Patents

Literature

109results about How to "Improve ash removal effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

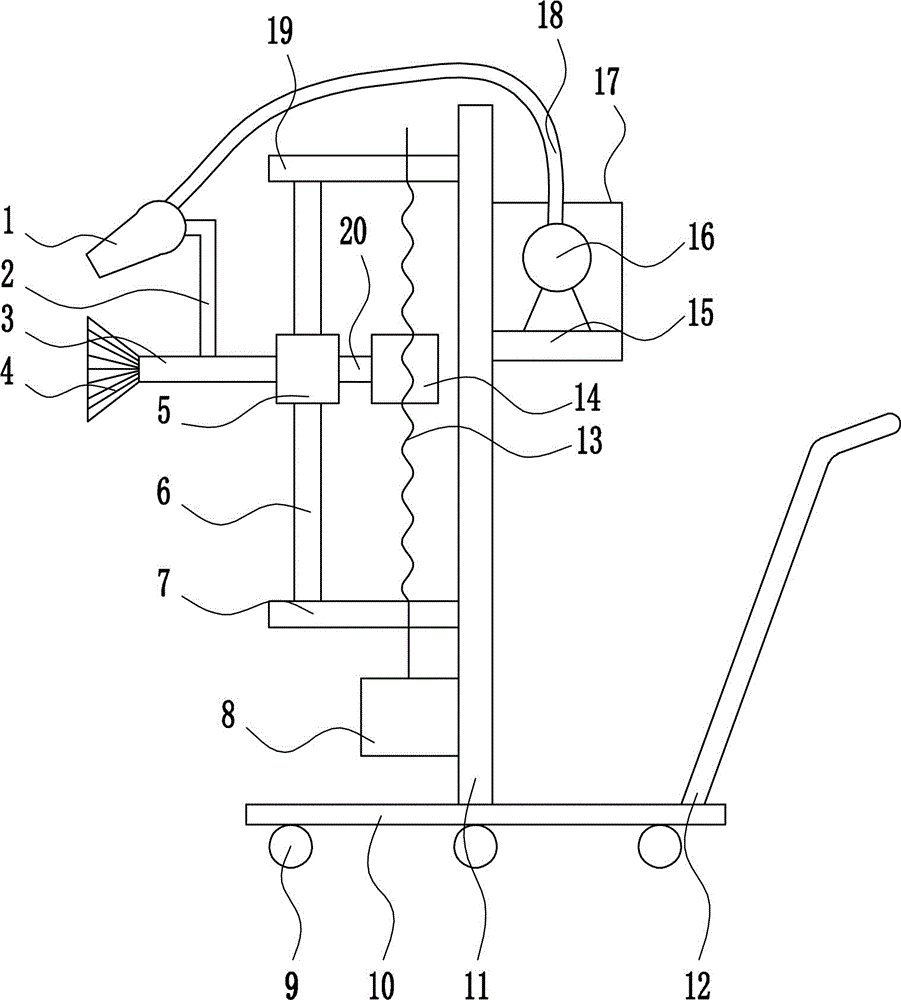

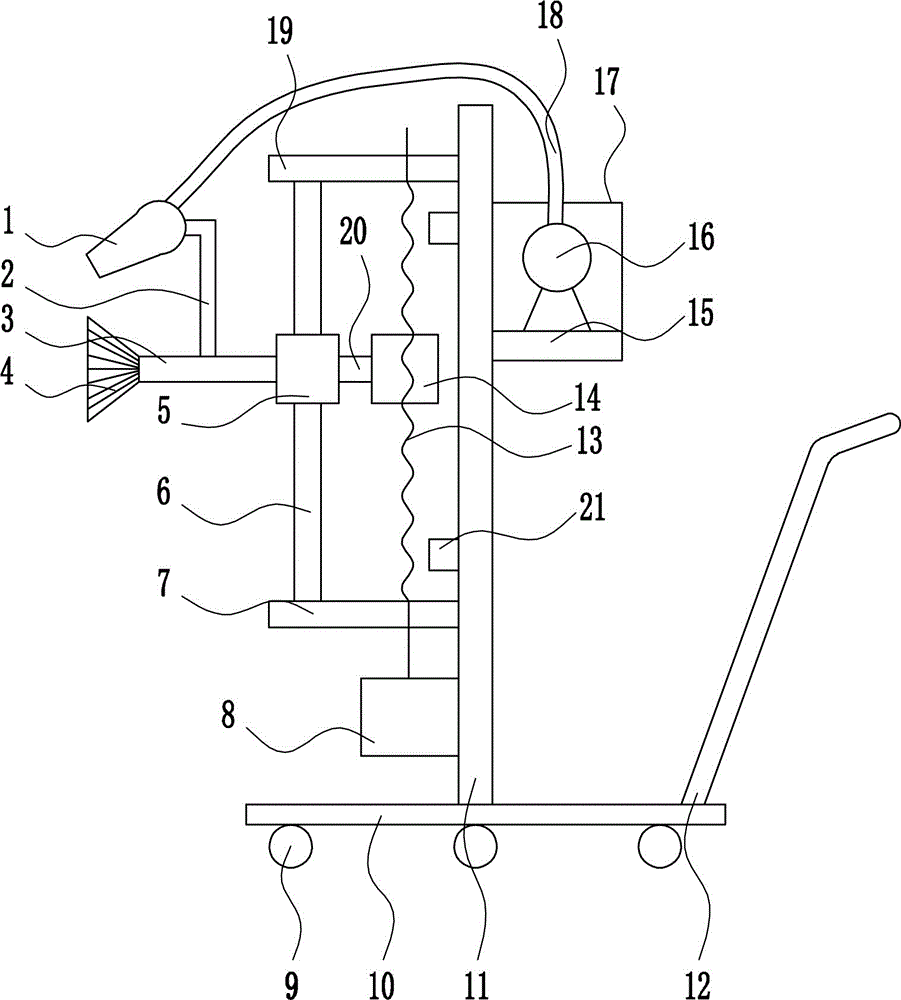

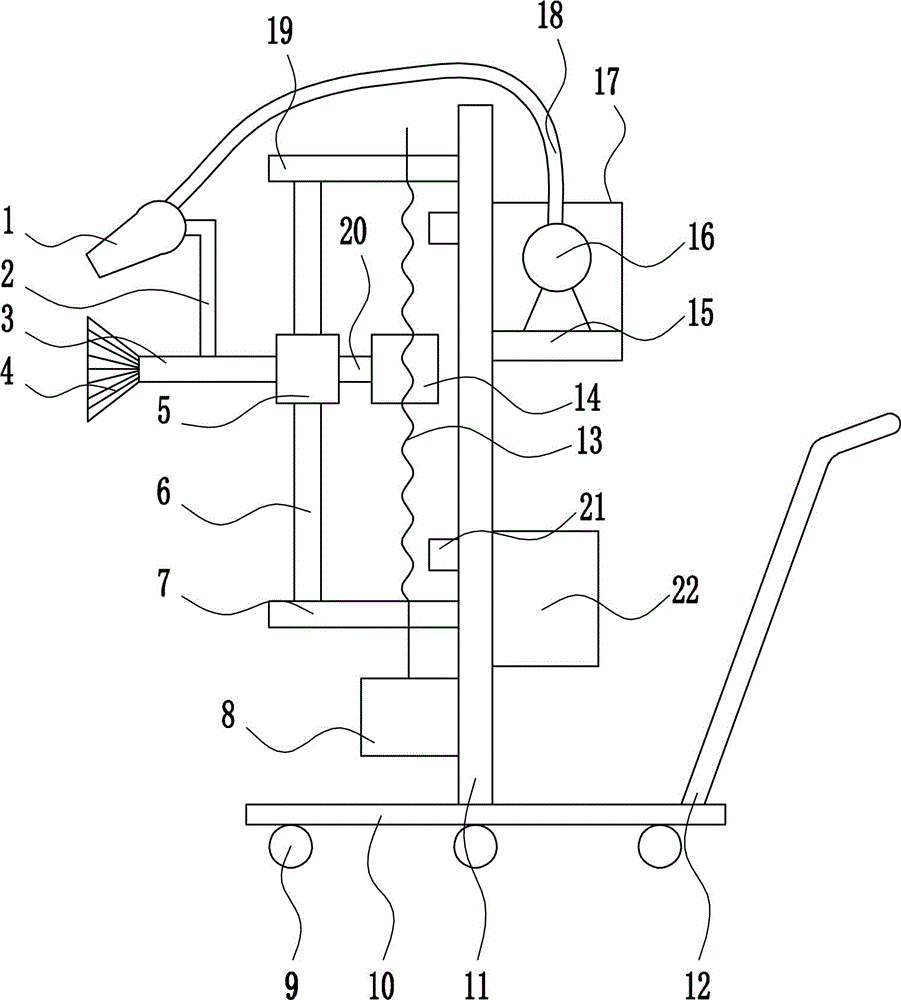

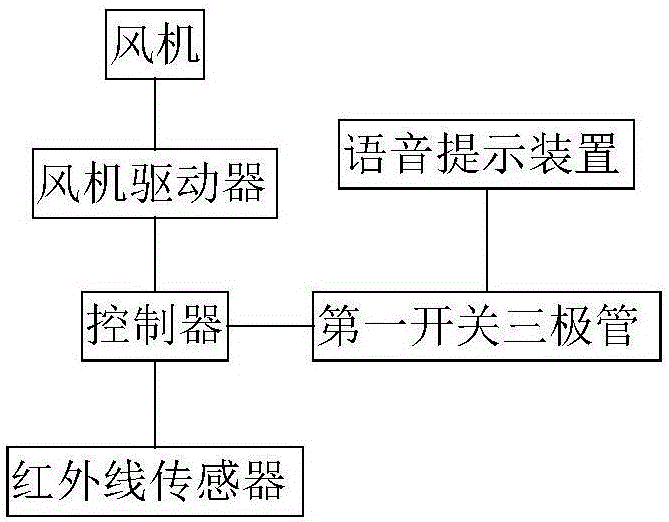

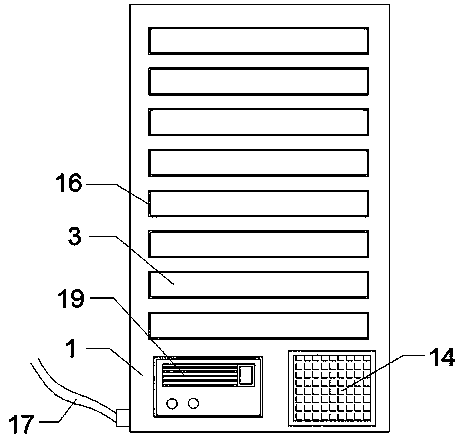

Surface dust removing device for internet display screen

InactiveCN106362968AFully removeImprove work efficiencyCleaning using toolsCleaning using gasesThe InternetEngineering

The invention relates to a dust removing device, in particular to a surface dust removing device for an internet display screen and aims at achieving the technical purpose of providing the surface dust removing device for the internet display screen, wherein the surface dust removing device is high in dust removing speed, good in dust removing effect and capable of saving time and labor in the dust removing process. To achieve the above technical purpose, the surface dust removing device for the internet display screen is provided and comprises a sprayer, a support, a supporting rod, a brush, a guiding sleeve, a guiding column, a second bearing block, a rotation motor, wheels, a bottom plate, a fixing plate, a push handle, a lead screw, a nut and the like. The bottom of the bottom plate is connected with the wheels through fixing rods, the wheels can freely rotate, and the fixing plate is welded to the center of the top of the bottom plate. The surface dust removing device achieves the effects that the dust removing speed is high, the dust removing effect is good, and time and labor are saved in the dust removing process. Through the up-down reciprocating movement of the brush and the sprayer, the dust on the surface of the internet display screen is sufficiently removed.

Owner:麻城英太利济智能物联网科技有限公司

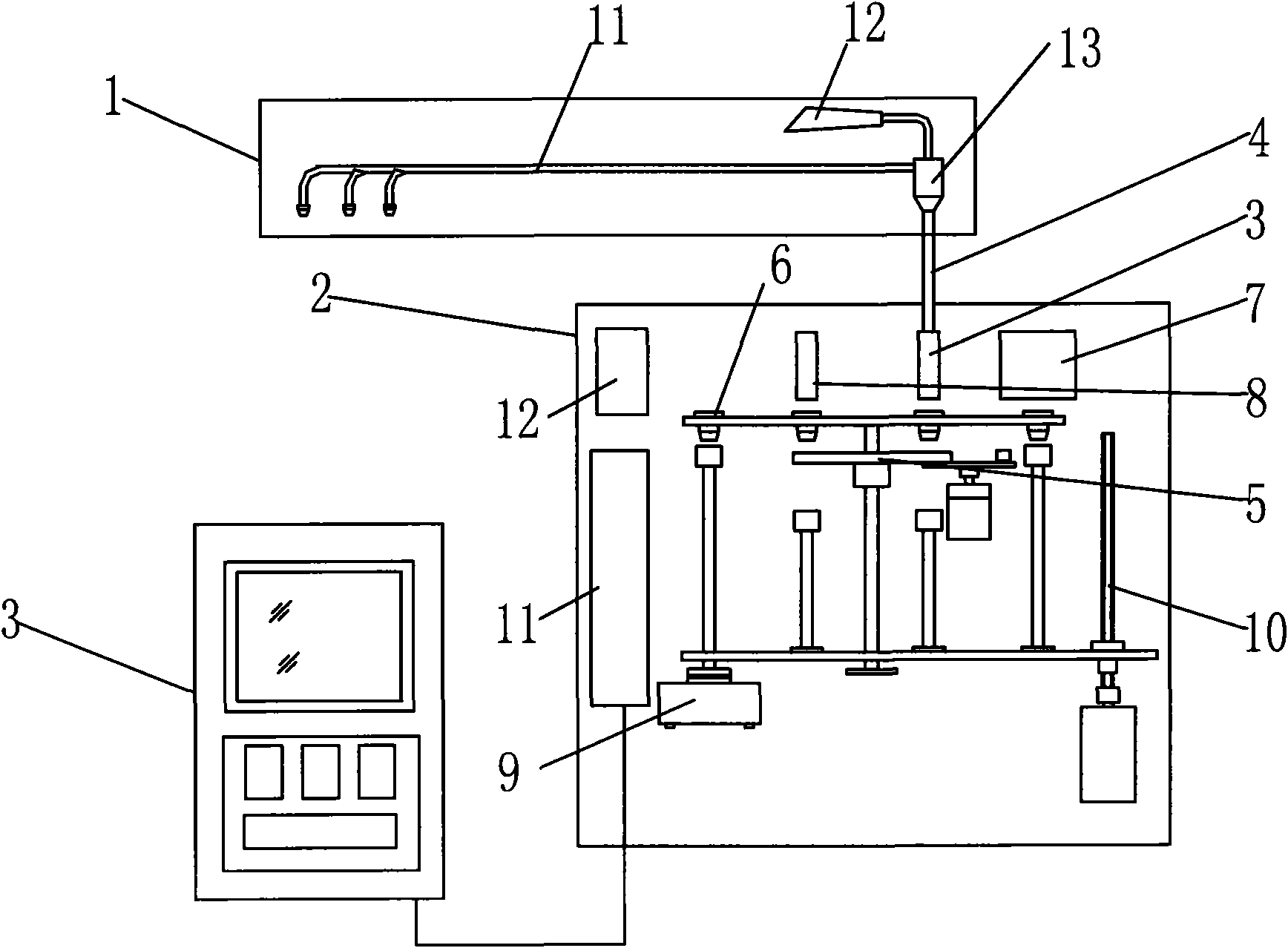

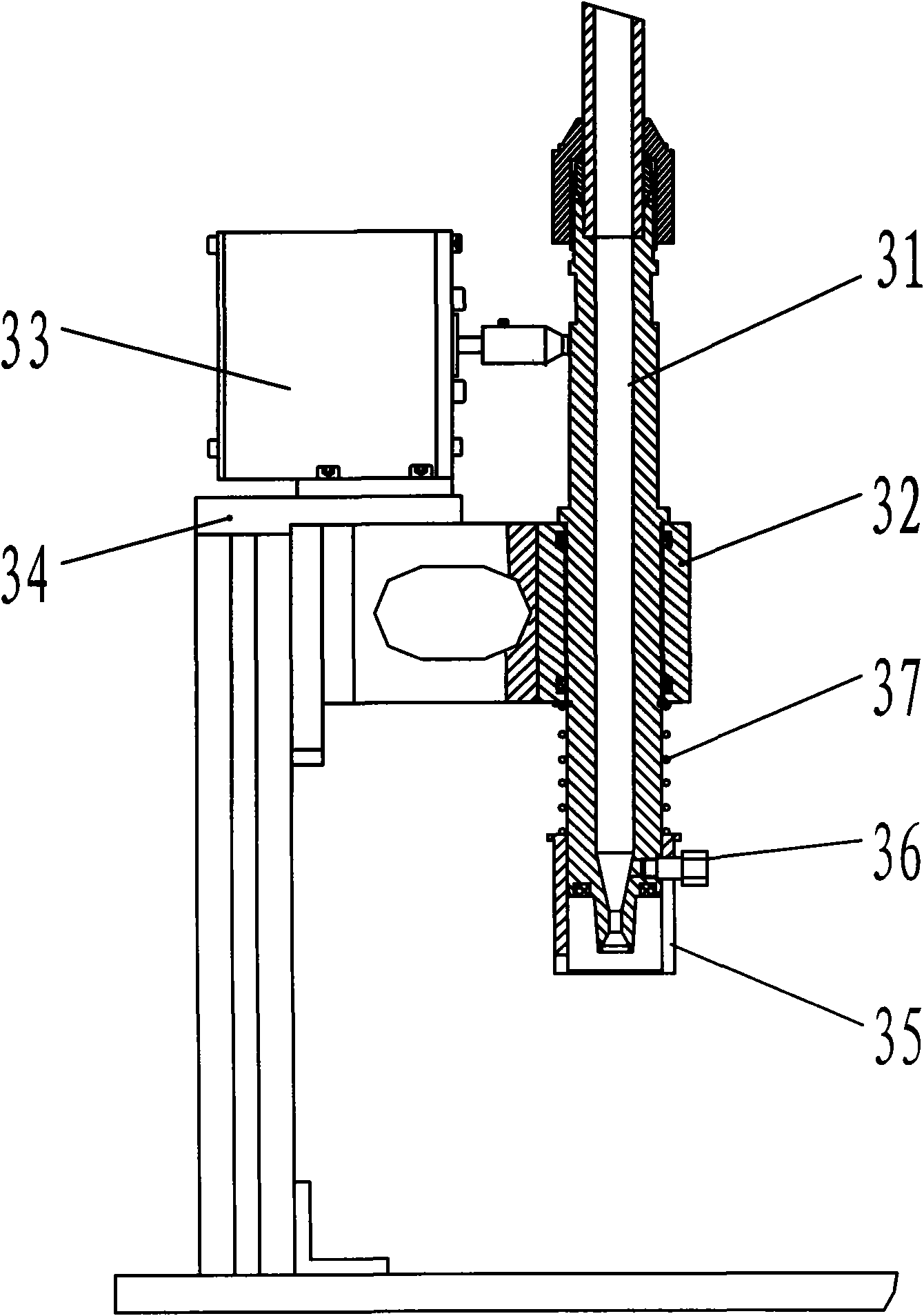

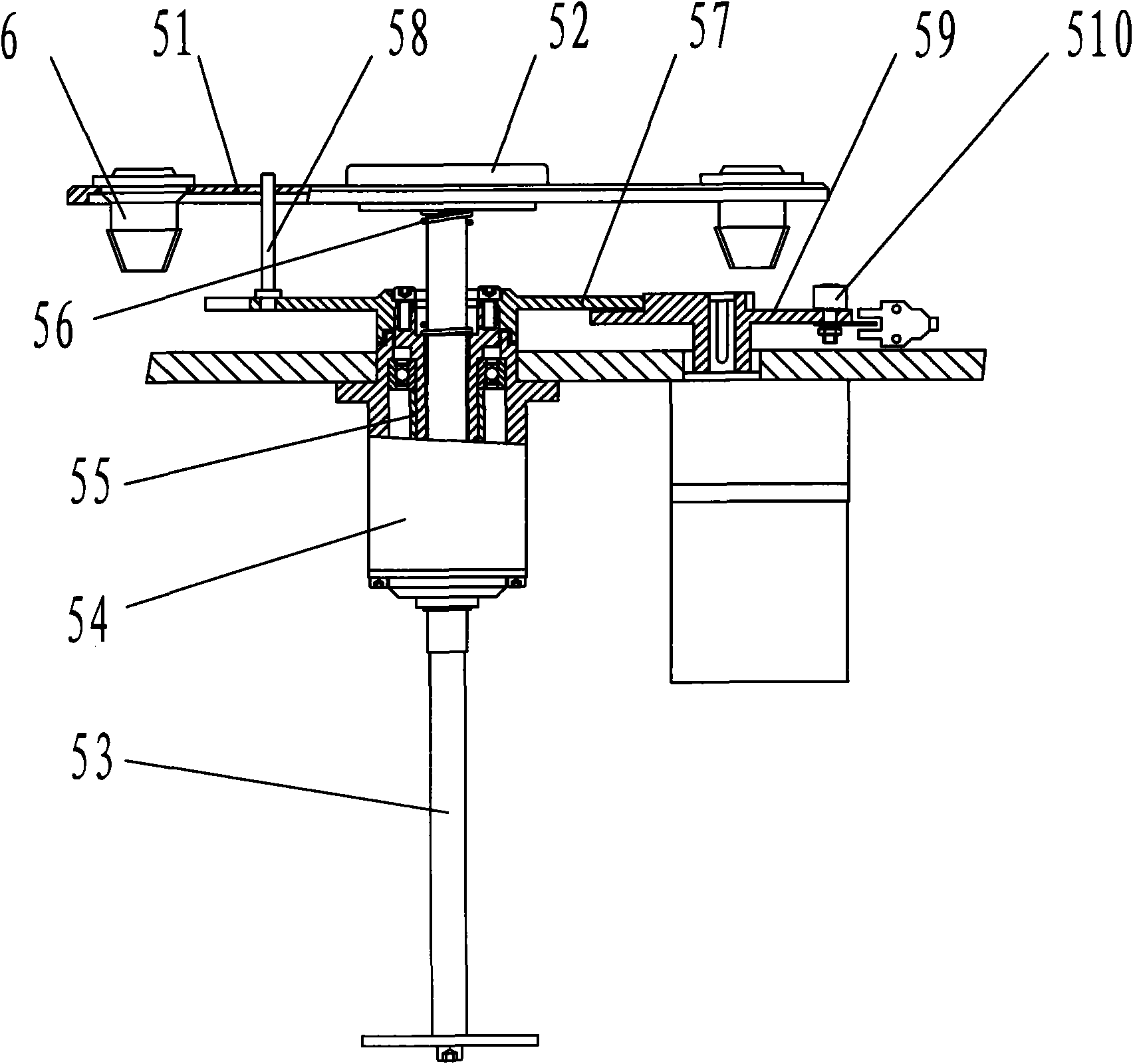

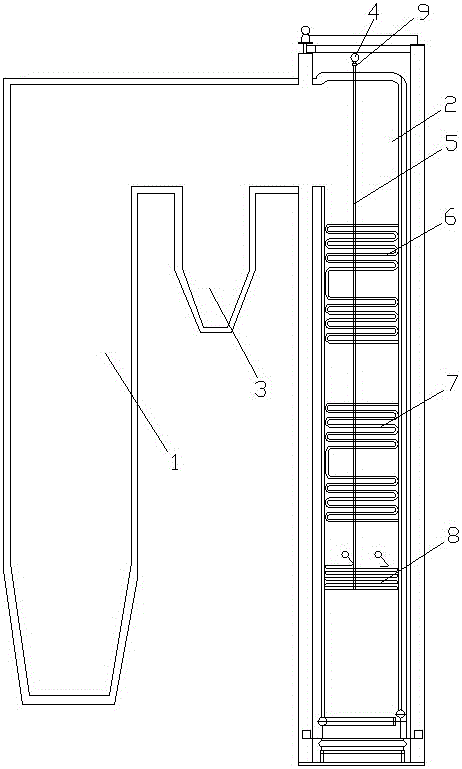

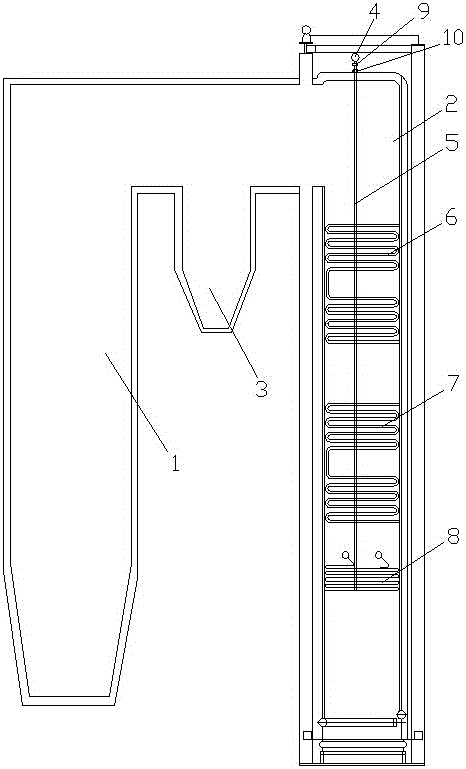

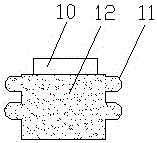

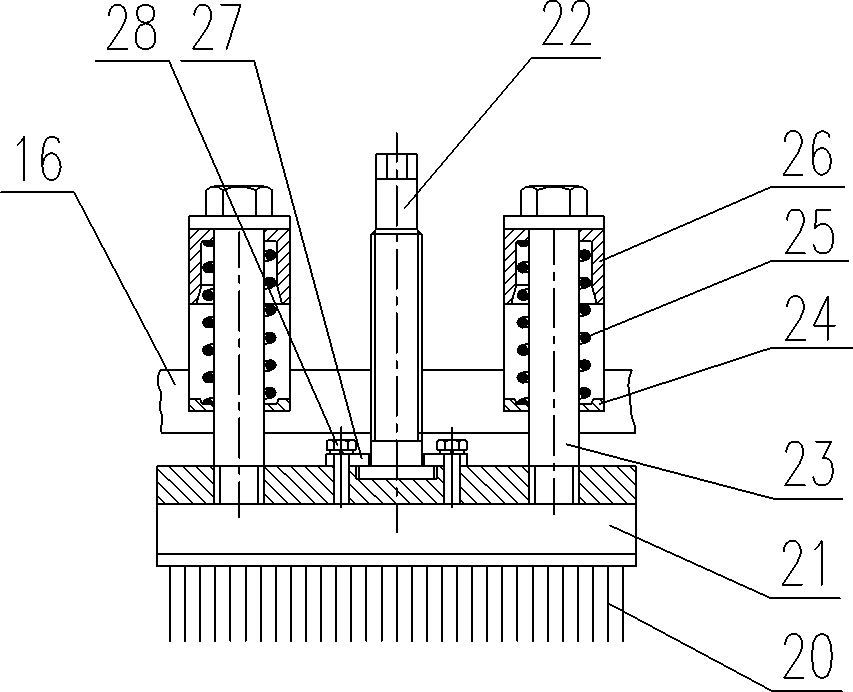

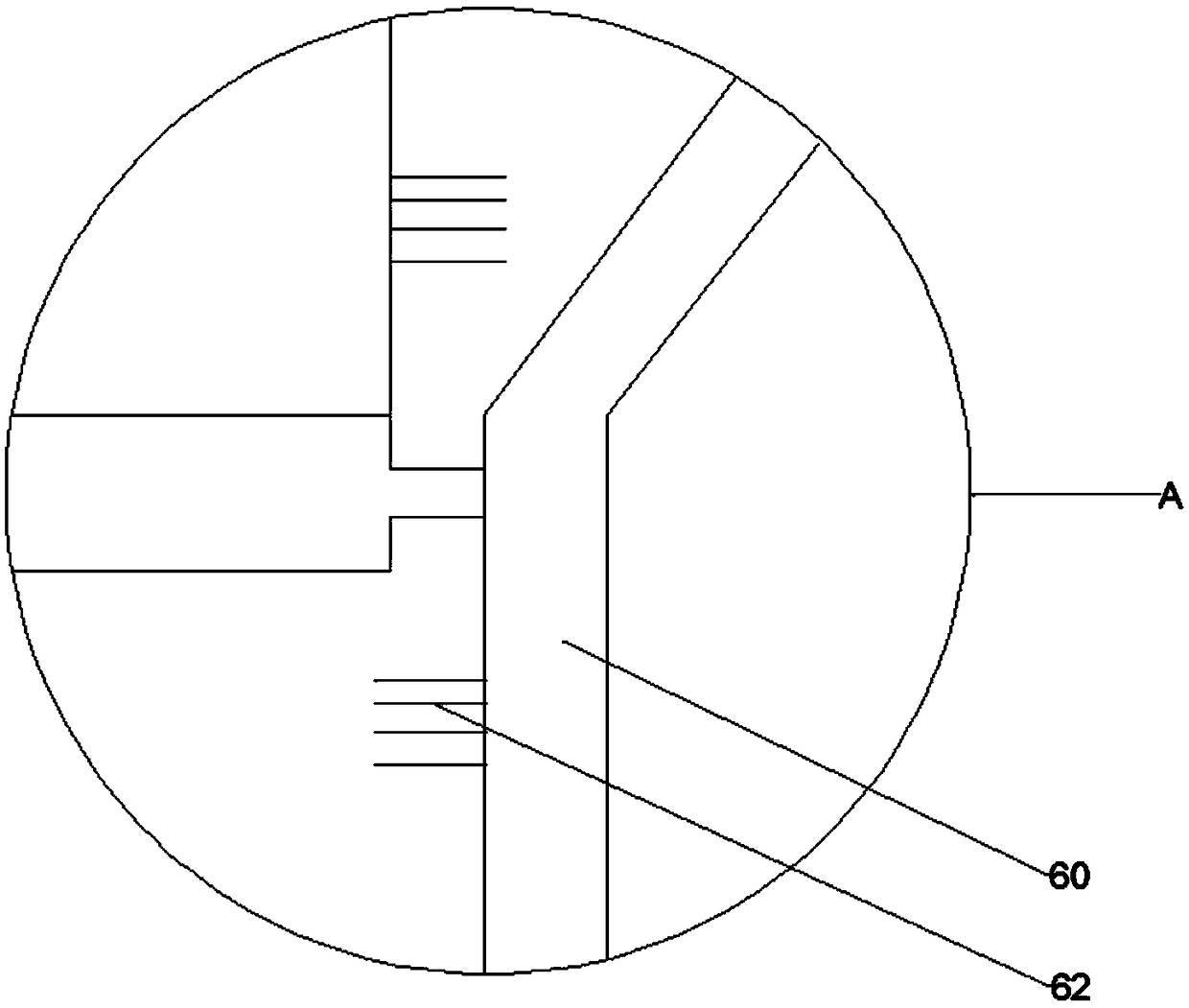

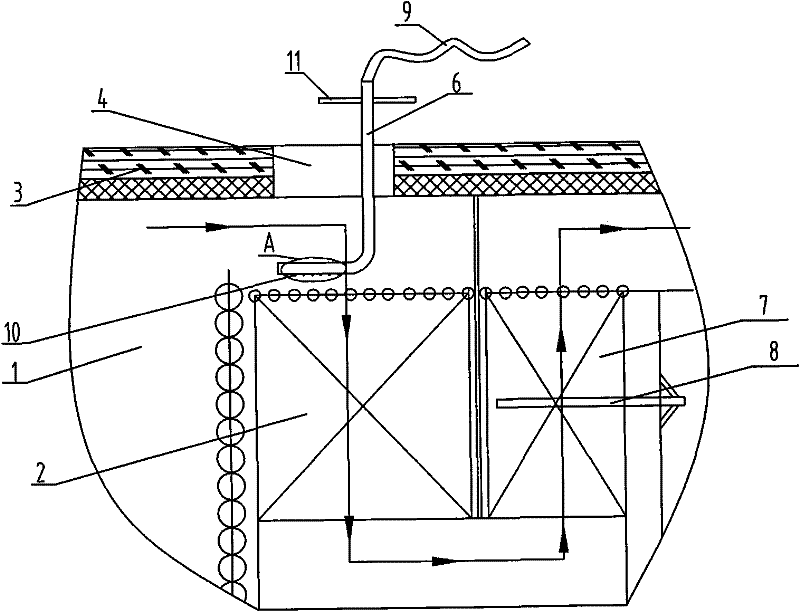

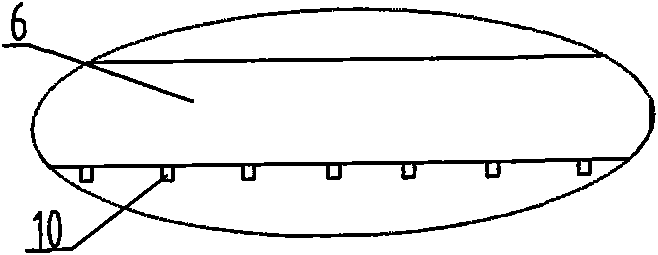

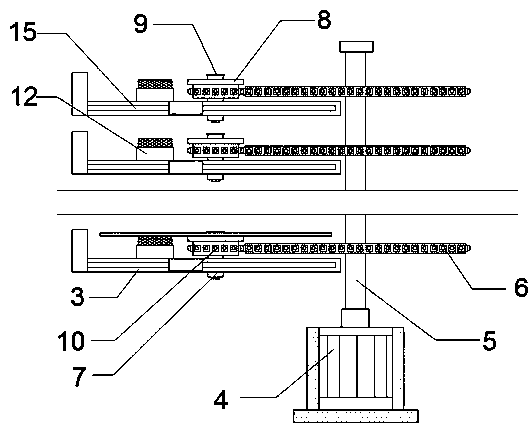

Measurement device for residual carbon quantity in fly ash

ActiveCN102012350AAvoid cloggingGuarantee smooth feedingWeighing by removing componentMeasurement deviceEngineering

The invention discloses a measurement device for residual carbon quantity in fly ash. The device comprises a sampling unit, a measurement unit and a control unit, wherein the sampling unit is connected with an ash collecting device in the measurement unit through an ash collecting pipe; in the measurement unit, four crucibles are uniformly arranged on a rotating device along the circumference, the ash collecting device, a burning device and an ash discharge device are respectively arranged above the crucibles, a weighing device is arranged below the crucibles, an ejector rob is arranged on an elevating device, the ash collecting device, the ash discharge device, the rotating device, the elevating device and the weighing device are all connected with an electric device, and the burning device is connected with a temperature controller; and the measurement unit is connected with the control unit by the electric device. The invention has the advantages of excellent ash collection and discharge effect, high accuracy, no noise and no clamp phenomena.

Owner:NANJING ZHONGYU AUTOMATION

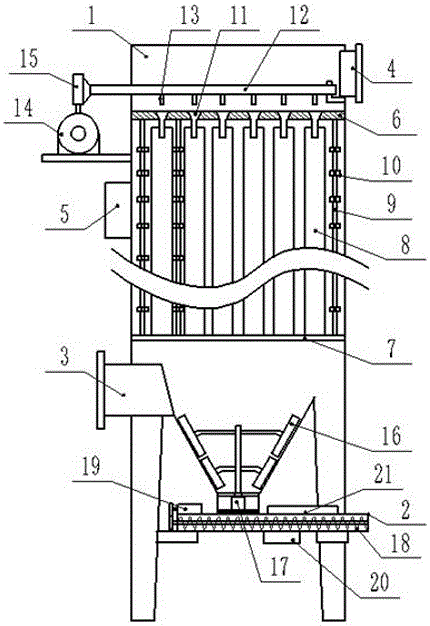

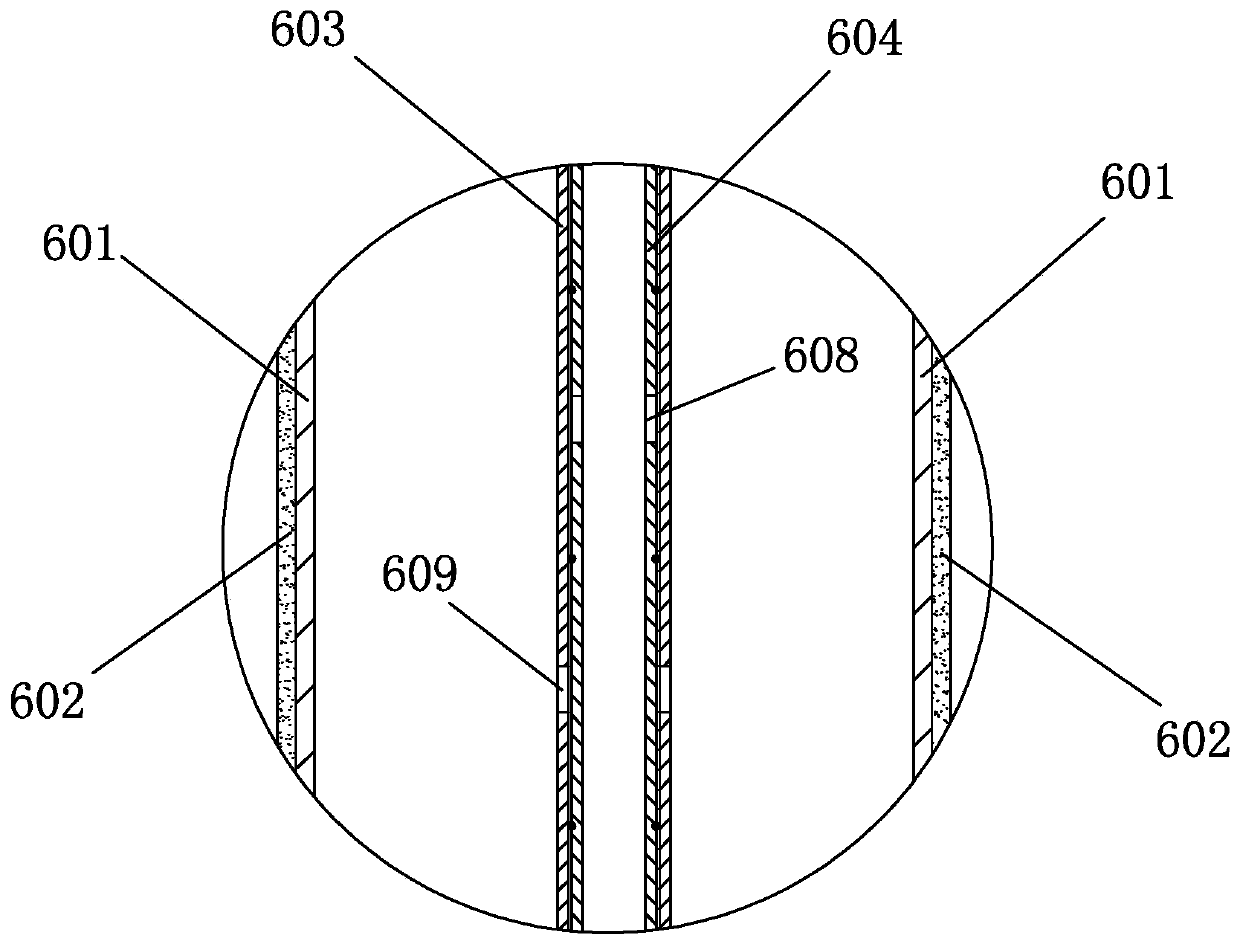

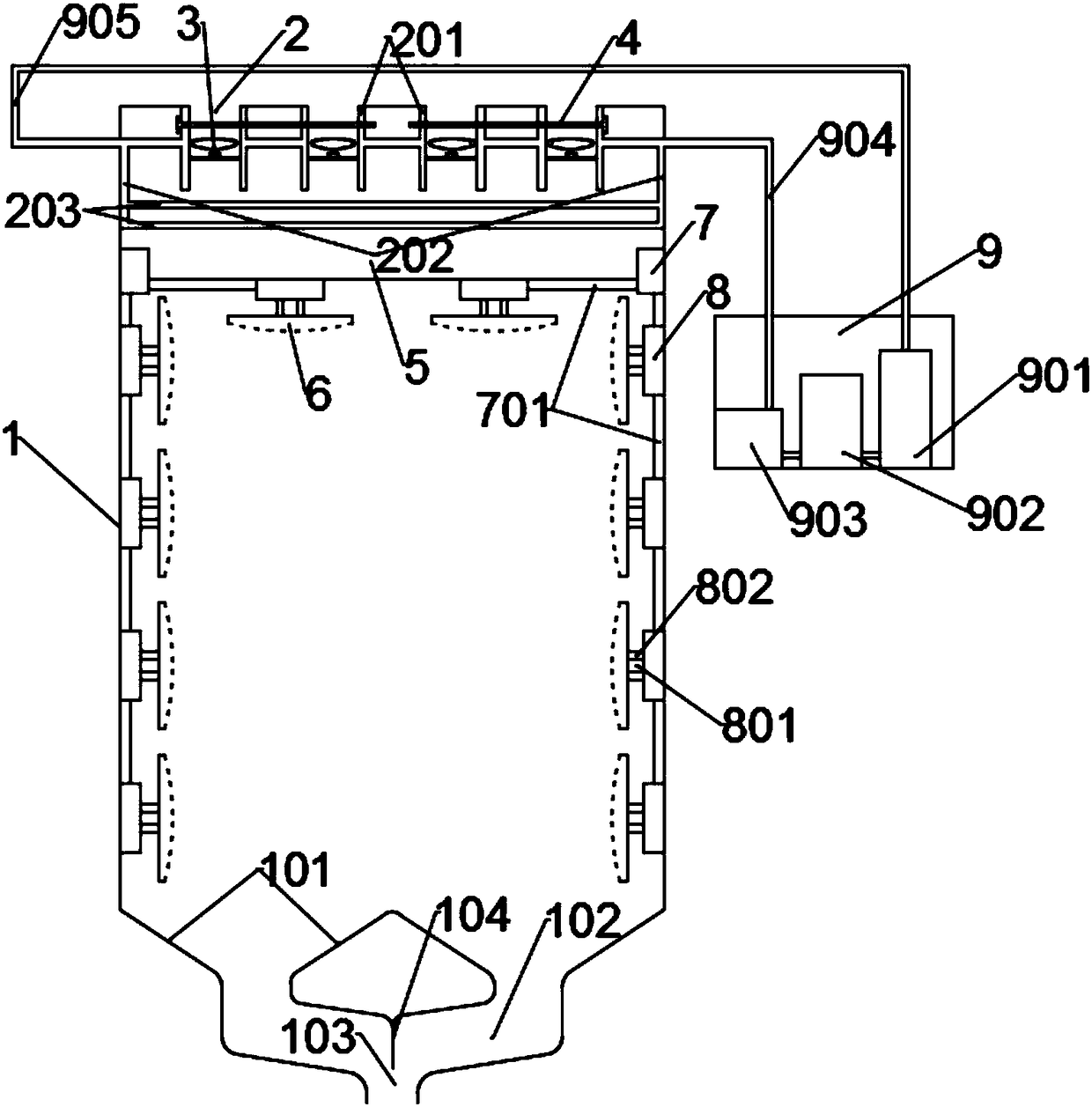

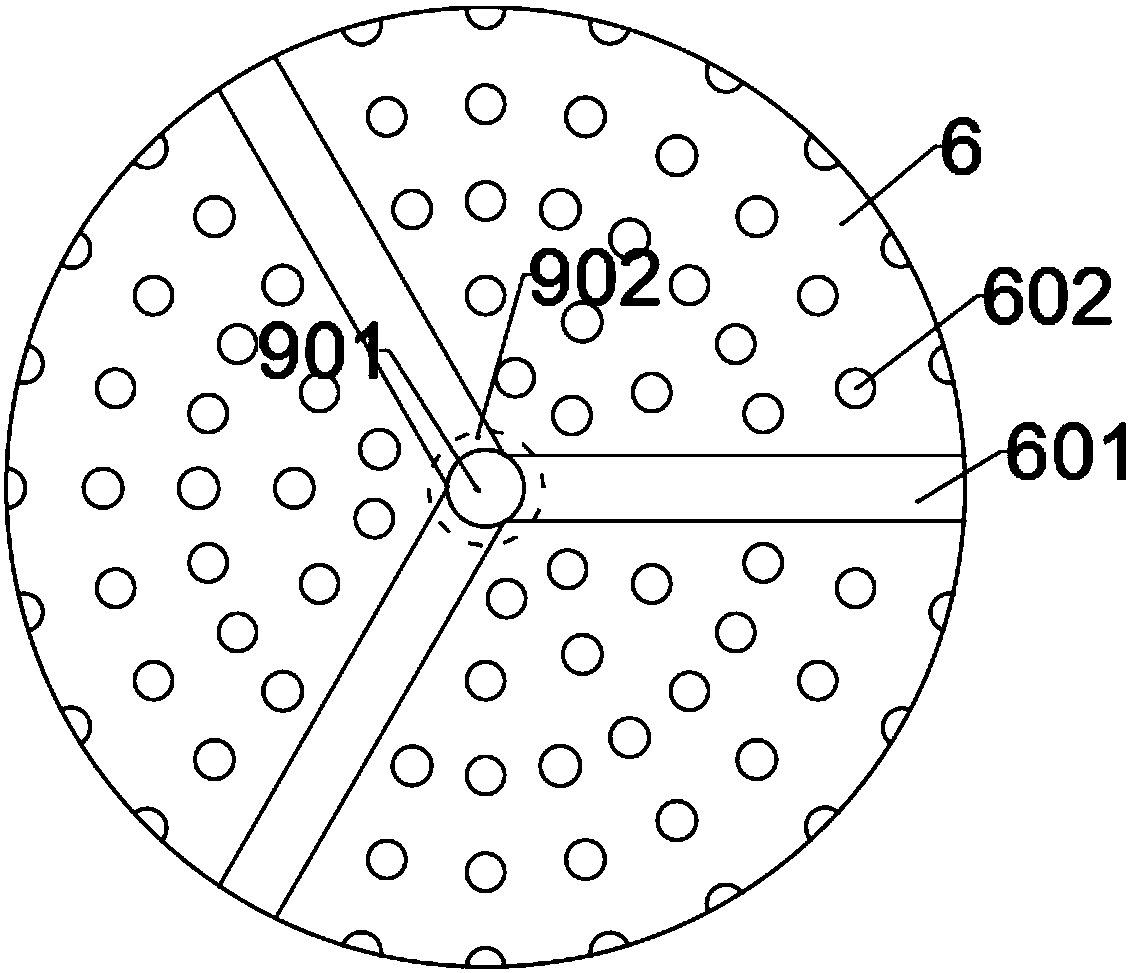

Pulse cloth bag dust remover capable of easily collecting ash

InactiveCN106377952AImprove ash removal effectBetter and faster dust removalDispersed particle filtrationSpiral bladeBaghouse

The invention discloses a pulse cloth bag dust remover capable of easily collecting ash. The pulse cloth bag dust remover comprises a box body and an ash outlet pipe, wherein a ceiling and a cage framework are fixedly connected in the box body; a plurality of filter bags are fixedly connected between the ceiling and the cage framework; beating blades are connected between the ceiling and the cage framework and at two sides of the filter bags in a rotary manner; upper ends of the filter bags are connected with a venturi tube penetrating through the ceiling; a blowing pipe is further fixedly connected with a position, located above the ceiling, in the box body; the lower part of the box body is connected with a brushing shaft in the rotary manner; the brushing shaft is fixedly connected with a plurality of brushing plates; an opening formed in the lower end of the box body is communicated with the upper end of the ash outlet pipe; the ash outlet pipe is fixedly connected below the box body; the ash outlet pipe is internally connected with a spiral blade in the rotary manner; an atomizer is further fixedly connected with the lower end of the ash outlet pipe; an outlet of the atomizer is communicated with a flow spitting box; the lower end of the flow spitting box is communicated with a plurality of humidifying nozzles introduced into the ash outlet pipe. The pulse cloth bag dust remover capable of easily collecting the ash is high in reverse blowing and ash falling efficiency, dust is not stuck and remained and does not cause secondary pollution after being discharged; energy saving and high efficiency are realized.

Owner:广西金邦泰科技有限公司

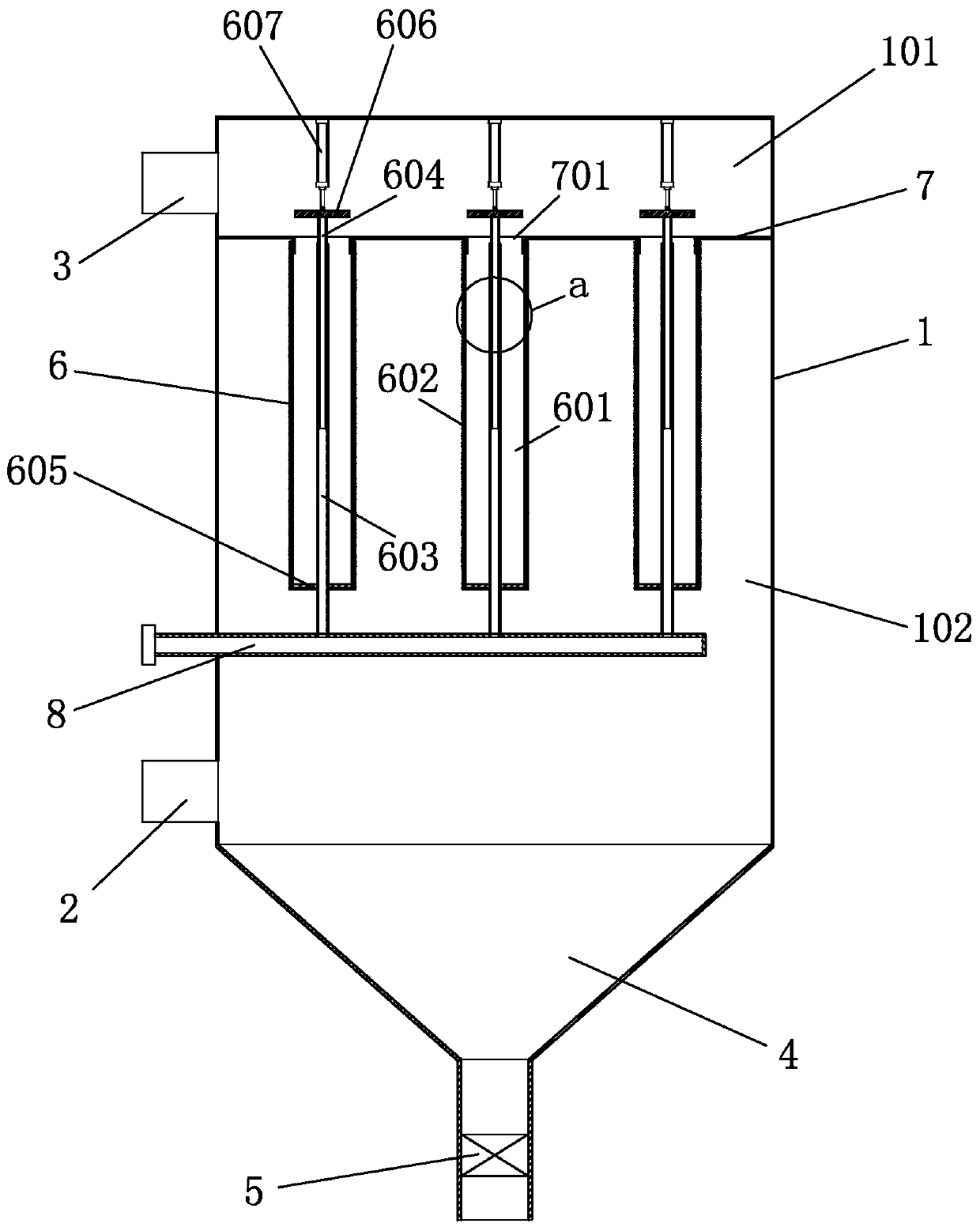

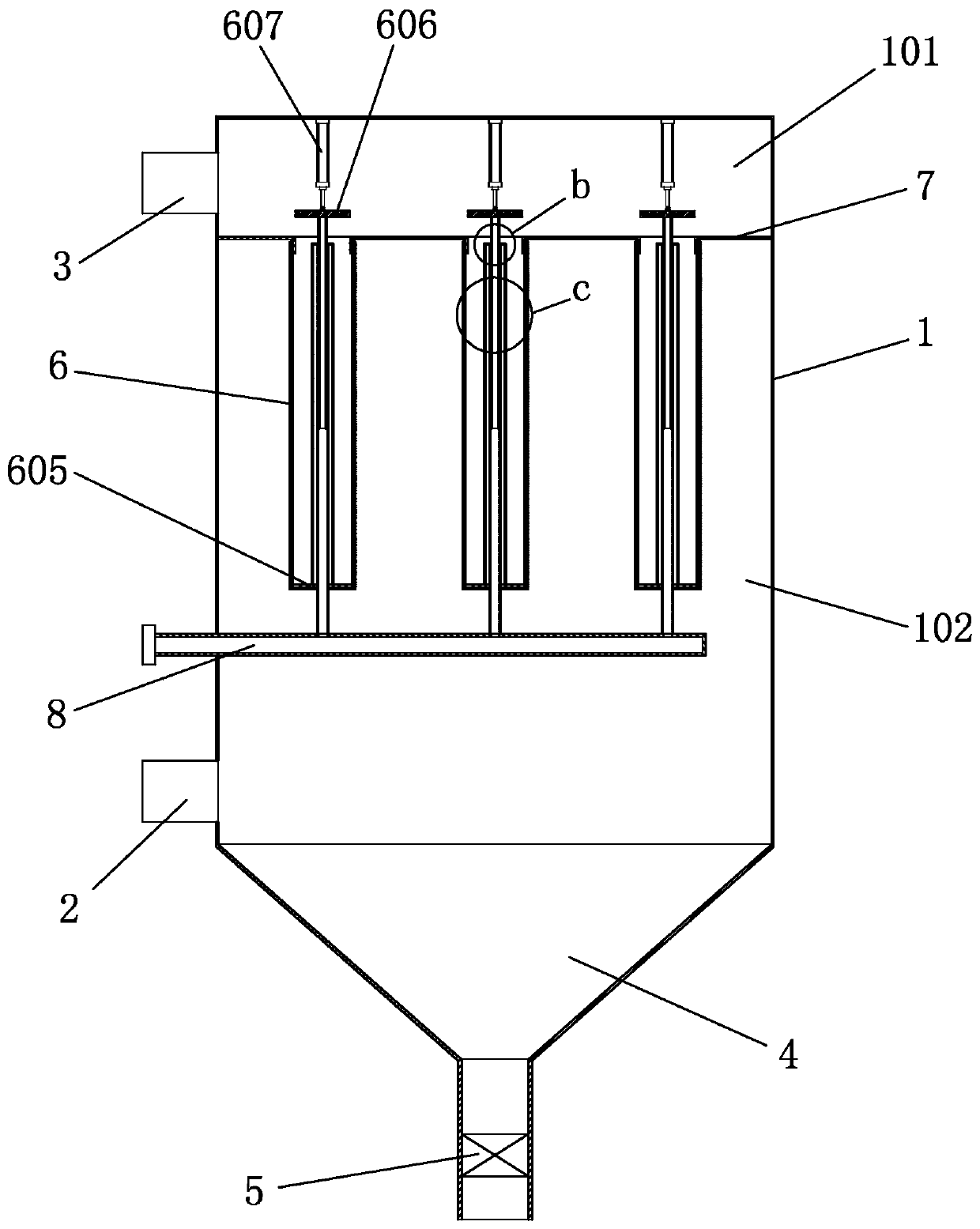

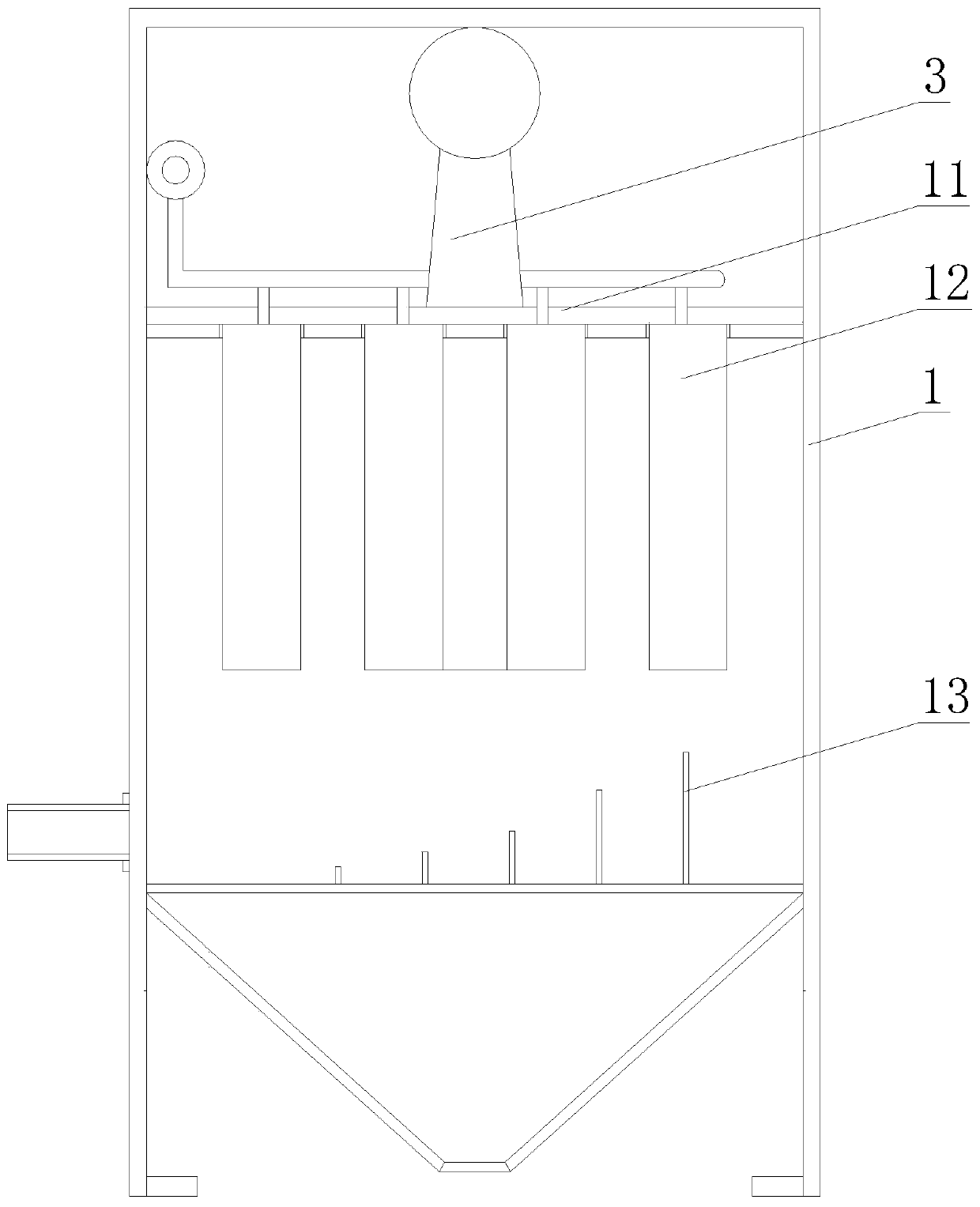

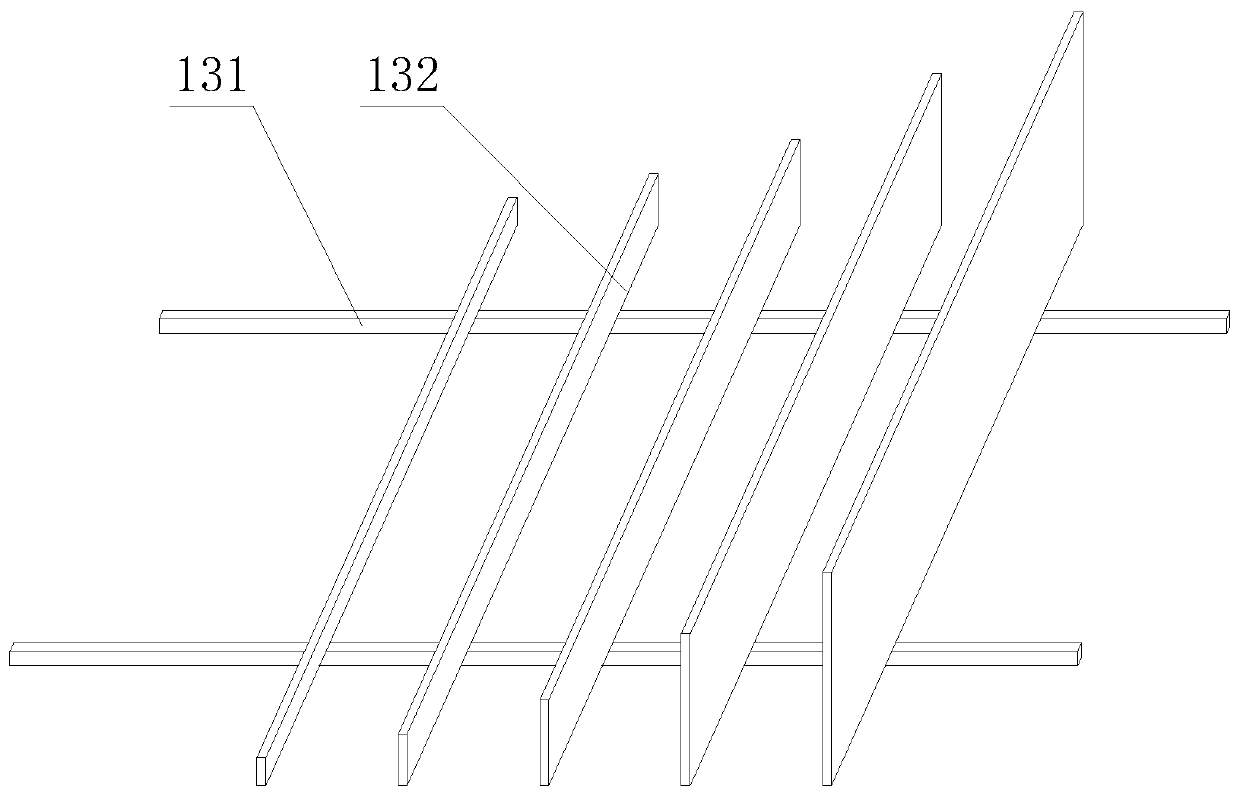

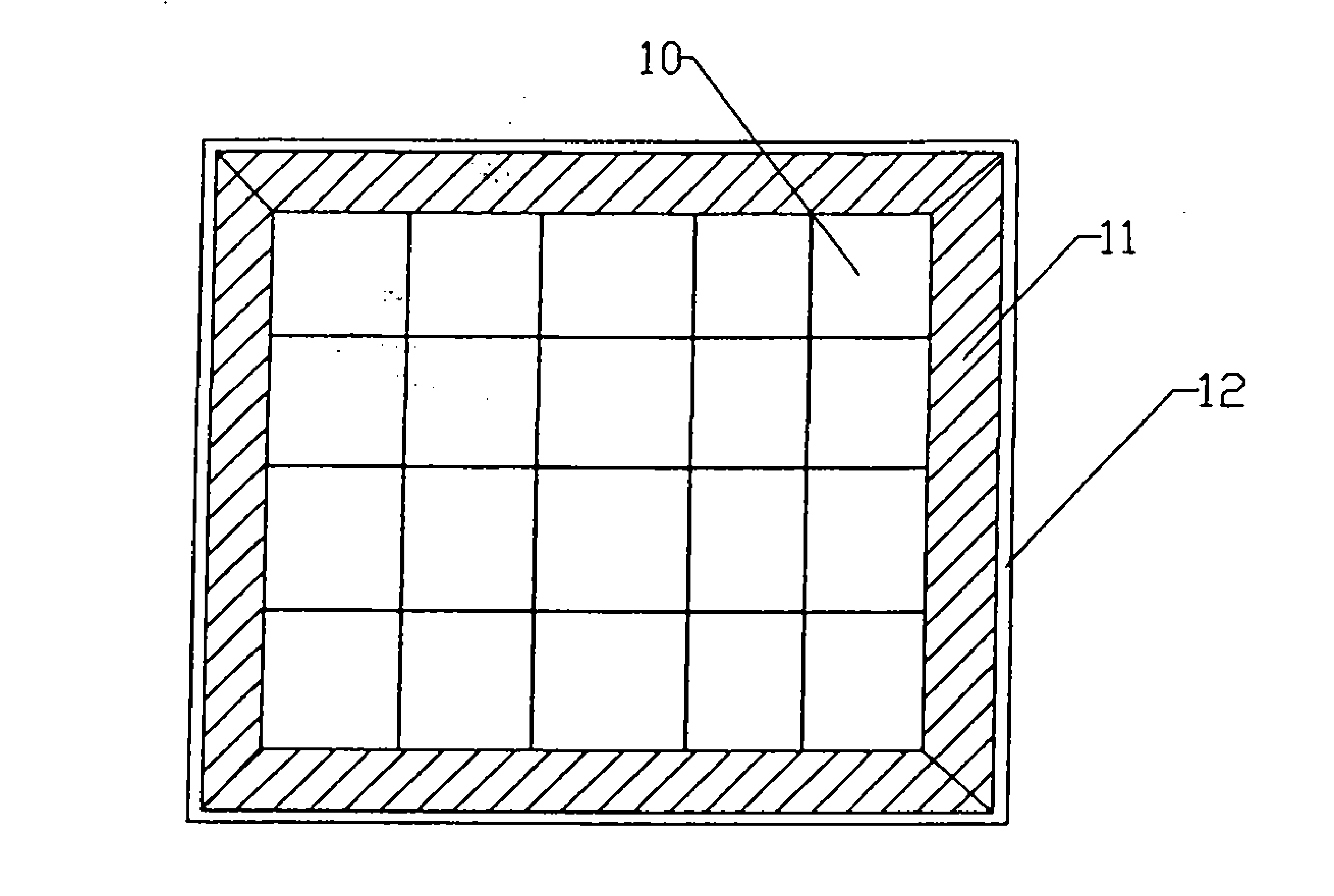

Bag dust remover

ActiveCN109999576AWon't leakEasy to removeDispersed particle filtrationTransportation and packagingBaghouseEngineering

The invention discloses a bag dust remover, and relates to the technical field of dust removers. The bag dust remover comprises a casing, an air inlet pipe and an air outlet pipe, wherein a dust collecting bucket is arranged at the lower end of the casing, a dust discharging valve is arranged at the lower mouth of the dust collecting bucket, and a basal plate is arranged in the casing; the inner cavity of the casing is divided into an upper cavity body and a lower cavity body by the basal plate, and a plurality of bag filter assemblies are arranged on the basal plate; each bag filter assemblycomprises a skeleton, a filter bag, a high pressure pipe and a lifting pipe, a flow divider is arranged in the lower cavity body, and the lower ends of the high pressure pipes are connected with the flow divider in a communicating mode; a cover plate for sealing positioning holes is fixed at the upper ends of the lifting pipes, the lower ends of the lifting pipes are slidably disposed in the uppermouths of the high pressure pipe, and a plurality of first air outlet holes are formed in the pipe wall of each lifting pipe; and a plurality of second air outlet holes corresponding to the first airoutlet holes are formed in the pipe wall of each high pressure pipe, and an electric push rod for driving the cover plate to perform vertical movement is arranged in the upper cavity body. The invention provides the bag dust remover capable of cleaning the filter bags inside the device and prolonging the service life of the filter bags.

Owner:中石化催化剂山东有限公司

Straw cutting-free method for preparing straw pulp by spherical digester alkali digestion

InactiveCN102400404AImprove the environmentImprove qualityPulping with inorganic basesNon-woody plant/crop pulpAnthraquinonesBlack liquor

The invention provides a straw cutting-free method for preparing straw pulp by spherical digester alkali digestion. The method comprises the following steps of: washing a straw raw material; adding a hot alkali solution, adding water, mixing uniformly, and heating; performing digestion by adopting a conventional sulfate method or a caustic soda anthraquinone method; stopping the digestion when the lignin discharged from the straw raw material by the digestion reaches 75 to 90 percent, discharging a black liquor I, and thus obtaining straw pulp; and adding the hot alkali solution into the straw pulp, performing digestion and conventional washing and thus obtaining unbleached pulp, wherein the thin black liquor discharged during washing is a black liquor II, the black liquor II and water are added into the new straw raw material together, and the unbleached pulp is continuously obtained by repeating. The straw cutting process is eliminated in the method, so that the flow for preparing the pulp by using the straw is simplified; and on the premise of ensuring the digestion effect, the concentration of the solid matter of the black liquor can be improved to over 13 percent, the stock loss of the raw material is reduced by about 5 percent, the single-pot digestion capacity is improved by 10 to 15 percent, and the yield and the viscosity of the formed pulp are raised with different degrees.

Owner:KUNMING UNIV OF SCI & TECH TECH IND SALES MANAGEMENT

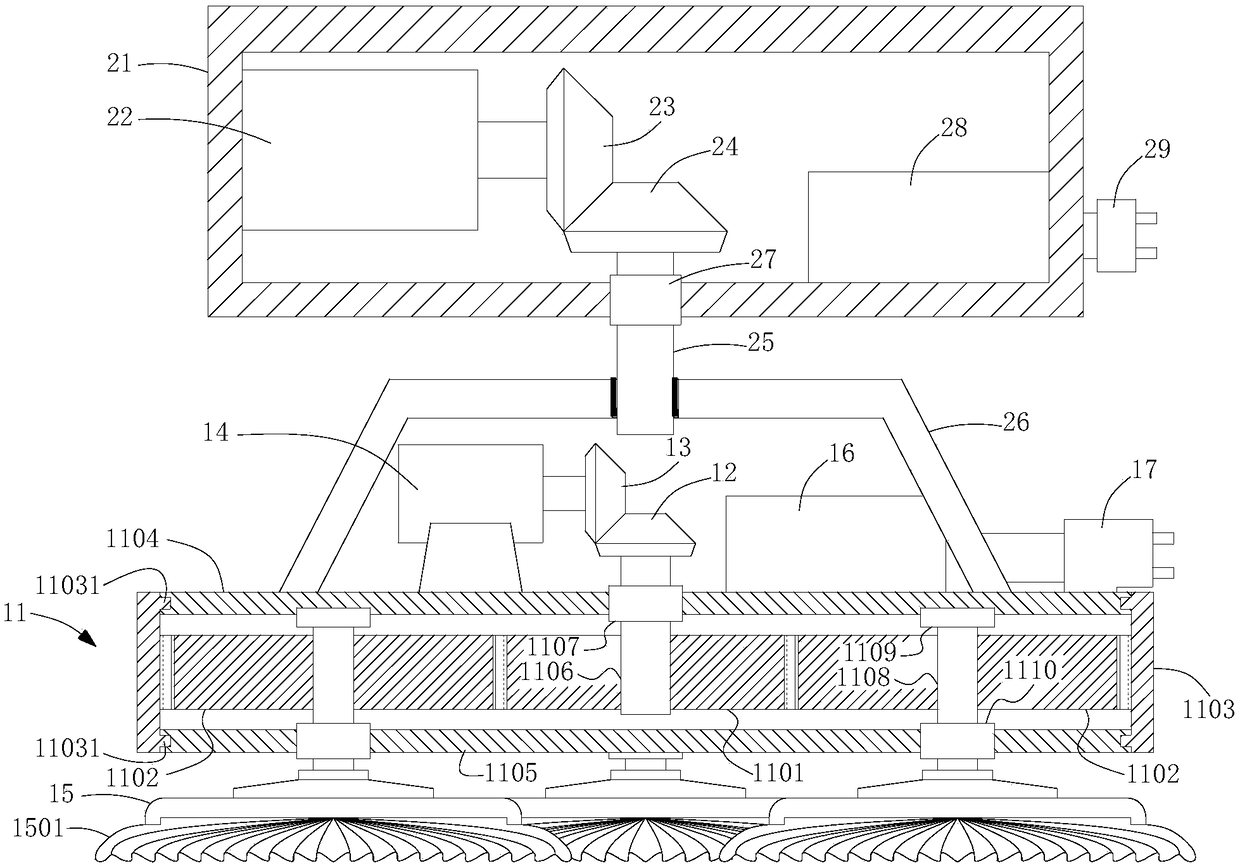

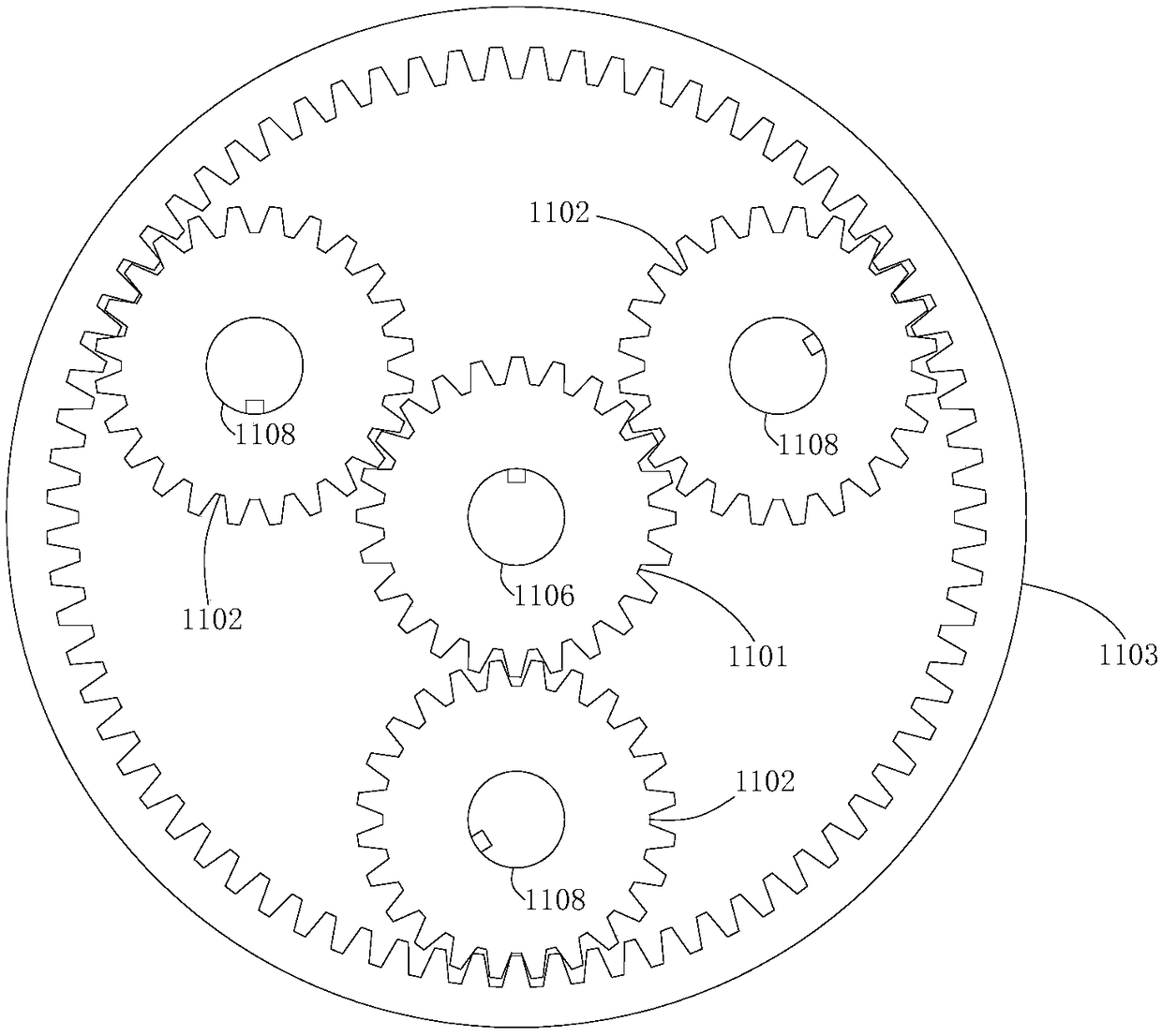

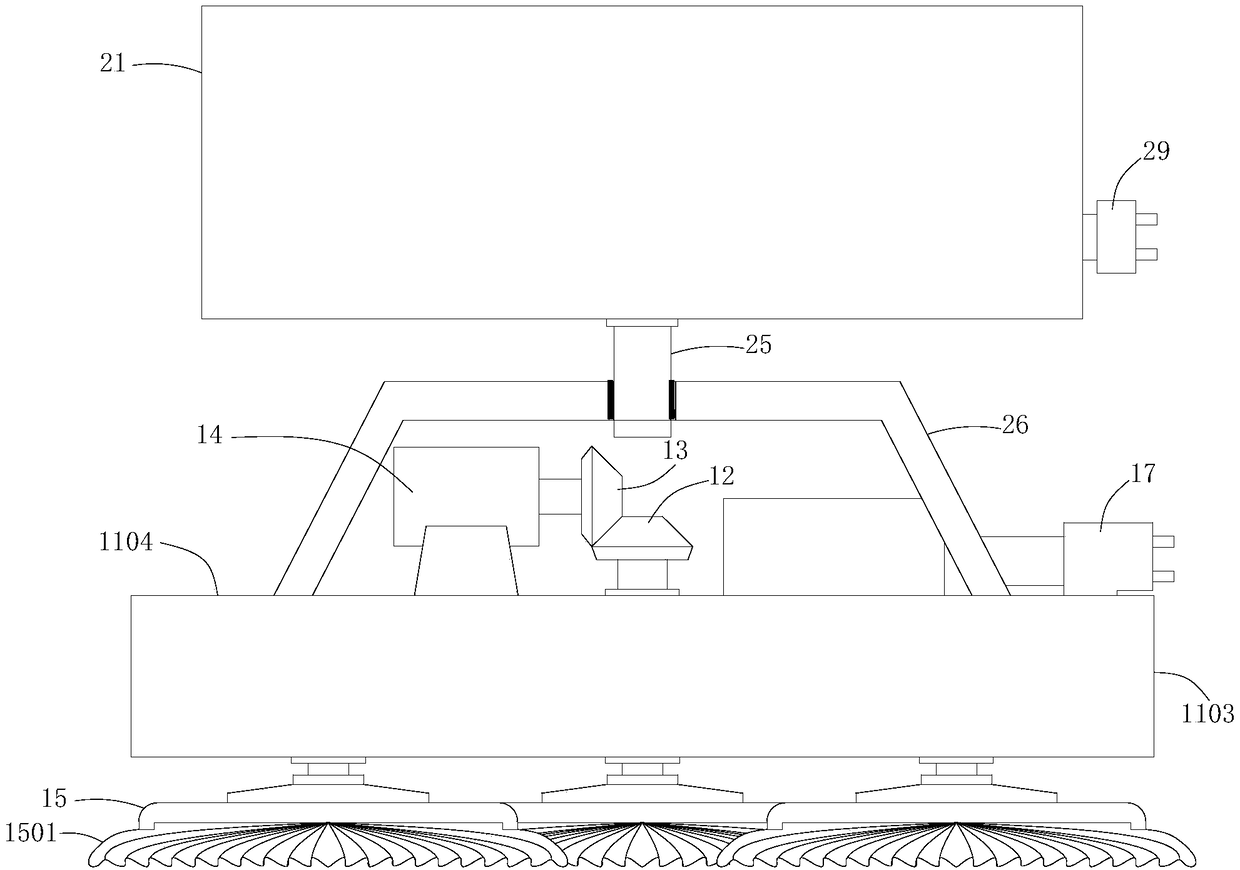

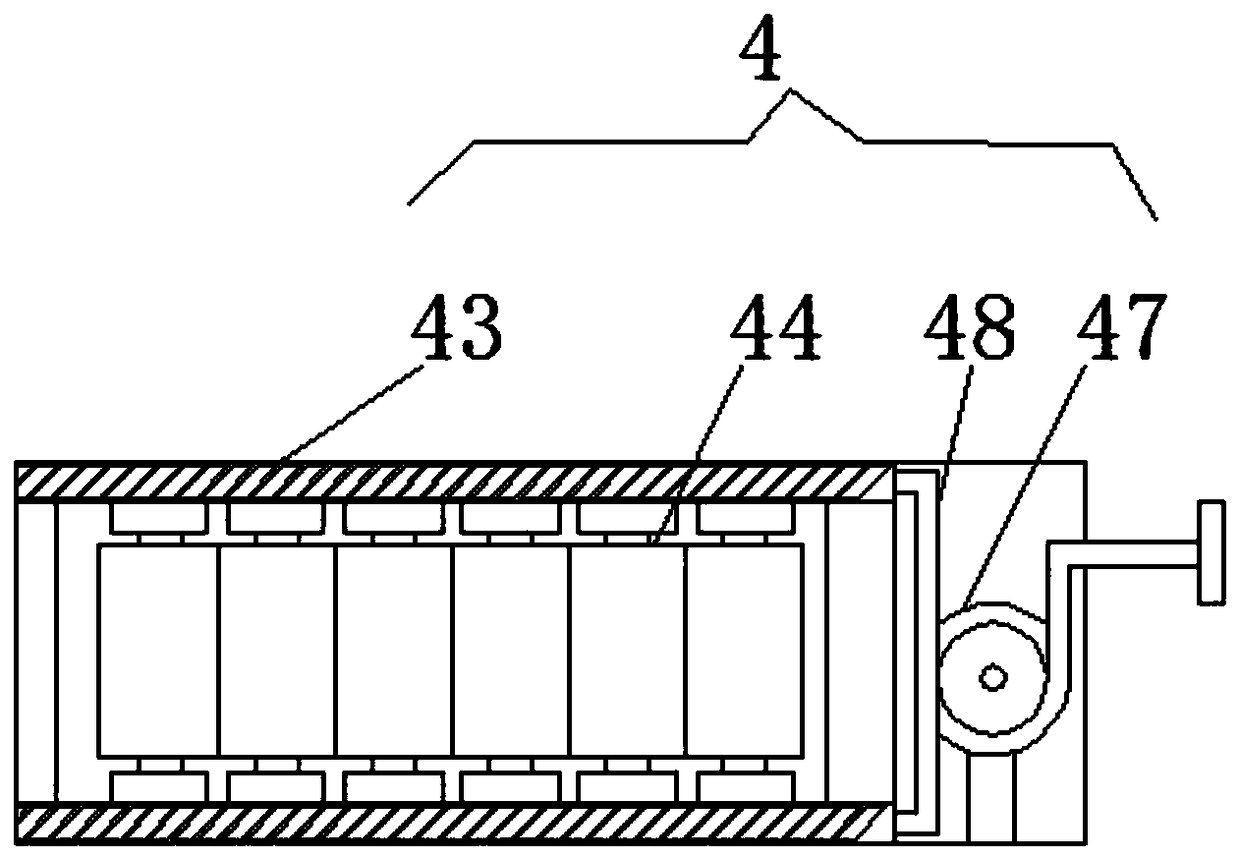

Automatic outdoor LED screen ash removal machine

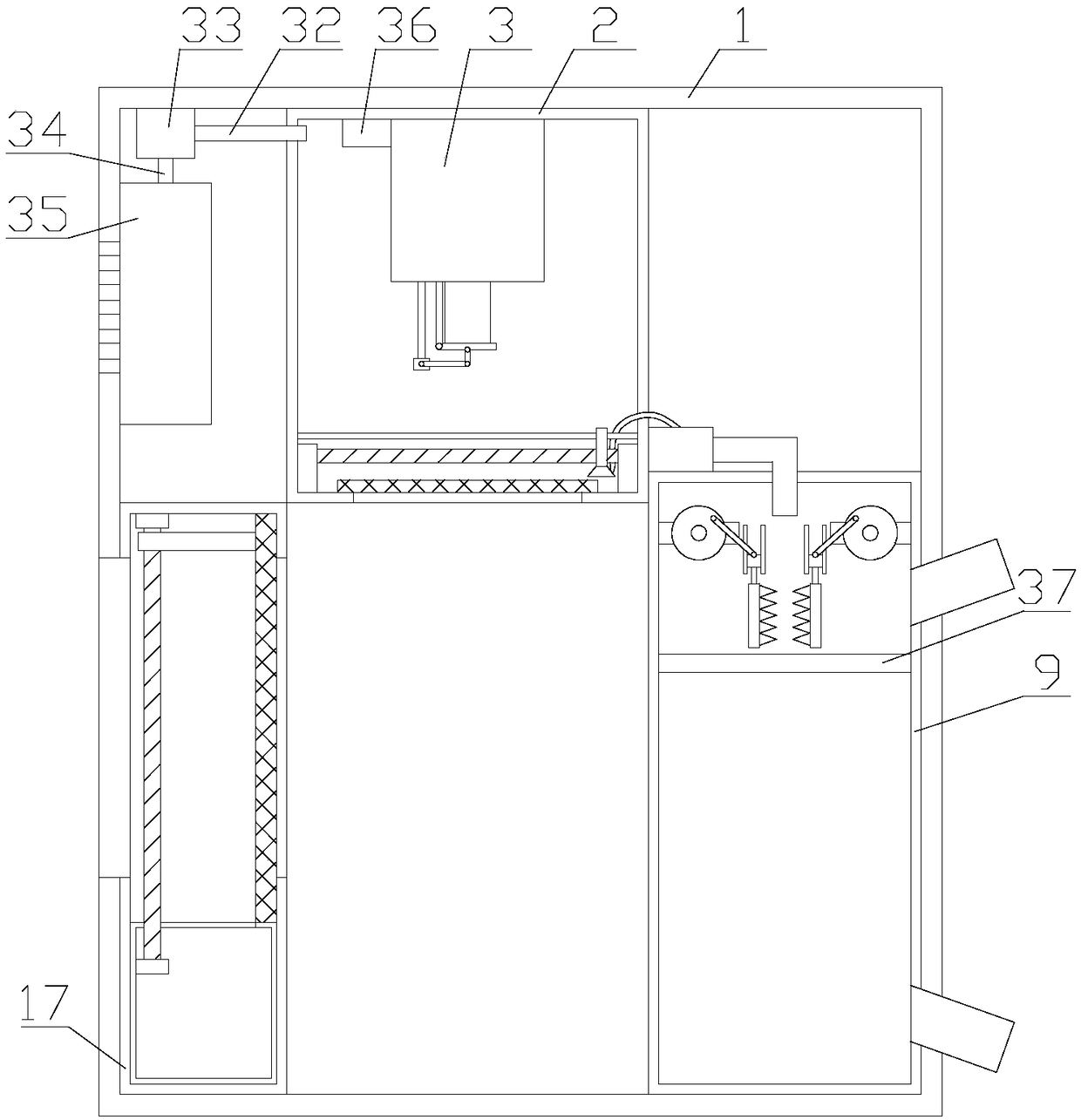

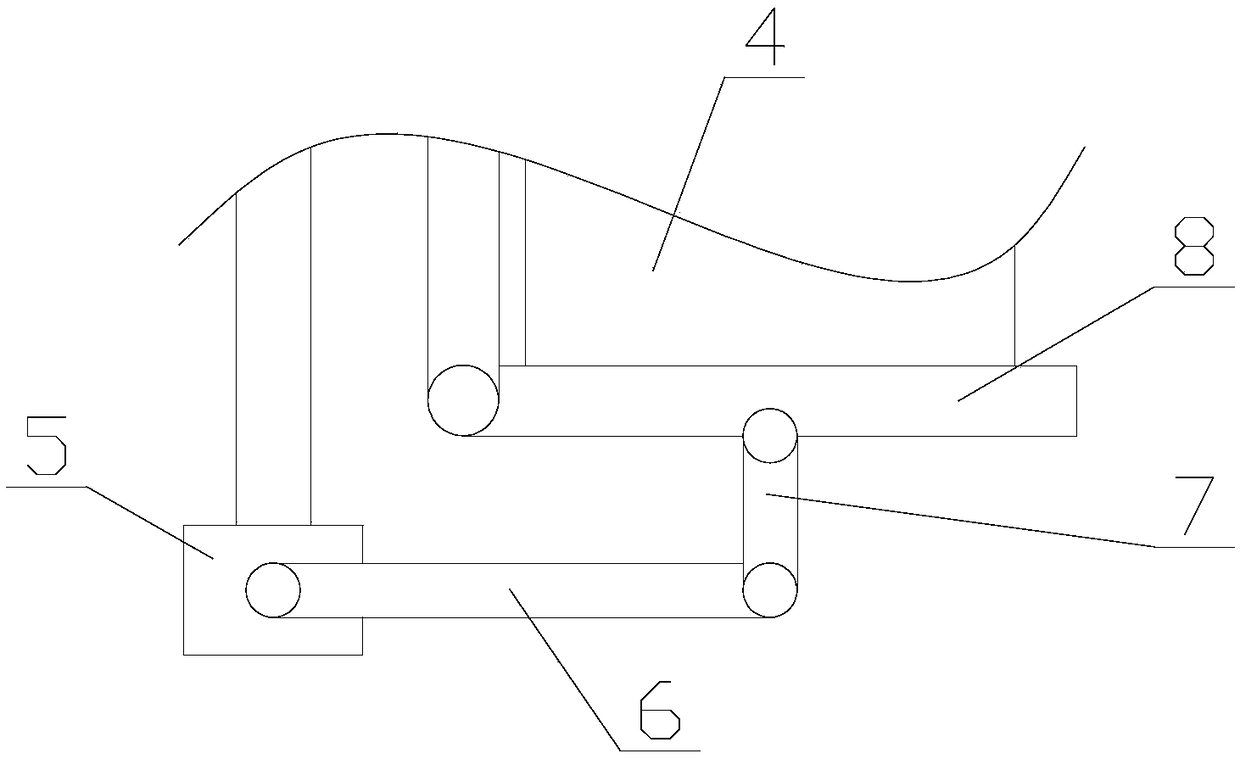

PendingCN108435616AAct quicklyImprove cleanlinessCleaning using toolsMechanical componentsEngineering

The invention discloses an automatic outdoor LED screen ash removal machine. The automatic outdoor LED screen ash removal machine comprises an ash removal assembly, an ash removal assembly rotation mechanism, a first movable mechanism and a second movable mechanism. The ash removal assembly comprises a planet gear set, a first motor and three ash removal brush discs, wherein the first motor can drive the three ash removal brush discs to rotate around the respective axes through the planet gear set. The ash removal assembly rotation mechanism comprises a second motor, and the second motor can drive the three ash removal brush discs to revolve around the common center of the three ash removal brush discs through corresponding components. The first movable mechanism can drive the ash removalassembly and the ash removal assembly rotation mechanism to move in the transverse direction of an LED screen. The second movable mechanism can drive the ash removal assembly and the ash removal assembly rotation mechanism to move in the vertical direction of the LED screen. According to the automatic outdoor LED screen ash removal machine, through a series of mechanical components and mechanicalstructures, automatic outdoor LED screen ash removal can be achieved, current manual ash removal can be replaced, and the beneficial effects that the ash removal efficiency is high, and the human costis low are achieved.

Owner:四川益泽丰信息科技有限公司

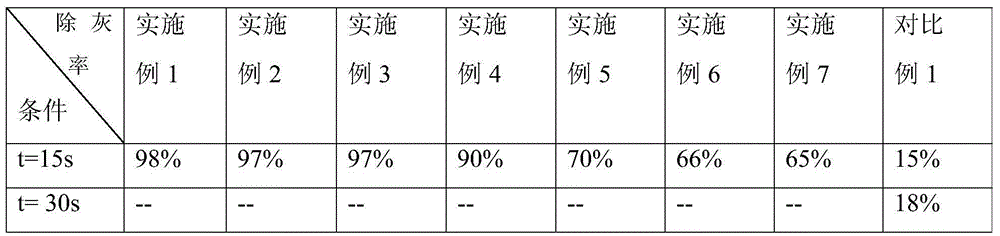

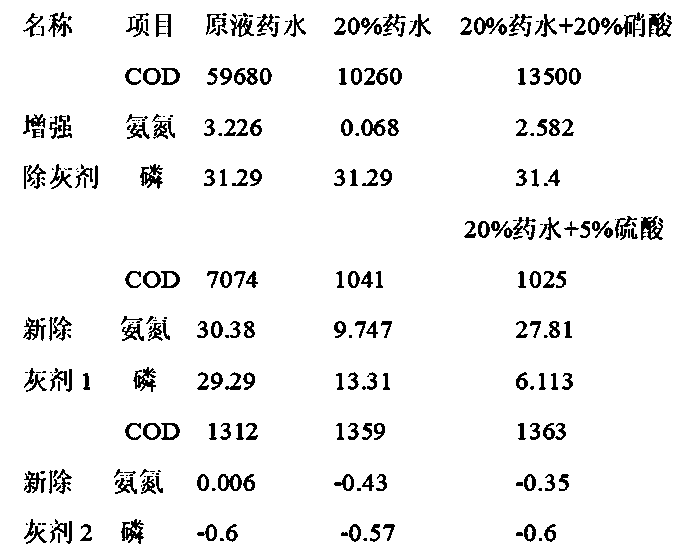

Aluminum surface ash removing agent and preparation method thereof, and surface ash removing method

InactiveCN105463482AGood ash removal effectIncrease the speed of ash removalSurface reaction electrolytic coatingCorrosion inhibitorMaterials science

The invention discloses an aluminum surface ash removing agent and a preparation method thereof, and a surface ash removing method. The aluminum surface ash removing agent is mixed liquid prepared by uniformly mixing HNO3, NH4HF2, an aluminum corrosion inhibitor and water; and in terms of 1 L of the aluminum surface ash removing agent, the usage amount of HNO3 is 540 to 720 g, the usage amount of NH4HF2 is 100 to 150 g, and the usage amount of the aluminum corrosion inhibitor is 1 to 8 g, with the balance being water. The aluminum surface ash removing agent has ideal ash removing effect and a fast ash removing speed when applied to surface ash removal of high-silicon cast aluminum.

Owner:BYD CO LTD

Vibration ash removal type circulating fluidized bed boiler

ActiveCN104990070AAvoid lateral scourReduce wearFluidized bed combustionSolid removalSuperheaterHearth

The invention discloses a vibration ash removal type circulating fluidized bed boiler. The bed boiler comprises a hearth, a rear smoke channel, a separator and a collection box, wherein the separator connects the hearth with the rear smoke channel, and the collection box is located above the rear smoke channel. The vibration ash removal type circulating fluidized bed boiler is characterized by further comprising a hanging tube penetrating the top wall of the rear smoke channel, the rear smoke channel is arranged vertically, and a reheater, a superheater and a coal economizer are sequentially arranged inside the rear smoke channel from top to bottom; the stretching-out end of the hanging tube is connected with the collection box, and the stretching-in end of the hanging tube is sequentially connected with the reheater, the superheater and the coal economizer; and a pneumatic vibrator is arranged between the collection box and the top wall of the rear smoke channel, and the pneumatic vibrator is fixed to the hanging tube through a clamp. According to the vibration ash removal type circulating fluidized bed boiler, heating surface tube bundles of the reheater, the superheater and the coal economizer are driven by continuous reciprocating vibration of the hanging tube to shake continuously, and ash attached to the heating surface tube bundles falls off and is taken away along with smoke, so that the ash removal efficiency is greatly improved.

Owner:HMEI THREAD CO LTD OF YINBIN SICHUAN +1

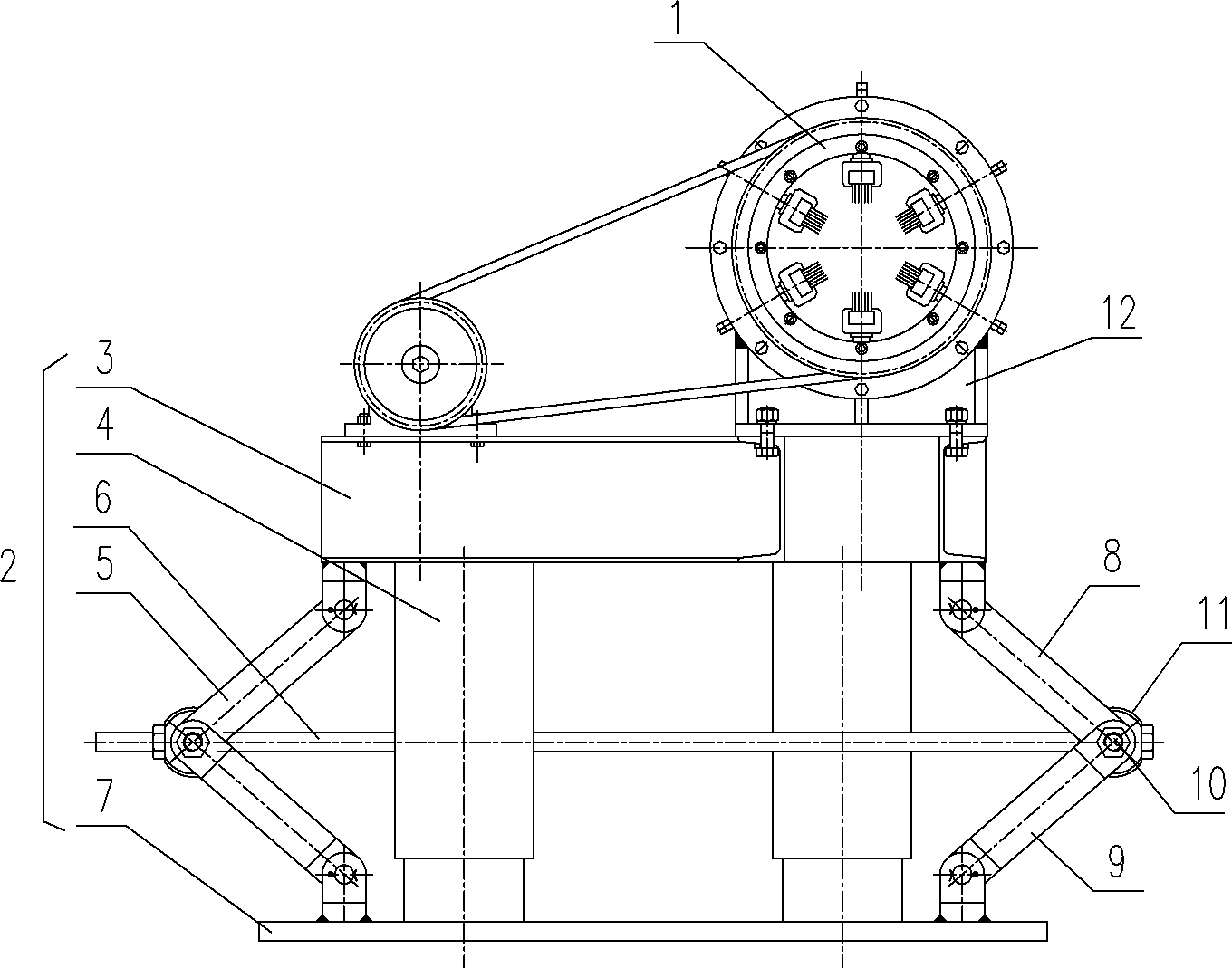

Rotary type steel pipe surface cleaning device

InactiveCN102716877ALarge coverageGood ash removal effectHollow article cleaningSteel tubeHinge angle

The invention relates to a rotary type steel pipe surface cleaning device which is characterized by comprising a rotary brush bracket and a lifting base, wherein the rotary brush bracket is arranged on the lifting base and comprises a fixing seat, bearings, brush heads, a belt pulley and an inner ring; the bearings are arranged between the inner ring and the fixing seat; the brush heads are centripetally and circumferentially distributed on the inner ring; the belt pulley is arranged on one sides of the inner ring; the lifting base comprises an upper platform, lifting guide devices, lifting hinges, a spiral adjusting mechanism and a tail margin bearing plate; the lifting guide devices and the lifting hinges are arranged between the upper platform and the tail margin bearing plate respectively; and the two groups of lifting hinges are connected with each other through the spiral adjusting mechanism. Compared with the prior art, the invention has the benefits as follows: the covering area of steel brushes is large, the dust removing effect is good, and the accuracy of pipe body flaw detection is improved; and 2, the change of steel pipe specification is convenient and only requires corresponding adjustment but large-scale disassembly and dismounting, so as to reduce auxiliary operation time and labor intensity.

Owner:ANGANG STEEL CO LTD

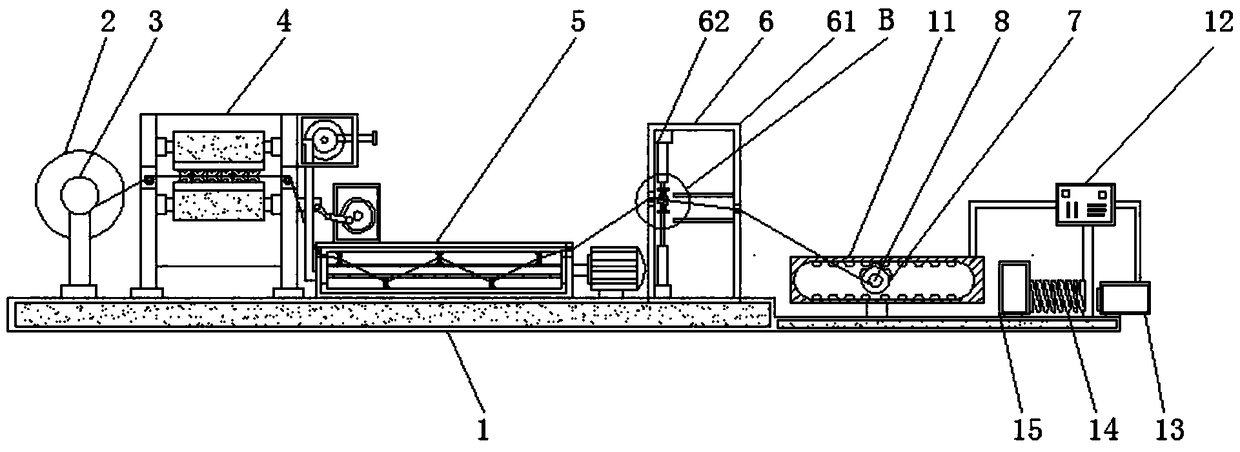

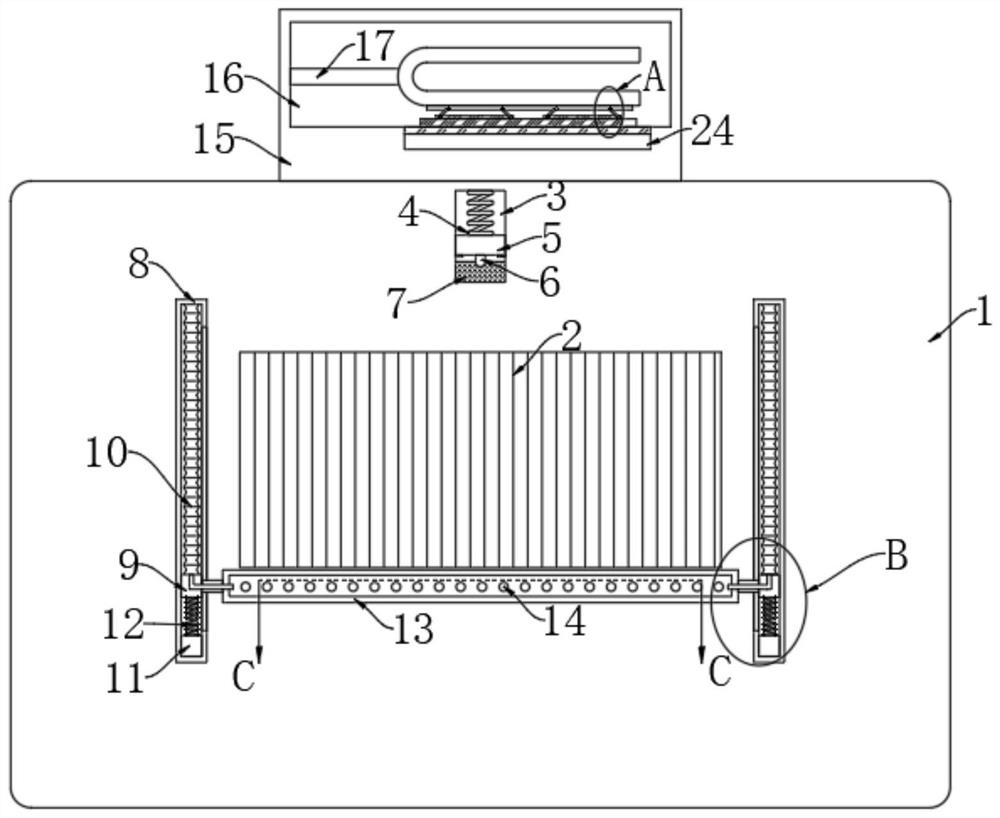

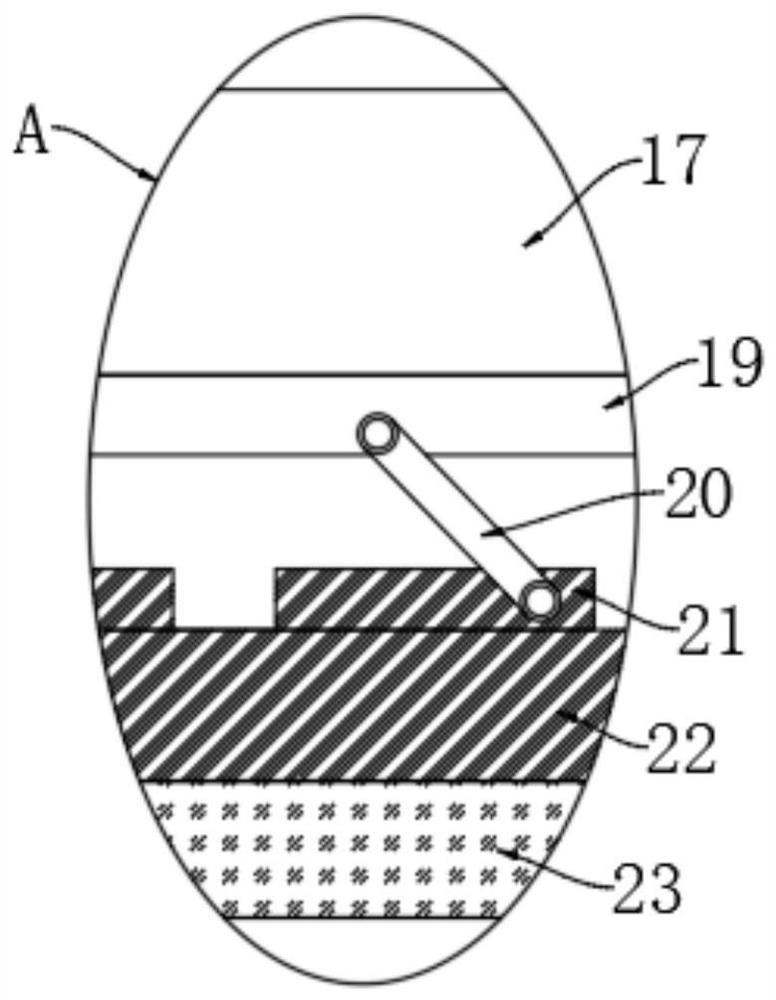

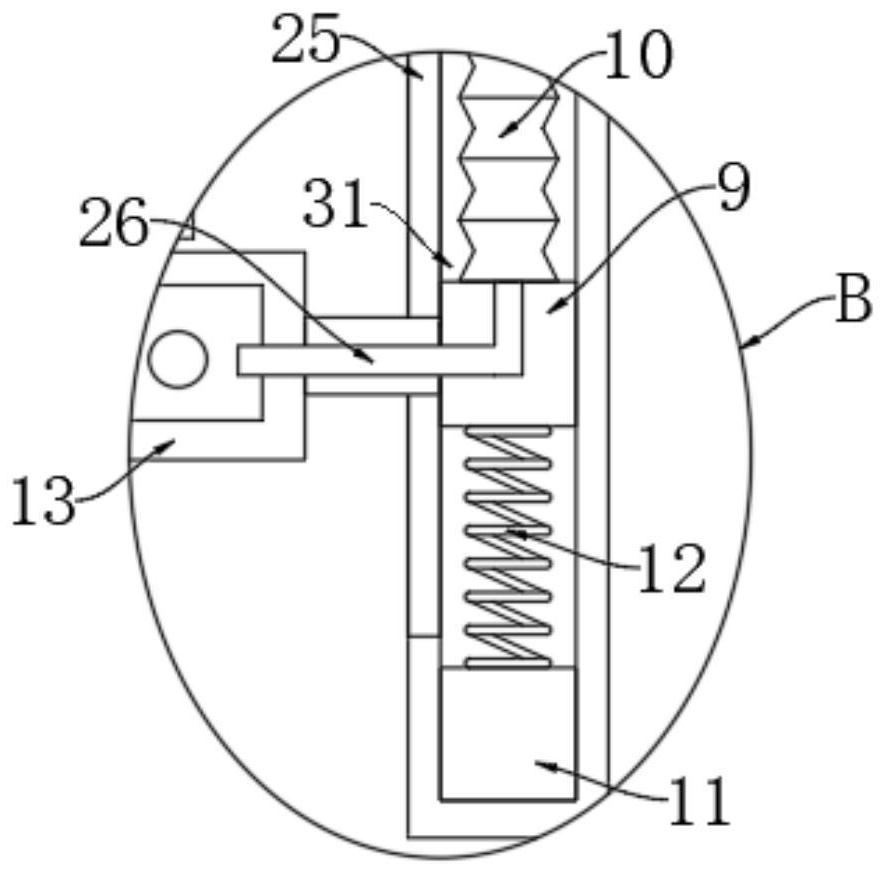

Gauze leveling drying integrate machine with excellent compressing effect

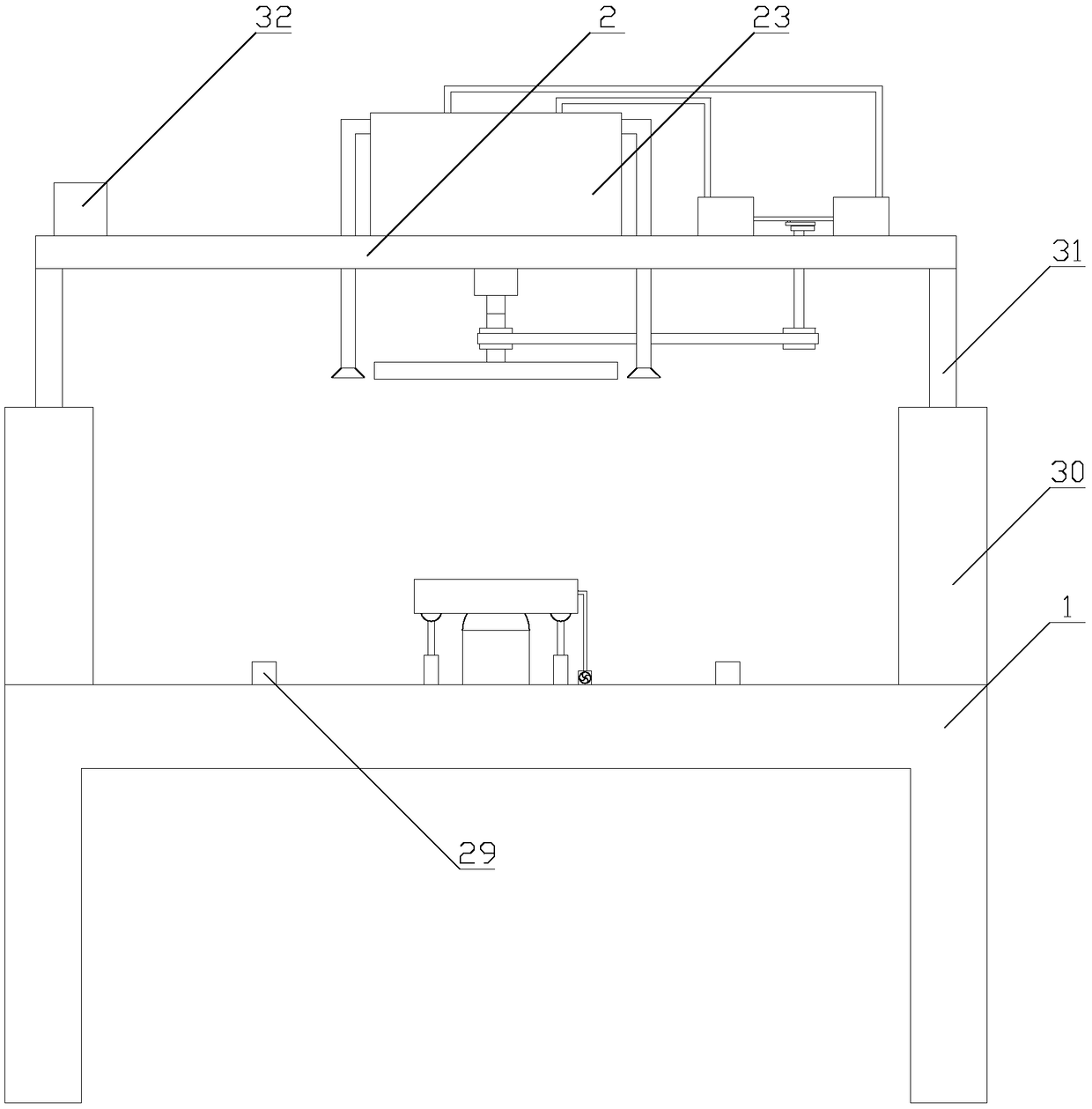

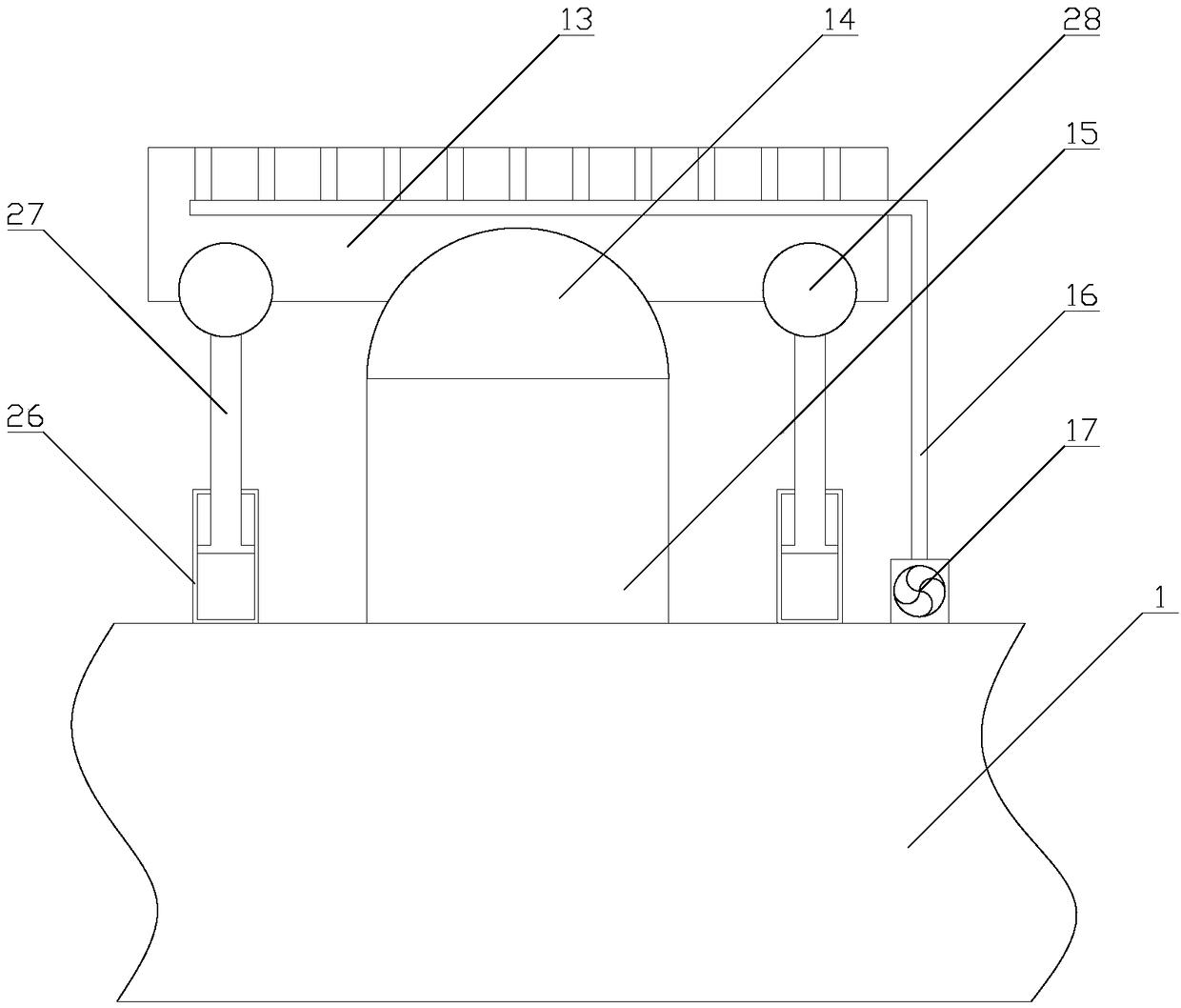

ActiveCN109099678ACompress tightlyCompression effect is tightMechanical cleaningPressure cleaningPulp and paper industry

The invention provides a gauze leveling drying integrate machine with an excellent compressing effect, and relates to the technical field of medical application. The gauze leveling drying integrate machine with the excellent compressing effect comprises a machine body. A first motor is fixedly mounted at the top of the machine body by a supporting bracket. The output end of the first motor is movably connected with a first coil. A dewatering device is fixedly mounted at the top of the machine body. The dewatering device comprises an installation bracket. Hollow pipes are fixedly mounted on theopposite sides of the inner wall of the installation bracket. Cylinders are arranged on the outer surfaces of the hollow pipes in a sleeving mode. Rubber sleeves are fixedly mounted in the cylinders.A draught fan is fixedly mounted on the right side of the installation bracket. An air outlet pipe communicates with an air outlet of the draught fan. A sleeve is fixedly mounted on the inner wall ofthe installation bracket. According to the gauze leveling drying integrate machine with the excellent compressing effect, water in gauze can be completely squeezed out, dewatering efficiency is improved, the dewatering time is shortened, and the dewatering effect is more reasonable.

Owner:MEDWELL MEDICAL PROD

Environment-friendly ash removal agent

ActiveCN110306196AReduce pollutionAvoid corrosionProcess efficiency improvementSURFACTANT BLENDAmmonia nitrogen

The invention belongs to the technical field of chemical polishing of aluminum alloy, and specifically discloses an environment-friendly ash removal agent. The environment-friendly ash removal agent is prepared from the following components in parts by weight: 1% to 2% of sulfuric acid, 20% to 25% of oxidizing agent, surfactant, polycarboxylic acid compounds and the balance of water. Compared withthe prior art, the environment-friendly ash removal agent has the advantages that a sulfuric acid and hydrogen peroxide system is adopted, ammonia nitrogen is not contained, the ash removal effect isquick, the ash removal operation takes more than one minute on the market, but the ash removal operation can be completed by the product within 25 seconds to 30 seconds, the ash removal effect is good, the speed is high, the ammonia nitrogen is not contained, so that environmental pollution is reduced, the effects of environmental friendliness, safety, high use efficiency and low cost are achieved, the surfactant prepared from sodium dodecyl benzene sulfonate is added and is used as a stabilizing agent of the oxidizing agent, the polycarboxylic acid compounds are combined so as to prevent thesurface of an aluminum product from being corroded, the product is used for removing ash only and cannot corrode, and the use safety is high.

Owner:东莞市尚南电子科技有限公司

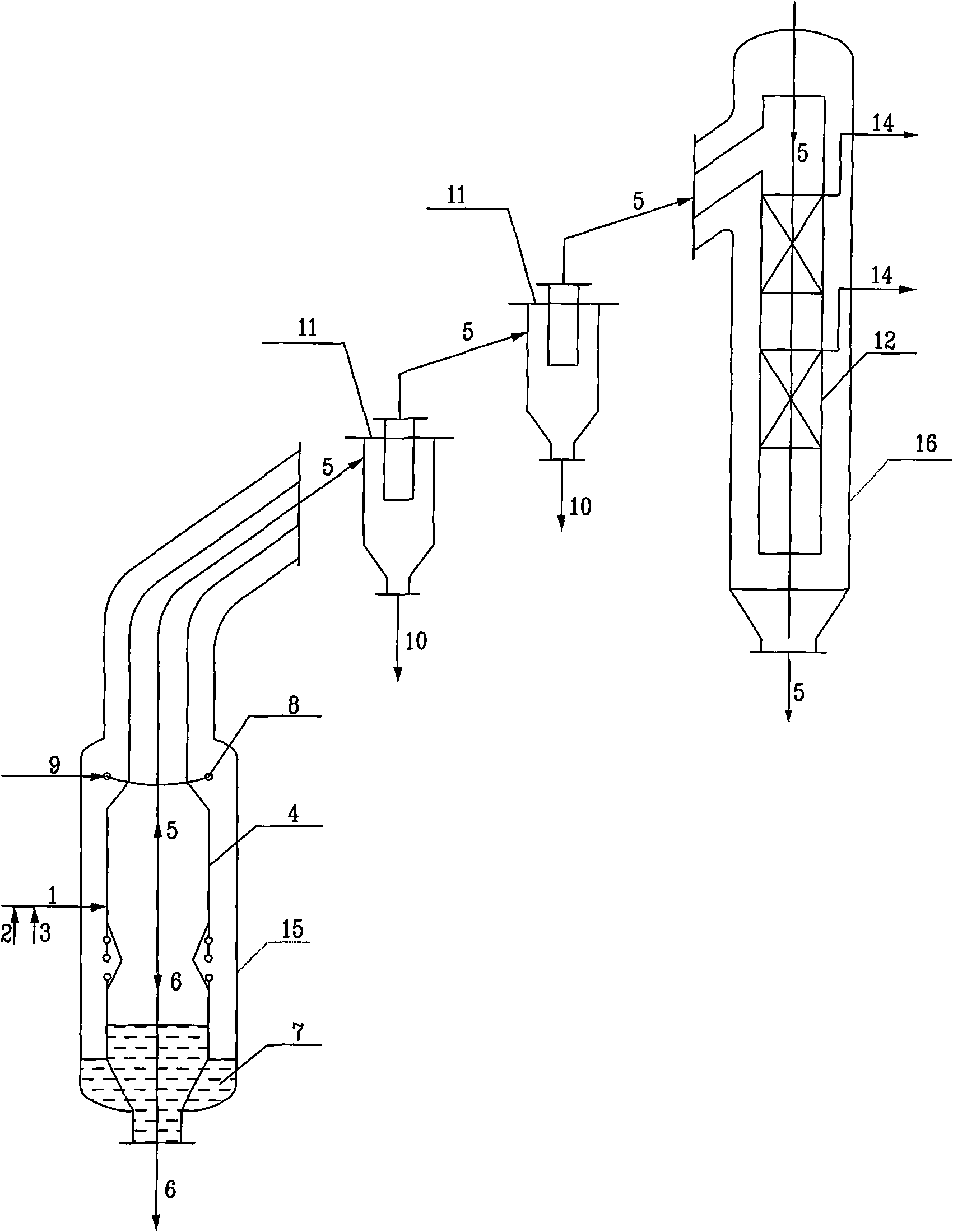

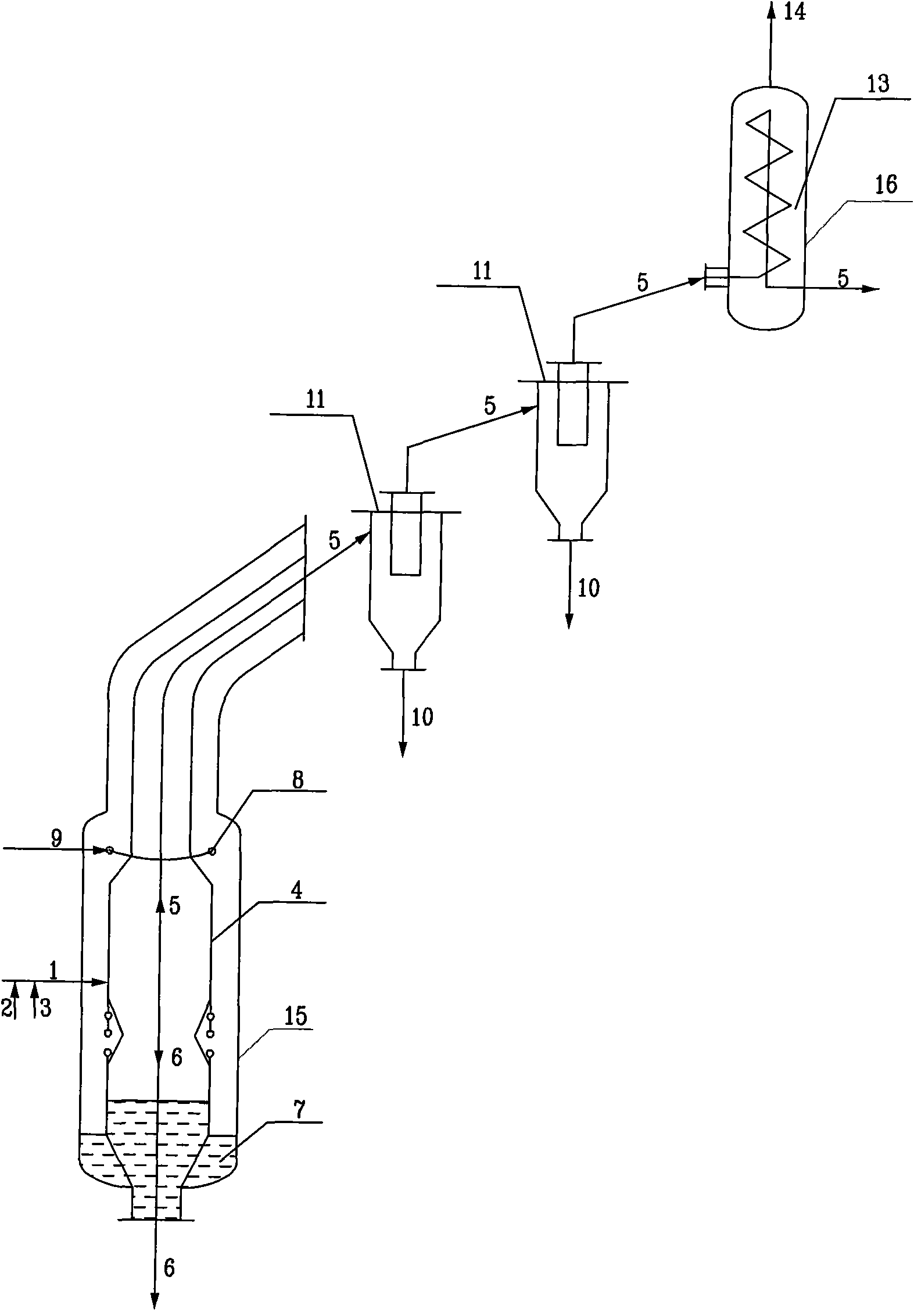

Gasification method of carbon-containing solid raw material and used reactor

ActiveCN102041106AGuaranteed stabilityGuaranteed continuityEnergy inputCombustible gas productionSyngasSlag

The invention relates to a gasification method of a carbon-containing solid raw material and a used reactor. The gasification method is characterized by comprising the following steps of: reacting the carbon-containing solid raw material with oxygen in a reactor unit so as to generate synthesis gas, wherein ash flows downwards into a slag pool at the lower end of a gasification reactor in the slag form under the action of gravity force; allowing high-temperature synthesis gas which entrains molten ash residues to rise to a chill zone in the gasification reactor, injecting steam or / and water into the chill zone by using chilling equipment and chilling the high-temperature synthesis gas so as to freeze the molten ash residues entrained in the high-temperature synthesis gas into solid dust; introducing the synthesis gas which entrains the chilled solid dust into a dust removing unit so as to remove dust entrained in the synthesis gas; and introducing the synthesis gas into a waste boiler unit and generating steam by using process waste heat of the synthesis gas. The reactor provided by the invention isolates a gasification furnace from the waste boiler unit through respective shell and the dust removing unit is arranged between the gasification furnace and the waste boiler unit. The equipment has low wear rate and can run for a long time.

Owner:CHINA PETROCHEMICAL CORP +2

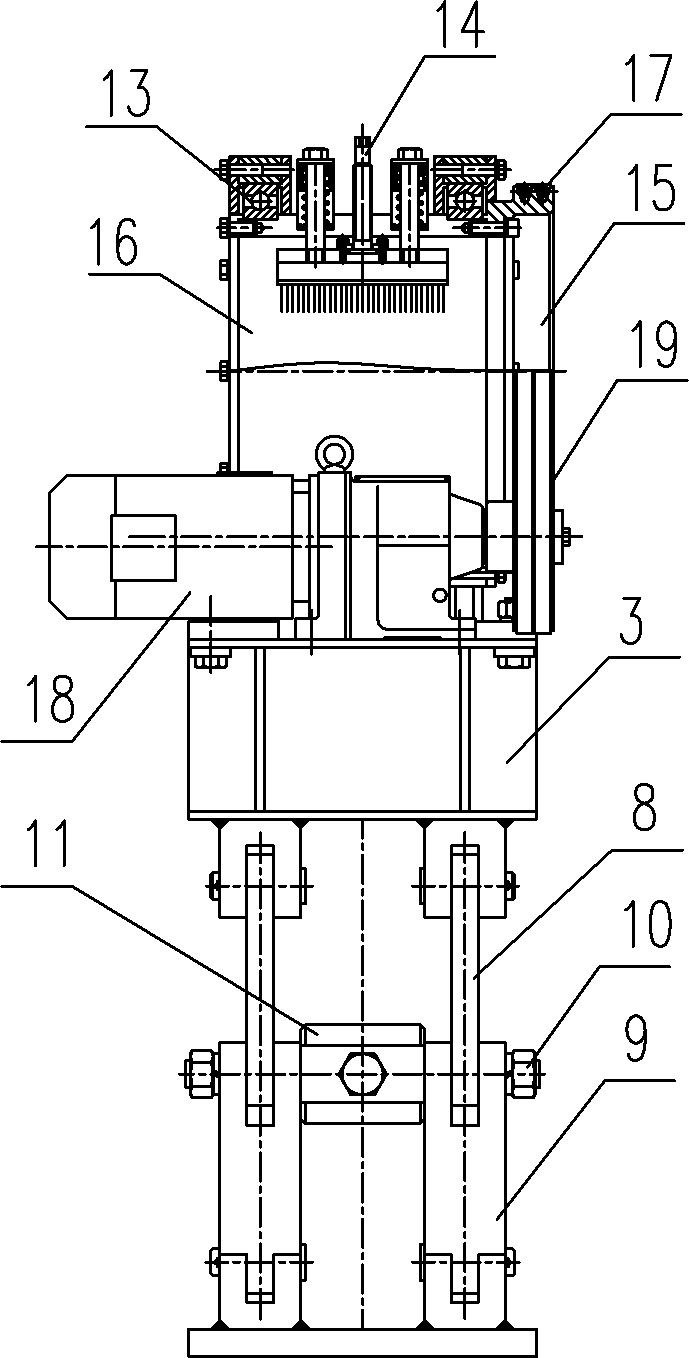

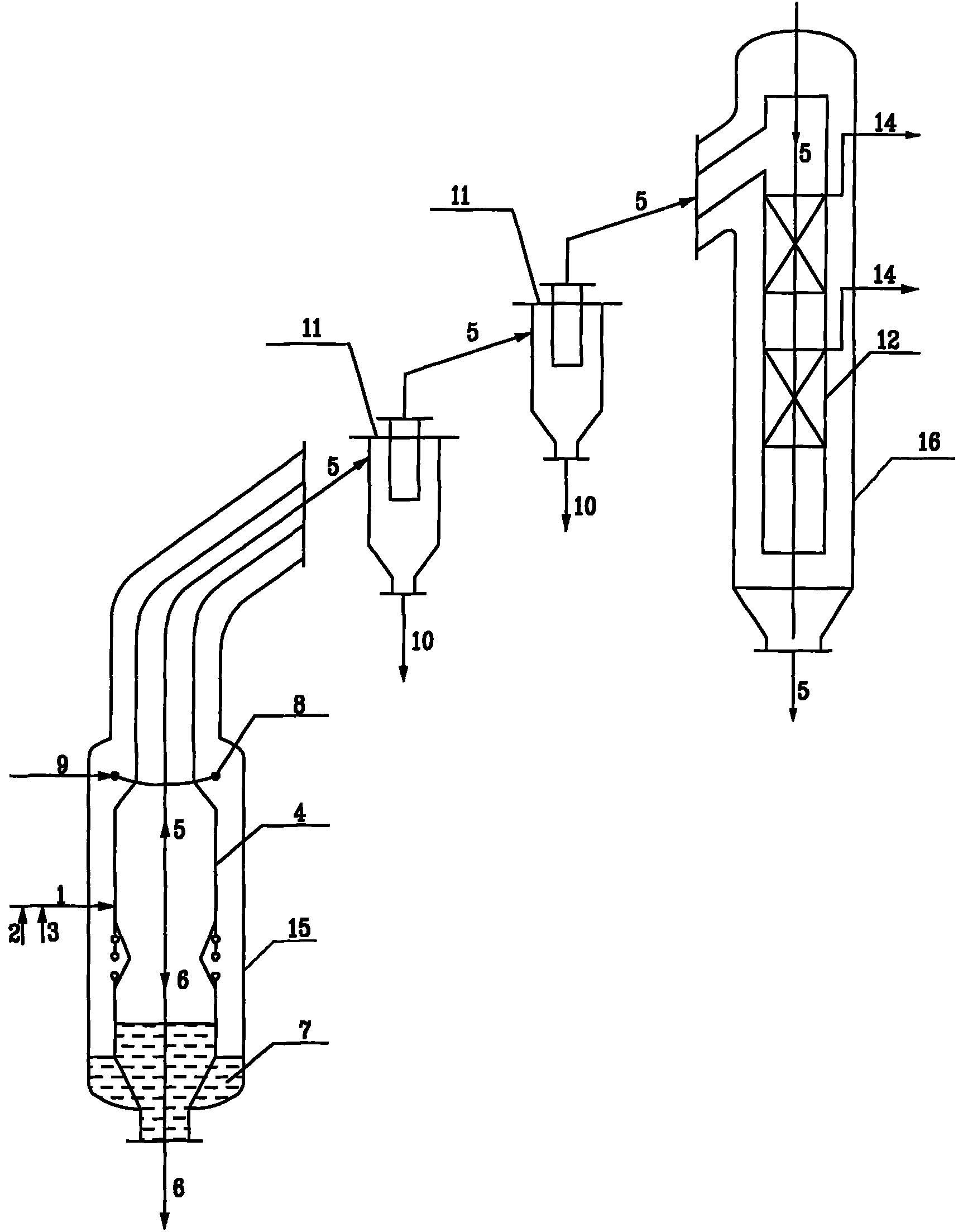

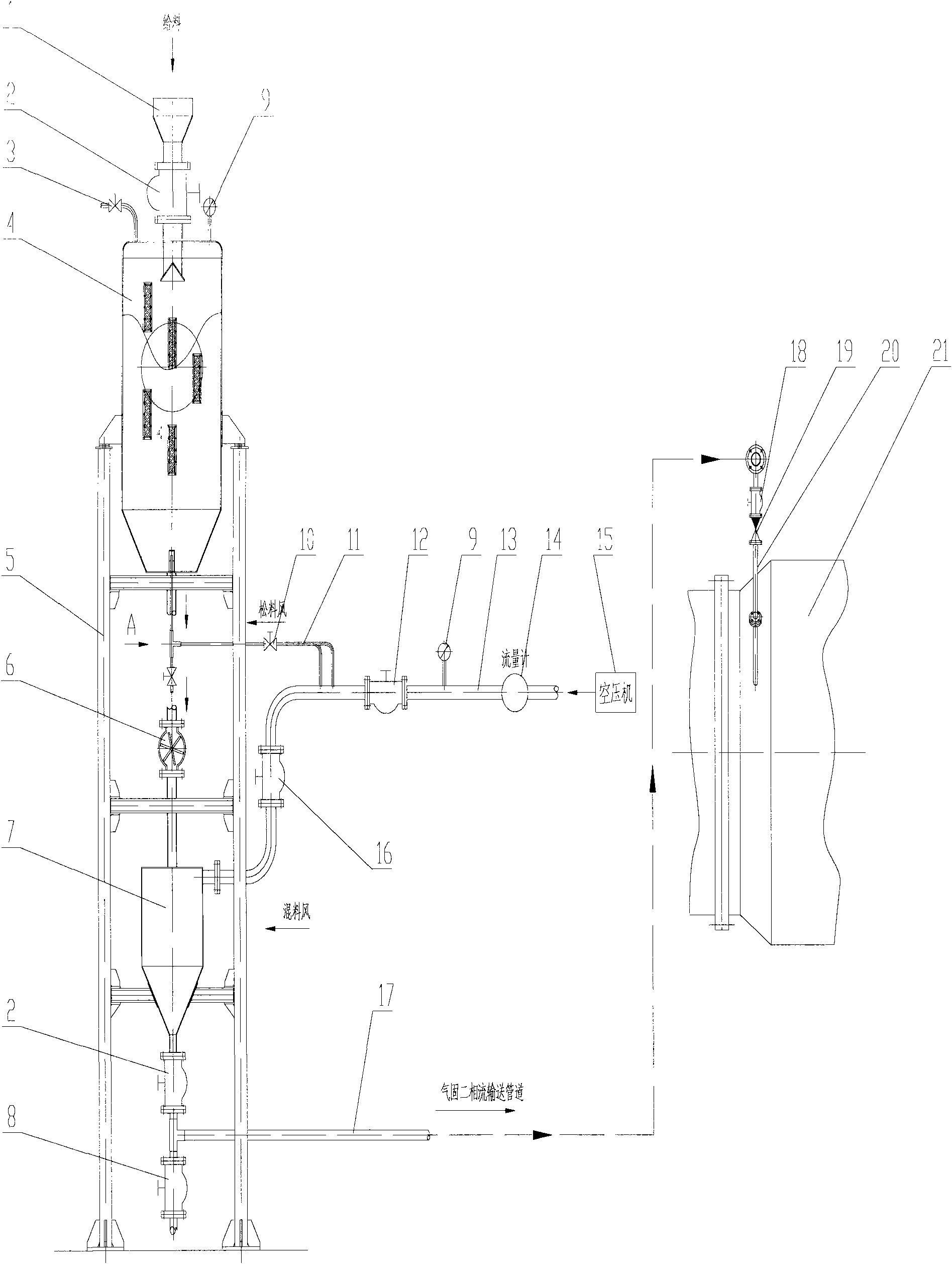

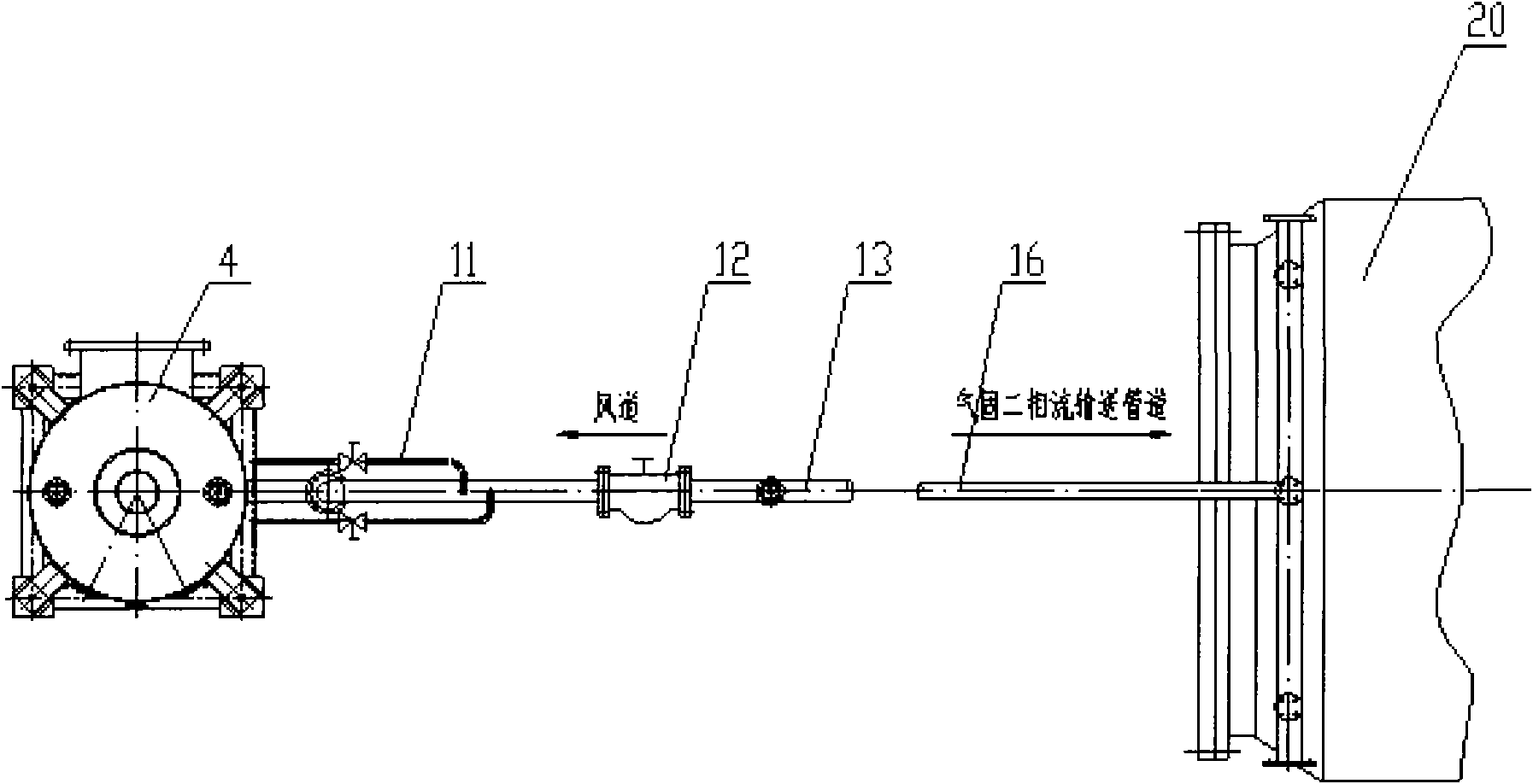

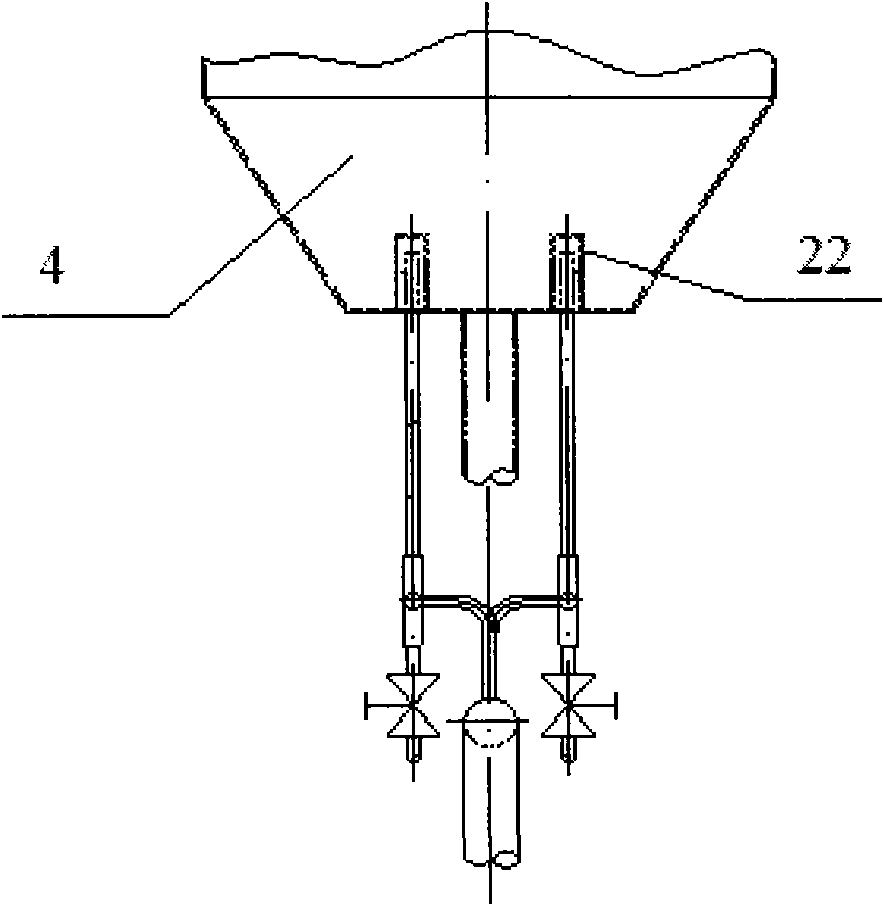

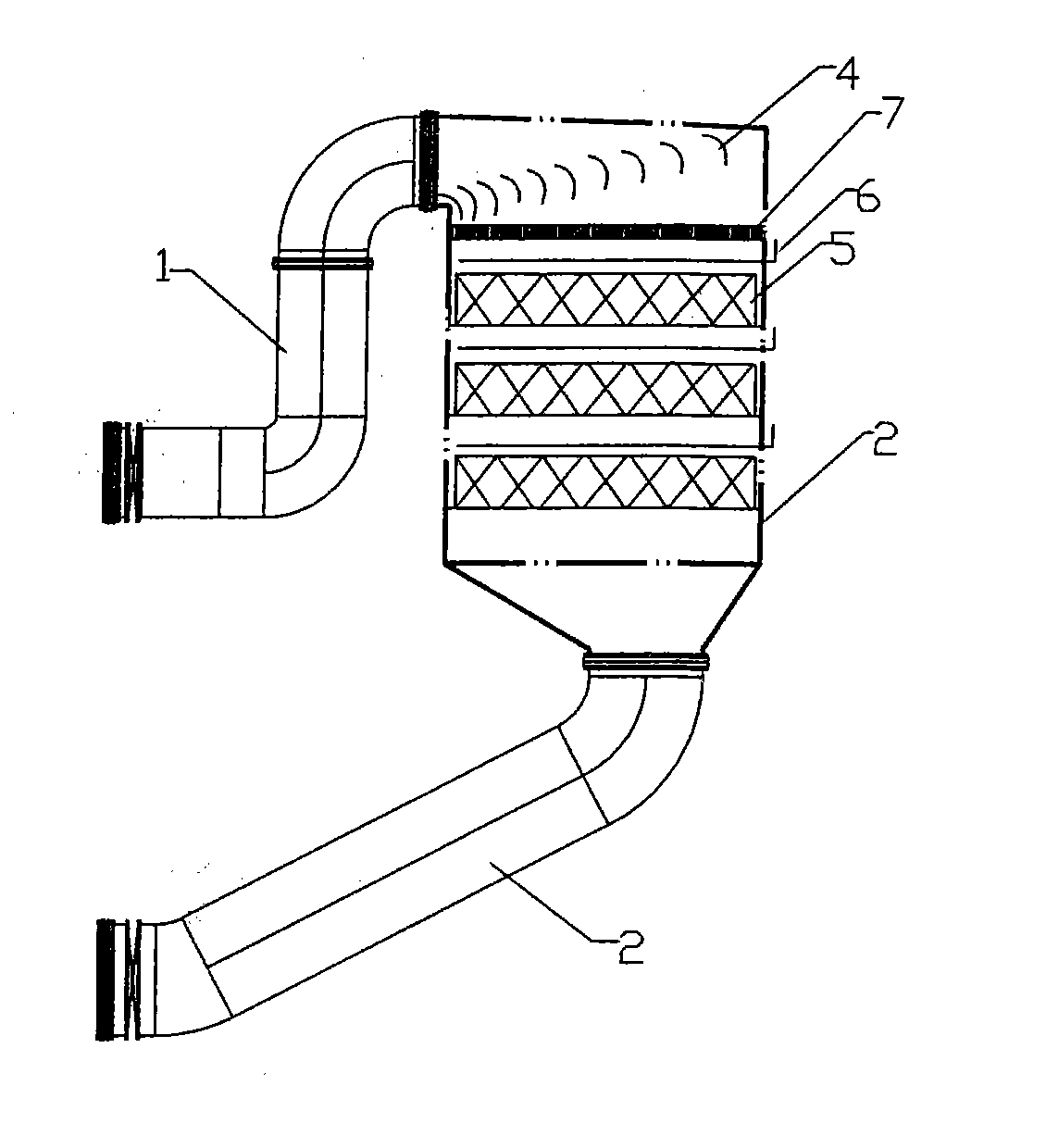

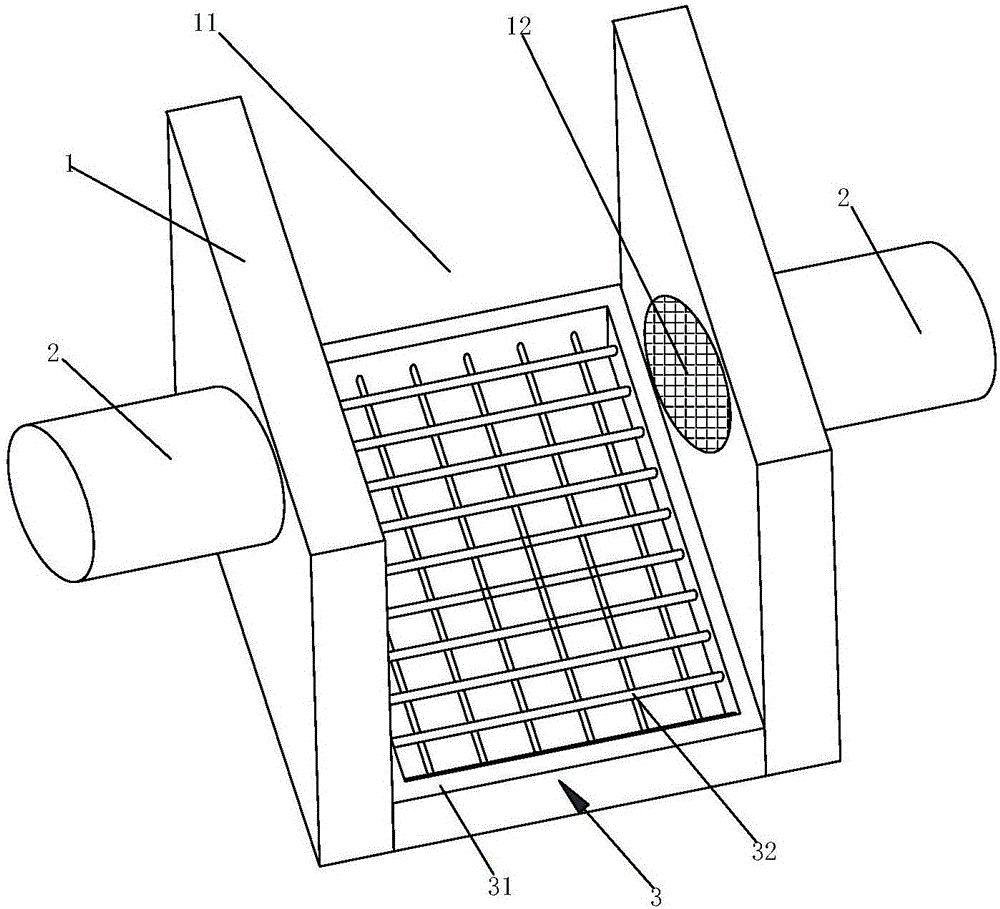

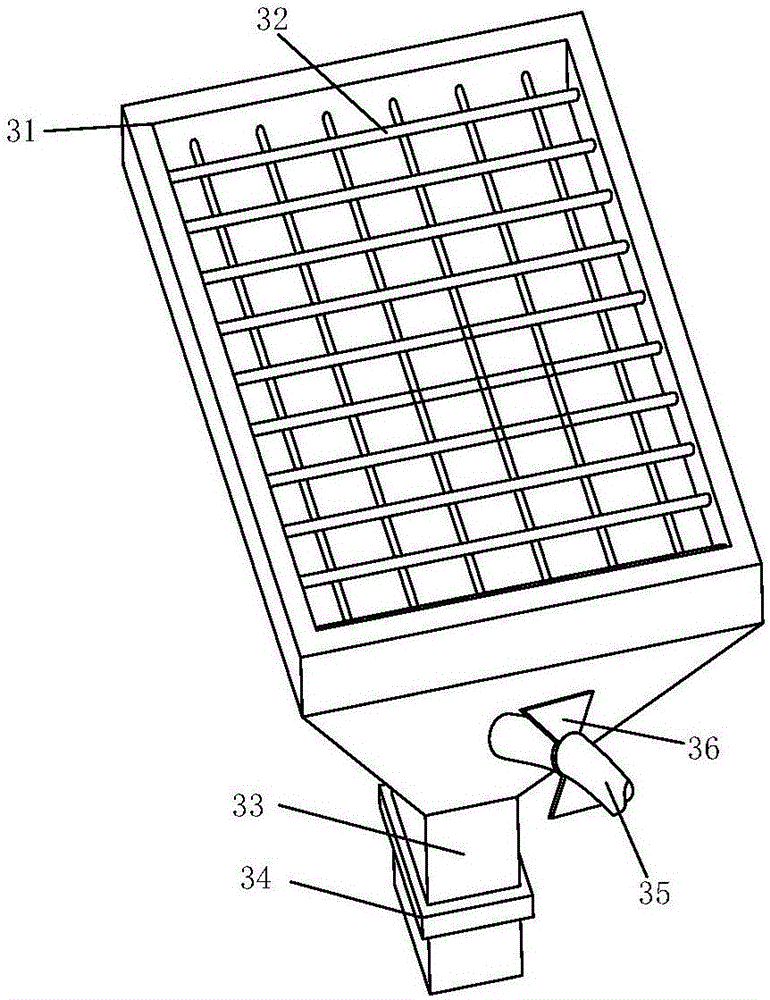

Fluidized grain dust removing system

ActiveCN101634456ASimple preparation processImprove controllabilitySolid removalEngineeringAir compressor

The invention provides a fluidized grain dust removing system which comprises a charging hopper, a material storage pot, a screwed feeder and a material even mixing pot which are sequentially connected from the top down and fixed on a steel bracket, wherein a cylinder body of the material storage pot is divided into an upper part and a lower part, the upper part is cylindrical, and the lower part is of an inverted cone shape; an upper sealing head of the material storage pot is connected with an outlet of the charging hopper through a pipeline, and a lower sealing head of the material storage pot is connected with an inlet of the screwed feeder through a pipeline; an outlet of the screwed feeder is connected with the top of the material even mixing pot; the upper part of the material even mixing pot is cylindrical, while the lower part is of the inverted cone shape; the top end of material even mixing pot is connected with one end of a main air pipe, while the other end of the main air pipe is connected with an air compressor, and a material loosing air pipe is also led out from the main air pipe; and the bottom end of the material even mixing pot is connected with one end of a material conveying pipeline, while the other end of the material conveying pipeline is connected with a front smoke box of a boiler. The system can mix fine sand with air so as to enable the fine sand to be fluidized and has simple manufacturing process, strong controllability, high safety, good stability, ideal dust removing effect as well as convenient use and maintenance.

Owner:BEIJING HANGHUA ENERGY SAVING ENVIRONMENTAL PROTECTION TECH CO LTD

Dedusting and heat-radiating integrated cabinet

InactiveCN108064125AReduce the temperatureReduce internal temperatureCooling/ventilation/heating modificationsInlet channelCooling chamber

The invention discloses a dedusting and heat-radiating integrated cabinet which relates to the technical field of computer equipment. The dedusting and heat-radiating integrated cabinet settles a problem of low dedusting and heat-radiating efficiency in an existing cabinet. The cabinet comprises a cabinet body. An air inlet channel is arranged above the cabinet body. The air inlet channel is internally provided with an air inlet fan. The cabinet is characterized in that the periphery of the air inlet channel is provided with a first cooling wall; a cooling chamber is arranged below the air inlet channel; the periphery of the cooling chamber is provided with a second cooling wall; the cooling chamber is internally provided with a cooling tube; the inner wall at the periphery of the cabinetbody is provided with a mounting table; the mounting table is internally provided with a rotating motor; the rotating motor is connected with a rotating shaft; the rotating shaft is connected with a turntable; the surface of the turntable is provided with air guiding holes and air guiding strips; the periphery of the rotating shaft is provided with second air guiding pipes; and the lower end in the cabinet body is provided with an ash discharging channel. The dedusting and heat-radiating integrated cabinet has advantages of high efficiency, high effect, and no harm to health.

Owner:HENAN YUNLE TECH CO LTD

Ash removal device of dust remover used for flue gas from submerged arc furnace, and ash removal method for dust remover

InactiveCN111514693AImprove cleanlinessAvoid damageCombination devicesDispersed particle filtrationFlue gasReciprocating motion

The invention discloses an ash removal device of a dust remover used for flue gas from a submerged arc furnace, and an ash removal method for the dust remover. According to the ash removal device, theoutput end of a water cooling flue is connected with a settling bin through a pipeline; the settling bin is connected with a dust remover body through a pipeline and an explosion-proof centrifugal fan; a partition plate, single bag filter members, a flow guide frame and an ash removal assembly are installed on the inner side of the dust remover body; and the flow guide frame is located below thesingle bag filter members and the ash removal assembly. According to the invention, dust removal cloth bags are used for removing dust; the flow guide frame is installed so as to reasonably divide rapidly-entering flue gas, and the overall ash removal and dust clearing effect is improved; the ash removal assembly is movably connected with the single bag filter members; when a servo motor works, abevel gear is driven to rotate, then a rotary disc rotates along with the bevel gear, then a sliding rod drives a sliding column to reciprocate up and down, and a transverse frame reciprocates up anddown at the same time; and when the transverse frame moves, the preset bristles of the transverse frame can make contact with the outer wall of the single bag filter members, and the bristles can brush away dust accumulated on the outer walls of the single bag filter members, so ash removal effect is good.

Owner:ANHUI HANSHAN COUNTY TIANSHUN ENVIRONMENTAL PROTECTION EQUIP

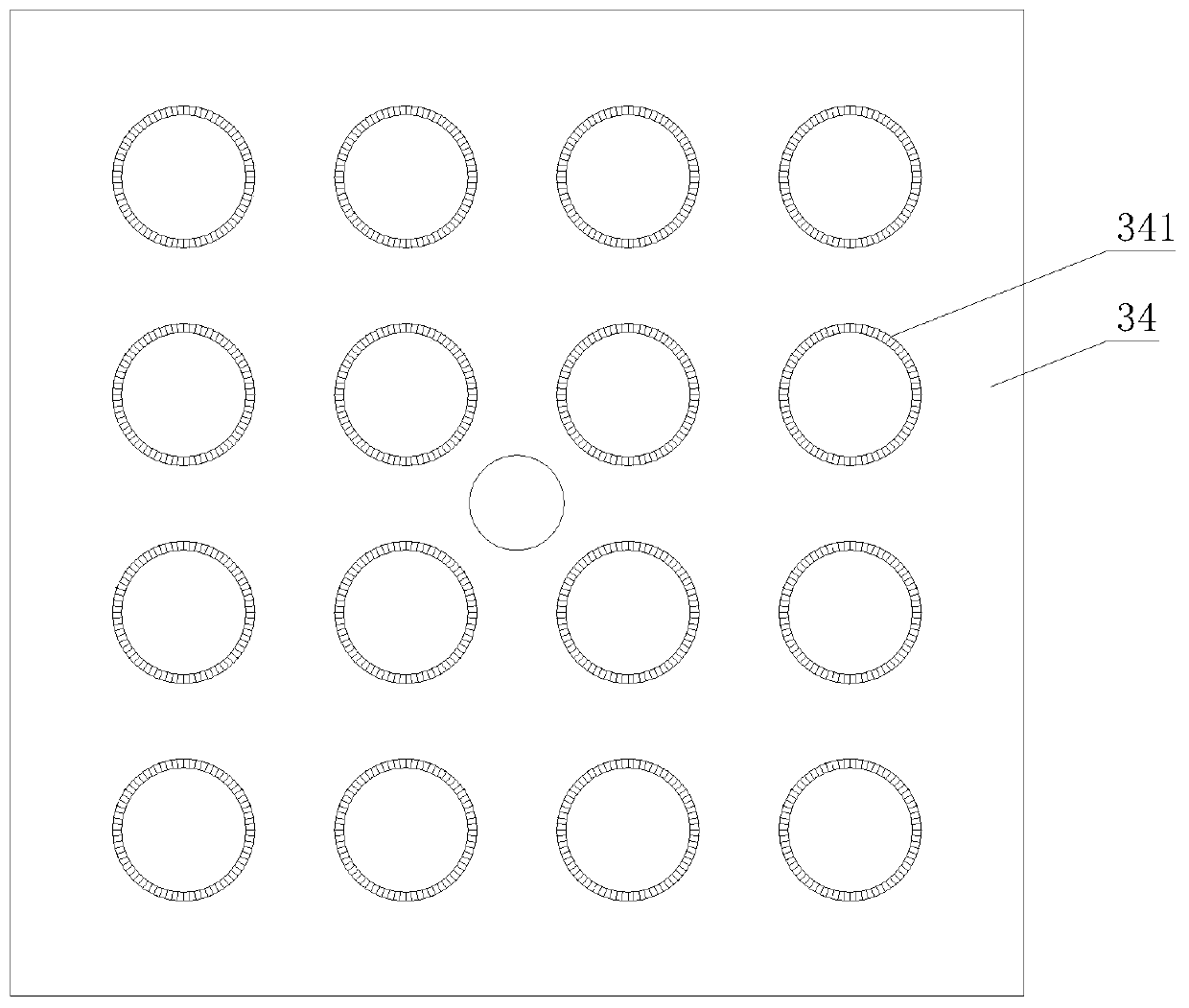

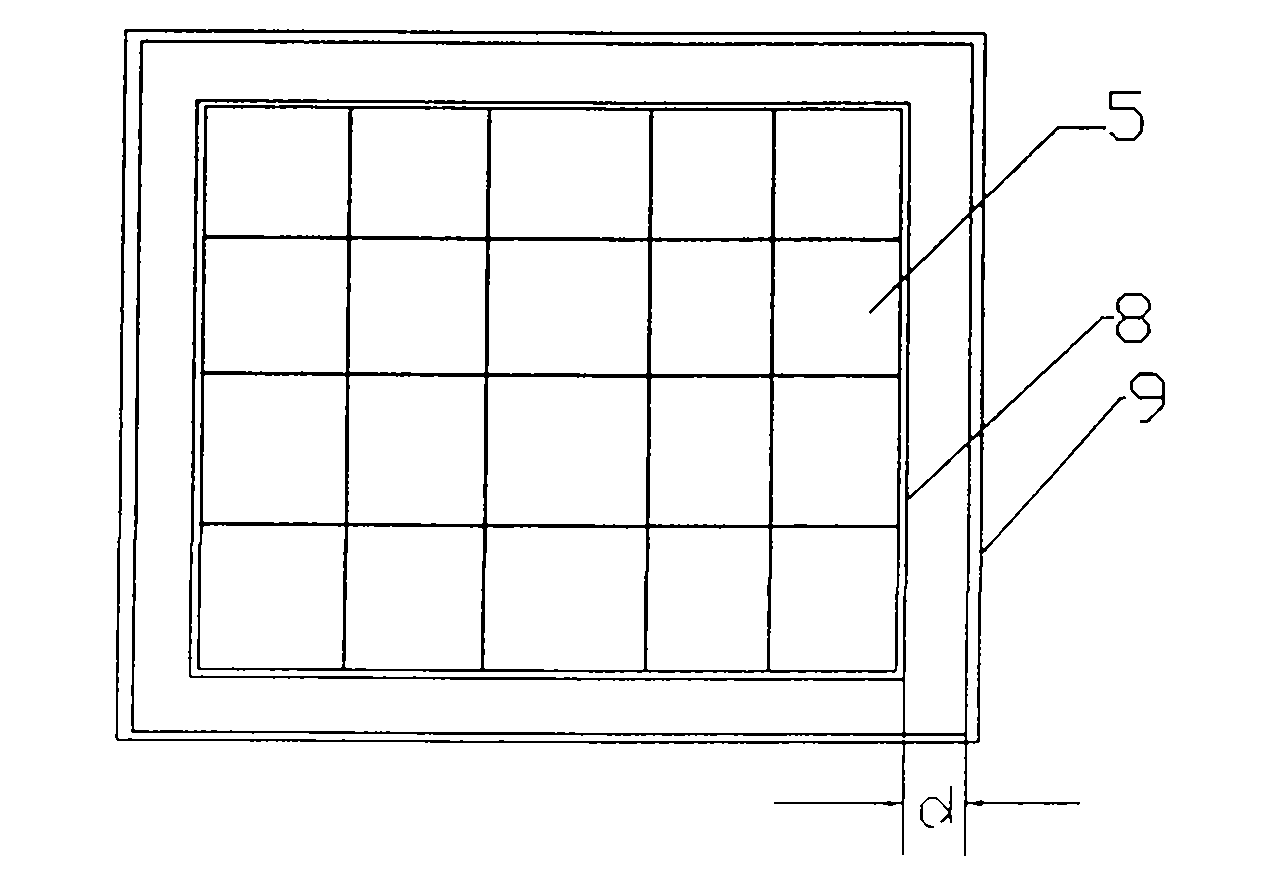

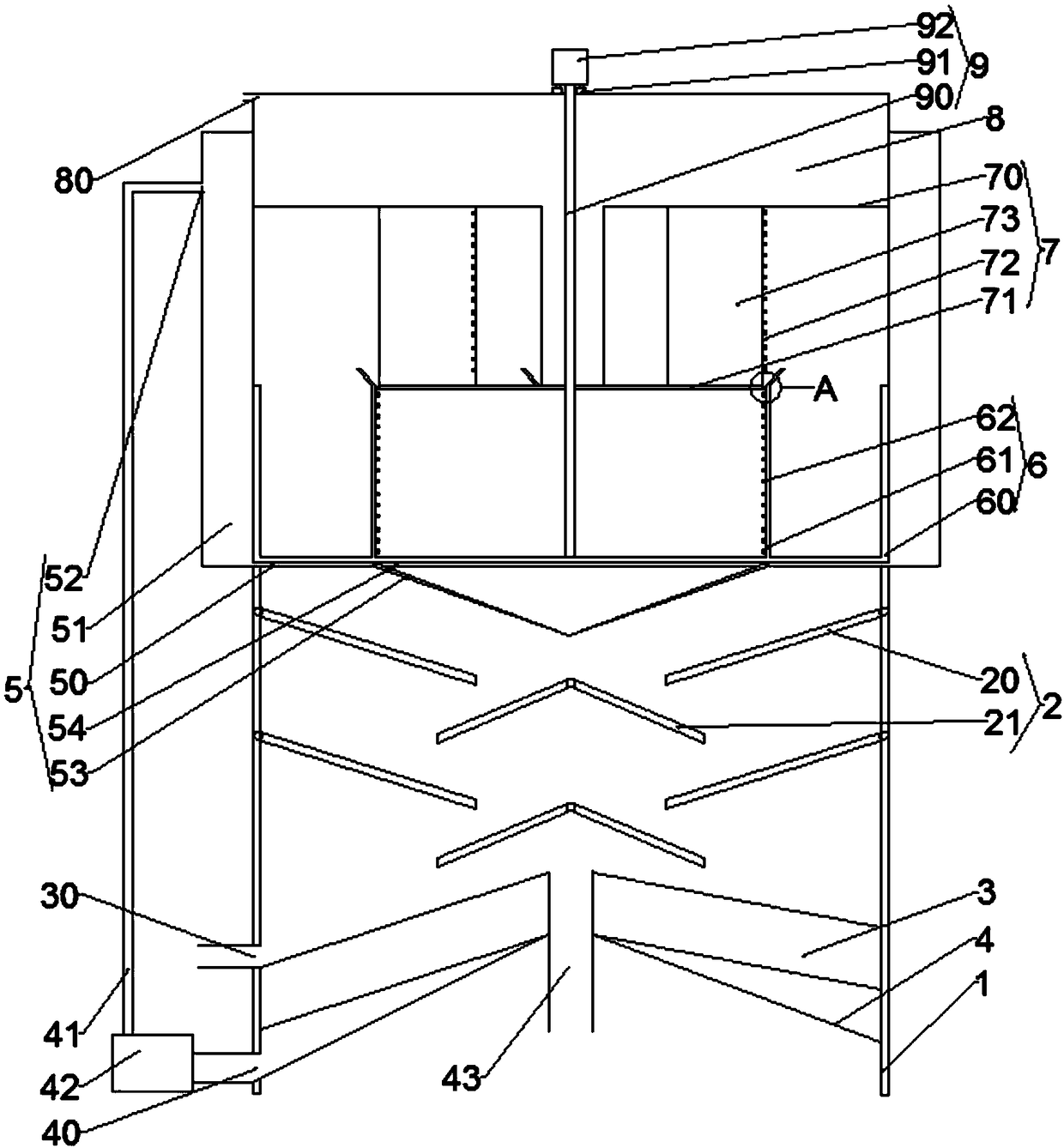

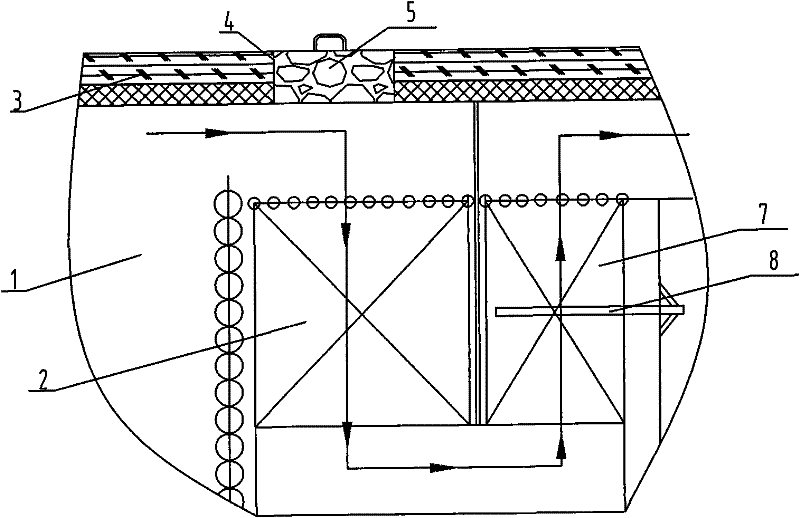

Denitration system in favor of blowing deposited ash and catalyst arrangement method of denitration system

ActiveCN101791518AReduce cloggingImprove ash removal effectDispersed particle separationThermodynamicsPtru catalyst

The invention discloses a denitration system in favor of blowing deposited ash, which comprises an air inflow gas duct, a reactor and an air leaving gas duct, wherein the interior of the reactor is provided with a spoiler and a rectifier; a plurality of catalyst composite modules which are horizontally arranged are arranged under the rectifier; the catalyst composite modules are arranged in the interior of the reactor along the longitudinal layering of the reactor of the denitration system; the corresponding position under each layer of catalyst composite module is provided with a soot blower; the periphery of each layer of catalyst composite module keeps a certain gap with the wall of the reactor; the ratio between the width of the gap and the inner bore of the catalyst composite module is 0.8-1.5:1; the denitration system can ensure that most of ash content is discharged from the periphery of the wall of the reactor by the certain gap between the catalyst composite module and the wall of the reactor and the coordination arrangement of the soot blower, thus lightening or avoiding the blockage of the ash content; and the invention also discloses a catalyst arrangement method of the denitration system in favor of blowing deposited ash.

Owner:CPI YUANDA ENVIRONMENTAL PROTECTION ENG

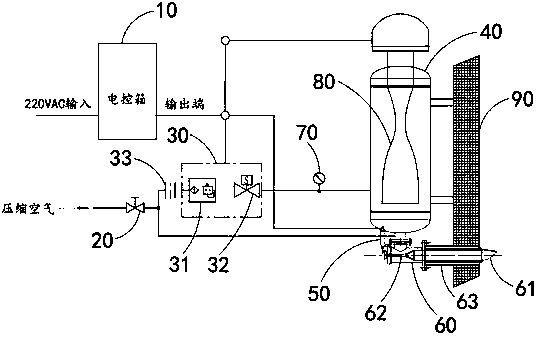

Accurate and controllable air shock wave soot blower

PendingCN108413422AImprove efficiencyImprove heat transfer efficiencySolid removalShock waveMotor drive

The invention discloses an accurate and controllable air shock wave soot blower including an electric cabinet, a ball valve, a pneumatic control cabinet, a shock wave generator, and a rotating nozzlearranged on a furnace wall. An air outlet of the ball valve is connected to an air inlet of the pneumatic control cabinet and an air outlet of the shock wave generator through air transmission pipelines. An air outlet of the pneumatic control cabinet communicates with an air inlet of the shock wave generator through the air transmission pipelines. The air outlet of the shock wave generator communicates with the rotating nozzle. A jet pipe is arranged in the shock wave generator. The air outlet end of the jet pipe is towards the air outlet of the shock wave generator. The blowing end of the rotating nozzle is arranged in the furnace wall. The rotating nozzle includes an outer pipe and an inner pipe. One end of the inner pipe is the blowing end, and the other end of the inner pipe is provided with a rotating shaft arranged along the axis of the inner pipe. The rotating shaft is connected to a stepping motor driving the rotating shaft to rotate. The input end of the electric cabinet is connected to a power supply. The output end of the electric cabinet is connected to the shock wave generator, the pneumatic control cabinet and the stepping motor through control cables.

Owner:上海隼帛商贸有限公司

Efficient heat dissipation system of air conditioner outdoor unit for communication network computer room

InactiveCN111964164AImprove ash removal effectGood ash removal effectGenerators/motorsAir conditioning systemsTuning forkEngineering

The invention discloses an efficient heat dissipation system of an air conditioner outdoor unit for a communication network computer room. The system comprises a shell and a power generation module, wherein a ventilation opening is provided in the shell in a penetrating manner, a plurality of heat dissipation fins are arranged in the ventilation opening, mounting strips are symmetrically providedon the front side of the shell, a strip-shaped cavity is formed in each of the two mounting strips, a vertical cavity is formed in the shell, a mounting block is arranged at the upper end of the shell, and a power generation cavity is formed in the mounting block; and the power generation module comprises a tuning fork horizontally arranged in the power generation cavity, a connecting plate is fixedly connected to the lower end of the tuning fork, and a second friction plate is arranged at the inner bottom of the power generation cavity. The heat dissipation system is provided with a cleaningmechanism and a self-generating mechanism. During work, the heat dissipation fins of the outdoor unit can be self-cleaned, so that an air conditioner is always in a high heat dissipation state, manpower is not needed, and the cleaning effect is good at the same time.

Owner:王丽丽

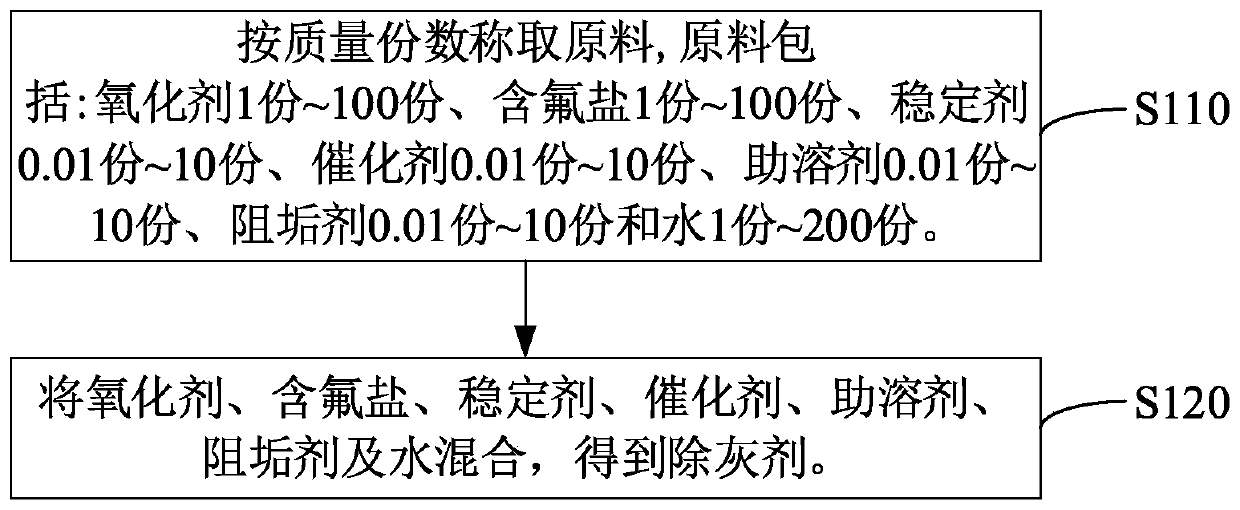

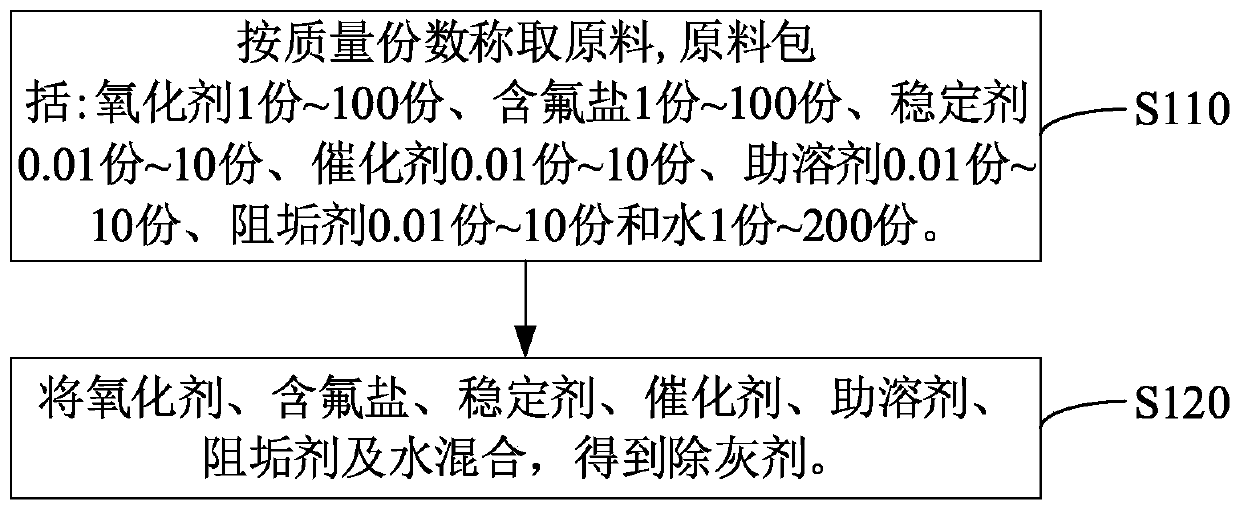

Ash removing agent, preparation method and application thereof, and ash removing method for silicon-aluminum alloy

The invention relates to an ash removing agent, a preparation method and application thereof, and an ash removing method for silicon-aluminum alloy. Raw materials for preparing the ash removing agentcomprise, in parts by mass, 1-100 parts of an oxidizing agent, 1-100 parts of a fluorine-containing salt, 0.01-10 parts of a stabilizer, 0.01-10 parts of a catalyst, 0.01-10 parts of cosolvent, 0.01 -10 parts of a scale inhibitor and 1-200 parts of water. The ash removing agent has a good ash removing effect, the silicon-aluminum alloy treated by the ash removing agent meets the electroplating requirement, and the pollution to the environment by the ash removing agent is small.

Owner:江门市众鸿新材料科技有限公司

Formaldehyde treatment equipment with continuous purification function

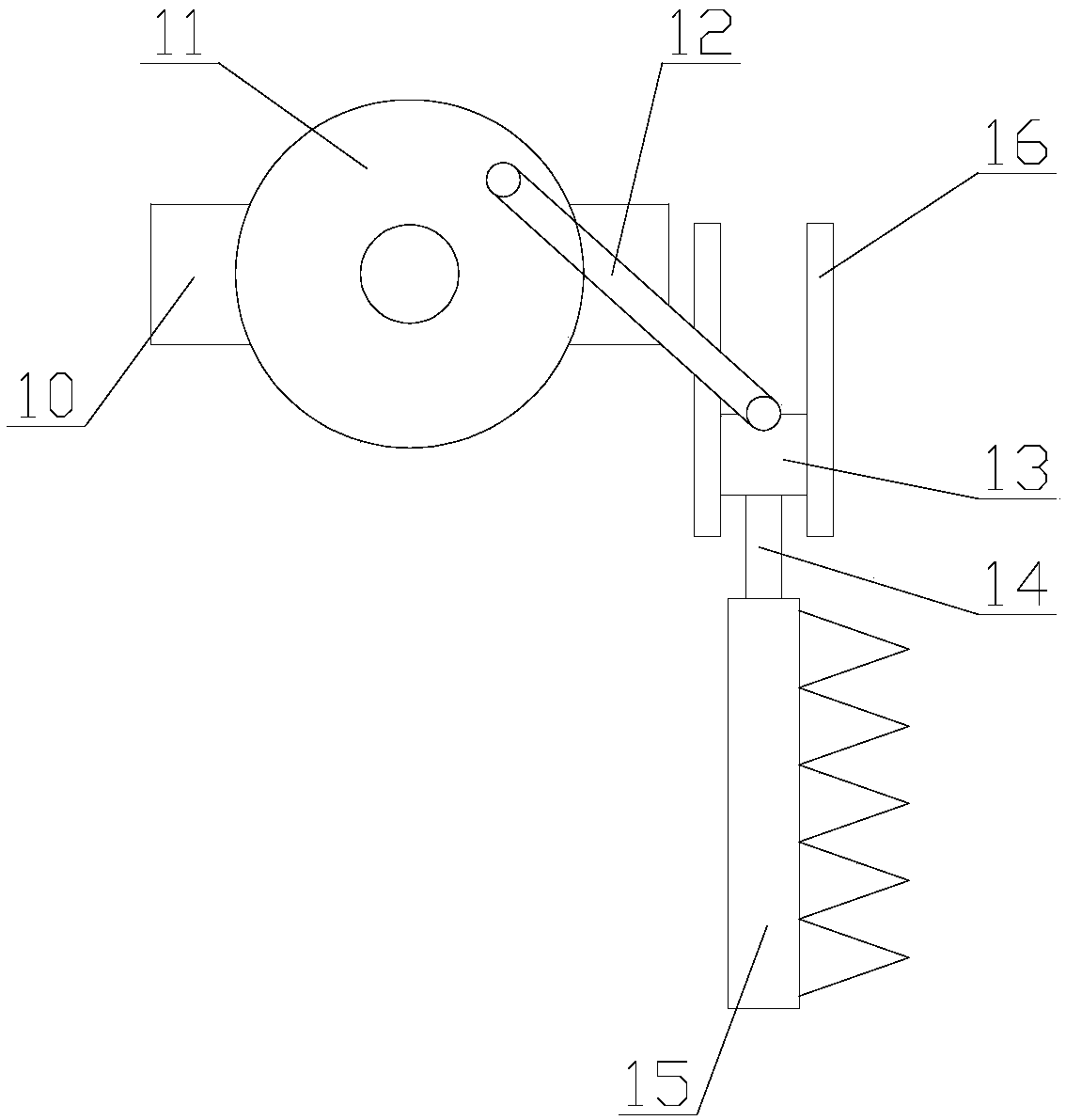

InactiveCN108889087ACause secondary pollutionAvoid pollutionGas treatmentDispersed particle separationActivated carbonWater storage tank

The invention relates to formaldehyde treatment equipment with a continuous purification function. The formaldehyde treatment equipment comprises a main body, wherein an PLC, a purifying mechanism, anexhausting mechanism and a dust removal mechanism, wherein the purifying mechanism comprises a purifying chamber and a water storage tank, a charging tank, a charging pipe, a sealing cover assembly and a filtering screen are arranged in the purifying chamber; the sealing cover assembly comprises a first motor, a swinging rod, a connecting rod, a fixed block, a support shaft and a sealing plate, two crushing assemblies are arranged in the water storage tank, and each crushing assembly comprises a second motor, a rotating disc, a rotating rod, a sliding block, a connecting block and sawtooth; and the dust removal mechanism comprises a dust removal chamber, a dust storage tank and a dust removal assembly. According to the formaldehyde treatment equipment, activated carbon can be automatically replaced by virtue of the purifying mechanism, so that the secondary pollution caused due to saturated activated carbon is avoided; and dust on the second filtering screen can be removed through thedust removal assembly, so that the situation that the air circulation is included due to the blockage of the second filtering screen by the dust is avoided.

Owner:SHENZHEN ANSIKE ELECTRONICS TECH CO LTD

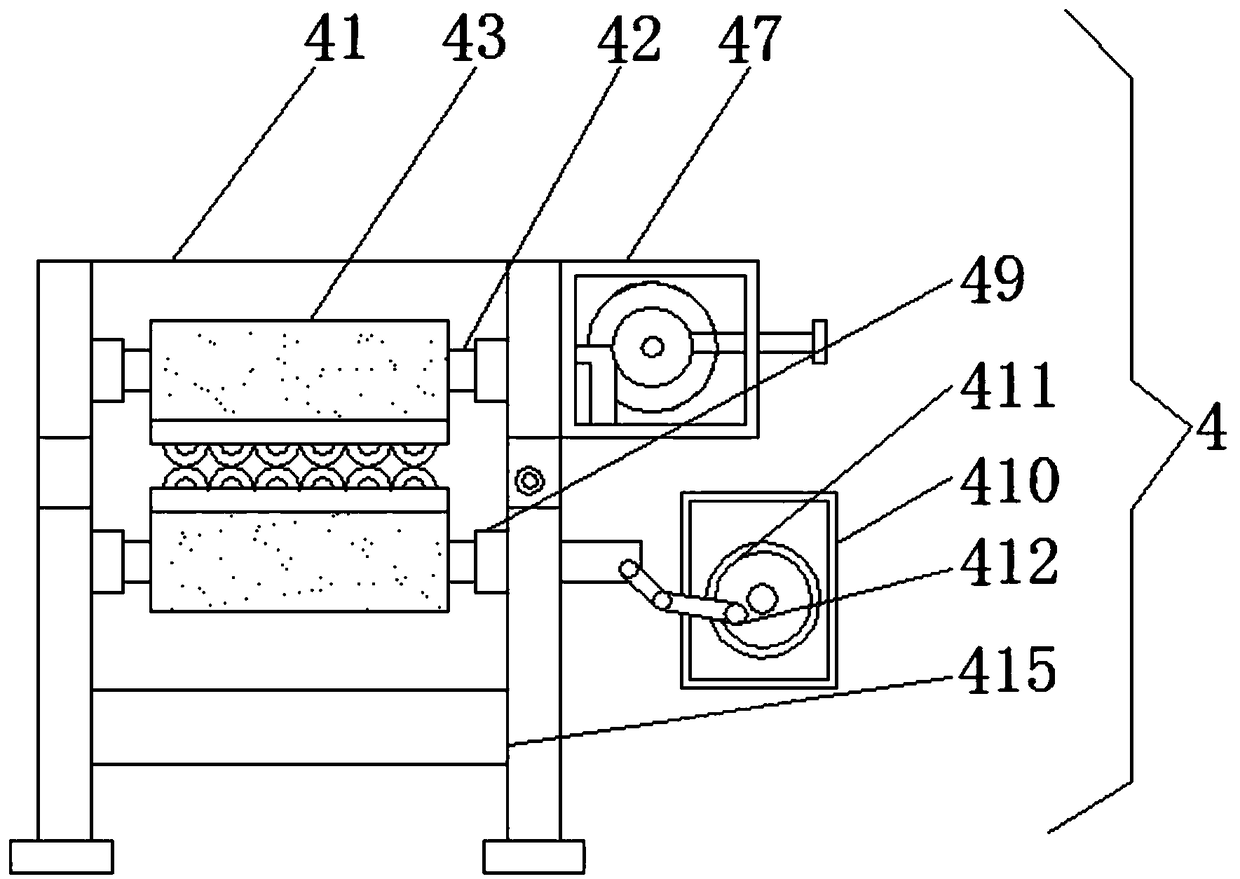

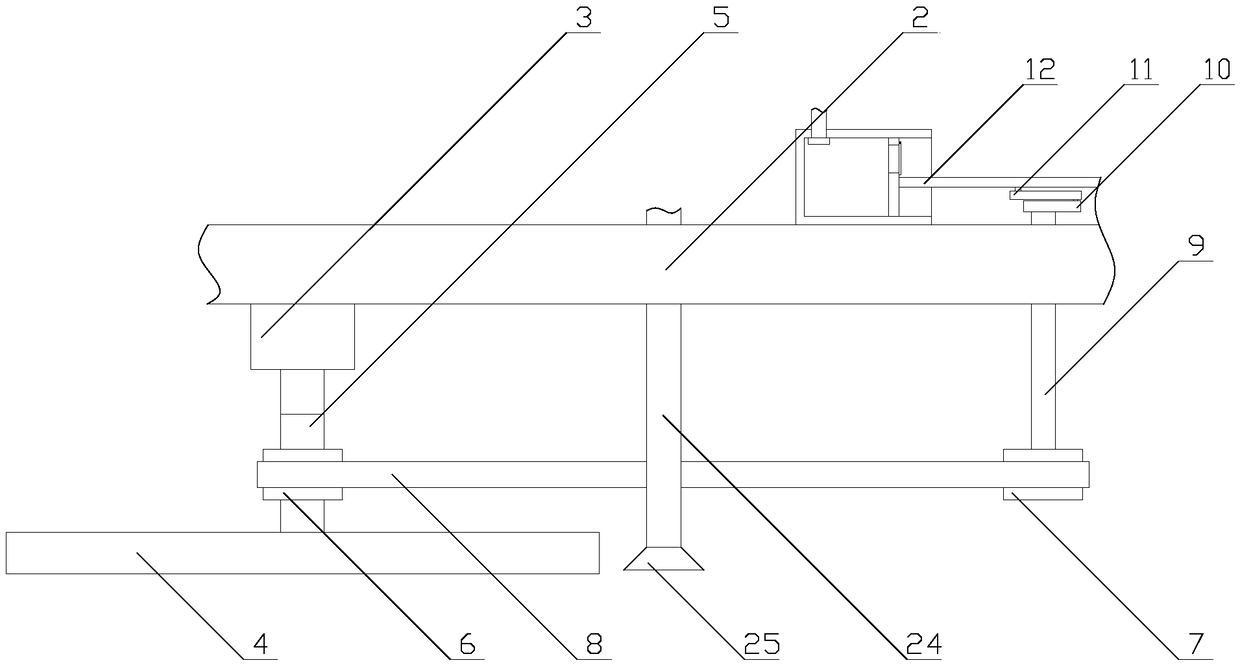

Polishing machine with good processing effect

ActiveCN108972290AEasy to processIngenious structurePolishing machinesGrinding drivesDrive wheelTransmission belt

The invention relates to a polishing machine with good processing effect, comprising a workbench, a support plate, a driving motor, a polishing disc, a transmission shaft and two lifting components. The support plate is arranged horizontally above the workbench; the two sides of the support plate are connected with the workbench through the two lifting components; the driving motor is fixed to thebottom end of the support plate; the transmission shaft is vertically arranged; the driving motor is in transmission connection with the top end of the transmission shaft; the polishing disc is mounted at the bottom end of the transmission shaft; a dust cleaning mechanism is arranged on the support plate; an adjusting mechanism is arranged on the workbench; the dust cleaning mechanism includes adriving component and an execution component; the driving component includes a driving wheel, a driven wheel, a transmission belt, a rotary shaft, a crank, a connection bar, a moving bar and two exhaust units. The polishing machine provides dust removal by means of the dust cleaning mechanism, and provides a level adjusting function via the adjusting mechanism.

Owner:温州耐洁机电科技有限公司

Gas shock wave ash removing system equipped with Archimedes spiral accelerator

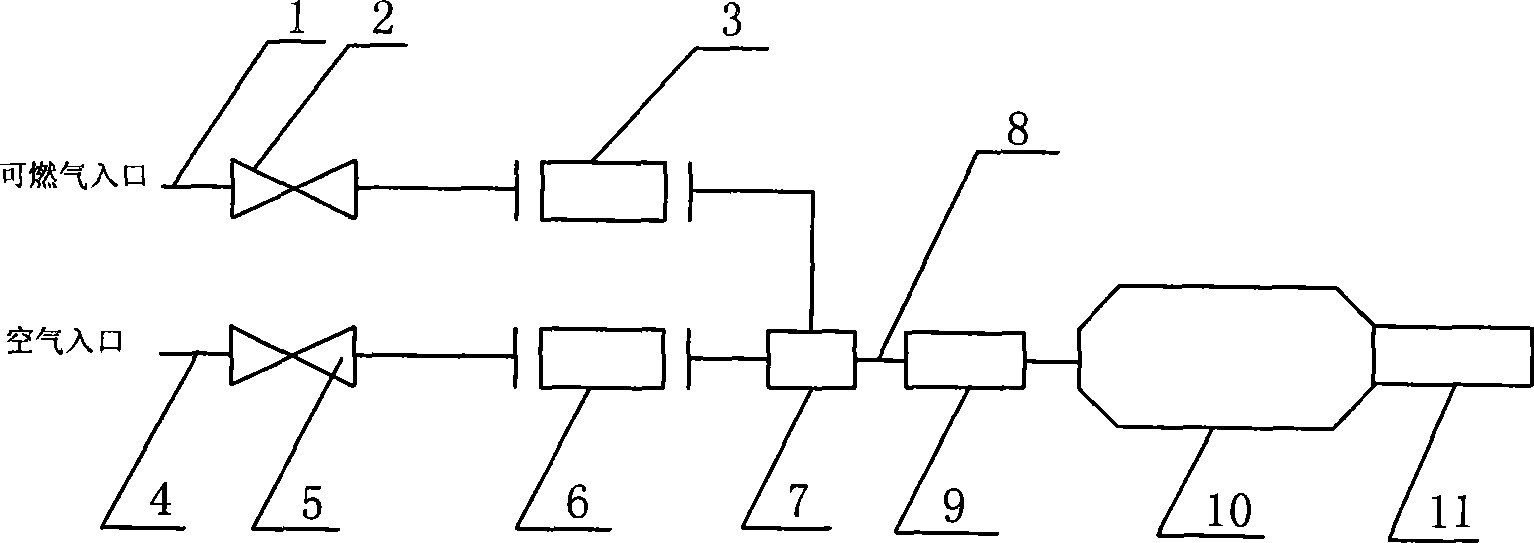

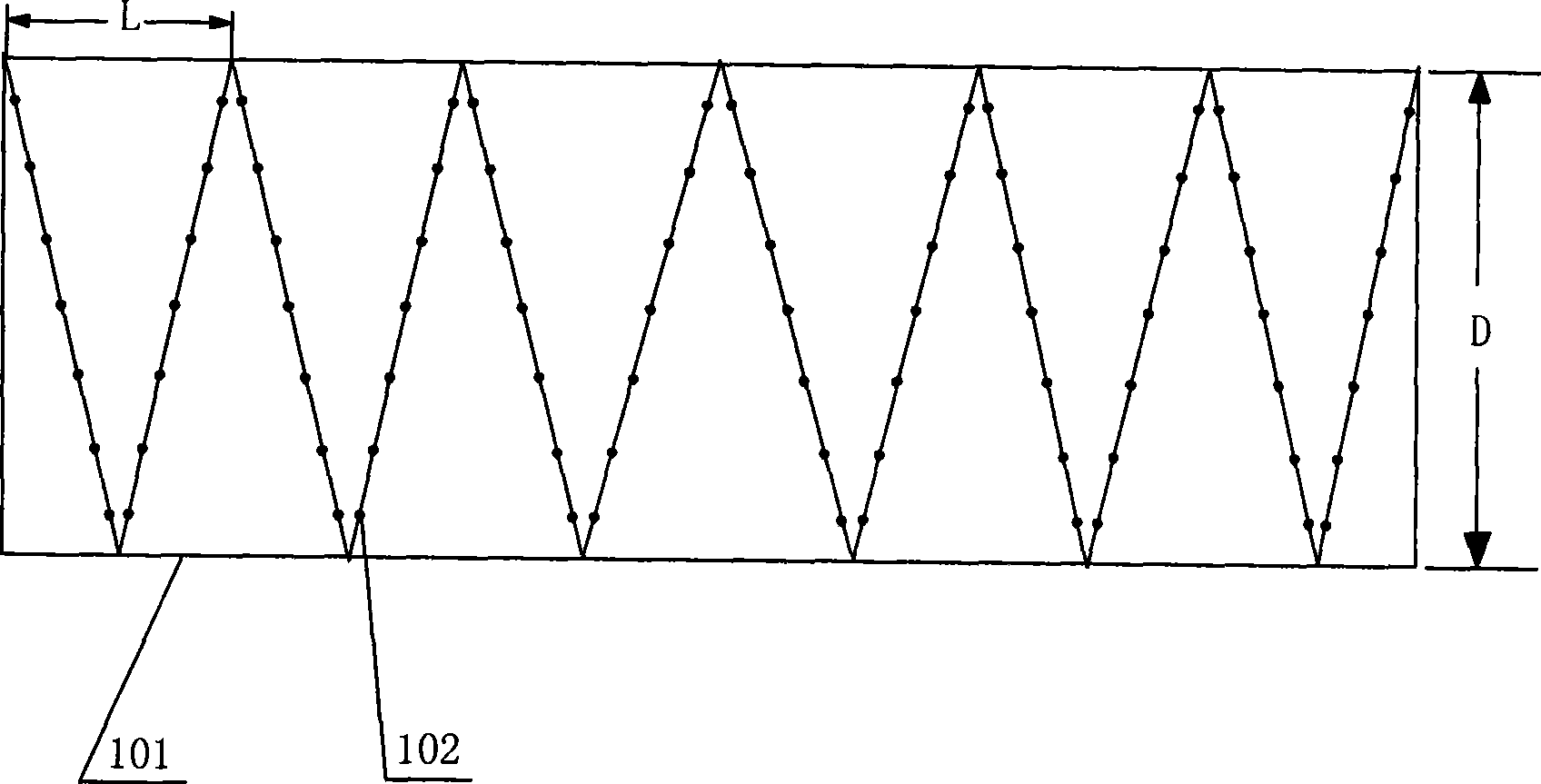

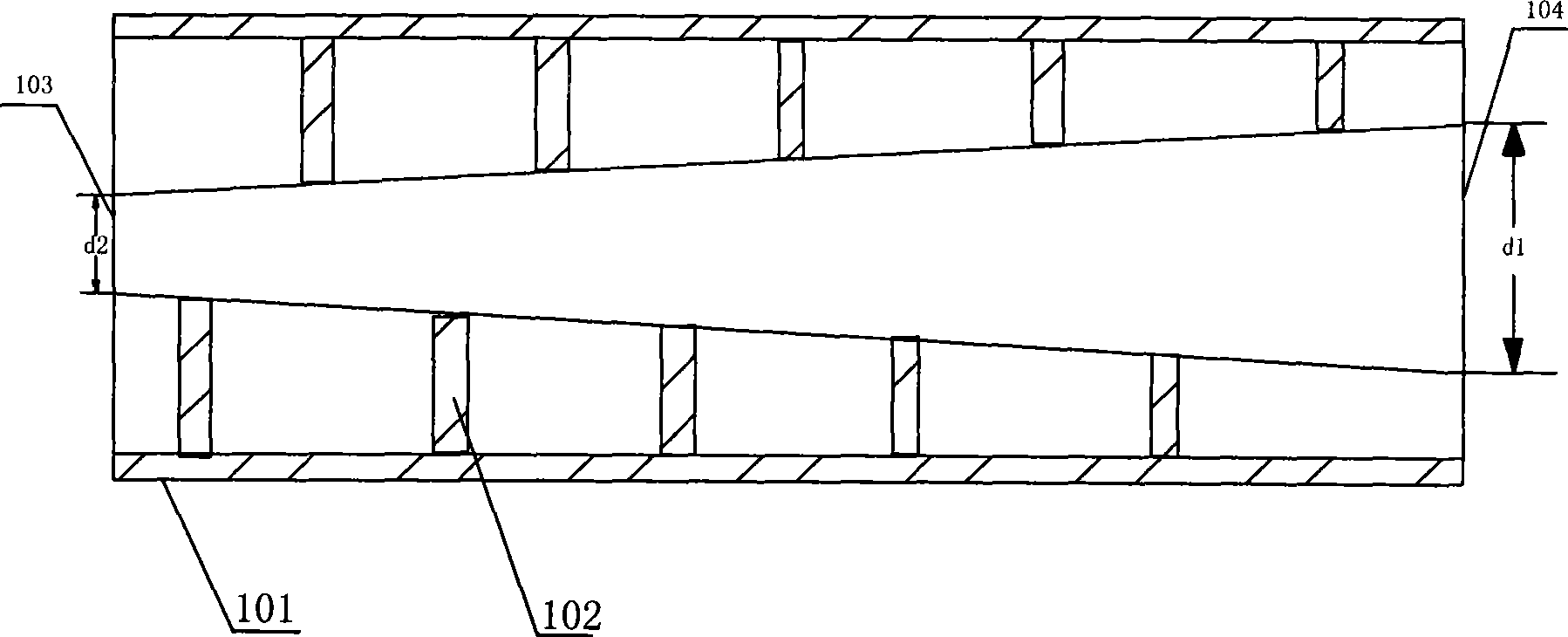

InactiveCN101463998AIncrease outlet pressurePowerful pulse energySolid removalShock waveCombustible gas

The invention provides a fuel gas shock wave ash disposal system equipped with an Archimedes spiral accelerating installation, comprising a combustible gas pipeline, a combustible gas valve, a combustible gas flow meter and an air duct, an air valve and an air flow meter; the combustible gas valve and the combustible gas flow meter are connected in sequence by the combustible gas pipeline, the air valve and the air flow meter are connected in sequence by the air duct, the combustible gas flow meter is connected with a premixer by the combustible gas pipeline, the air flow meter is connected with the premixer by the air duct, the right end of the premixer is connected with an igniter by a premixing pipeline, the igniter is connected with an Archimedes spiral explosion mixture space formed by arranging pins in the explosion tube, the explosion mixture space is connected with an output tube. In the invention, pins are arranged on the inner wall of the explosion tube according to the Archimedes spiral, thus forming a disturbed cone-type structure, therefore, pressure at the outlet of the explosion mixture space is greatly increased and fuel gas shock wave with powerful pulse energy is generated when cleaning ash of high viscosity and high adhesive attraction on a heat exchange surface, ensuring better ash removal effect.

Owner:李志强

Self-cleaning bag type dust collector

The invention discloses a self-cleaning bag type dust collector. The self-cleaning bag type dust collector comprises a casing, wherein the casing is internally provided with at least one set of flow guiding components, a filter component, a base, a water tank, a rotary filter cartridge, a filter bag component and a transmission component; each set of flow guiding component comprises a pair of first flow guiding plates and a V-shaped plate; the water tank comprises a water spray portion and a water storage portion, the inner side wall of the water spray portion is condensed downwards to form afirst filter screen, and water spray holes are formed in the bottom surface of the water spray portion; the rotary filter cartridge comprises an outer filter cartridge and an inner filter cartridge, and the side wall of the inner filter cartridge comprises a horn portion and a columnar portion which communicate with each other from top to bottom; and the filter bag component comprises an upper fixing plate coaxially disposed on the inner side wall of the water storage portion in a clamped manner, a lower fixing plate located below the upper fixing plate and coaxially disposed below the upper fixing plate, and a plurality of columnar filter cloth coaxially disposed between the upper fixing plate and the lower fixing plate to form multi-layered filtering space from the outside to the inside.The self-cleaning bag type dust collector has the benefits that the dust removing effect is good, the dust collector is not needed to be disassembled, and the targeted brushing can be performed so asto realize the self-cleaning inside the dust collector.

Owner:王小平

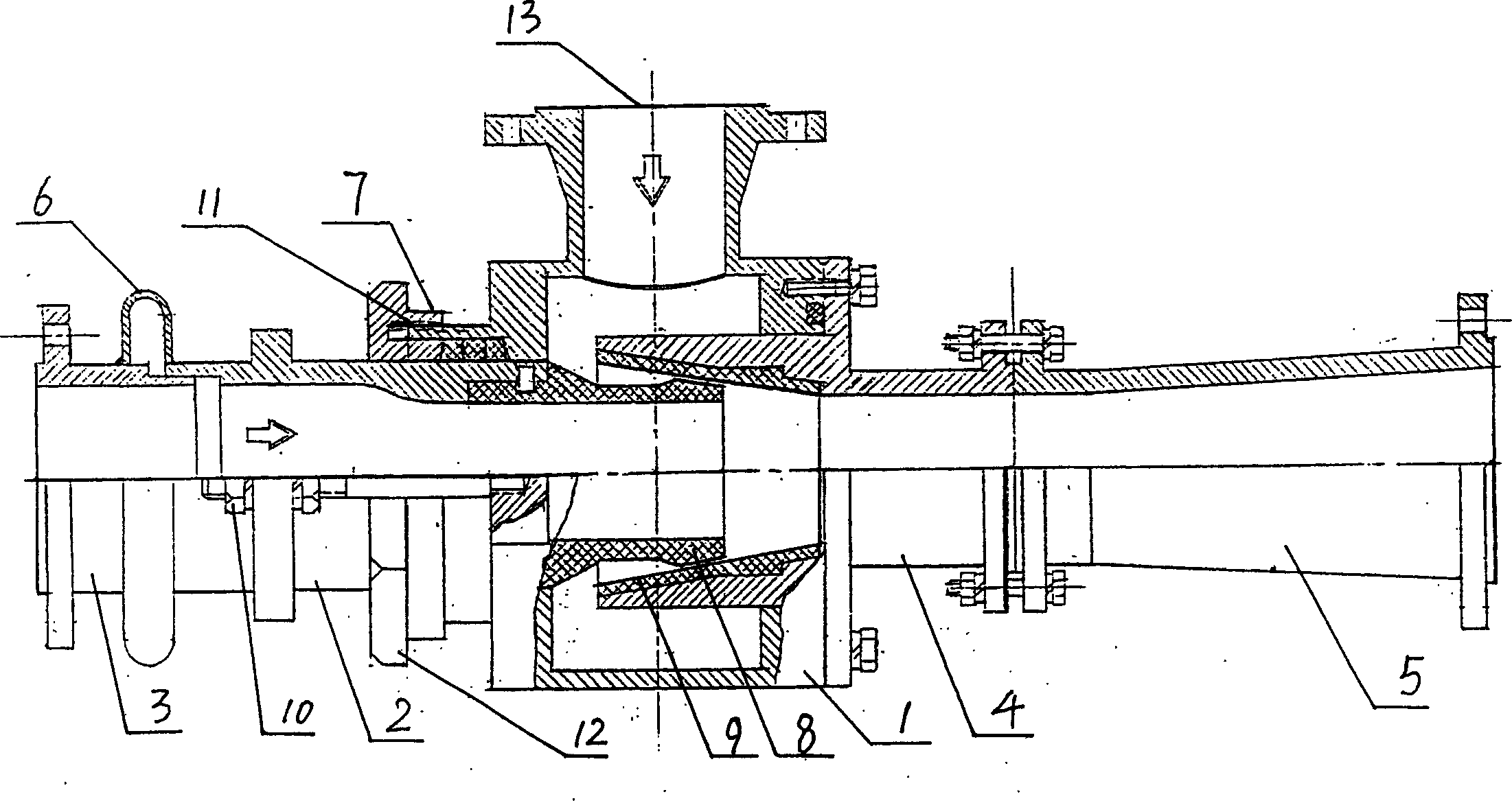

Ash water treatment pump

InactiveCN1598327AClearance adjustment is simpleEasy to useJet pumpsMachines/enginesMutual positionEngineering

The invention discloses a grey water handing pump, it includes pump body, mouth piece jet nozzle, mouth piece adapter, agitate chamber, and expand chamber. One end of the mouth piece jet nozzle is connected hermetically with the mouth piece adapter by extension-type coupling device, another is extended to the pump body to connected with its activity by sealing device; one end of the agitate chamber is connected with the expand chamber, another is extended to the pump body; fitting together conical surface is equipped on the out surface of the mouth piece jet nozzle and the inner surface of the expand chamber in the pump body; the conical out surface of the mouth piece jet nozzle is extended to the conical inner surface of the agitate chamber; actuating device is equipped on the out surface of the mouth piece jet nozzle to accommodate the mutual position the out surface conical surface and the conical inner surface. It is easy to adjust, use, and maintain, eject grey and save water effectively.

Owner:孙付江

Clean room with automatic entry dust collection device

Owner:重庆淳祥电子科技有限公司

Soot blower structure of coal burning organic heating medium furnace

InactiveCN101749862AEffectively blows out dust depositsImprove ash removal effectStorage heatersSolid removalWorking lifeEngineering

The invention relates to a soot blower structure of a coal burning organic heating medium furnace. The soot blower structure has good soot removing effect and long working life and is beneficial to maintenance. The soot blower structure comprises a furnace hearth, a high-temperature convection section, a furnace top, a low-temperature convection section and a fixed soot blower. The fixed soot blower is arranged in the low-temperature convection section, soot in the furnace hearth enters an active groove which is open in the furnace top in the high-temperature convection section space, and the active groove is covered by and provided with a detachable cover plate. The soot blower structure is characterized in that the juncture of the high-temperature convection section and the furnace hearth is provided with an active soot blowing device.

Owner:JIANGSU TAIHU BOILER

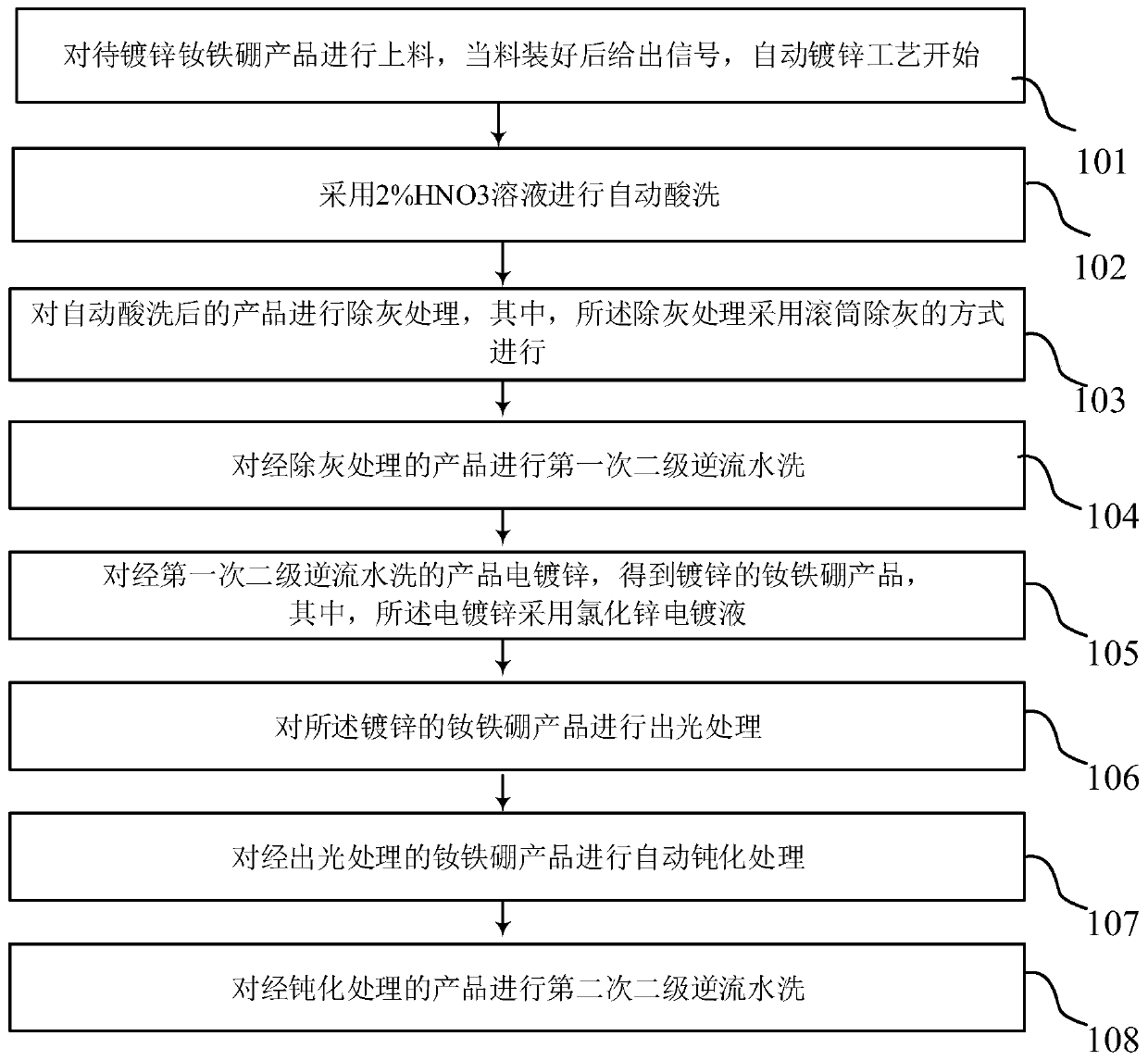

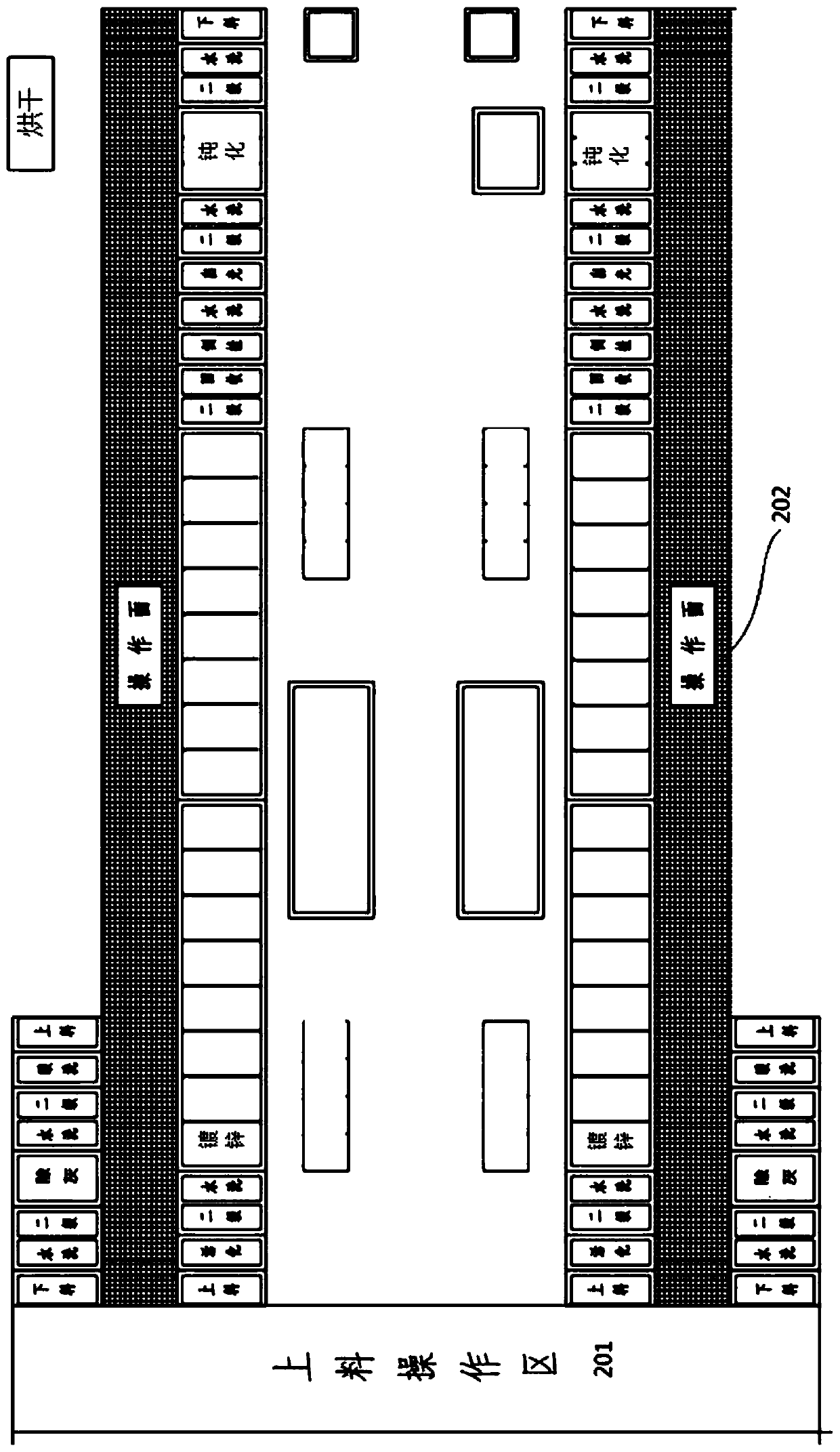

Full-automatic galvanizing process for neodymium iron boron

InactiveCN111321441AAvoid exposure to acidsReduce acid allergiesCleaning using toolsCleaning using liquidsElectrogalvanizationElectroplating

The invention discloses a full-automatic galvanizing process for neodymium iron boron. The process comprises the following steps of: feeding a galvanized neodymium iron boron product, and starting anautomatic galvanizing process when a material is loaded and a signal is given; and carrying out automatic pickling for 30s by 2%HNO3 solution; carrying out ash removal to the product after automatic pickling, wherein the ash removal is carried out by roller ash removal; first secondary backflow washing is carried out to the product after ash removal; a first secondary backflow washing product is electrogalvanized, and the electroplating zinc uses potassium chloride electroplating solution to obtain the galvanized neodymium iron boron product; the galvanized neodymium iron boron product is polished; automatic passivation treatment is carried out to the polished neodymium iron boron product; and a second secondary backflow washing is carried out to a passivation product.

Owner:SINO MAGNETICS TECH

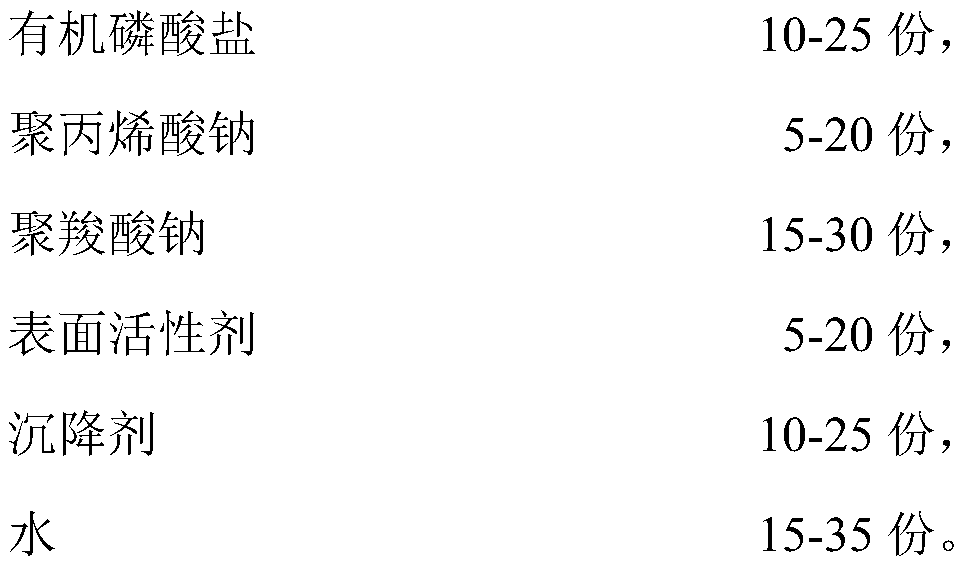

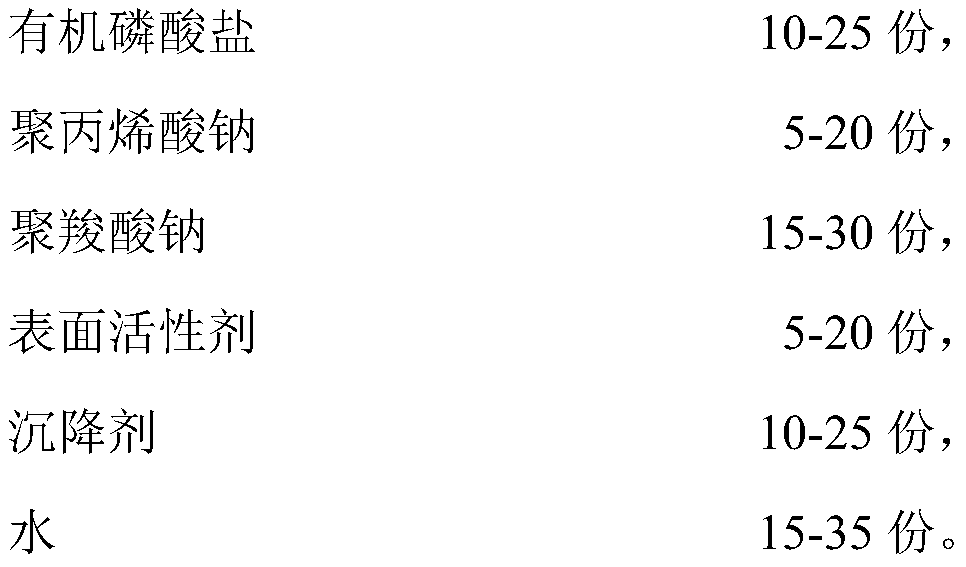

Cleaning agent for removing oil and dust and preparation method thereof

The invention provides a corrosion-free cleaning agent which can be used under heating condition (60-75 DEG C), can remove oil and dust and has fast cleaning speed. The cleaning agent comprises the following components in parts by weight: 10-25 parts of organic phosphate, 5-20 parts of sodium polyacrylate, 15-30 parts of sodium polycarboxylic acid, 5-20 parts of surfactants, 10-25 parts of settling agents, and 15-35 parts of water. The corrosion-free cleaning agent innovatively utilizes the organic dispersants and the settling agents in combination with the surfactants such as isomeric alcoholpolyoxyethylene ether with high permeability and in cooperataion with the chelating property of organic phosphate, so that the cleaning agent maintains excellent dust removal effect and also has an extremely good oil removal effect. The corrosion-free cleaning agent for removing oil and dust has obviously stronger oil and dust removing effect than the conventional cleaning agent, and is nearly neutral and has no corrosion to metal products such as a magnesium alloy, so that the corrosion-free cleaning agent has very high practical application value.

Owner:GUANGDONG REDSUNSTAR IND

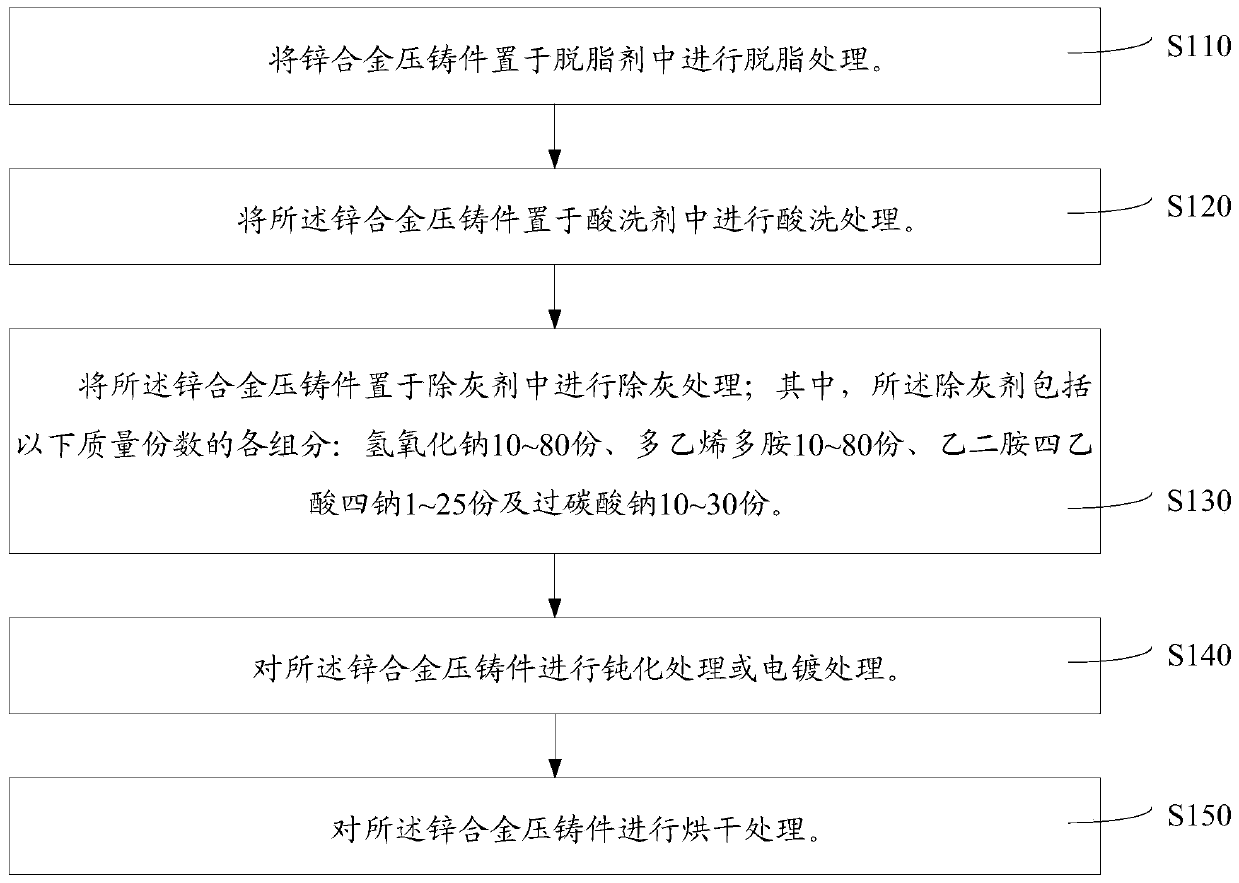

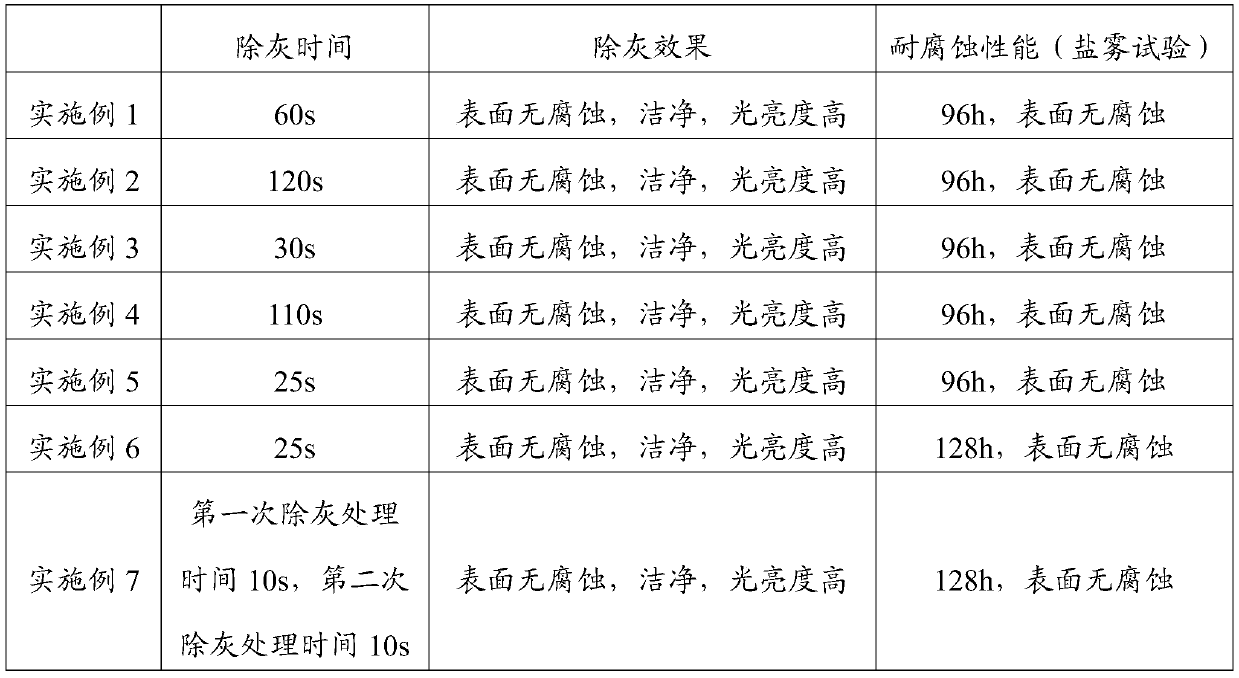

Ash removing agent and surface treatment method for zinc alloy die casting

InactiveCN111549352ACorrosiveImprove responseMetallic material coating processesEthylene diamine tetra aceticEthylene diamine

The invention relates to the technical field of metal surface treatment, and discloses an ash removing agent and a surface treatment method for a zinc alloy die casting. The ash removing agent is prepared from components by mass: 10-80 parts of sodium hydroxide, 10-80 parts of polyethylene polyamine, 1-25 parts of ethylene diamine tetraacetic acid tetrasodium and 10-30 parts of sodium percarbonate. The surface treatment method of the zinc alloy die casting includes the following steps that the zinc alloy die casting is put in a degreasing agent for degreasing; the zinc alloy die casting is putin an acid pickling agent for acid pickling; the zinc alloy die casting is put in the ash removing agent for ash removing; the zinc alloy die casting is passivated or electroplated; and the zinc alloy die casting is dried. The ash removing agent in the formula is alkaline, good in safety, beneficial for environmental protection and good in ash removing effect, the surface of the zinc alloy die casting is not corroded, the surface of the acid-pickled or alkali-pickled zinc alloy die casting is clean and bright, and adhesive force of paint on the surface of the zinc alloy die casting obtained after ash removing is better.

Owner:广东东明新材科技有限公司

Computer software optical disc storage device

InactiveCN109509489AImprove ash removal effectReduce wear rateApparatus modification to store record carriersReducing carrier contaminationEngineeringSoftware

Disclosed is A computer-used software optical disk storage device including a storage box and an optical disk holder, miniature vacuum cleaners and stereos, At both side of that storage box, An optical disc holder is arranged between the sliders, A slide groove corresponding to the slider is arranged on both sides of the optical disc rack, A support sheet is welded on that top of the rotate shaft,a fastening sheet is arranged on the top of the supporting sheet through bolts, a welding gear is sleeve on the bottom of the supporting sheet, a sponge wiper block is arranged on one side of the supporting sheet, and the sponge wiper block is fixed on the optical disc shelf through a connecting rod. Through the setting of the sponge rubbing block, the bottom of the optical disc is effectively cleaned when the optical disc is rotated, and through the setting of the micro vacuum cleaner, the dust removal effect of the optical disc can be increased, the wear rate of the optical disc due to dustparticles when the optical disc is used in the computer can be reduced, and the service life of the optical disc can be prolonged.

Owner:天津华融金服科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com