Self-cleaning bag type dust collector

A bag-type dust collector and self-cleaning technology, applied in chemical instruments and methods, dispersed particle separation, combined devices, etc., can solve the problems of poor cleaning effect and untargeted cleaning, so as to enhance the dust removal effect and enhance the self-cleaning effect. Cleaning effect, the effect of enhancing the filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

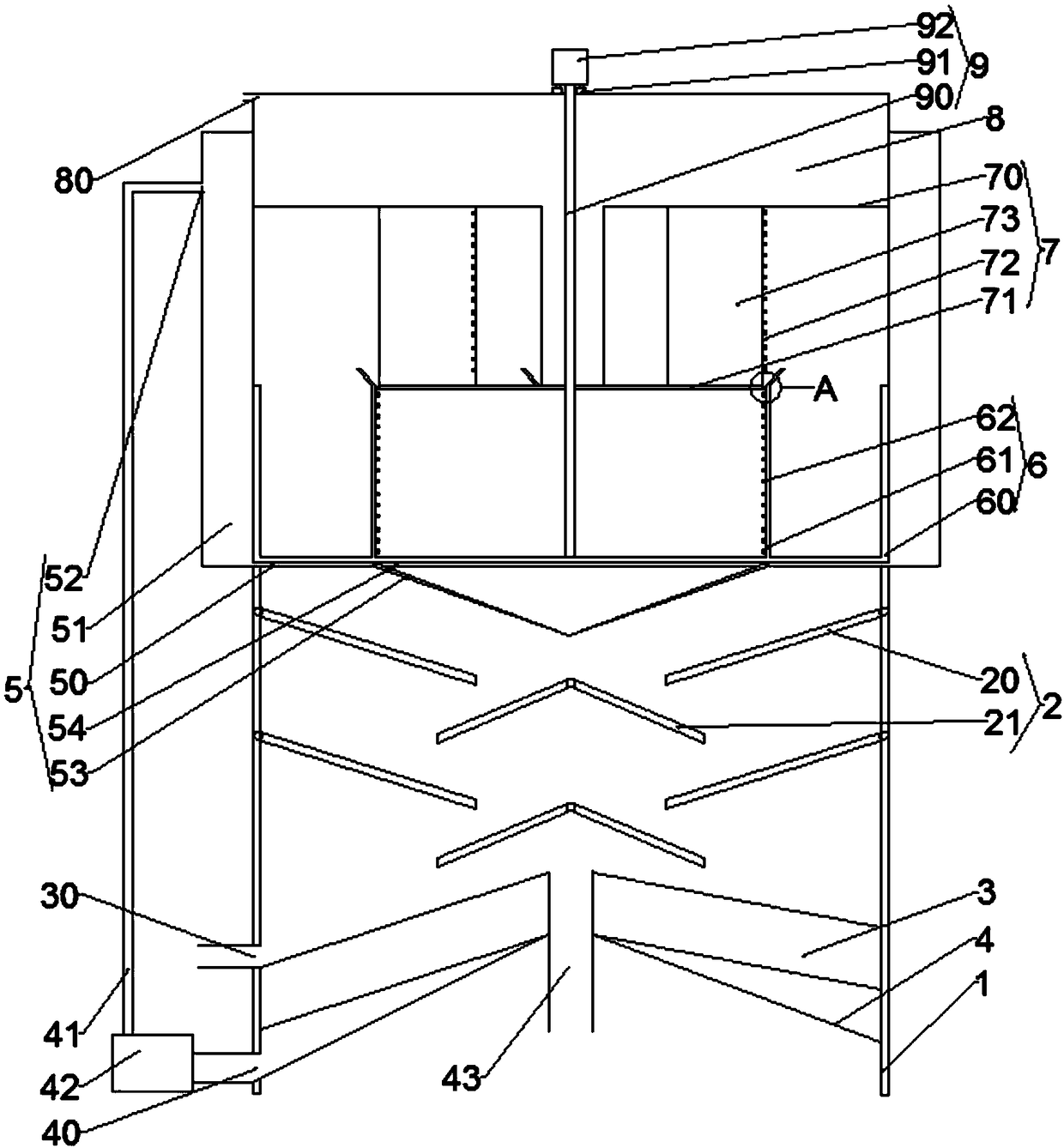

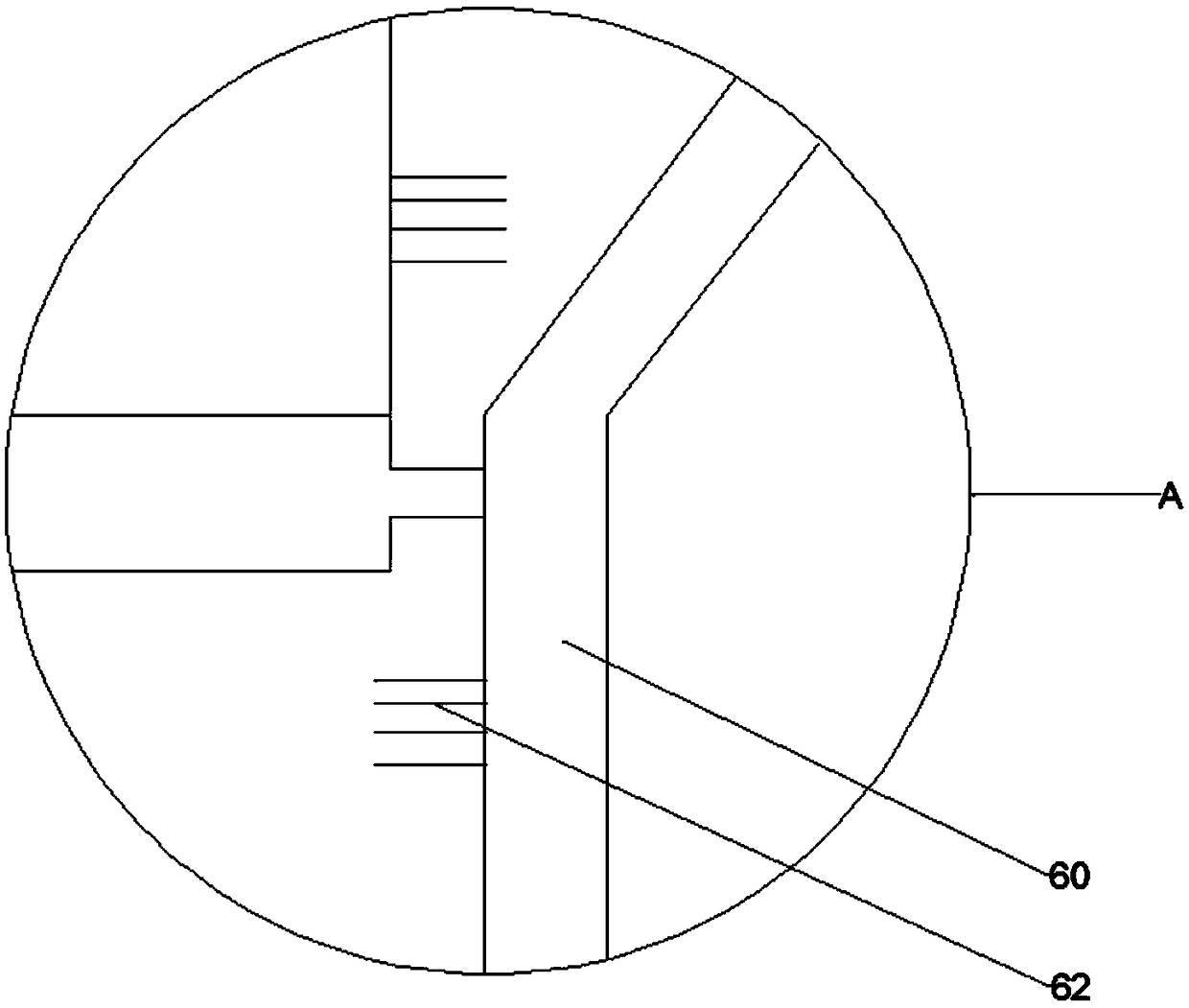

[0037] Such as Figure 1-2 As shown, the present invention provides a self-cleaning bag filter, comprising:

[0038] The housing 1 is a hollow quadrangular column with an open top, and the housing 1 is sequentially arranged from top to bottom:

[0039] At least one set of deflector assemblies 2, each set of deflector assemblies 2 includes a pair of first deflectors 20 that are mirror-symmetrical along the central axis of the housing 1, and are located below the pair of first deflectors 20 (such as figure 1 As shown, including the situation that the height of the top of the V-shaped plate 21 is higher than the height of the bottom end of the first deflector 20, only the V-shaped plate 21 is located below the first deflector 20 for receiving from the first deflector. 20 water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com