Preparation method of silicon-carbon composite material for lithium ion battery

A silicon-carbon composite material, lithium-ion battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as high requirements for equipment and gas purity, unsuitable for large-scale production applications, and slow product deposition rates. Improve the mixing effect, excellent battery cycle performance, and facilitate the effect of insertion and extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

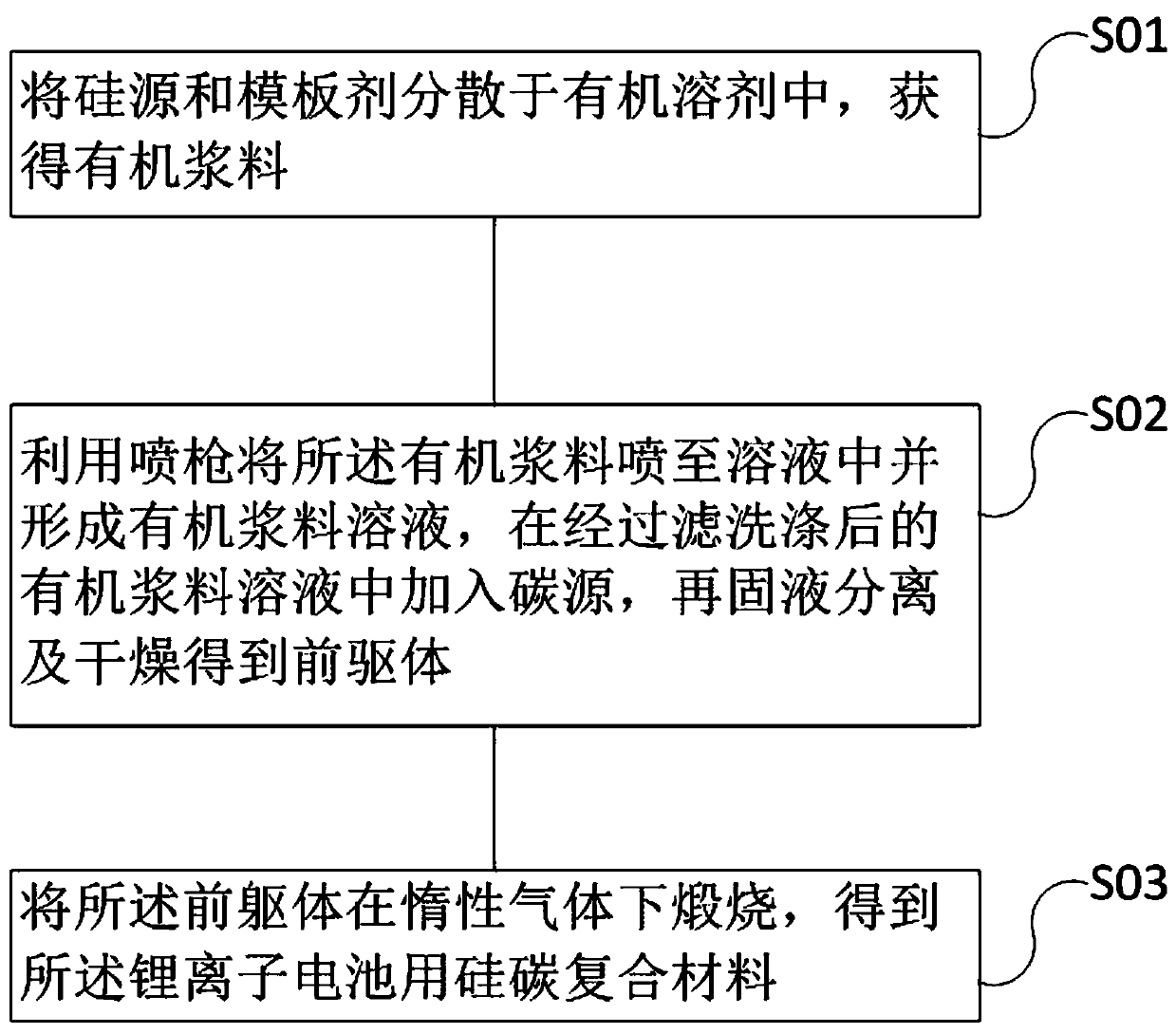

[0039] figure 1 It is a flow chart of a method for preparing a silicon-carbon composite material for a lithium-ion battery according to an embodiment of the present invention. The diagram shows a method for preparing a silicon-carbon composite material for a lithium-ion battery, comprising the following steps:

[0040] Step S01 dispersing the silicon source and template in an organic solvent to obtain an organic slurry;

[0041] Step S02 using a spray gun to spray the organic slurry into the solution to form an organic slurry solution, adding a carbon source to the filtered and washed organic slurry solution, and then separating the solid from the liquid and drying to obtain a precursor;

[0042] Step S03 Calcining the precursor under an inert gas to obtain the silicon-carbon composite material for lithium-ion batteries.

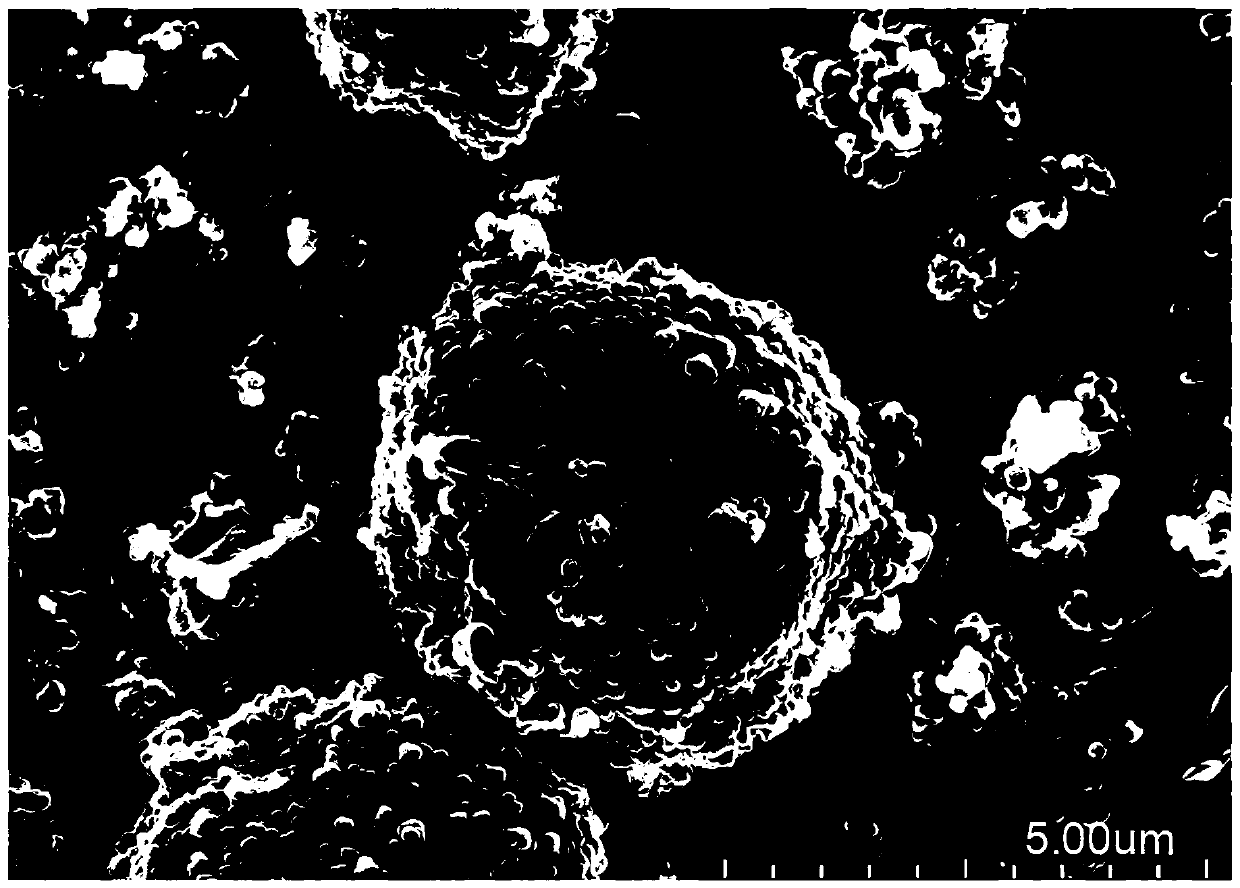

[0043]Embodiments of the present invention form fine and uniform mist droplets by the spray gun, and then spray into the solution, because the organic sol...

Embodiment 1

[0046] A method for preparing a silicon-carbon composite material for a lithium-ion battery, comprising the steps of:

[0047] Step S1-1. Weigh 50 g of nano-silicon oxide particles (with a particle size of 100 nm) and 32 g of polymethyl methacrylate (a type of acrylic resin) respectively, and ultrasonically disperse them at a ratio of 6 wt% solid content Forming an organic slurry in N,N-dimethylformamide;

[0048] Step S1-2, using a spray gun to spray the organic slurry into water to form an organic slurry solution, the atomization pressure of the spray gun is 0.1 Mpa, the spray width pressure is 0.3 Mpa, and the organic slurry is stirred within 30 minutes from the start of spraying to the end of spraying material solution; in the filtered and washed organic slurry solution, add 100 g citric acid solution (5% by mass) and mix well, then slowly add pyridine to adjust the pH value to 8.0, and then obtain the precursor by vacuum filtration and vacuum drying body;

[0049] Step ...

Embodiment 2

[0051] A method for preparing a silicon-carbon composite material for a lithium-ion battery, comprising the steps of:

[0052] Step S2-1. Weigh 50 g of nanometer elemental silicon particles (with a particle size of 80 nm) and 20 g of bisphenol A epoxy resin (a type of epoxy resin), and weigh them in proportions with a solid content of 5 wt%. Ultrasonic dispersion in N-methylpyrrolidone to form an organic slurry;

[0053] Step S2-2, using a spray gun to spray the organic slurry into absolute ethanol, the atomization pressure of the spray gun is 0.06 Mpa, the spray width pressure is 0.25 Mpa, and the organic slurry solution is stirred within 30 minutes from the start of spraying to the end of spraying; Add 100 g of starch solution (3% by mass) to the filtered and washed organic slurry solution and mix well, then slowly add N, N-dimethylaniline to adjust the pH value to 8.5, and then vacuum filter and vacuum dry to obtain Precursor;

[0054] Step S2-3, calcining the precursor a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com