Ash discharging gland, valve seat structure and ball valve

A technology of gland and valve seat, which is applied in the field of valve seat structure, ball valve and ash unloading gland, which can solve the problems that the pre-tightening spring 4 is difficult to move, fails, and affects the sealing of the valve seat 2 and the valve core, so as to ensure the sealing performance , prevent failure, prevent the effect of preload spring failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

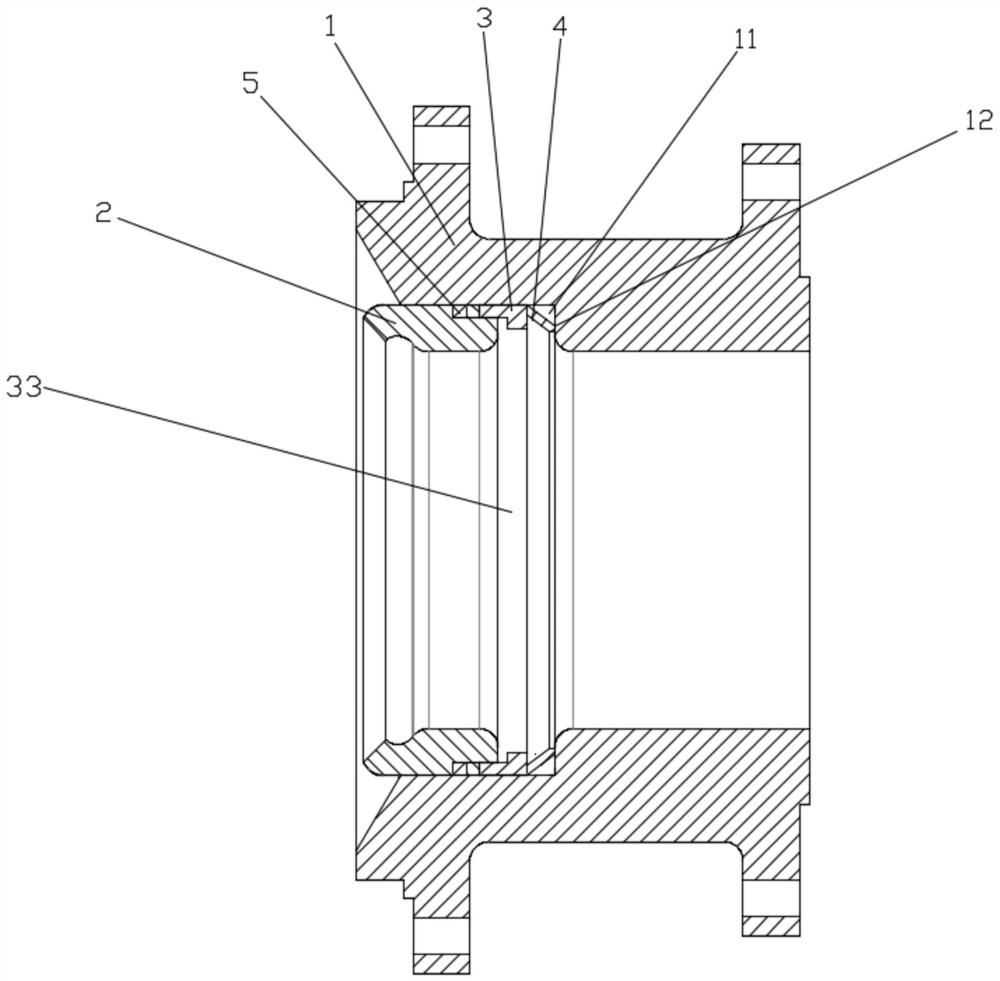

[0040] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

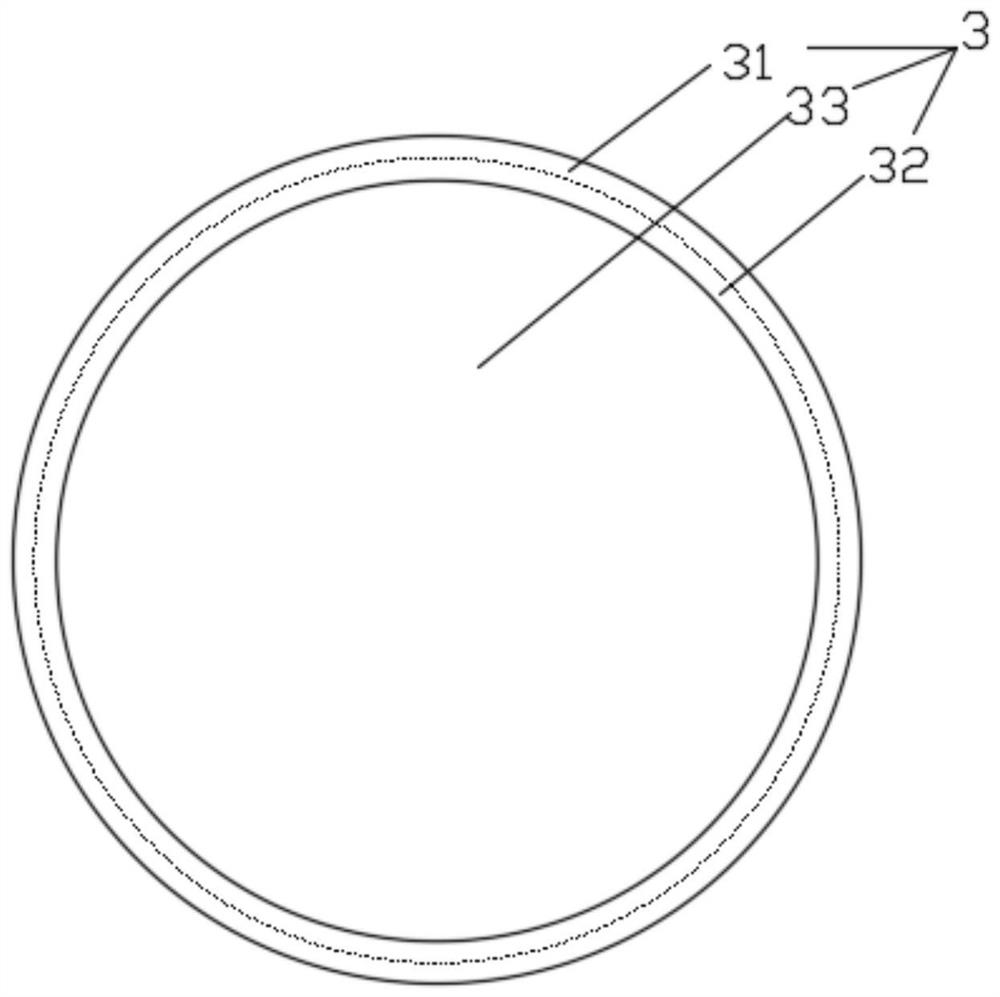

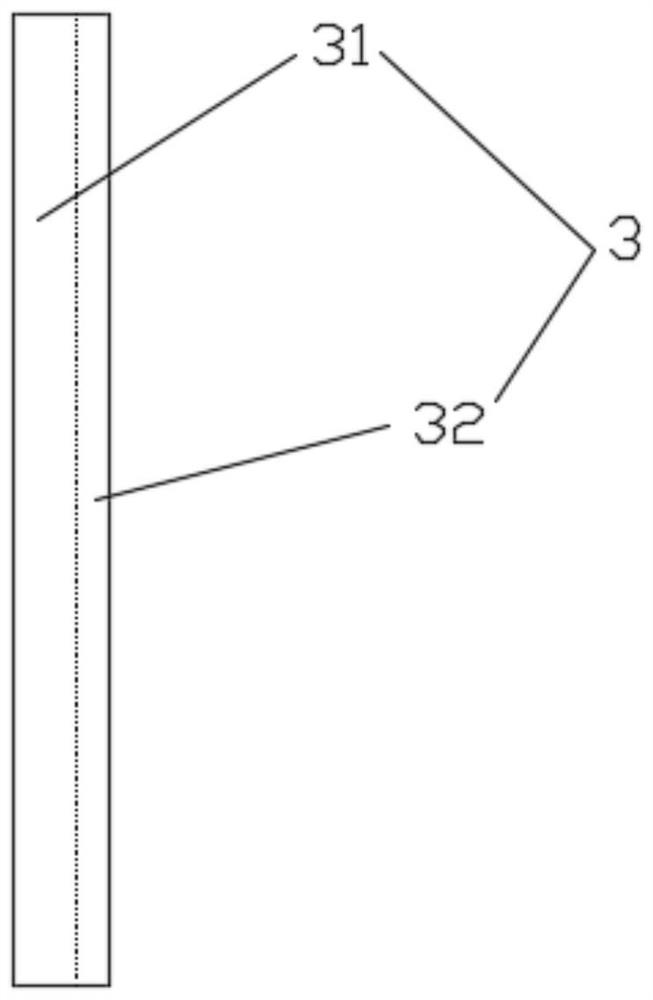

[0041] Such as Figure 5-Figure 9 As shown, the embodiment of the ash unloading gland disclosed by the present invention includes a sealing compression ring 61 and a spring pressing member 62, the middle part of the sealing compression ring 61 is a medium circulation channel 33, and one end of the sealing compression ring 61 is used for pressing Tighten the sealing member 5, the sealing compression ring 61 is fixedly connected or integrally formed with a spring pressing member 62, the spring pressing member 62 is used to abut against the pre-tension spring 4, the spring pressing member 62 and the sealing pressing ring 61 There is an ash discharge port 63 between them, and the ash discharge port 63 communicates with the medium circulation channel 33 and the medium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com