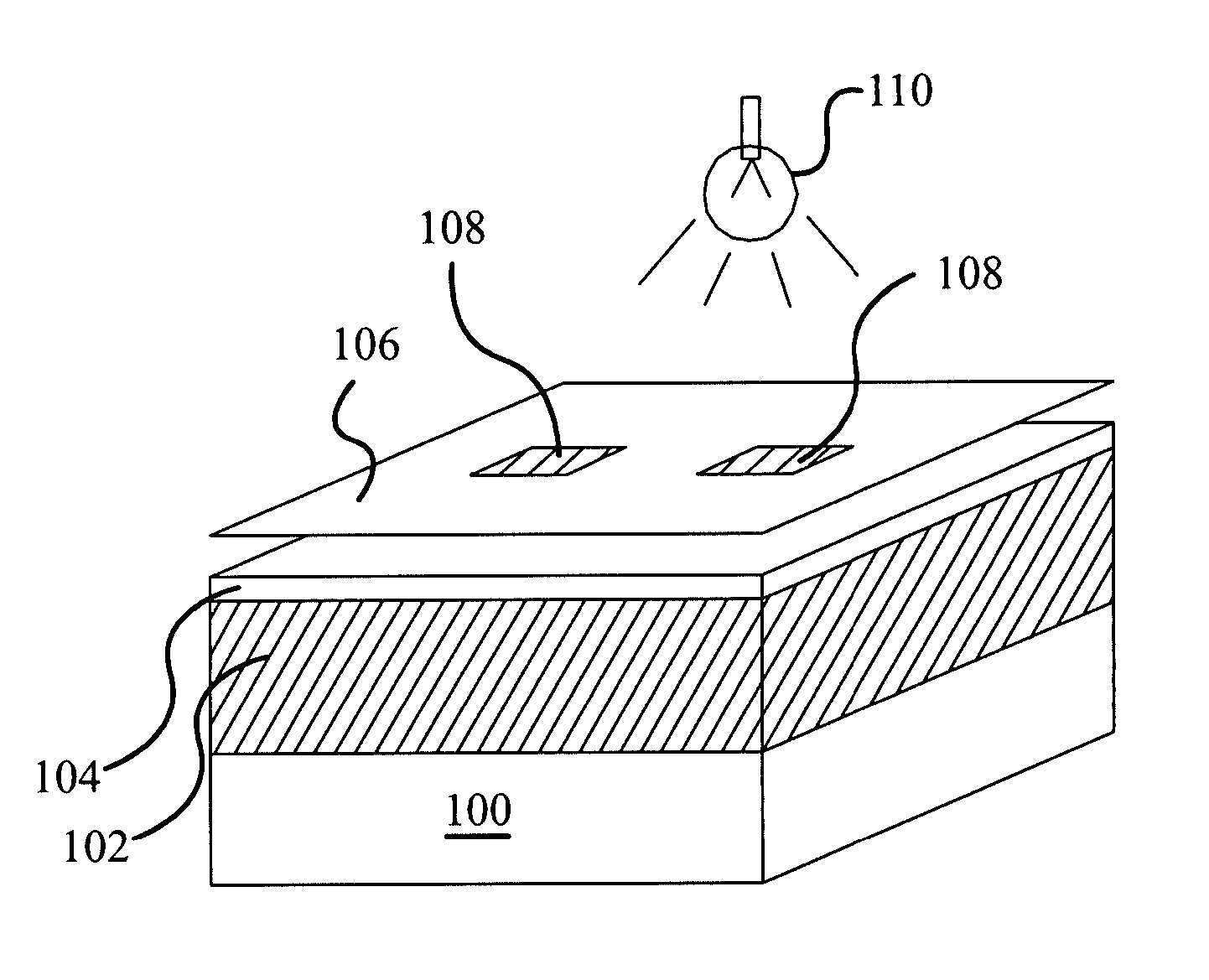

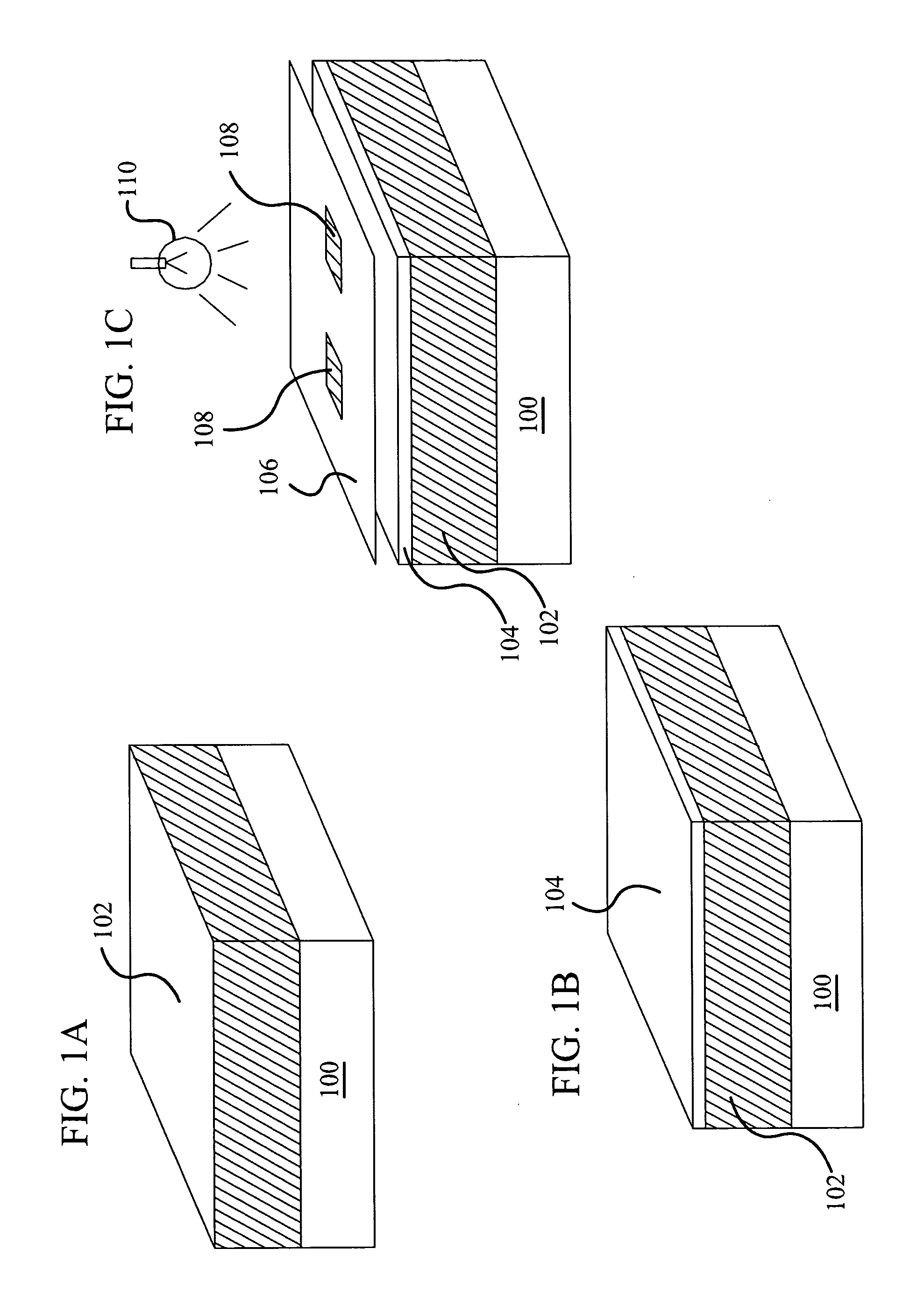

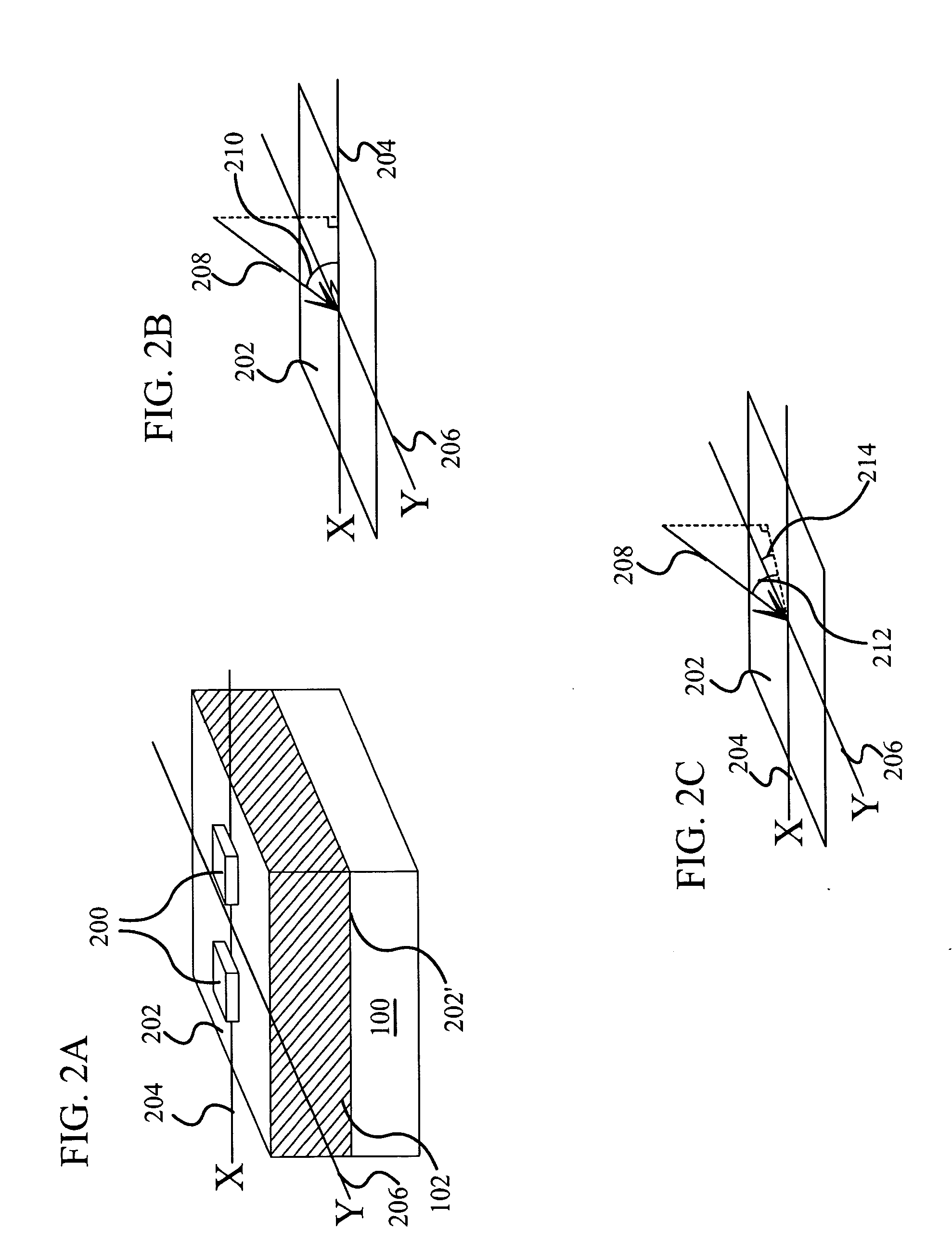

Process for making angled features for nanolithography and nanoimprinting

InactiveUS6897158B2Facilitates insertion and extractionSemiconductor/solid-state device manufacturingNon-linear opticsResistNanolithography

This invention provides a directional ion etching process for making nano-scaled angled features such as may be used, for example, in liquid crystal displays and or nanoimprinting templates. In a particular embodiment a semiconductor wafer substrate is prepared with at least one layer of material. A photoresist is applied, masked, exposed and developed. Anisotropic ion etching at a high angle relative to the wafer is performed to remove portions of the non protected material layer. The remaining photoresist caps shadow at least a portion of the material layer, and as the ion etching is performed at an angle, the protected portions of the material layer also appear at an angle.

Owner:HEWLETT PACKARD DEV CO LP

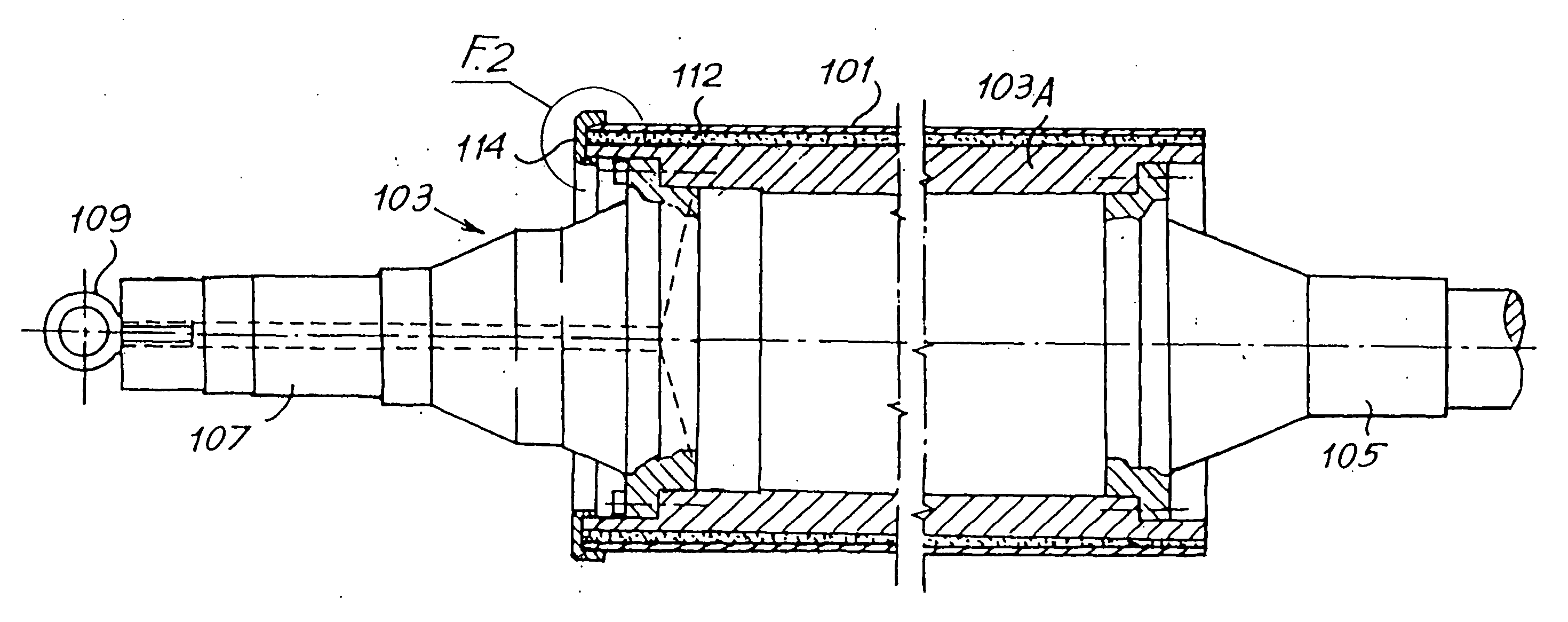

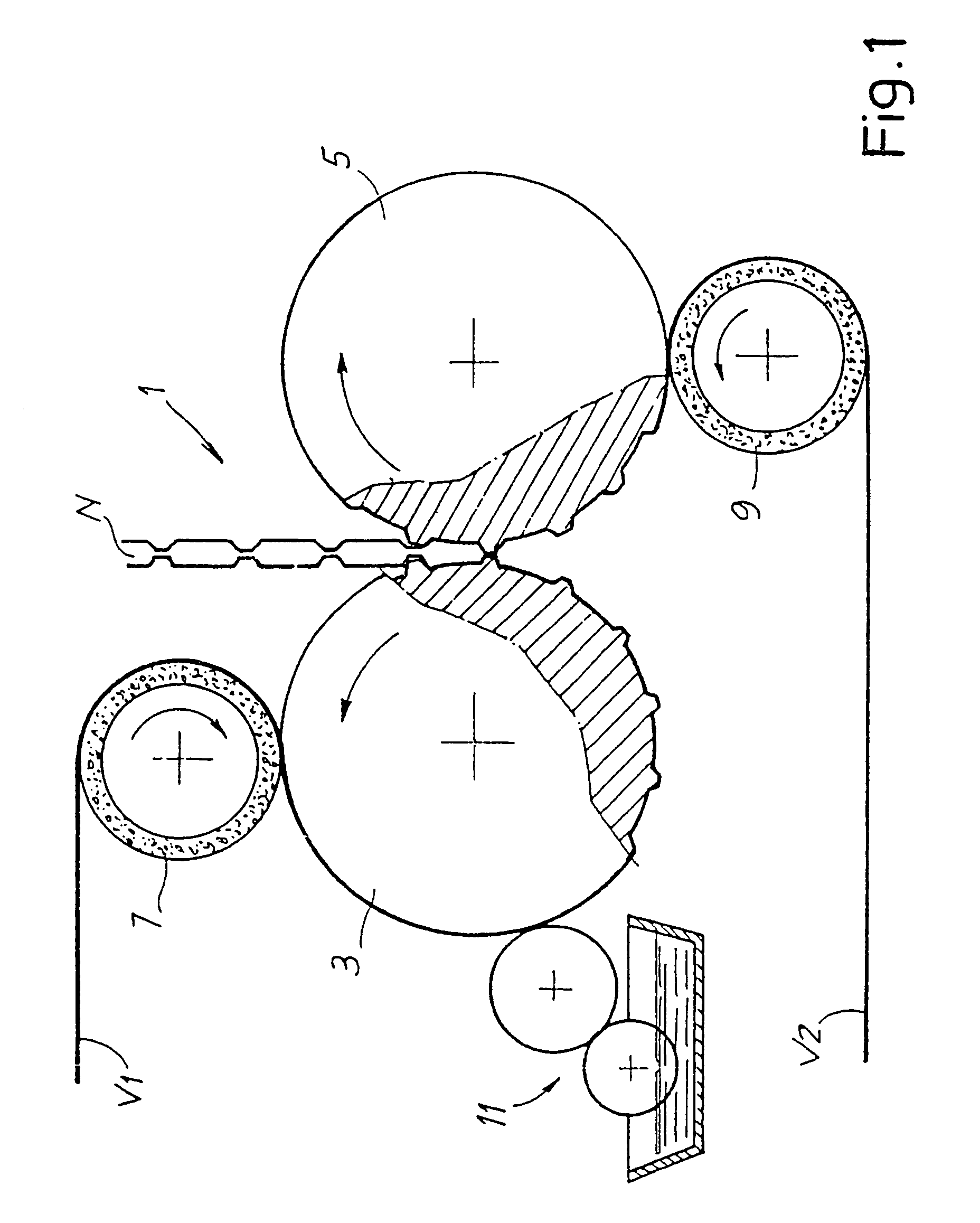

Cylinder with interchangeable sleeve method of manufacturing the same and associated unit

InactiveUS20040242392A1Facilitates insertion and extractionEliminate the problemLiquid surface applicatorsMechanical working/deformationFriction forceBiomedical engineering

Owner:FABIO PERINI SPA

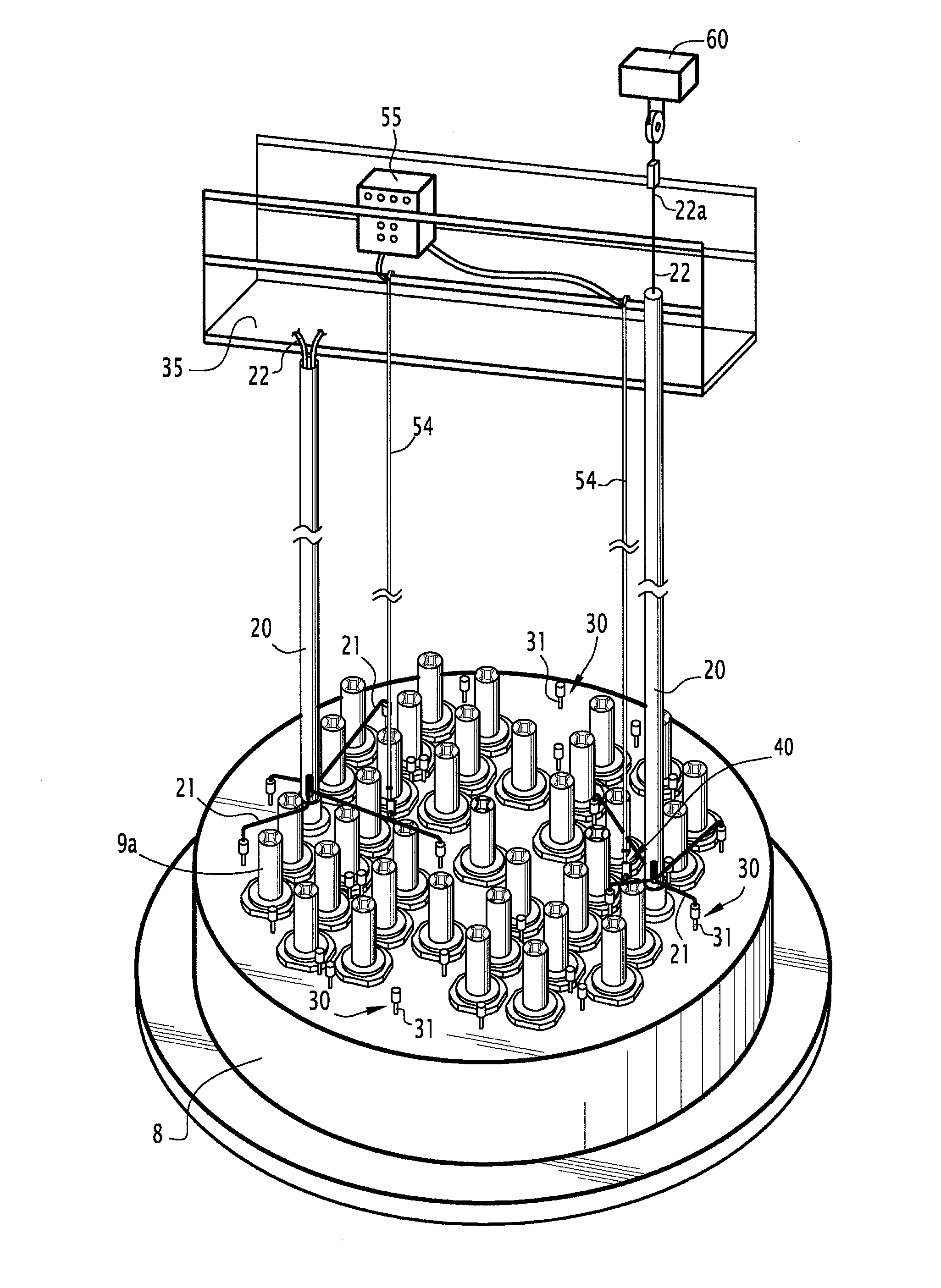

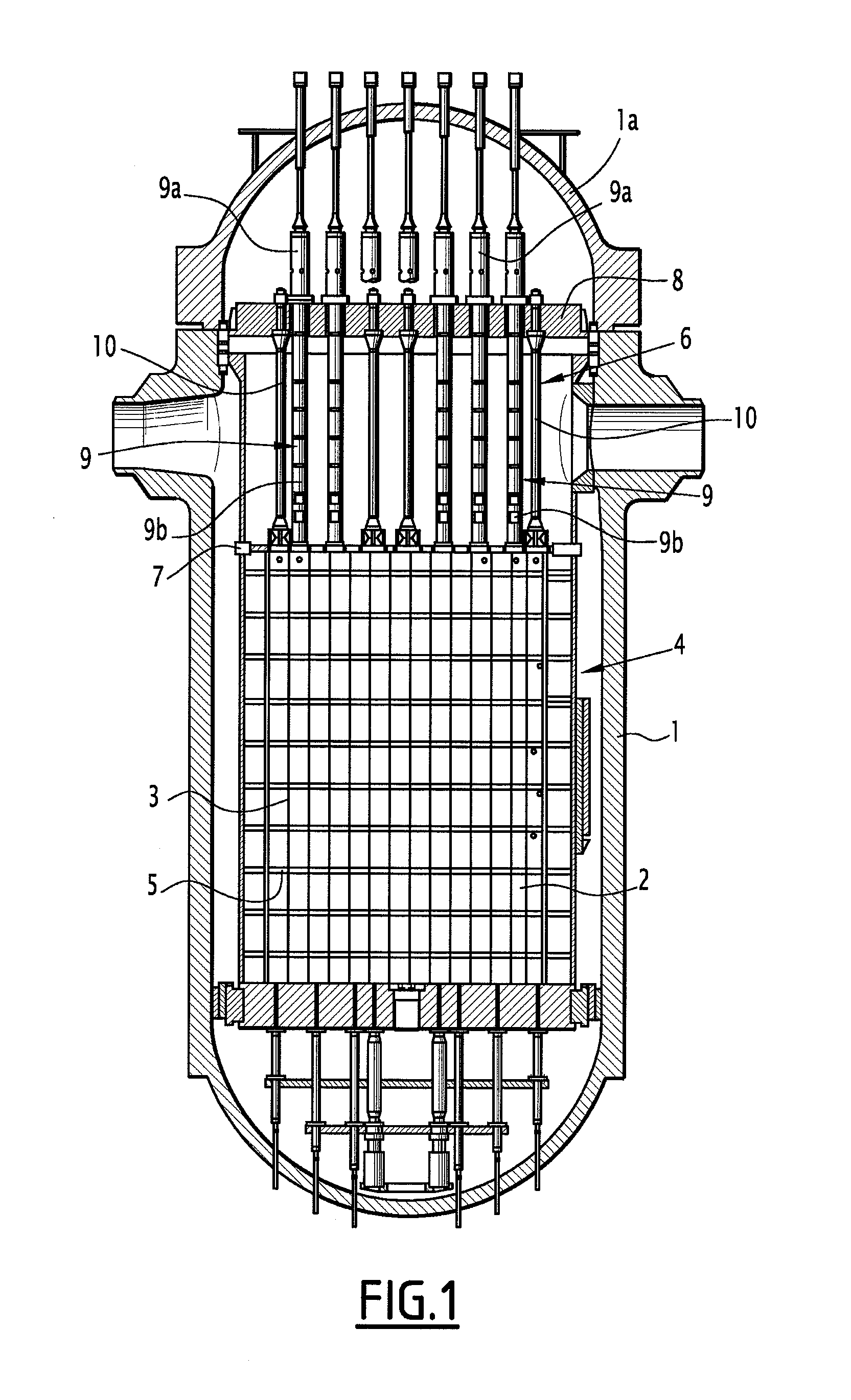

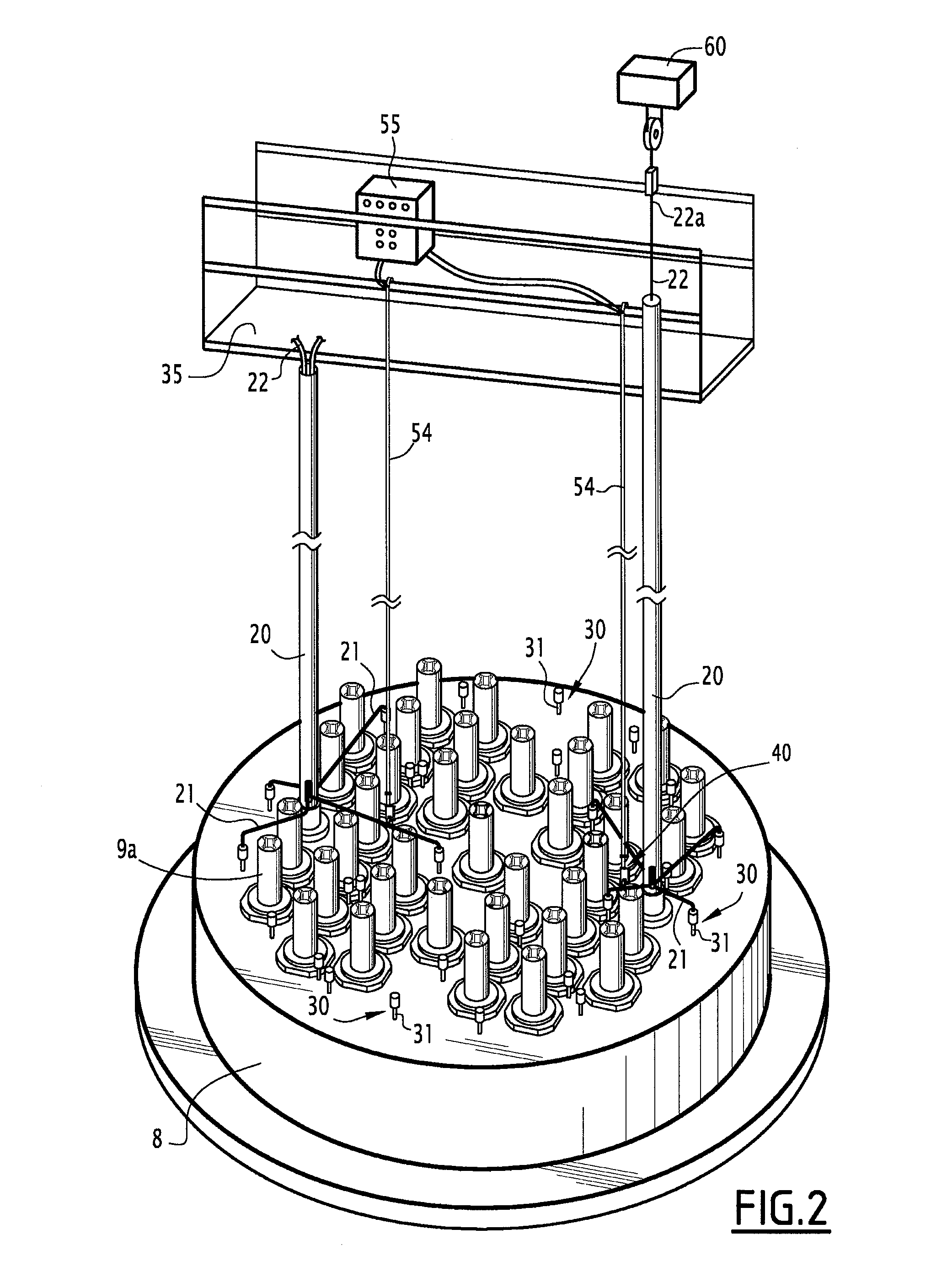

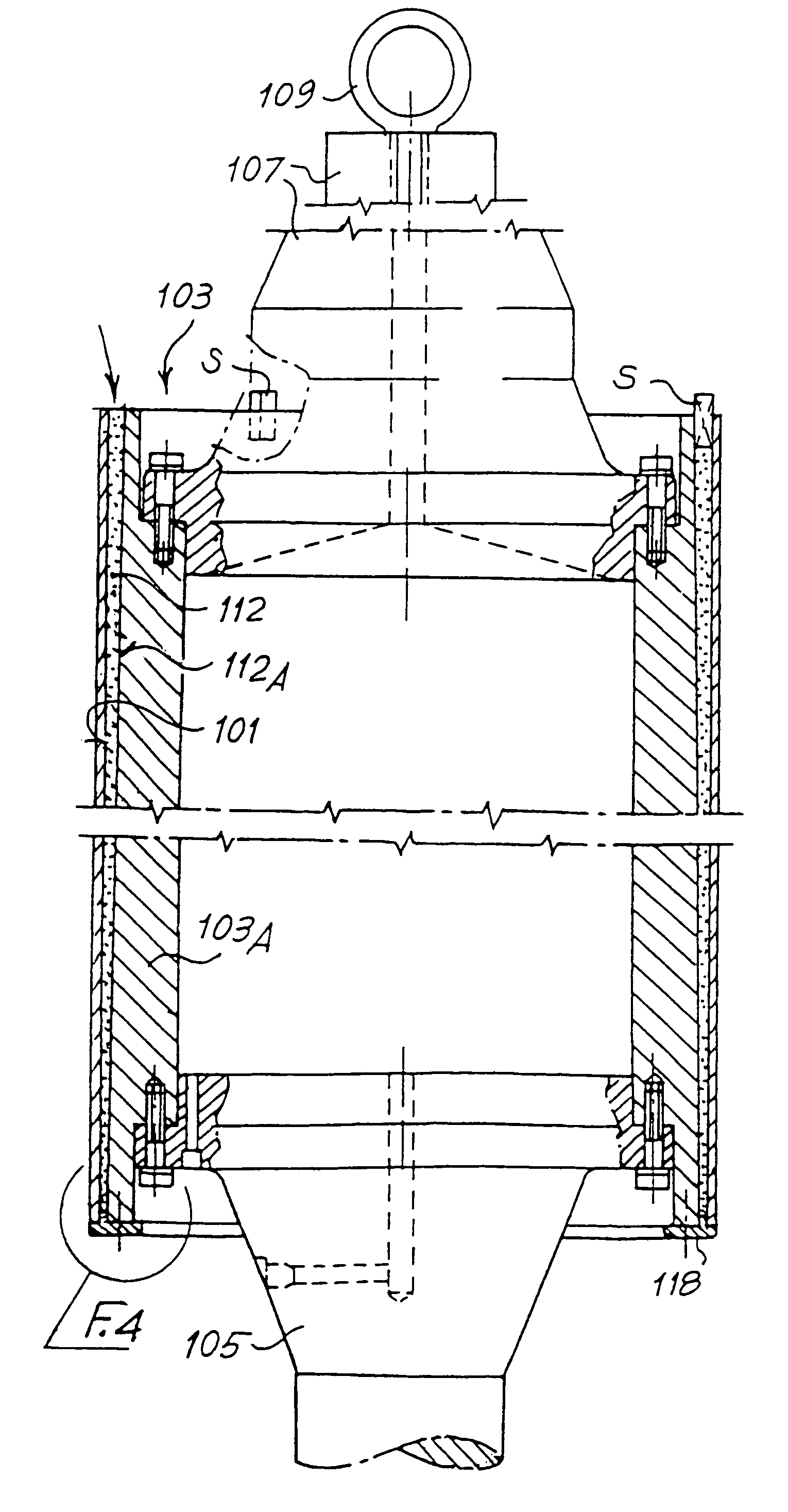

Device for assisting in the underwater extraction or insertion of an elongate element disposed in a pipe, and method for assisting in the extraction or insertion of one such element

InactiveUS20120213320A1Facilitates insertion and extractionNuclear energy generationNuclear monitoringBiomedical engineeringGrippers

A device for assisting in the underwater extraction or insertion of an elongate element disposed in a pipe is provided. The device includes a clamping and vibration-generating assembly including a sealed housing bearing a gripper and including a member for tightening the gripper on the pipe, an adjustable vibrator for vibrating the housing and the gripper, and a member for measuring the vibration produced by the vibrator on the pipe in order to determine the optimum vibration The device also includes a controller for remotely controlling the gripper and the vibrator. A method for assisting in the extraction or insertion of an elongate element is also provided.

Owner:AREVA NP SAS

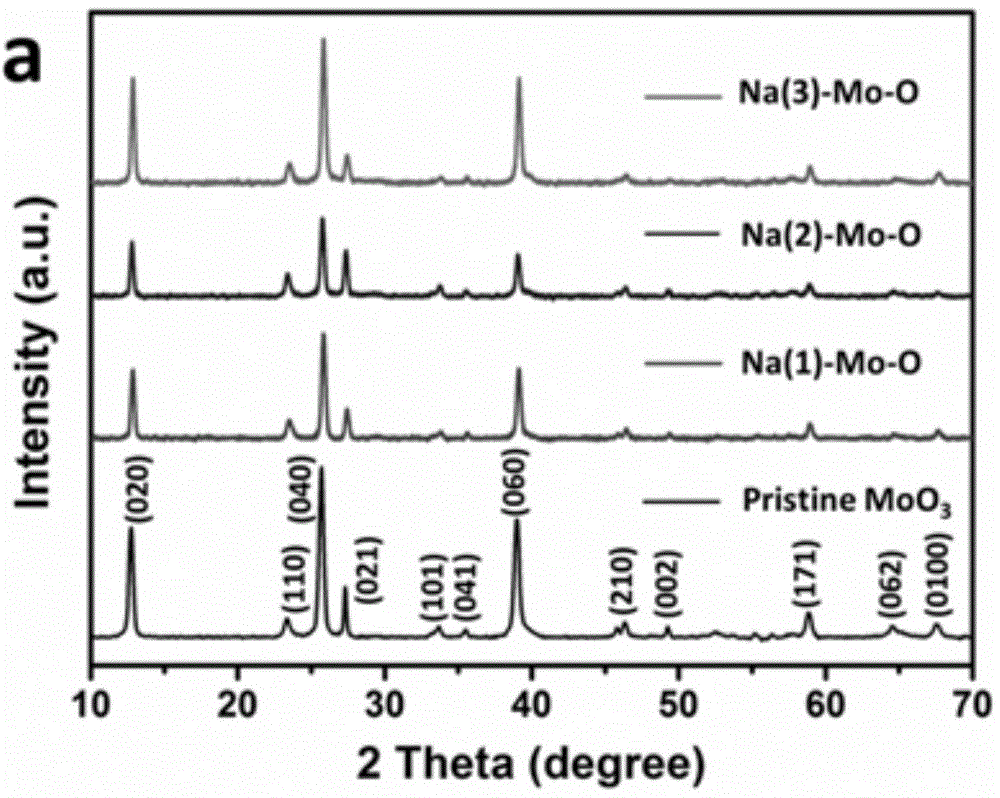

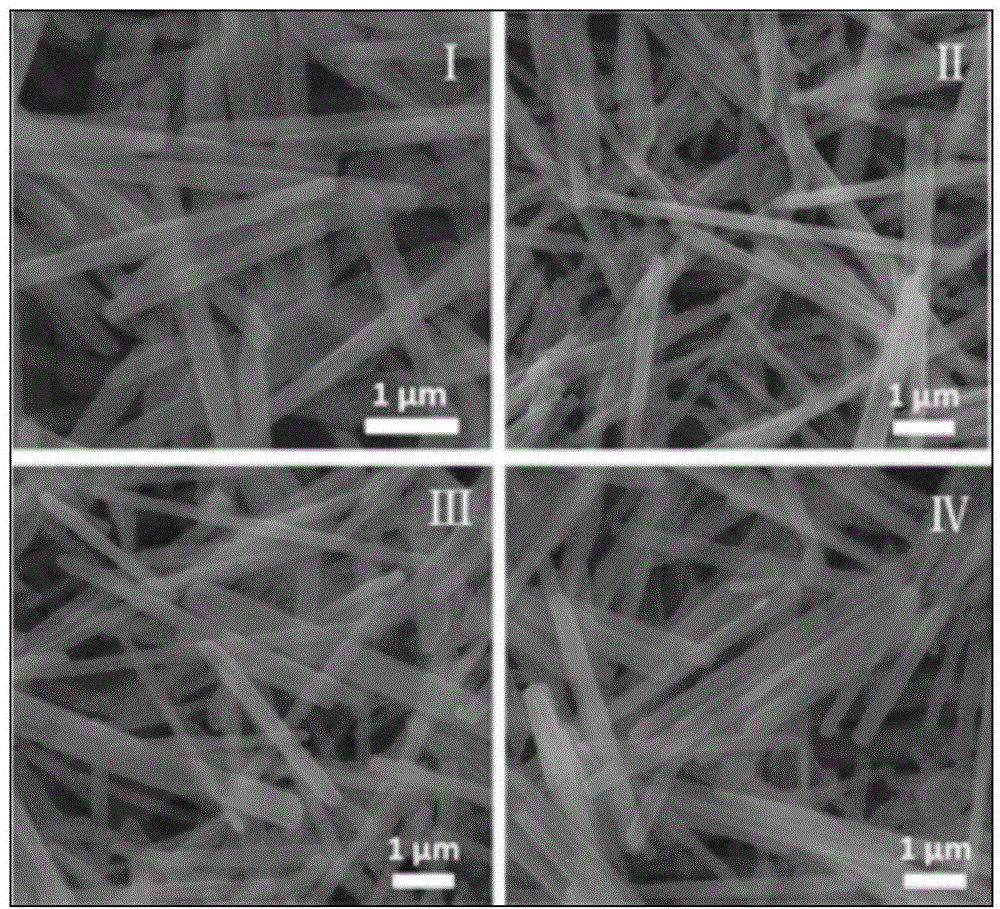

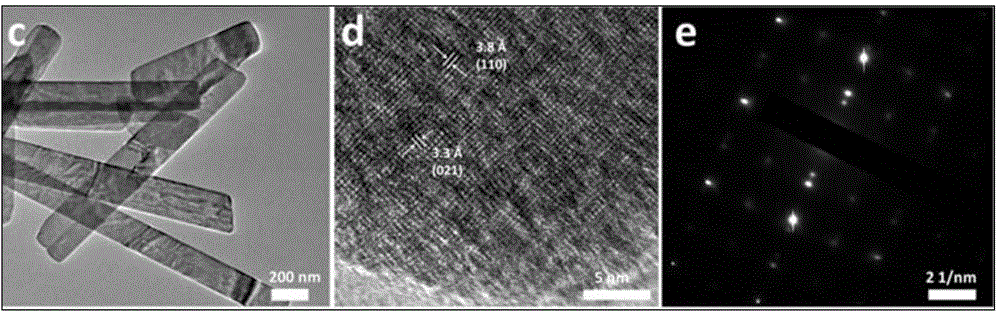

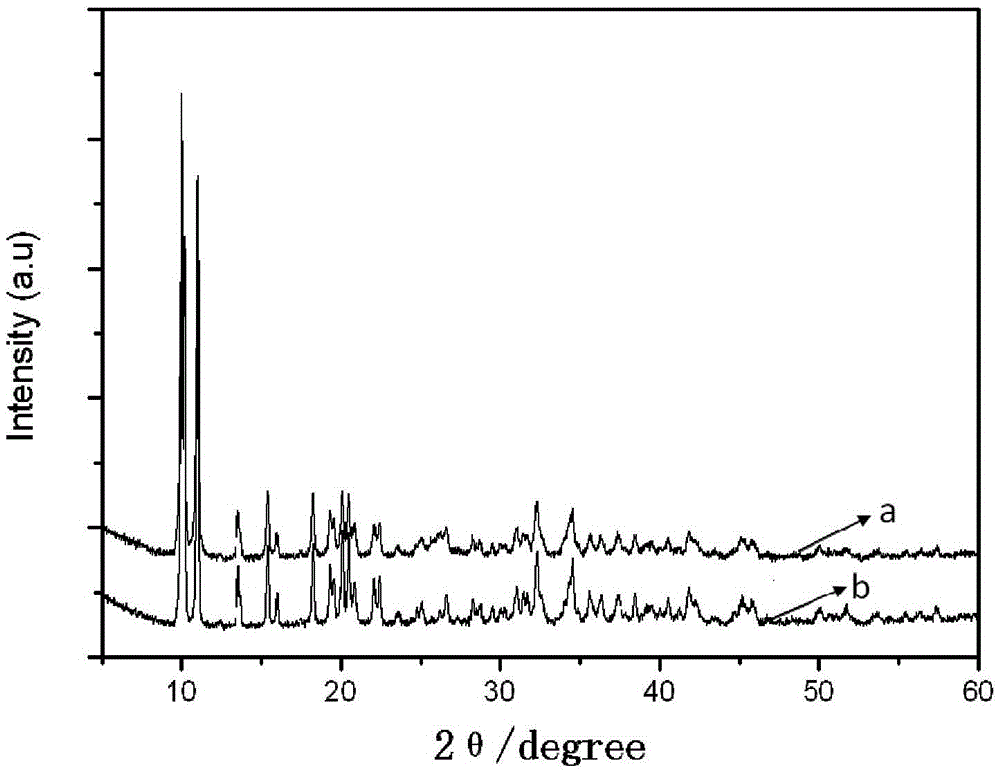

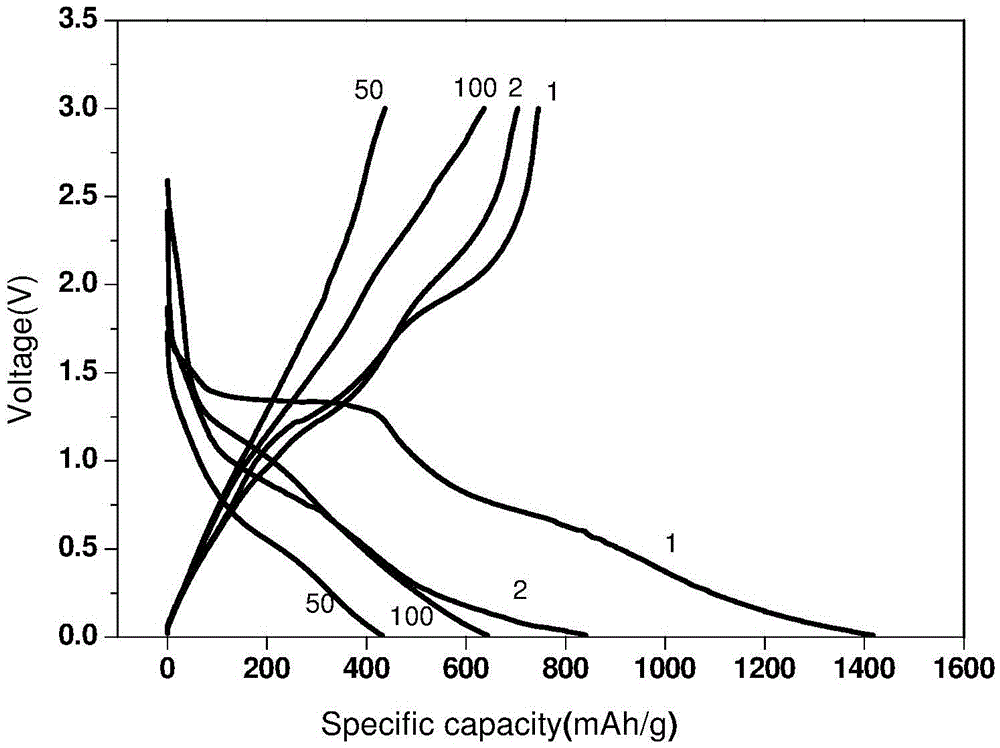

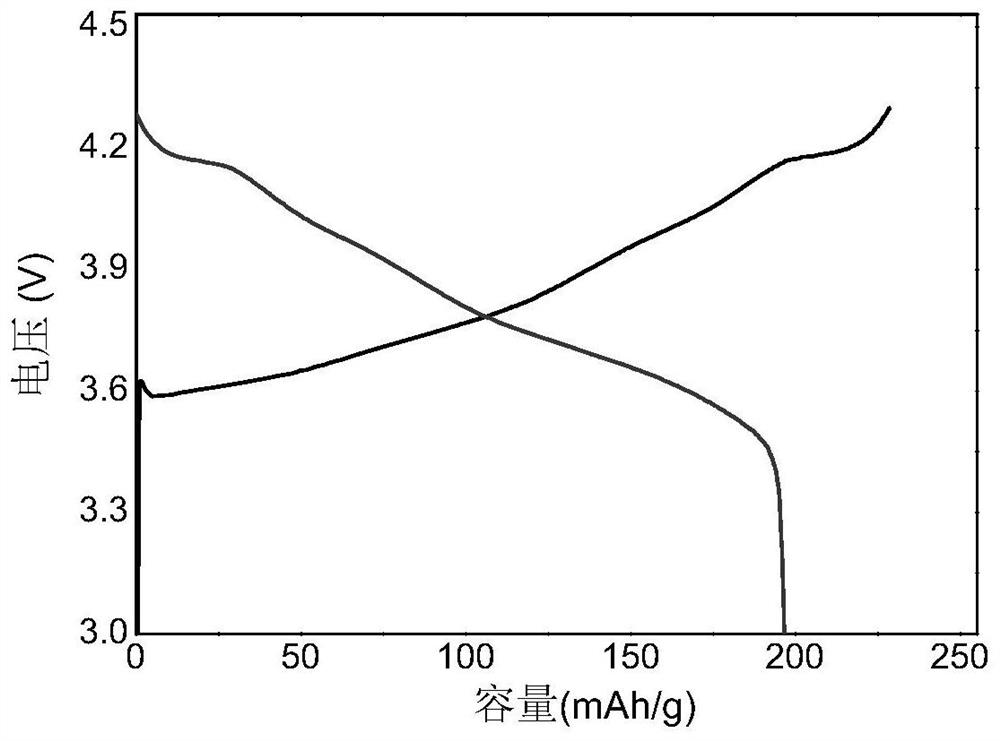

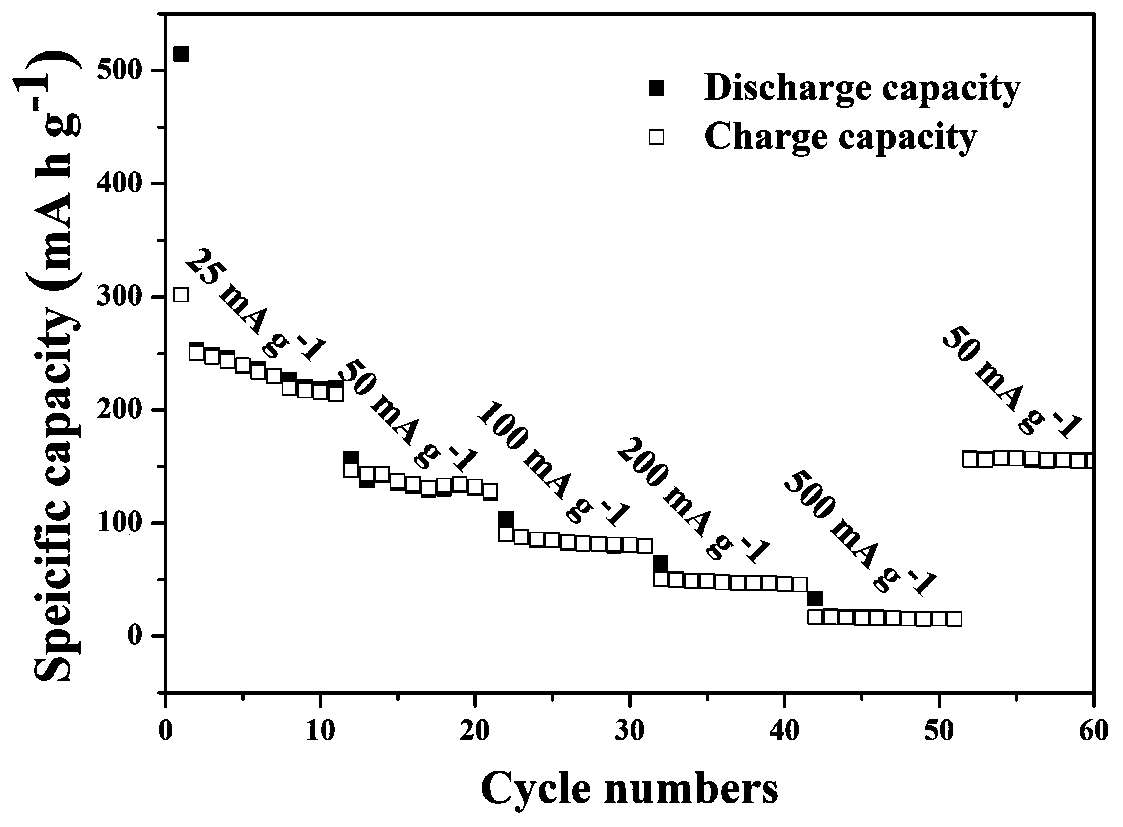

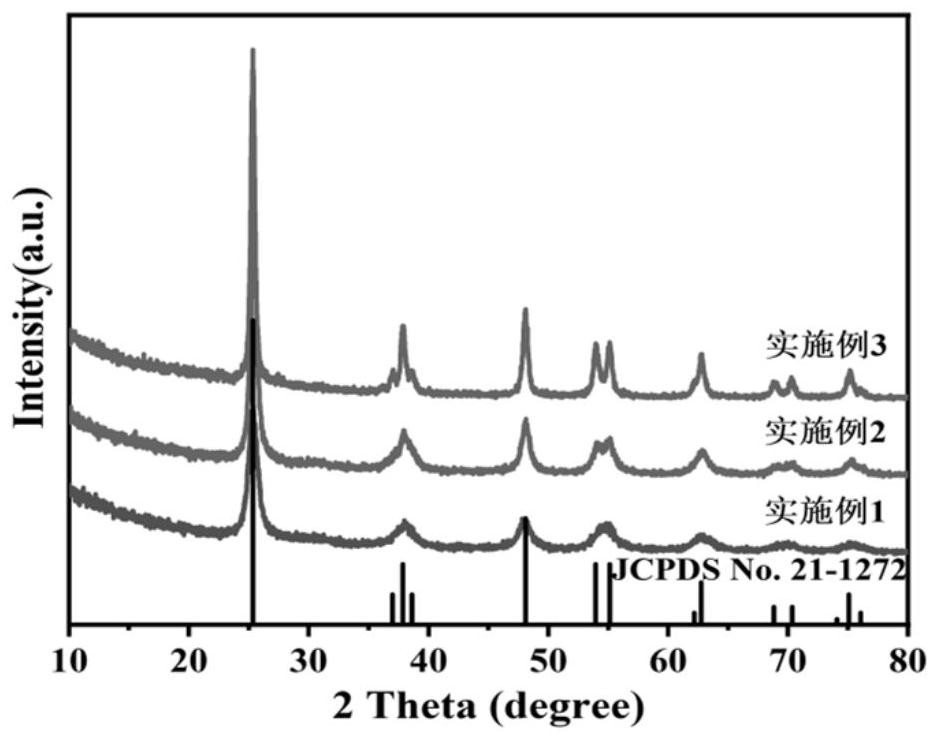

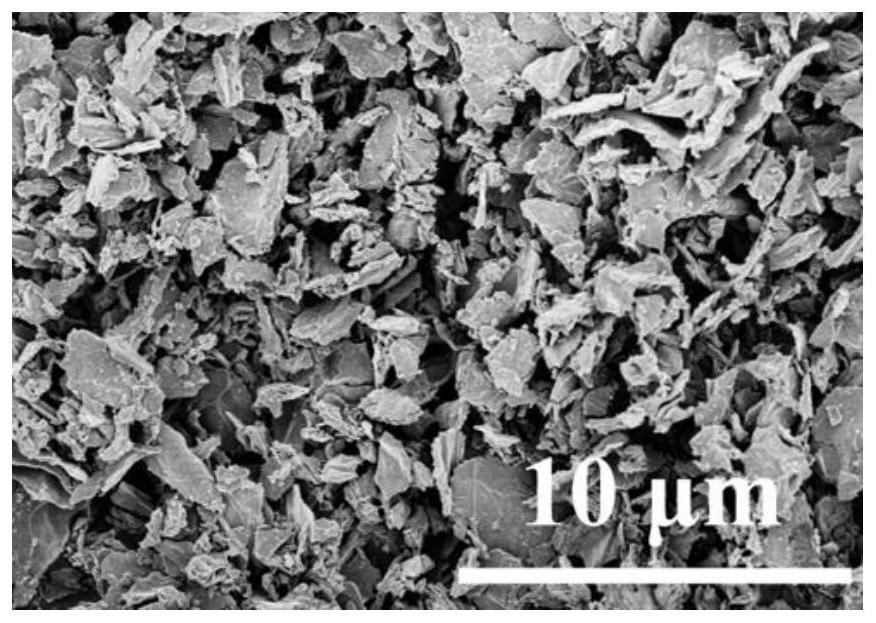

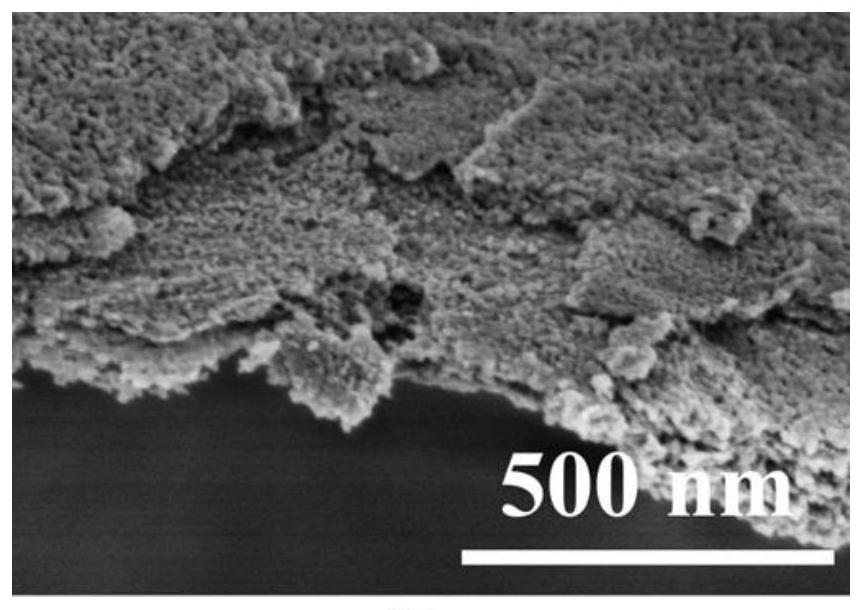

Sodium ion pre-embedded MoO3 nanobelt as well as preparation method and application of sodium ion pre-embedded MoO3 nanobelt

ActiveCN104659351AImprove electrochemical performanceImprove cycle stabilityMaterial nanotechnologyCell electrodesLithium-ion batteryGreen chemistry

The invention relates to a sodium ion pre-embedded MoO3 nanobelt as well as a preparation method and application of the sodium ion pre-embedded MoO3 nanobelt. The sodium ion pre-embedded MoO3 nanobelt can be used as a positive electrode active material of a lithium ion battery. The preparation method comprises the following steps: (1) adding MoO3 nanobelt, PEG4000 and NaCl into deionized water, and stirring; (2) transferring the solution into a reaction kettle, carrying out hydrothermal reaction, taking out the solution, and cooling to the room temperature; and (3) after carrying out centrifugal separation on the obtained product, repeatedly washing the product with deionized water and ethanol, and finally drying the product in a drying box, so as to obtain the sodium ion pre-embedded MoO3 nanobelt. The preparation method has the beneficial effects that sodium ions are pre-embedded among layers, so that the substantial attenuation of the capacity in a primary cycle period is avoided, the electrochemical property of MoO3 is improved, the conductivity of the material is improved, furthermore, the cycling stability of the electrode material is effectively improved, and the electrode material can be used as a potential application material of the lithium ion battery, can meet the requirements of green chemistry and is beneficial to market promotion.

Owner:WUHAN UNIV OF TECH

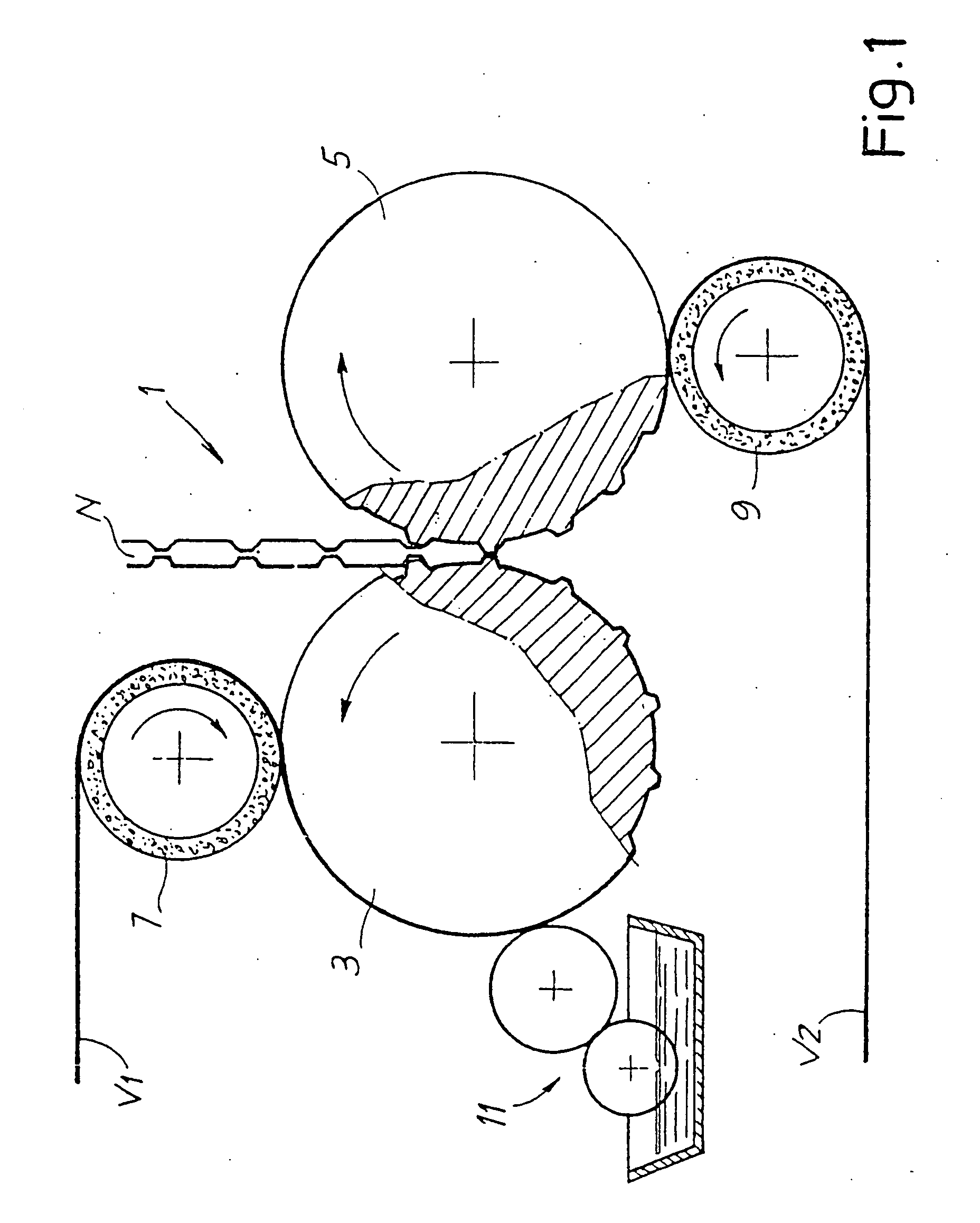

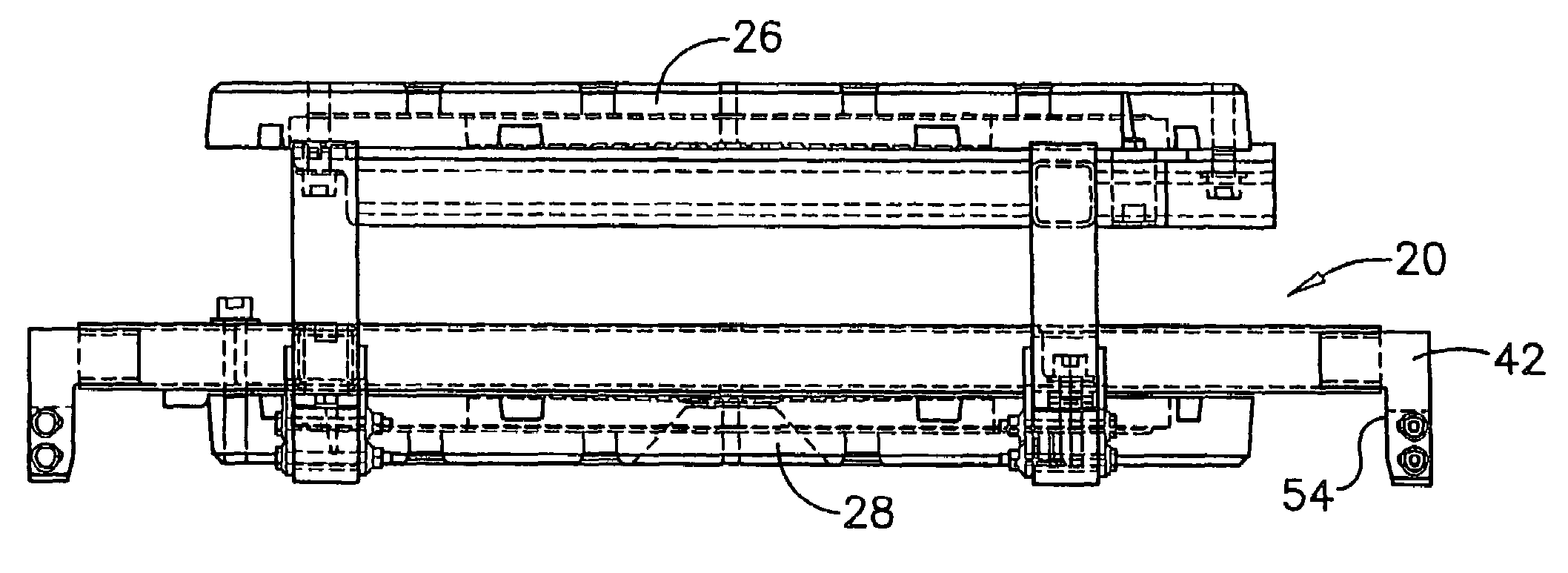

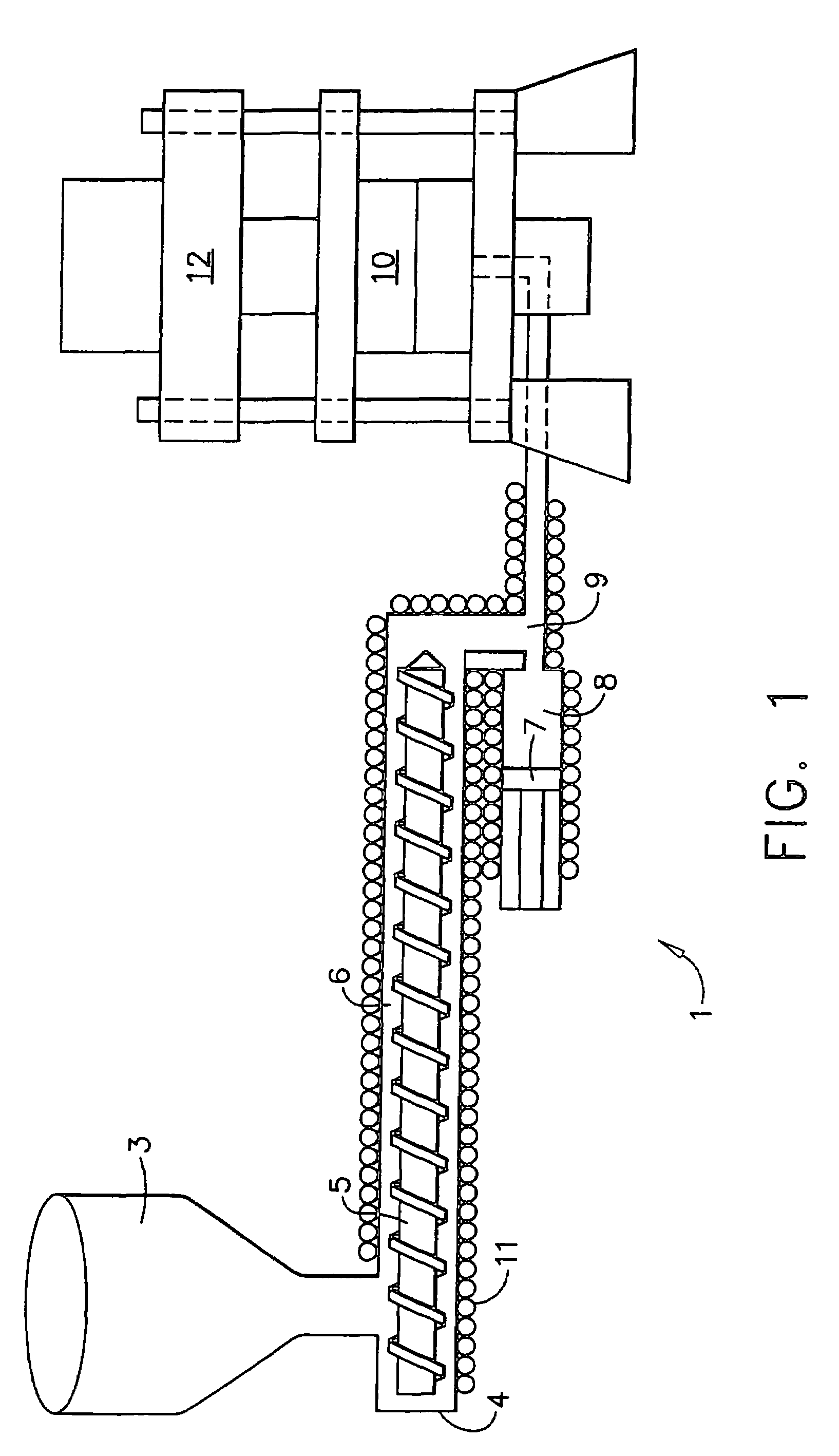

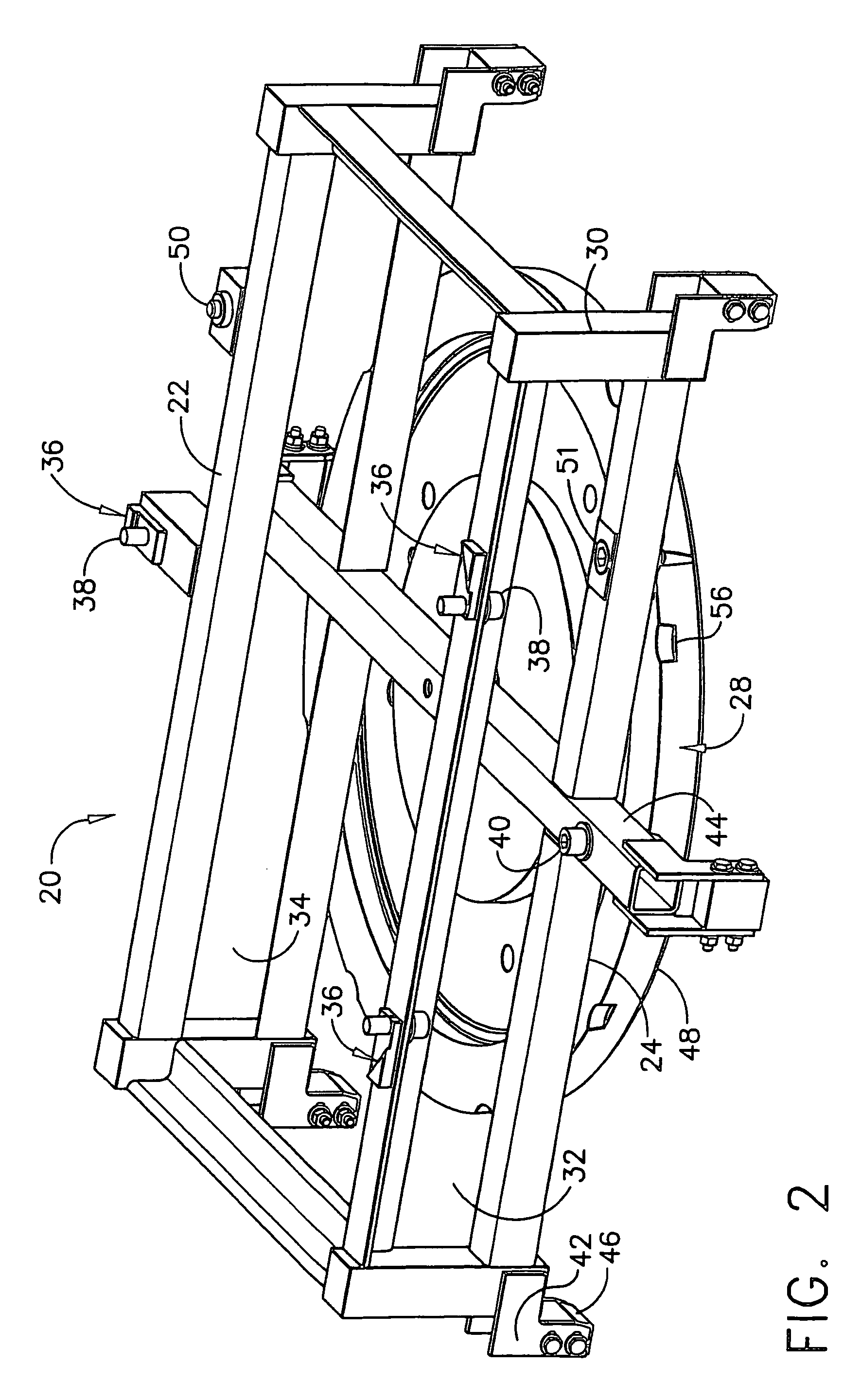

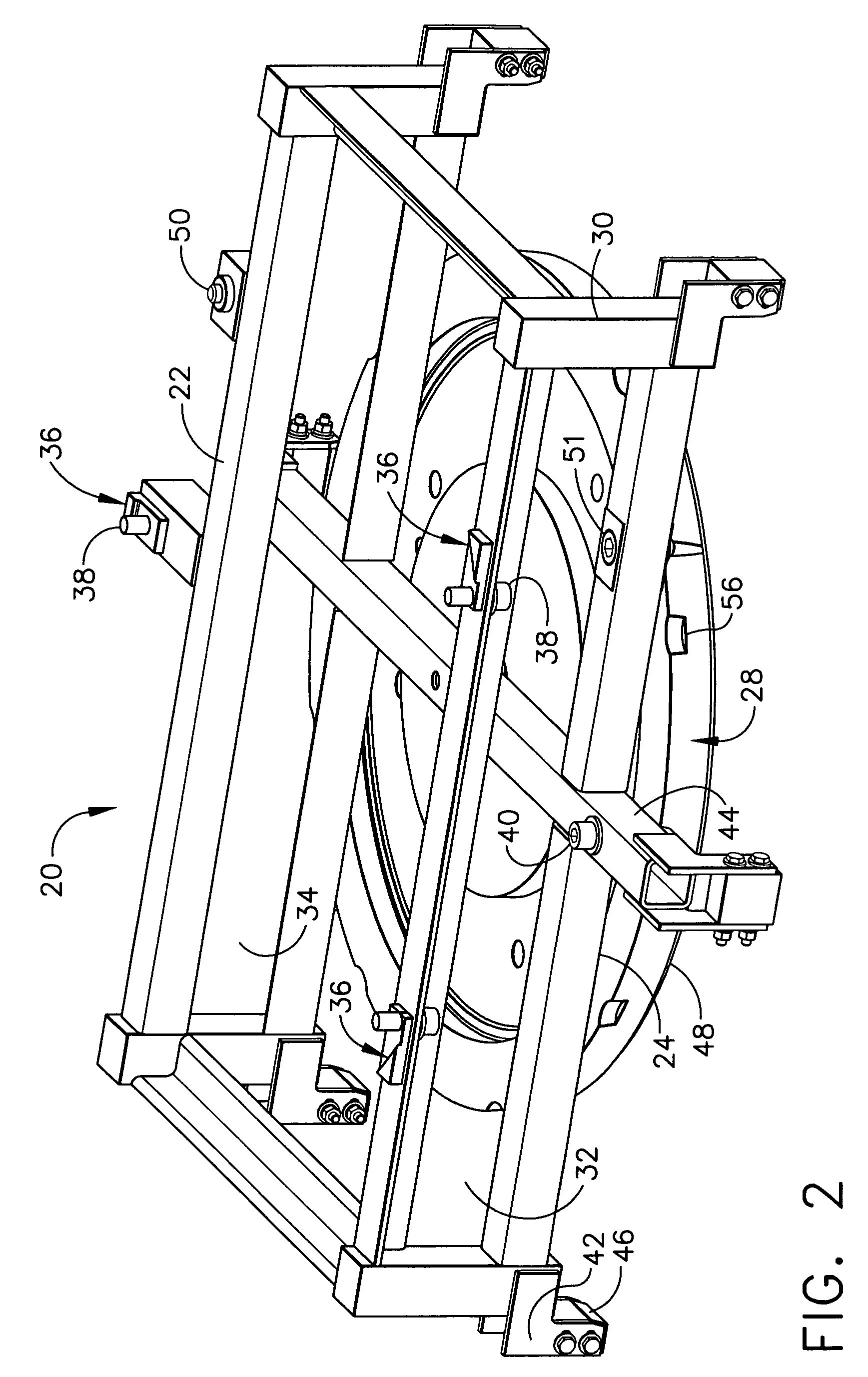

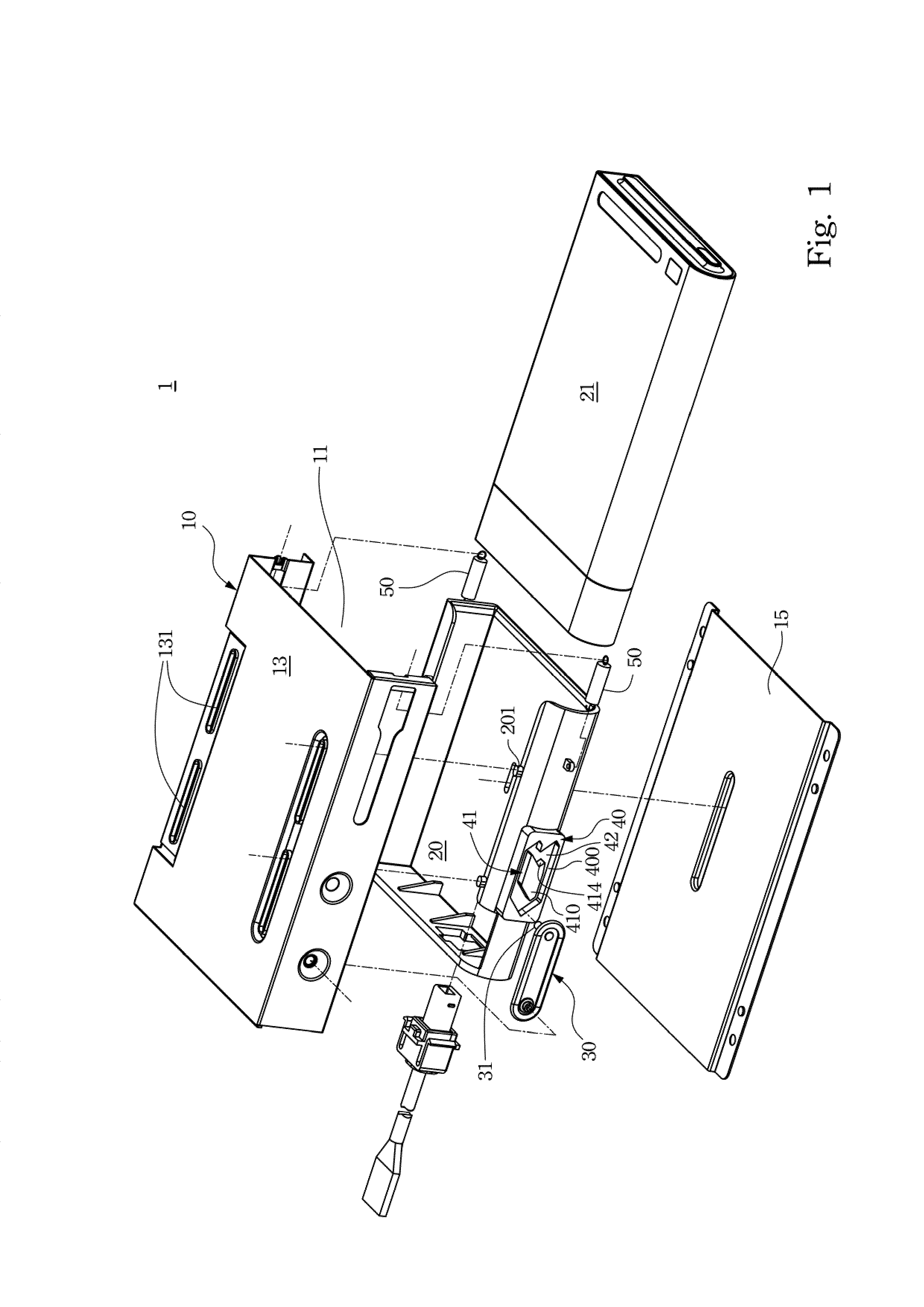

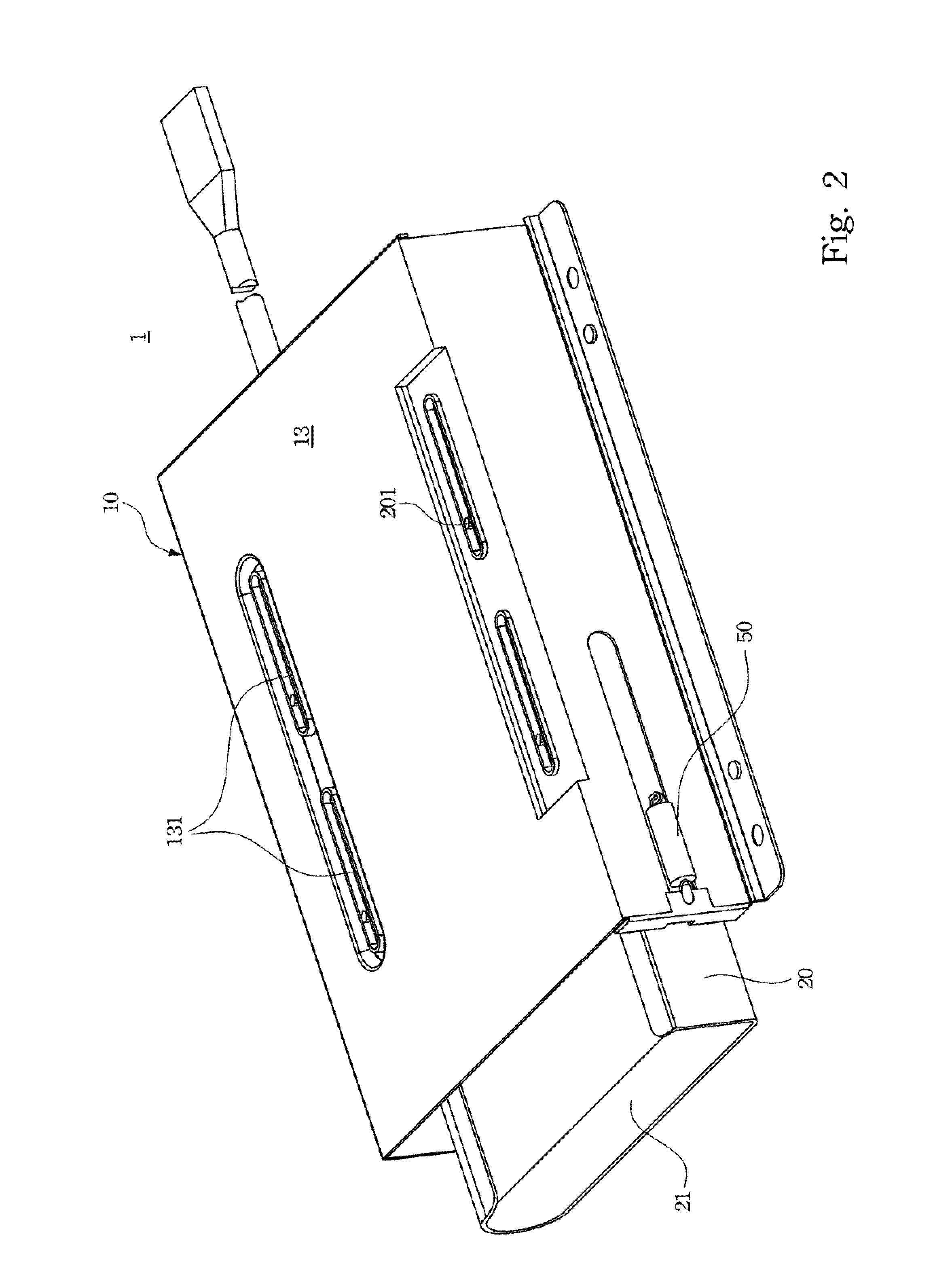

Mold fixture for extracting and inserting upper and lower molds

InactiveUS7442024B2Safe and efficient extraction and insertionFacilitates insertion and extractionConfectioneryMeat processingMolding machineEngineering

A mold fixture 20 for safe and efficient extraction, insertion and storage of mold inserts 26, 28 is provided. The mold fixture 20 includes a lower receiving area 24 for fixedly receiving a lower mold insert 28, an upper receiving area 22 for fixedly receiving an upper mold insert 26. The mold fixture 20 facilitates insertion or extraction of the upper and lower mold inserts 26, 28 into / from a molding machine 1 in a safe and secure manner. Furthermore, the upper and lower mold inserts 26, 28 can be securely stored within the mold fixture 20 at a storage location.

Owner:HONEYWELL INT INC

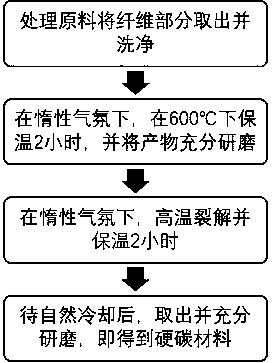

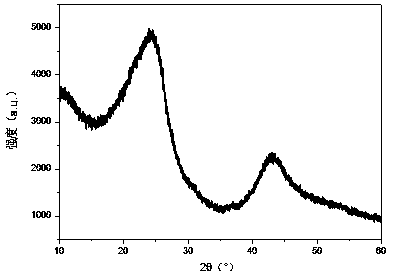

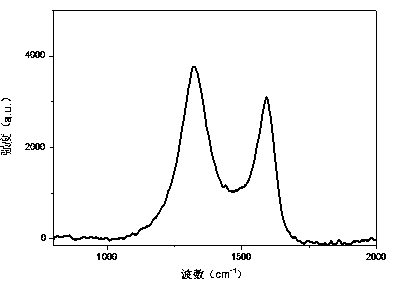

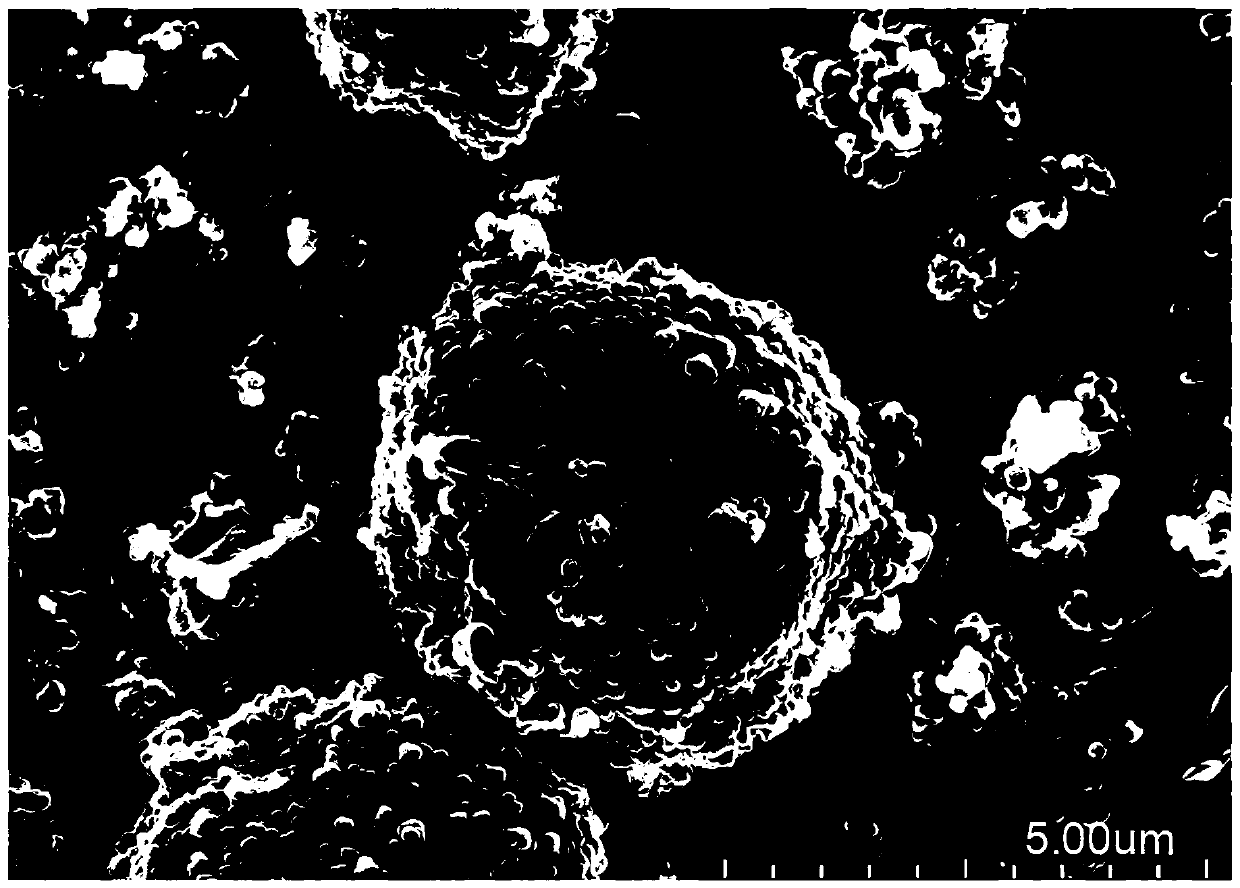

Fibrous hollow hard carbon material capable of being used for sodium-ion battery negative electrode and preparation method thereof

ActiveCN108862235AWide variety of sourcesLow costMaterial nanotechnologyCell electrodesMicron scaleSmart grid

The invention discloses a fibrous hollow hard carbon material. The amorphous fibrous hollow hard carbon material with the d002 value within the range of 0.36-0.42 nm and the ID / IG within the range of1.5-2.0 is prepared by taking a fibrous biomass material as a raw material through a direct pyrolysis method. A preparation method thereof comprises the following steps of 1) carrying out pretreatmenton the raw material; and 2) carrying out high-temperature pyrolysis. According to the fibrous hollow hard carbon material, as a negative electrode active material in a sodium-ion secondary battery, the specific capacity of the fibrous hollow hard carbon material is 150-350 mAh / g, the fibrous hollow hard carbon material under 2 C can keep the capacity of 60% or above at 0.1C, and the capacity retention ratio can be kept within the range of 90-100% after 100 weeks of circulation. The fibrous hollow hard carbon material and the preparation method thereof have the advantages that 1, through a stable micron-scale fiber structure, the cycle life is prolonged; 2, a natural tubular hollow structure is utilized, so that the wettability of an electrolyte is improved, the ion transmission distance is shortened, and the dynamics performance of the battery is improved; and 3, the preparation method is simple, and the processing cost for preparing the special morphology is lowered. The fibrous hollow hard carbon material is a very potential negative electrode material of the sodium-ion battery and can be applied to the fields of intelligent power grids, secondary clean energy power generation and other large-scale energy storage systems or power batteries.

Owner:SHANGHAI UNIV

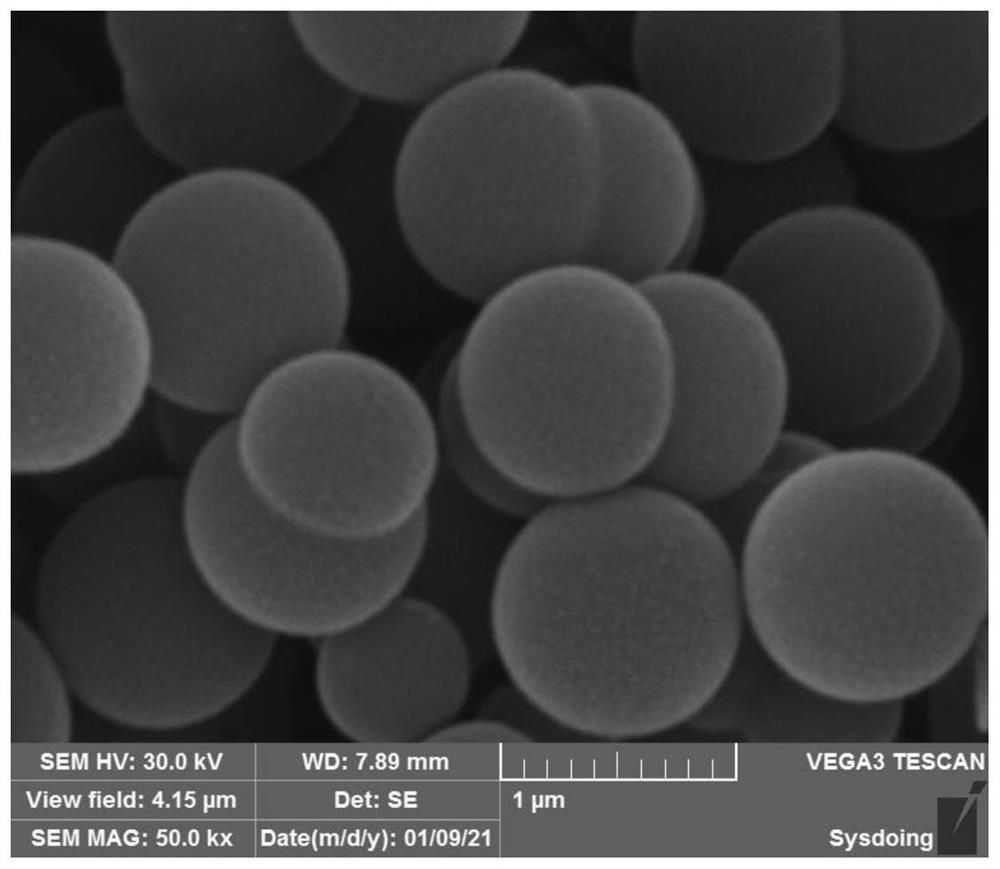

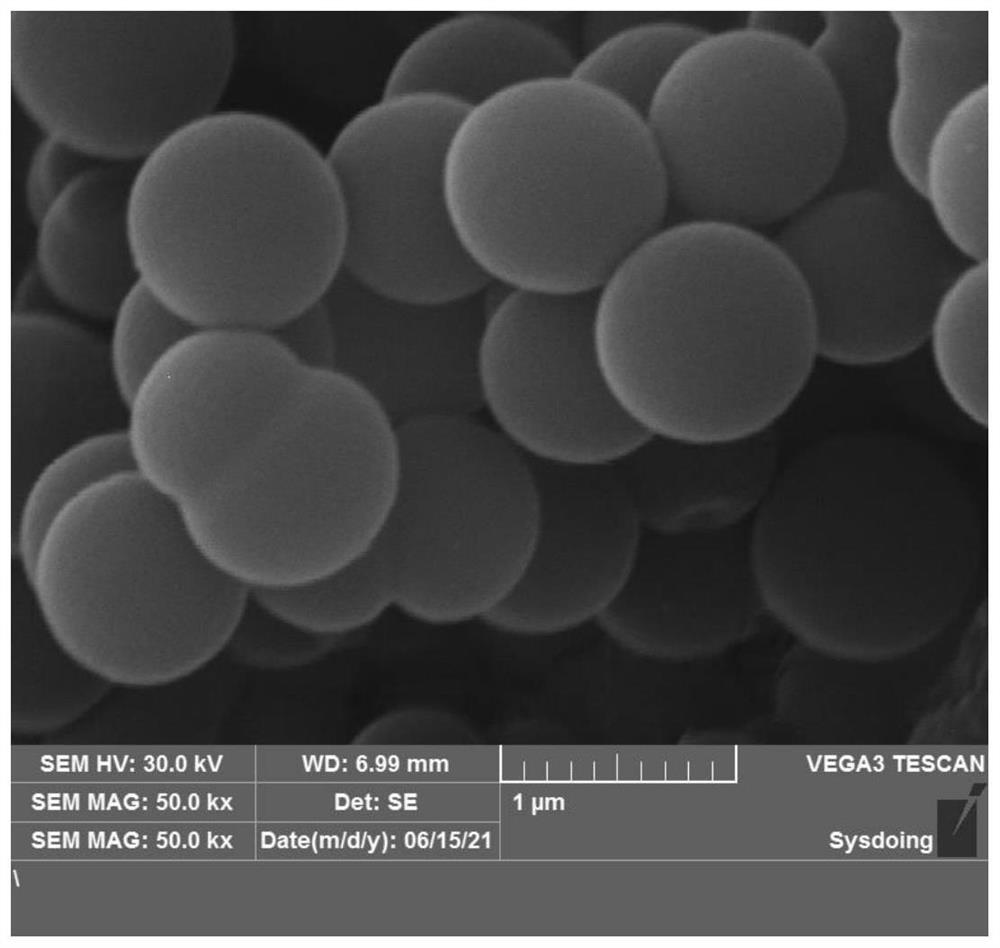

NCMA quaternary system material and preparation method thereof, lithium battery positive electrode material and lithium battery

InactiveCN111640928AImprove electrochemical cycle performanceIncreased charge transfer rateMaterial nanotechnologySecondary cellsElectrolytic agentPhysical chemistry

The invention provides an NCMA quaternary system material and a preparation method thereof, a lithium battery positive electrode material and a lithium battery. The NCMA quaternary system material comprises an NCMA quaternary positive electrode material and a coating layer, wherein the coating layer comprises Co3O4 and V2O5. The co-coating layer of Co3O4 and V2O5 not only can solve the problem ofresidual alkali on the surface of the material, but also can inhibit the dissolution of transition metal in the NCMA quaternary positive electrode material. Through the mutual synergistic effect of Co3O4 and V2O5, the charge transmission rate of the material body and the ion transmission rate between the material and the electrolyte are further improved, so that intercalation and deintercalation of lithium ions are promoted, side reactions of residual lithium and the surface of the NCMA quaternary positive electrode material are reduced, and the electrochemical properties such as capacity andstability of the NCMA quaternary positive electrode material are further improved.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

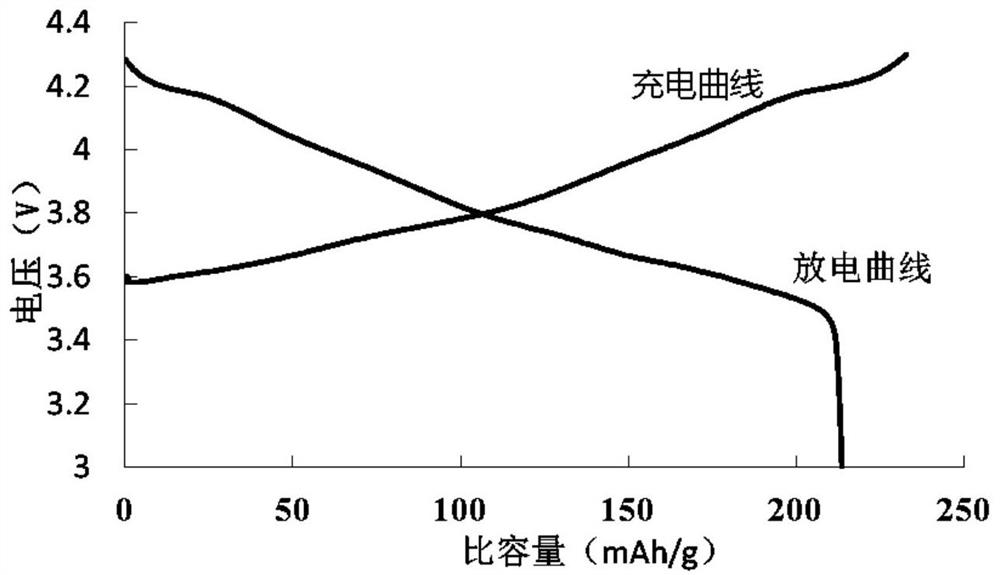

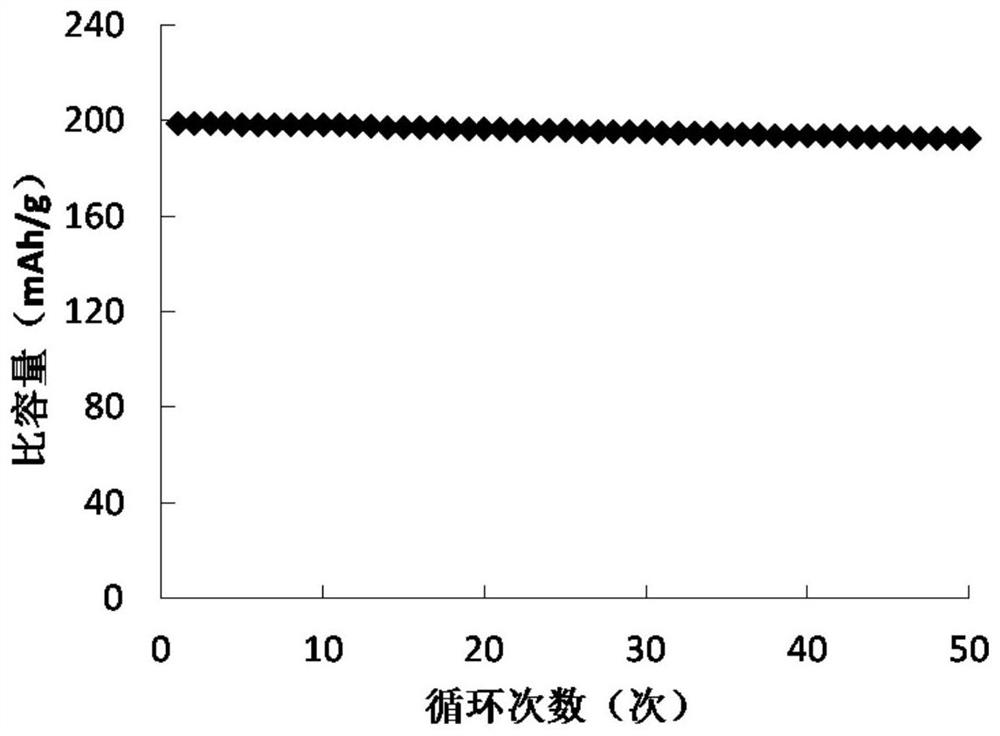

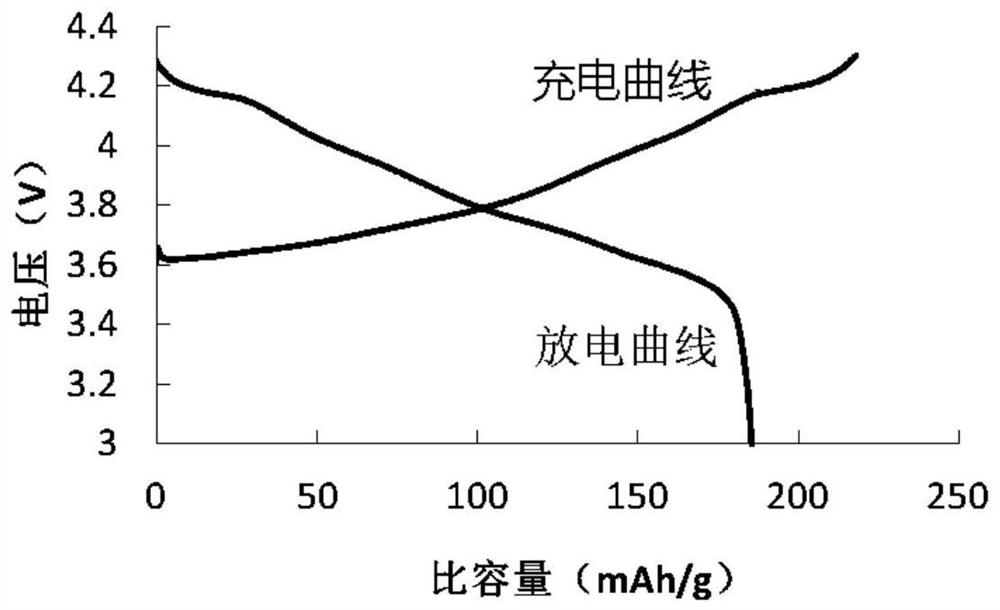

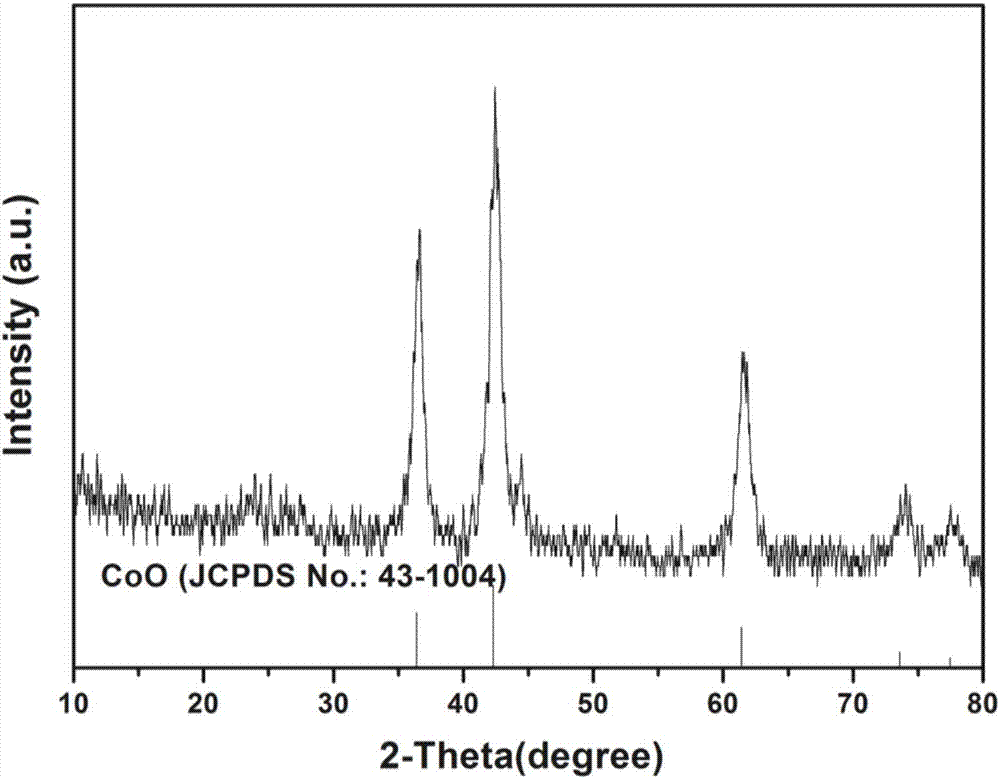

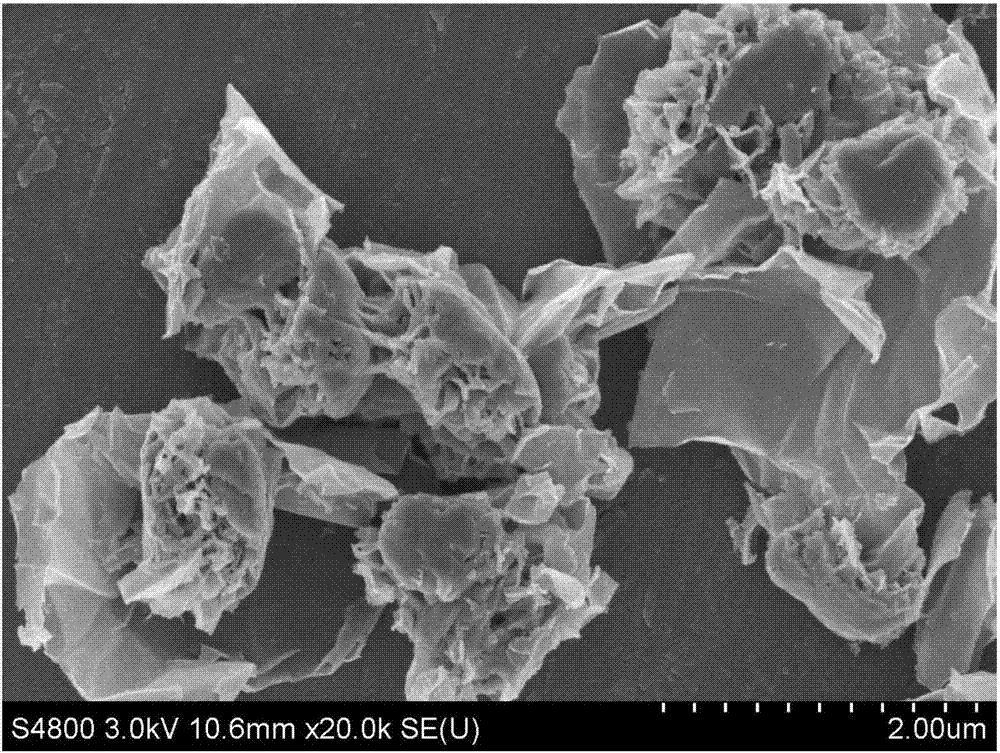

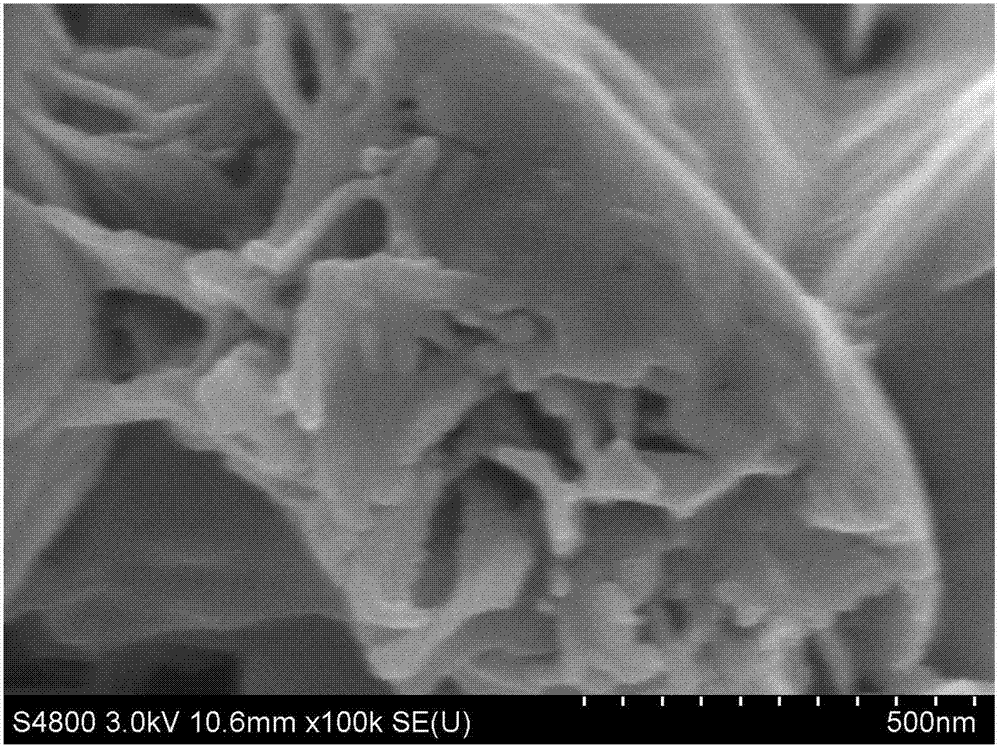

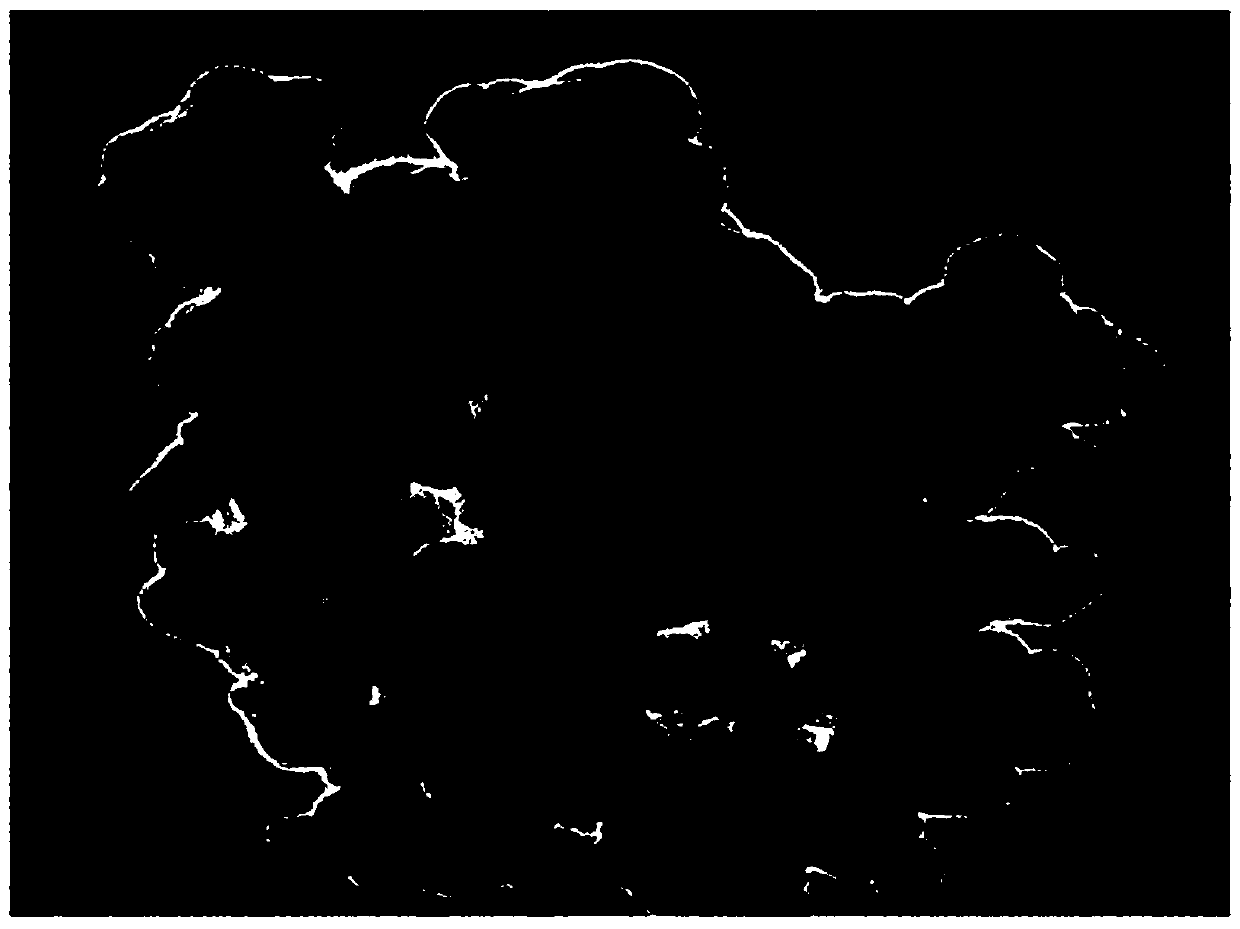

CoO/reduced graphene oxide composite negative pole material and preparation method thereof

ActiveCN107256951AThe preparation process is simple and gentleShort preparation cycleMaterial nanotechnologyCell electrodesLithium ion intercalationVolume expansion

The invention relates to a CoO / reduced graphene oxide composite negative pole material and a preparation method thereof. The method includes: adding oleylamine and oleic acid into isopropanol solution to obtain A; adding a cobalt source and a precipitating agent into A, and well stirring to obtain B; adding graphene oxide into B, and well stirring to obtain C; subjecting C to ultrasonic treatment and oil bath reaction to generate a precipitate; separating out the precipitate, washing, drying, keeping the temperature for 0.5-2h in an atmosphere furnace at 300-500 DEG C, cooling to the room temperature to obtain the CoO / reduced graphene oxide composite negative pole material. The composite material is small in CoO particle size, lithium ion intercalation and deintercalation in a charging-discharging process are facilitated, and electrode specific capacity is increased; due to generation of dionaea muscipula shaped compound, maintaining of material stability is greatly facilitated, volume expansion of the material is decelerated, and electrochemical performances of the material are improved due to an auxiliary conductivity improving effect of carbon materials.

Owner:SHAANXI UNIV OF SCI & TECH

Metal formate/carbon nano tube lithium ion battery cathode material and preparing method thereof

InactiveCN105489894AGood electronic conductivityImprove conductivityCell electrodesSecondary cellsCarbon nanotubeFormic acid

The invention belongs to the technical field of lithium ion battery electrode materials, and discloses a metal formate / carbon nano tube lithium ion battery cathode material and a preparing method thereof. The lithium ion battery cathode material is prepared from metal nitrate, formic acid, N,N-dimethylformamide and acidized carbon nano tubes, wherein the metal nitrate includes nickel nitrate, cobalt nitrate, zinc nitrate and manganous nitrate, the molar ratio of the metal nitrate to formic acid is 1:5-1:8, and the mass of the acidized carbon nano tubes accounts for 10-40% that of the metal nitrate. The preparing method adopts a solvothermal method, conductivity of the obtained metal formate / carbon nano tube lithium ion battery cathode material is remarkably improved by means of effective cladding of the carbon nano tubes, the material has high specific capacity and circulation stability, respective advantages of the carbon nano tubes and a metal-organic framework material can be brought into play, and the material is an ideal lithium ion battery cathode material. The preparing method is simple in preparation technology and convenient and easy to operate.

Owner:CHANGAN UNIV

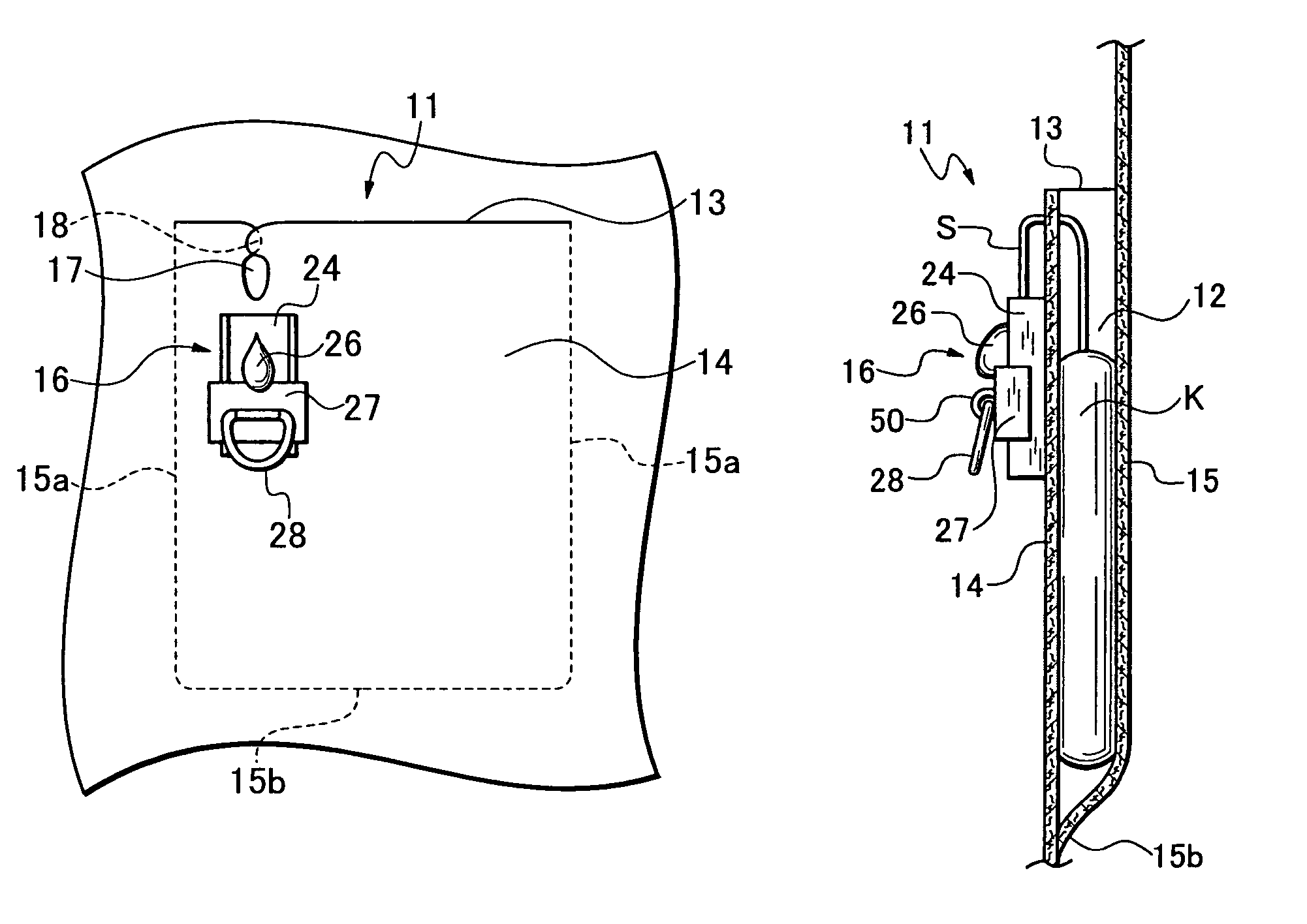

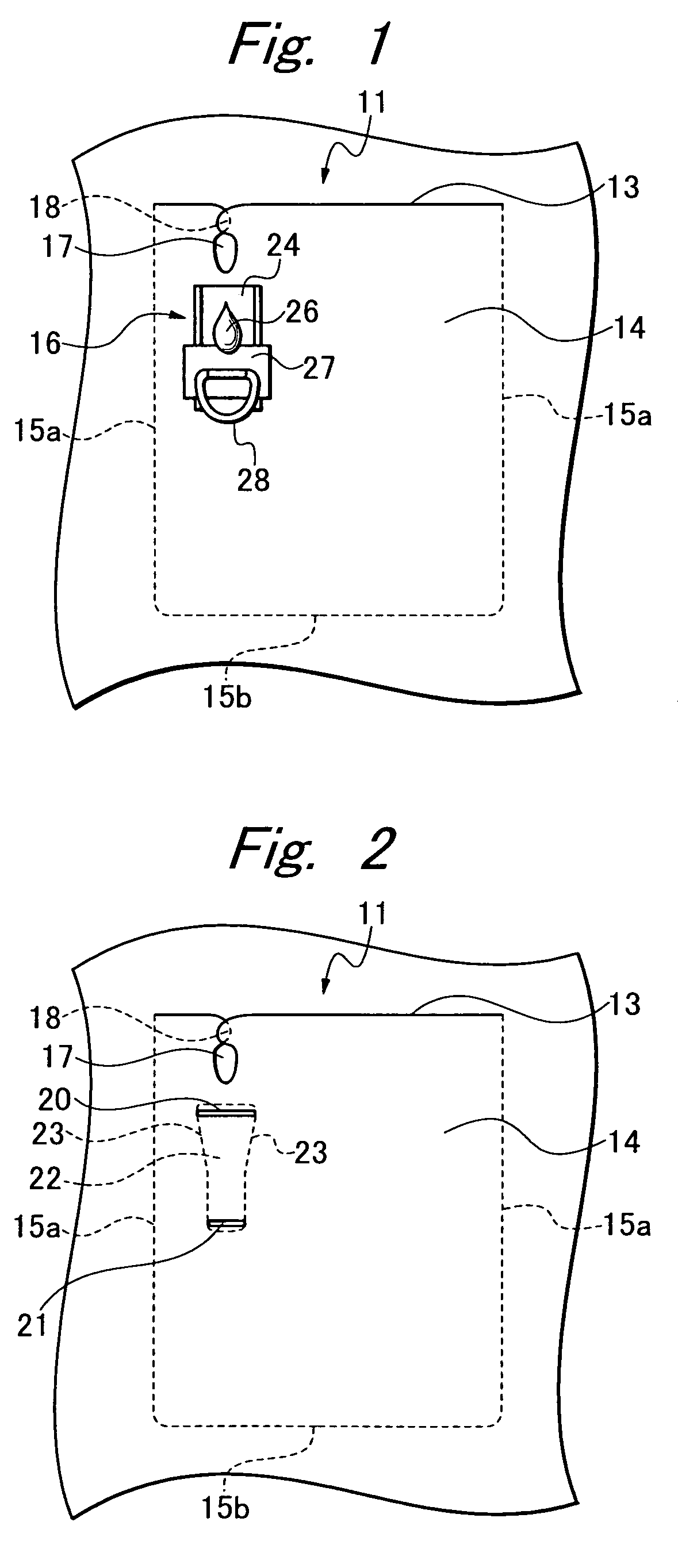

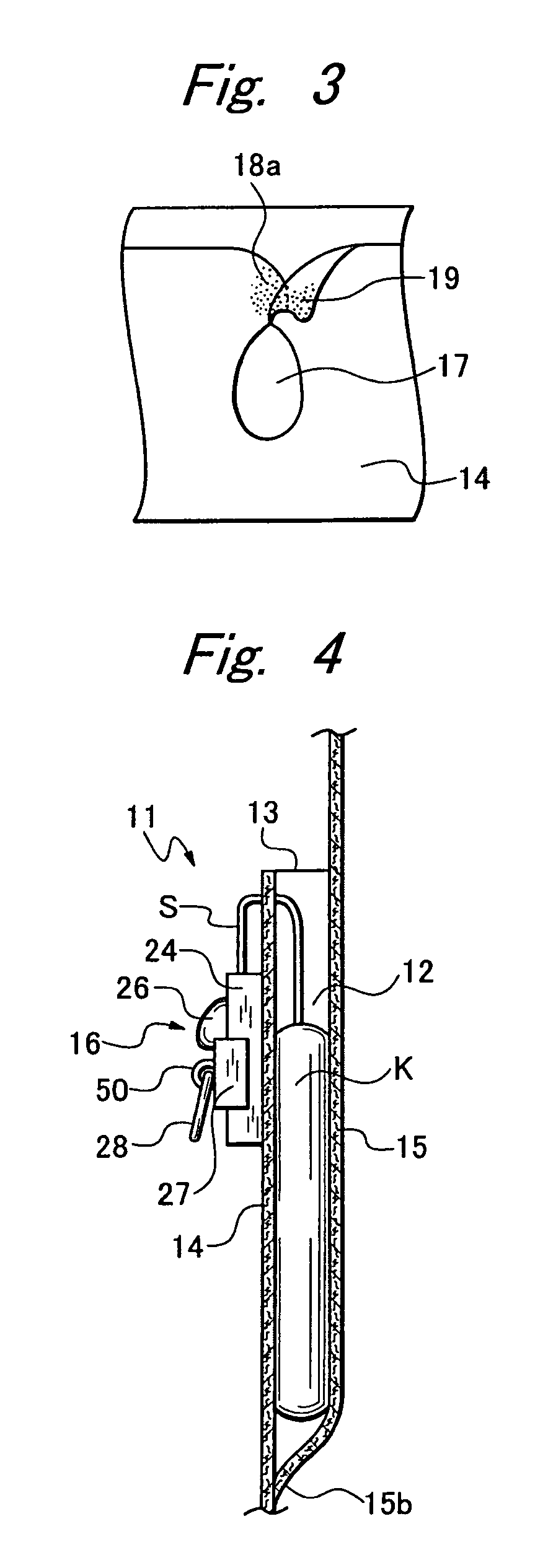

Pocket provided with fastener

InactiveUS7621001B2Facilitates insertion and extractionRetain easeTravelling carriersHoldersEngineeringFastener

A pocket provided with fastener includes a pocket formed by a base cloth and an outer cloth disposed atop the base cloth whose bottom and both lateral side portions are sewed to the base cloth, a top portion thereof being open so as to create a pocket portion; and a fastener detachably provided on the outer cloth, with at least one attachment hole for mounting the fastener formed in the outer cloth. The fastener includes a planar base portion; a mounting belt portion one end of which is fixedly mounted on the planar base portion for detachable attaching the fastener to the pocket through the attachment hole; a fastening projecting portion that projects above the base portion and fastens an object to be fastened; and a lid member that opens and doses to maintain a state in which the object to be fastened is fastened to the fastening projecting portion.

Owner:EBIHARA KENZO

Anthraquinone-2-copper carboxylate/graphene nano-composite as well as preparation and application thereof

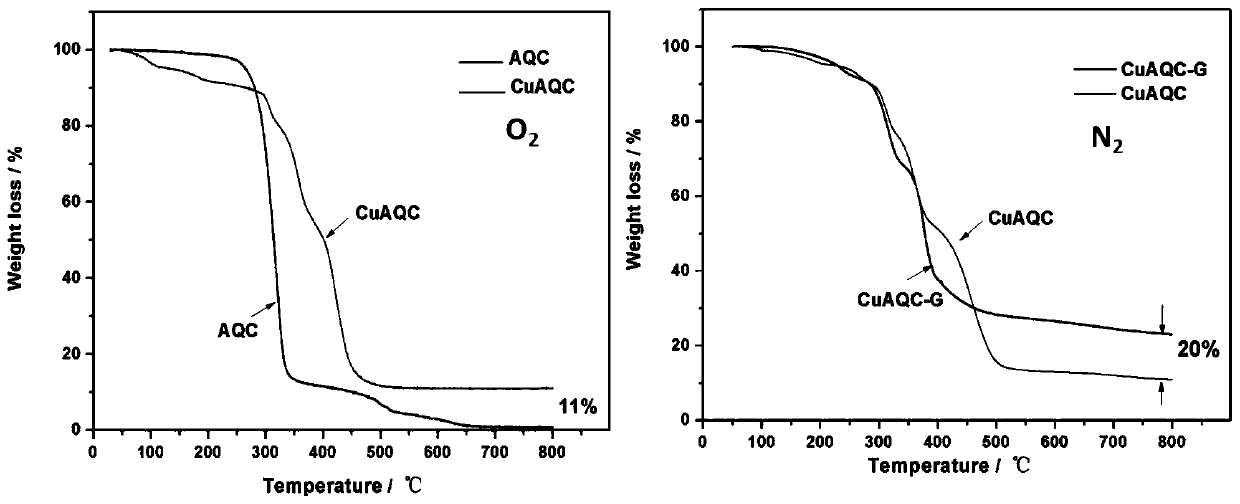

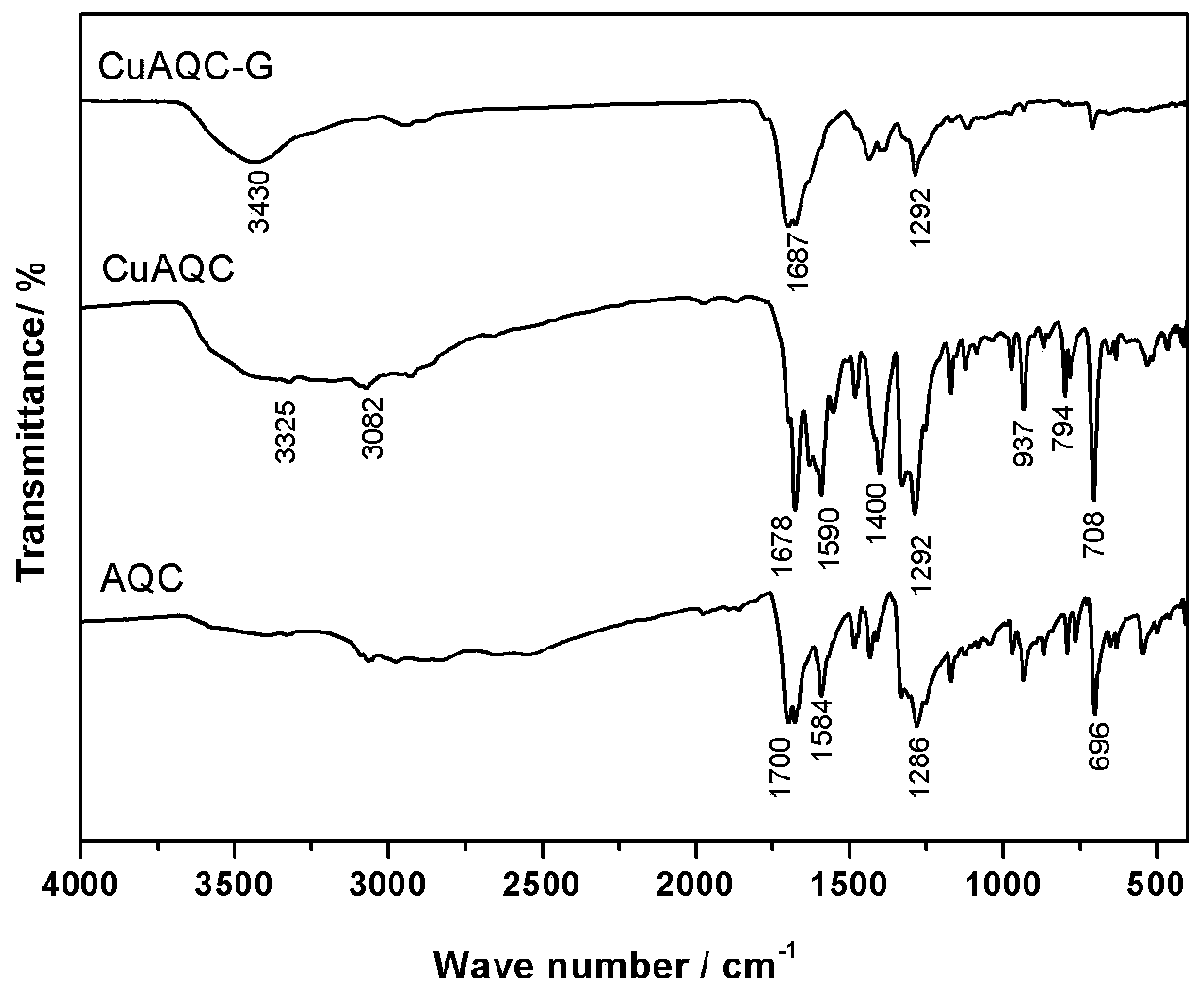

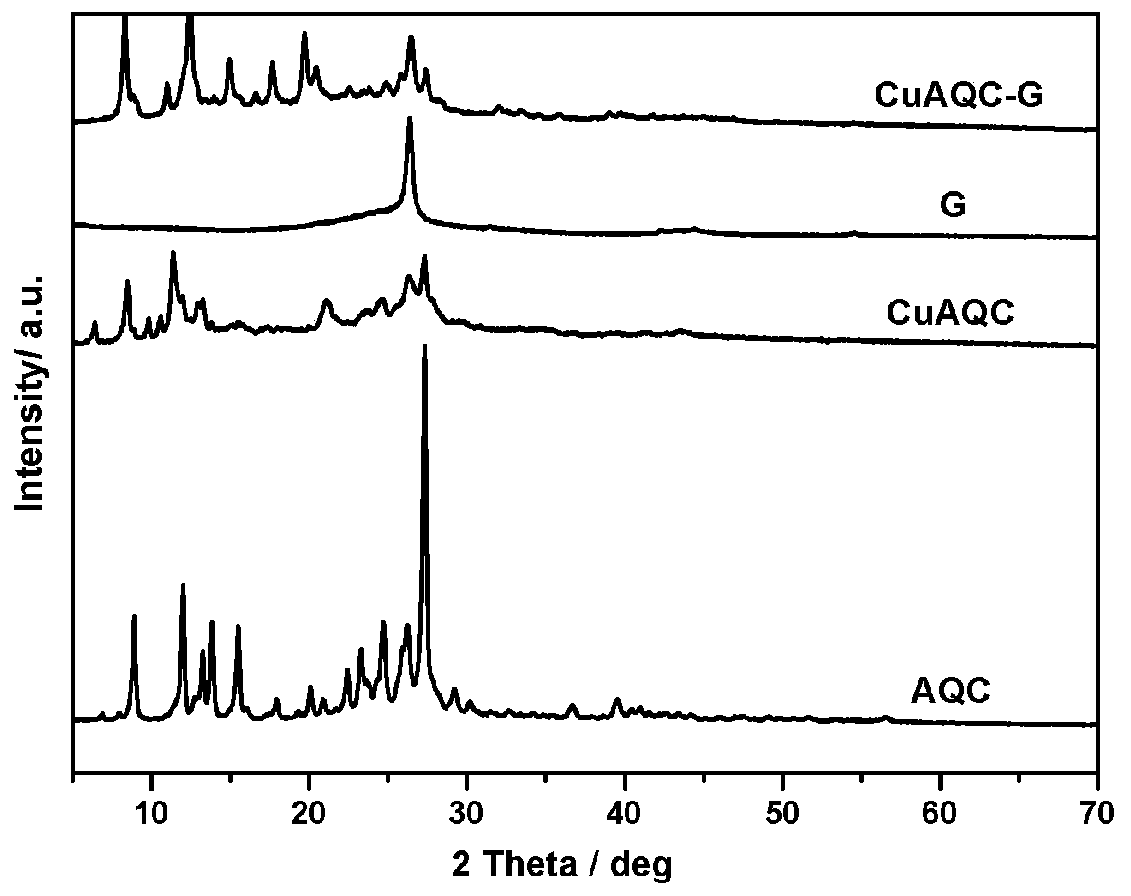

InactiveCN111403736AThe synthetic route is simpleLow equipment requirementsMaterial nanotechnologySecondary cellsCopper nitrateCarboxylic acid

The invention belongs to the field of lithium ion battery materials, and discloses an anthraquinone-2-copper carboxylate / graphene nano-composite as well as preparation and application thereof. The preparation method comprises the following steps: adding anthraquinone-2-carboxylic acid into a solvent, uniformly stirring and dissolving, dropwise adding a copper nitrate solution, and stirring for reflux reaction to obtain CuAQC; grinding the CuAQC, dispersing CuAQC and graphene into a solvent, and sequentially carrying out ball milling and ultrasonic treatment to obtain a uniform mixed dispersionliquid; and finally, carrying out forced air drying and coprecipitation to obtain the anthraquinone-2-copper carboxylate / graphene nano-composite. According to the method disclosed by the invention, the anthraquinone-2-carboxylic acid copper salt complex and the graphene are compounded by adopting simple ball milling and forced air drying coprecipitation, and the obtained compound has a characteristic structure of coating the rod-like anthraquinone-2-carboxylic acid copper salt complex with the graphene. The composite has excellent electrochemical performance as a lithium ion battery positiveelectrode material.

Owner:SOUTH CHINA NORMAL UNIVERSITY

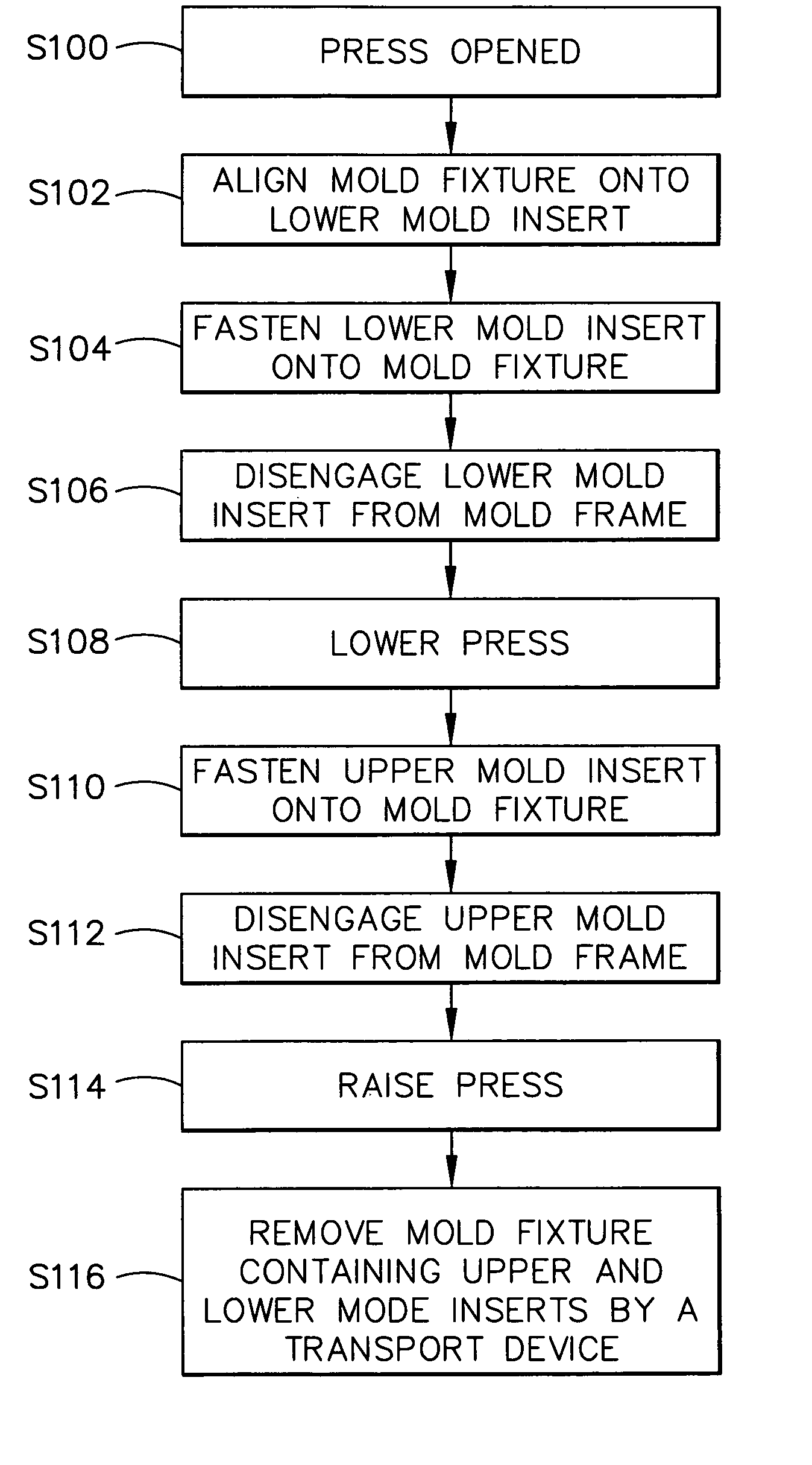

Method of extracting and inserting upper and lower molds

InactiveUS7007361B2Safe and efficient extractionSafe and efficient and insertionConfectionerySweetmeatsEngineeringMolding machine

A mold fixture 20 for safe and efficient extraction, insertion and storage of mold inserts 26, 28 is provided. The mold fixture 20 includes a lower receiving area 24 for fixedly receiving a lower mold insert 28, an upper receiving area 22 for fixedly receiving an upper mold insert 26. The mold fixture 20 facilitates insertion or extraction of the upper and lower mold inserts 26, 28 into / from a molding machine 1 in a safe and secure manner. Furthermore, the upper and lower mold inserts 26, 28 can be securely stored within the mold fixture 20 at a storage location.

Owner:HONEYWELL INT INC

Process for making angled features for nanolithography and nanoimprinting

InactiveUS20050064720A1Easy to insertEasy extractionSemiconductor/solid-state device manufacturingNon-linear opticsNanolithographyEtching

This invention provides a directional ion etching process for making nano-scaled angled features such as may be used, for example, in liquid crystal displays and or nanoimprinting templates. In a particular embodiment a semiconductor wafer substrate is prepared with at least one layer of material. A photoresist is applied, masked, exposed and developed. Anisotropic ion etching at a high angle relative to the wafer is performed to remove portions of the non protected material layer. The remaining photoresist caps shadow at least a portion of the material layer, and as the ion etching is performed at an angle, the protected portions of the material layer also appear at an angle.

Owner:HEWLETT PACKARD DEV CO LP

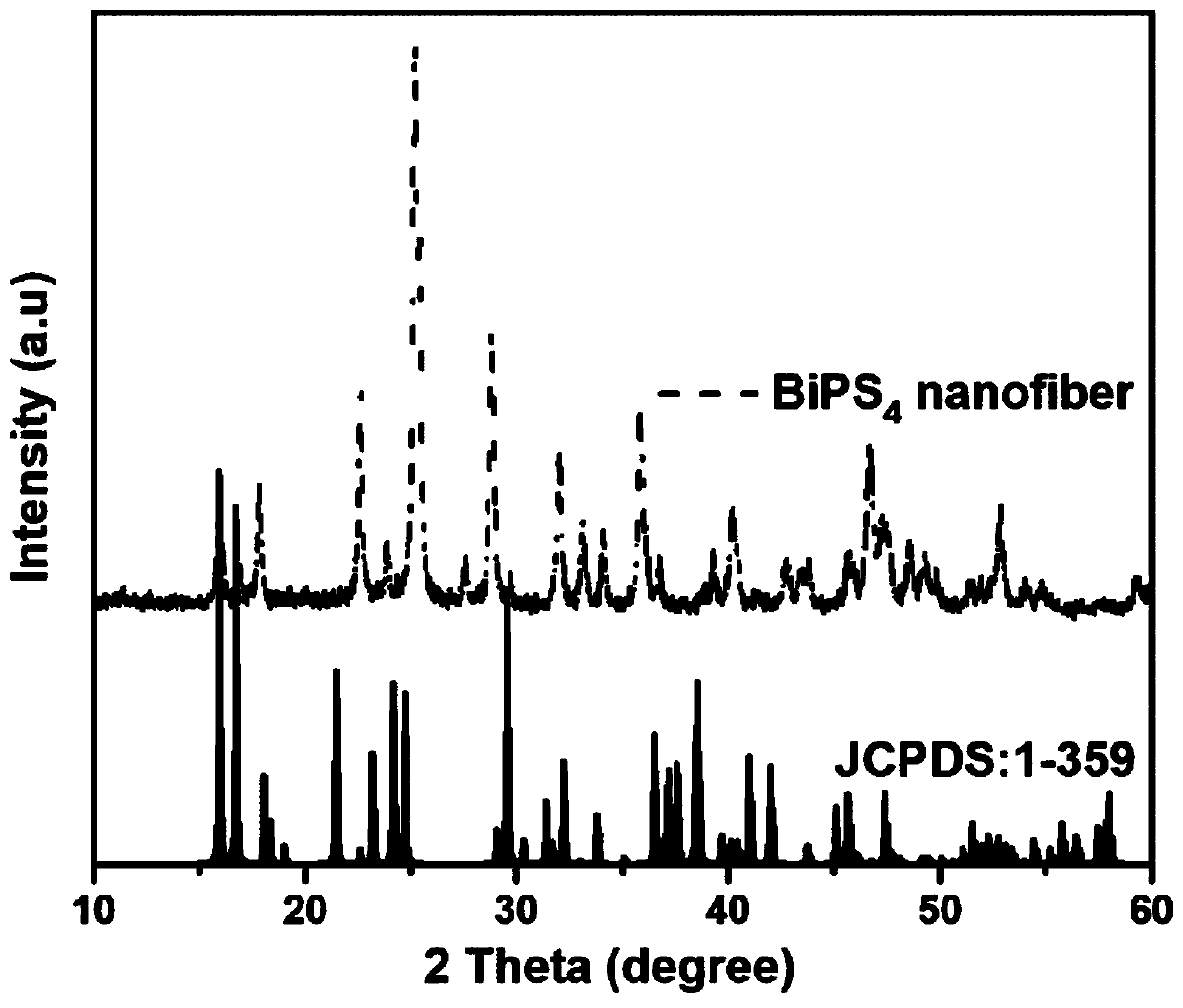

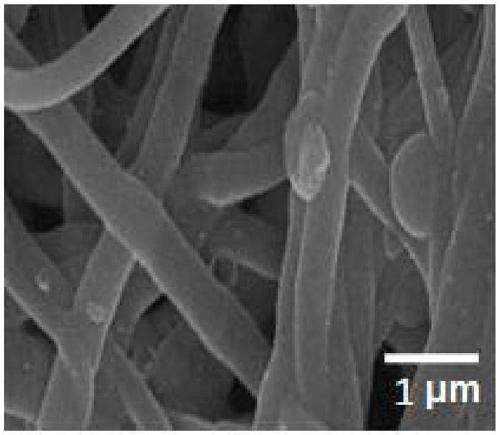

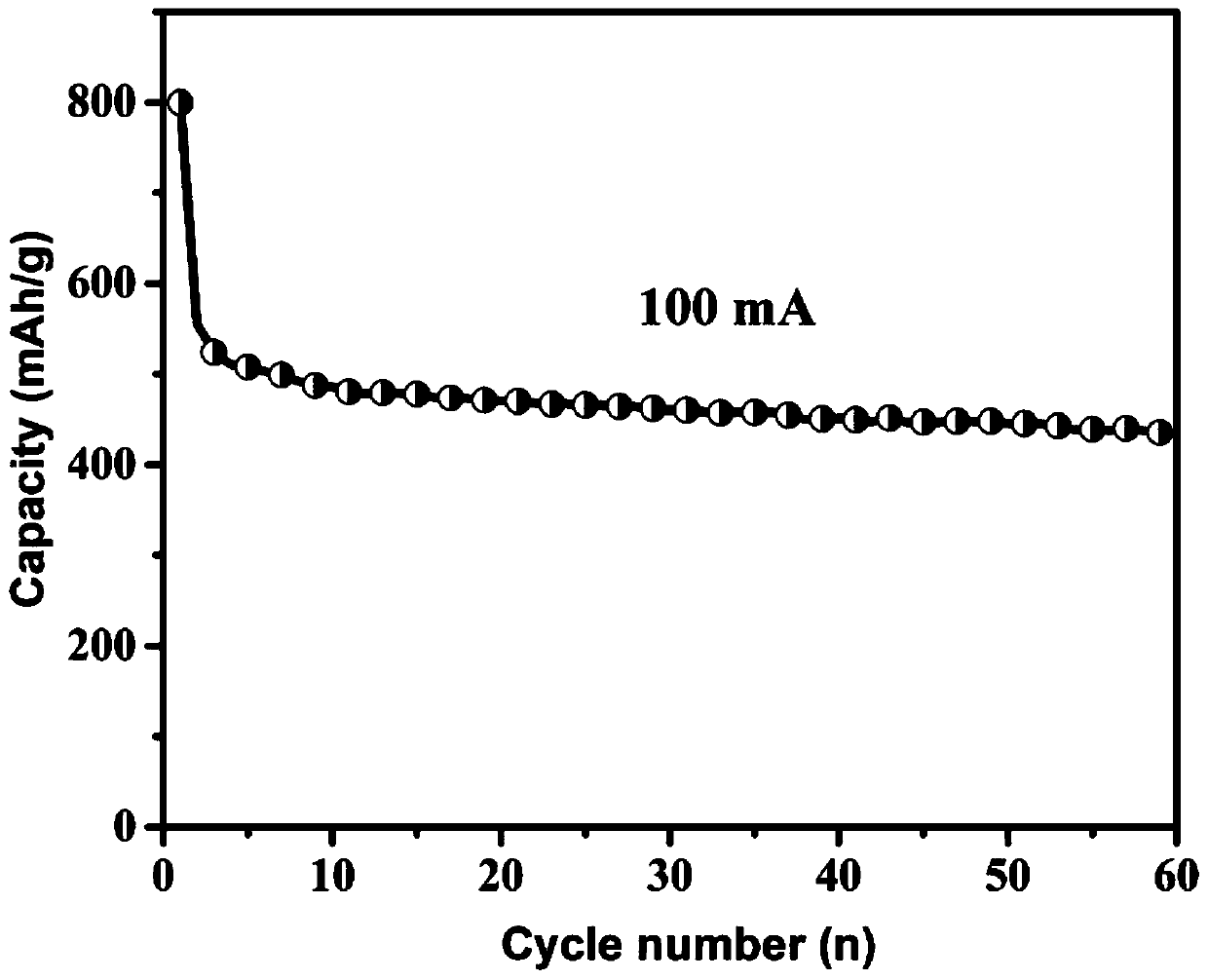

Bismuth phosphorus sulfur/carbon composite nanofiber negative electrode material for sodium-ion battery, preparation method of bismuth phosphorus sulfur/carbon composite nanofiber negative electrode material and sodium-ion battery

ActiveCN111235696AEasy to prepareEasy to operateMaterial nanotechnologySecondary cellsCarbon compositesComposite nanofibers

The invention relates to a bismuth phosphorus sulfur / carbon composite nanofiber negative electrode material for a sodium-ion battery, a preparation method of the bismuth phosphorus sulfur / carbon composite nanofiber negative electrode material and the sodium-ion battery, and belongs to the technical field of sodium-ion batteries. The preparation method of the bismuth phosphorus sulfur / carbon composite nanofiber negative electrode material for the sodium-ion battery comprises the following steps of mixing polyacrylonitrile, bismuth salt and an organic solvent to prepare a mixed solution, and then performing electrostatic spinning to prepare spinning fibers; preserving the heat of the prepared spinning fibers at 250-300 DEG C for 1-3 hours for pre-oxidation, and then preserving the heat in aninert atmosphere at 700-900 DEG C for 1-3 hours to prepare a precursor; and uniformly mixing the prepared precursor with phosphorus and sulfur, and carrying out calcining at 500-700 DEG C for 4-7 days to obtain the bismuth phosphorus sulfur / carbon composite nanofiber negative electrode material. The material prepared by the preparation method of the bismuth phosphorus sulfur / carbon composite nanofiber negative electrode material for the sodium-ion battery is of a one-dimensional nanowire structure and stable in structure in the charging and discharging process, and has relatively high specific discharge capacity and good cycling stability.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

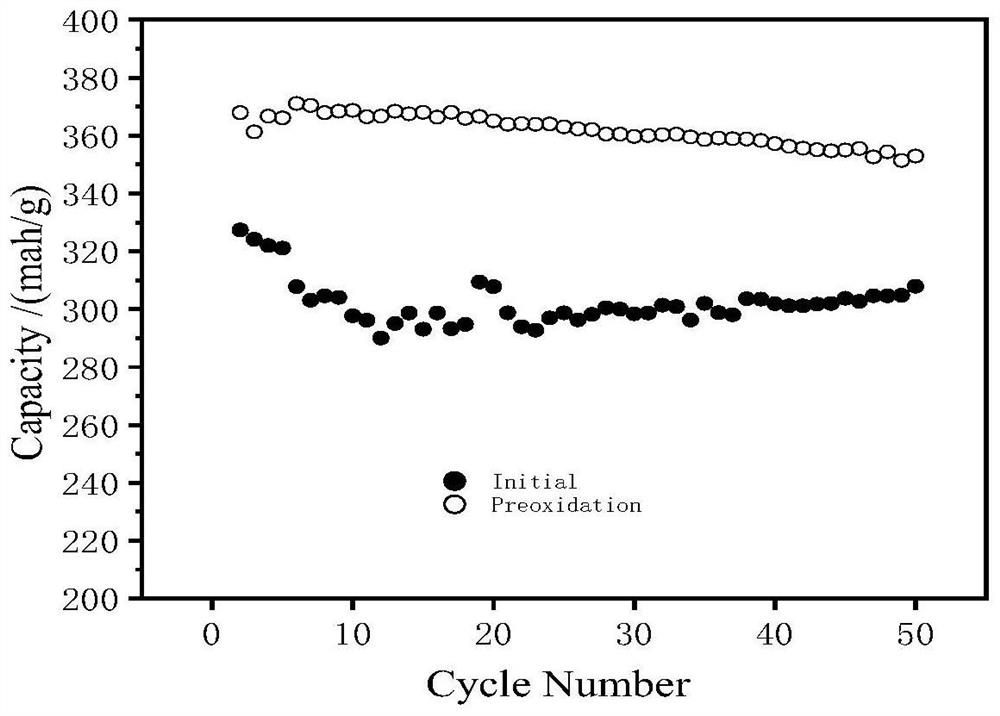

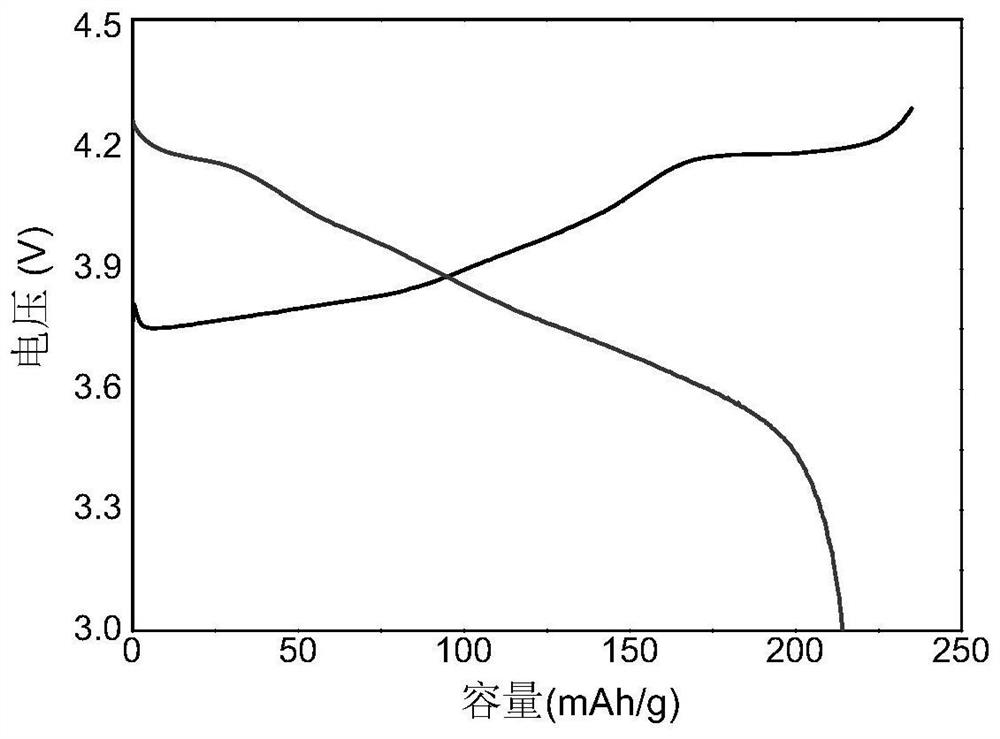

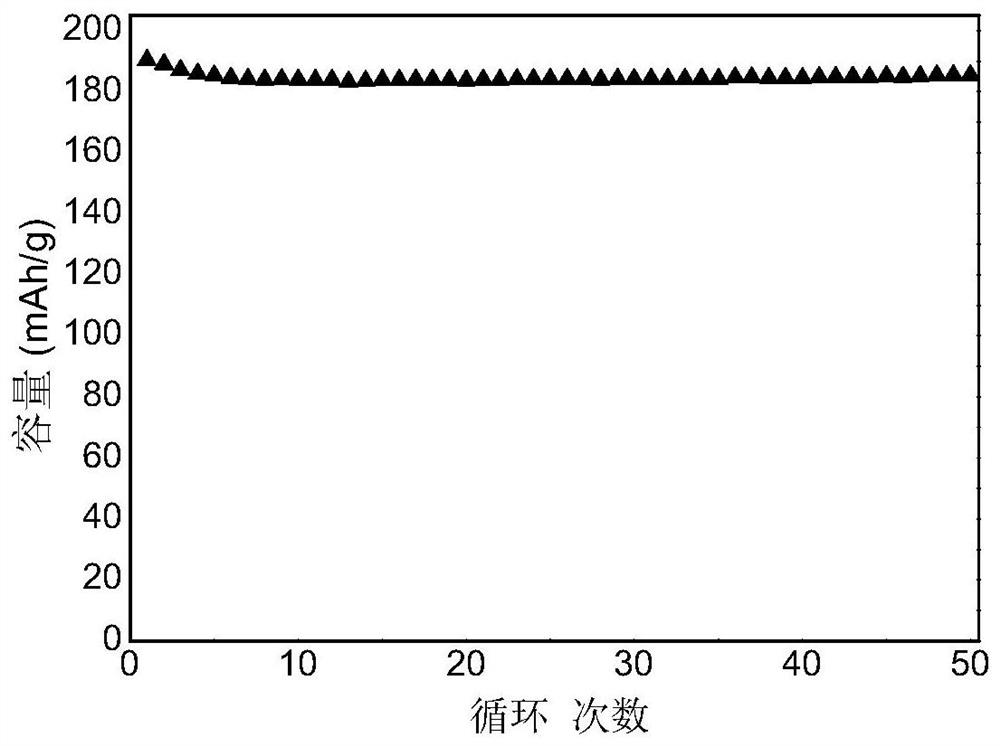

Hard carbon material and preparation method and application thereof

ActiveCN114436237AGrowth inhibitionInhibition orientationCell electrodesSecondary cellsElectrical batterySodium-ion battery

The invention relates to a preparation method of a hard carbon material. The preparation method comprises the following steps: S100, pre-oxidizing a hard carbon precursor; s200, grinding the pre-oxidized hard carbon precursor into powder; s300, the powder is subjected to microwave treatment; and S400, calcining the powder obtained in S300 to obtain the hard carbon material. The hard carbon material is prepared by the preparation method. The hard carbon material prepared by the preparation method is applied to the negative electrode of the sodium-ion battery. The method has the advantages that the prepared hard carbon material serves as a sodium ion battery negative electrode material to be assembled into a sodium half-battery pair, within the voltage range of 0-2 V, the cycling stability is good, the initial reversible capacity reaches up to 370 mAh / g, the capacity retention rate reaches 95.9% after 50 cycles under the current density of 20 mA / g, compared with a traditional preparation method, the hard carbon specific capacity is obviously improved, and the method is simple and easy to implement. The method is low in cost and suitable for large-scale industrial production.

Owner:HUAZHONG UNIV OF SCI & TECH

Quaternary polycrystalline positive electrode material, and preparation method and application thereof

InactiveCN112701276AIncrease the diffusion coefficientImprove structural stabilityCell electrodesSecondary cellsDopantPhysical chemistry

The invention provides a quaternary polycrystalline positive electrode material, and a preparation method and application thereof. The positive electrode material comprises a main body and a doping agent, the doping agent is uniformly doped into the main body, the chemical general formula of the main body is LiNixCoyMnzAl(1-x-y-z)O2, the doping agent comprises selenium oxide and calcium oxide, and Se / Ca is uniformly doped into the main body of the material, so the layered positive electrode material has characteristics of enhanced structure stability, reduced Li<+> / Ni<2+> cation mixing effect, inhibition of the oxidation process from O<2-> to O2, and obstruction of the phase change of the material from layering to spinel to a certain extent so as to improve the electrochemical performance of the positive electrode material.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

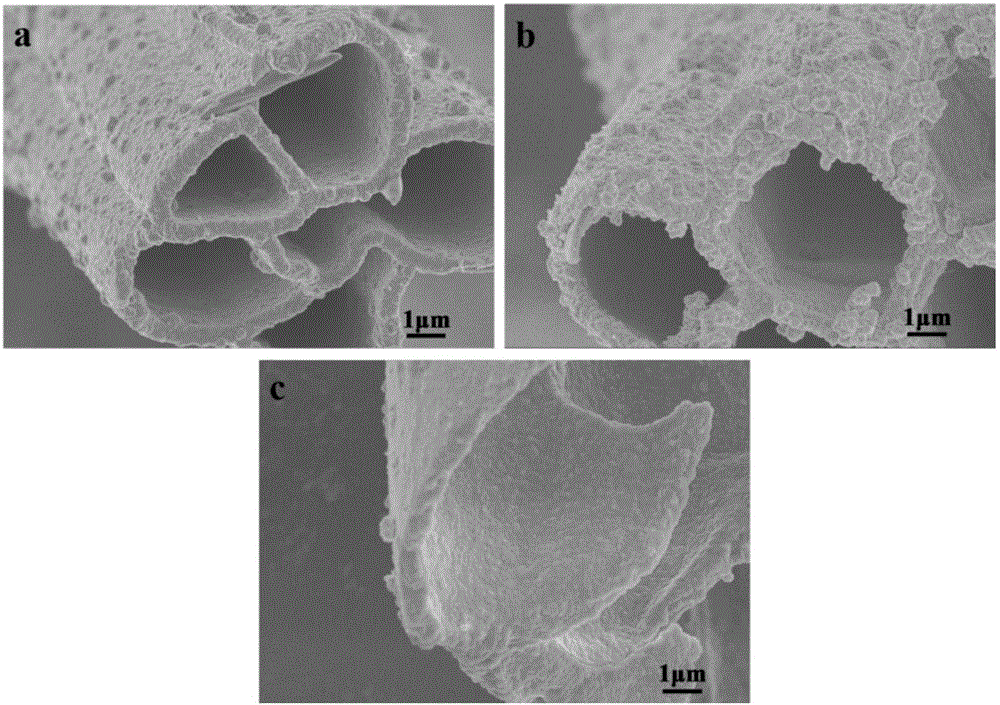

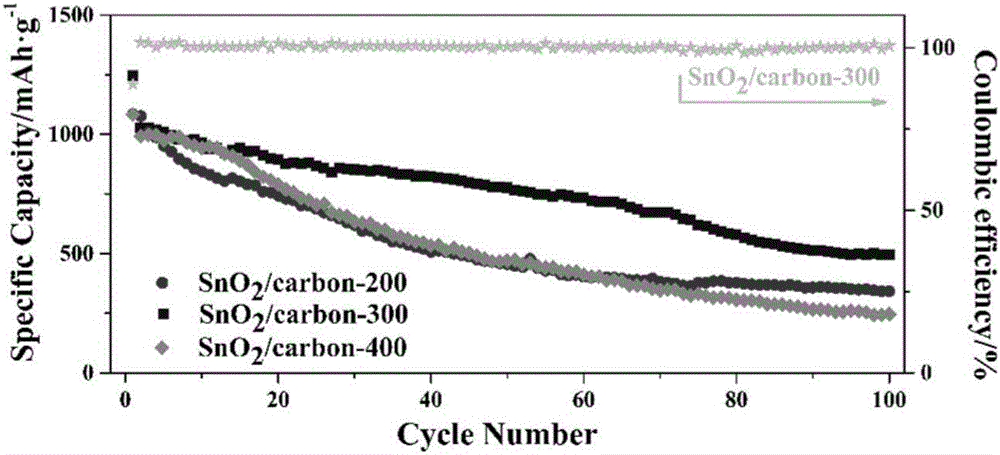

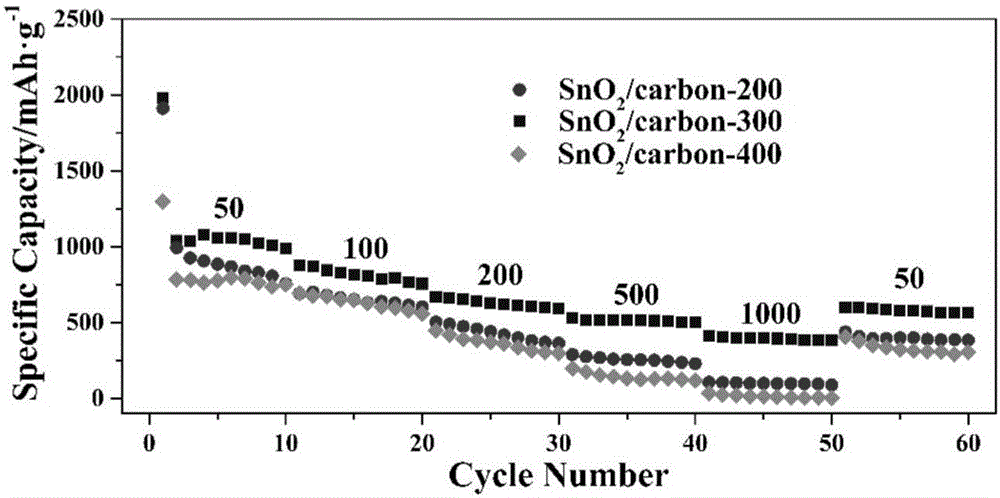

Preparation method of compound powder with tubular biochar-coated SnO<2> structure and application of compound powder

ActiveCN106602035AAlleviate volume expansionImprove adsorption capacityCell electrodesSecondary cellsMicrowaveProcess equipment

The invention relates to a preparation method of compound powder with a tubular biochar-coated SnO<2> structure and an application of the compound powder. According to the preparation method, villus plants such as dandelion are subjected to earlier-stage alkali activation treatment at an earlier stage, so that a large quantity of oxygen-containing functional groups similar to hydroxyl and carboxyl exist inside a carbon tube. A microwave-ultraviolet-ultrasound synthetic mode is adopted, so that the adsorption of SnO<2> particles by a carbon framework can be facilitated; the problem of volume expansion of the SnO<2> in charging and discharging processes is effectively solved; and the tubular biochar-coated SnO<2> structure is obtained finally. The preparation method is simple, low in reaction temperature, short in reaction period, simple in process equipment, environmentally friendly and suitable for large-scale production, and does not need subsequent treatment.

Owner:SHAANXI UNIV OF SCI & TECH

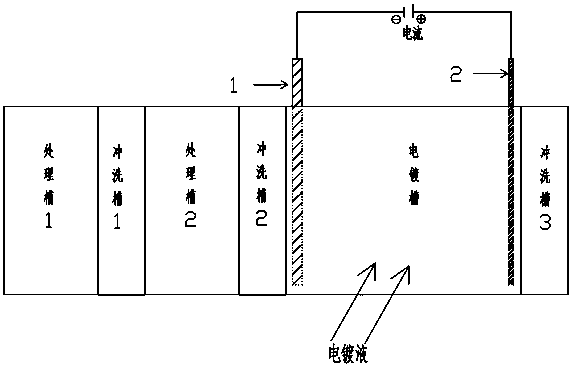

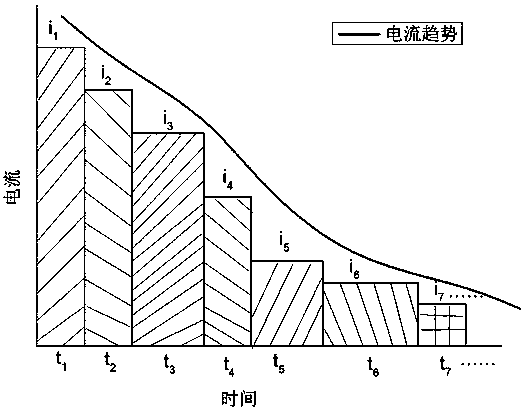

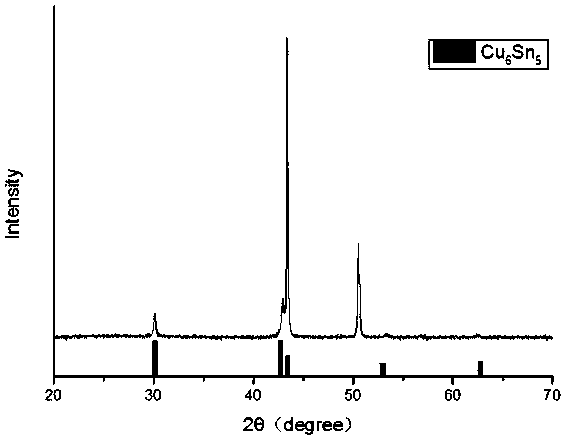

Preparation method of novel tin-based nanocrystalline alloy flexible film electrode

ActiveCN108574084AImprove bindingSolve the problem of easy falling off from the current collectorSecondary cellsElectrode collector coatingElectroplatingCopper salt

The invention discloses a novel tin-based nanocrystalline alloy flexible film electrode and a preparation method thereof, and belongs to the technical field of preparation of tin-based alloy film electrodes. The preparation method is characterized by comprising the following steps of: preparing electroplating solution main salt soluble copper salt and soluble tin salt and a electroplating complexing agent into an electroplating solution A; adding additives to the electroplating solution A to obtain an electroplating solution B; continuing to add the electroplating solution main salt soluble copper salt and the soluble tin salt to the electroplating solution B to obtain an electroplating solution C; conducting surface-treatment on a current collector for electroplating; placing the electroplating solution C and the surface-treated current collector in a plating bath for electroplating to obtain the tin-based nanocrystalline alloy flexible film electrode; and rinsing and drying the tin-based nanocrystalline alloy flexible film electrode to obtain a copper-tin nanocrystalline alloy flexible film electrode. The novel tin-based nanocrystalline alloy flexible film electrode and the preparation method thereof effectively solve a problem that a tin-based active material is easily detached from the current collector during a charging and discharging process, and a preparation process issimple, operation is convenient, cost is low, and production efficiency is high.

Owner:河南电池研究院有限公司 +1

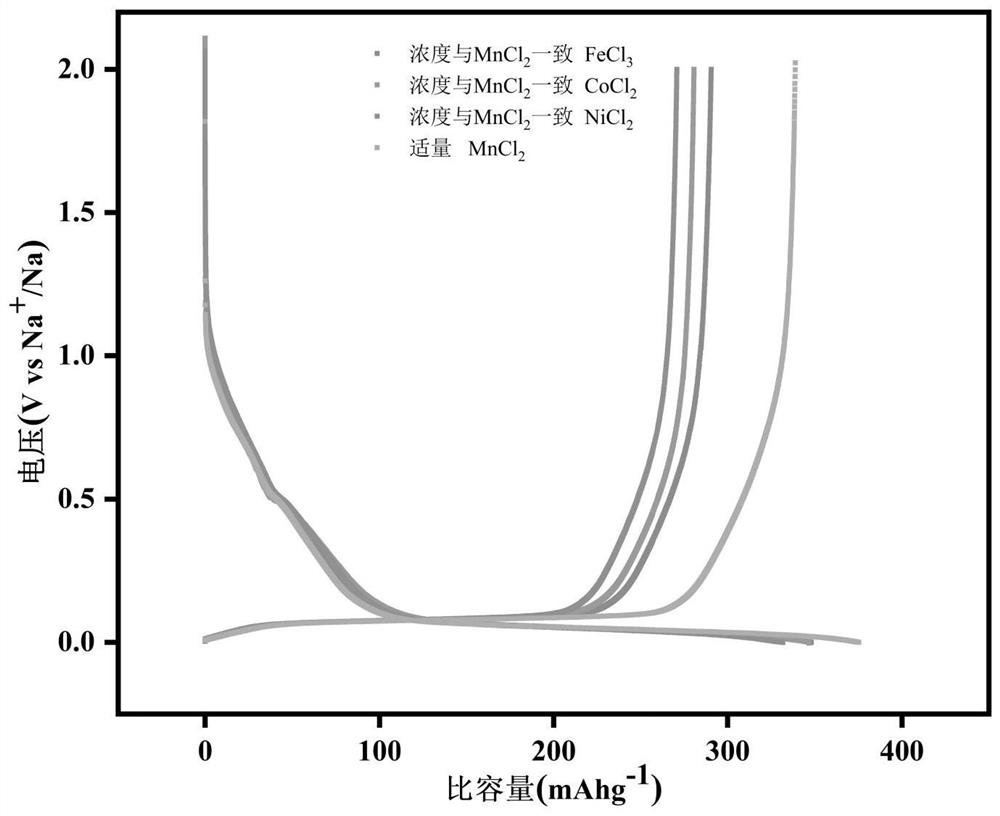

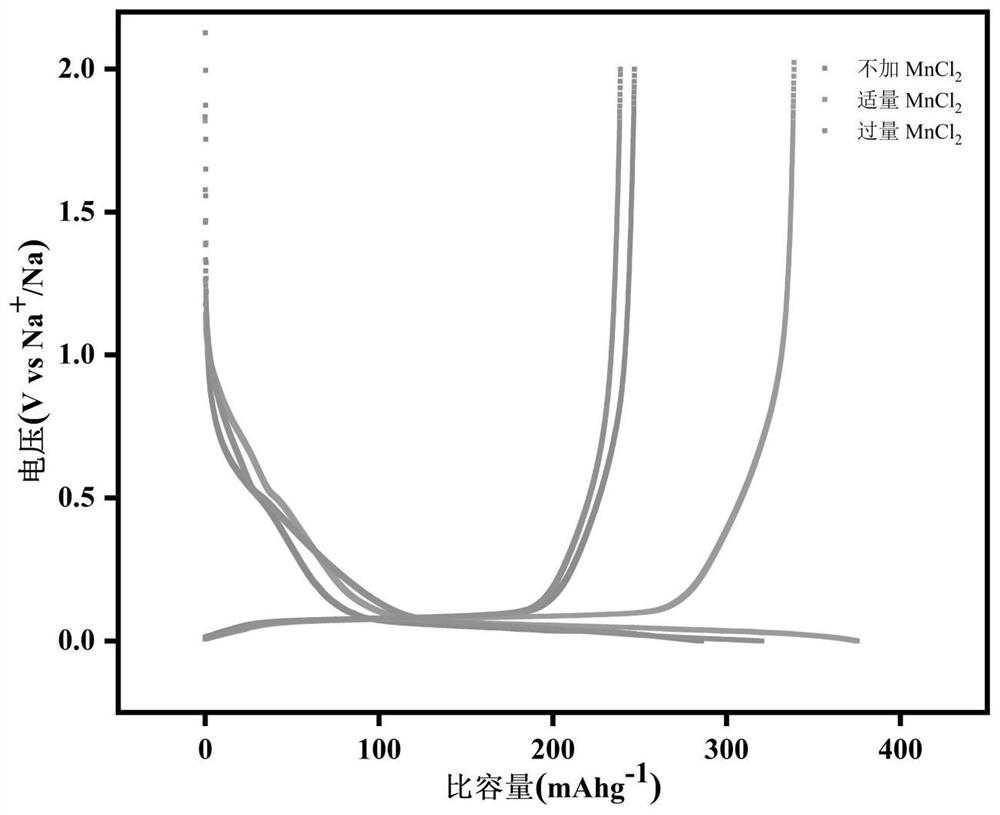

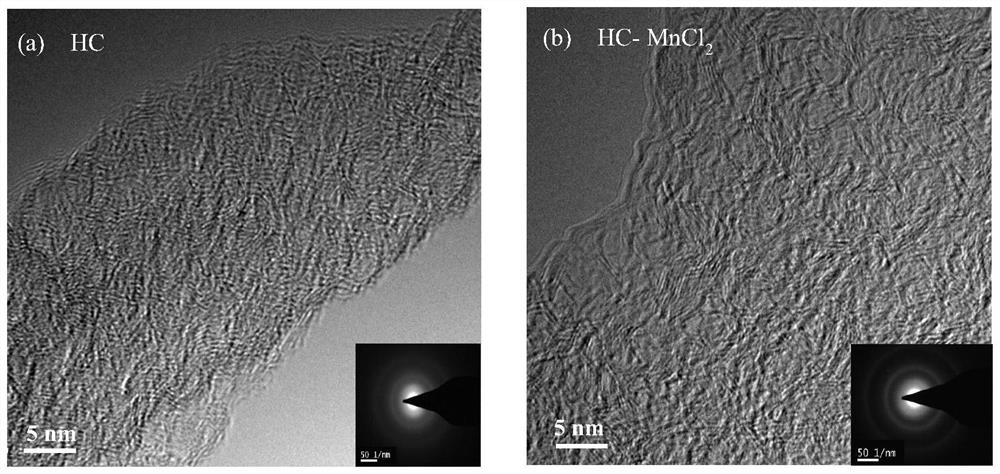

Preparation and application of high-performance sodium-ion battery energy storage material based on regulation and control of hard carbon structure through ion catalysis

ActiveCN114497543AGood repeatabilityImproved magnification performanceNegative electrodesSecondary cellsGraphene flakeManganese

The invention relates to the field of sodium ion secondary batteries, and provides a method for regulating and controlling a hard carbon structure based on transition metal manganese, which is used for a sodium ion battery negative electrode material. Cheap and easily available biomass is used as a carbon source, and manganese is ensured to be uniformly dispersed in a precursor polymer through coordination of manganese ions (Mn < 2 + >) and one-dimensional cellulose nanofibers and a coordination effect; according to the present invention, the graphene sheets are introduced into the graphene sheets, such that the conversion between the SP3 carbon and the SP2 carbon is effectively catalyzed so as to freely rearrange the graphene sheets, such that the expanded nano-graphite and the carbon micro-pores are formed, and the controllable adjustment of the carbon interlayer spacing and the micro-pores is achieved by adjusting the concentration; and finally, 92.05% of ultrahigh first efficiency and excellent circulating performance are obtained (the capacity retention ratio of 200 cycles is 95.80% under the current density of 20mA g <-1 >). The problems of low sodium ion first efficiency and poor cycling stability are solved through ion catalysis regulation and control, the first efficiency can be improved to 90% or above, the performance is improved by 30% or above, the energy density of the battery is greatly improved, and the total battery with sodium vanadium phosphate as the positive electrode has excellent electrochemical performance, has a good industrialization prospect and is suitable for industrial production. The method is very suitable for large-scale energy storage systems.

Owner:温州大学碳中和技术创新研究院

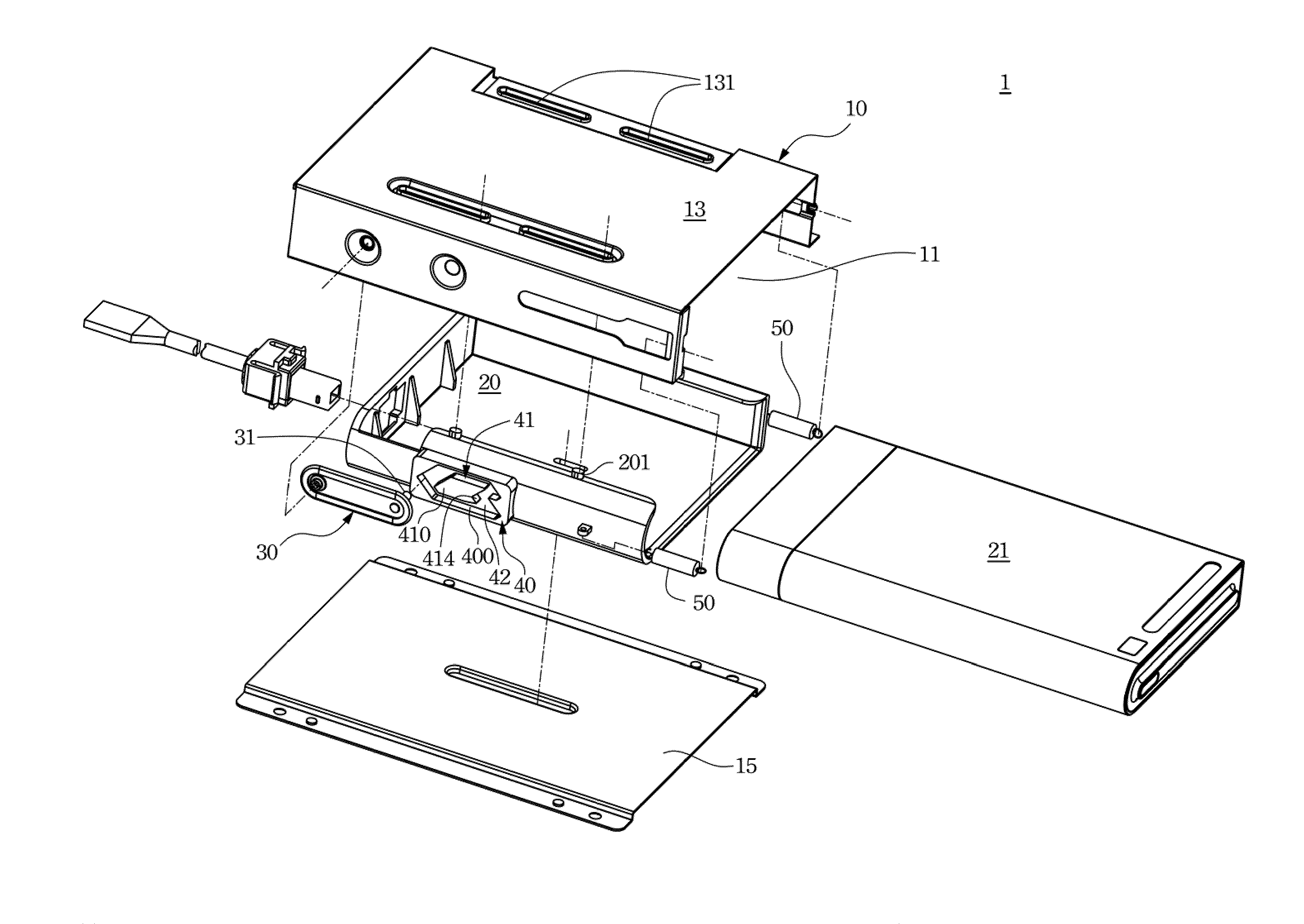

Mobile rack

InactiveUS20090301981A1Smooth slidingEasy extractionShow cabinetsDigital data processing detailsMechanical engineering

Owner:PEGATRON

Method of manufacturing cylinder with interchangeable sleeve

InactiveUS7357892B2Facilitates insertion and extractionCooperate with safe and reliableLiquid surface applicatorsMechanical working/deformationFriction forceBiomedical engineering

Owner:FABIO PERINI SPA

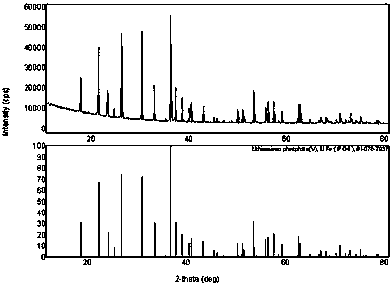

Positive electrode material for lithium ion battery, preparation method of positive electrode material and lithium ion battery

PendingCN114665085AFacilitates insertion and extractionImprove cycle performanceElectrode thermal treatmentPositive electrodesPhysical chemistryLithium-ion battery

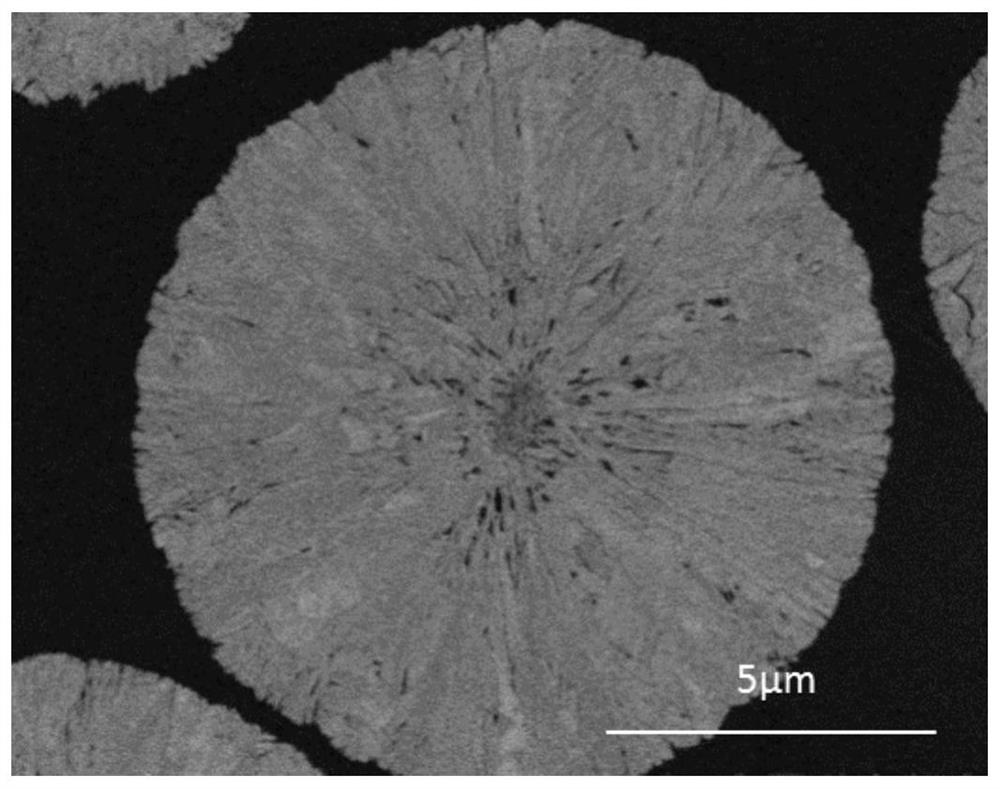

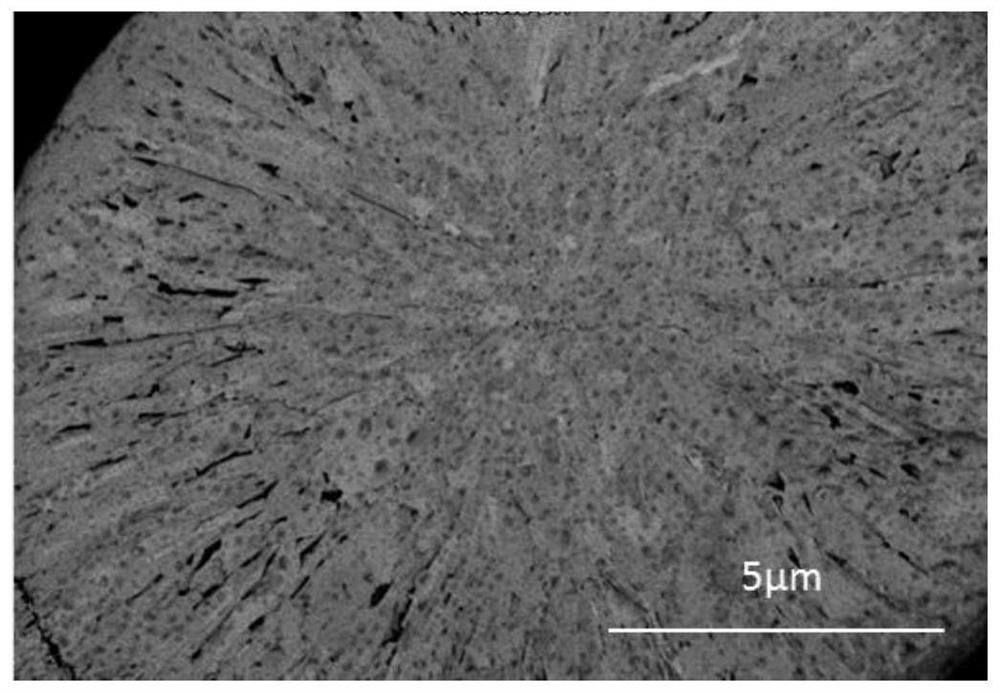

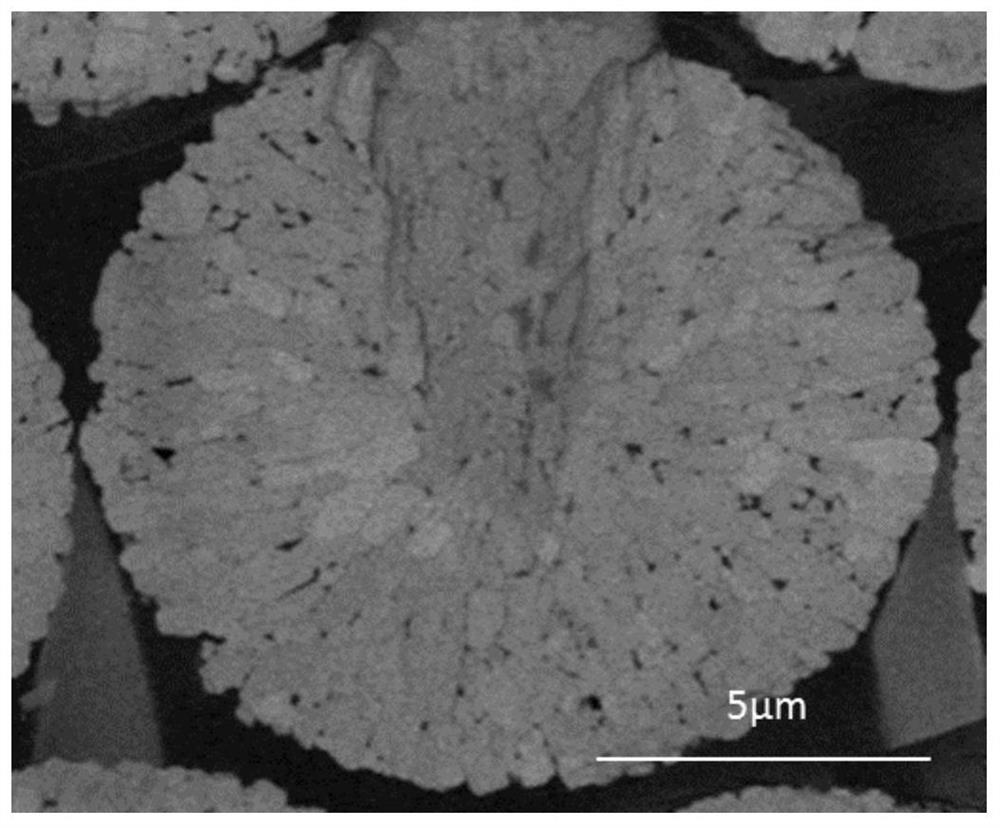

The invention relates to the technical field of secondary batteries, and discloses a positive electrode material for a lithium ion battery, a preparation method of the positive electrode material and the lithium ion battery. The positive electrode material comprises a high-nickel multi-element positive electrode material, the high-nickel multi-element positive electrode material is formed by agglomeration of a plurality of primary crystal grains, and the primary crystal grains are distributed in a divergent manner along the diameter direction of the high-nickel multi-element positive electrode material; wherein the length-diameter ratio L / R of the primary crystal grains in the positive electrode material is greater than or equal to 3, and the radial distribution proportion of the primary crystal grains in the positive electrode material is greater than or equal to 60%. The lithium ion battery containing the positive electrode material is high in capacity, the particle strength is greatly improved, and the battery capacity is high.

Owner:BEIJING EASPRING MATERIAL TECH CO LTD

Positive electrode for nonaqueous electrolyte secondary batteries, positive electrode active material used for same, and secondary battery using same

InactiveCN108780883AHigh Li-ion conductivityInhibit deteriorationFinal product manufacturePositive electrodesChemical physicsElectrical conductor

Provided is a positive electrode for nonaqueous electrolyte secondary batteries, which enables a battery to have a higher output power if used as a positive electrode of the battery, and which causesless deterioration in the battery performance. Provided is a positive electrode for nonaqueous electrolyte secondary batteries, which comprises a positive electrode element that is configured from a positive electrode active material composed of a lithium metal composite oxide and an amorphous coating layer that is formed on the surface of the positive electrode element from a compound containingniobium and lithium, and wherein the compound is a lithium ion conductor. Consequently, lithium ion conductivity in the electrode is able to be improved, and deterioration in the lithium ion conductivity and dielectric properties in the atmosphere is able to be suppressed. In addition, a positive electrode for nonaqueous electrolyte secondary batteries, which is able to achieve a higher output power and is not susceptible to deterioration in the high output performance if handled in the atmosphere can be obtained by using the above-described electrode.

Owner:SUMITOMO METAL MINING CO LTD

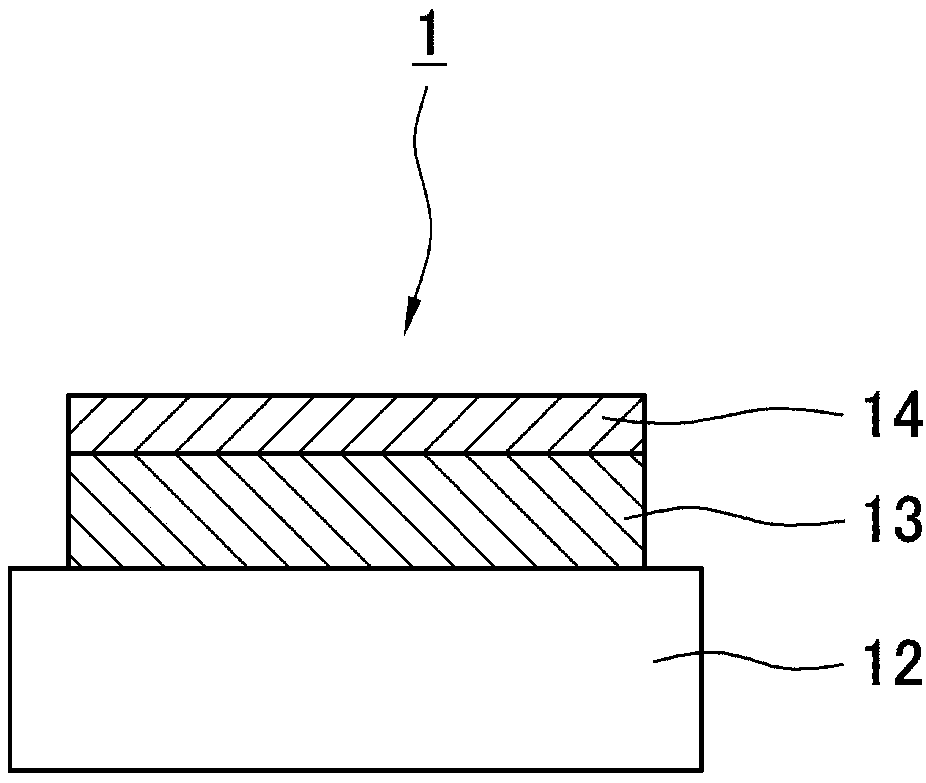

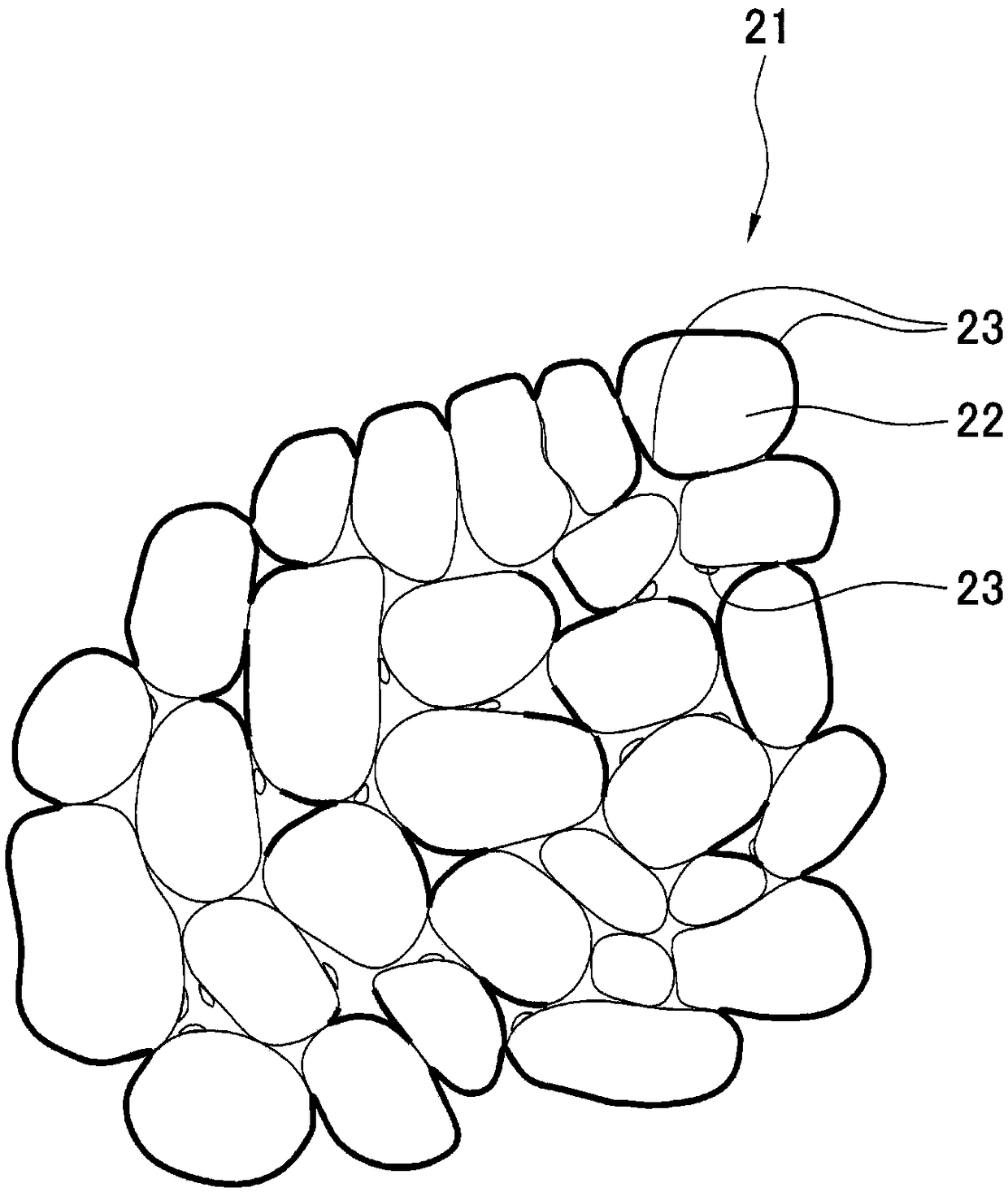

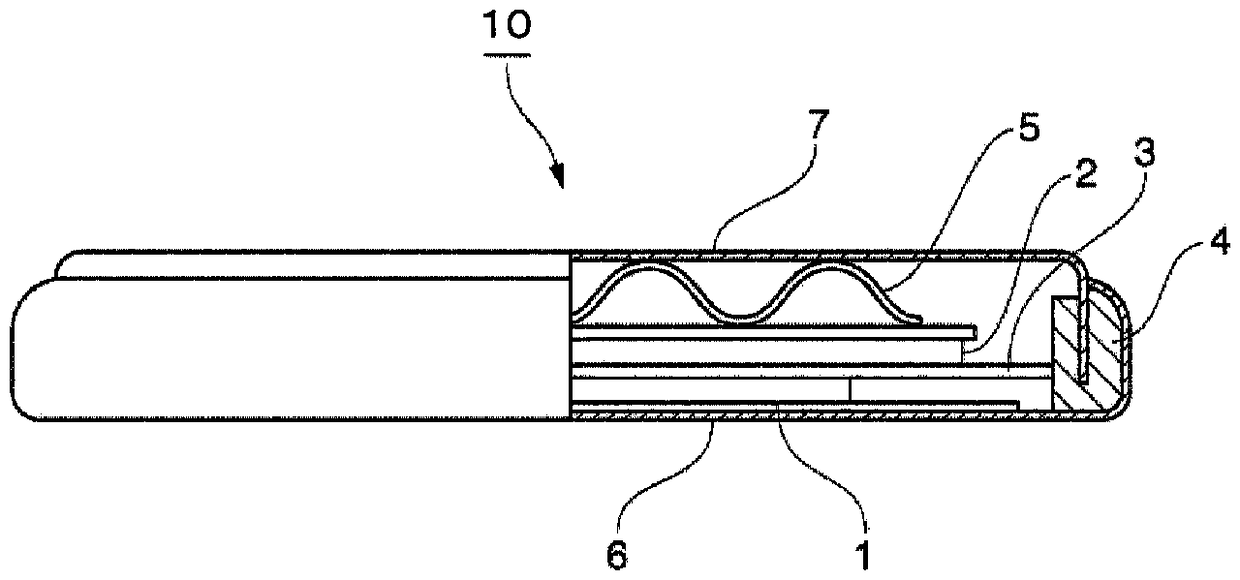

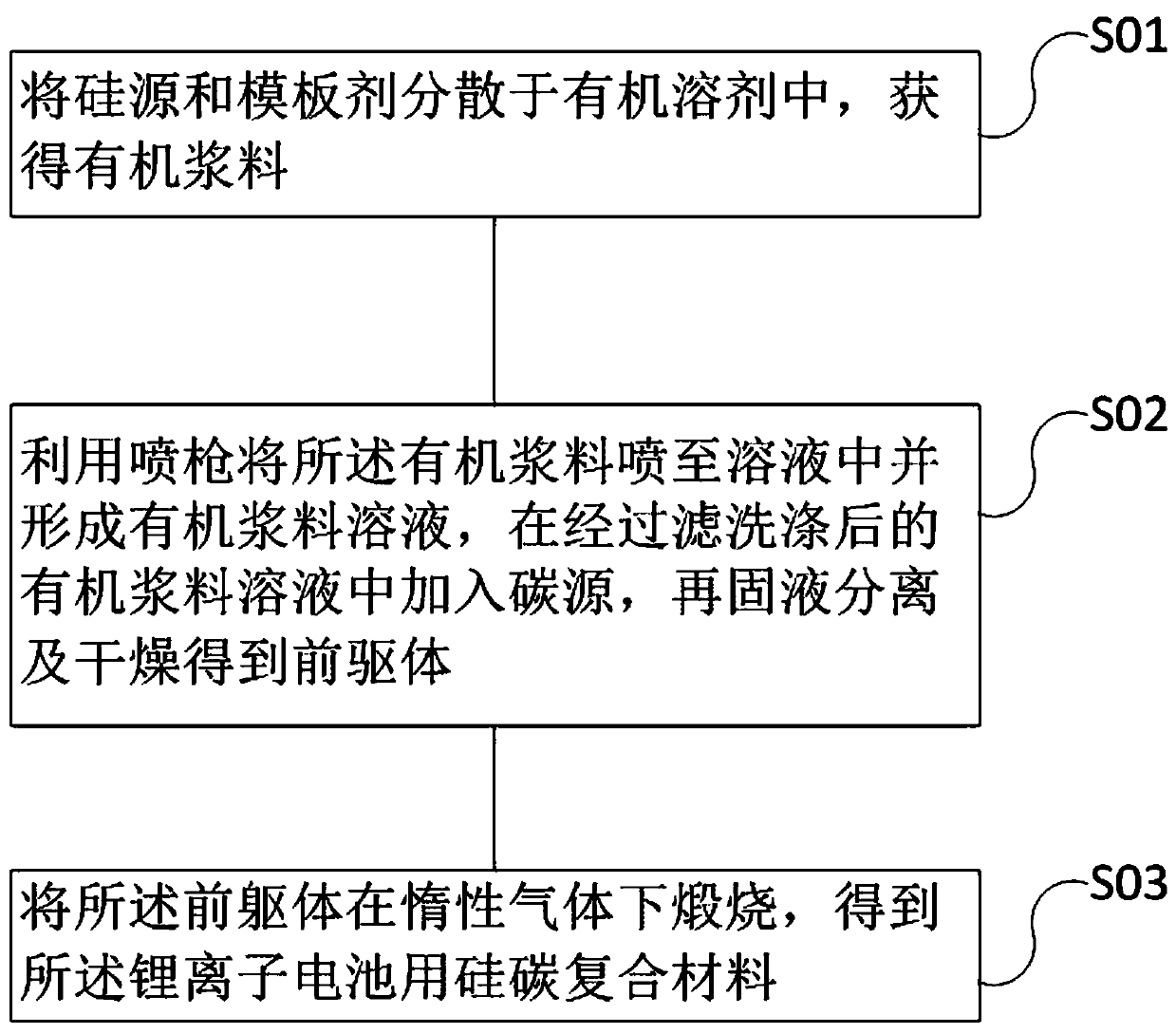

Preparation method of silicon-carbon composite material for lithium ion battery

ActiveCN110931760AImprove the mixing effectUniform growth environmentSecondary cellsNegative electrodesCarbon compositesOrganic solvent

The invention discloses a preparation method of a silicon-carbon composite material for a lithium ion battery, which comprises the following steps: step A, dispersing a silicon source and a template agent in an organic solvent to obtain organic slurry; step B, spraying the organic slurry into the solution by using a spray gun to form an organic slurry solution, adding a carbon source into the filtered and washed organic slurry solution, and performing solid-liquid separation and drying to obtain a precursor; and step C, calcining the precursor under inert gas to obtain the silicon-carbon composite material for the lithium ion battery. The composite material prepared by the preparation method disclosed by the invention has the advantages that carbon is uniformly distributed on the surface of silicon or among silicon particles, the volume effect of silicon in the charging and discharging process can be effectively reduced, and the conductivity of an electrode material is improved, so that the capacity and the cycle performance of the lithium ion battery are obviously improved.

Owner:INNER MONGOLIA UNIVERSITY

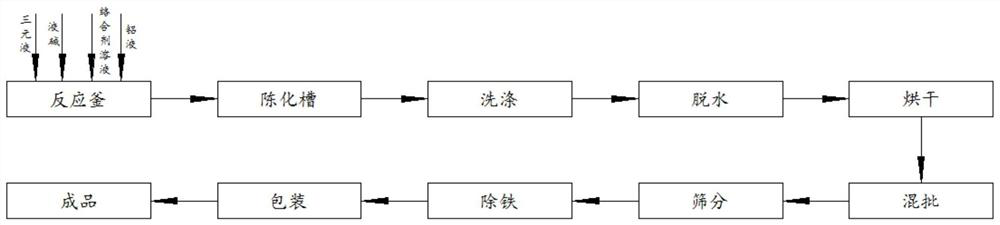

Preparation method of nickel-cobalt-aluminum ternary positive electrode material precursor

PendingCN113582255AClear passageFacilitates insertion and extractionNickel compoundsDiamineAmmonium sulphide

The invention relates to a preparation method of a nickel-cobalt-aluminum ternary positive electrode material precursor. The preparation method comprises the following steps: respectively preparing a nickel-cobalt binary solution, a sodium metaaluminate solution, a liquid alkali solution and a complexing agent solution, wherein the complexing agent is one or more of ammonium sulfite, ammonium bisulfite, ammonium sulfate, ammonium bisulfate, ammonium sulfide, ammonium hydrosulfide, diamine pentasulfide and ammonium thiosulfate; adding the base solution into the reaction kettle, introducing nitrogen, and controlling the temperature and the stirring rotating speed; adding the nickel-cobalt binary solution, the sodium metaaluminate solution, the liquid caustic soda solution and the complexing agent solution into a reaction kettle in a parallel flow manner for reaction; when the particle D50 generated by the reaction reaches 3.0-18.0 [mu]m, stopping feeding; performing aging, washing and impurity removal, dehydration, drying, batch mixing, screening and iron removal on the obtained material, and performing packaging to obtain a finished product. In the process of synthesizing the nickel-cobalt-aluminum ternary precursor, the variety and the adding amount of the added complexing agent are adjusted, and the problems that pores in the precursor are few and are irregularly distributed are solved.

Owner:JINGMEN GEM NEW MATERIAL

A kind of ferrous phosphate and preparation method thereof, lithium iron phosphate positive electrode active material and preparation method thereof

ActiveCN105293458BWell formedEasy transferPhosphatesCell electrodesLithium iron phosphateElectrical battery

Owner:BYD CO LTD

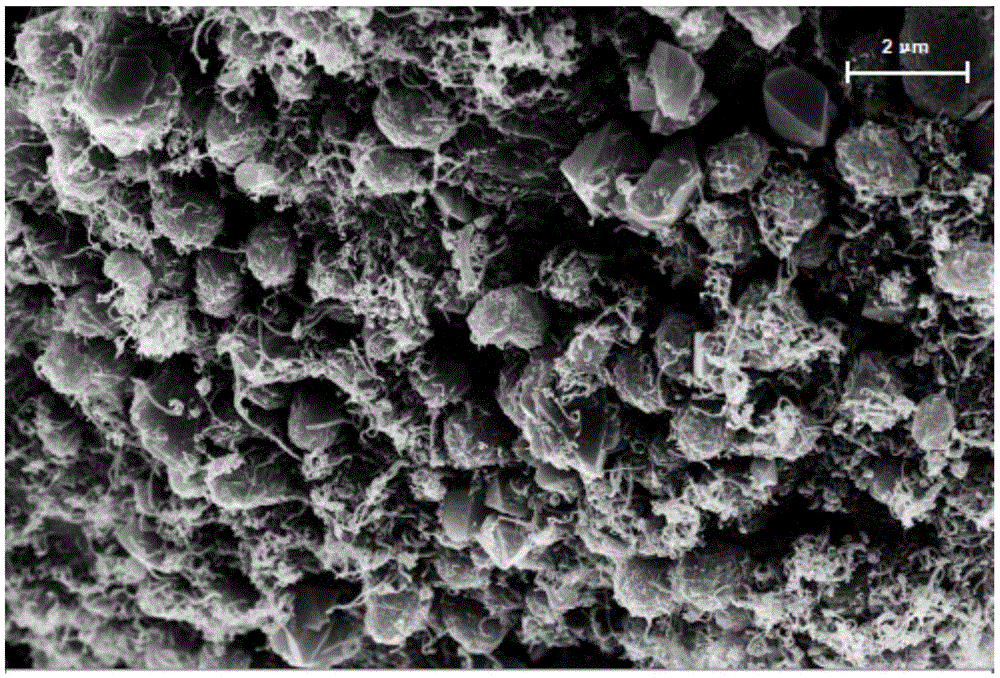

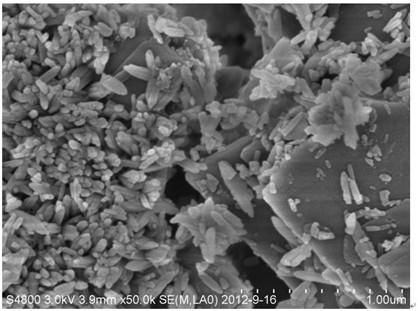

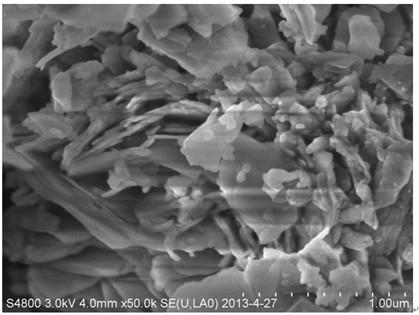

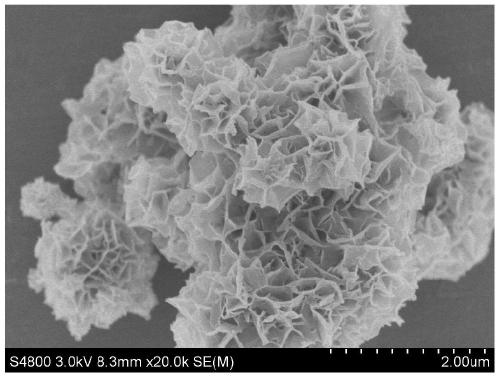

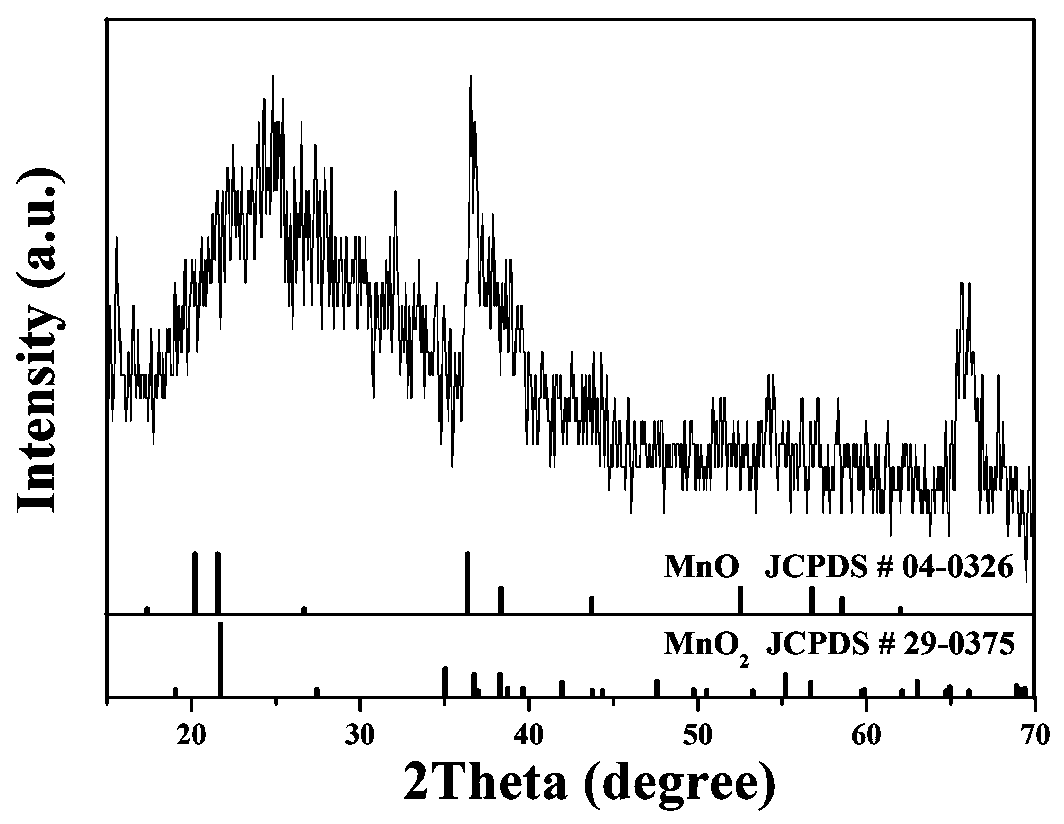

MNO, a negative electrode material for sodium ion batteries x preparation method

ActiveCN107946587BFacilitates insertion and extractionHigh active specific surface areaCell electrodesSecondary cellsMANGANESE ACETATEElectrical battery

A preparation method of a sodium ion battery negative electrode material MnOx comprises the steps of respectively preparing a manganese acetate solution and an ammonium persulfate solution from manganese acetate and ammonium persulfate; dispersing lauryl sodium sulfate in the manganese acetate solution to obtain a mixed solution; dropwise adding ammonium persulfate into the mixed solution, and continuously stirring until a system is uniform; moving the uniformly-dissolved system to an ultrasonic generation device for ultrasonic processing until a black precipitant is generated; and washing, filtering and drying the black precipitant, thereby obtaining the sodium ion battery negative electrode material MnOx. According to the preparation method, the acetate solution and the ammonium persulfate are used as raw materials, and the MnOx is prepared with ultrasound. Compared with the prior art, the preparation process is simple, the raw material is simple and available, the flower-shaped morphology comprising the MnOx is prepared with ultrasound, so that the active specific area of the negative electrode material is greatly improved, intercalation and de-intercalation of sodium ions are facilitated, and the capacity is improved.

Owner:SHAANXI UNIV OF SCI & TECH

Preparation method of porous sheet-shaped sodium ion battery negative electrode material

ActiveCN114853061AReduce manufacturing costHigh pore volumeCylindrical casing cells/batteryNegative electrodesPtru catalystSodium-ion battery

According to the preparation method, graphene oxide is taken as a template, organic or inorganic titanium is taken as a titanium source, under the action of an alkali catalyst, the titanium source and functional groups on the surface of the graphene oxide form chemical bonds, and the chemical bonds are deposited on the surface of the graphene oxide; the titanium dioxide / graphene oxide / titanium dioxide sandwich framework is obtained. After filtering, drying and calcining, the template is completely removed, and the amorphous titanium dioxide is converted into the mesoporous anatase-phase porous titanium dioxide nanosheet. The particle calcining device can effectively prevent the pore structure from being blocked due to insufficient gasification of the graphene oxide template in the calcining process, so that the prepared mesoporous material has relatively large pore volume and pore diameter, and the porous structure can improve the liquid retention capacity, is beneficial to intercalation and deintercalation of sodium ions, reduces the internal stress of the material, avoids de-molding and sodium separation of a pole piece, and improves the production efficiency. The material is suitable for high-voltage density design and high-rate charge and discharge, and can improve the energy density and rate capability of the battery cell.

Owner:WUHU ETC BATTERY LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com