Fluidized grain dust removing system

A fluidized and granular technology, used in the removal of solid residues, combustion products treatment, combustion methods, etc., can solve the problems affecting the heat exchange effect of boilers, safe operation, and large adhesion, and achieve ideal ash removal effects. Good stability and strong controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

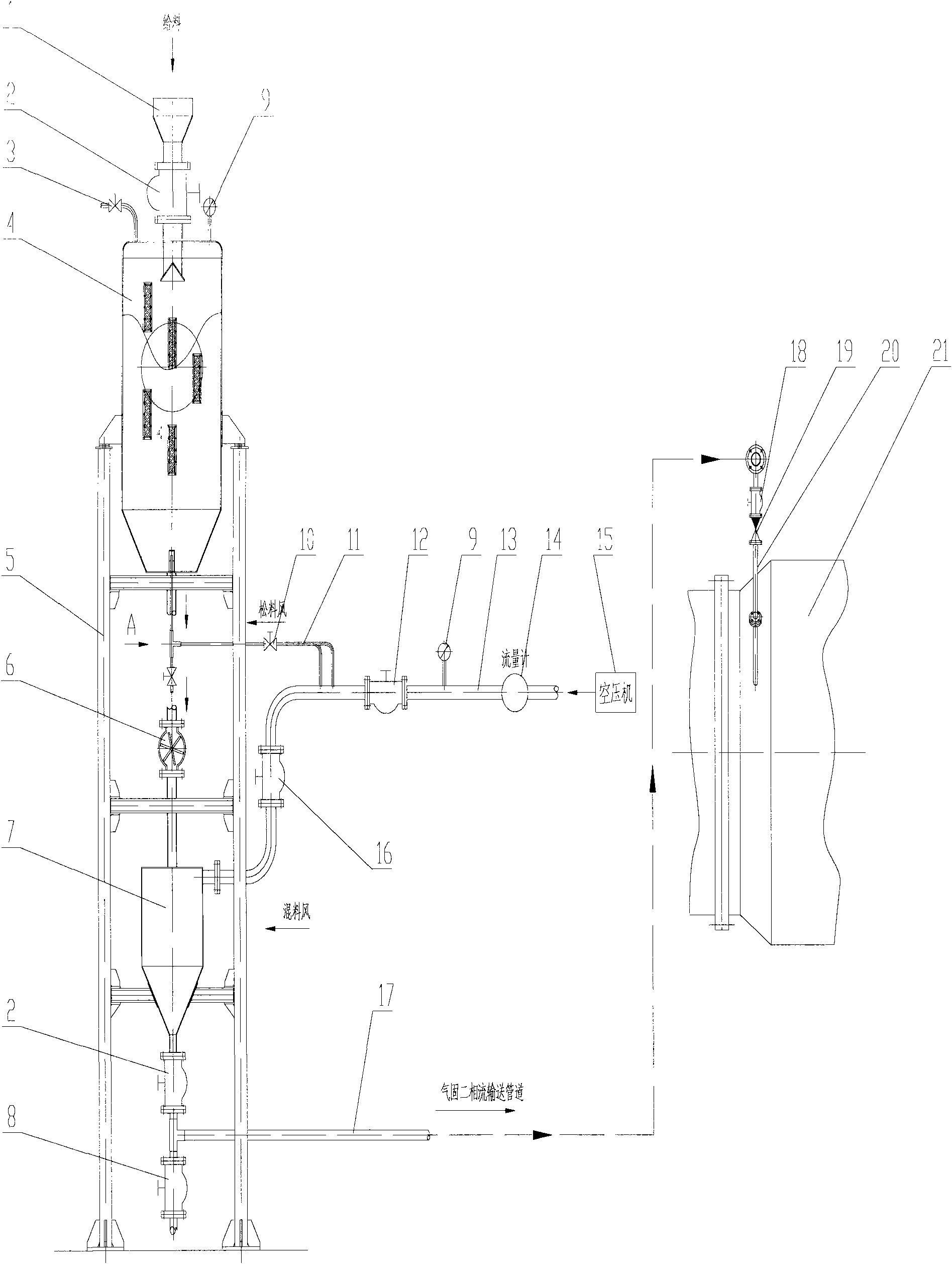

[0016] A fluidized particle ash removal system according to the present invention will be further described below in conjunction with the accompanying drawings and specific examples.

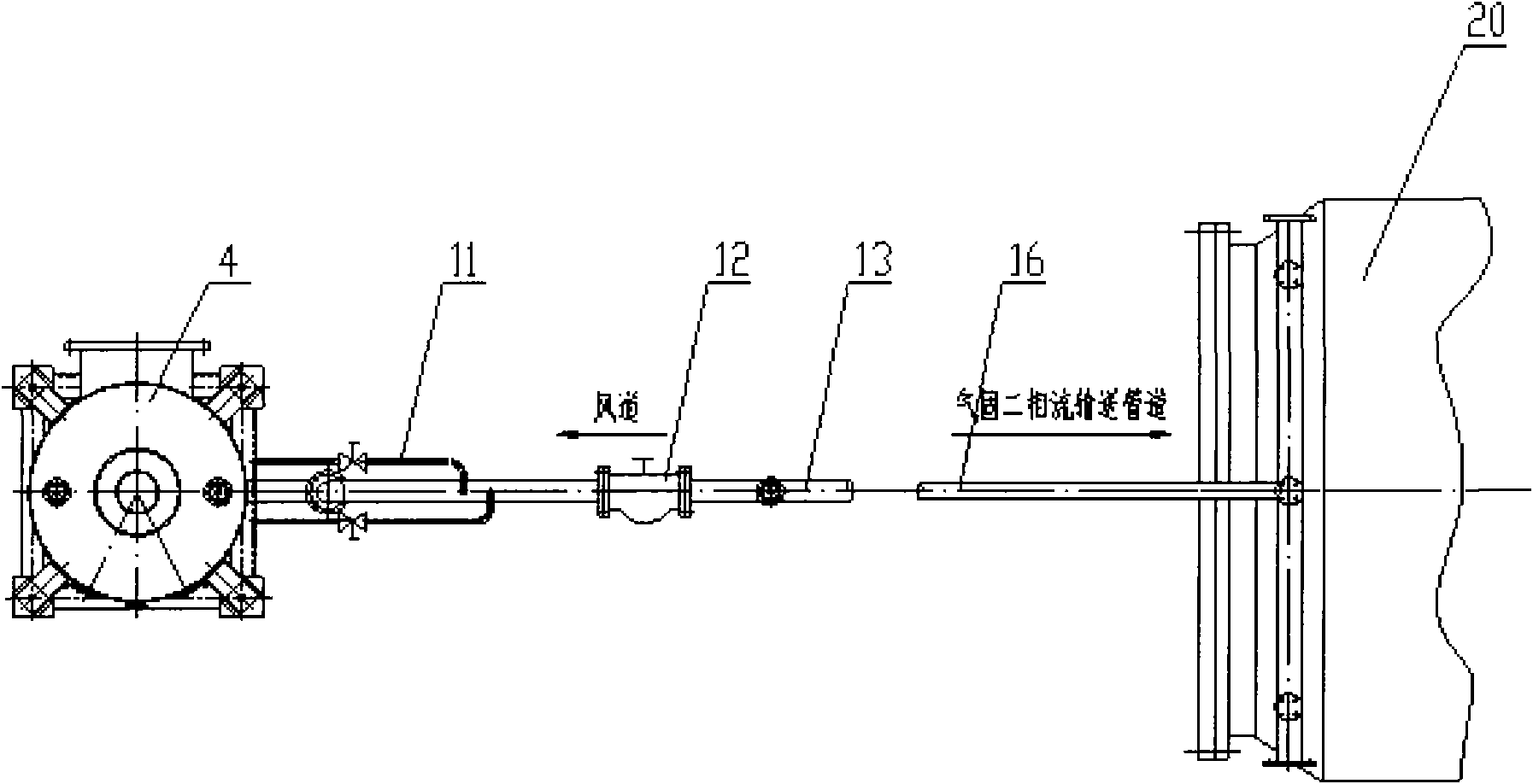

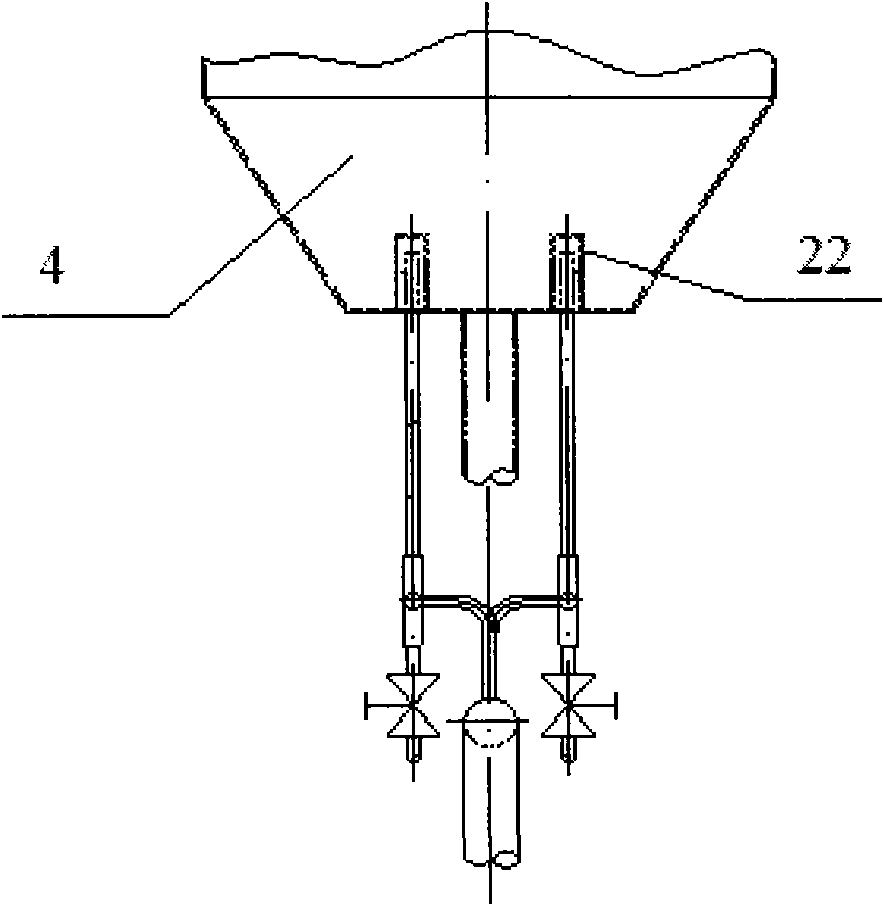

[0017] Such as figure 1 and figure 2 As shown, the fluidized particle ash removal system of the present invention mainly includes a hopper 1, a storage tank 4, a steel support 5, a screw feeder 6, a uniform mixing tank 7, a loose material air duct 11, a main Air duct 13, air compressor 15, material delivery pipeline 17, smoke box 21 in front of the boiler.

[0018] The feeding hopper 1, the storage tank 4, the screw feeder 6, and the uniform mixing tank 7 are connected sequentially from top to bottom, and fixed on the steel bracket 5. The main body weight of the system falls on the steel support 5 .

[0019] The upper part of the uniform mixing tank 7 is cylindrical, and the lower part is an inverted cone; the top of the uniform mixing tank 7 is connected to one end of the main air duct 13, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com