Patents

Literature

41results about How to "Clear passage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

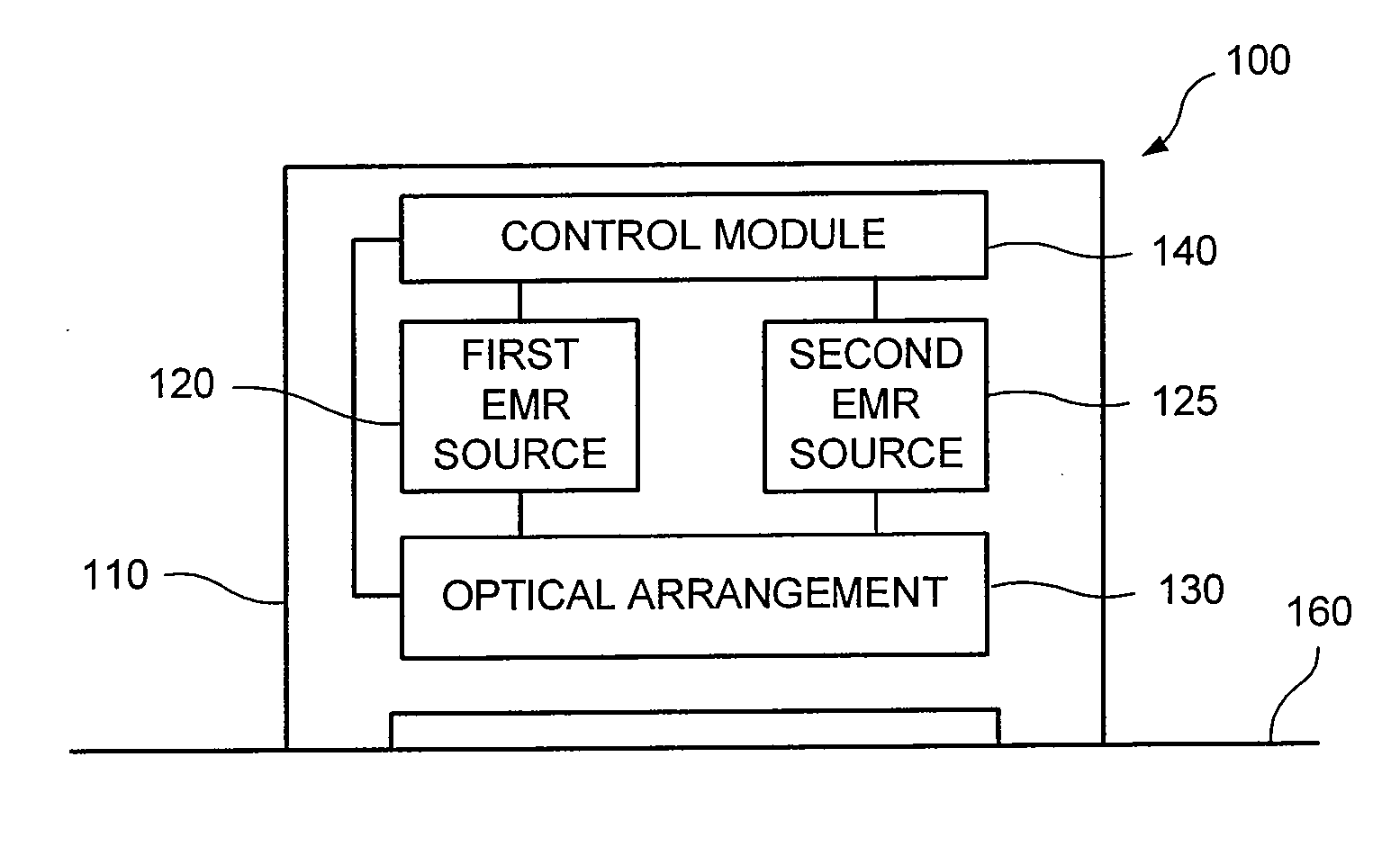

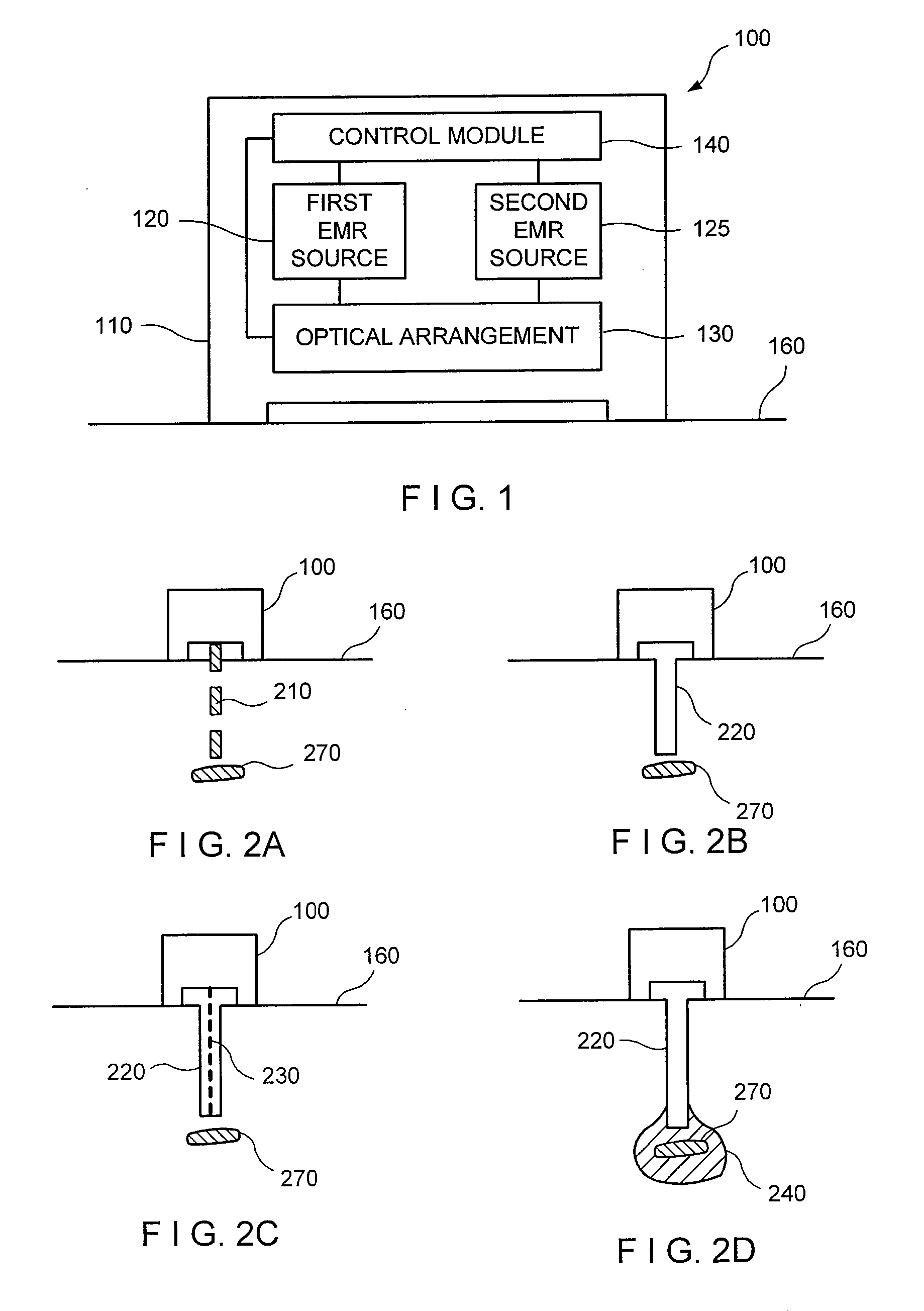

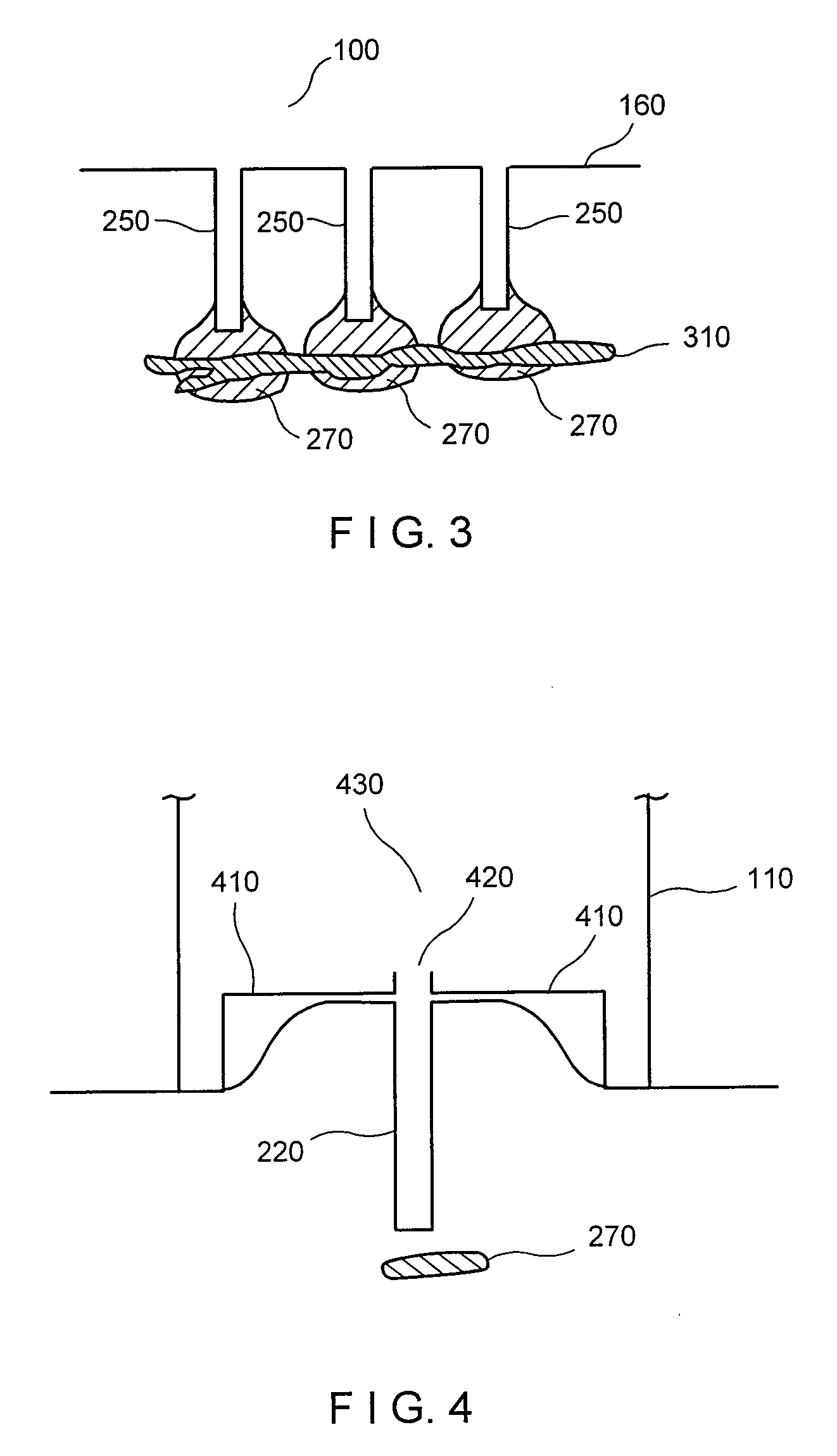

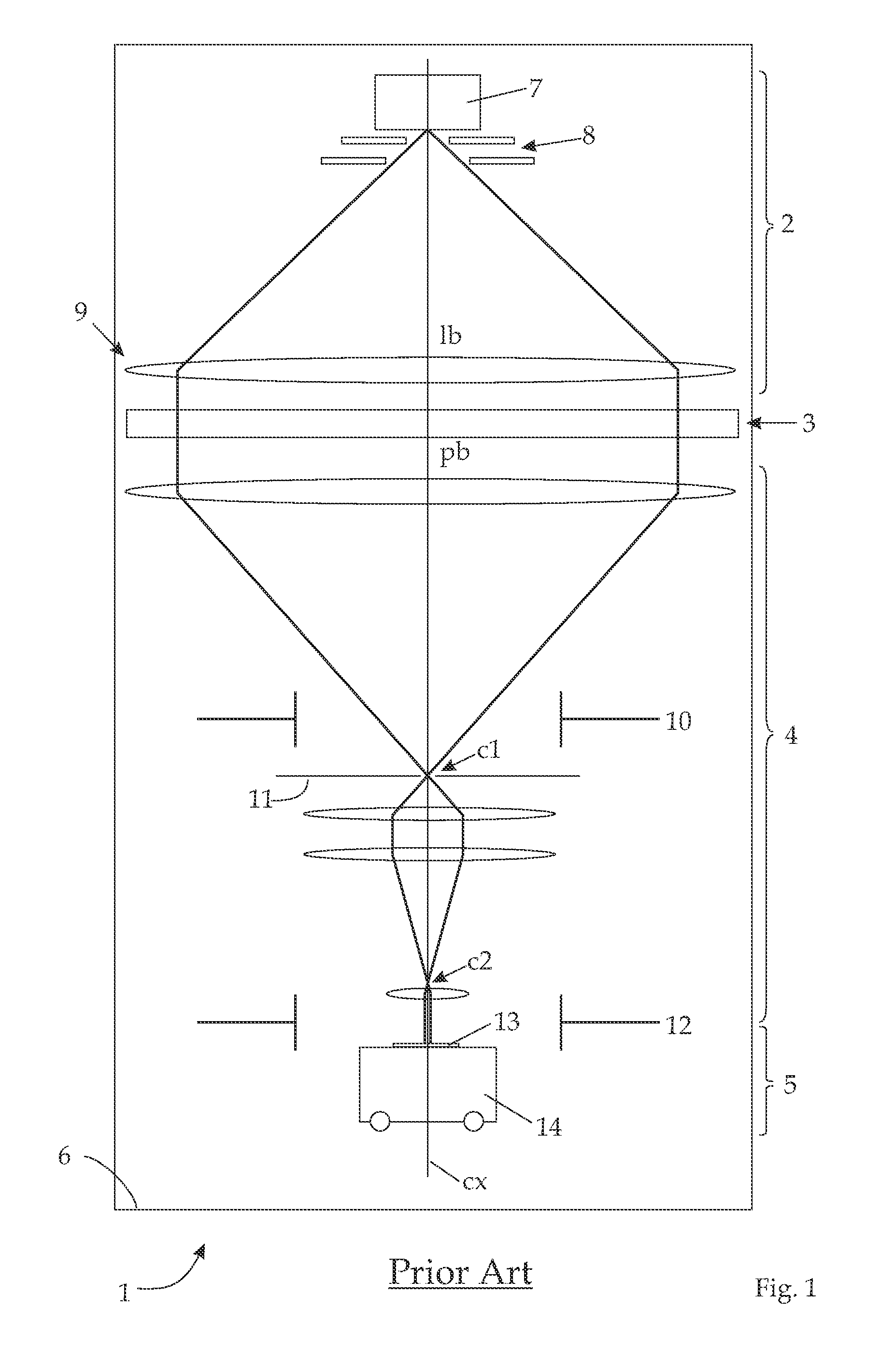

Method and apparatus for producing thermal damage within the skin

InactiveUS20070239236A1Minor side effectsAccurate locationSurgical instrument detailsLight therapyEr:YAG laserAnalgesics effects

A method and apparatus are provided for treating dermatological conditions, in which a first beam of radiation is used to ablate a hole in skin tissue, and a second beam of radiation is directed into the hole and onto a region of skin tissue adjacent to and / or at the bottom of the hole. The first beam can be provided by an ablative laser such as a CO2 laser or an ER:YAG laser. The second beam can be provided by, e.g., an ablative laser operating at a lower peak power level than the first beam, a non-ablative laser, a flashlamp, a tungsten lamp, a diode or a diode array. A controlled amount of thermal damage can thereby be provided at a desired depth within the skin, using radiation sources that would be absorbed closer to the surface of the skin if an ablated hole were not present. Cooling and / or freezing of the skin prior to ablation can be provided to provide an analgesic effect and / or stabilize the tissue surrounding the ablated hole. The region of skin to be treated can optionally be pulled towards the radiation source using a vacuum to stretch and / or stabilize the skin tissue surrounding the volume to be ablated.

Owner:THE GENERAL HOSPITAL CORP

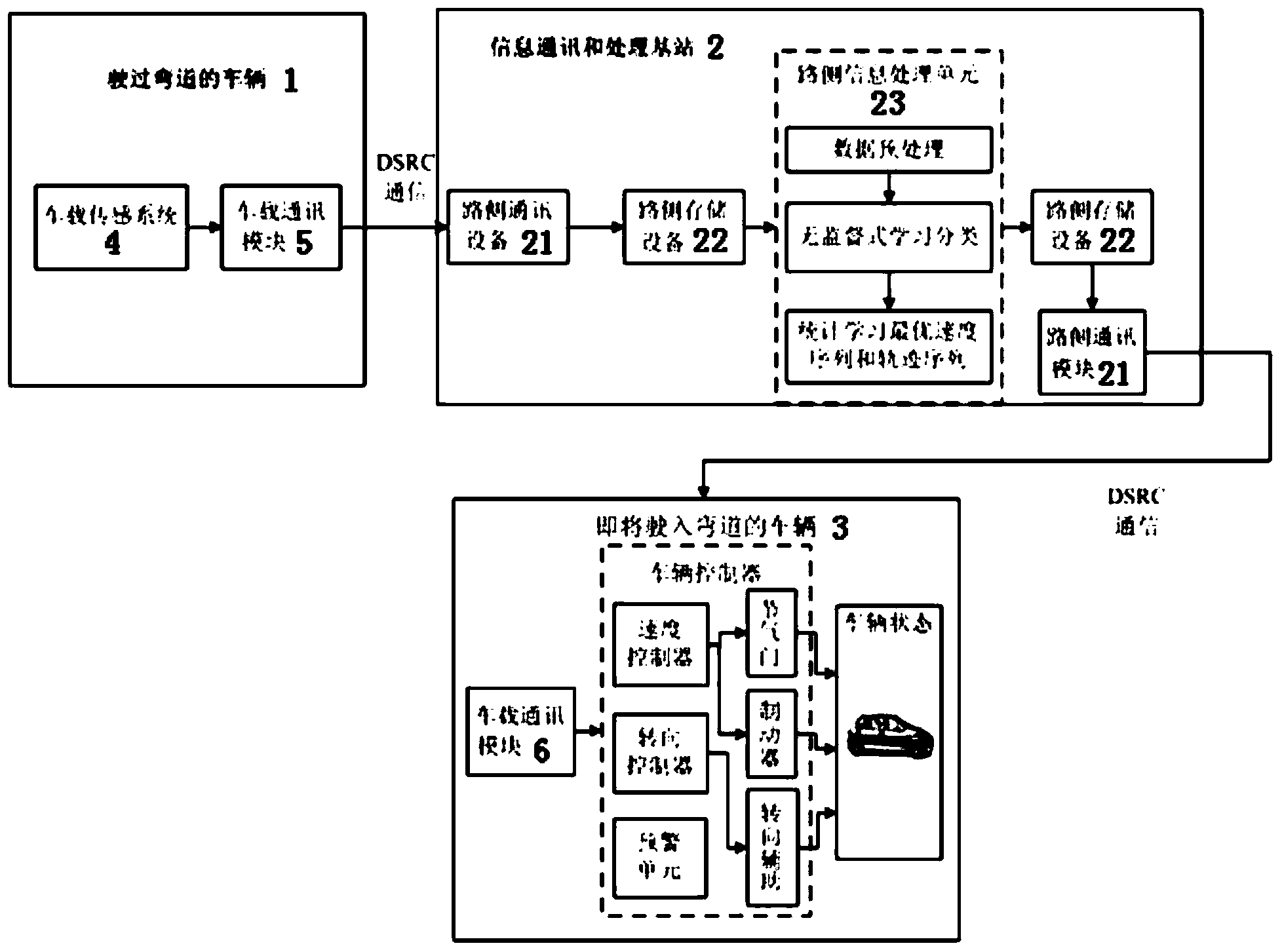

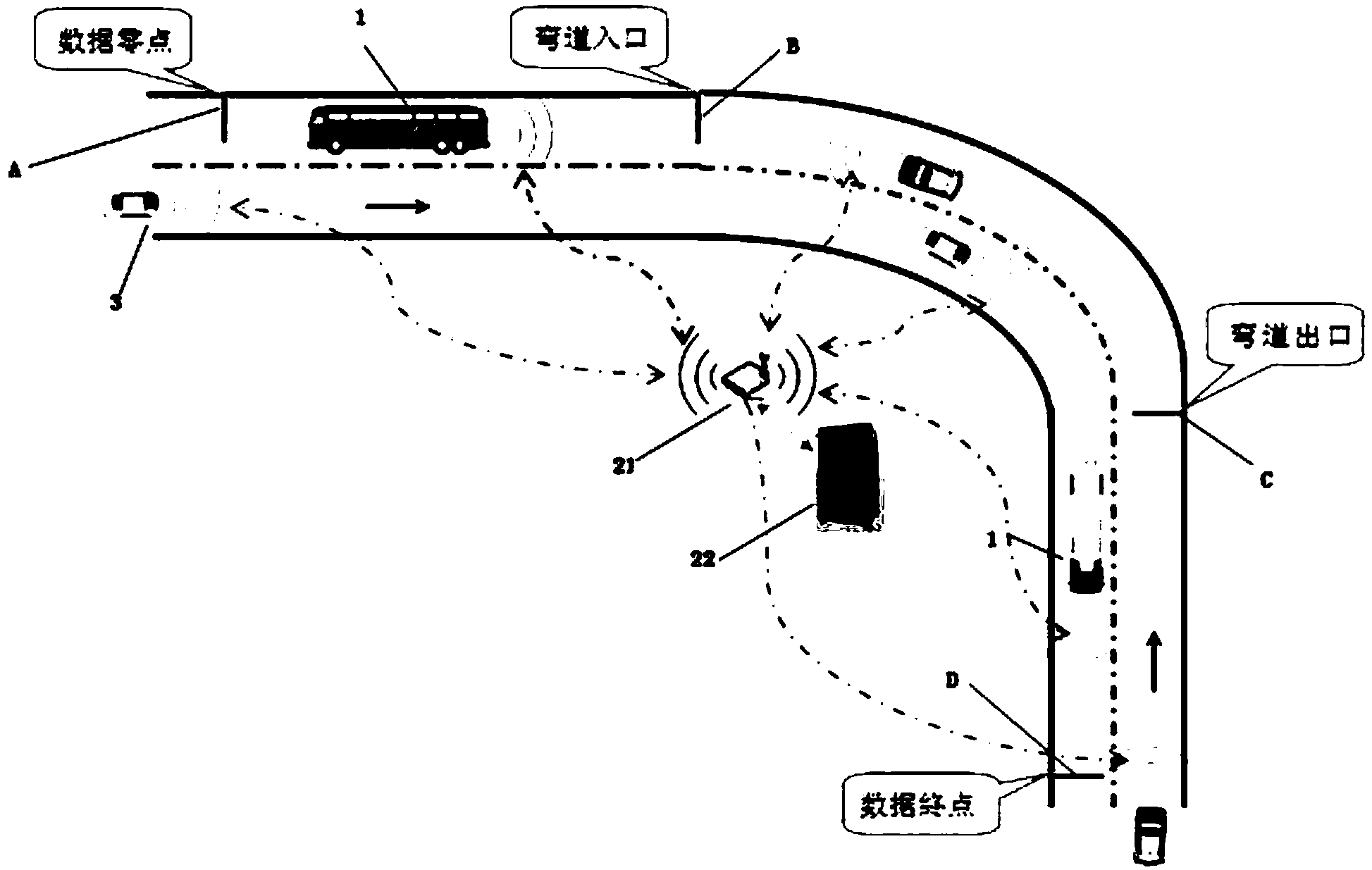

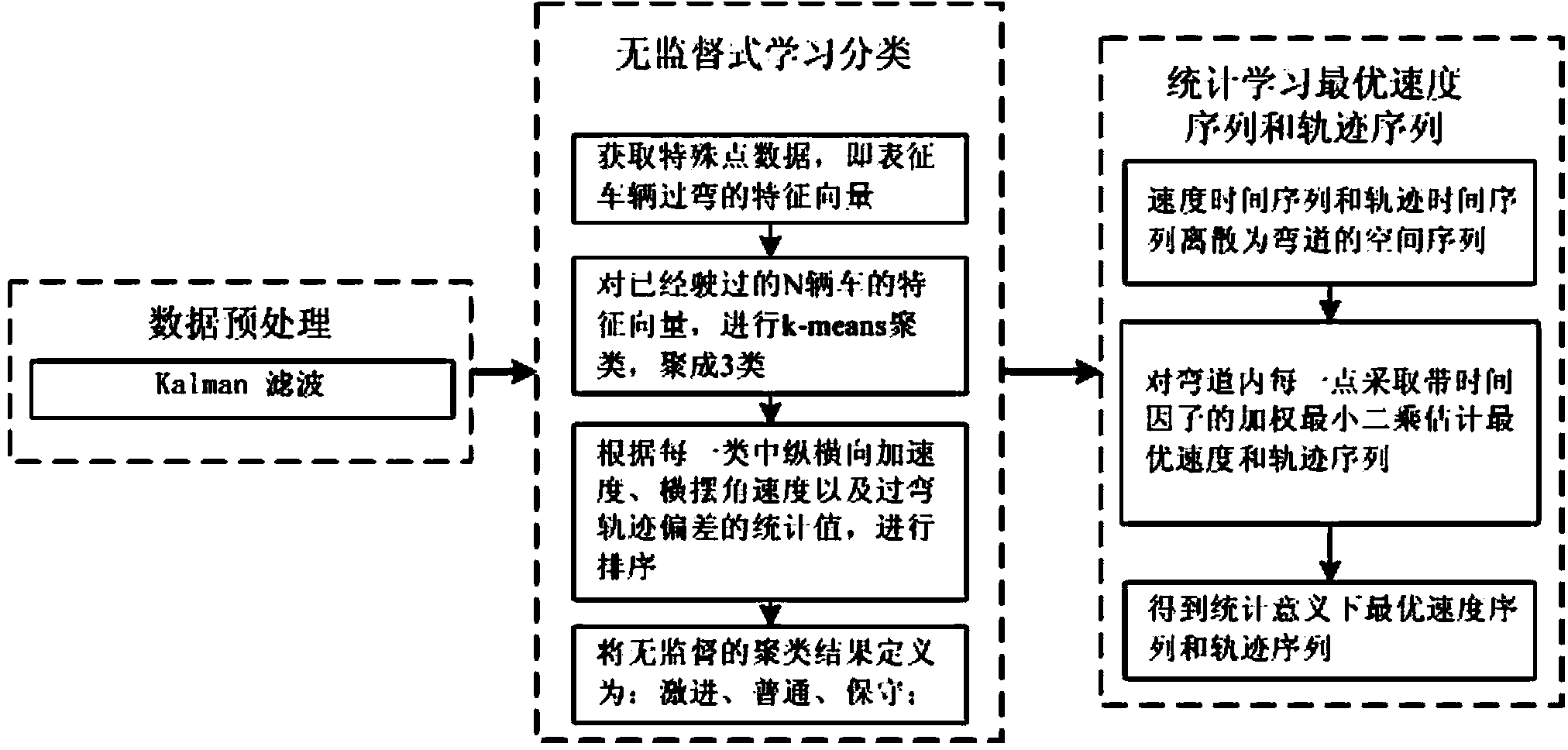

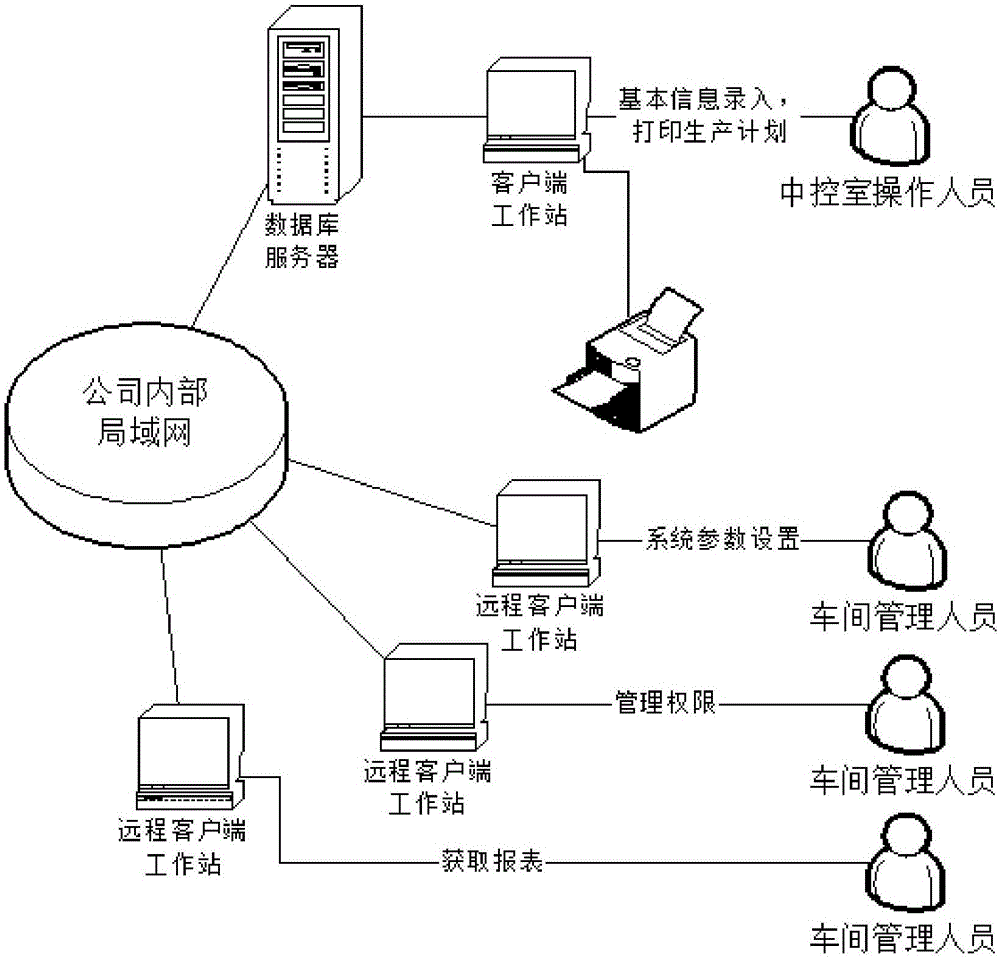

Vehicle curve passing through auxiliary system based on vehicle-road/vehicle-vehicle communication

ActiveCN103927895APass safelyClear passageArrangements for variable traffic instructionsDetection of traffic movementSide informationIn vehicle

The invention relates to a vehicle curve passing through auxiliary system based on vehicle-road / vehicle-vehicle communication. The system comprises a plurality of vehicles passing through a curve, an information communication and processing base station and a vehicle coming into the curve. A vehicle-mounted sensing system and a vehicle-mounted communication module are arranged on each vehicle passing through the curve, a vehicle-mounted communication module is also arranged on the vehicle coming into the curve, and the information communication and processing base station is arranged on one side of the curve. The vehicle-mounted sensing system collects transport condition information of the vehicles passing through the curve and sends the transport condition information to a road side communication device through the vehicle-mounted communication modules, the road side communication device sends the received transport condition information of the vehicles passing through the curve to a road side storage device, data are classified by a road side information processing unit according to different types of the vehicles, non-supervision type cluster and statistic learning are conducted on the transport condition data of the same type of the vehicles to obtain the optimal speed sequence and the trajectory sequence, the obtained optimal speed sequence and the trajectory sequence are transmitted to the vehicle coming into the curve, the speed suggestion or auxiliary control of curve passing through is conducted on the vehicle coming into the curve according to the type of the vehicles through the optimal speed sequence and the trajectory sequence.

Owner:TSINGHUA UNIV

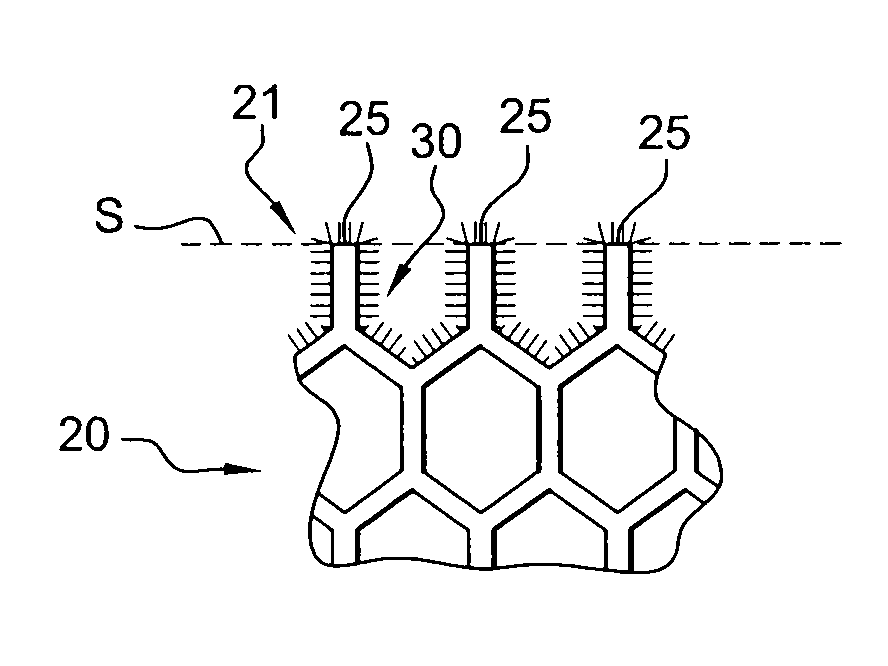

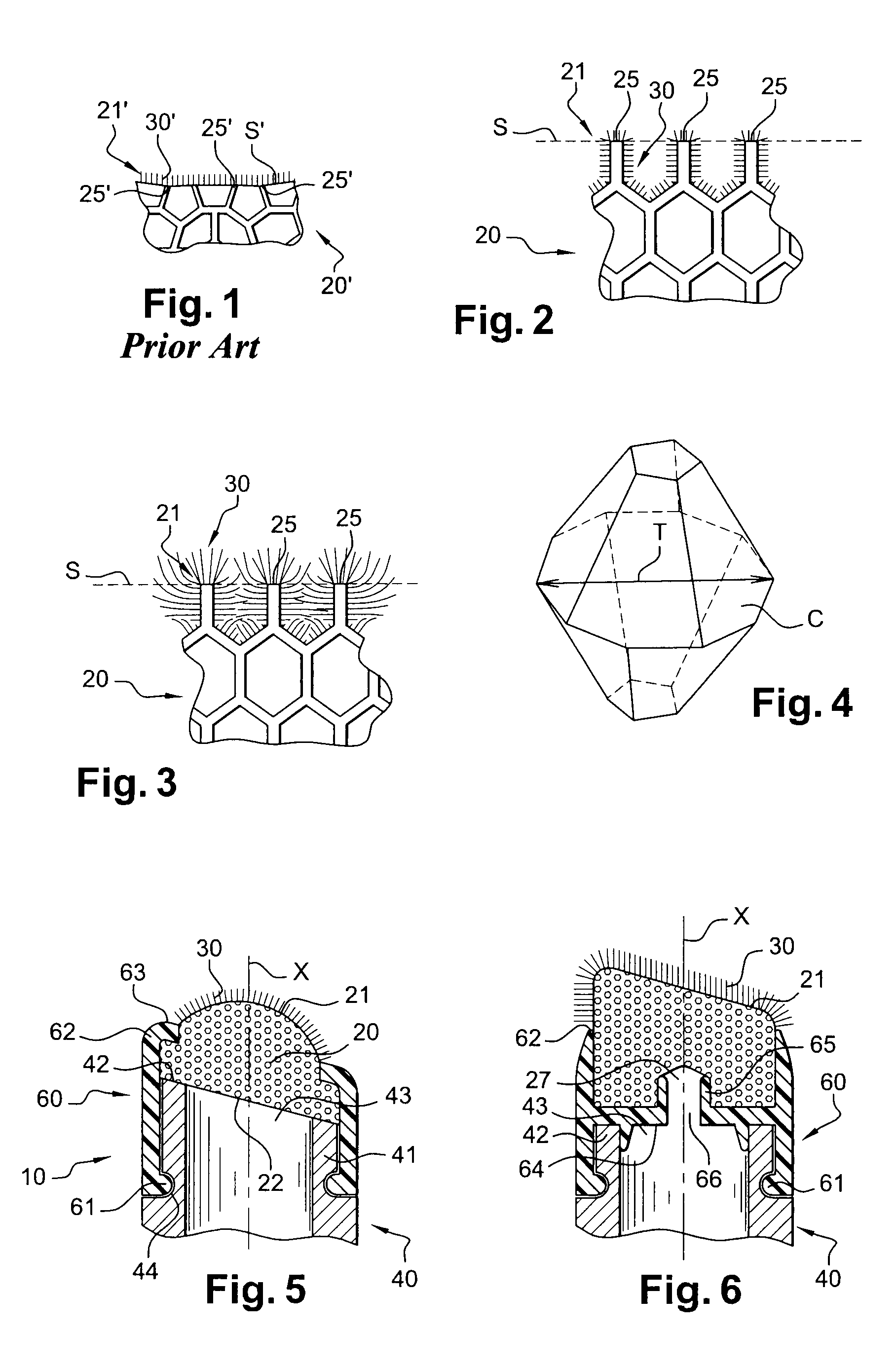

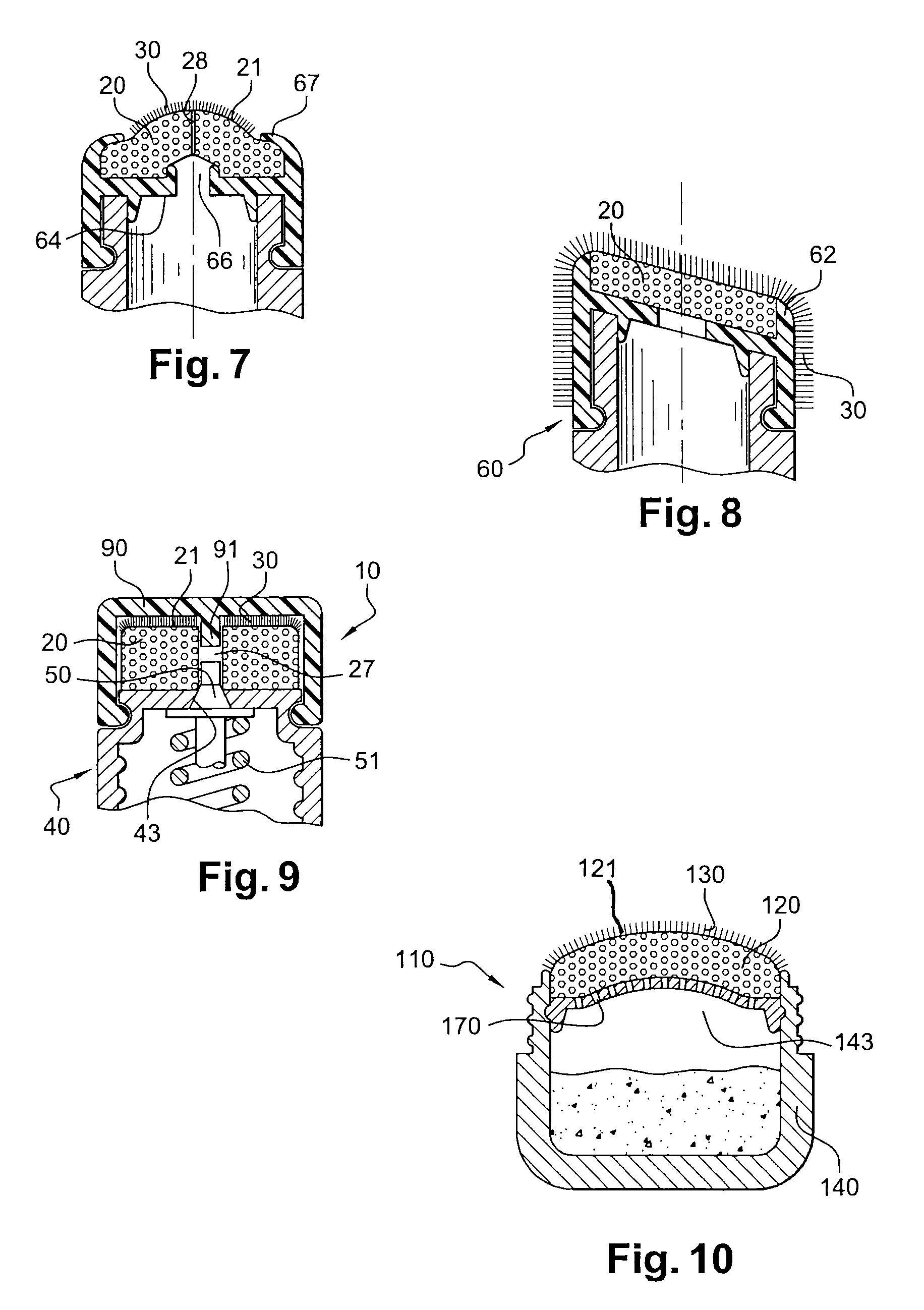

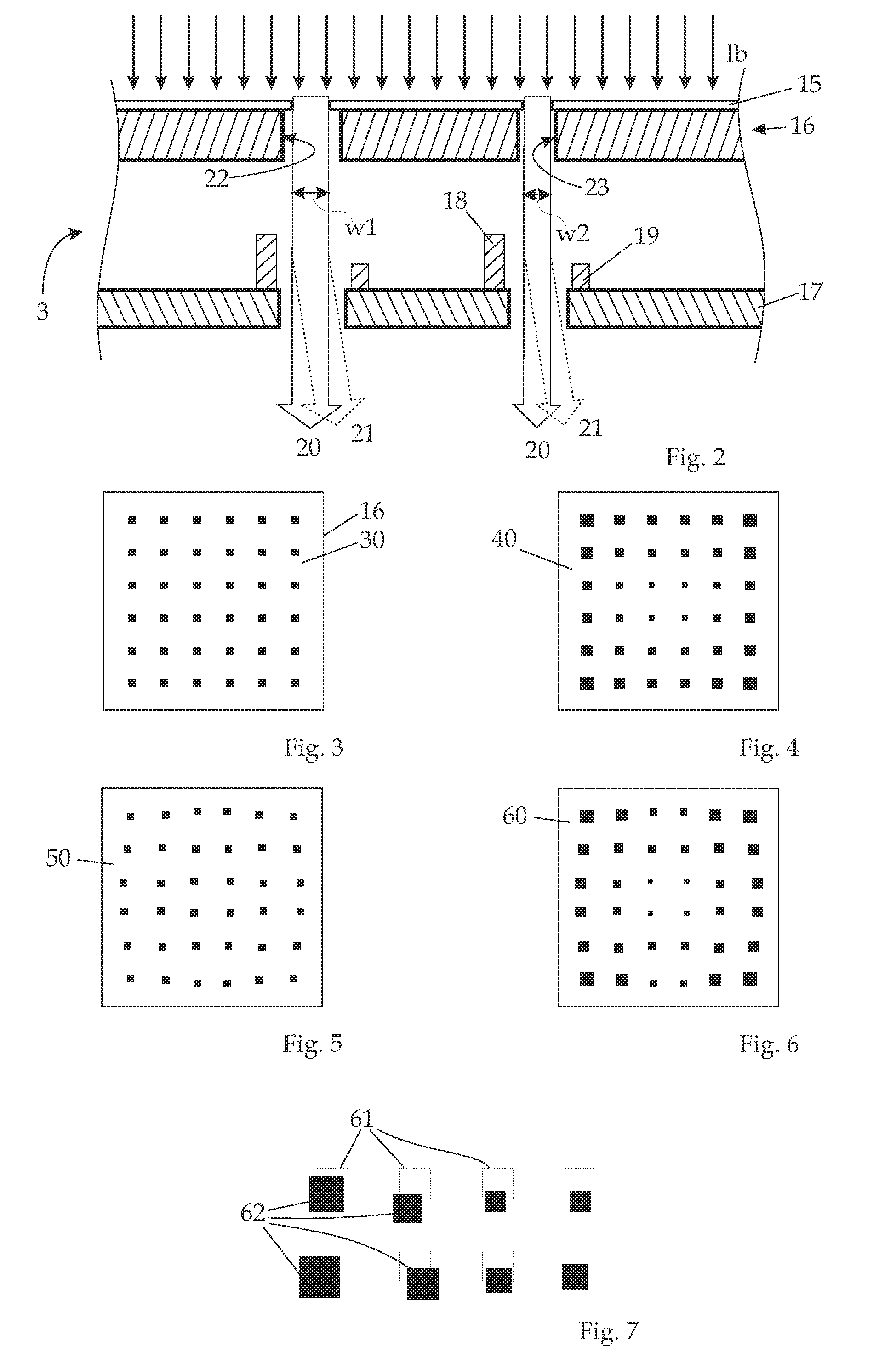

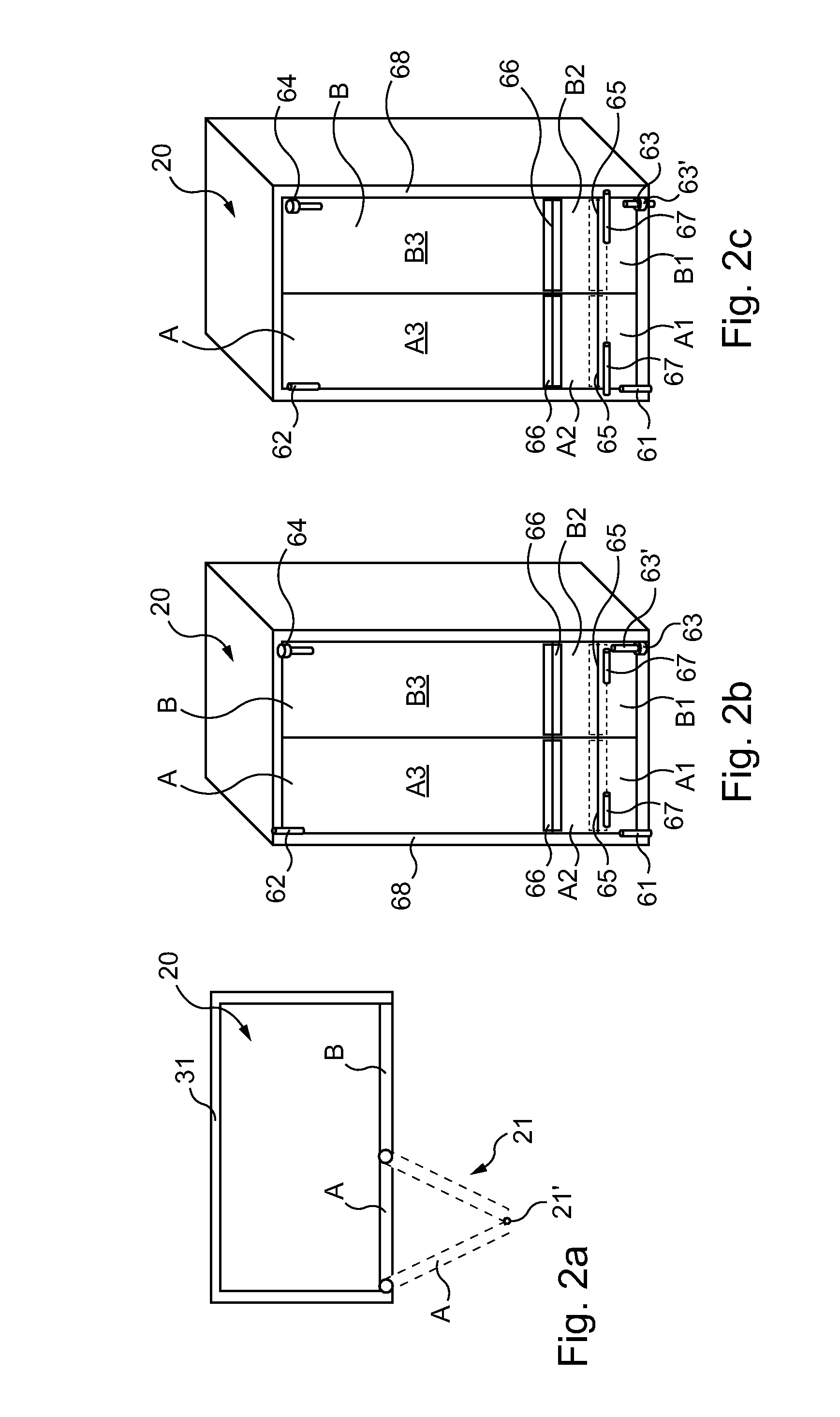

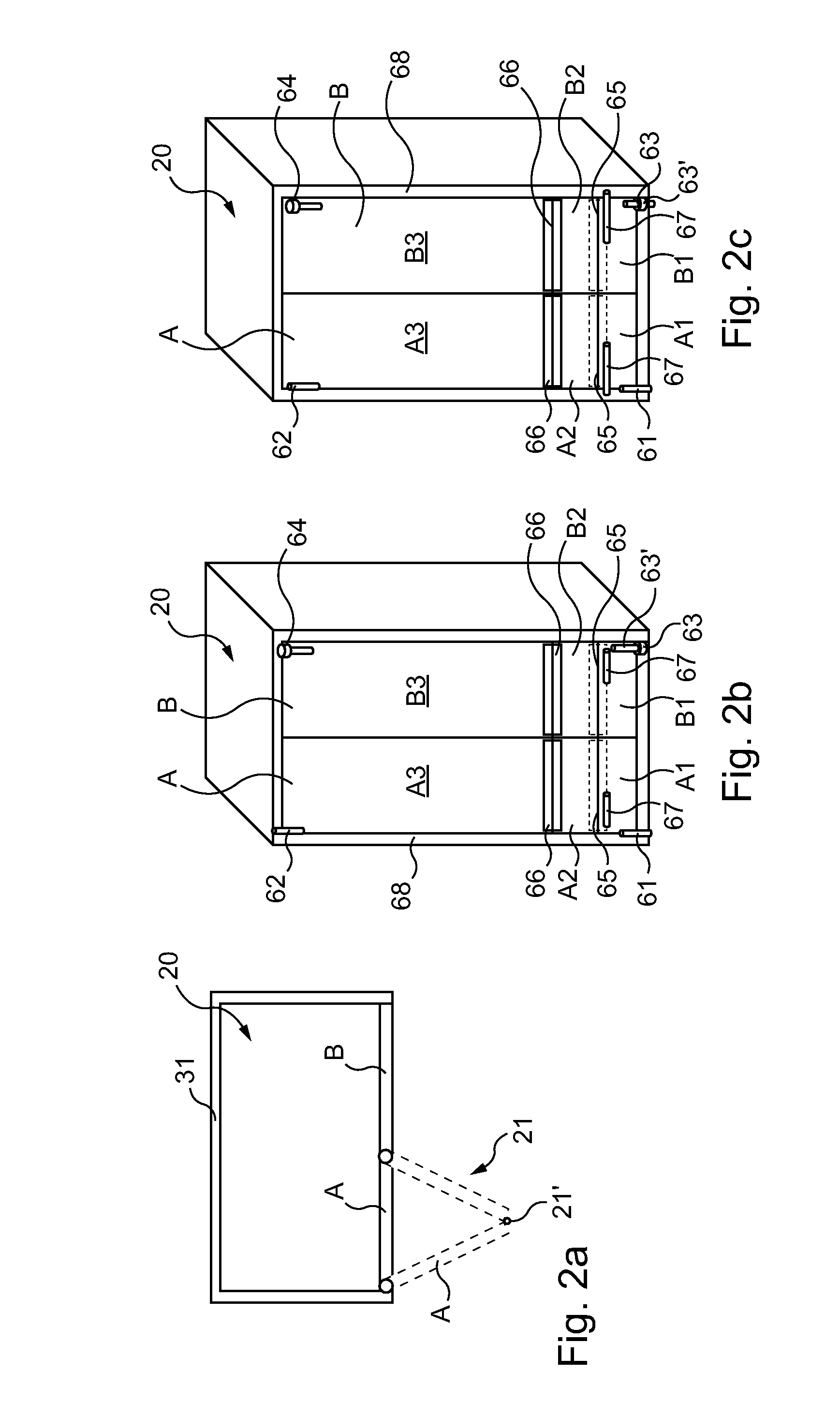

Product applicator, in particular for cosmetics

InactiveUS7811021B2Increase the number ofGreat product take-up capacityLiquid surface applicatorsPackaging toiletriesFiberEngineering

An applicator including an application face formed by a material incorporating a plurality of cells opening onto the application face via at least one emergent edge, the application face being at least partially covered by a flock coating formed from fibers, the average size of the cells being such that the surface on which the flocking fibers are placed is of a different profile from that of an envelope surface of the application face containing the emergent edges of the cells.

Owner:LOREAL SA

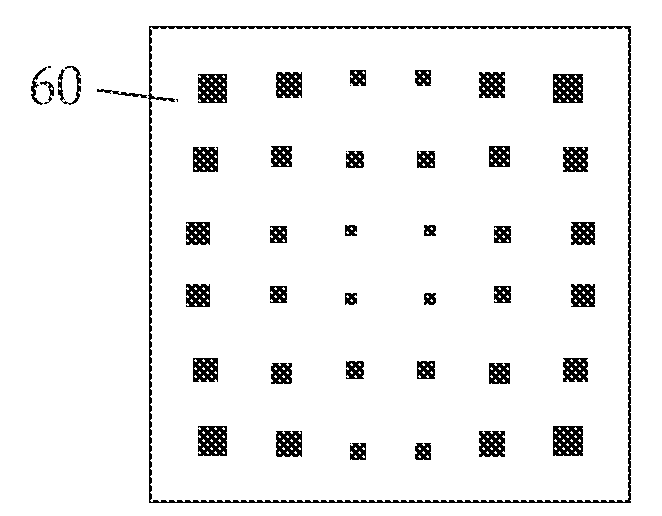

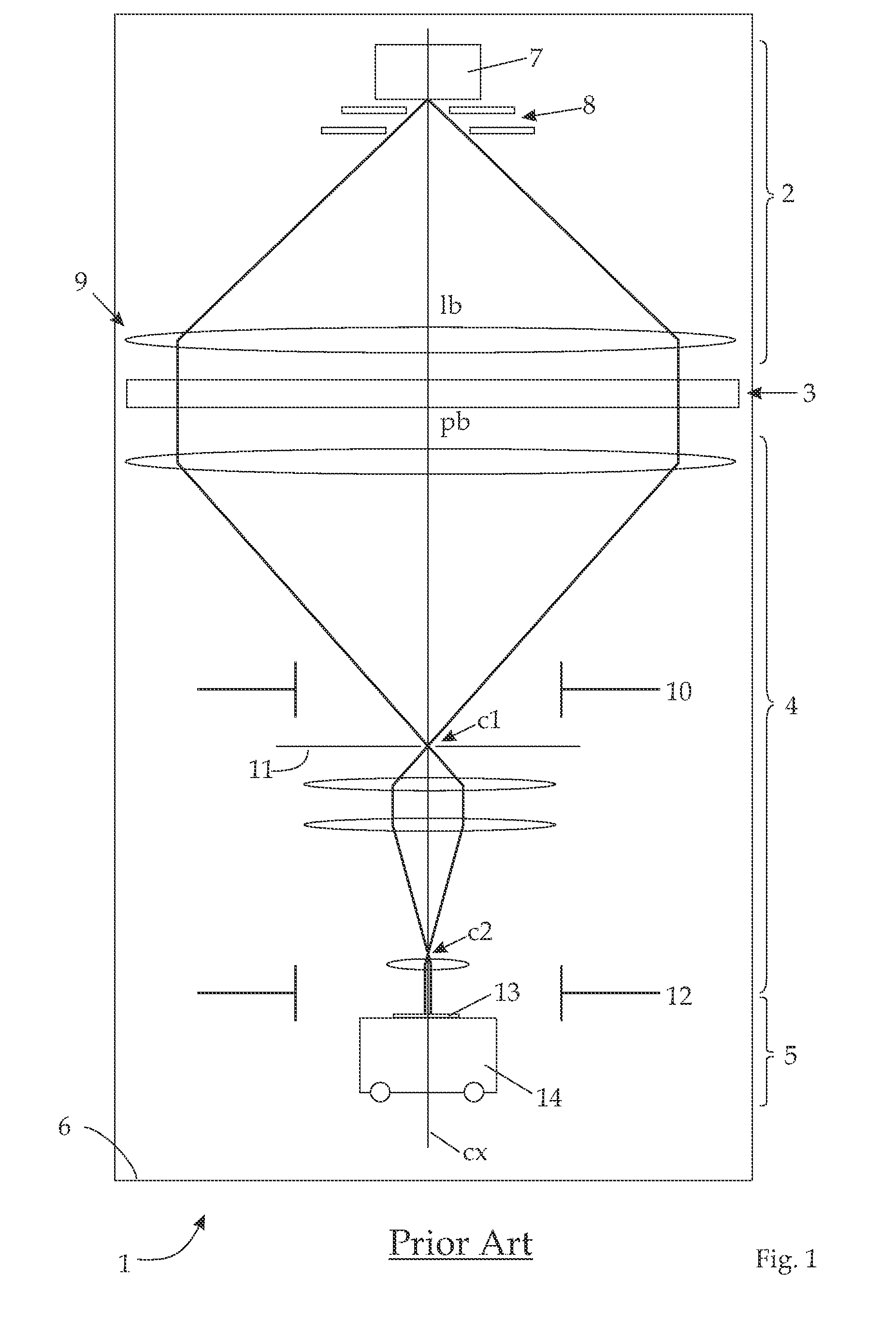

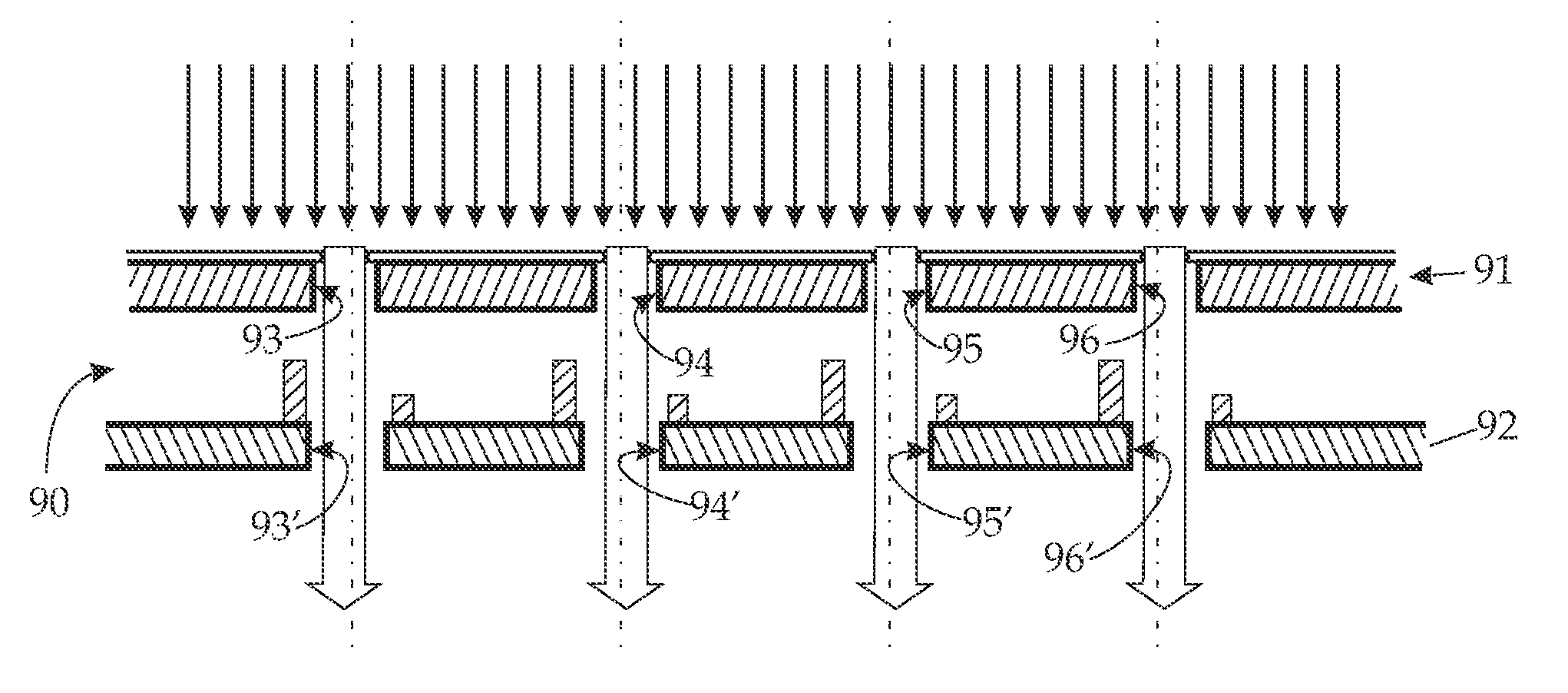

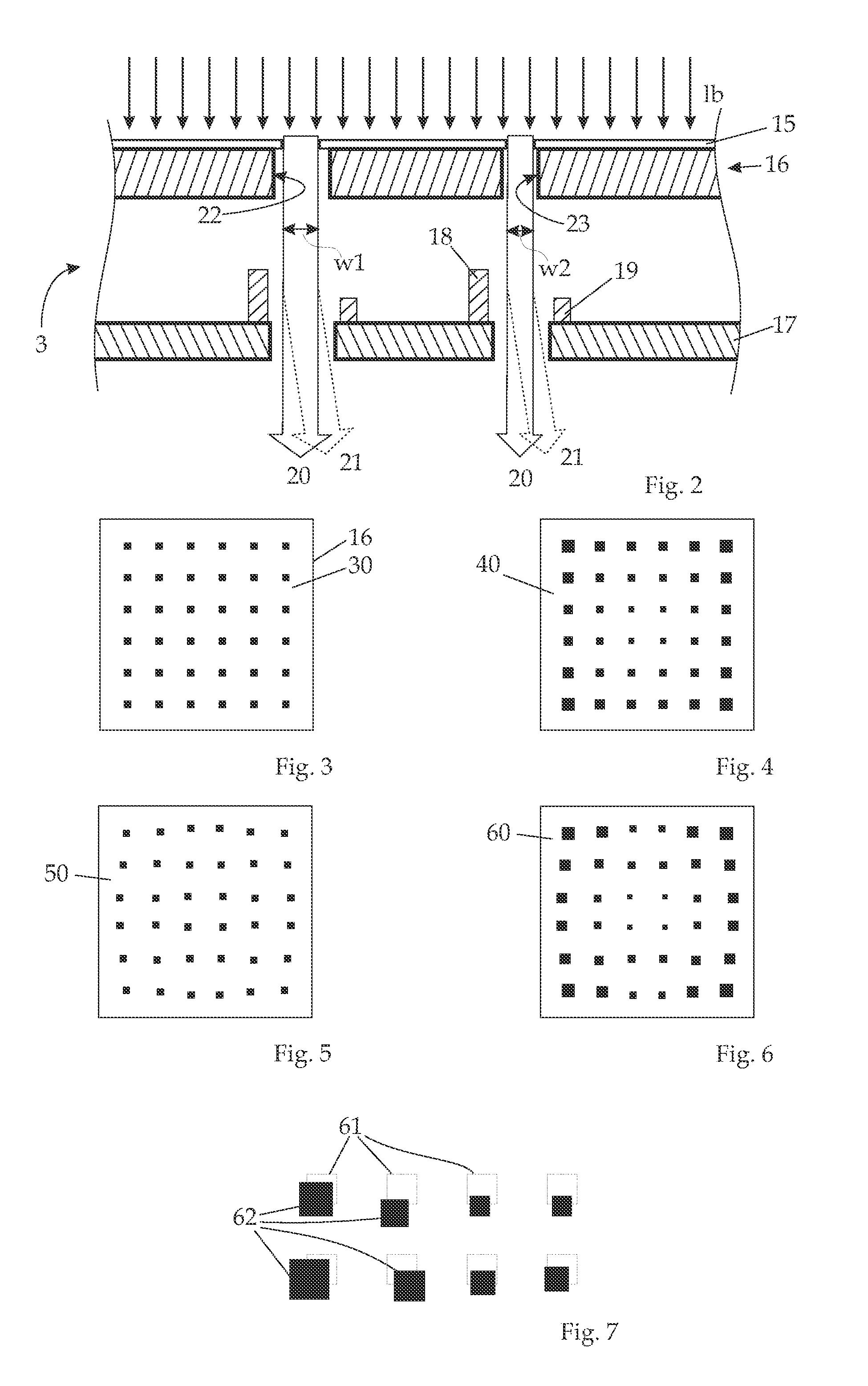

Compensation of dose inhomogeneity and image distortion

ActiveUS8258488B2Easy to controlPre-calculated quite accuratelyThermometer detailsBeam/ray focussing/reflecting arrangementsParticle beamRadiology

An improved aperture arrangement in a device for defining a pattern on a target, for use in a particle-beam exposure apparatus, by being irradiated with a beam of electrically charged particles and allowing passage of the beam only through a plurality of apertures. The device includes an aperture array having a plurality of apertures of identical shape defining the shape and relative position of beamlets permeating the apertures. A blanking device switches off the passage of selected beamlets permeating the apertures and defined by them. The apertures are arranged on the aperture array according to an arrangement deviating from a regular arrangement by small deviations, adjusting for distortions caused by the particle-beam exposure apparatus, and the size of the apertures of the aperture array differs across the aperture array in order to allow for an adjustment of the current radiated on the target through the apertures and the corresponding openings.

Owner:IMS NANOFABTION

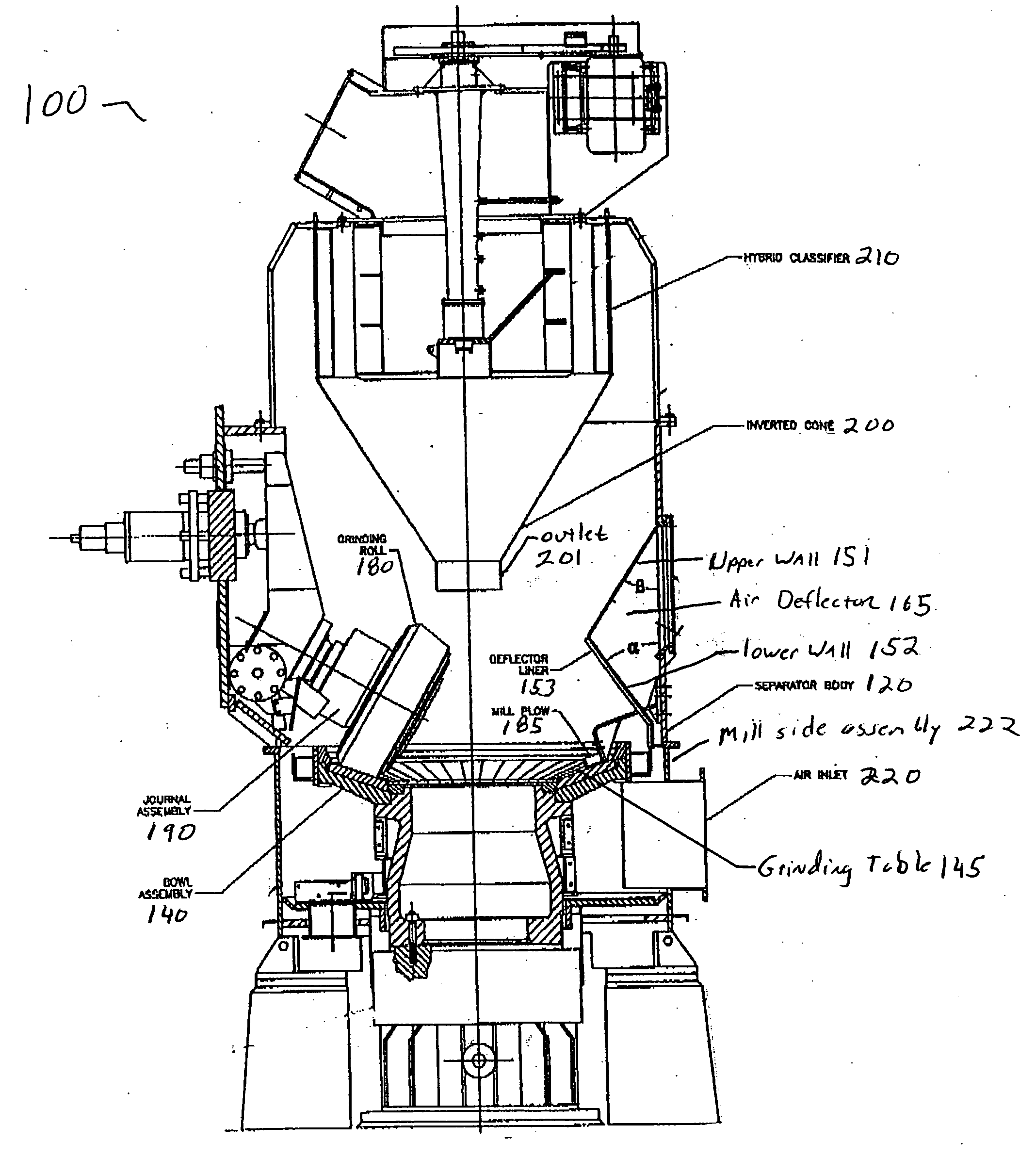

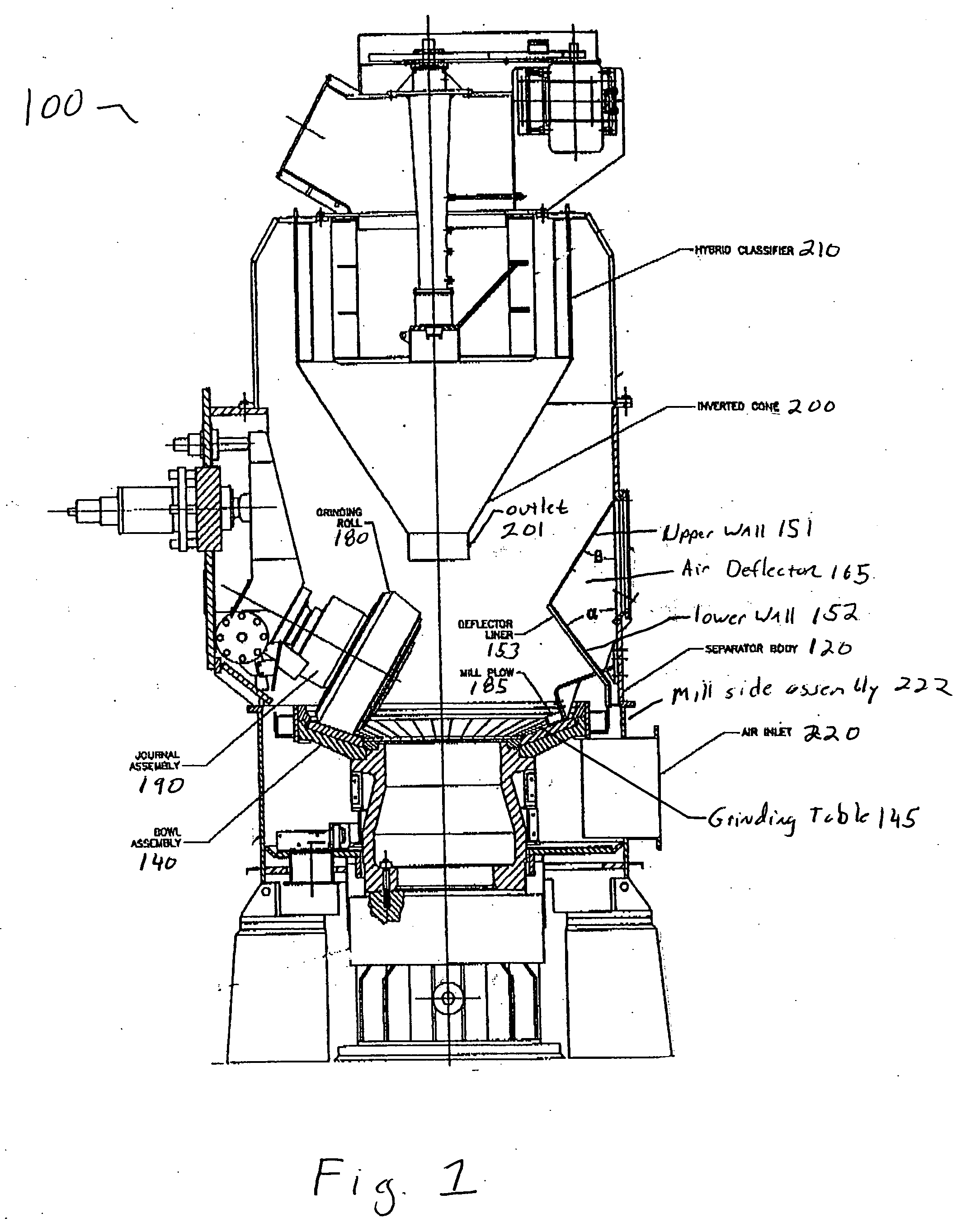

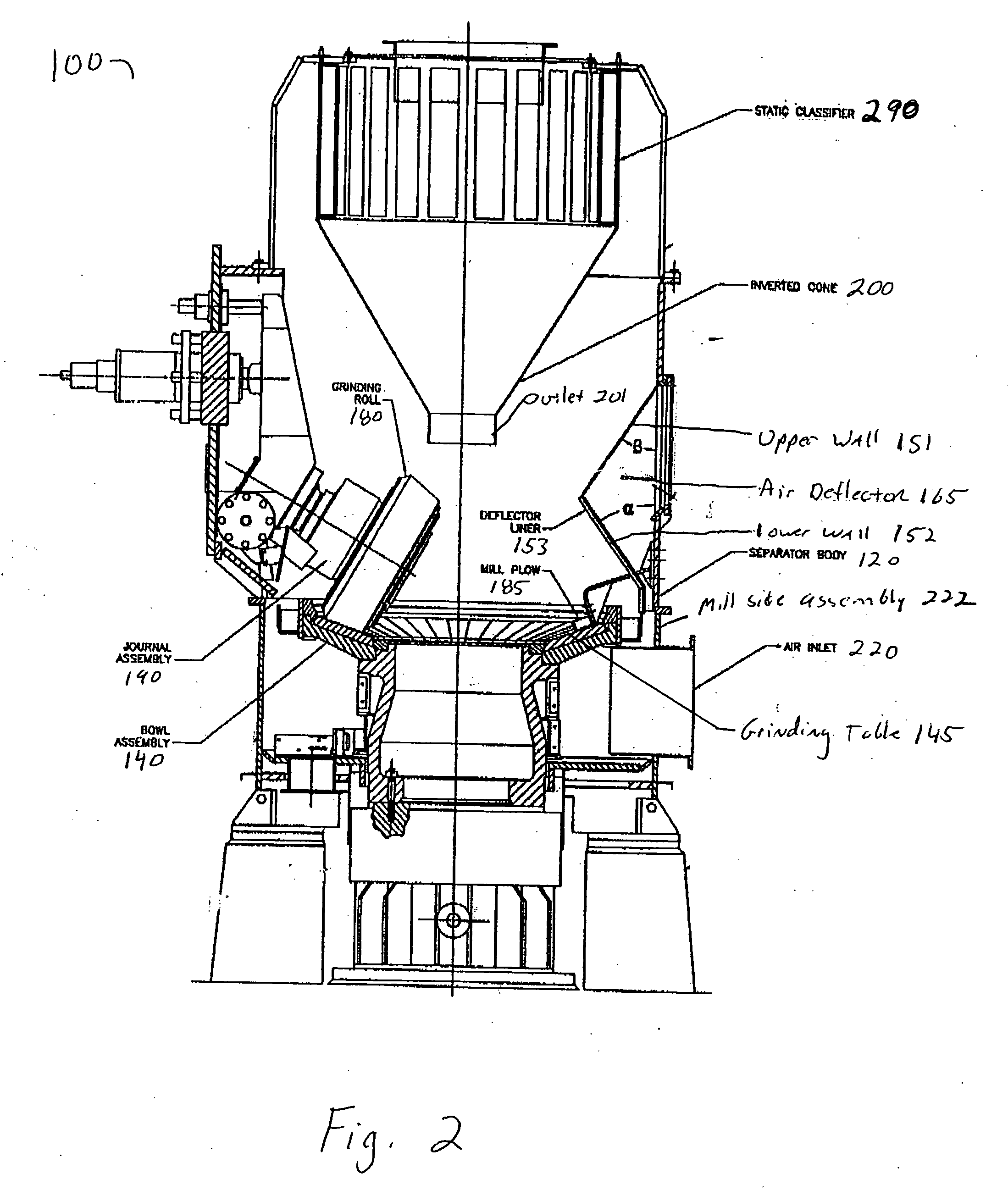

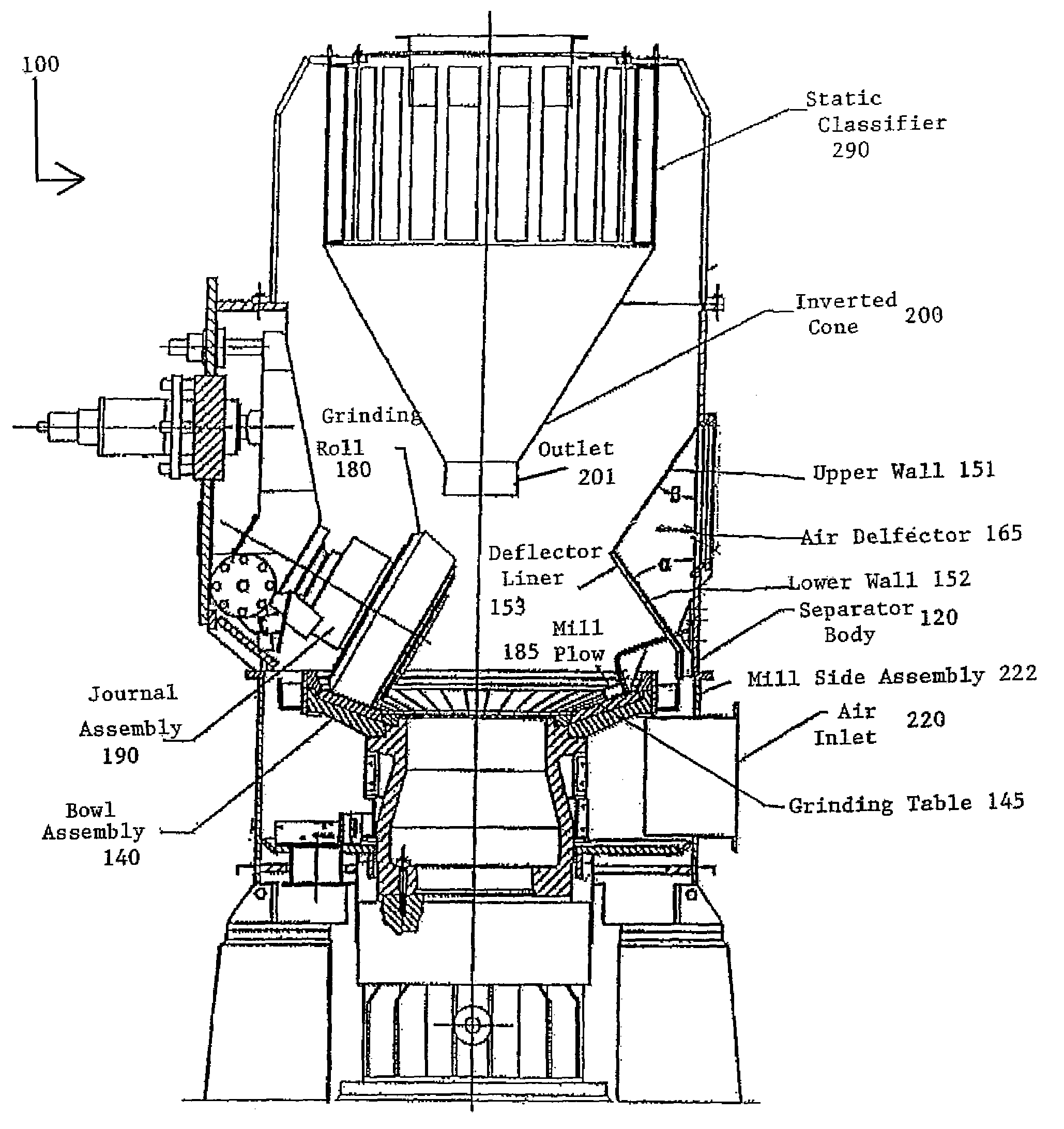

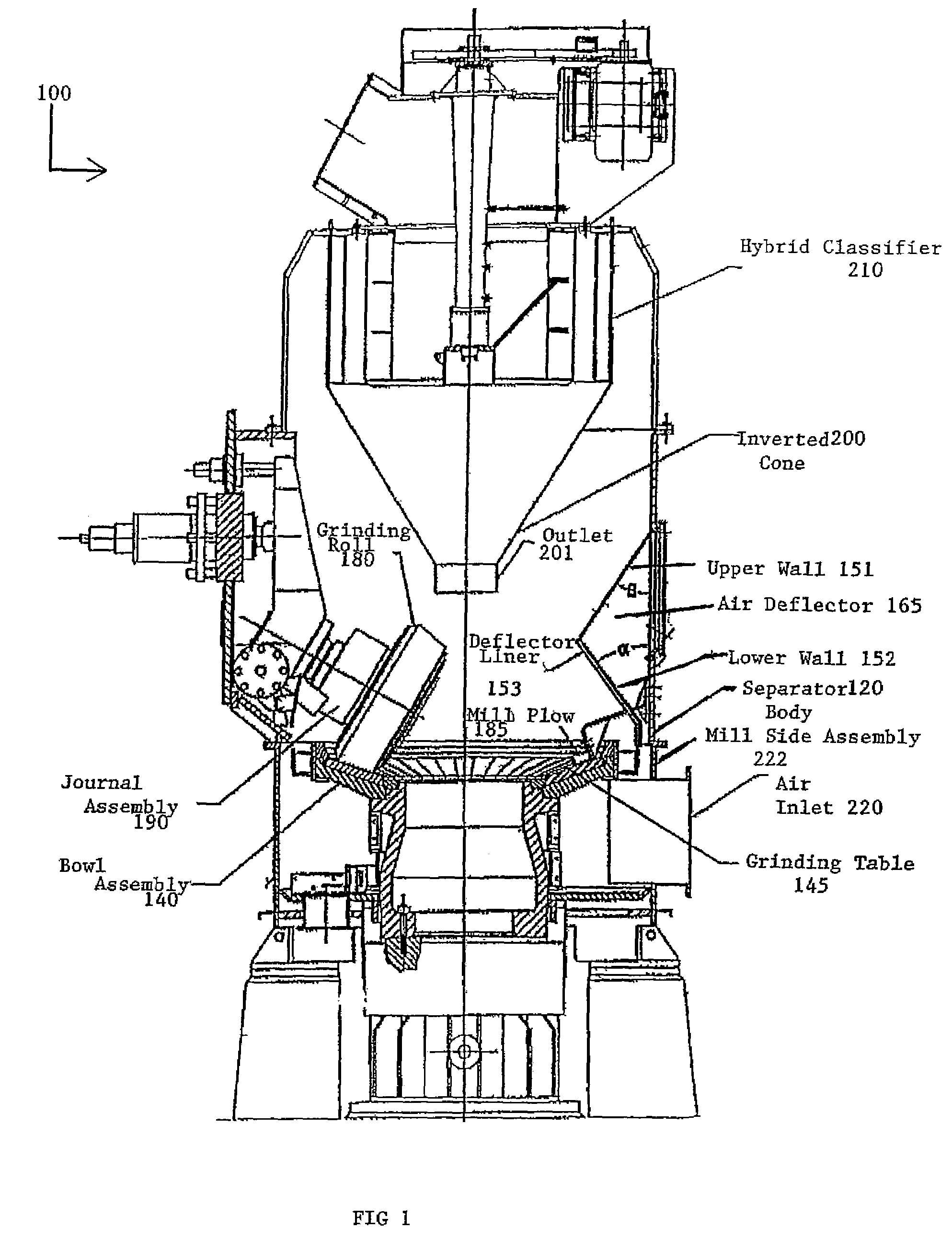

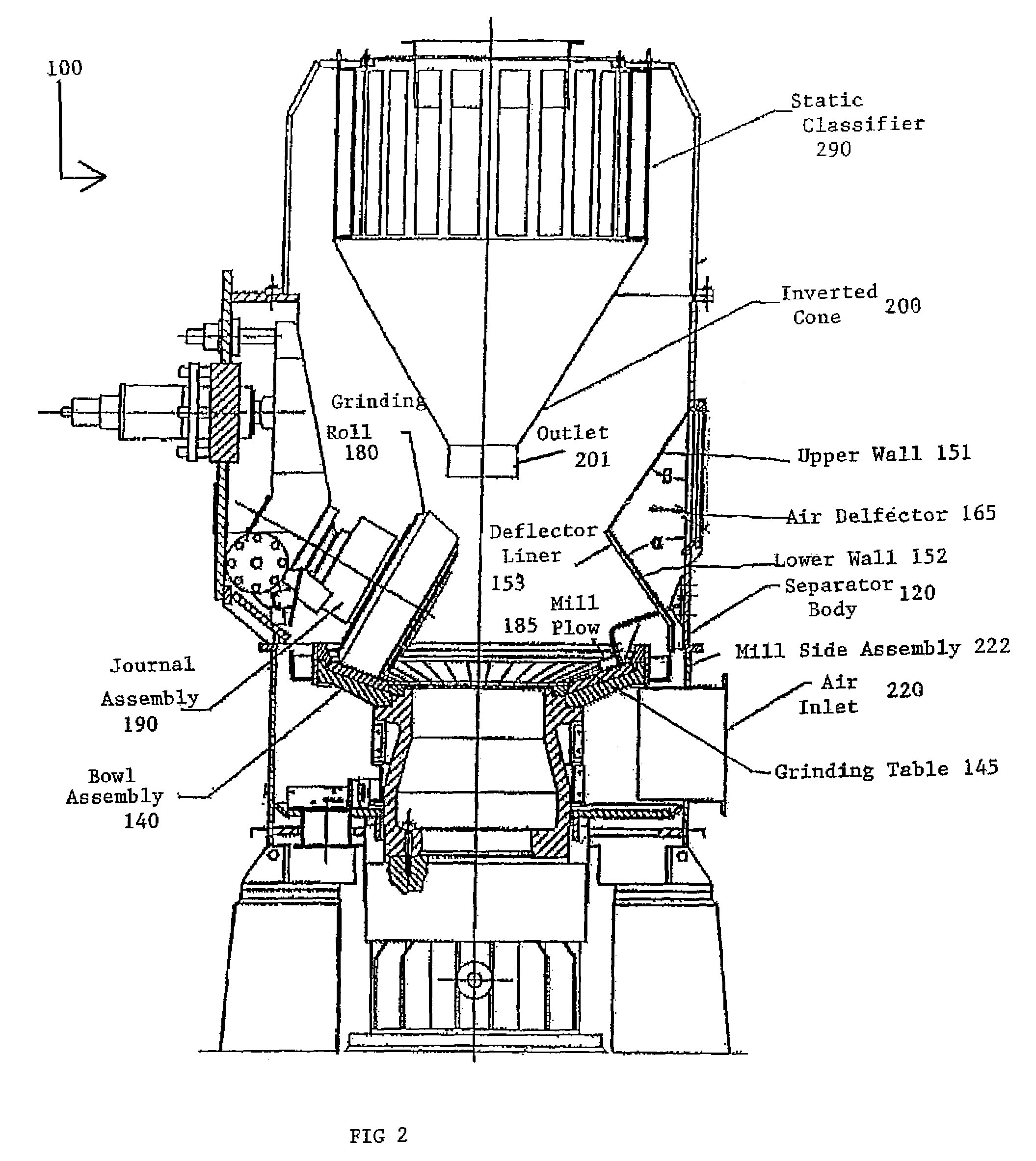

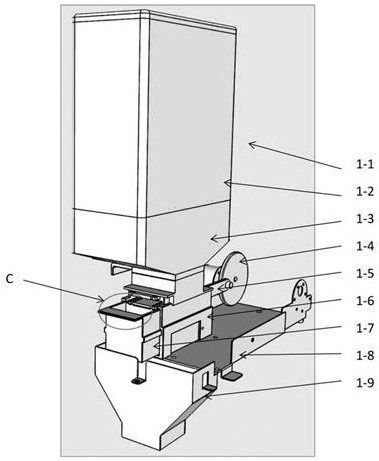

High efficiency bowl mill

A high efficiency bowl mill (100) is provided by the present invention. Included in the high efficiency bowl mill (100) is a plow (185) that is downstream of a grinding roll (180) on a grinding surface (145). The plow (185) loosens material that has been compacted by the grinding roll (180). Also included is a deflector (165) that redirects an air stream so as to pick up material loosened by the plow (185) and deposit material requiring further grinding. An outlet (201) of an inverted cone (200) is positioned so as to deposit material for pulverization on the grinding surface (145) and to restrict the air stream from entering the inverted cone (200).

Owner:SCHENCK PROCESS LLC

High efficiency bowl mill

A high efficiency bowl mill (100) is provided by the present invention. Included in the high efficiency bowl mill (100) is a plow (185) that is downstream of a grinding roll (180) on a grinding surface (145). The plow (185) loosens material that has been compacted by the grinding roll (180). Also included is a deflector (165) that redirects an air stream so as to pick up material loosened by the plow (185) and deposit material requiring further grinding. An outlet (201) of an inverted cone (200) is positioned so as to deposit material for pulverization on the grinding surface (145) and to restrict the air stream from entering the inverted cone (200).

Owner:SCHENCK PROCESS LLC

Compensation of dose inhomogeneity and image distortion

ActiveUS20100038554A1Easy to controlPre-calculated quite accuratelyThermometer detailsStability-of-path spectrometersParticle beamLight beam

An improved aperture arrangement in a device for defining a pattern on a target, for use in a particle-beam exposure apparatus, by being irradiated with a beam of electrically charged particles and allowing passage of the beam only through a plurality of apertures. The device includes an aperture array having a plurality of apertures of identical shape defining the shape and relative position of beamlets permeating the apertures. A blanking device switches off the passage of selected beamlets permeating the apertures and defined by them. The apertures are arranged on the aperture array according to an arrangement deviating from a regular arrangement by small deviations, adjusting for distortions caused by the particle-beam exposure apparatus, and the size of the apertures of the aperture array differs across the aperture array in order to allow for an adjustment of the current radiated on the target through the apertures and the corresponding openings.

Owner:IMS NANOFABTION

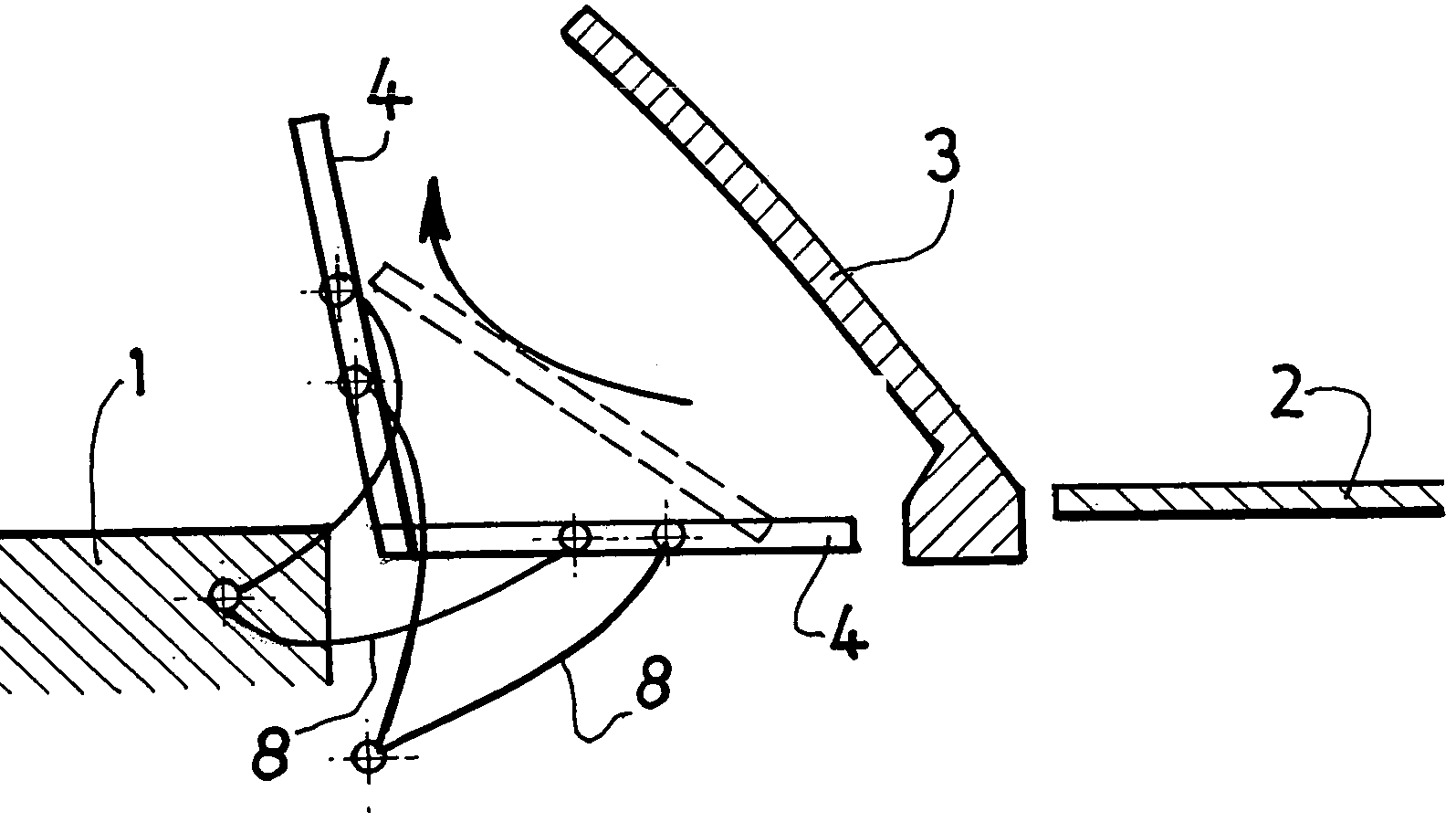

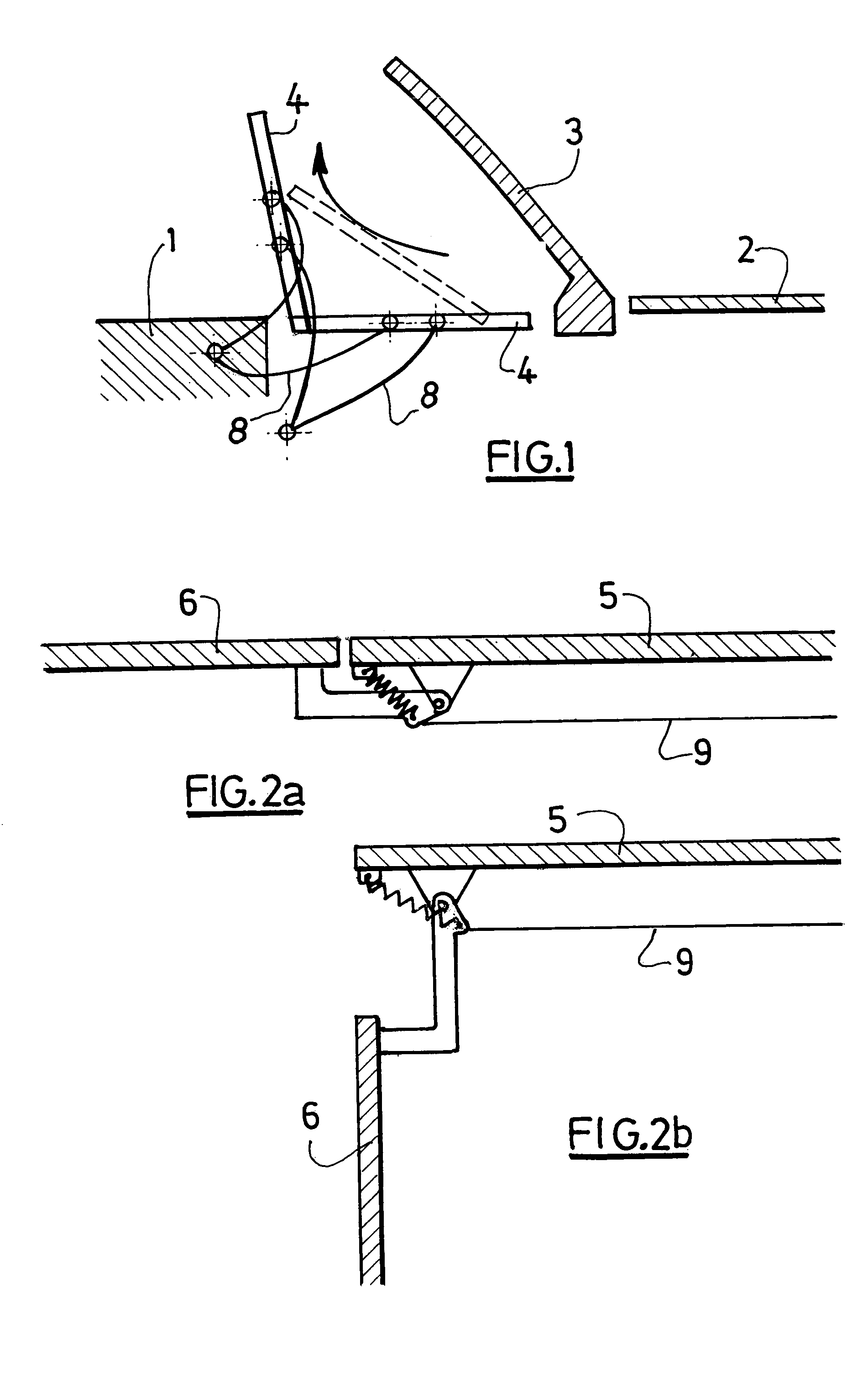

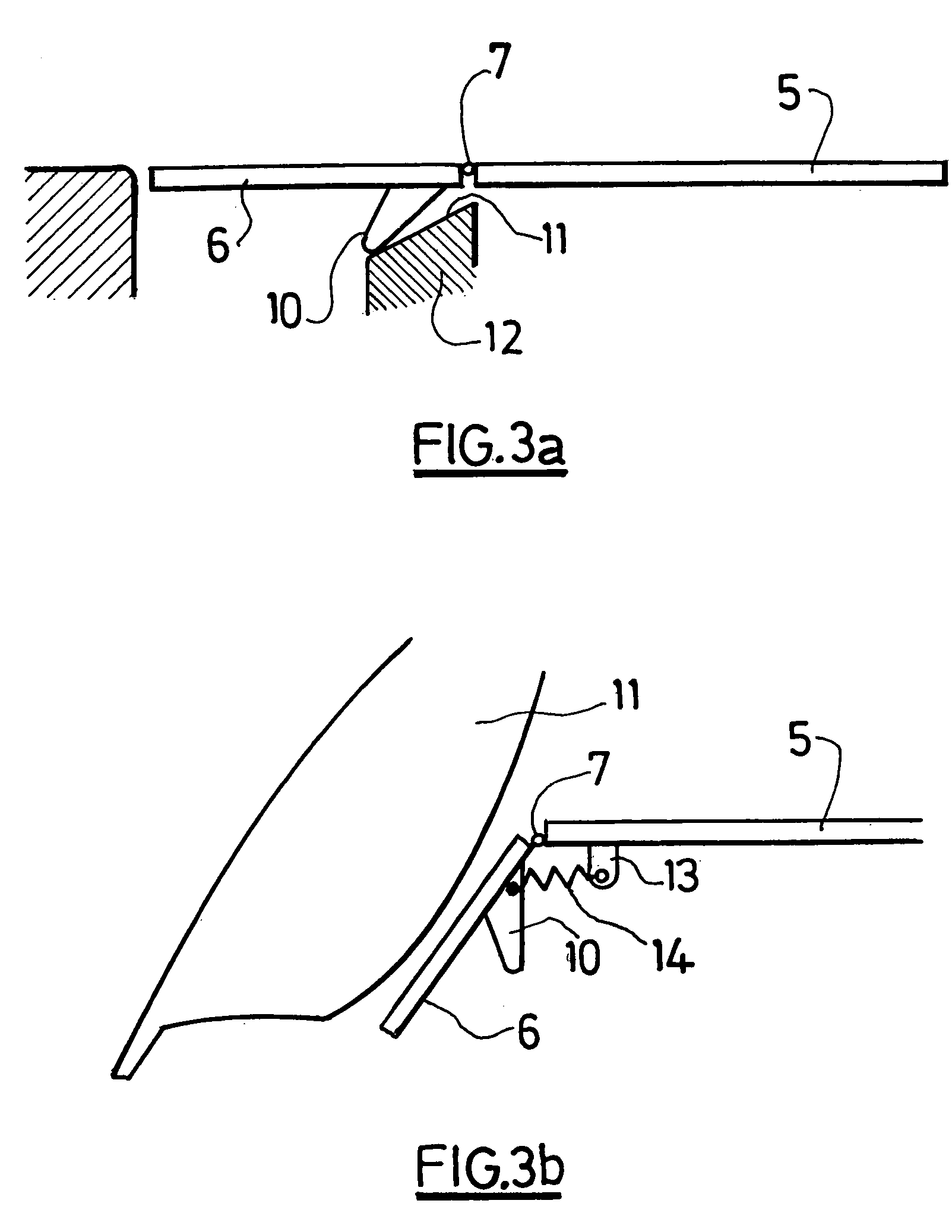

Rear shelf for motor vehicle equipped with a folding roof

A motor vehicle roof can fold from a position of use to a retracted position in a rear boot of the motor vehicle. The roof has a central element and a pair of lateral elements, each rotatably attached at one of two transverse edges of the central element. A mechanism connected between each lateral element and the central element cooperates with features carried on a chassis of the vehicle to cause the lateral elements to rotate into an inclined position respective the central element as the roof folds into the retracted position. The mechanism also causes the lateral elements to rotate as the roof moves into the position of use.

Owner:SOC EUROENNE DE BREVETAB AUTOMOBILES

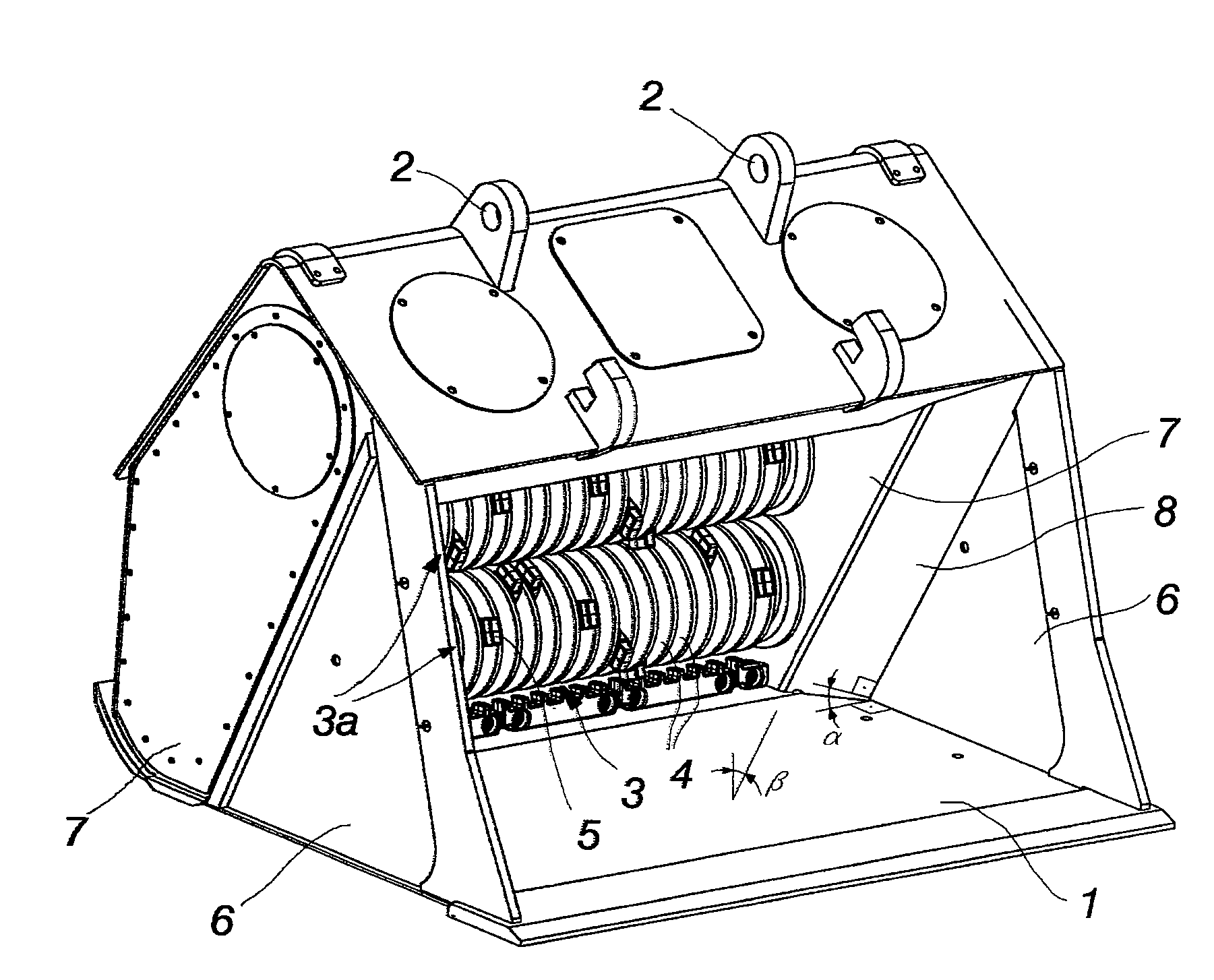

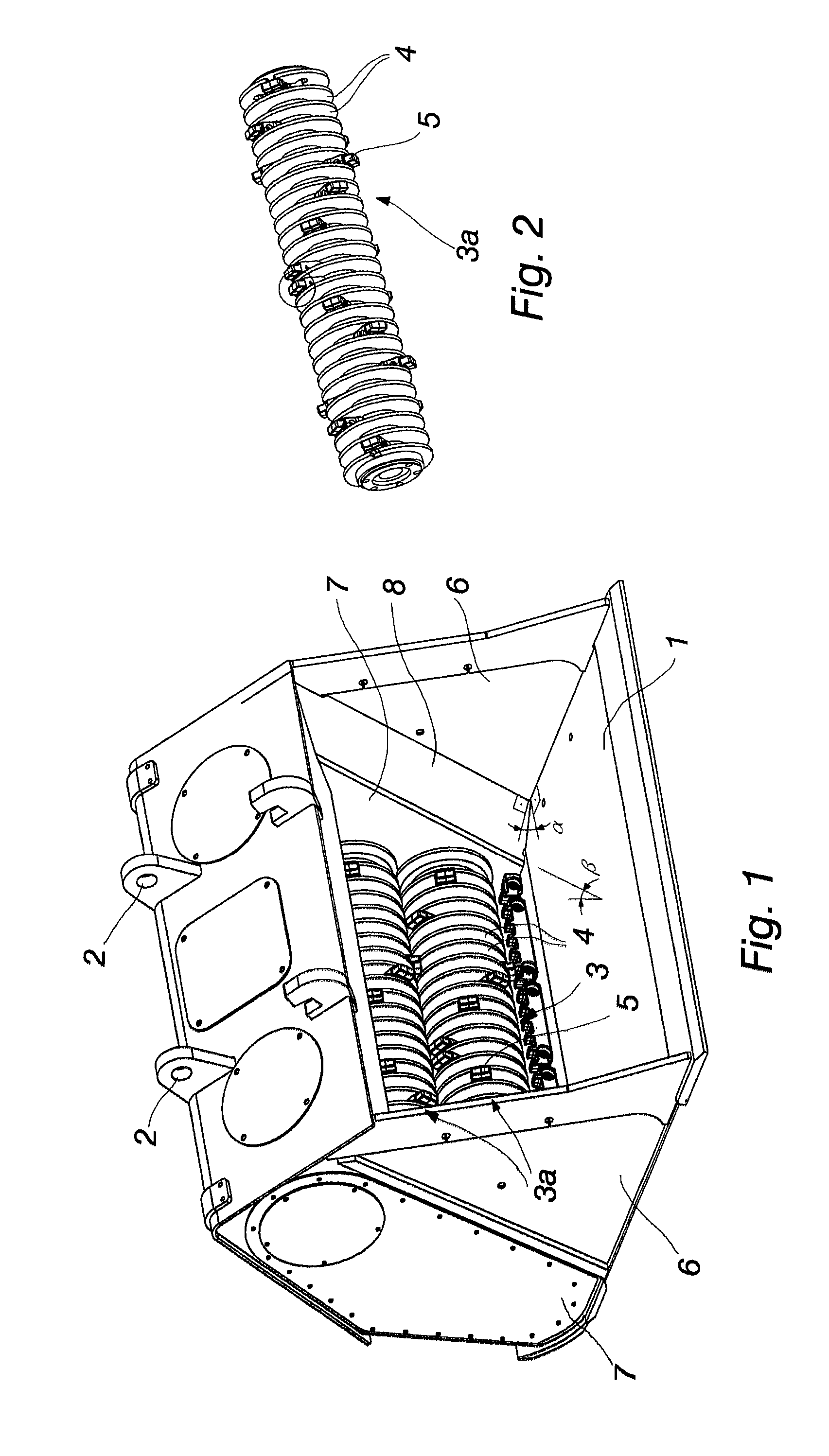

Screening, crushing or mixing bucket

ActiveUS7506461B2Easy to dropEasy to disassembleMechanical machines/dredgersGrain treatmentsEngineering

Owner:ALLU FINLAND

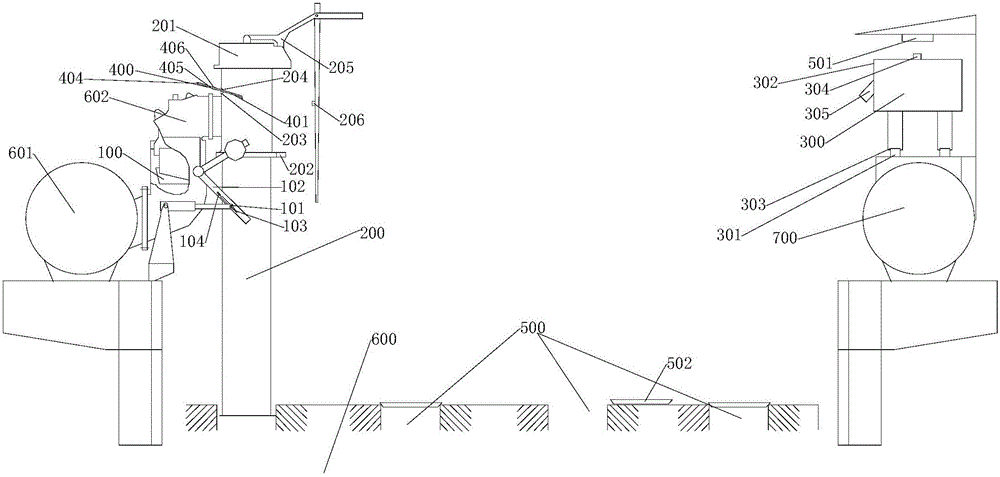

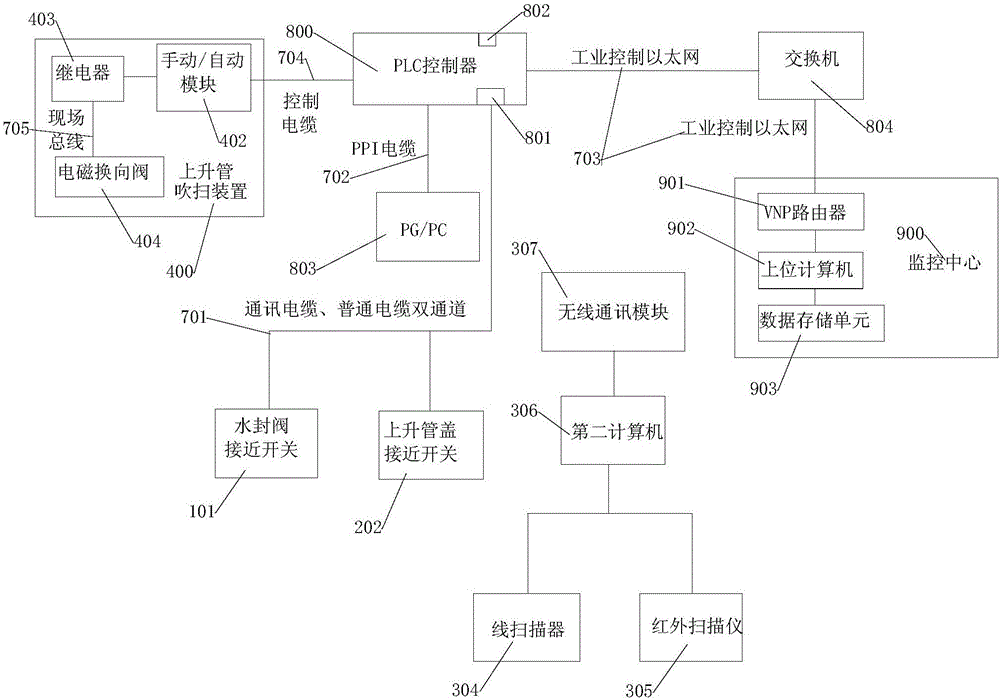

Coke oven ascending pipe cleaning interconnected control method and system

ActiveCN106774134ARealize automatic controlQuick fixCoke oven safety devicesEnergy inputControl systemProcess engineering

The invention discloses a coke oven ascending pipe cleaning interconnected control method and system, and belongs to the technical field of waste heat utilization. The coke oven ascending pipe cleaning interconnected control method comprises the step of recognizing closing of an ascending pipe cover, the step of recognizing closing of a water-sealed valve connected with an ascending pipe, the step of recognizing opening of a coal charging hole cover, the step of matching an ascending pipe address corresponding to a sensor, and the step of recognizing that the ascending pipe is located at the coking last stage corresponding to coke inside a coking chamber. According to the coke oven ascending pipe cleaning interconnected control system, the phenomenon that the inner wall of the ascending pipe is at high temperature for a long time at the coking last stage is avoided, graphite is cleaned away, the service life of an ascending pipe heat exchanger is prolonged, ascending pipe graphite is periodically cleaned away, and labor force is saved.

Owner:江苏龙冶节能科技有限公司

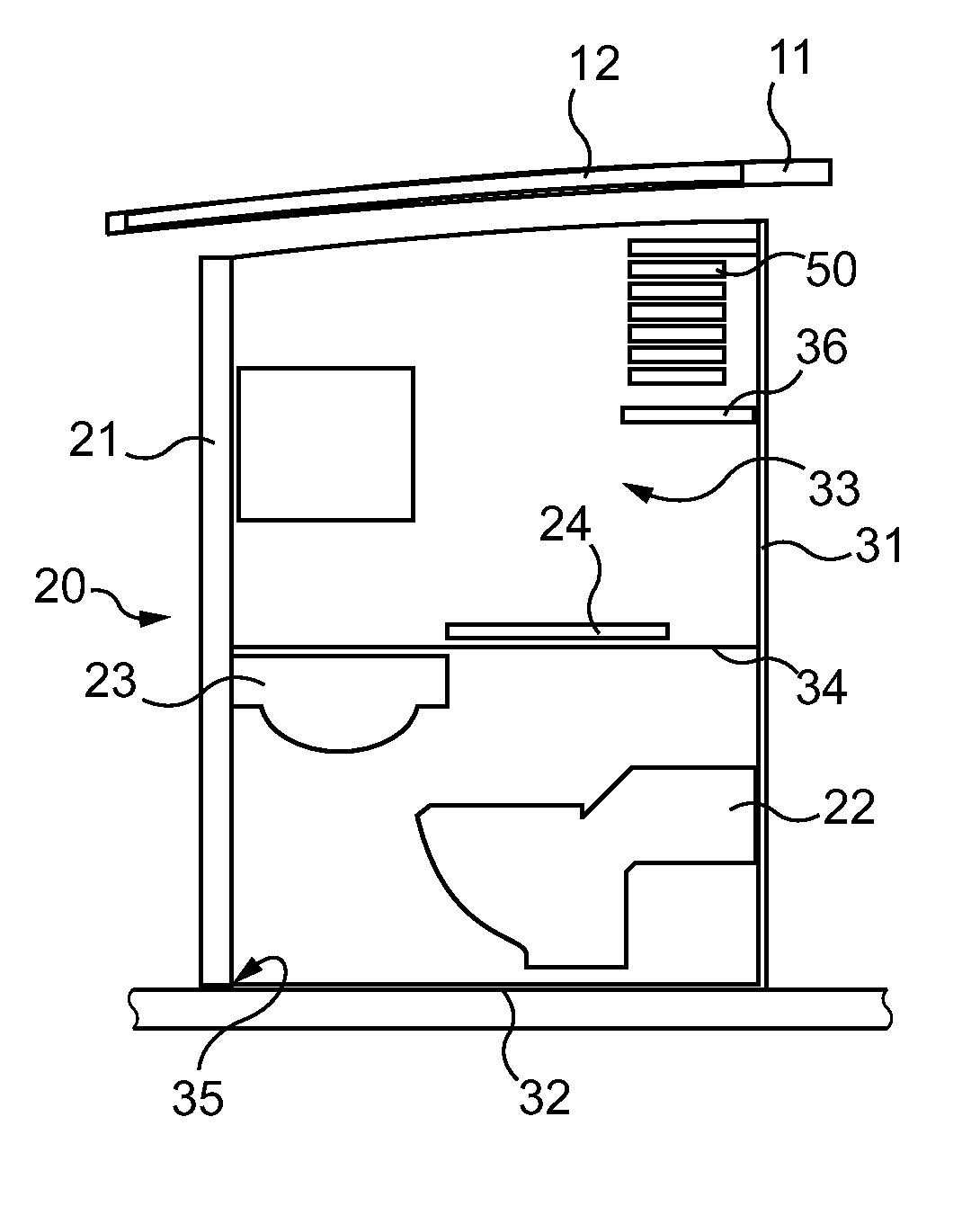

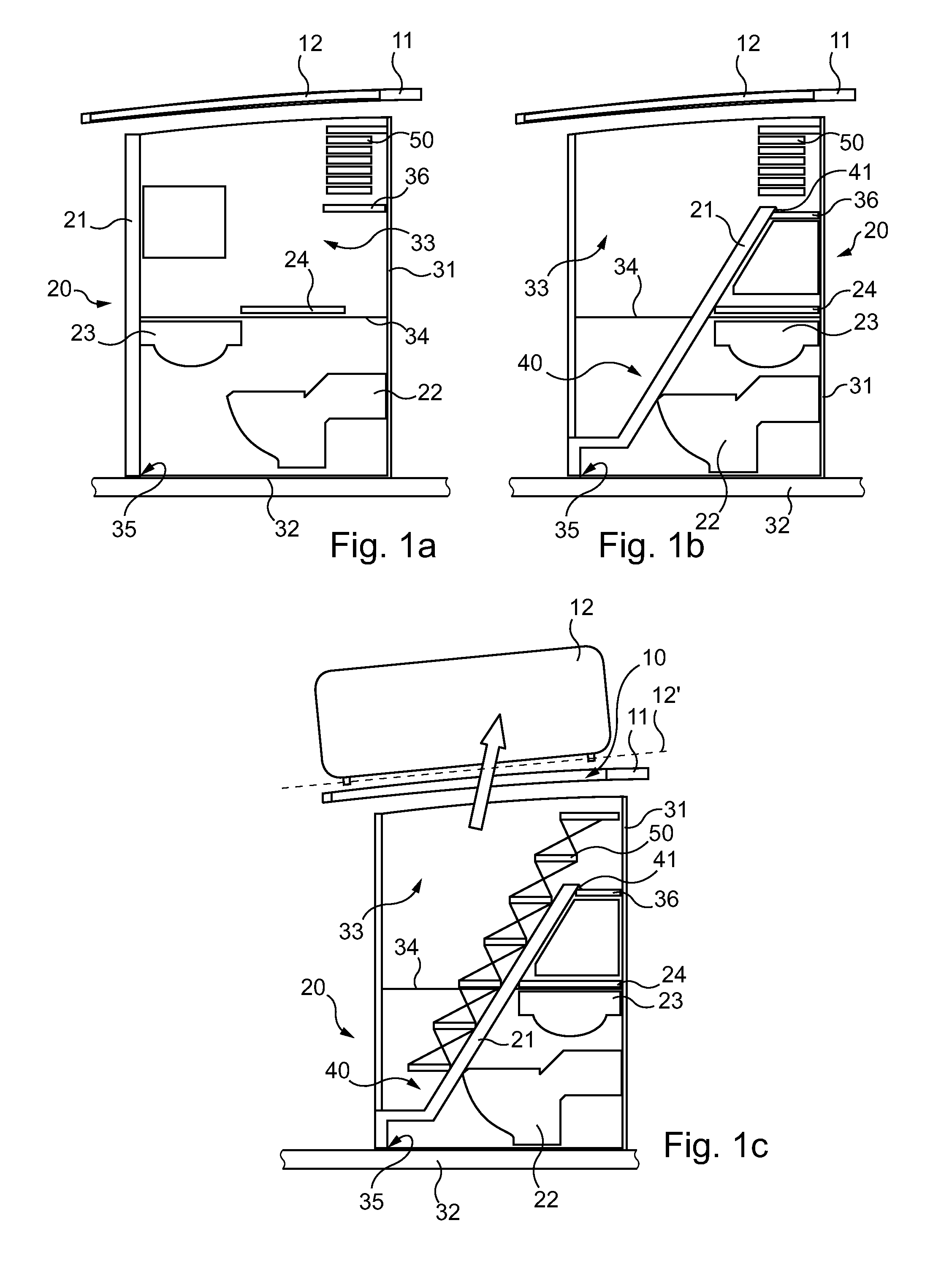

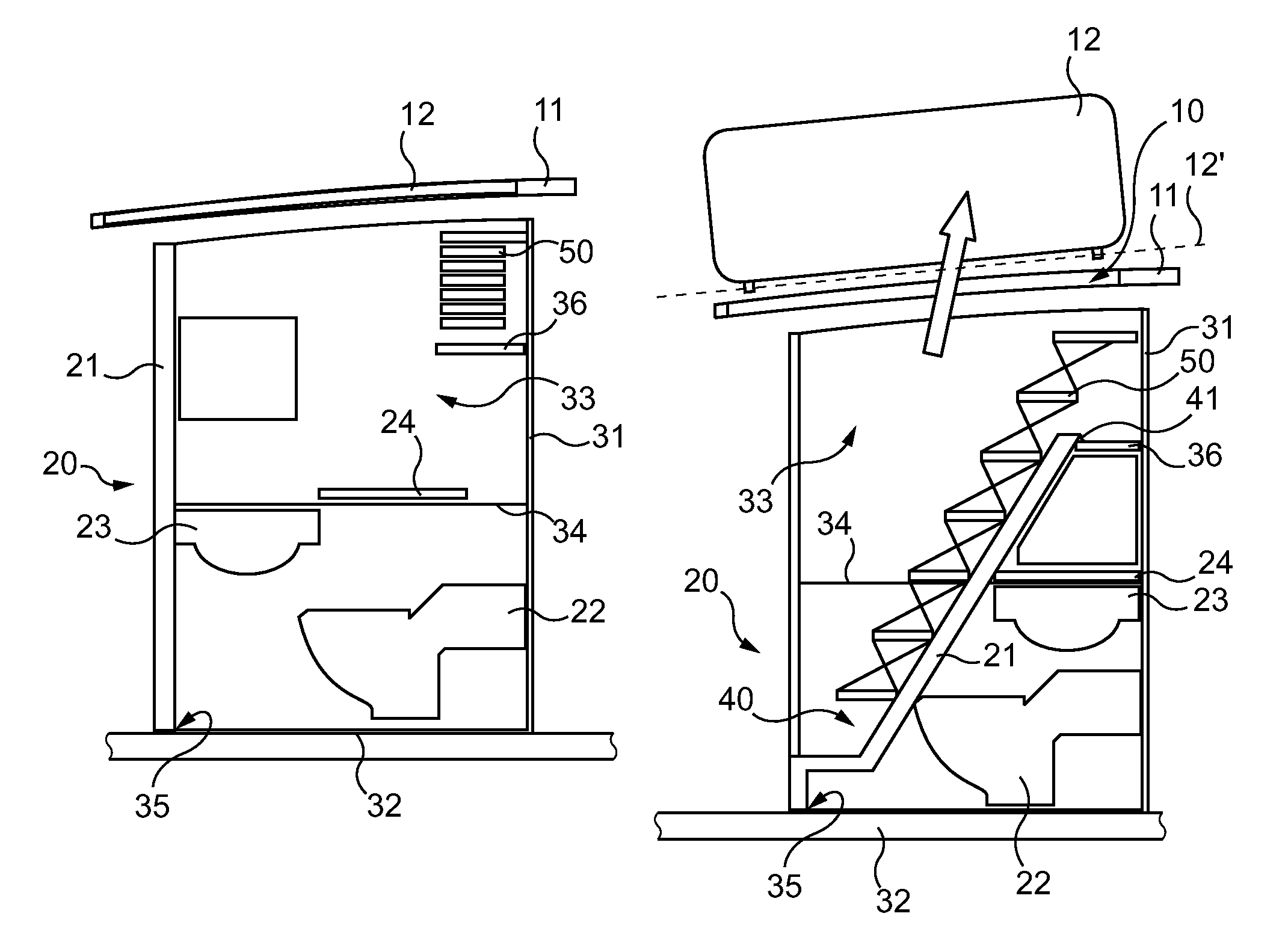

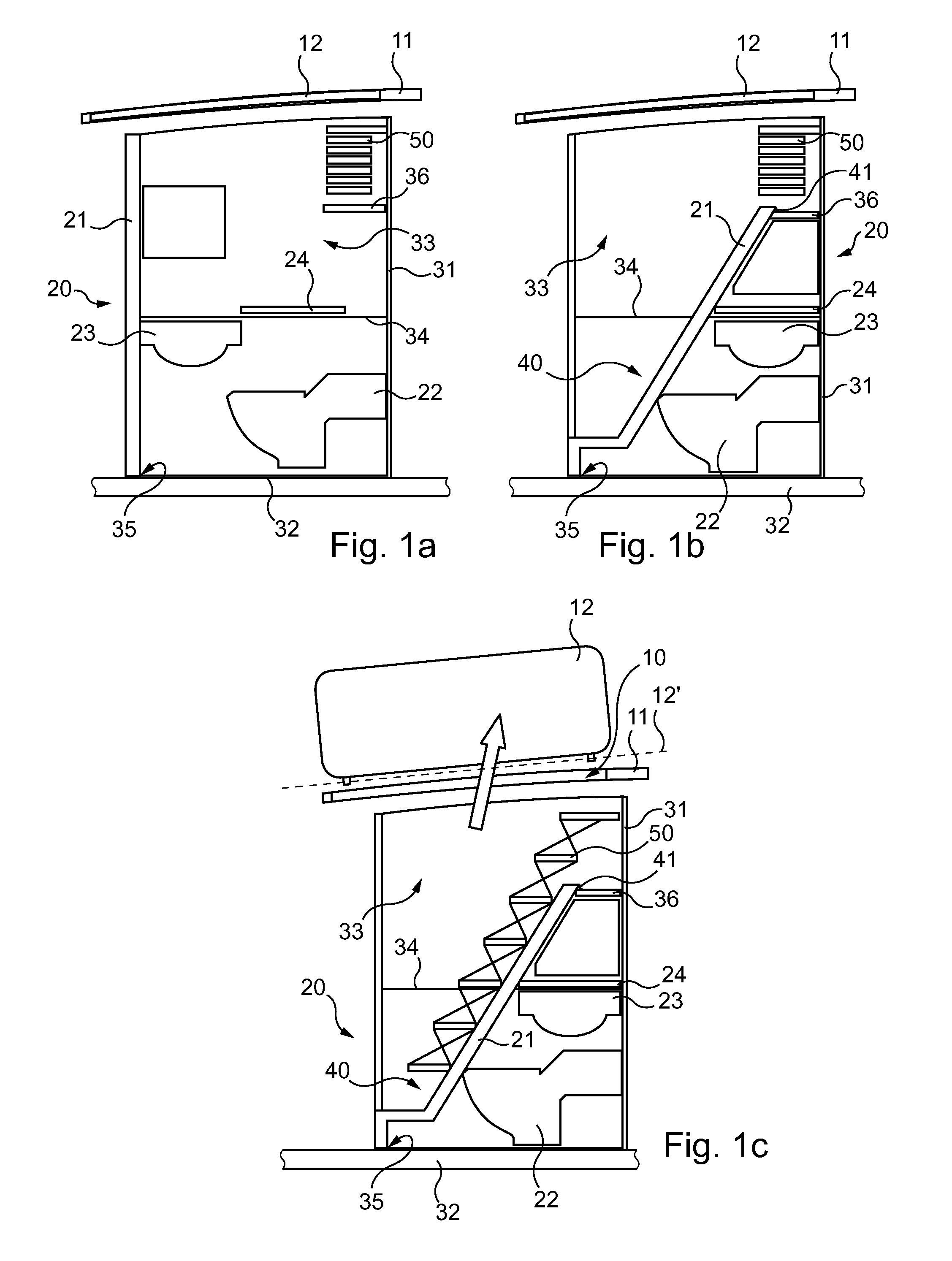

Toilet area for an aircraft cabin, in particular for a flying wing aircraft

ActiveUS20140165285A1Reduce the overall heightEasy accessWater closetsAircraft ejection meansJet aeroplaneToilet

A toilet area for an aircraft cabin comprising an access door and housing a toilet bowl. The toilet area also comprises an evacuation exit, the access door occupying a closed position in the toilet area in a toilet configuration and a folded position in the toilet area in an evacuation configuration. Usage in particular in a flying wing aircraft is provided.

Owner:AIRBUS OPERATIONS (SAS)

Low-temperature denitration and heat storage integrated catalytic type honeycomb ceramic material

InactiveCN108249896AImprove performanceNo pollution in the processDispersed particle separationCatalyst activation/preparationFiberGlass fiber

The invention discloses a low-temperature denitration and heat storage integrated catalytic type honeycomb ceramic material. The ceramic material is characterized by being mainly prepared from 70 to 80 parts of nano-scale aluminum oxide, 35 to 40 parts of nanometer magnesia, 30 to 35 parts of nano titanium dioxide, 1 to 3 parts of boron nitride, 50 to 60 parts of silicon dioxide powder, 4 to 10 parts of methyl methacrylate-butadiene-styrene terpolymer, 3 to 8 parts of glass fiber, 0.8 to 1 part of stearic acid, 0.8 to 1 part of a macromolecular polymer fiber and 0.8 to 1 part of aminocellulose. The ceramic material is prepared by kneading the components to form catalyst mud, decaying the catalyst mud, extruding and forming the catalyst mud, forming a catalyst, drying a wet green body and calcining the wet green body. According to the low-temperature denitration and heat storage integrated catalytic type honeycomb ceramic material disclosed by the invention, the catalysis efficiency ofthe catalyst is improved, and the use cost of the catalyst is reduced; by the adding of the stearic acid, forming and demolding of the catalyst are facilitated, and the finished product ratio of catalyst manufacturing is increased. The preparation steps are simple; reaction conditions under a medium-temperature environment are mild; the cost is low.

Owner:HUBEI SHENWU THERMAL ENERGY TECH

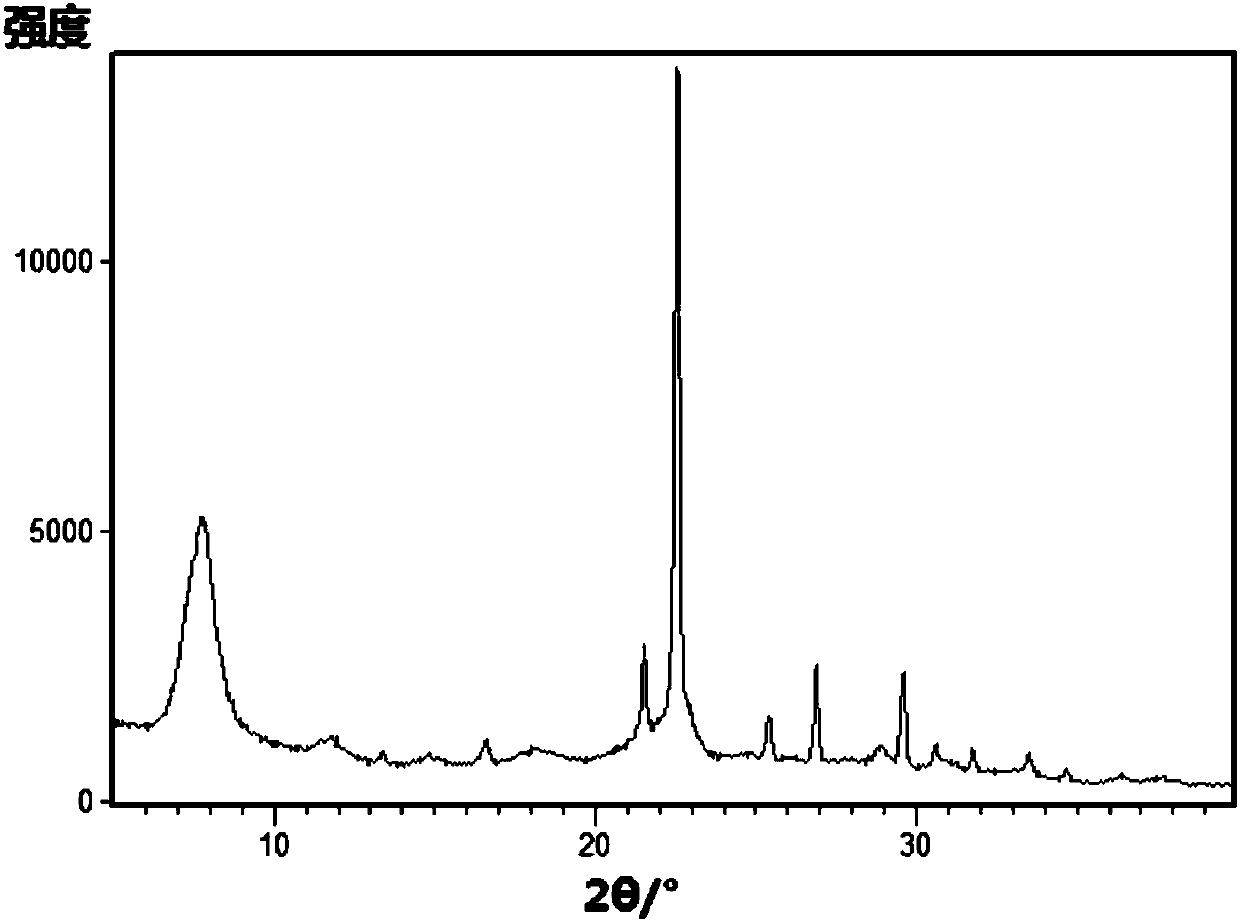

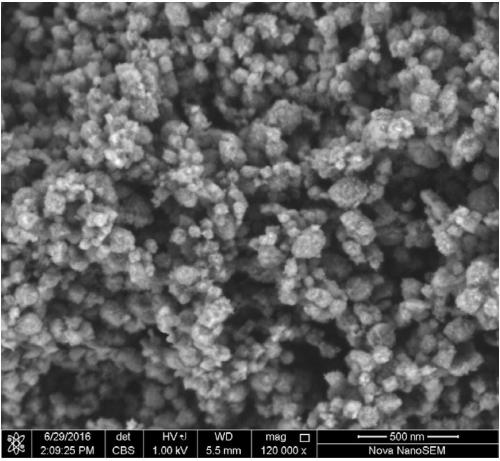

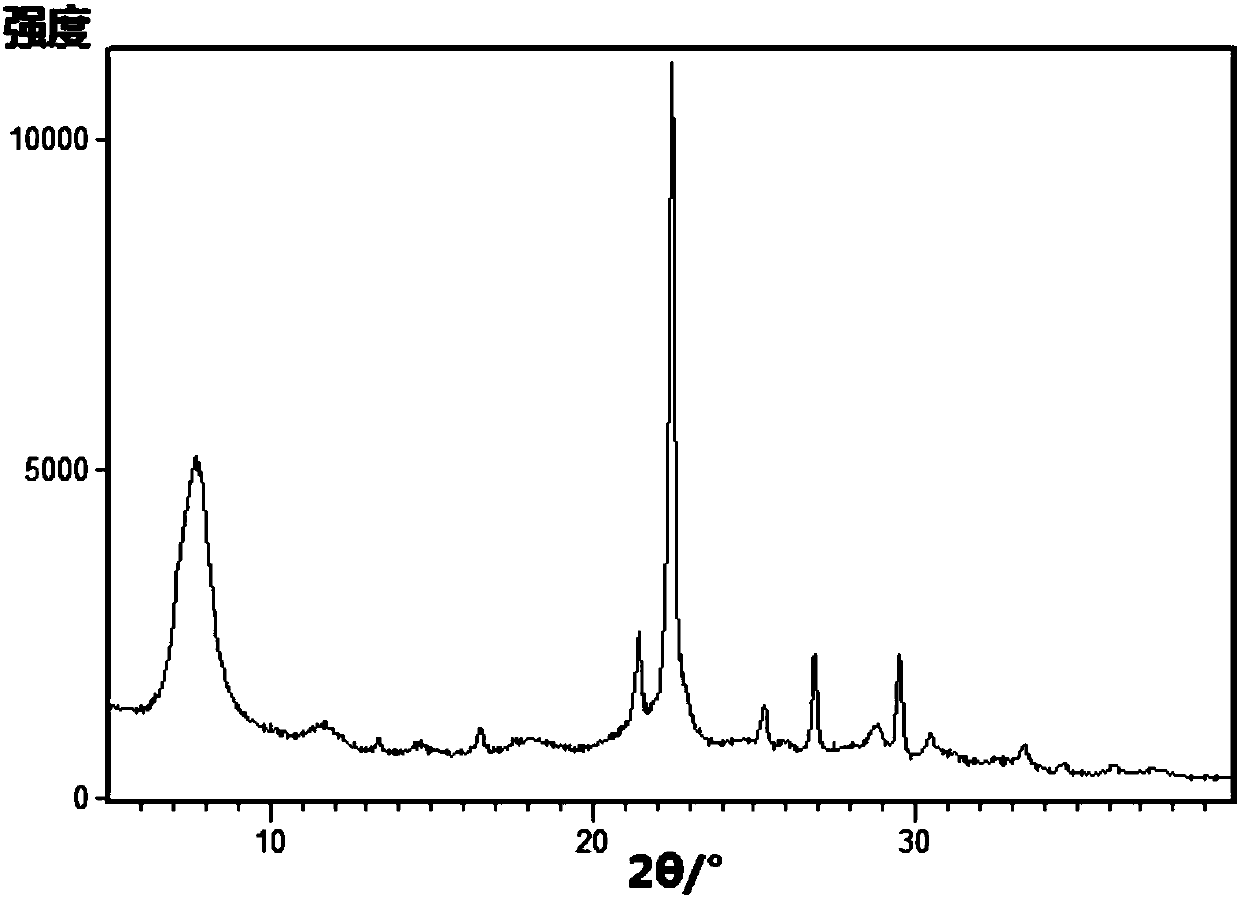

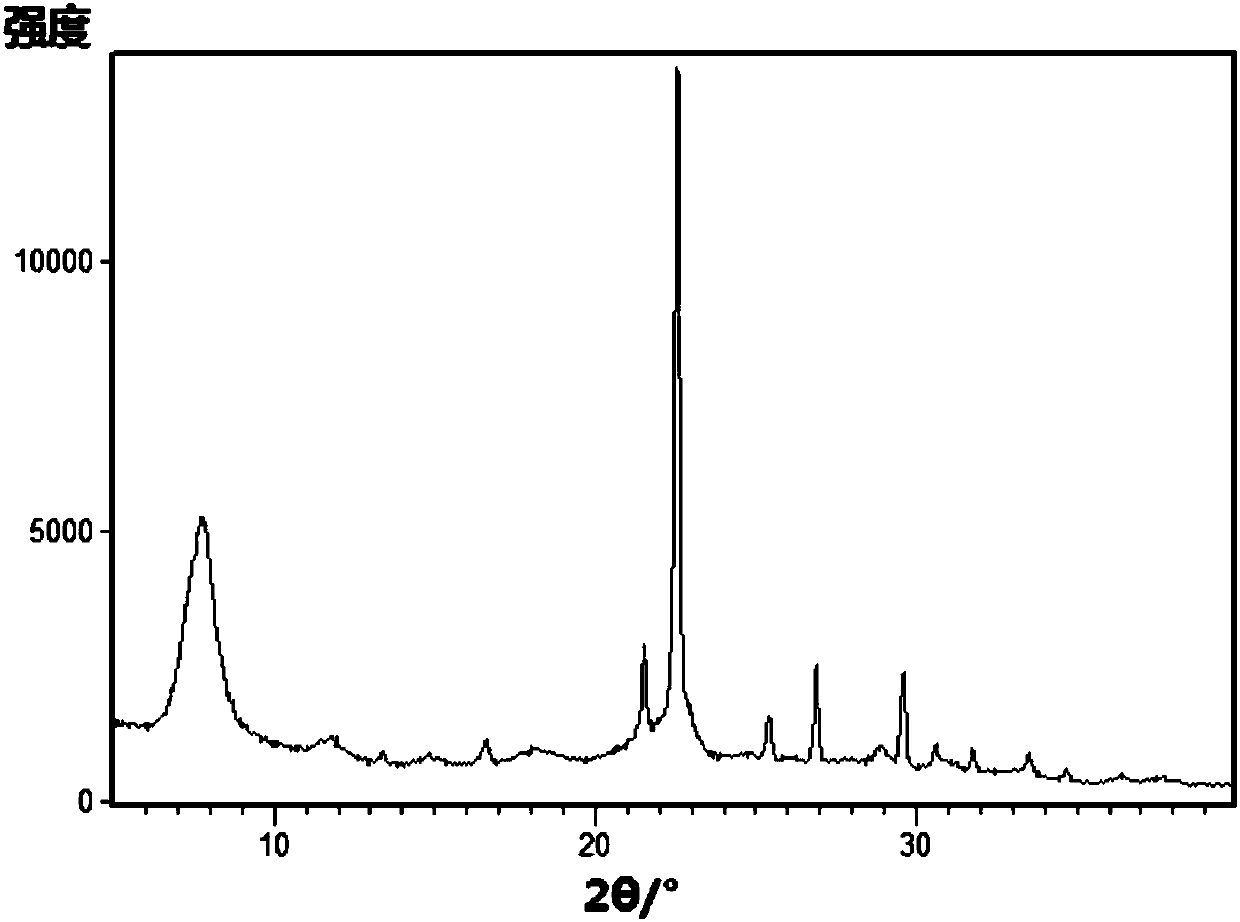

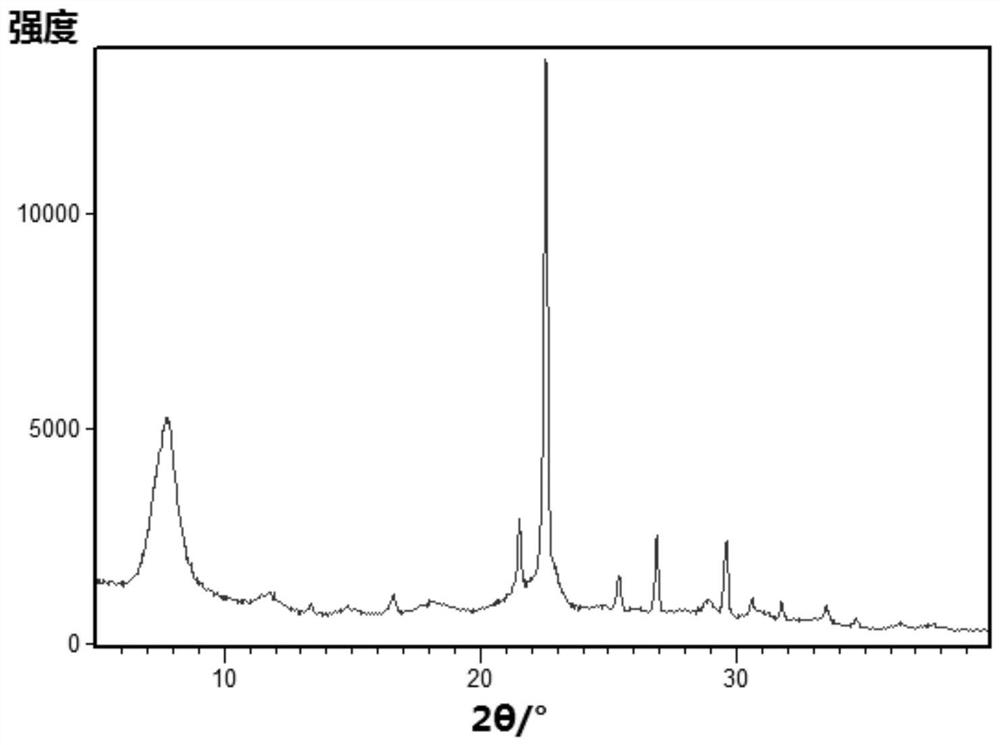

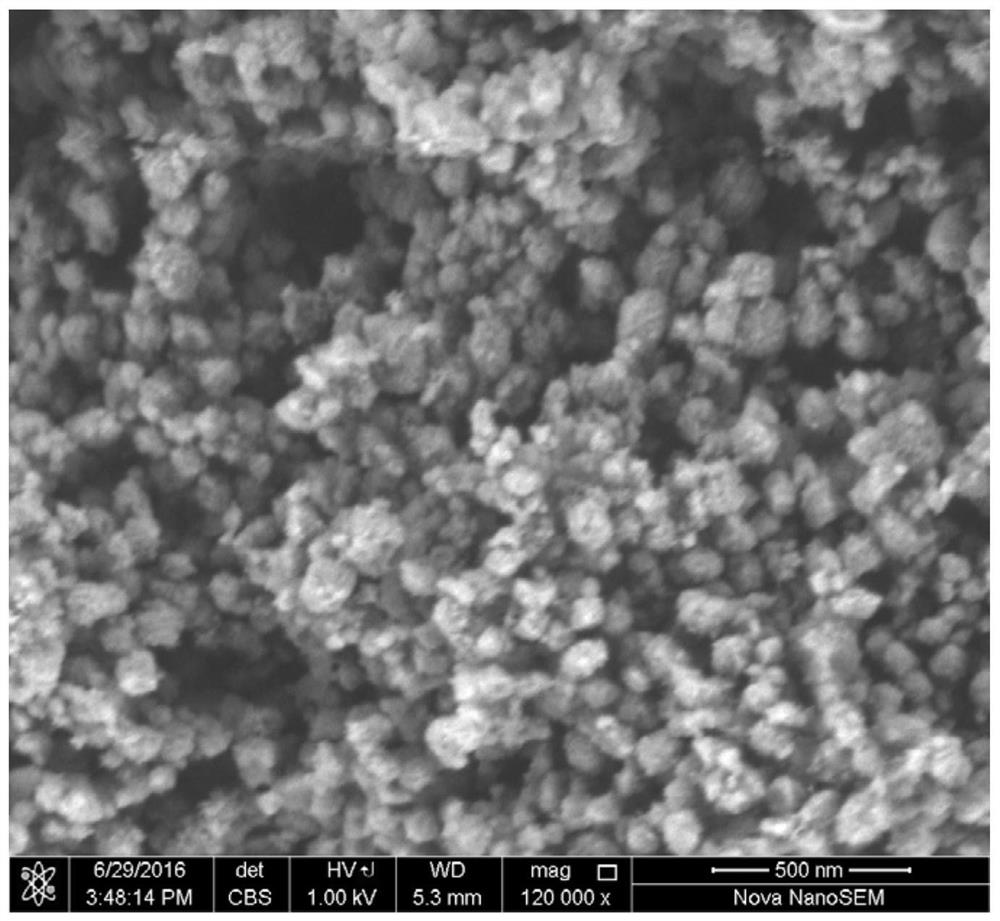

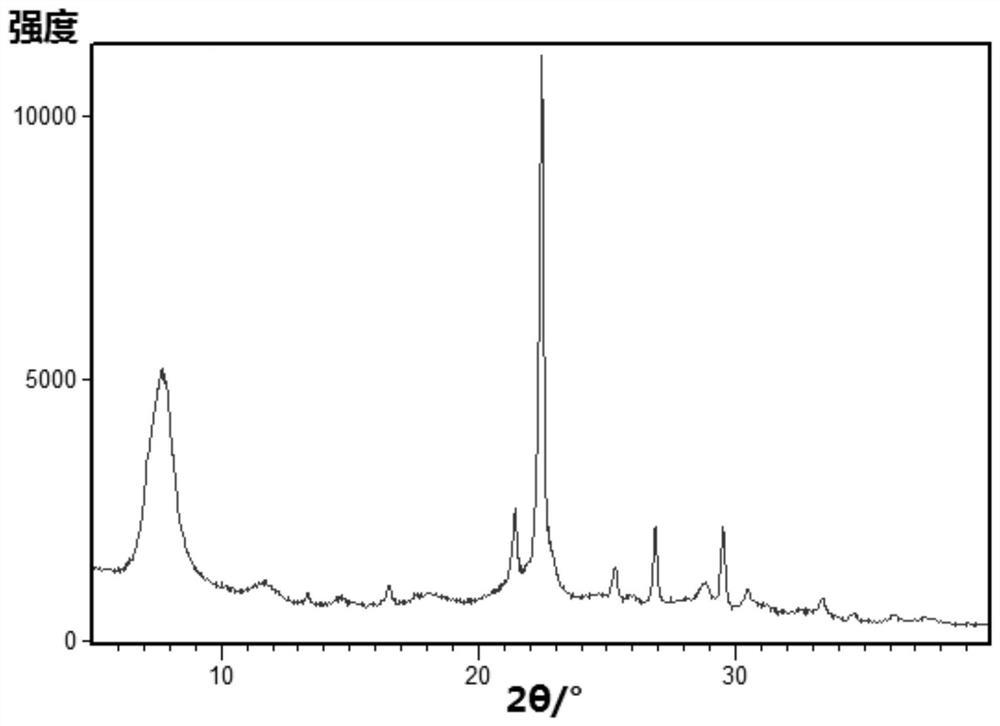

Preparation method of beta molecular sieve

InactiveCN110156037AHigh yieldHigh crystallinityNanotechnologyCrystalline aluminosilicate zeolitesMolecular sieveHeating time

The invention discloses a preparation method of a beta molecular sieve. The preparation method comprises the steps of: 1. synthesis of initial gel: mixing a silicon source, an aluminum source, a template agent, an alkaline metal source, water and a beta molecular sieve seed crystal evenly to synthesize an initial gel, wherein the silicon source is calculated in terms of SiO2, the aluminum source is calculated in terms of Al2O3, the template agent is calculated in terms of TEA<+>, the alkaline metal source is calculated in terms of Na2O, and the raw materials for synthesizing the initial gel are in the following mole ratios that: SiO2 / Al2O3=25-150:1, TEA<+> / SiO2=0.07-0.23:1, Na2O / SiO2=0.03-0.12:1, and H2O / SiO2=3.0-11.5:1, the beta molecular sieve seed crystal has a Si-Al ratio of SiO2 / Al2O3=20-100:1, and in terms of mass, the adding amount is 0%-10% of the mass of SiO2; and 2. microwave heating crystallization reaction: conducting microwave heating treatment on the initial gel preparedby step 1, controlling the heating temperature at 120DEG C-180DEG C and the heating time at 4-25h, thus obtaining a beta molecular sieve product. The method provided by the invention can synthesize the beta molecular sieve with high crystallinity and abundant pore structures by only one step, and compared with the conventional hydrothermal synthesis method, the method provided by the invention cangreatly shorten the synthesis time of the beta molecular sieve, the grain size of the molecular sieve is smaller, and the pore channels are smoother.

Owner:PETROCHINA CO LTD

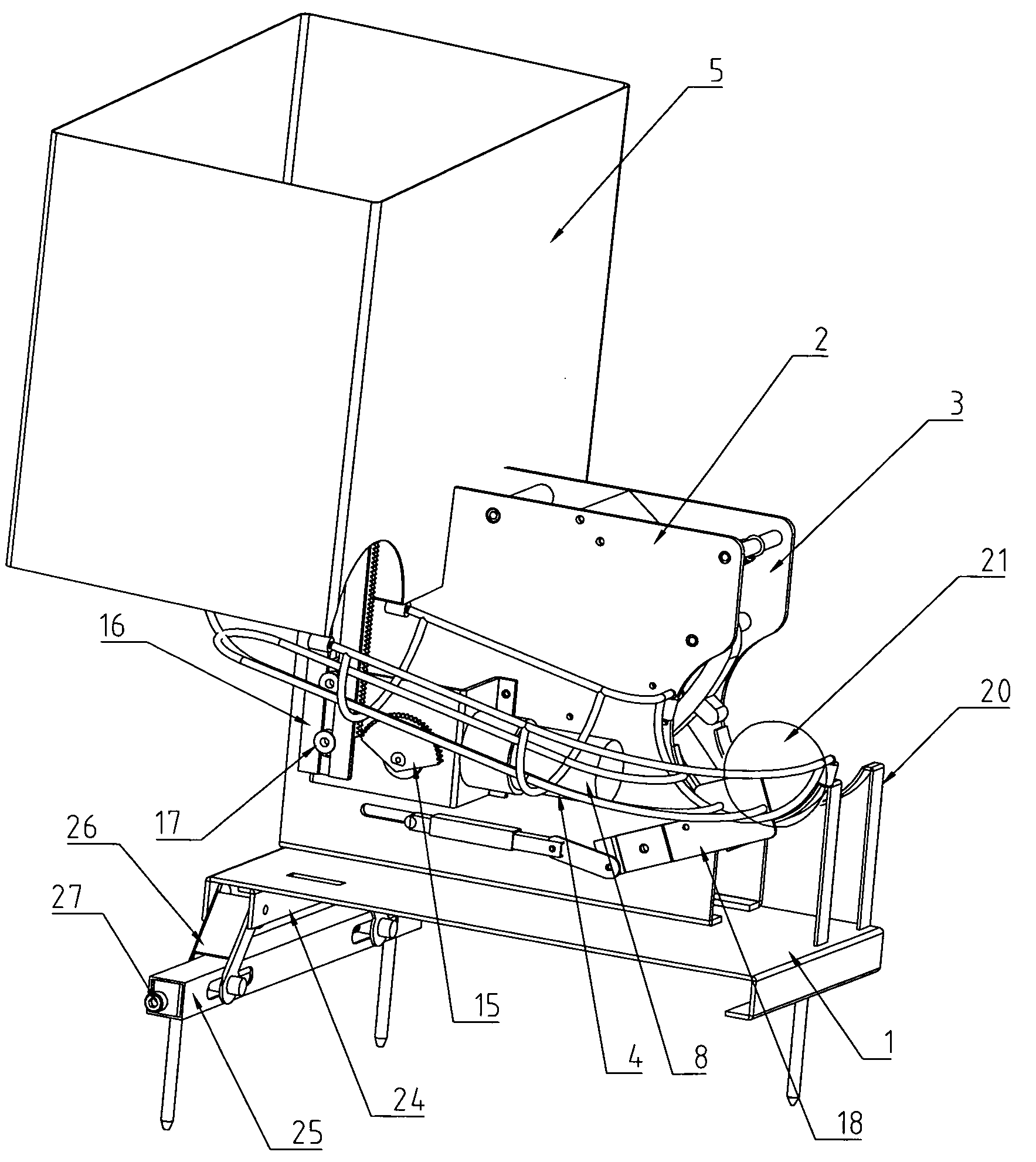

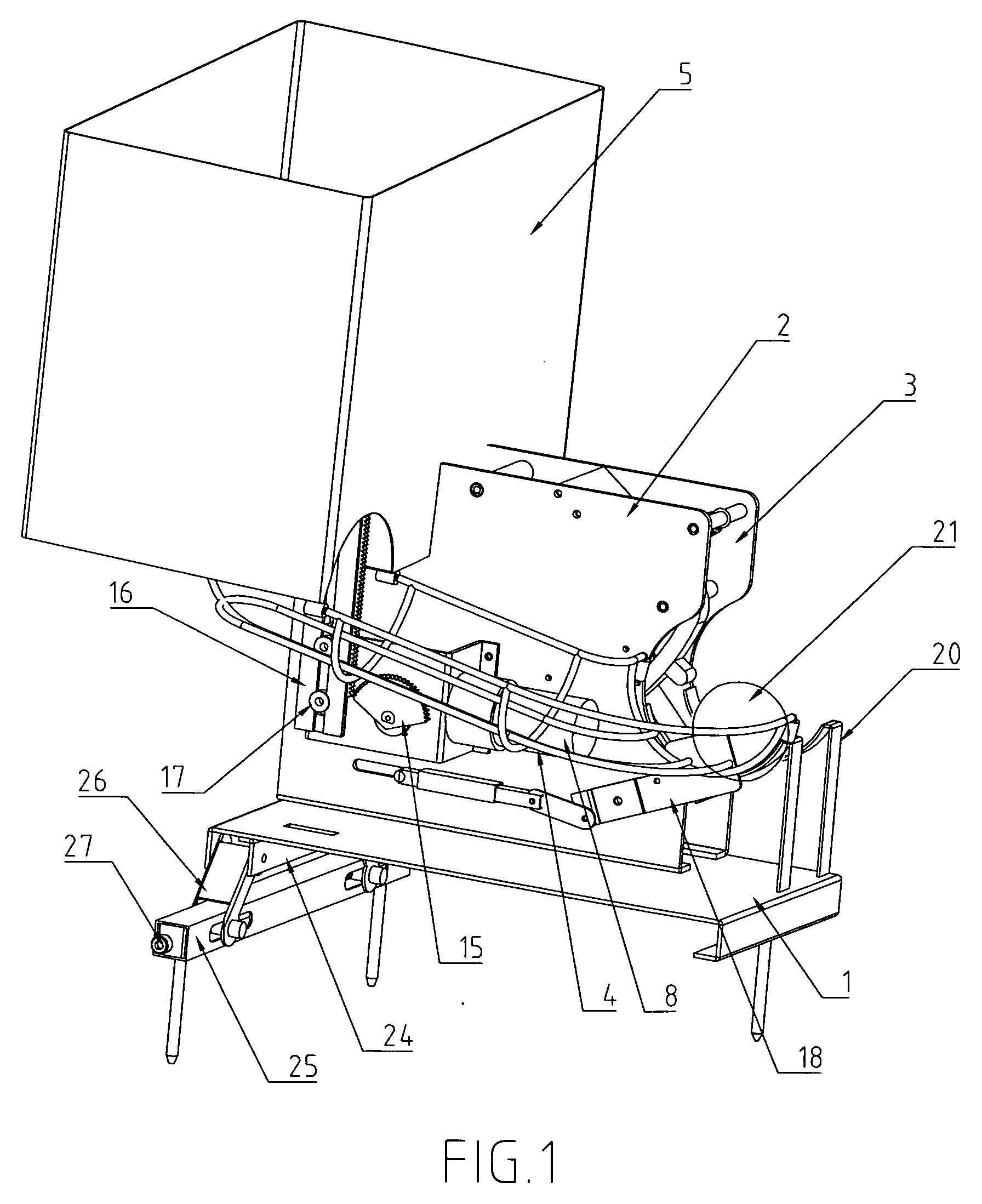

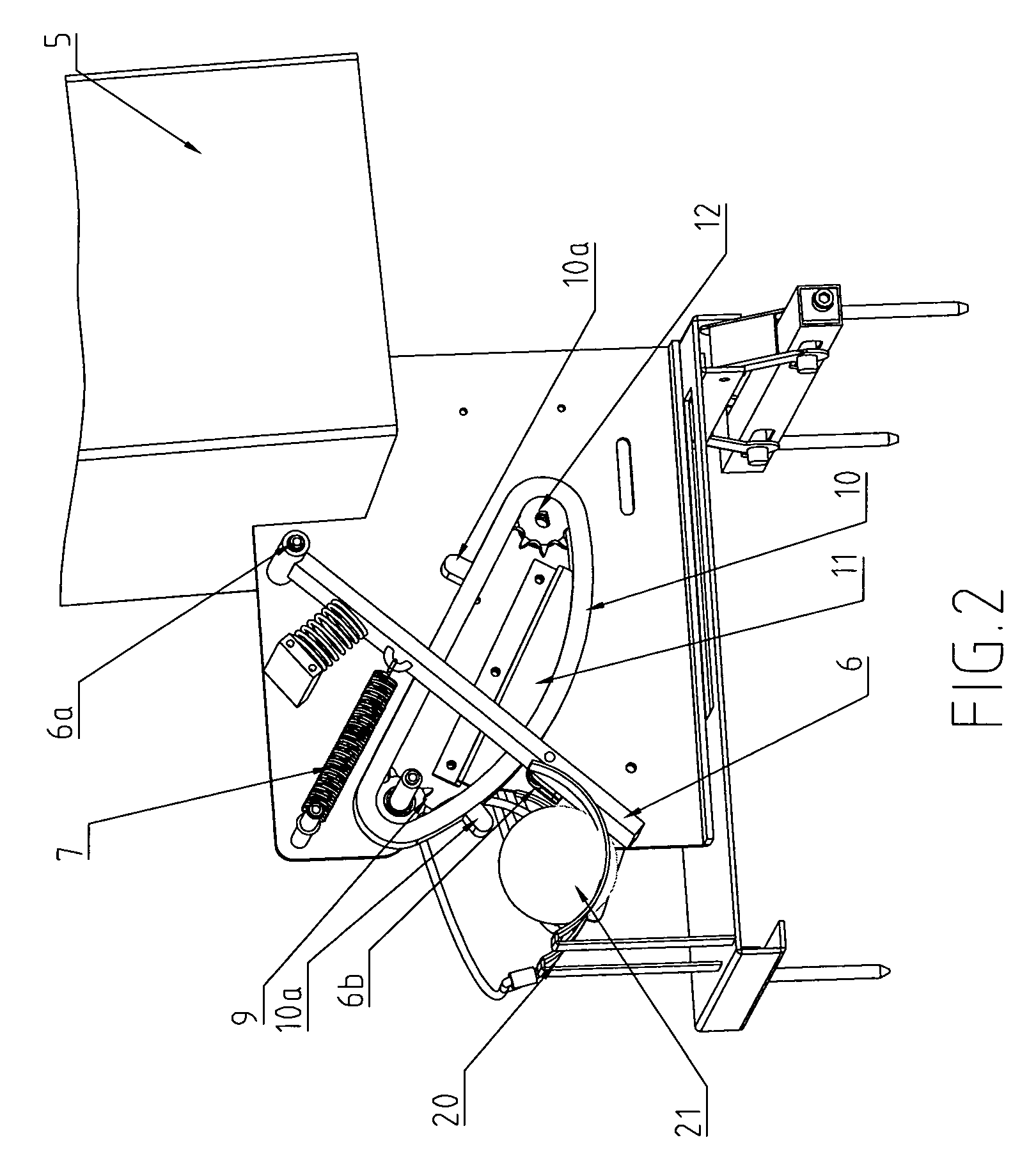

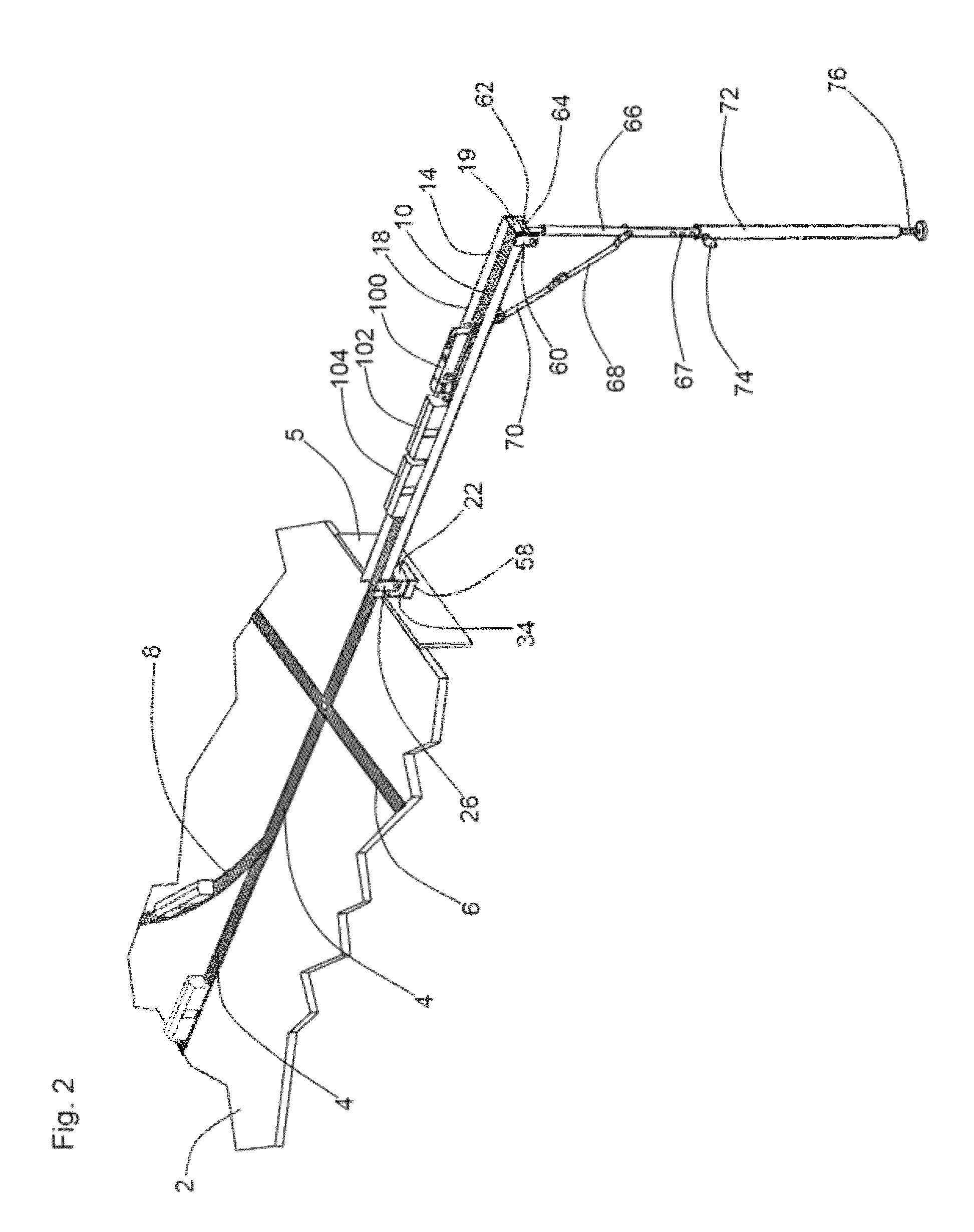

Pitching machine

InactiveUS20090229590A1Simple and safe operationClear passageBall sportsCompressed gas gunsPull forceEngineering

A pitching machine includes a pedestal, a hopper, a guide channel connecting the hopper with a ball rack for guiding a ball in the hopper to the ball rack, and a ball hitting mechanism which includes a striking rod pivotally coupling with the pedestal, a resilient element for applying a pulling force against the striking rod to drive a lower end thereof towards the ball rack, and a striking rod drive mechanism. The striking rod drive mechanism drives the lower end of the striking rod backward, wherein when the striking rod is pivotally and backwardly moved at an utmost limit, the lower end of the striking rod is released, such that the lower end of the striking rod rapidly swings towards the ball rack for hitting the ball thereat. Therefore, the pitching machine is safe and easy to operate and brings convenience for batters.

Owner:TAN GUANGMING

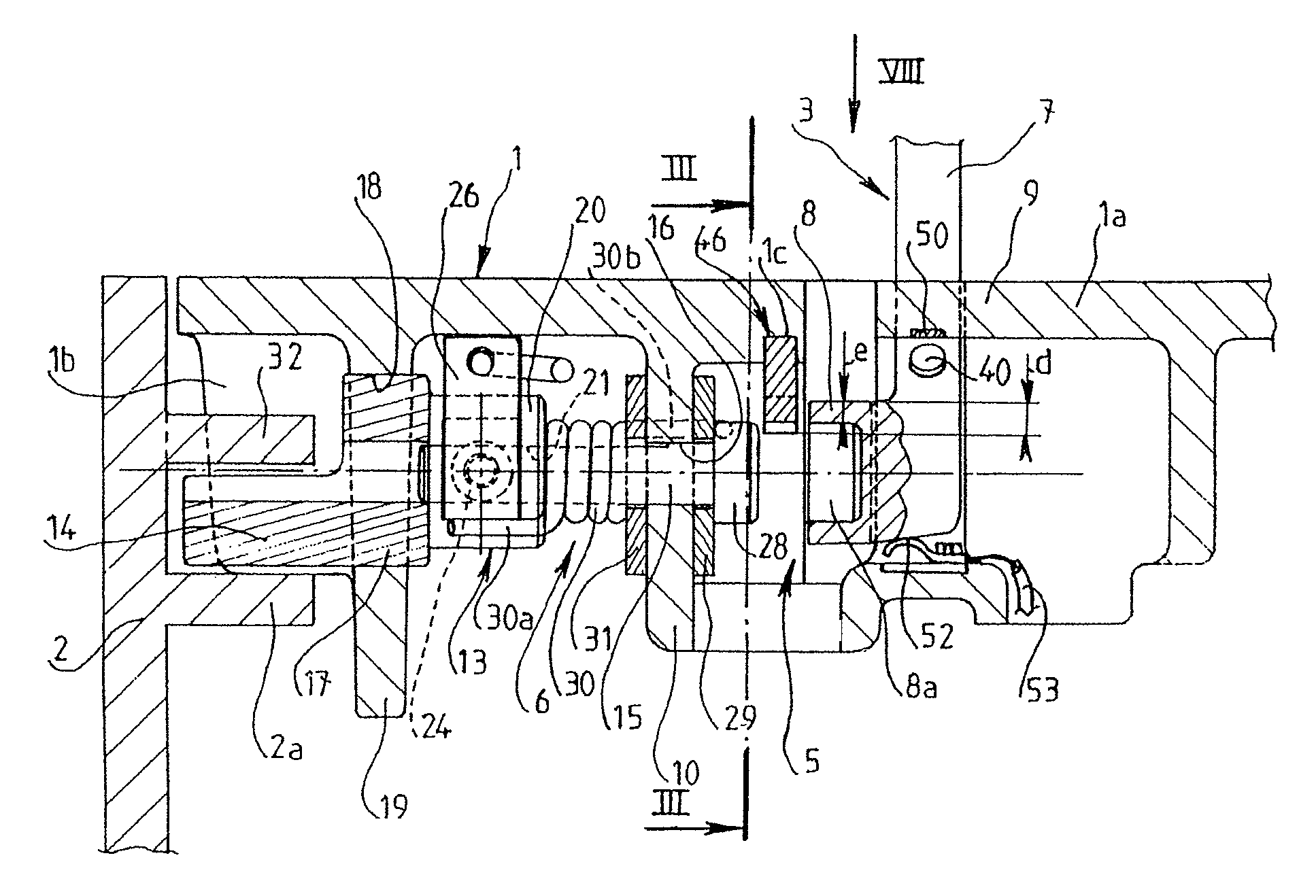

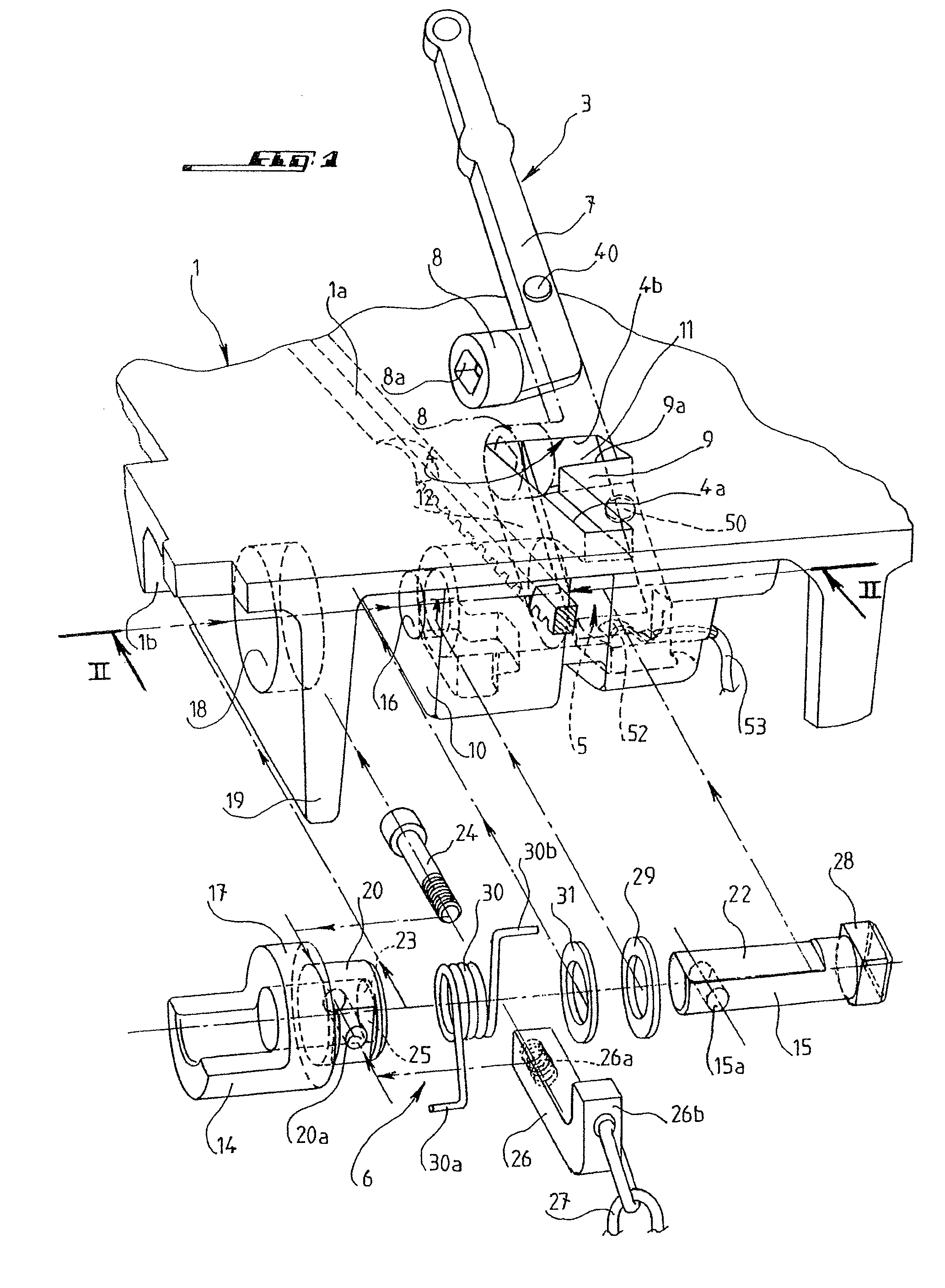

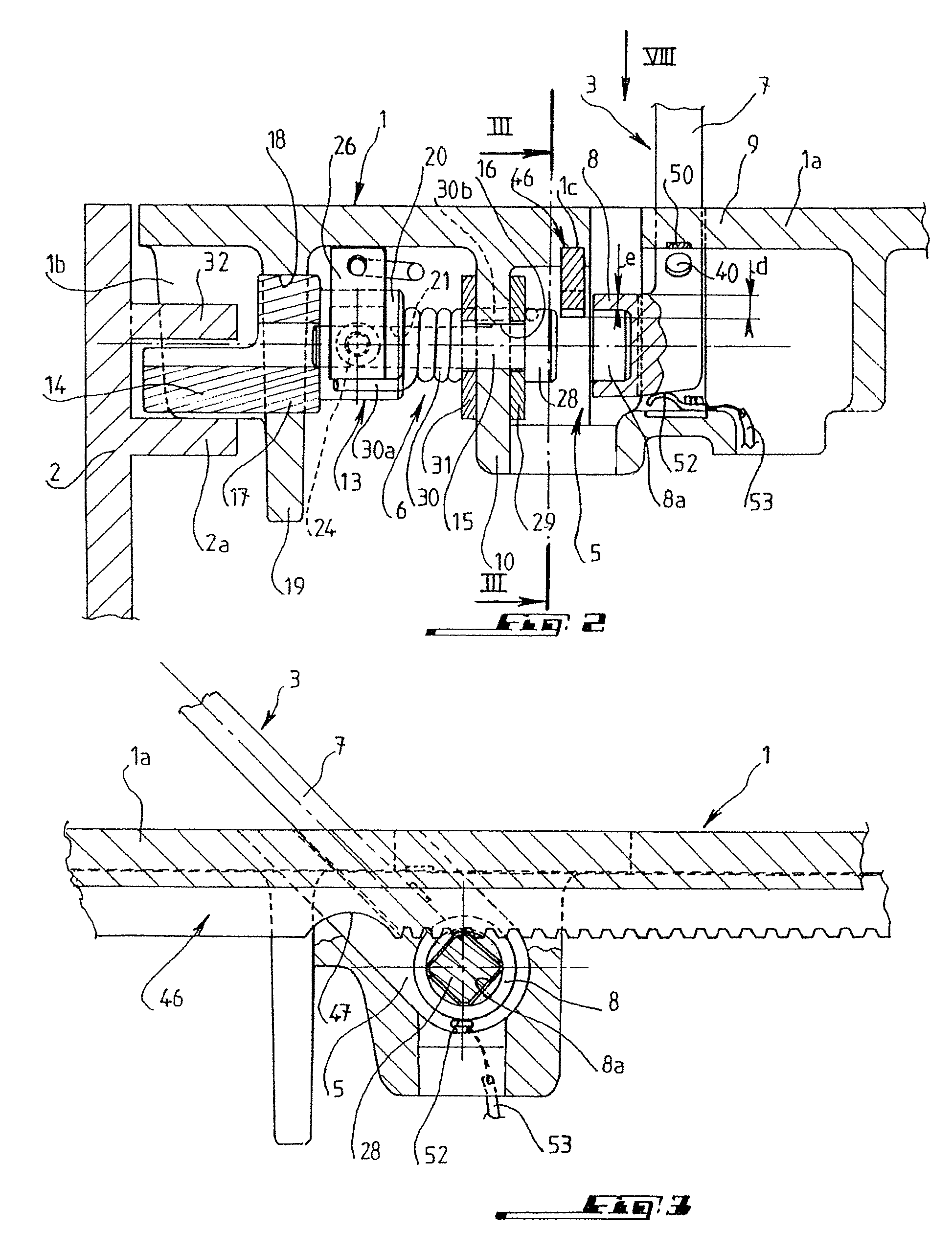

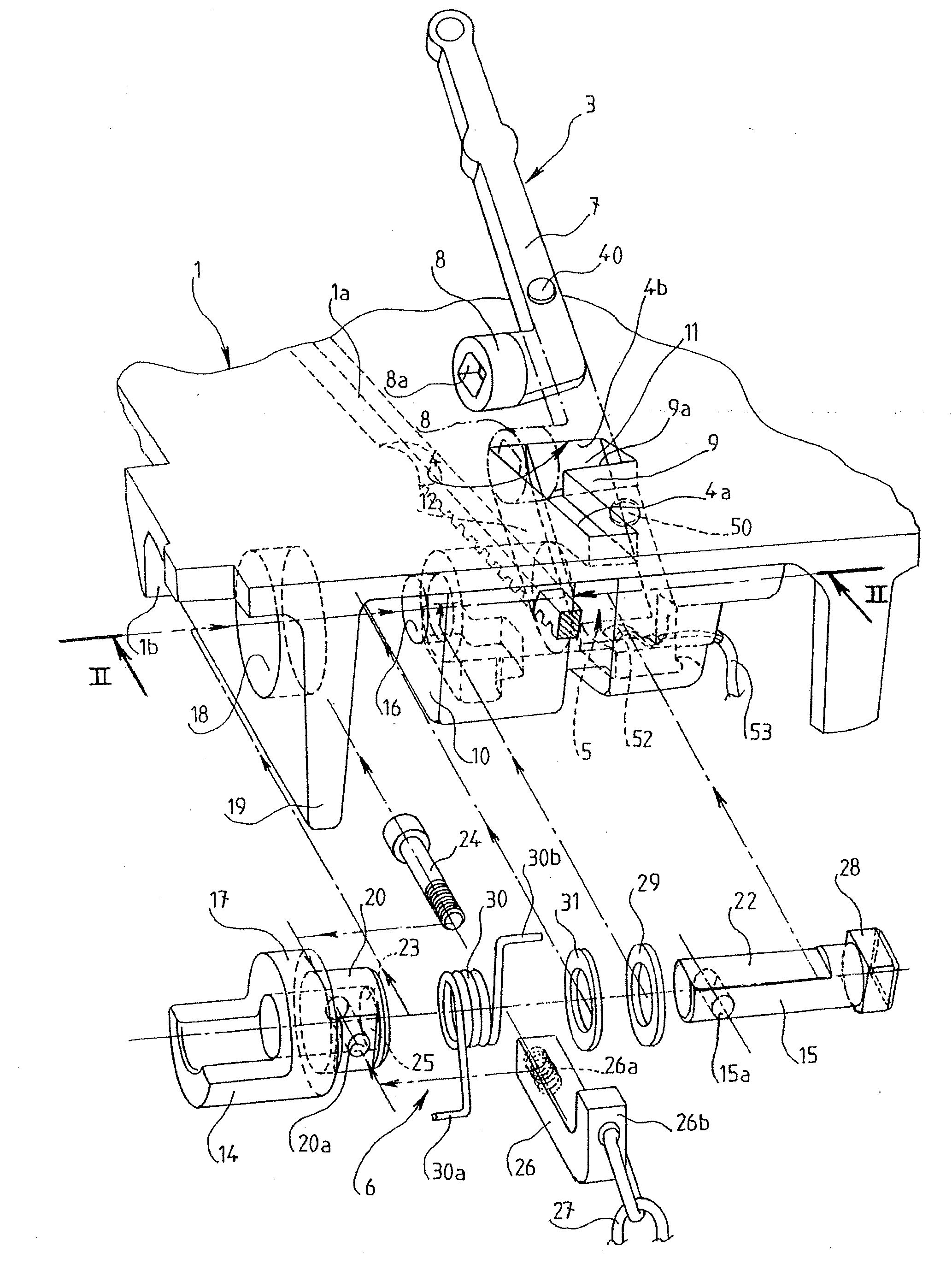

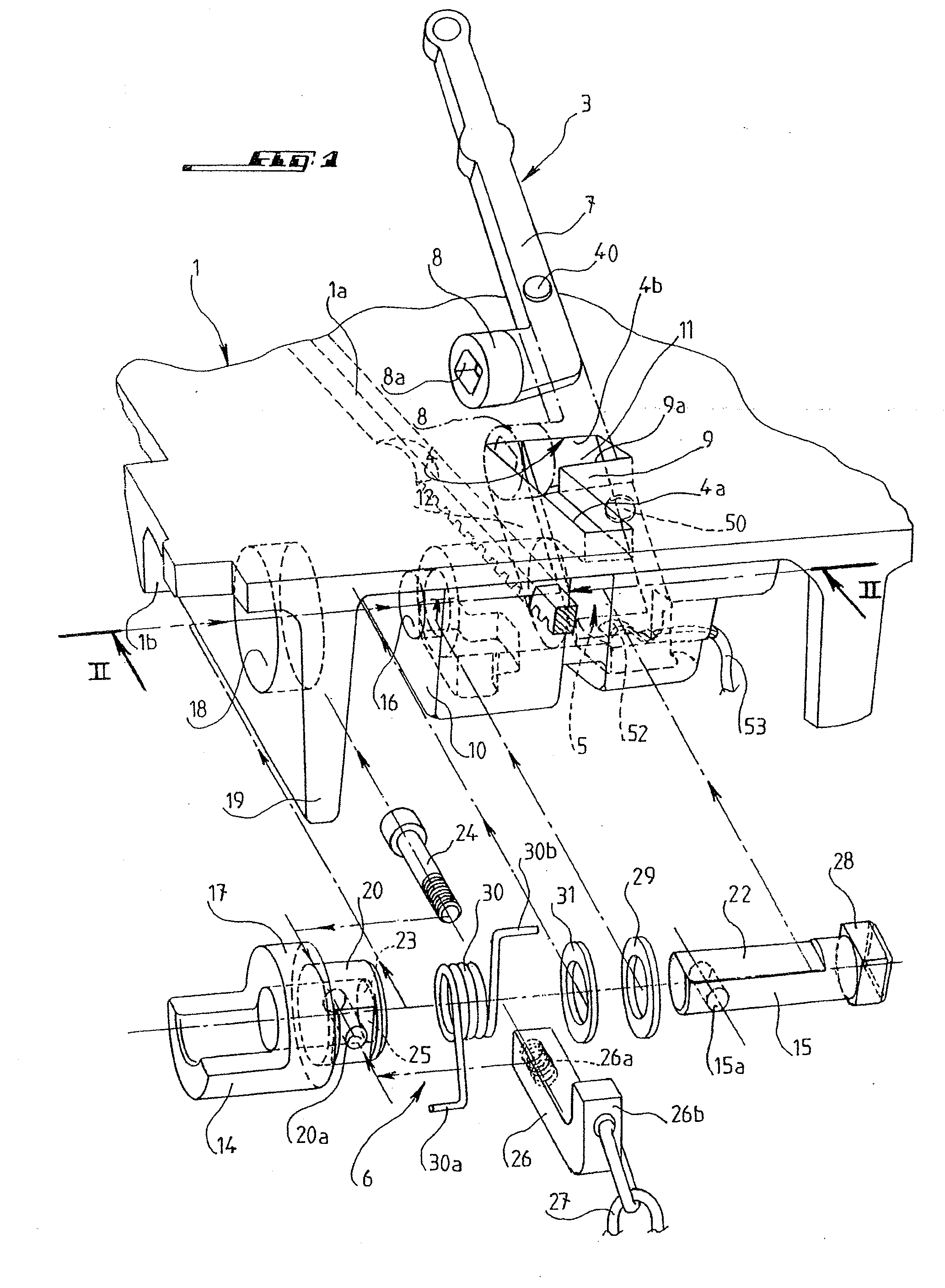

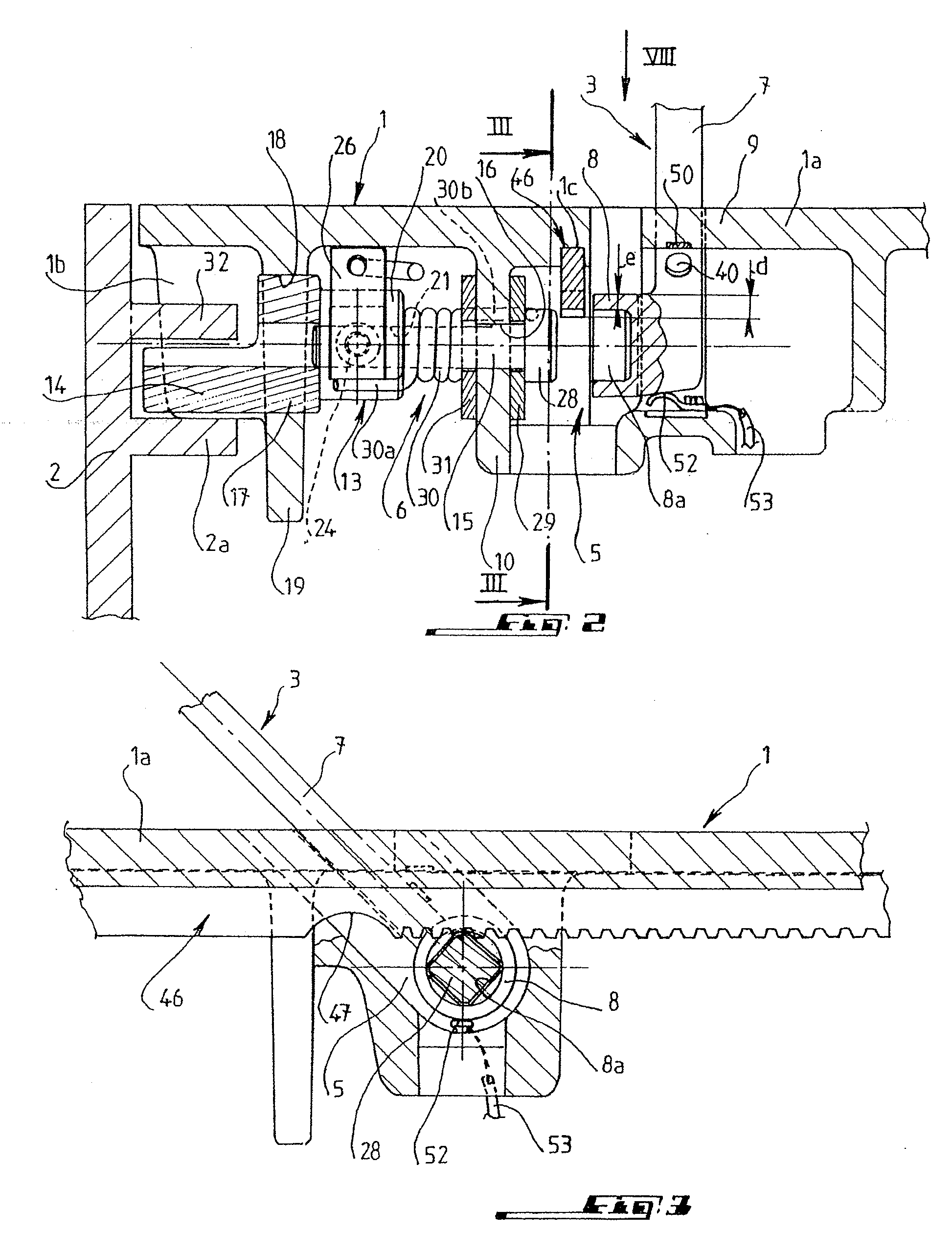

Device for locking and unlocking a plug on a frame using a wrench

The invention relates to a secured device for locking and unlocking a plug on a frame with a wrench. The device has an obstructing component that is mobile with respect to a plug and can be brought from an obstructing position to an unobstructing position in which the wrench can engage a rotor of a bolt when an identification code of the wrench, read by a reader, is in agreement with the code stored in an electronic module that is associated with the plug.

Owner:NORINCO SA

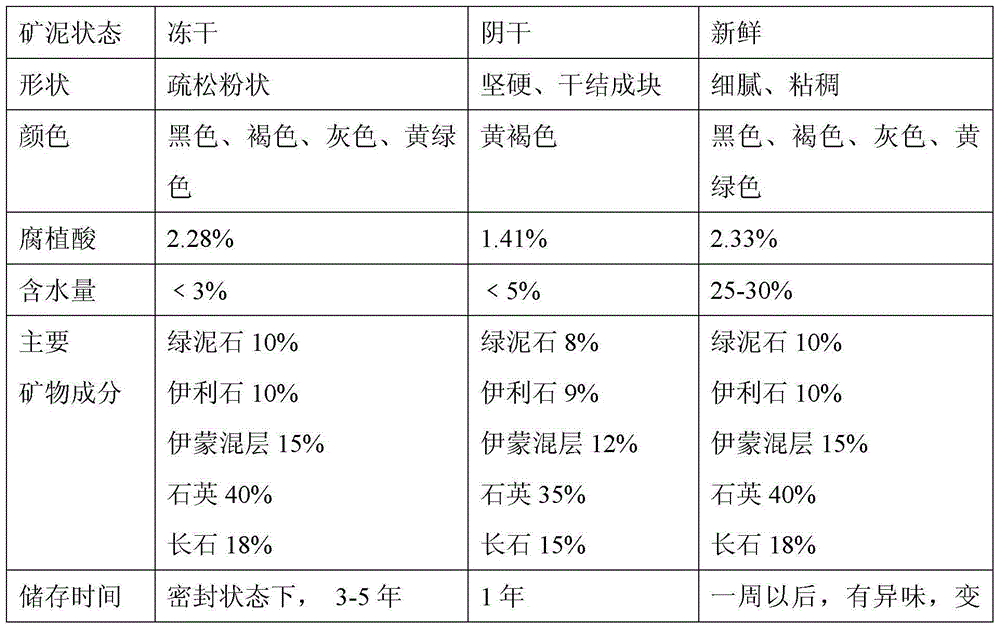

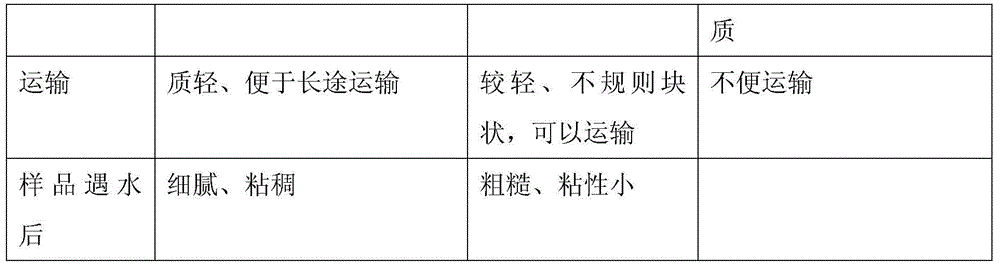

Manufacturing method for Wudalianchi volcano slime freeze-drying powder

InactiveCN104905994AKeep the skeletonLoose morphologyCosmetic preparationsToilet preparationsFreeze-dryingRefrigeration

The invention provides a manufacturing method for Wudalianchi volcano slime freeze-drying powder, relates to a manufacturing method for volcano slime freeze-drying powder and belongs to the slime freeze-drying powder manufacturing field. The manufacturing method is aimed to solve the problems that fresh slime is processed through drying in the sun and stoving, thus slime is hard and dry, color is changed, organic components are lost. The manufacturing method comprises steps: first, frozen slime is prepared; second, the frozen slime is put into a vacuum freeze drier, a vacuum pump and a vacuum gauge are started, when the vacuum degree is more than 10 Pa and less than 15 Pa, the vacuum degree is kept until the temperature of the frozen slime is minus 25- minus 30 DEG C for 1-2h; the vacuum degree is adjusted to be less than 10 Pa, and the vacuum degree is kept for 5-7h, and slime freeze-drying powder is obtained. The Wudalianchi slime freeze-drying powder can be blended into fresh Wudalianchi volcano slime with original components at any time. Ultralow temperature rapid refrigeration is employed, objects can be frozen rapidly in an ultralow temperature, cell wall fracture is prevented and biological activity is maintained.

Owner:黑龙江省科学院火山与矿泉研究所

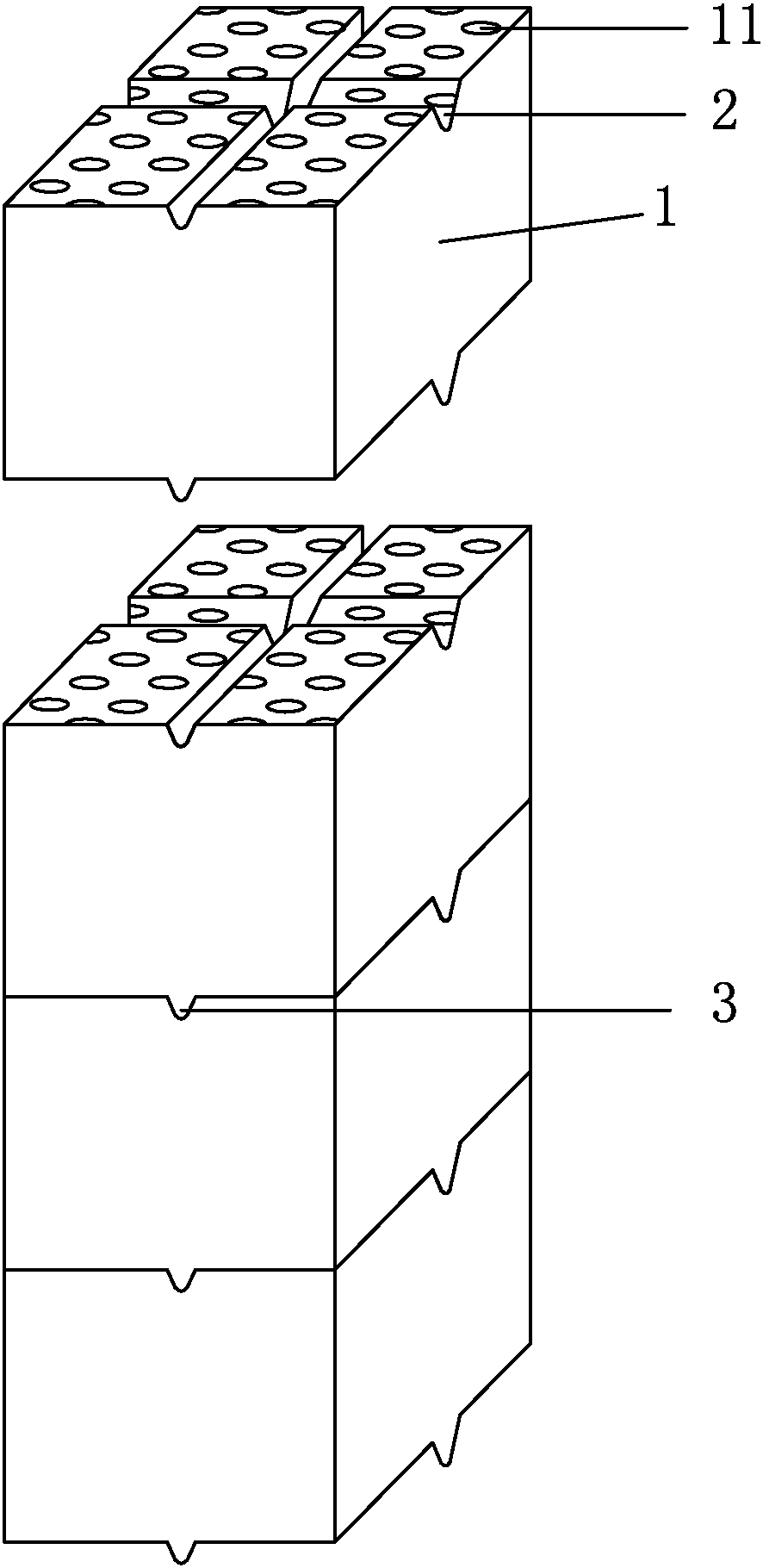

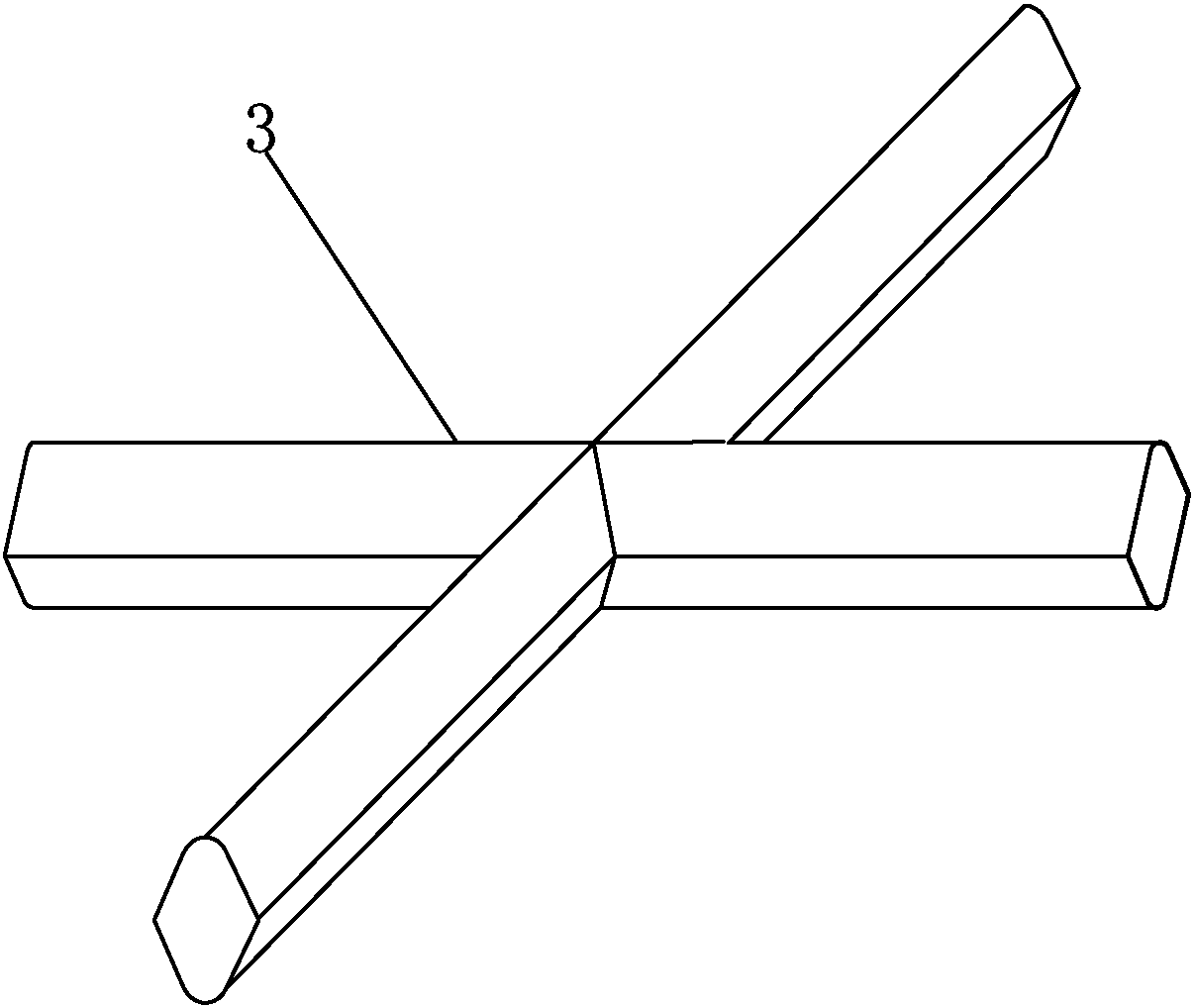

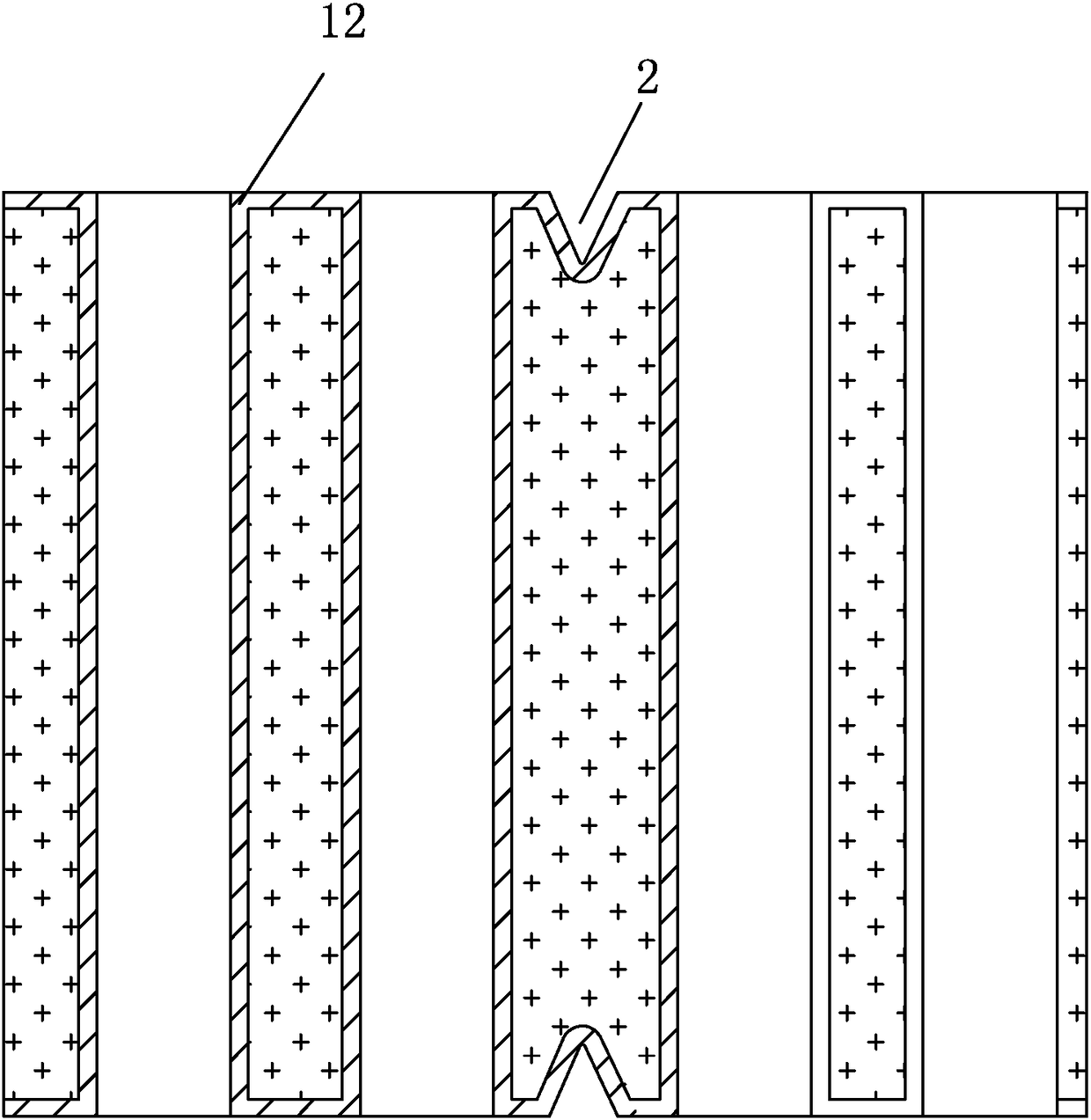

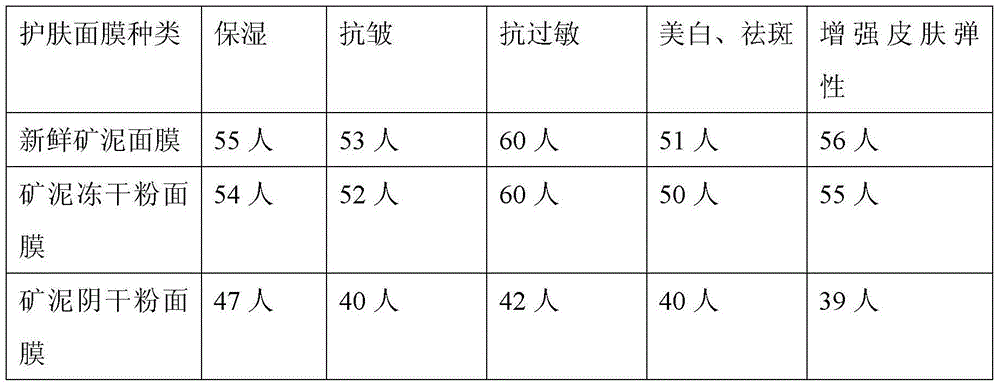

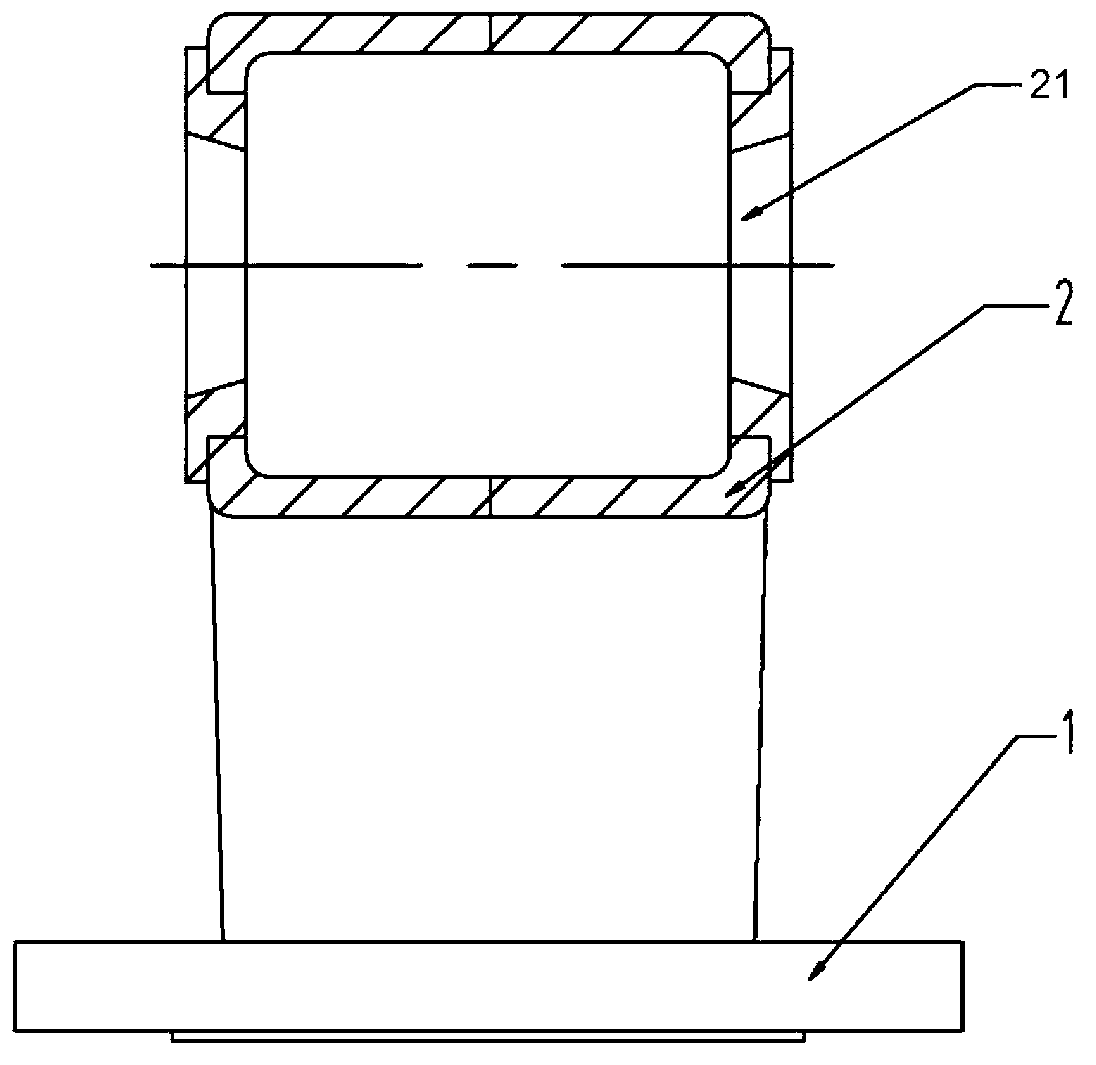

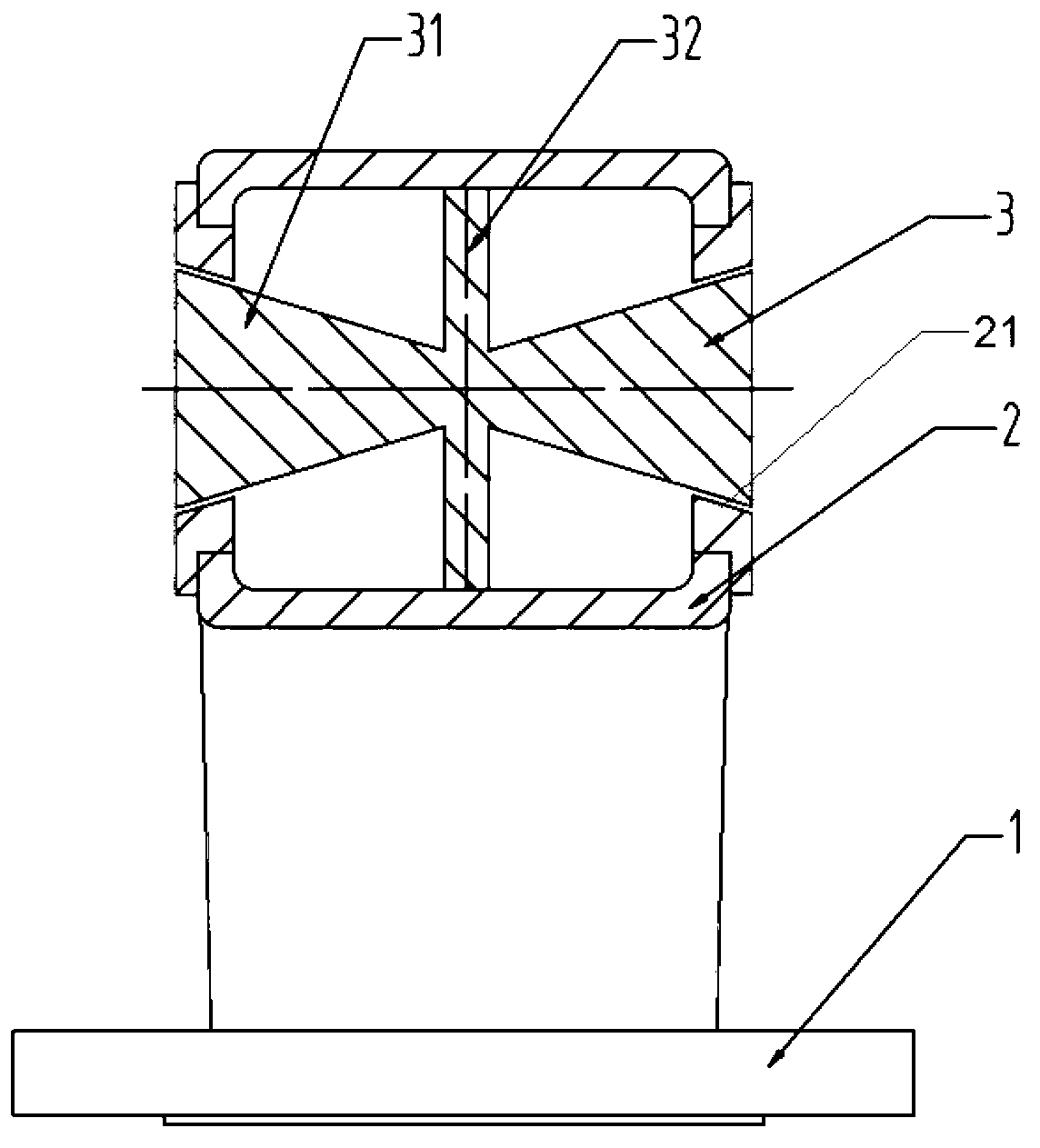

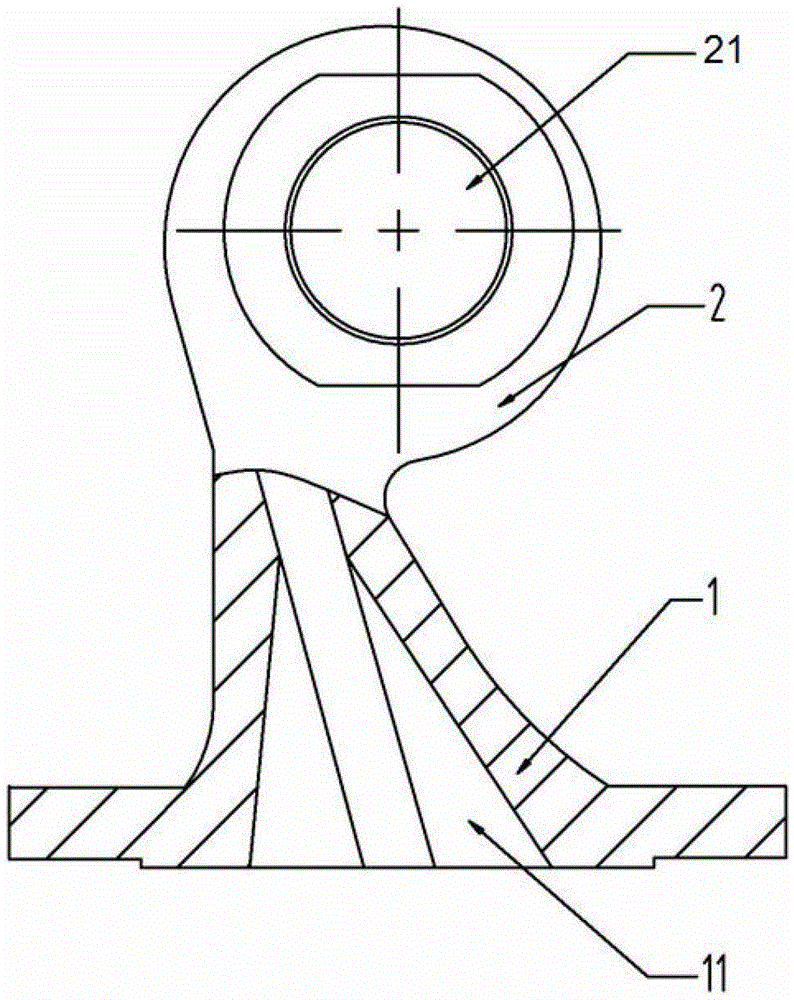

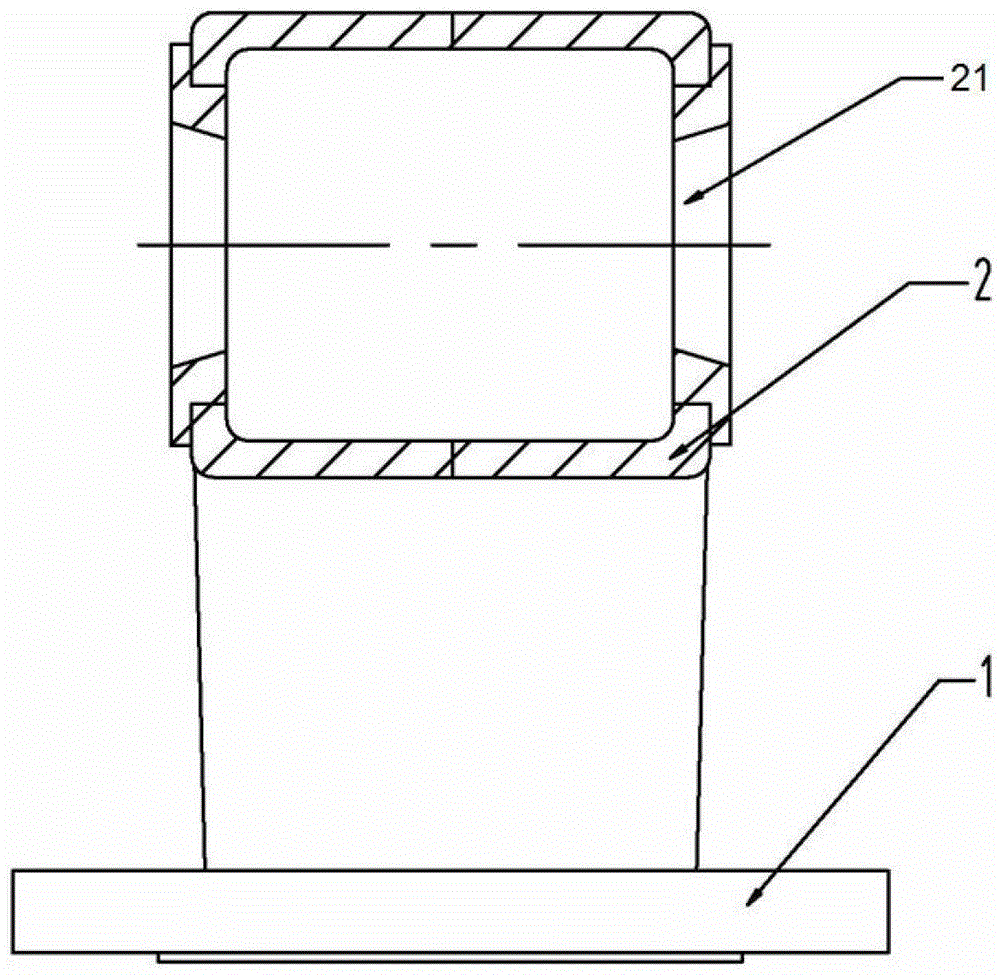

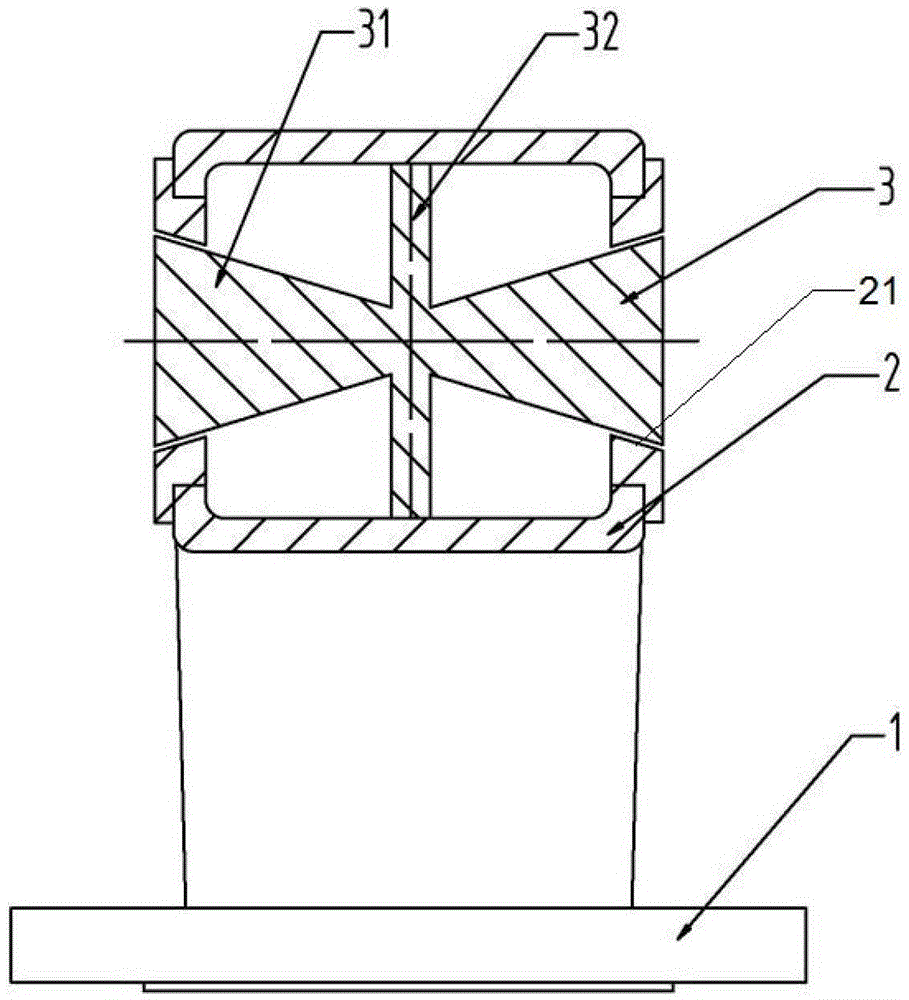

Flue gas purification tower nozzle

The invention discloses a flue gas purification tower nozzle. The flue gas purification tower nozzle comprises a base (1) and a nozzle body (2) which is of a hollow structure and integrated with the base (1), the base (1) is provided with a hollow cavity (11), the hollow cavity (11) of the base (1) is communicated with a hollow cavity inside the nozzle body (2), spray heads (21) are arranged at two ends of the nozzle body (2) respectively, a taper angle of the taper inner wall of each spray head (21) is 90 degrees, and spraying areas form hollow taper spraying shapes, so that low-flow-rate nozzle outlet water quantity can reach liquid flowing section multiple times as large as those of general nozzles.

Owner:WUHU HUAJIE ENVIRONMENTAL PROTECTION EQUIP CO LTD

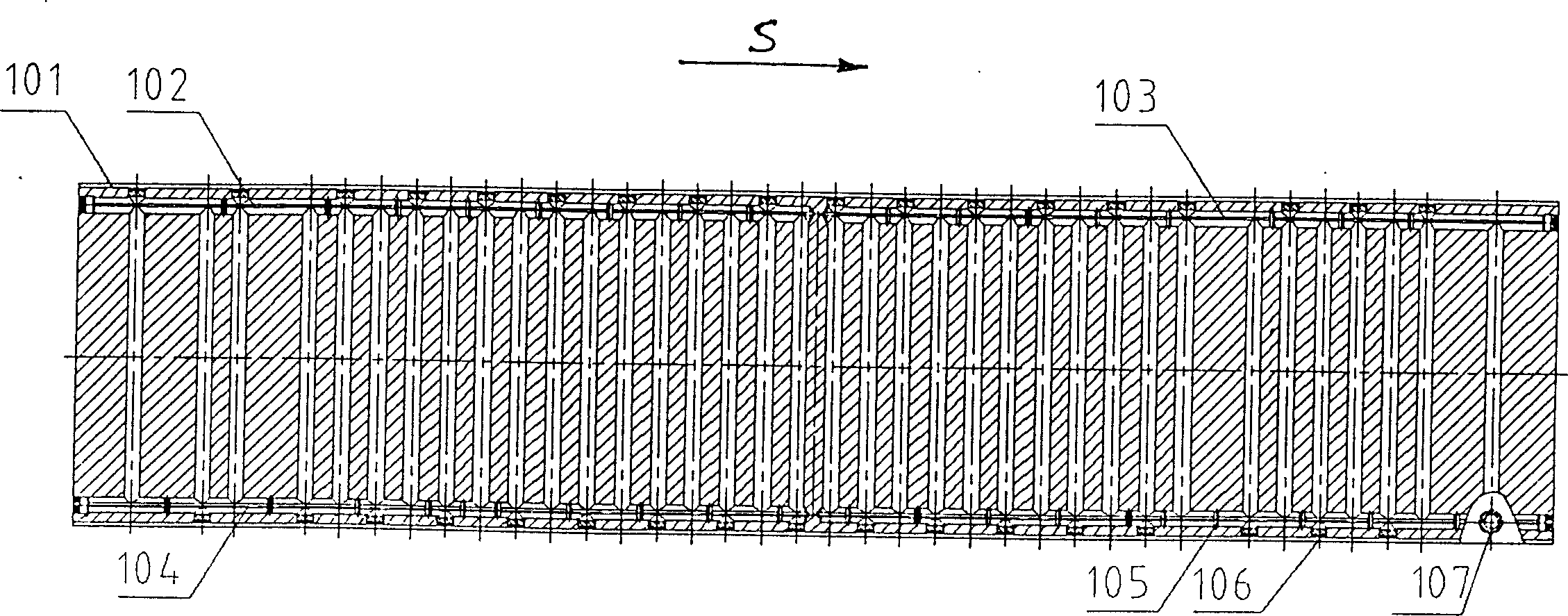

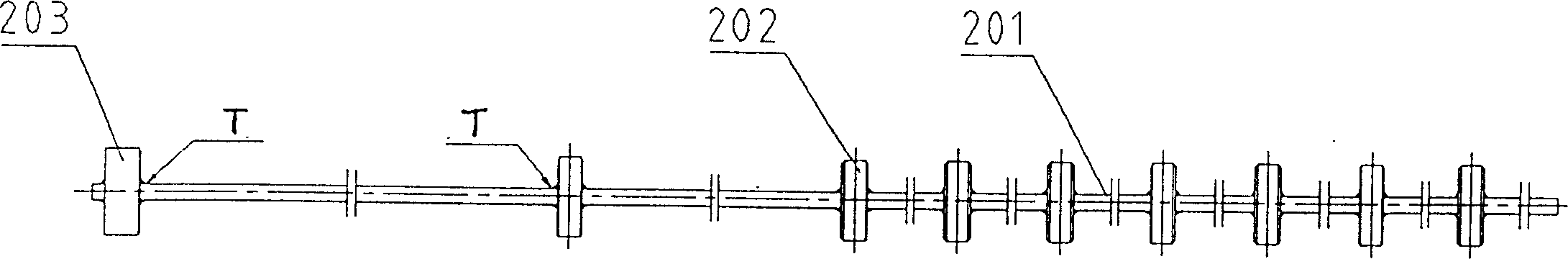

Technique and structure for transversal heating circuit of hot pressing plate of plate continuous press

This invention relates to wood-based plate platen continuous thermal pressed plate structure and especially to the one with level thermal circuit and welding bonding, which comprises the thermal pressed plate, guide lever a, b, c, d, sealed plate, connector, connection lever, isolation plate and sealed plate. The multi-circuit level hole heating pressed plate ensures the heating quality under the condition of large bending radius and adopts column weld bonding to improves the thermal pate safety property, wherein, the level hole heating pressed plate is at the longitude direction by step to be same to the plate blank feeding direction.

Owner:SHANGHAI WOOD-BASED PANEL MASCH CO LTD

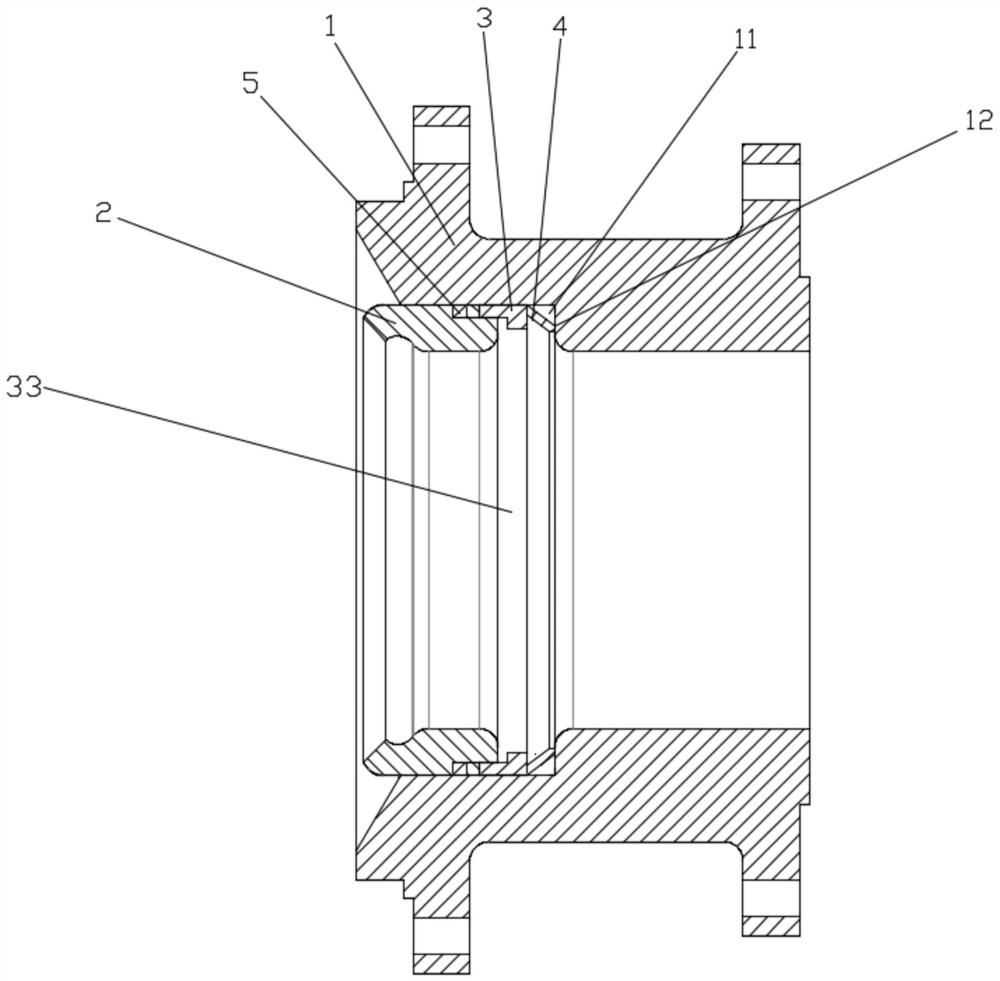

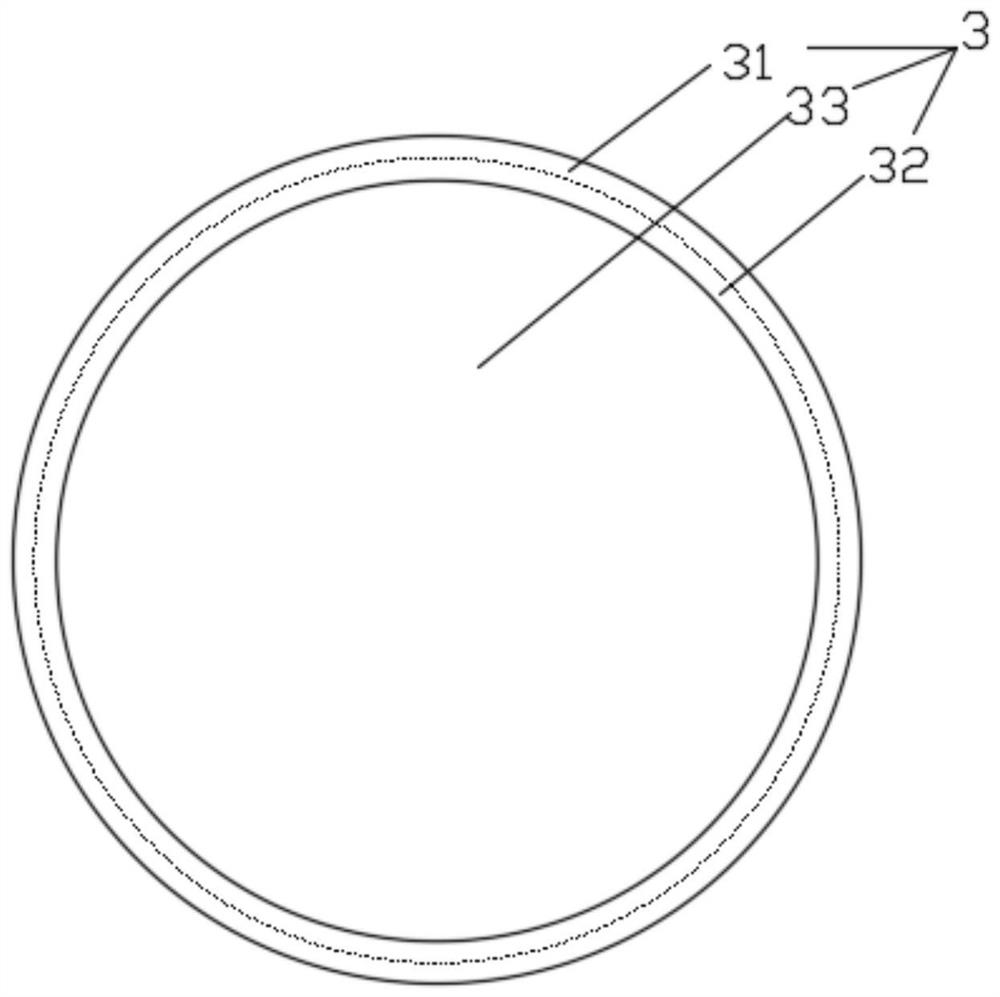

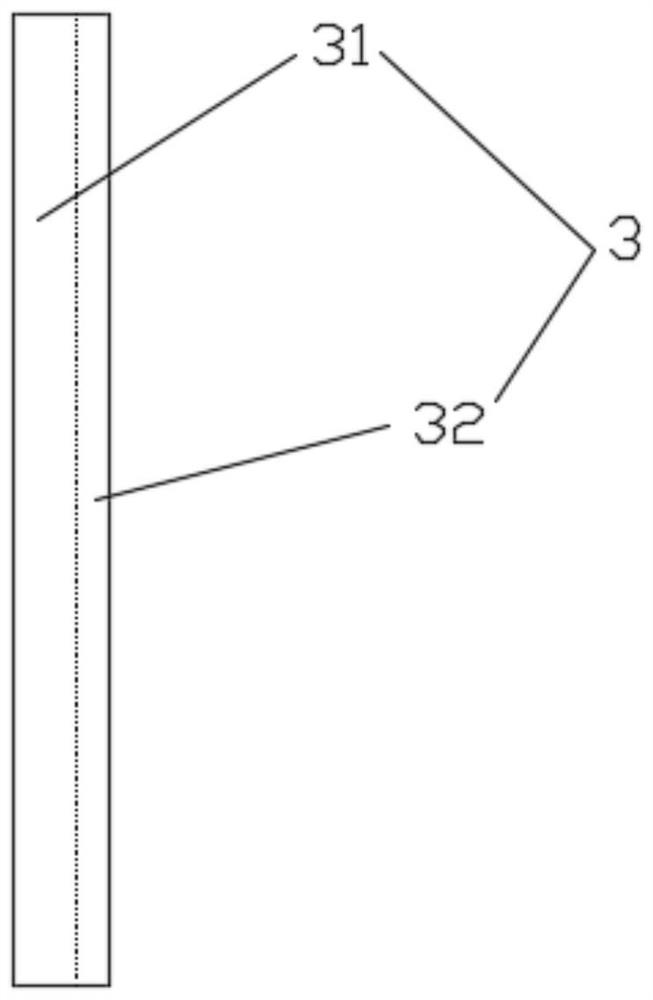

Ash discharging gland, valve seat structure and ball valve

The invention discloses an ash discharging gland. The ash discharging gland comprises a sealing pressing ring and a spring abutting part, a medium distribution channel is formed in the middle of the sealing pressing ring, one end of the sealing pressing ring is used for pressing a sealing part, the sealing pressing ring is fixedly connected with or integrally provided with the spring abutting part, the spring abutting part is used for being abutted with a pre-tightening spring, and an ash discharging opening is formed between the spring abutting part and the sealing pressing ring and communicates with the medium distribution channel and a medium accumulation area. The invention further discloses a valve seat structure comprising the ash discharging gland and a ball valve. According to theash discharging gland, the valve seat structure and the ball valve, medium accumulated between the ash discharging gland and the pre-tightening spring can be automatically discharged, the pre-tightening spring is prevented from losing efficacy due to accumulation of the medium, and the sealing performance between a valve seat and a valve element is guaranteed.

Owner:CHENGDU FLUTECH FLUID EQUIP CO LTD

Device for locking and unlocking a plug on a frame using a wrench

The invention relates to a secured device for locking and unlocking a plug on a frame with a wrench. The device has an obstructing component that is mobile with respect to a plug and can be brought from an obstructing position to an unobstructing position in which the wrench can engage a rotor of a bolt when an identification code of the wrench, read by a reader, is in agreement with the code stored in an electronic module that is associated with the plug.

Owner:NORINCO SA

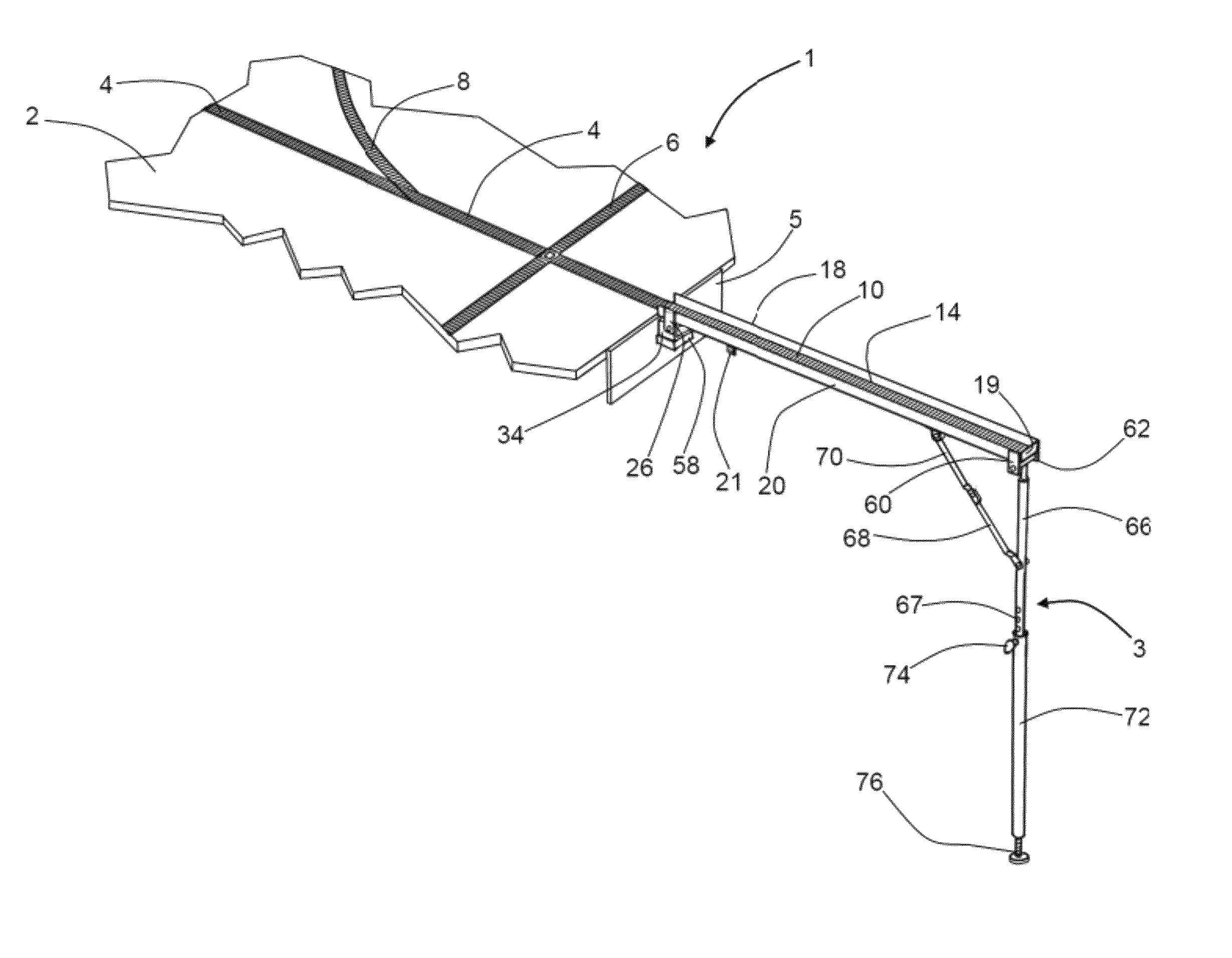

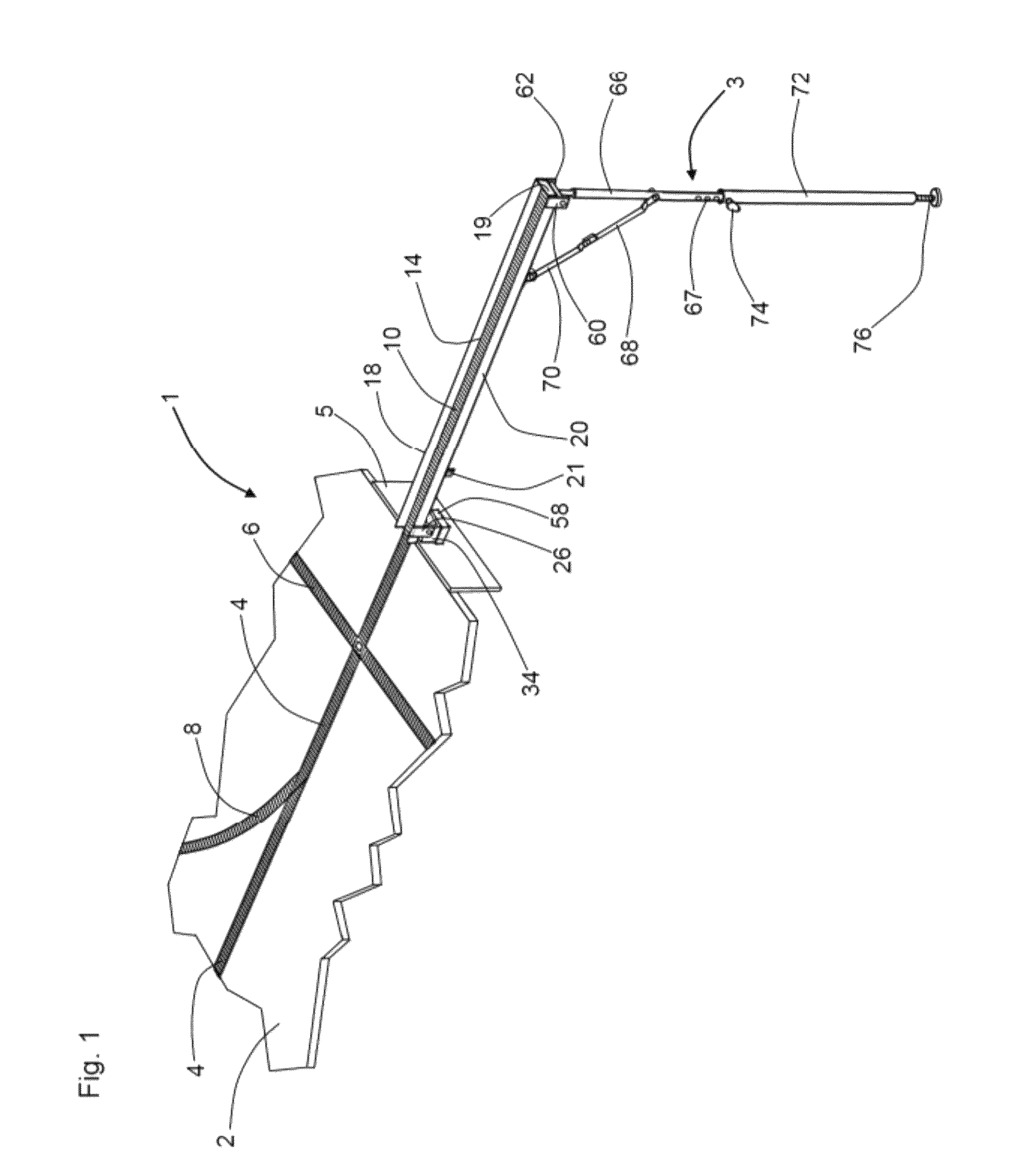

Model railroad assembly

InactiveUS8215567B1Facilitating switch clearanceClear passageMovable tracksModel railwaysEngineeringElectrical and Electronics engineering

A model railroad assembly incorporating a table, an arm having proximal and distal ends, first and second track matrices, the first and second track matrices having electrically positive rails and electrically negative rails, the first track matrix being positioned upon the upper surface of the table, and the second track matrix being positioned upon the arm's upper surface; a hinge connector operatively attaching the arm to the table, the hinge connector facilitating movement of the arm between first and second positions; and a plurality of pivoting electric switch contacts adapted for electrifying the second track matrix upon movement of the arm to the first position, and for de-electrifying the second track matrix upon movement of the arm toward the second position.

Owner:SCHLUETER WAYNE +1

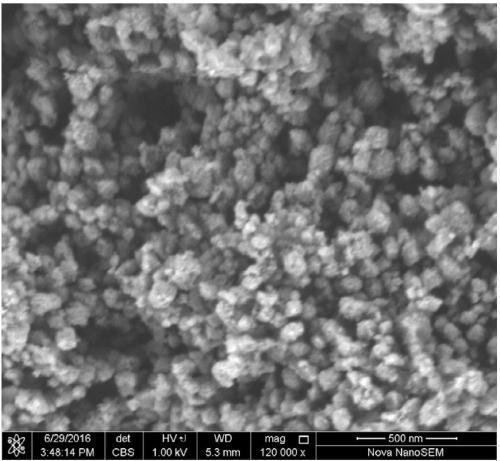

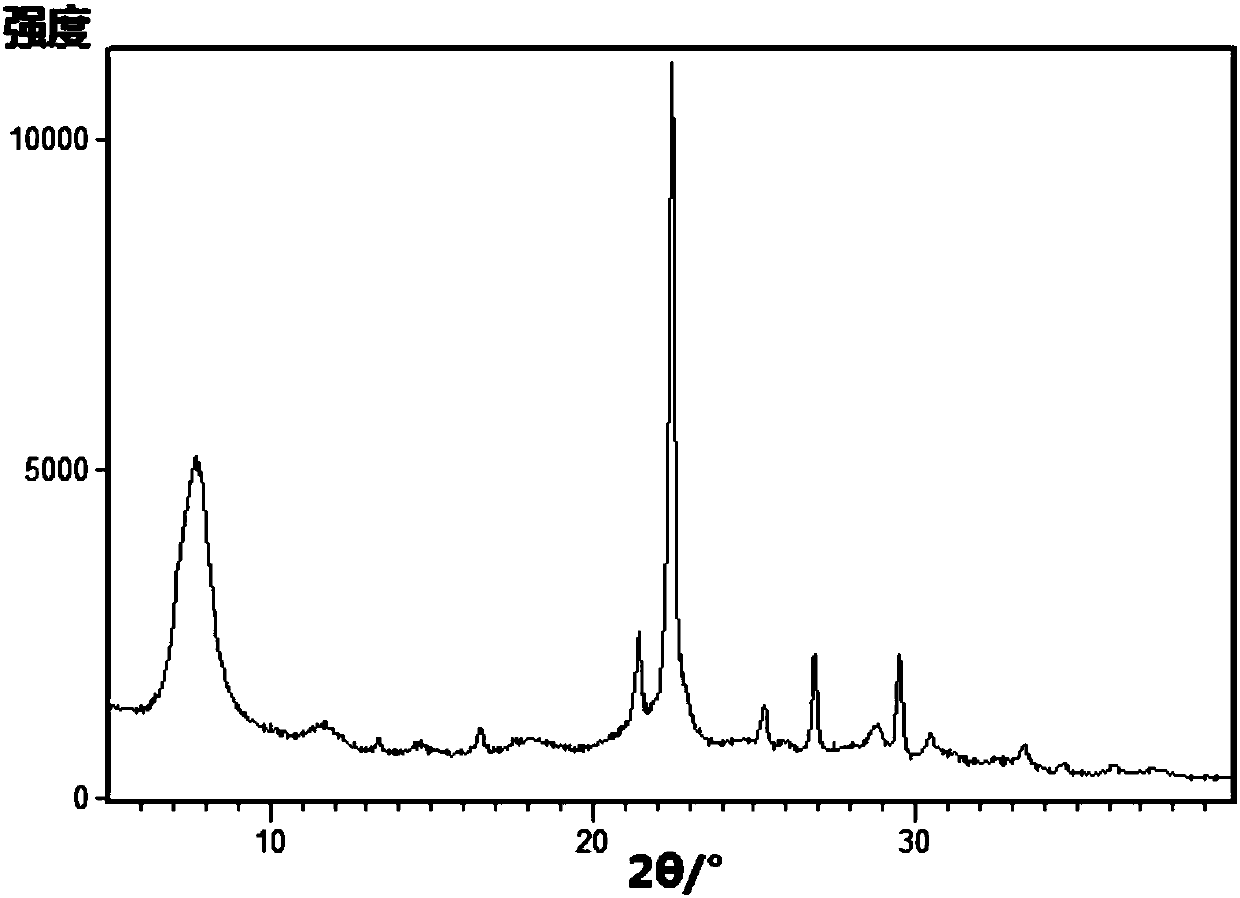

Preparation method of beta molecular sieve

ActiveCN110143602AHigh yieldHigh crystallinityNanotechnologyCrystalline aluminosilicate zeolitesMolecular sieveIsomerization

The invention discloses a preparation method of a beta molecular sieve. The method comprises the following steps: step 1, synthesizing initial gel: mixing a silicon source, an aluminum source, an alkaline metal source and water, and performing uniform stirring to synthesize the initial gel, wherein based on SiO2 of the silicon source, Al2O3 of the aluminum source, and Na2O of the alkaline metal source, molar ratios of raw materials for synthesizing the initial gel are as follows: SiO2 / Al2O3=(30-150):1, Na2O / SiO2=(0.03-0.35):1, and H2O / SiO2=(3.0-50.0):1; step 2, performing microwave treatment on the initial gel: adding a beta molecular sieve seed crystal into the initial gel prepared in the step 1, wherein a ratio of silicon to aluminum in the seed crystal is as follows: SiO2 / Al2O3=(20-100):1, and the adding amount is 3%-25% by mass of SiO2, performing uniform mixing, and performing microwave heating treatment to obtain crystallized precursor gel; and step 3, performing a crystallization reaction: performing a crystallization reaction on the crystallized precursor gel obtained in the step 2 by microwave heating to obtain the beta molecular sieve product, wherein the reaction temperature is 140-180 DEG C, and the reaction time is 4-20 h. According to the method provided by the invention, the molecular sieve obtained by the method has a smaller particle size, a rich pore structureand a relatively-smooth channel, thereby facilitating promoting catalytic cracking and isomerization.

Owner:PETROCHINA CO LTD

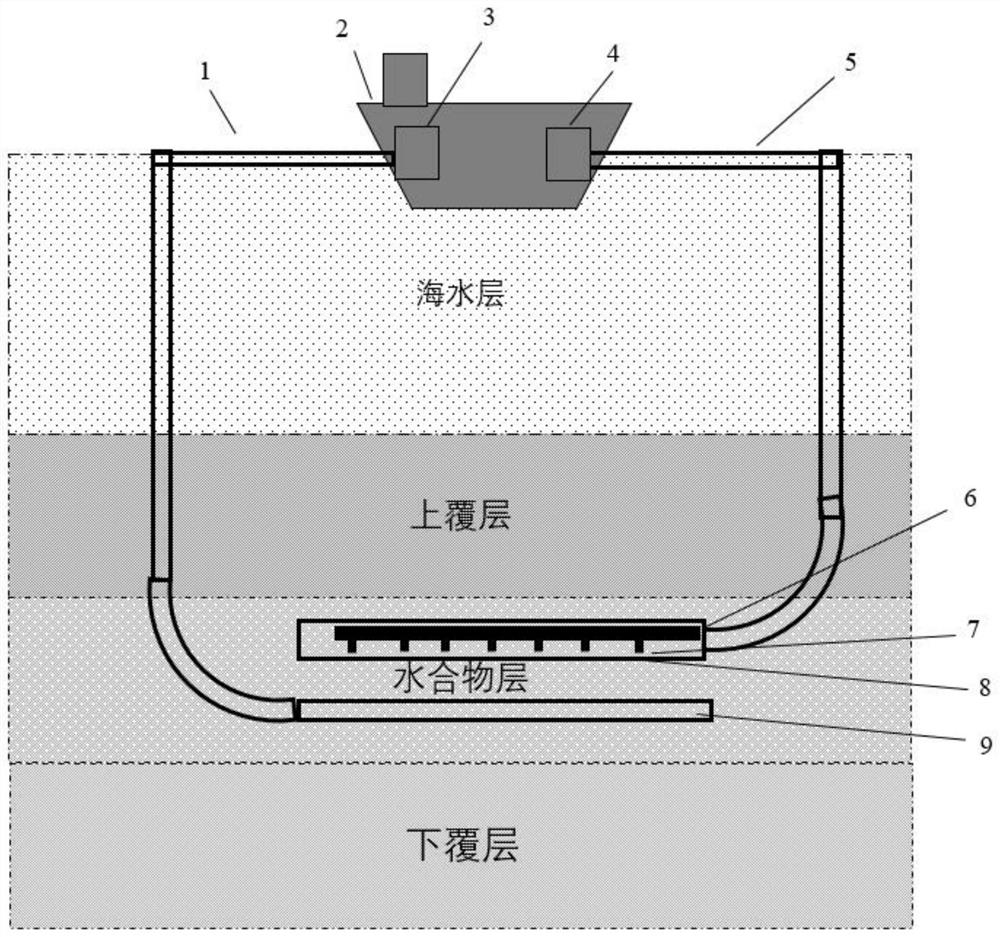

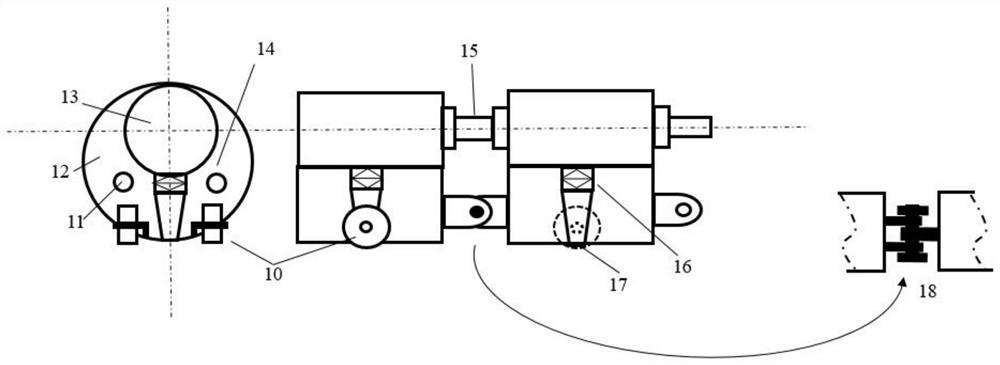

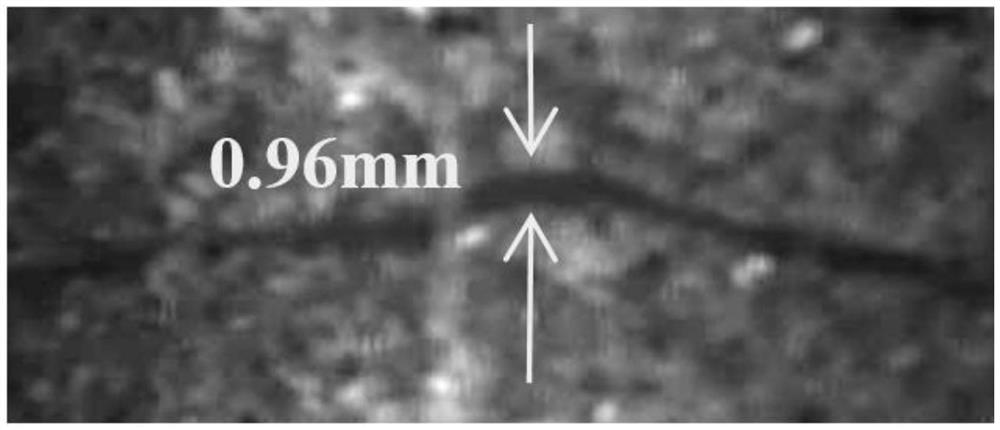

Nitrogen and carbon dioxide mixed gas jet device in horizontal well and mining method

PendingCN114320249AClear passageImprove efficiencyFluid removalOther gas emission reduction technologiesChemistryHigh carbon dioxide

The invention discloses a nitrogen and carbon dioxide mixed gas jet device in a horizontal well and an exploitation method, and relates to the technical field of energy exploitation, the nitrogen and carbon dioxide mixed gas jet device in the horizontal well comprises an offshore platform, a natural gas processing unit and a pressurizing unit, a gas injection horizontal well is arranged on a hydrate layer of a gas exploitation pipe, and a mixed gas jet unit and a nozzle assembly are arranged in the gas injection horizontal well; the mixed gas jet unit is used for mixing nitrogen and carbon dioxide and then dispersedly injecting the nitrogen and the carbon dioxide into a hydrate deposition layer of a hydrate layer through a nozzle assembly, and methane gas of the hydrate deposition layer is replaced by mixed gas of the nitrogen and the carbon dioxide; the gas production horizontal well is used for collecting methane gas and conveying the methane gas to the natural gas treatment unit. Gap injection of mixed gas can be achieved, smoothness of a replacement gas channel is guaranteed, and the efficiency of replacing methane with carbon dioxide is improved.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Toilet area for an aircraft cabin, in particular for a flying wing aircraft

ActiveUS9469401B2Easy to implementClear passageAircraft ejection meansToilet fittingsJet aeroplaneToilet

A toilet area for an aircraft cabin comprising an access door and housing a toilet bowl. The toilet area also comprises an evacuation exit, the access door occupying a closed position in the toilet area in a toilet configuration and a folded position in the toilet area in an evacuation configuration. Usage in particular in a flying wing aircraft is provided.

Owner:AIRBUS OPERATIONS (SAS)

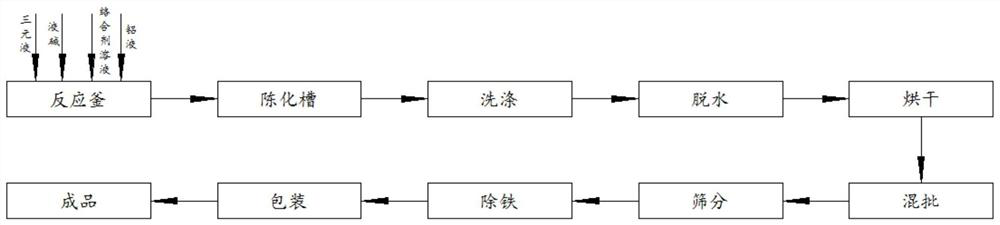

Preparation method of nickel-cobalt-aluminum ternary positive electrode material precursor

PendingCN113582255AClear passageFacilitates insertion and extractionNickel compoundsDiamineAmmonium sulphide

The invention relates to a preparation method of a nickel-cobalt-aluminum ternary positive electrode material precursor. The preparation method comprises the following steps: respectively preparing a nickel-cobalt binary solution, a sodium metaaluminate solution, a liquid alkali solution and a complexing agent solution, wherein the complexing agent is one or more of ammonium sulfite, ammonium bisulfite, ammonium sulfate, ammonium bisulfate, ammonium sulfide, ammonium hydrosulfide, diamine pentasulfide and ammonium thiosulfate; adding the base solution into the reaction kettle, introducing nitrogen, and controlling the temperature and the stirring rotating speed; adding the nickel-cobalt binary solution, the sodium metaaluminate solution, the liquid caustic soda solution and the complexing agent solution into a reaction kettle in a parallel flow manner for reaction; when the particle D50 generated by the reaction reaches 3.0-18.0 [mu]m, stopping feeding; performing aging, washing and impurity removal, dehydration, drying, batch mixing, screening and iron removal on the obtained material, and performing packaging to obtain a finished product. In the process of synthesizing the nickel-cobalt-aluminum ternary precursor, the variety and the adding amount of the added complexing agent are adjusted, and the problems that pores in the precursor are few and are irregularly distributed are solved.

Owner:JINGMEN GEM NEW MATERIAL

A flue gas purification tower nozzle

The invention discloses a flue gas purification tower nozzle. The flue gas purification tower nozzle comprises a base (1) and a nozzle body (2) which is of a hollow structure and integrated with the base (1), the base (1) is provided with a hollow cavity (11), the hollow cavity (11) of the base (1) is communicated with a hollow cavity inside the nozzle body (2), spray heads (21) are arranged at two ends of the nozzle body (2) respectively, a taper angle of the taper inner wall of each spray head (21) is 90 degrees, and spraying areas form hollow taper spraying shapes, so that low-flow-rate nozzle outlet water quantity can reach liquid flowing section multiple times as large as those of general nozzles.

Owner:WUHU HUAJIE ENVIRONMENTAL PROTECTION EQUIP CO LTD

A kind of preparation method of β molecular sieve

ActiveCN110143602BHigh yieldHigh crystallinityNanotechnologyCrystalline aluminosilicate zeolitesMolecular sieveReaction temperature

The invention discloses a preparation method of beta molecular sieve. Step 1, synthesizing initial gel: mix silicon source, aluminum source, alkaline metal source, water, stir evenly, and synthesize initial gel; silicon source is SiO 2 In terms of aluminum source as Al 2 o 3 In terms of alkaline metal sources as Na 2 In terms of O, the molar ratio of raw materials for synthesizing the initial gel is: SiO 2 / Al 2 o 3 =30~150:1, Na 2 O / SiO 2 =0.03~0.35:1, H 2 O / SiO 2 =3.0~50.0:1; step 2, microwave treatment of the initial gel: add β molecular sieve seed crystals to the initial gel prepared in step 1, the ratio of silicon to aluminum to SiO 2 / Al 2 o 3 =20~100:1, the amount added is calculated as SiO by mass 2 3% to 25% of the mass, mixed evenly and heated with microwaves to obtain a crystallized precursor gel; step 3, crystallization reaction: crystallize the crystallized precursor gel obtained in step 2 with microwave heating Reaction, the reaction temperature is 140°C-180°C, the reaction time is 4-20h, and the β molecular sieve product is obtained. The molecular sieve obtained by the method of the invention has small particle size, rich pore structure, and relatively unobstructed channels, which is beneficial to promoting catalytic cracking and isomerization.

Owner:PETROCHINA CO LTD

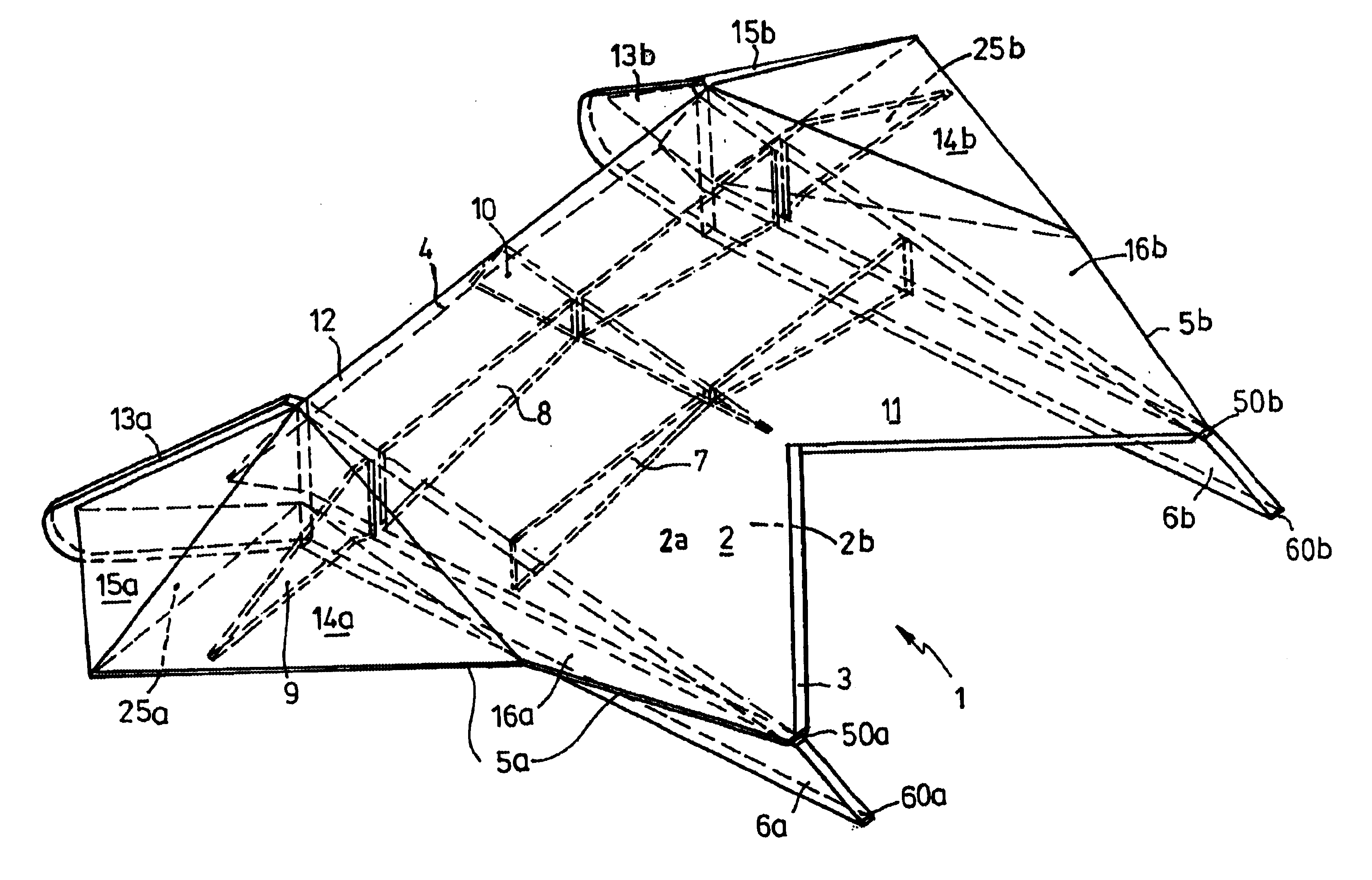

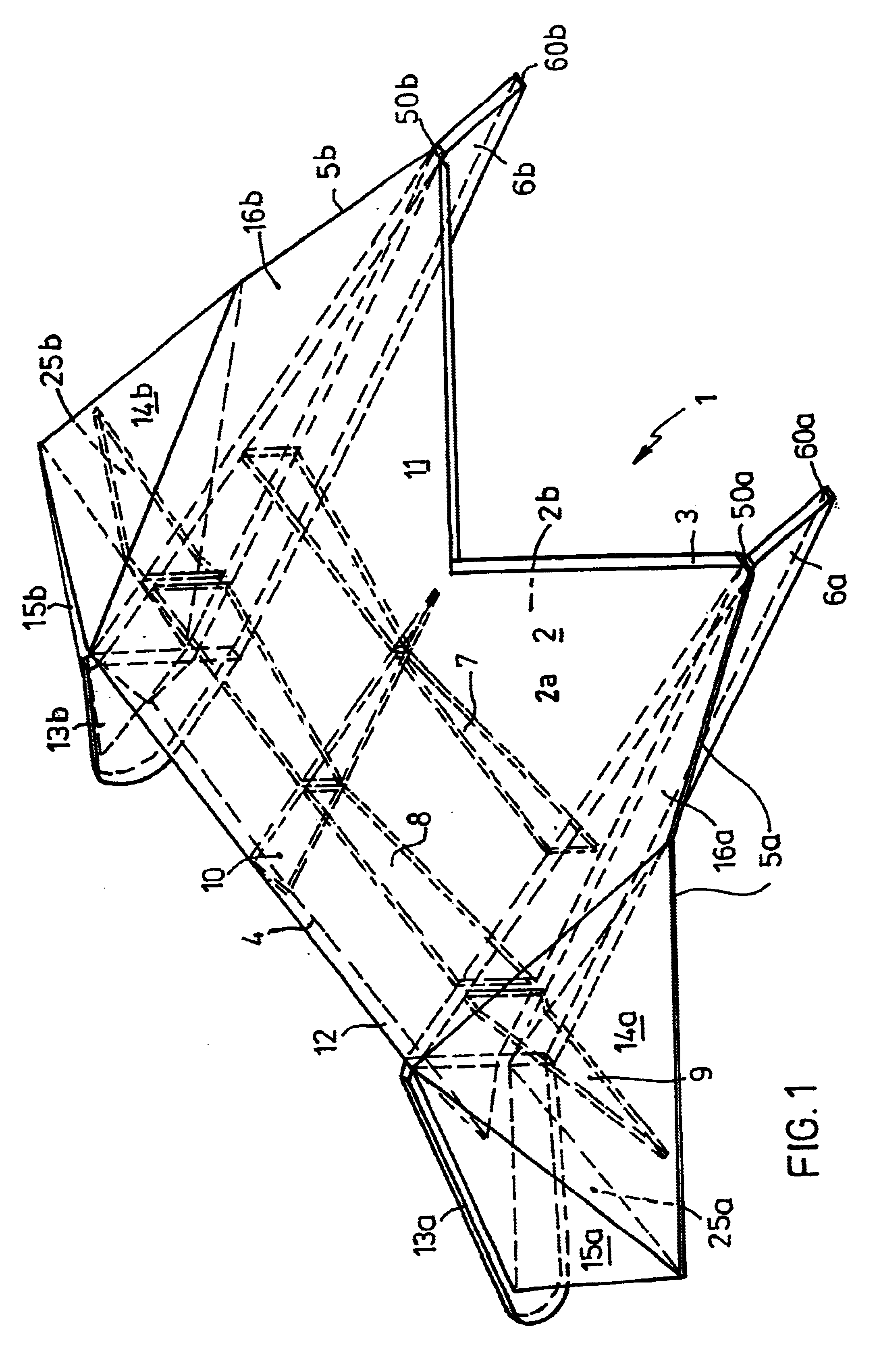

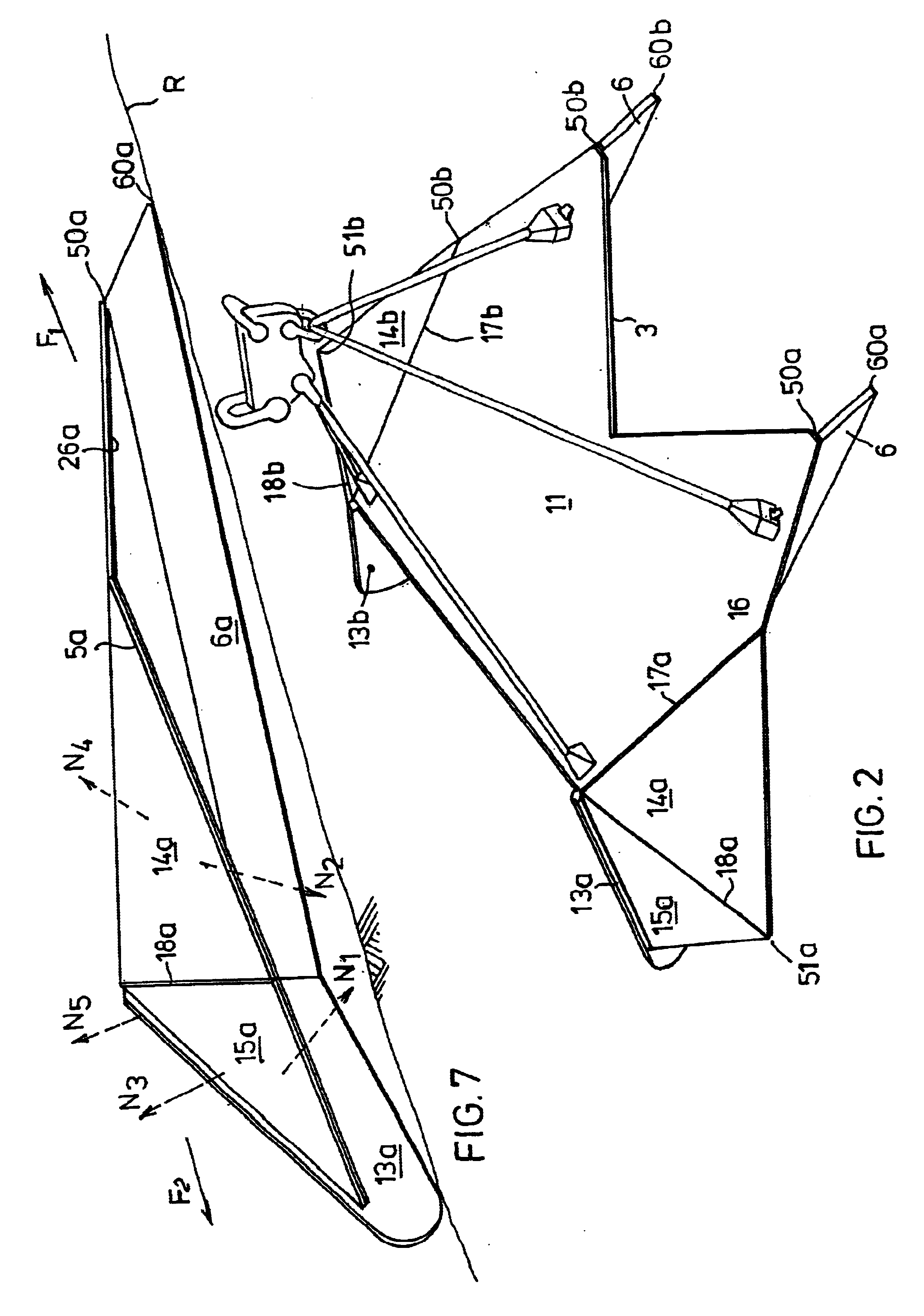

Anchor fluke

Anchor fluke (1) having a hollow plate-shaped body adapted for attachment to a shank and / or anchor lines, with a longitudinal axis and a front penetration edge (3) and a rear trailing edge (4), which are located at a distance from one another in the direction of the longitudinal axis, wherein the fluke has a plane of symmetry that contains the longitudinal axis and is substantially perpendicular to the plate-shaped body. The hollow plate-shaped body has an upper surface (2a) with a centre of gravity and a lower surface (2b) which surfaces are bounded by the penetration edge, the trailing edge and lateral edges (5a, 5b) and wherein the body, at the lower surface, substantially between the edges, is provided with surfaces for counteracting a rolling movement about the longitudinal axis during penetration of the anchor fluke in an anchorage ground, and with vertical trailing edges (13a, 13b) for counteracting a yawing movement about an axis that is perpendicular to the longitudinal axis and is located in the plane of symmetry during the penetration in an anchorage ground.

Owner:STEVLOS

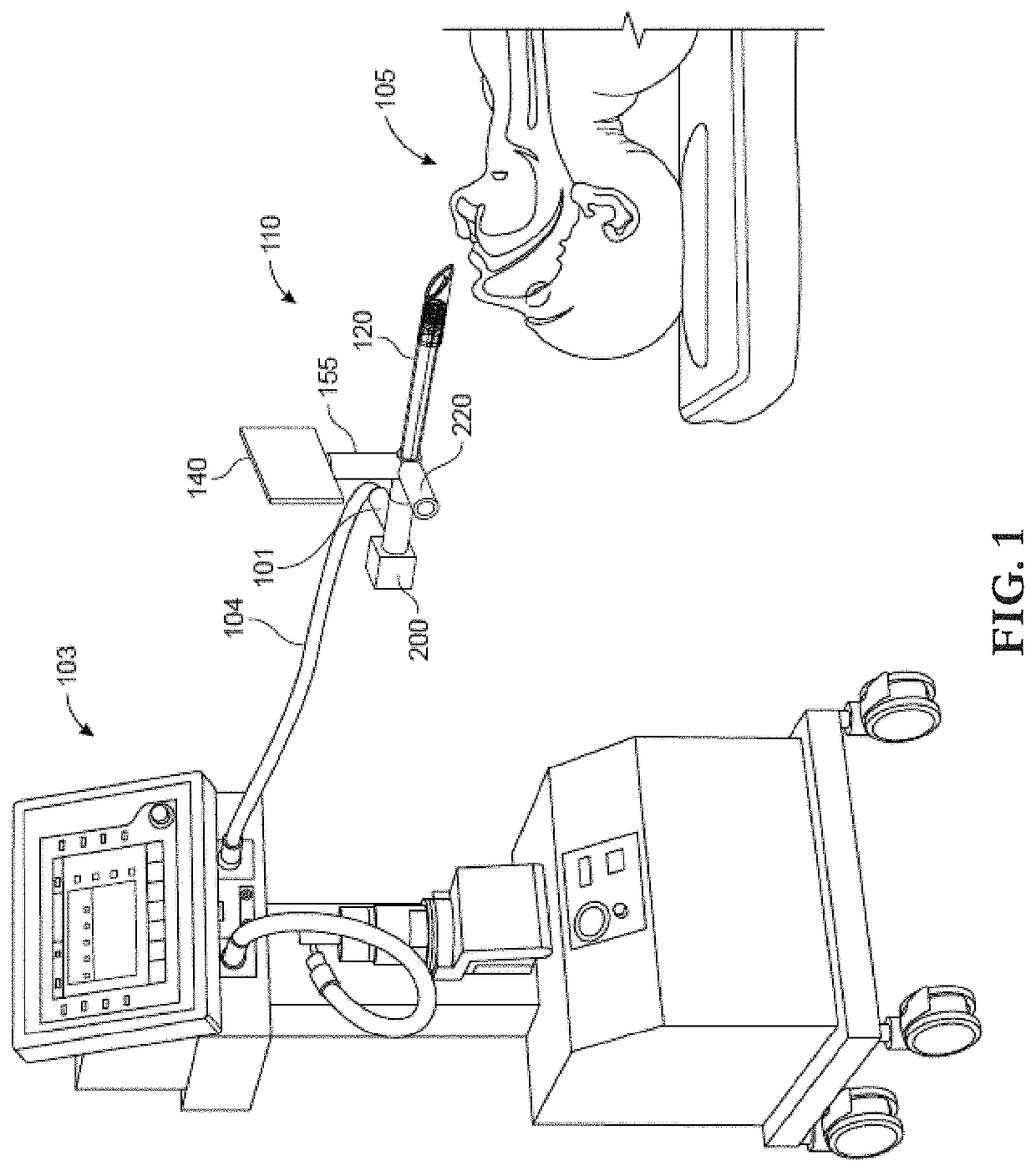

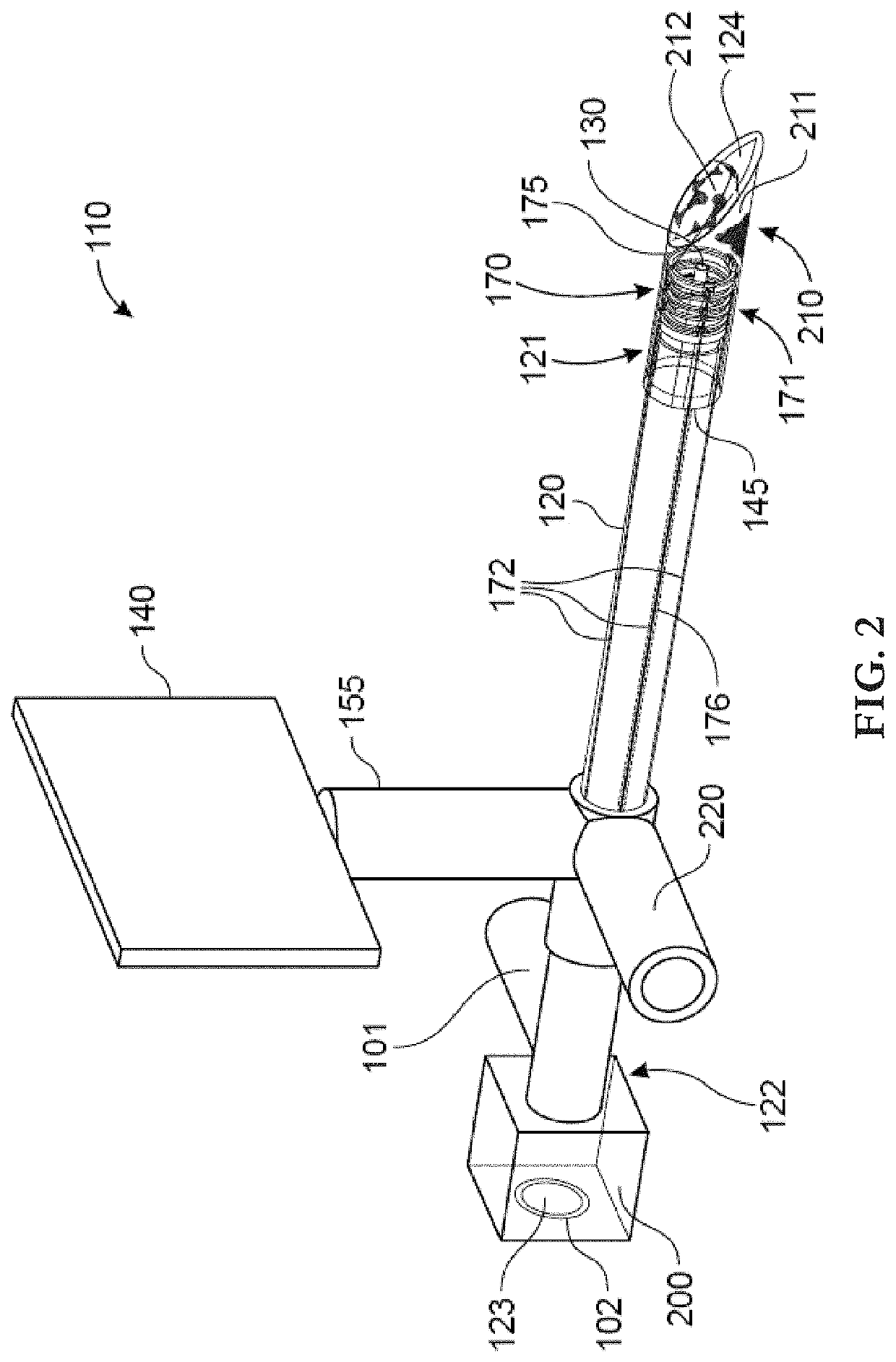

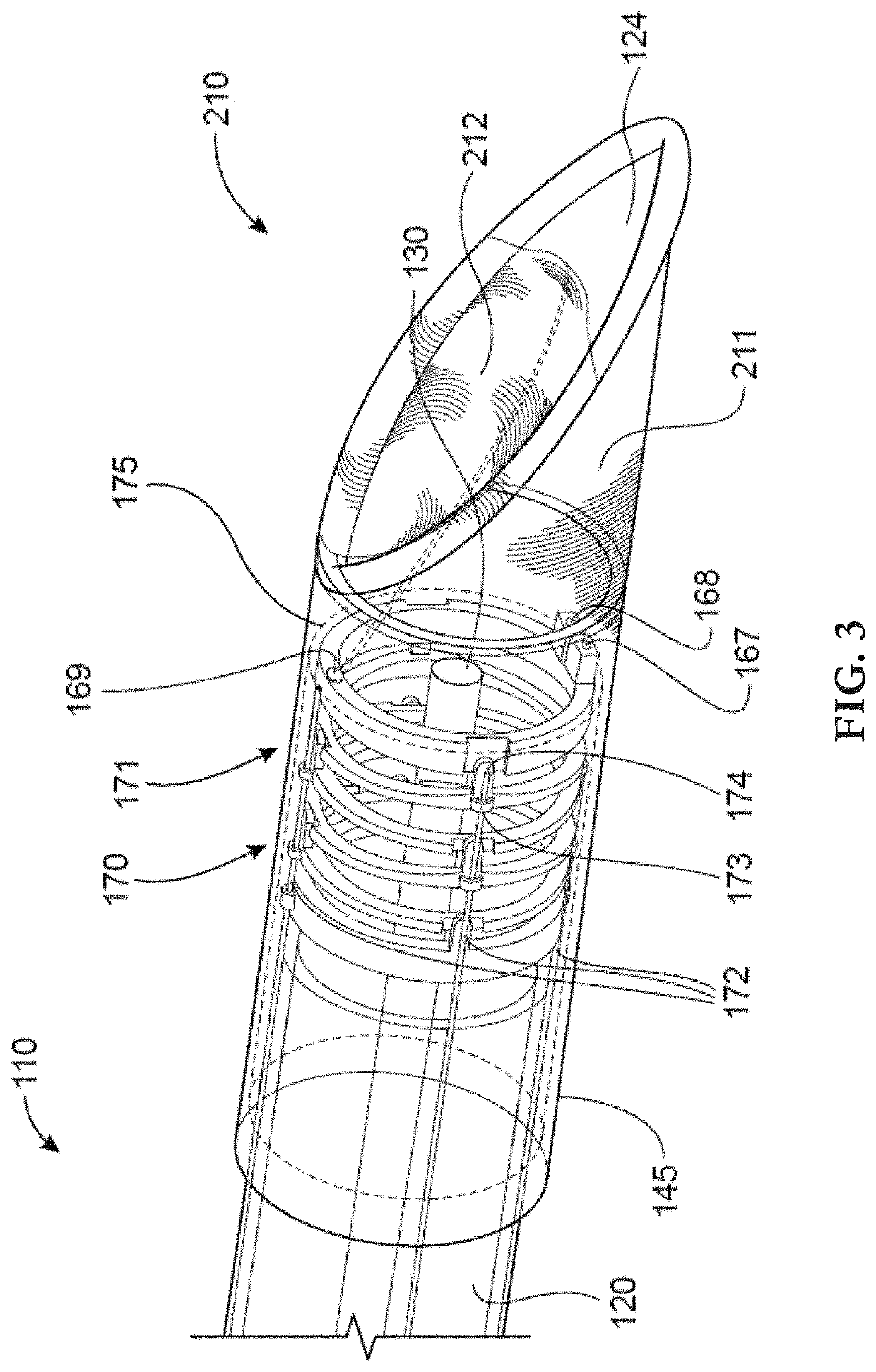

Multipurpose airway device

PendingUS20220280737A1Efficient removalClear passageBronchoscopesTracheal tubesTrach tubeBiomedical engineering

An airway device facilitates the insertion of an ETT into a patient, the delivery of oxygenated air into a patient, an exchange of the pre-inserted ETT in an intubated patient, and an evaluation of the larynx and trachea in an intubated patient, The device comprises an overtube having a mask section attached to a distal portion of the overtube. An inflatable bladder affixed to the mask section includes a shape and surface configured to seamlessly contact the circumference of the elliptical construction of the laryngeal opening. Once the inflatable bladder is positioned adjacent the laryngeal opening enhanced sealing properties are created so that the axis of the airflow entering the device matches the axis of the trachea, allowing for the improved delivery of oxygenated air into the patient's lungs. The specific utilization of the bladder allows for the device to be constructed smaller than a typical airway device, which may more easily facilitate the insertion process. Additionally, the device may provide a seamless transition into endotracheal intubation when necessary.

Owner:KIM CHONG S

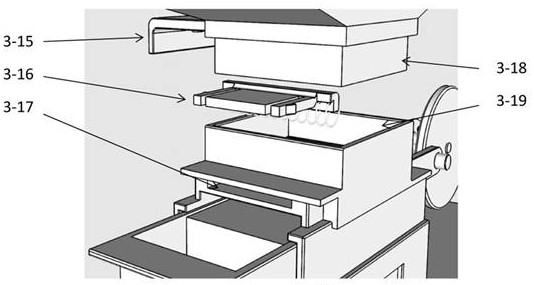

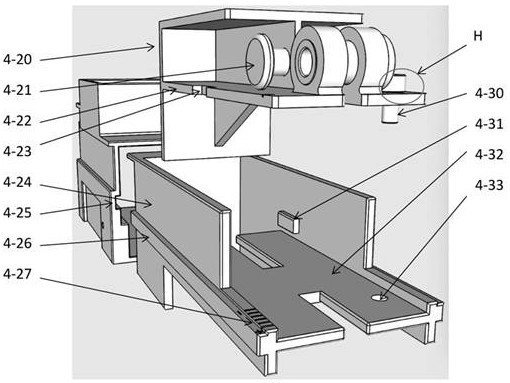

Corn raw material distribution mechanism of automatic corn popper and production process method of corn raw material distribution mechanism

The corn raw material distribution mechanism is characterized in that a transparent material box and a material box base are embedded into a whole to form a material box assembly, the material box base is provided with a material box pull switch which can be used for closing a raw material outlet when the material box is taken out, the material box outlet is inserted into an inlet of an outer cavity base for feeding, and the outer cavity base is provided with an inner cavity. And an elastic plate is inserted into an open groove below the feeding hole of the cavity and is self-locked. The inner cavity is composed of a sliding piece and an adjusting plate. And the outer cavity seat is fixed on the bottom surface of the stainless steel mounting plate through bolts. The connecting transmission system is composed of a pin shaft, a plastic connecting rod, a crank turning wheel and a gear motor. A discharging hopper of the distribution mechanism is inserted into a reserved hole in a bottom plate of a vending machine material chamber and connected with a boiler feeding port, lugs on the two sides of an installation plate are inserted into buckles of the bottom plate of the vending machine material chamber, and the other ends of the lugs are fixed through round screws. The device is small in size, light, economical, practical and convenient to install and use.

Owner:义乌市悦粒智能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com