Accurate and controllable air shock wave soot blower

An air shock and soot blower technology, which is applied in the treatment of combustion products, combustion methods, and removal of solid residues, etc., can solve the problems of uncontrollable shock energy, potential safety hazards, and the phenomenon of squibs, and achieve convenient use. And the effect of maintaining equipment, convenient gas source reference, and no dead space in ash removal space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

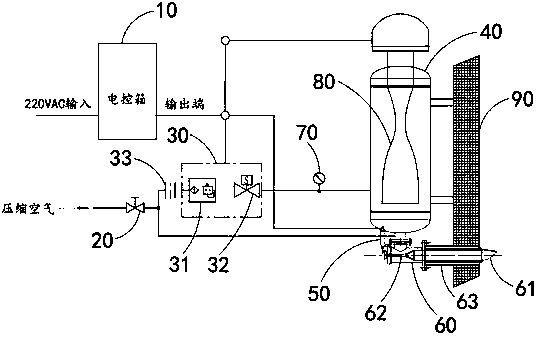

[0043] like figure 1As shown, a kind of air shock wave soot blower comprises electric control box 10, ball valve 20, air control box 30, shock wave generator 40 and the rotary nozzle that is arranged on furnace wall 90; The air outlet of described ball valve 20 is respectively Connect the gas inlet of gas control box 30 and the gas outlet of shock wave generator 40 by gas pipeline; The gas outlet of described gas control box 30 is connected with the gas inlet of shock wave generator 40 by gas pipeline; The air outlet of the device 40 is connected with the rotary nozzle, and the shock wave generator 40 is provided with a jet tube 80, and the gas outlet end of the jet tube 80 is towards the gas outlet of the shock wave generator 40; the gas jet end of the rotary nozzle is arranged on In the furnace wall 90; the rotary nozzle includes an outer tube 60 and an inner tube 61, one end of the inner tube 61 is a gas injection end, and the gas injection end of the inner tube 61 is seale...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com