Patents

Literature

106 results about "Grain dust" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Feed for mouth-open period of chickens as well as preparation method and application method thereof

ActiveCN102178090ANutritional balanceImprove digestibilityFood processingAnimal feeding stuffBiotechnologyWeight gaining

The invention discloses a feed for mouth-open period of chickens as well as a preparation method and an application method thereof. The feed for the mouth-open period of the chickens is prepared from the following raw materials in parts by weight: 50-70 parts of corn, 25-35 parts of dehulled soybean meal, 2-4 parts of grain dust, 2-4 parts of maize protein powder, 0.2-0.6 part of lysine, 0.1-0.5 part of methionine, 1.0-3.0 parts of calcium hydrophosphate, 0.8-2 parts of rock flour, 1-3 parts of soybean oil, 0.35 part of salt, 1 part of a chicken premix, 0.1 part of composite micro-ecological inoculum for poultry, 0.01 part of complex enzyme for poultry and 0.02 part of a colorant. The feed for the mouth-open period of the chickens can be applied to chickens which are 1-5 days old. Tests prove that the feed for the mouth-open period of the chickens has a feeding attraction effect on the newly hatched chickens, can be used for reducing the diarrhea rate and death rate of the chickens and is beneficial to the weight increment of the chickens.

Owner:云南西南农牧集团股份有限公司 +2

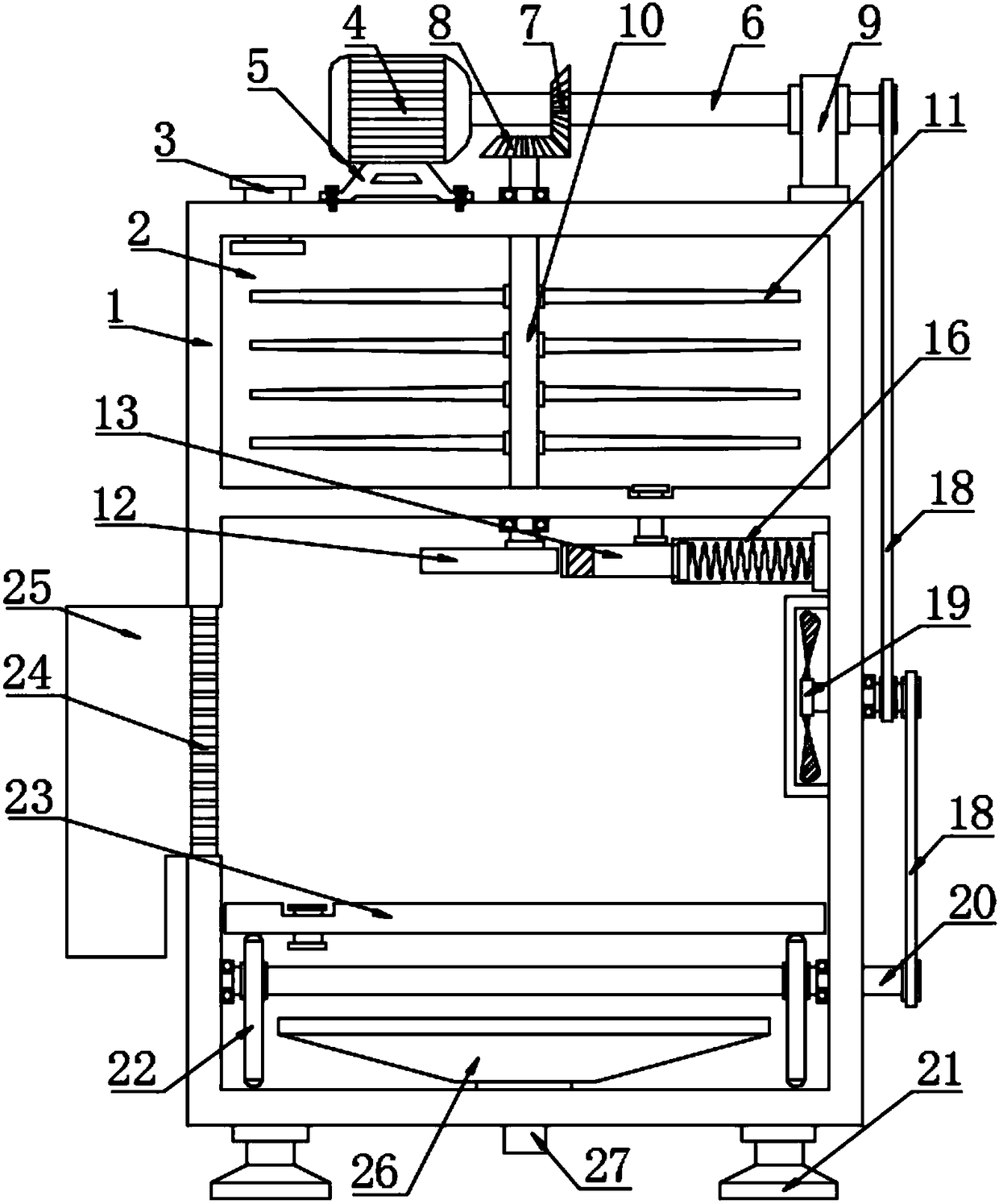

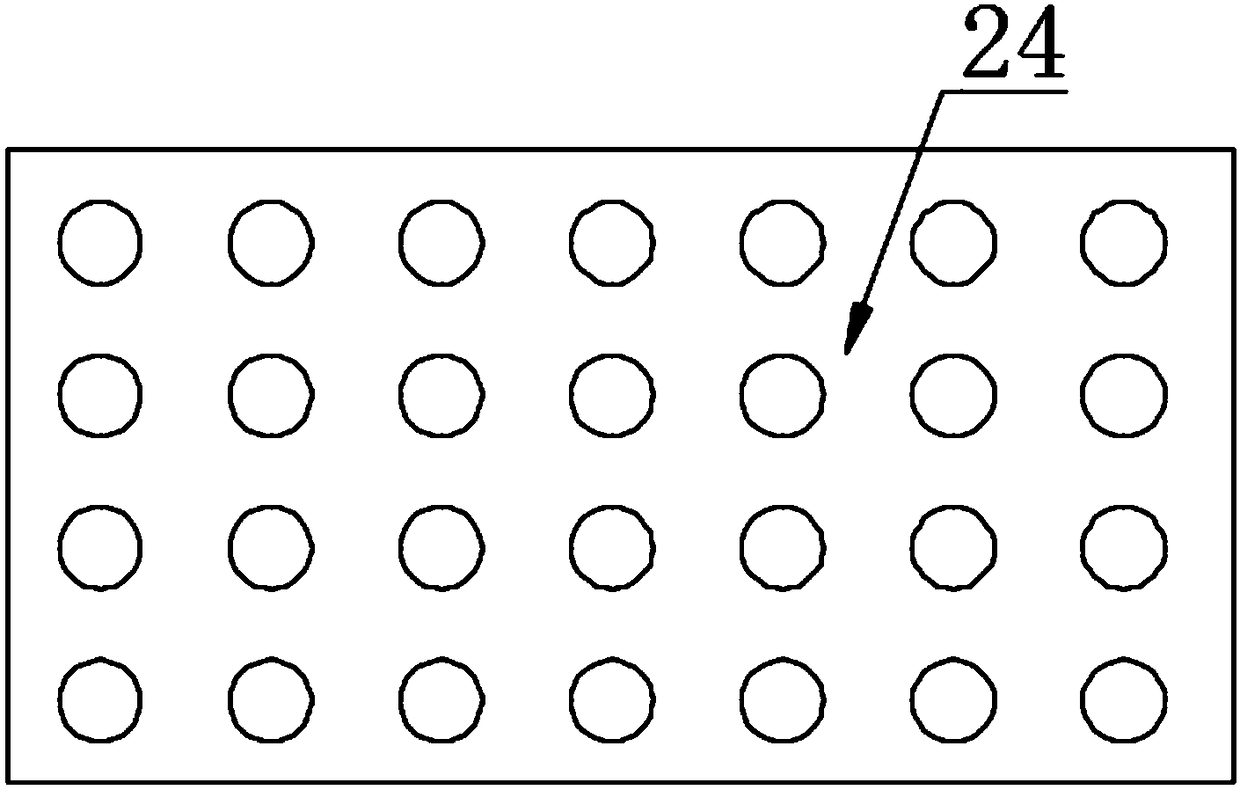

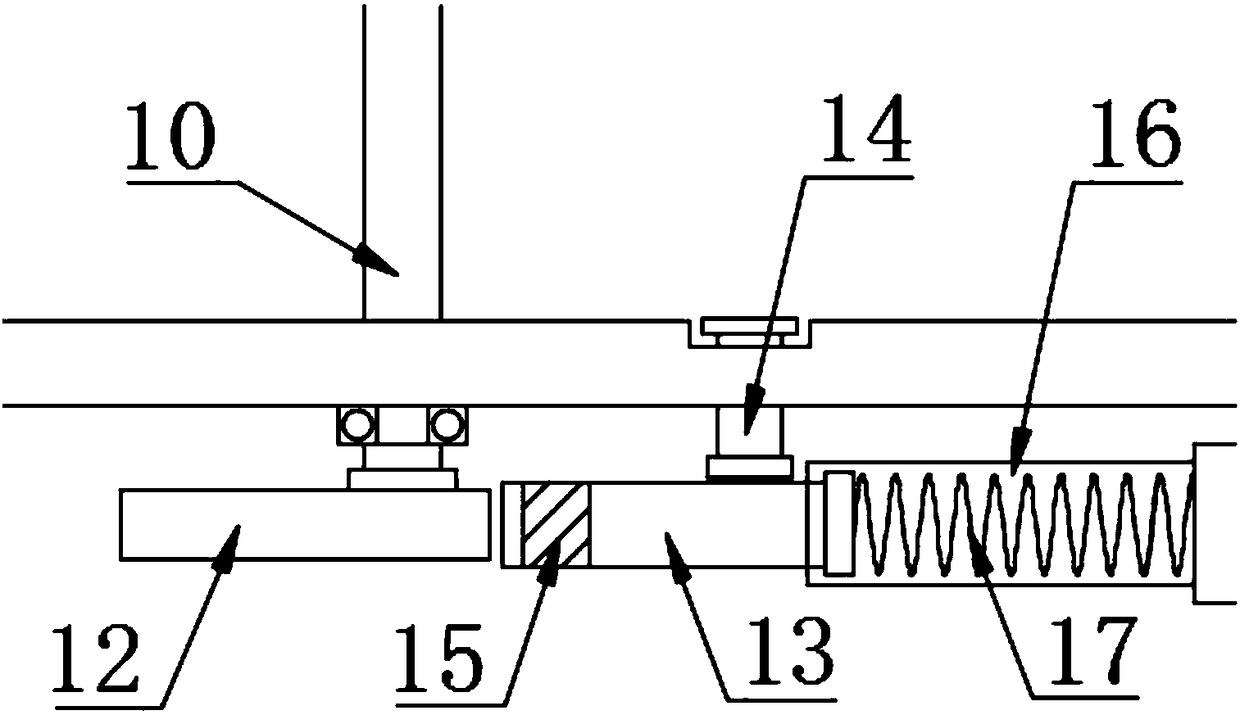

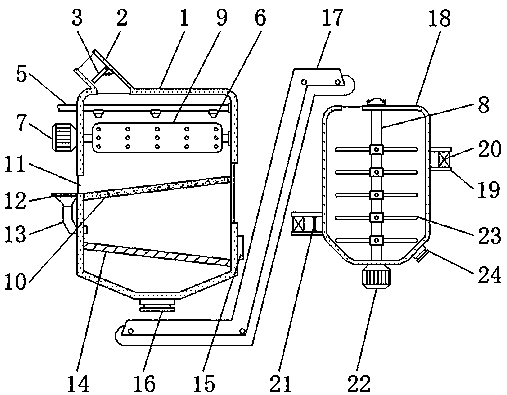

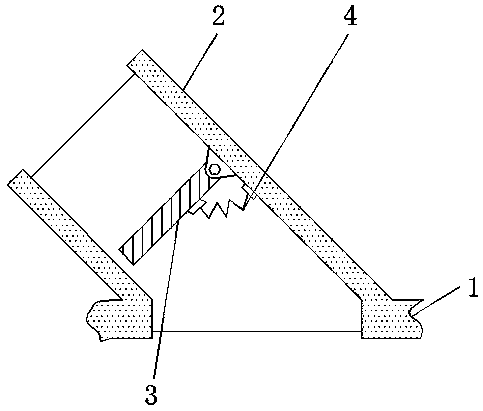

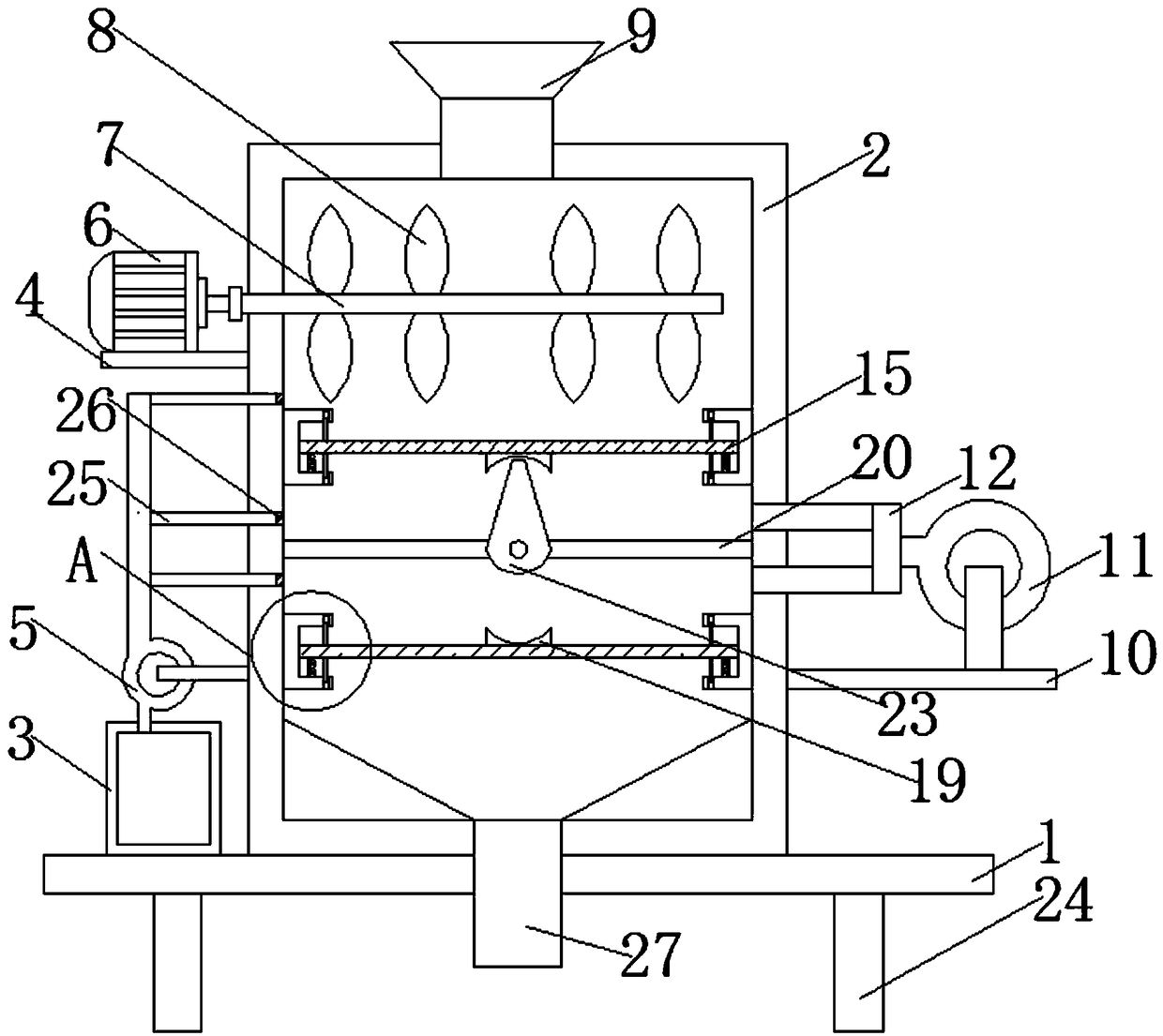

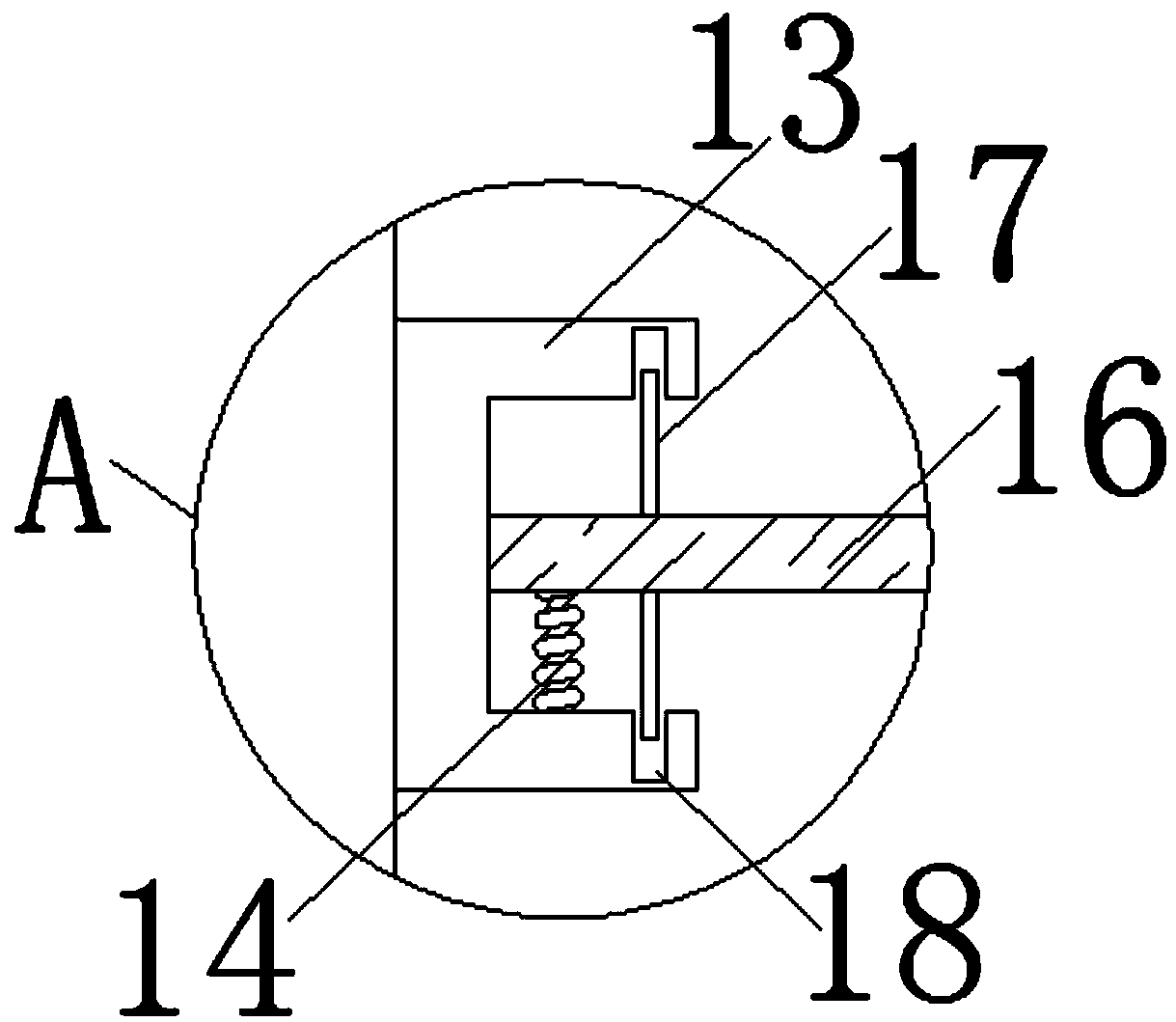

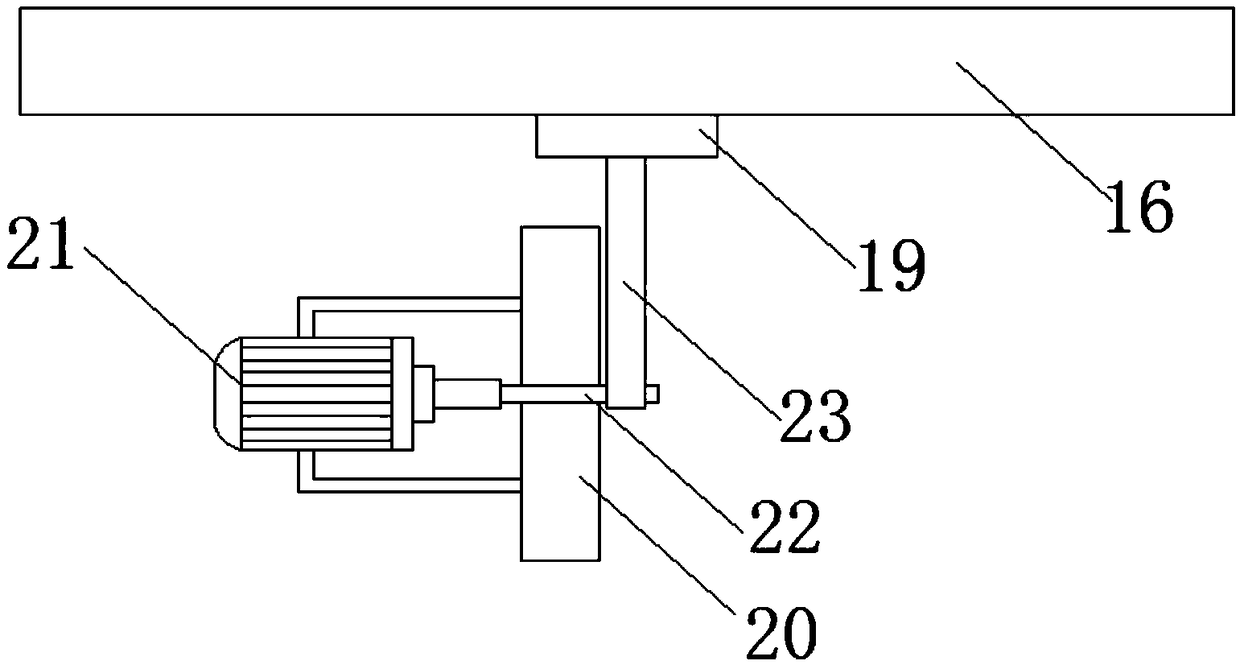

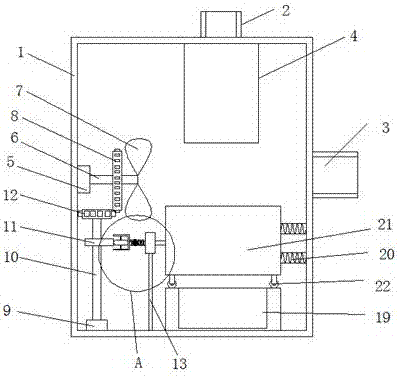

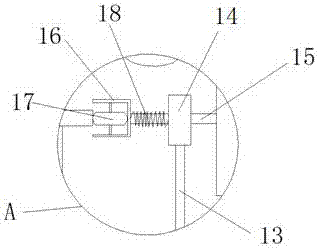

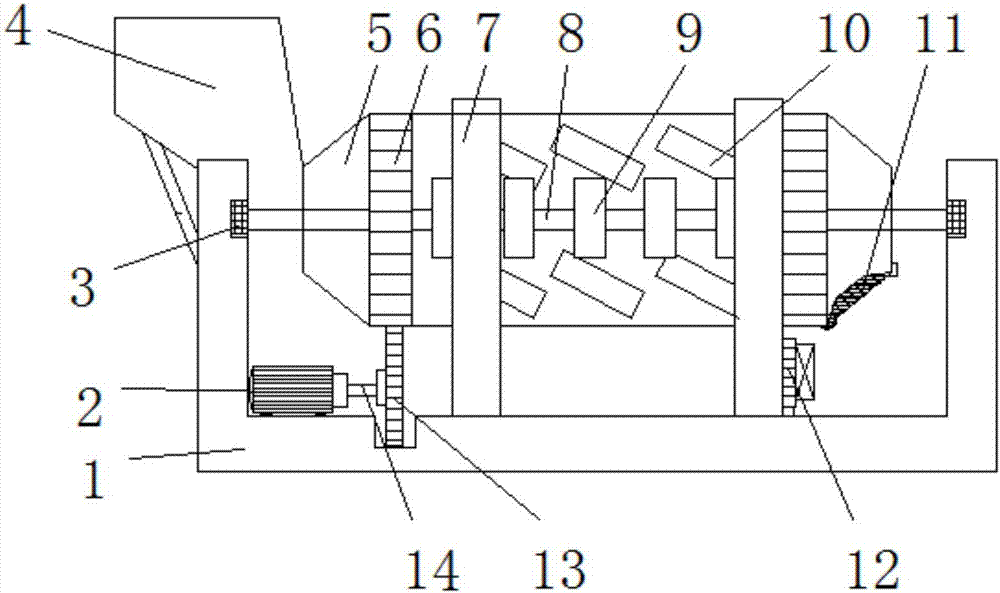

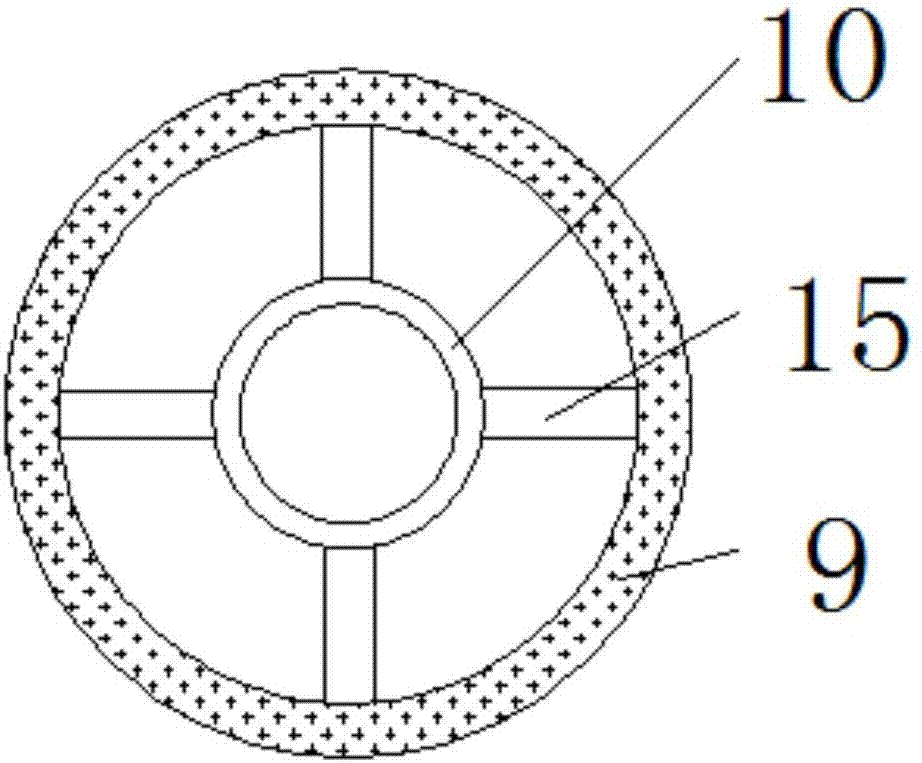

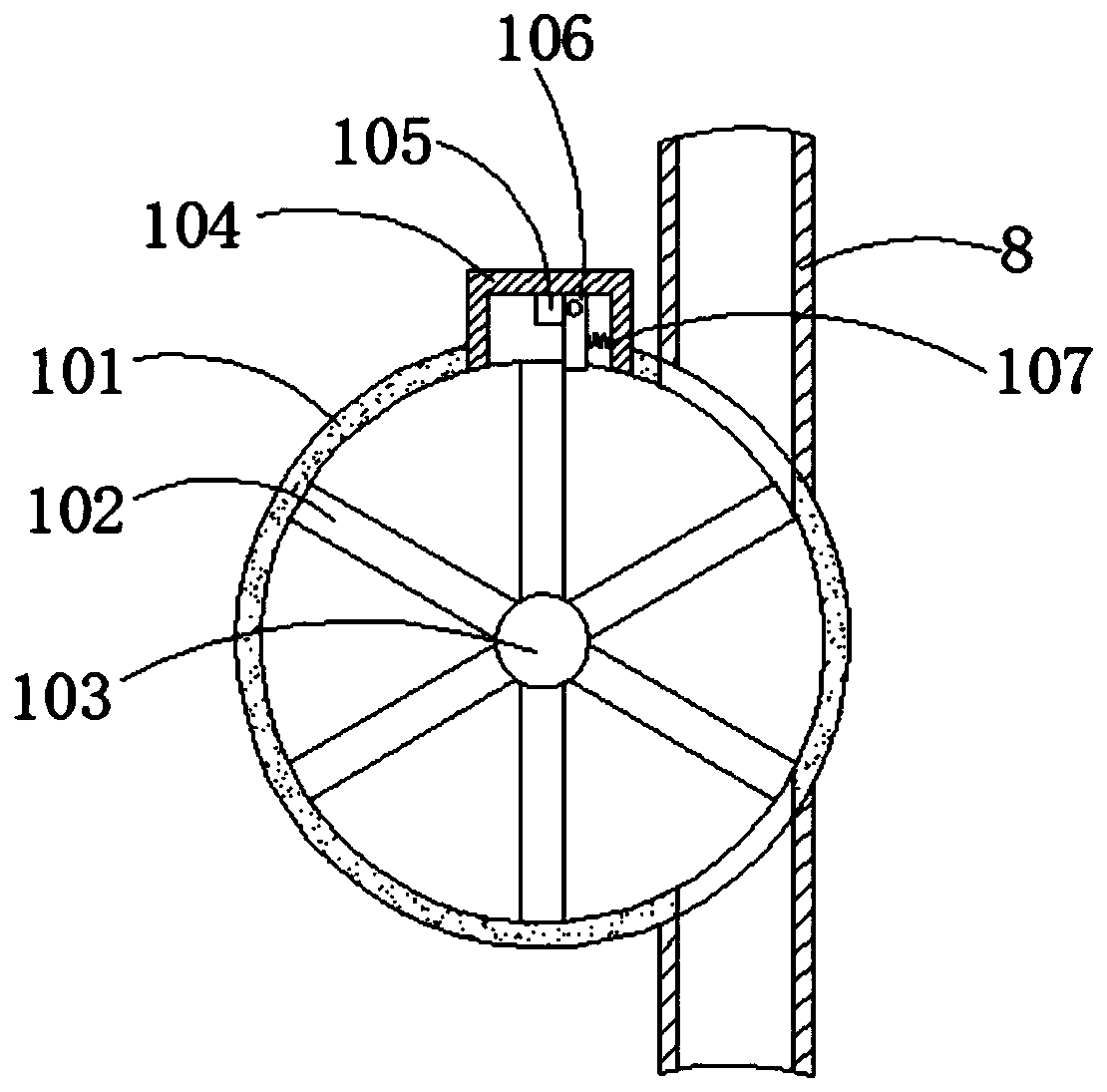

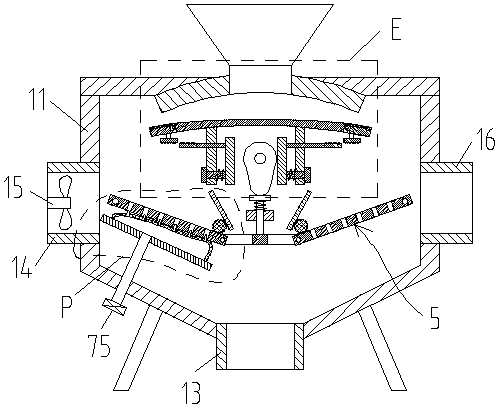

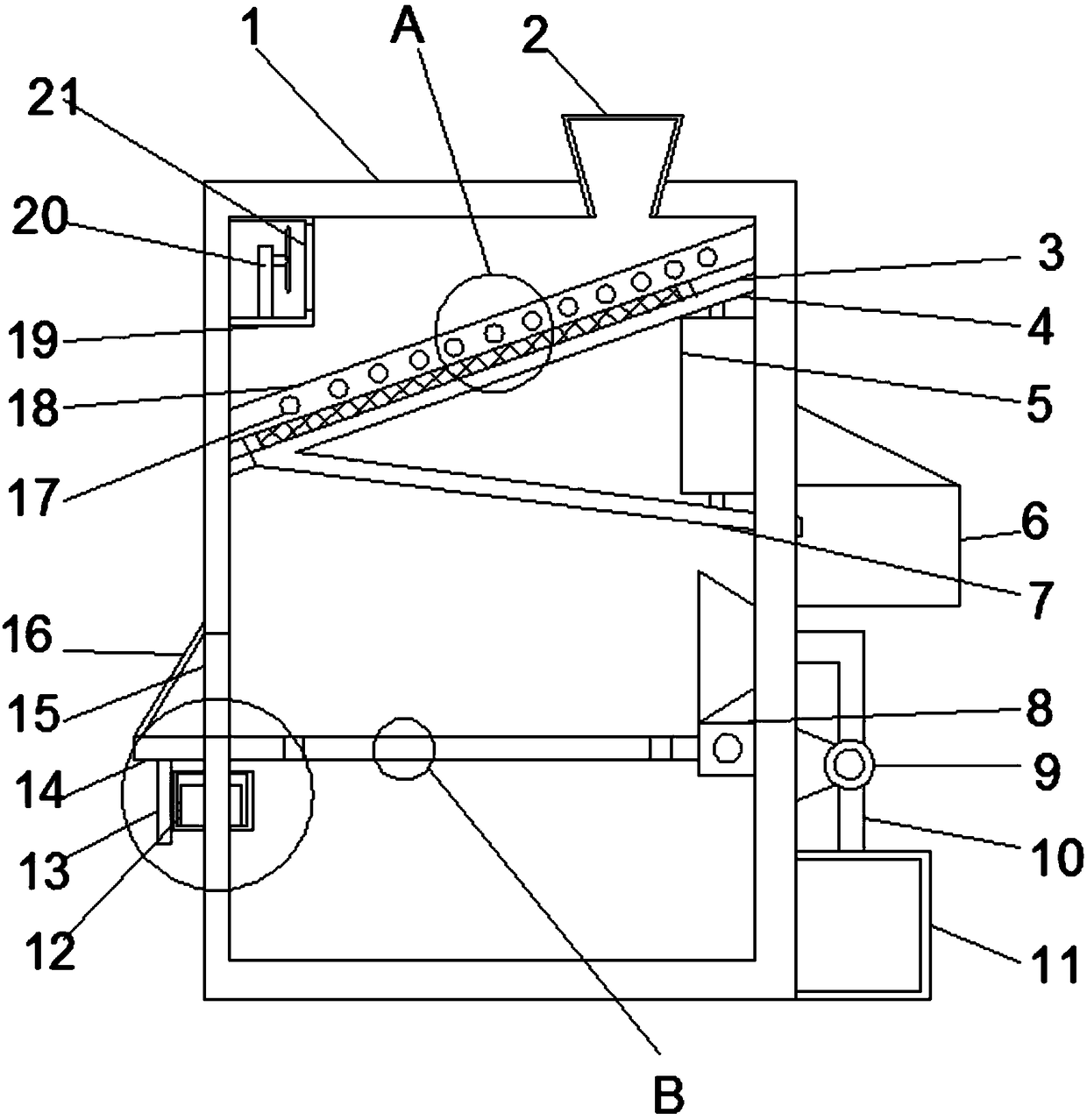

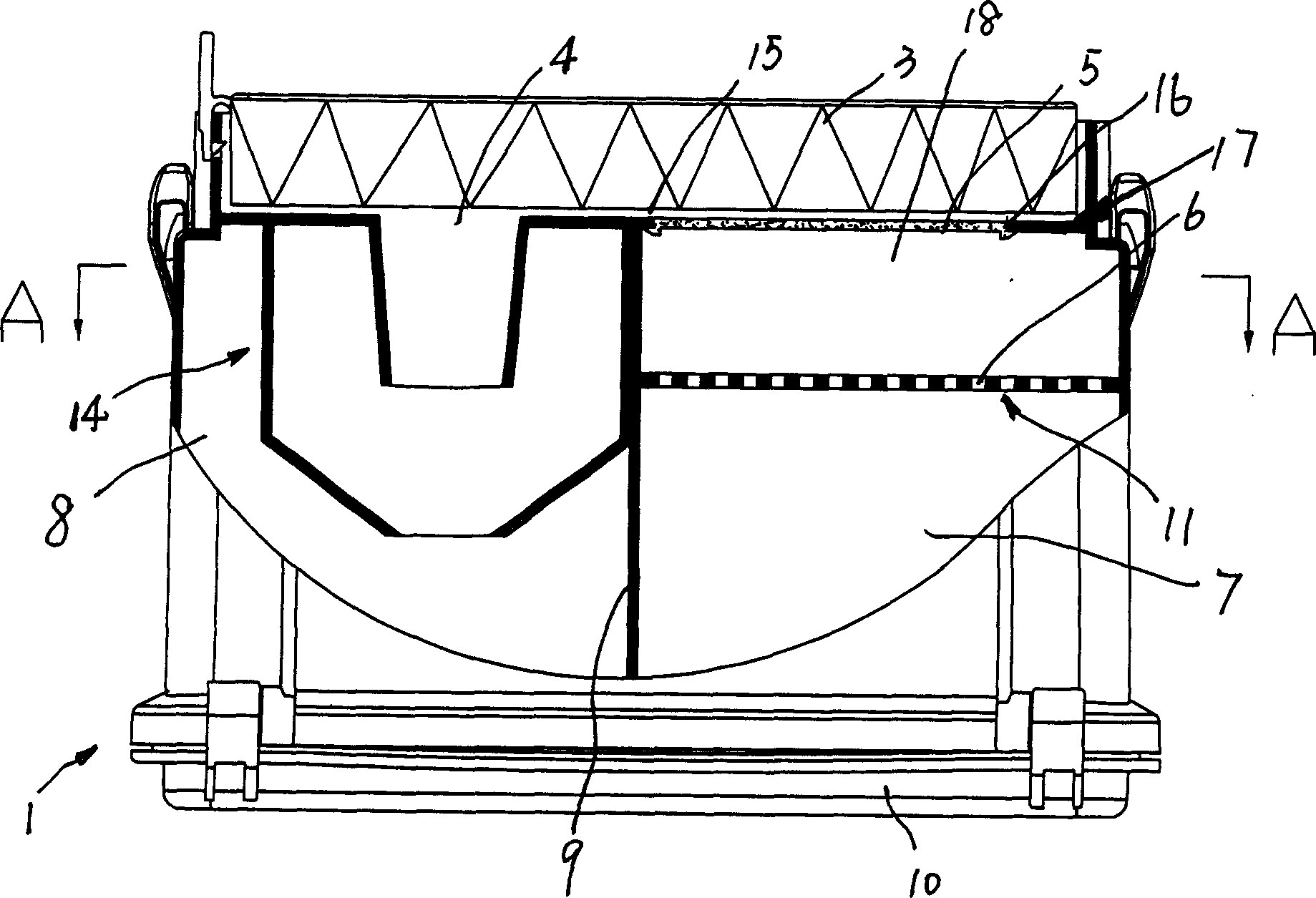

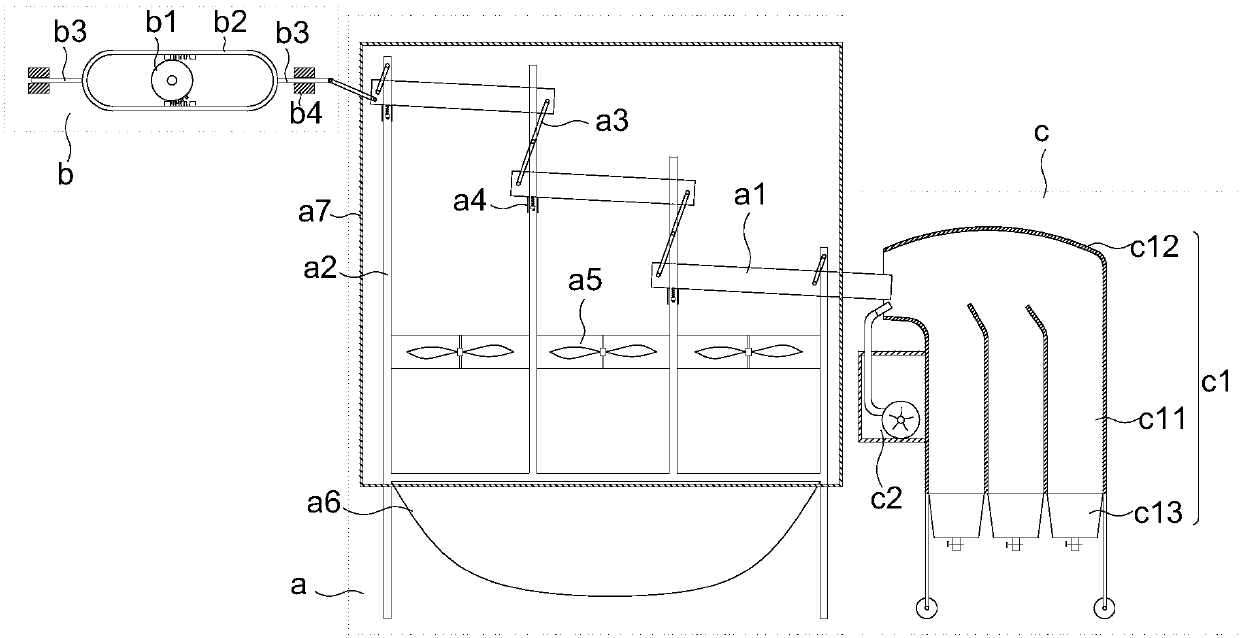

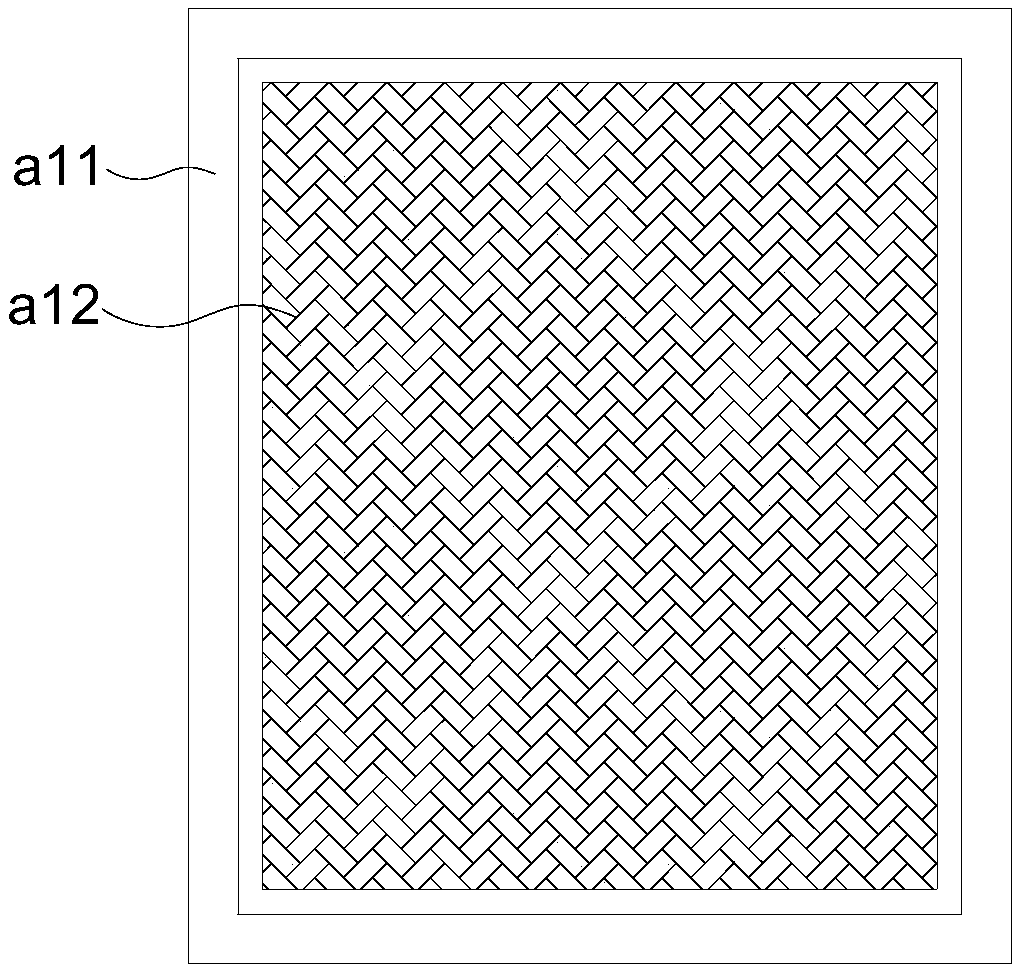

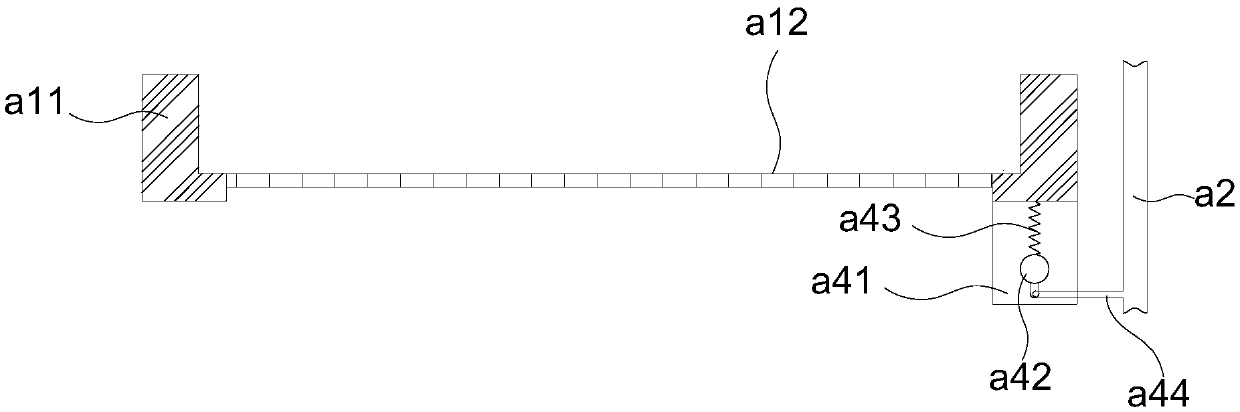

Agricultural grain dust raising and removing device

ActiveCN108393270AImprove cleaning efficiencyThorough cleaningGas current separationDrive shaftAgricultural engineering

The invention discloses an agricultural grain dust raising and removing device. A material storing box is arranged at the upper part of a device body; a driving motor is arranged at the upper end of the material storing box; the right side of the driving motor is rotationally connected with a driving shaft; the middle part of the driving shaft is fixedly connected with a first bevel gear; the first bevel gear is engaged with a second bevel gear; the second bevel gear is fixedly connected with a driven shaft; a bearing of the driven shaft is rotationally connected with the material storing box;a material guide pipe communicates with the bottom of the right side of the material storing box; the lower end of the material guide pipe is bonded with the upper surface of a movable baffle; a through hole is formed in the left side of the movable baffle; the right side of the movable baffle is connected with a sleeve plate in sleeved manner; the right side of the sleeve plate is fixedly connected with the device body; and a reset spring is arranged in the sleeve plate. With the adoption of the agricultural grain dust raising and removing device, the driving shaft drives the driven shaft tofollow to rotate, under the combined action of the reset spring and a first eccentric wheel, the movable baffle is driven to move leftwards and rightwards in a reciprocating manner, at the same timea transmission belt drives a rotating shaft to follow to rotate, grains are leaked from a leaking hole in the left side of a cross plate, and second eccentric wheels which rotate drive the cross plateto vibrate up and down in a reciprocating manner, so that the grains on the right side of the cross plate are raised and dust is removed.

Owner:奉节县增承稻谷种植专业合作社

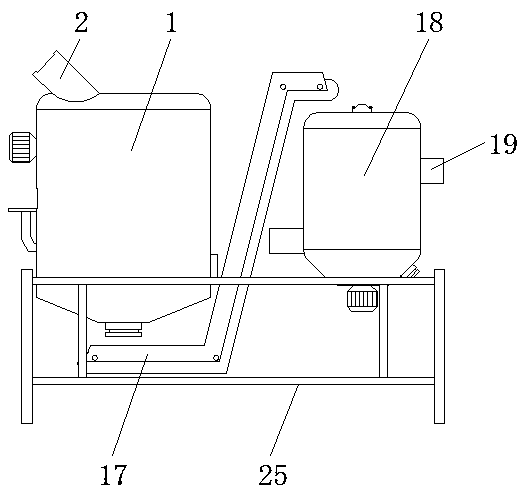

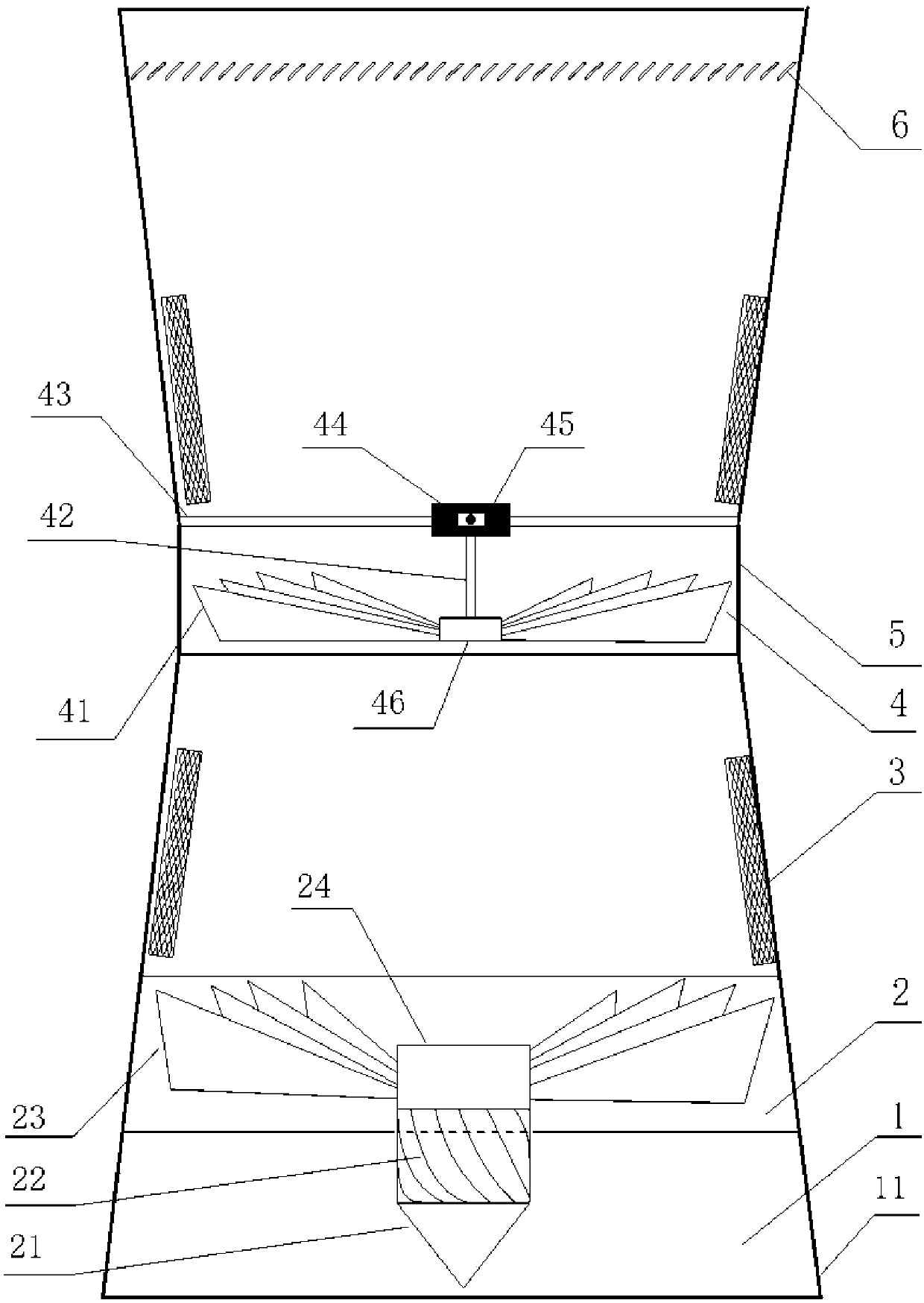

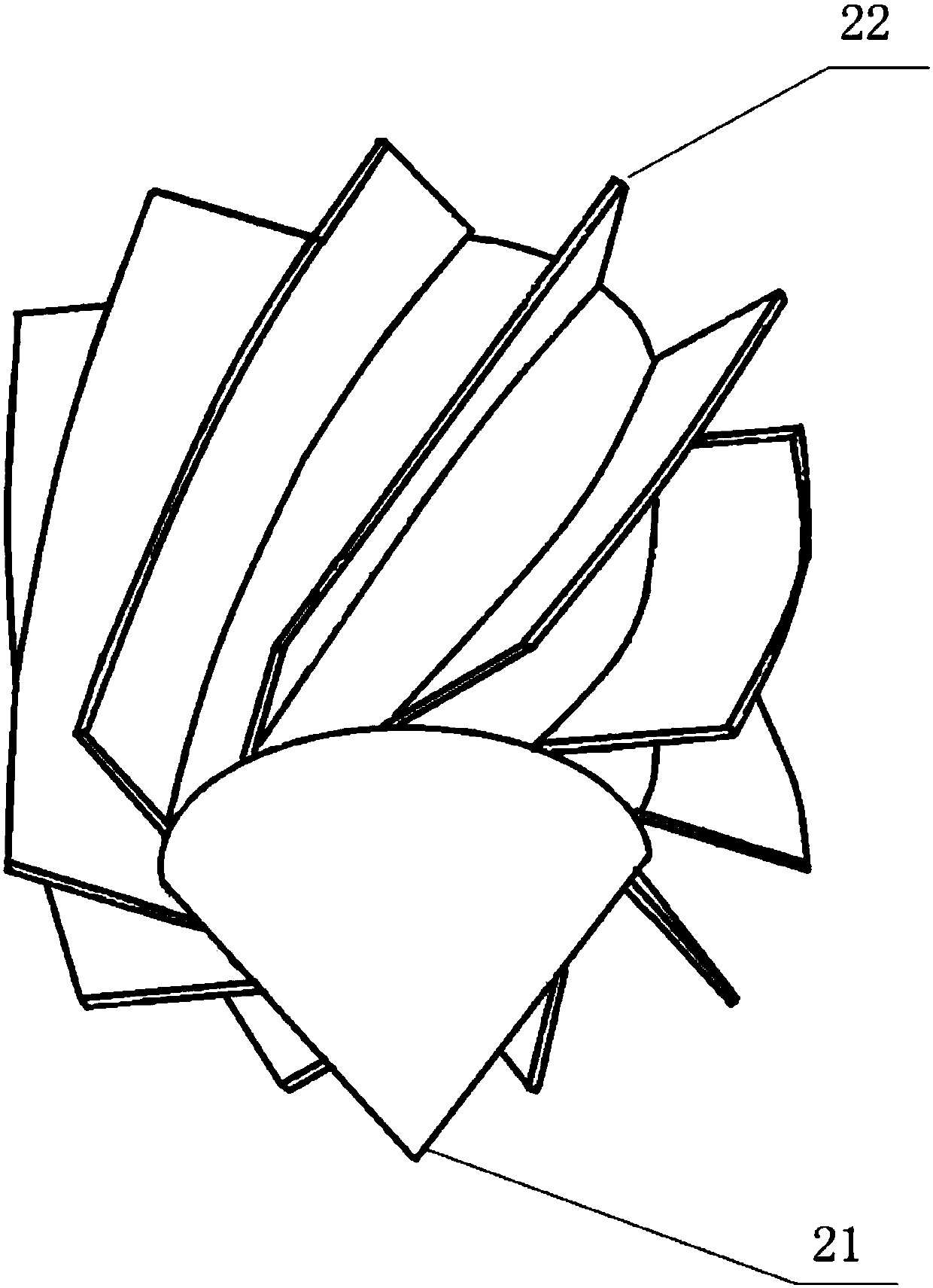

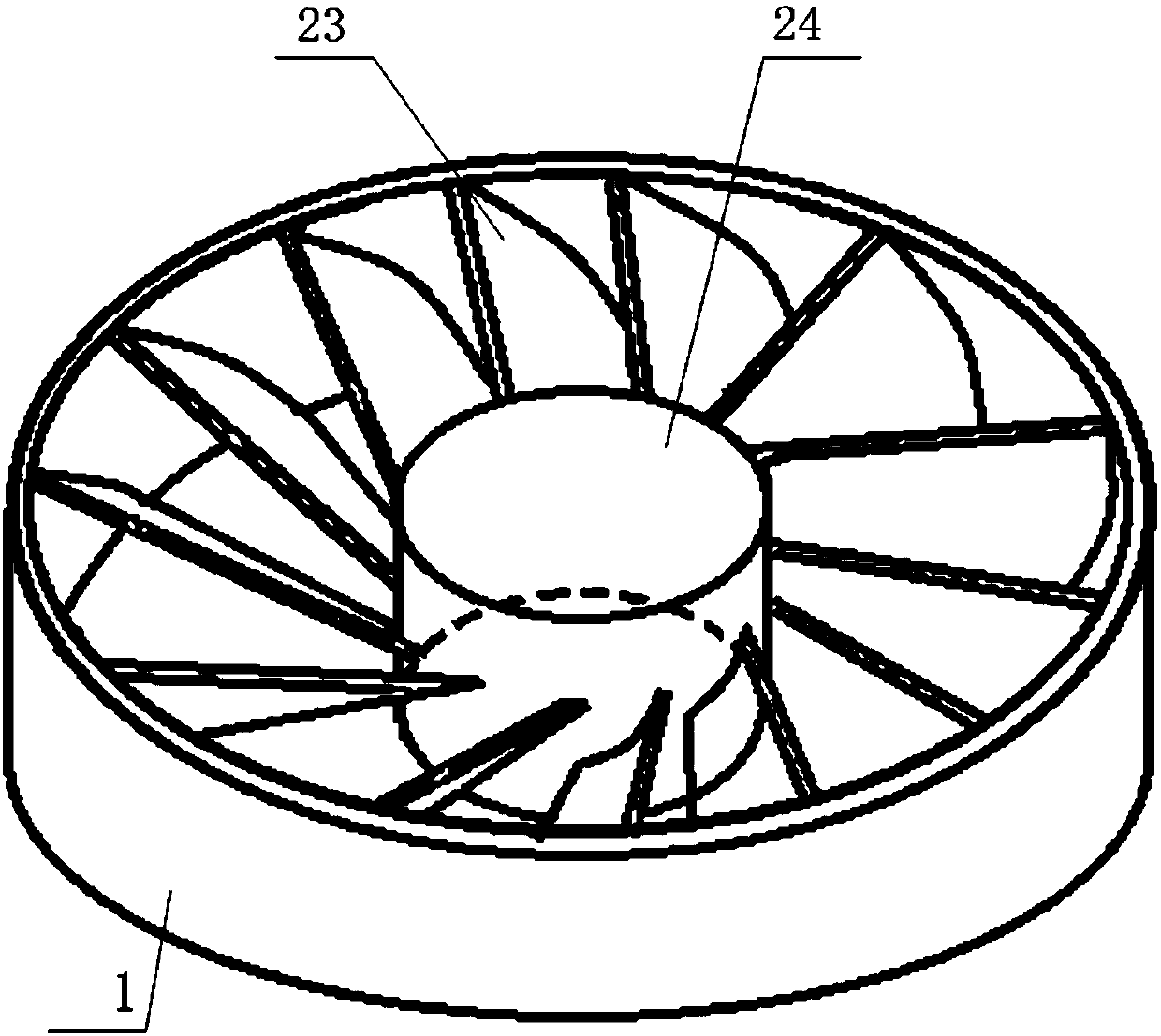

Combined type threshing device capable of quickly threshing and drying for corn processing

InactiveCN107771537AQuick drying and dust removalQuality improvementDrying gas arrangementsThreshersEngineeringWater pipe

The invention discloses a combined threshing device for corn processing capable of rapid threshing and drying, which comprises a threshing tank, a water pipe, a separation plate, a lifter and a drying tank. A feeding hopper is installed on the top of the threshing tank. The water pipe is installed inside the threshing tank, the side of the threshing tank is provided with a first motor, the bottom of the threshing cylinder is provided with a sieve plate, and one end of the elevator is located below the second discharge port. The drying tank is located below the other end of the hoist, a fan and a heating element are provided inside the ventilation pipe, and a second motor and a material intake are provided at the bottom of the drying tank. The combined threshing device for corn processing that can be quickly threshed and dried can reduce the loss caused by the operation of the threshing device by pre-soaking the corn, and can perform preliminary quality classification on the threshed corn. The grains are quickly dried and dust-removed, which greatly improves the quality of corn processing.

Owner:NANJING YUHUATAI DISTRICT INTPROP PROMOTION CENT

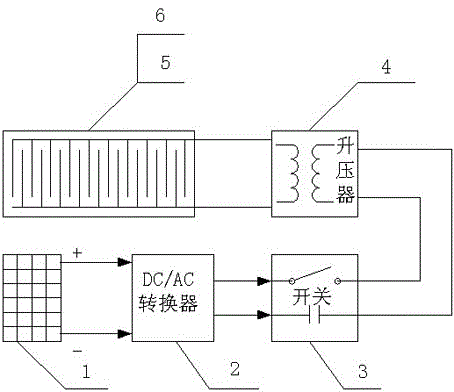

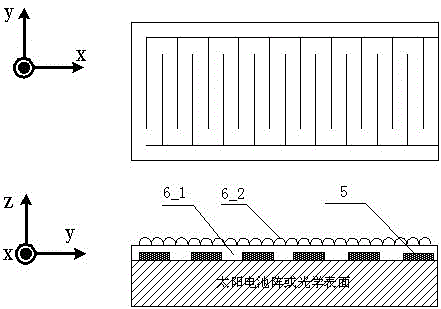

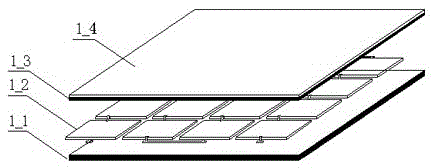

Energy closed-loop ultrahydrophobic electric curtain dust removal system applied to space solar cell array

ActiveCN105610397AImprove dust removal efficiencyDoes not affect optical performancePhotovoltaicsPhotovoltaic energy generationElectrical batteryTransformer

The invention provides an energy closed-loop ultrahydrophobic electric curtain dust removal system for a space. The energy closed-loop ultrahydrophobic electric curtain dust removal system comprises a high-voltage solar cell module, a DC / AC converter, a relay switch boosting transformer, a comb-type transparent electric curtain and an ultrahydrophobic layer. According to the working principle, 300V high voltage provided by a high-voltage power generation module provides an over 1,000V high-voltage AC power supply to the comb-type electric curtain through DC / AC conversion and boosting; and an AC field is formed on the surface of the comb-type ultrahydrophobic electric curtain which is periodically spaced. The ultrahydrophobic layer greatly reduces the surface energy; and the adsorptivity of dust on the surface of a solar cell array is reduced, so that the dust is easily lifted under the action of the electric field and moves along the direction vertical to an electrode; the dust removal target is achieved; and the removal effect on large-grain dust or accumulated dust can also be achieved under the action of gravity, shake and the like. The dust removal system provided by the invention is high in dust removal efficiency, does not affect the optical property, can achieve energy closed loop and can be isolated from a spacecraft power system.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

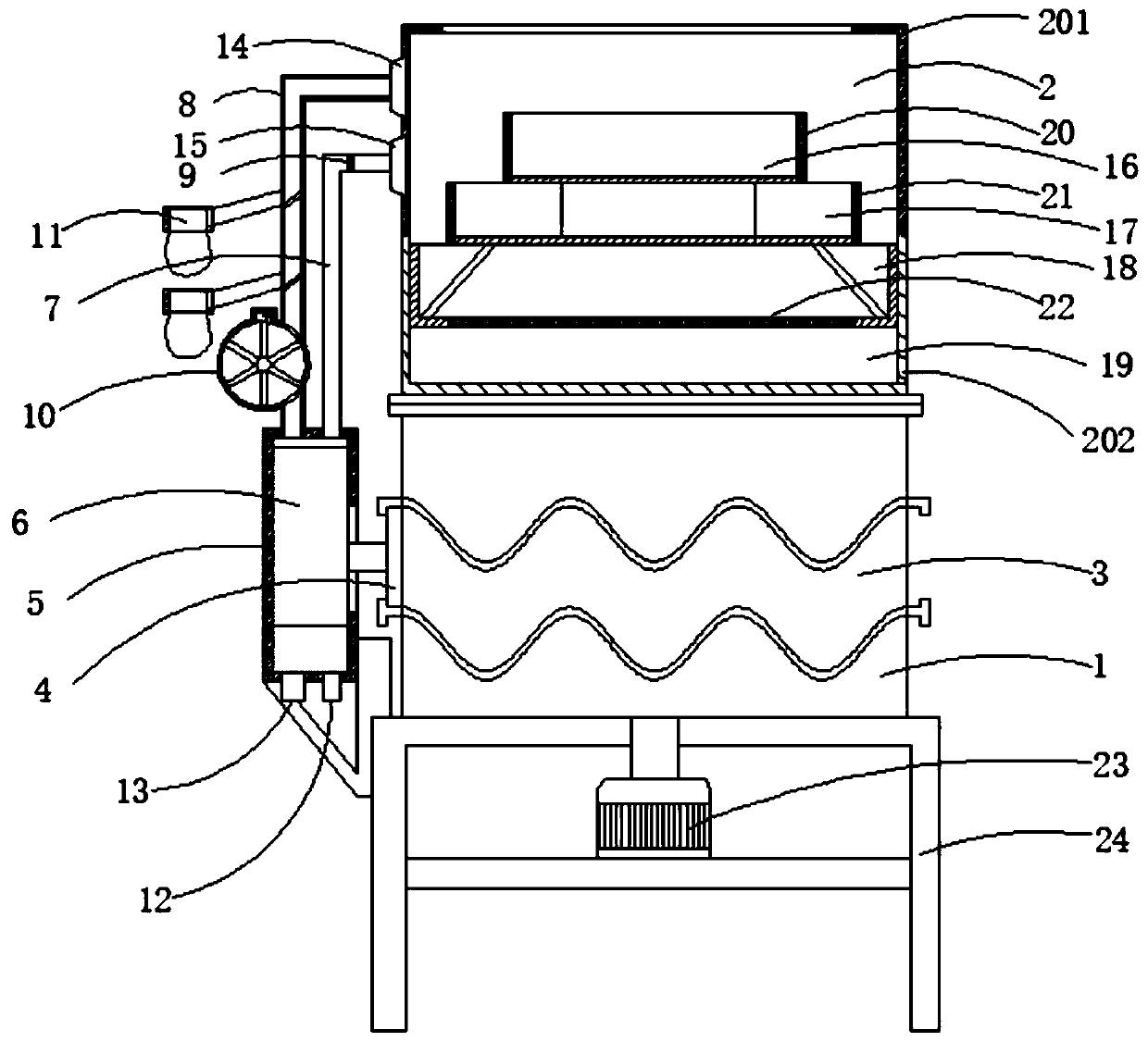

Grain dust removal drying machine

The invention provides a grain dust removal drying machine, and relates to the technical field of agricultural grain processing. The grain dust removal drying machine comprises a base, the top of thebase is fixedly provided with a drying box and a dust collecting box, the left side of the drying box is fixedly provided with a motor support and a dust suction pump, a first motor is fixedly arranged on the top of the motor support, according to the grain dust removal drying machine, firstly, grains required to be processed are conveyed to the drying box through a feeding opening, the first motor drives a stirring blade on a rotating shaft to stir grains in the drying box, a second motor drives a convex wheel on a transmission shaft to rotate, when the convex wheel makes contact with arc blocks on a first screening plate and a second screening plate, the first screening plate and the second screening plate are driven to move along the inner wall of a concave plate, through cooperation ofa spring, the first screening plate and the second screening plate begin to carry out vibration screening on the grains, and dust and unfilled grains in the grains can be selected through vibration.

Owner:宿迁市众创空间科技有限公司

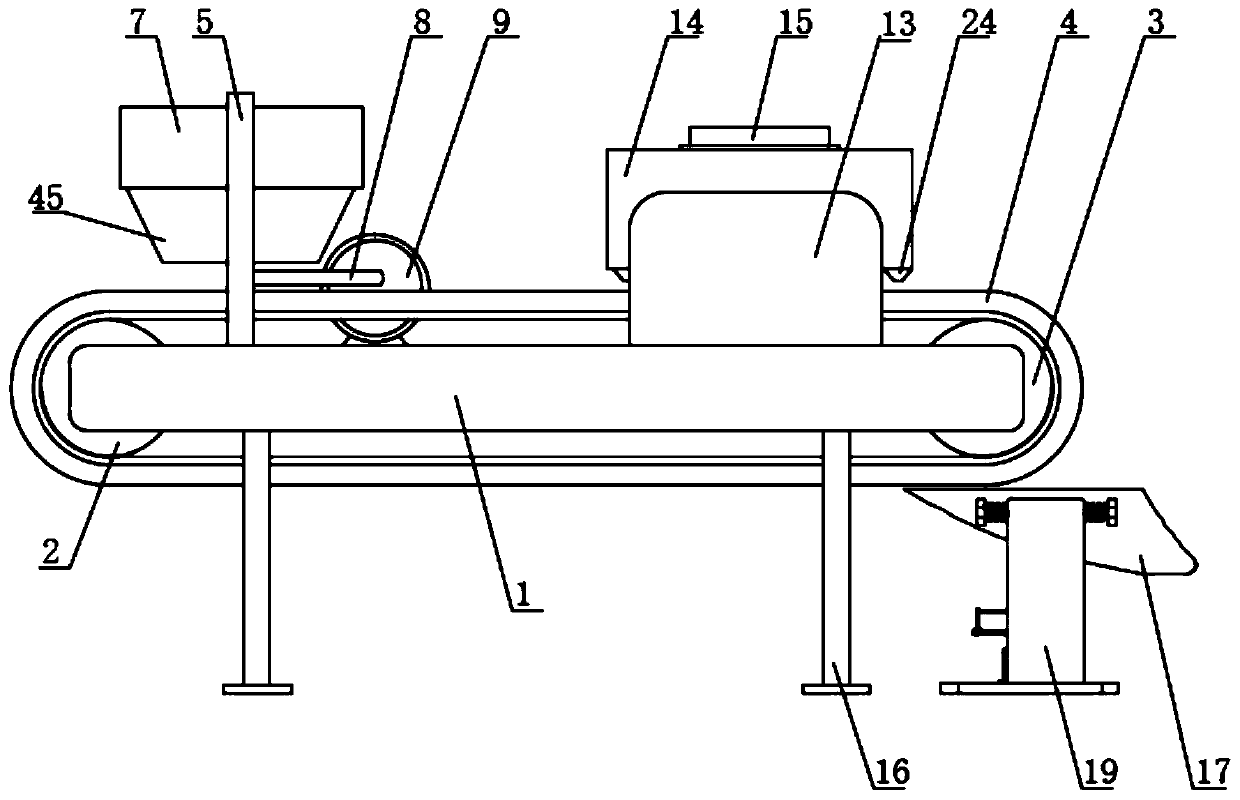

Grain dust removing equipment and use method thereof

ActiveCN111589708AReduce labor intensitySimple structureSievingGas current separationThermodynamicsElectric machine

The invention discloses grain dust removing equipment which comprises a first side plate and a second side plate. The first side plate is located on one side of the second side plate, and the sides, close to each other, of the first side plate and the second side plate are rotationally connected with a first rotary roll and a second rotary roll correspondingly. The grain dust removing equipment has the advantages that the structure is simple, a driving motor can drive a flange conveying belt to move from left to right, a conical plate can make grain to drop cylindrically, dust in the grain canbe blown away by an air blower through an annular bellow, and the grain can be dried by a drying box; in the reciprocating swing process of an arc-shaped box, the grain can be separated from large pebbles and other heavy particles, the dust removing effect and the dust removing efficiency are improved, and the work progress is guaranteed; and meanwhile the grain can be dried, the pebbles and theheavy particles doped in the grain can be removed, time and labor are saved, the labor intensity of workers is reduced, and use is convenient.

Owner:宁夏明翔粮油有限公司

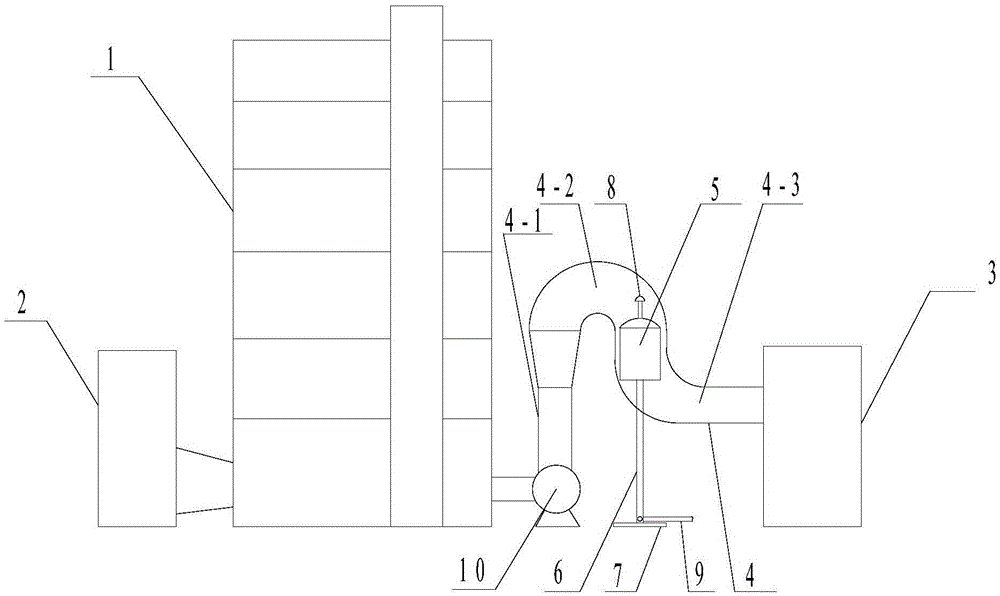

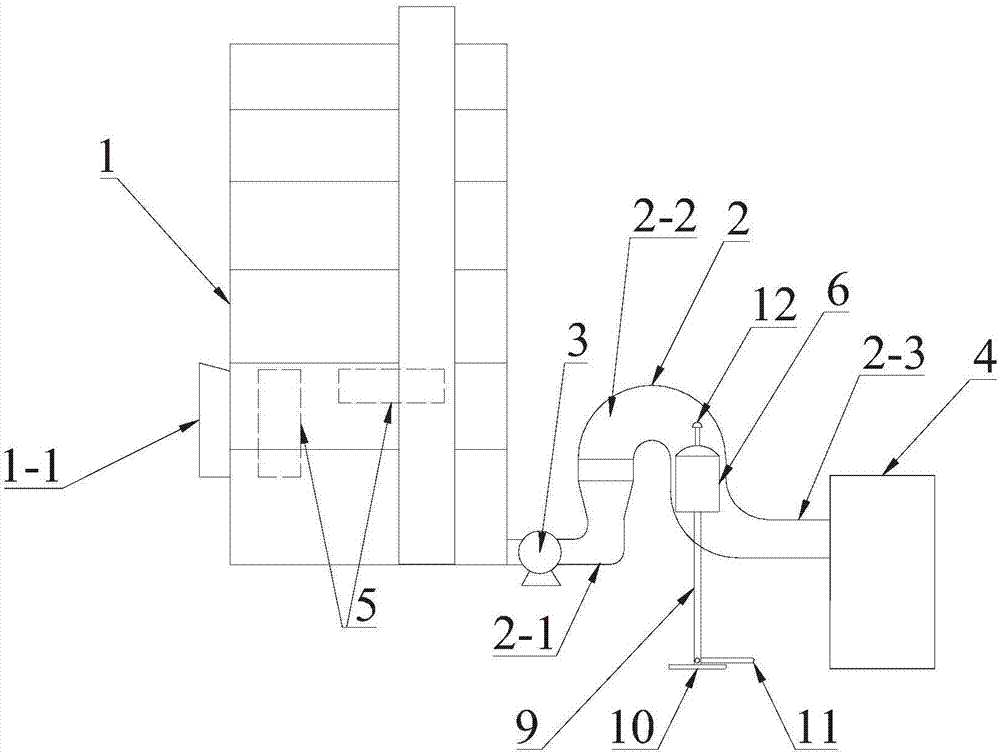

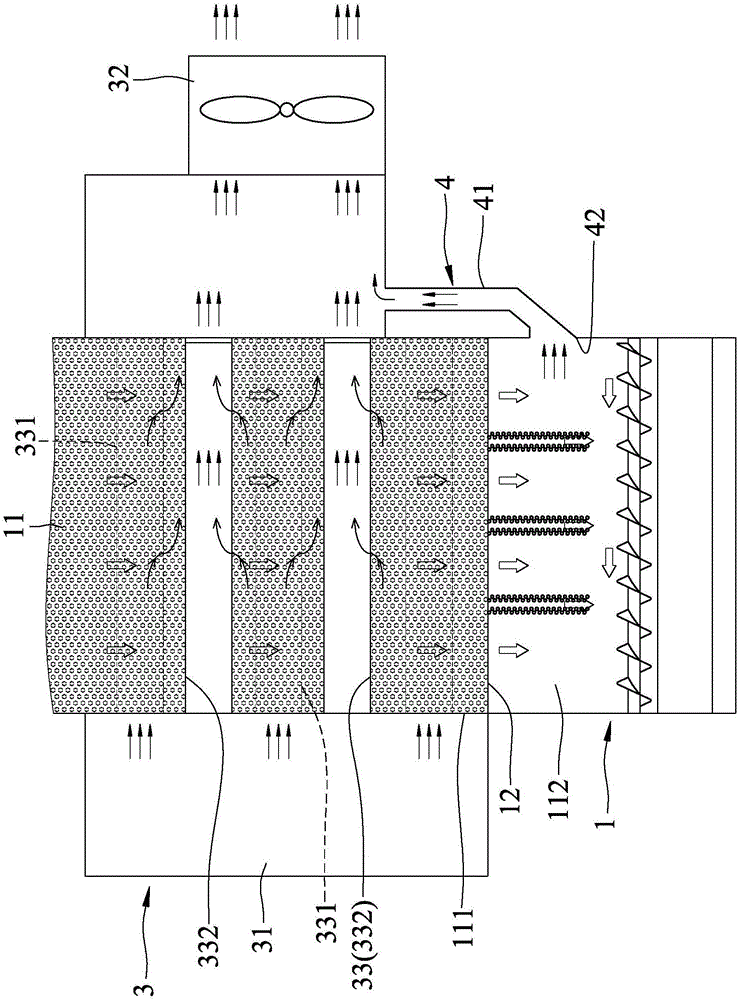

Grain drying device

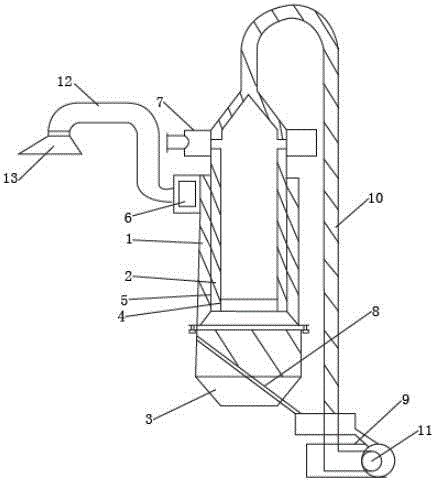

ActiveCN105486074AReduce volumeImprove efficiencyFood processingClimate change adaptationEngineeringTower

The invention discloses a grain drying device. The grain drying device comprises a drying tower (1); one side of the drying tower (1) is communicated with a heat pump (2) for supplying hot wind; a dust collecting chamber (3) for collecting grain dust is arranged on the other side of the drying tower (1), and is communicated with the drying tower (1) through a dust removing pipe (4); and an evaporator (5) of the heat pump (2) is arranged in the dust removing pipe (4). The grain drying device is provided with the evaporator of the heat pump in the dust removing pipe, can improve the efficiency of the evaporator by using heat of dust-contained gas, and is energy-saved and environment-friendly.

Owner:苏州市农业机械有限公司

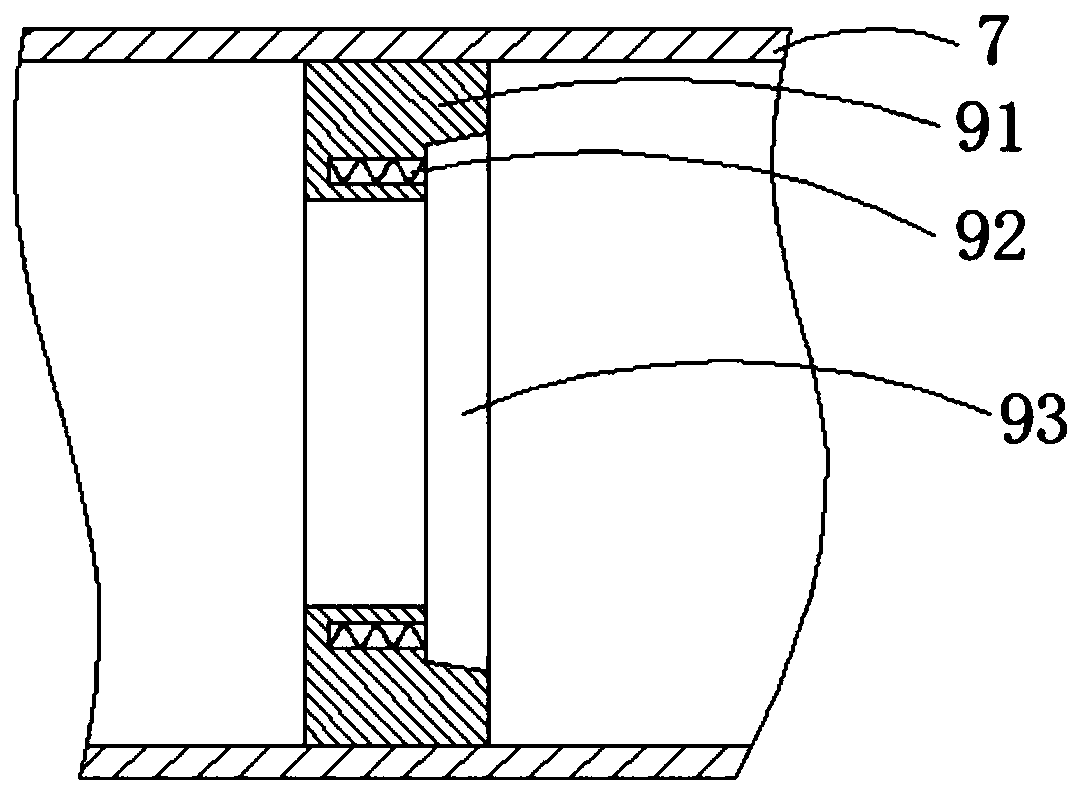

Double-cyclone dust-removing and demisting device

The invention provides a double-cyclone dust-removing and demisting device. The double-cyclone dust-removing and demisting device comprises a cyclone cylinder with a venturi tube shape, a primary cyclone unit and a secondary cyclone unit, wherein the middle part of the cyclone cylinder is a throat pipe; the primary cyclone unit is coaxially arranged at a bottom gas inlet in the cyclone cylinder; the secondary cyclone unit is coaxially arranged in the throat pipe; the secondary cyclone unit comprises a driven free type impeller arranged in the throat pipe. The double-cyclone dust-removing and demisting device provided by the invention is simple in structure and high in reliability; various manners including bent curved surface separation, inertial separation, centrifugal separation and thelike are combined to treatment flue gas for a plurality of times; small-grain dust and fog drops with the size of 5mu m or lower can be efficiently removed and a demisting effect of a desulfurizationtower is increased; the resistance loss also can be reduced, and the investment cost and the operation cost of the desulfurization tower are reduced; the double-cyclone dust-removing and demisting device provided by the invention can be applied to the wet type desulfurization tower.

Owner:MCC CAPITAL ENGINEERING & RESEARCH

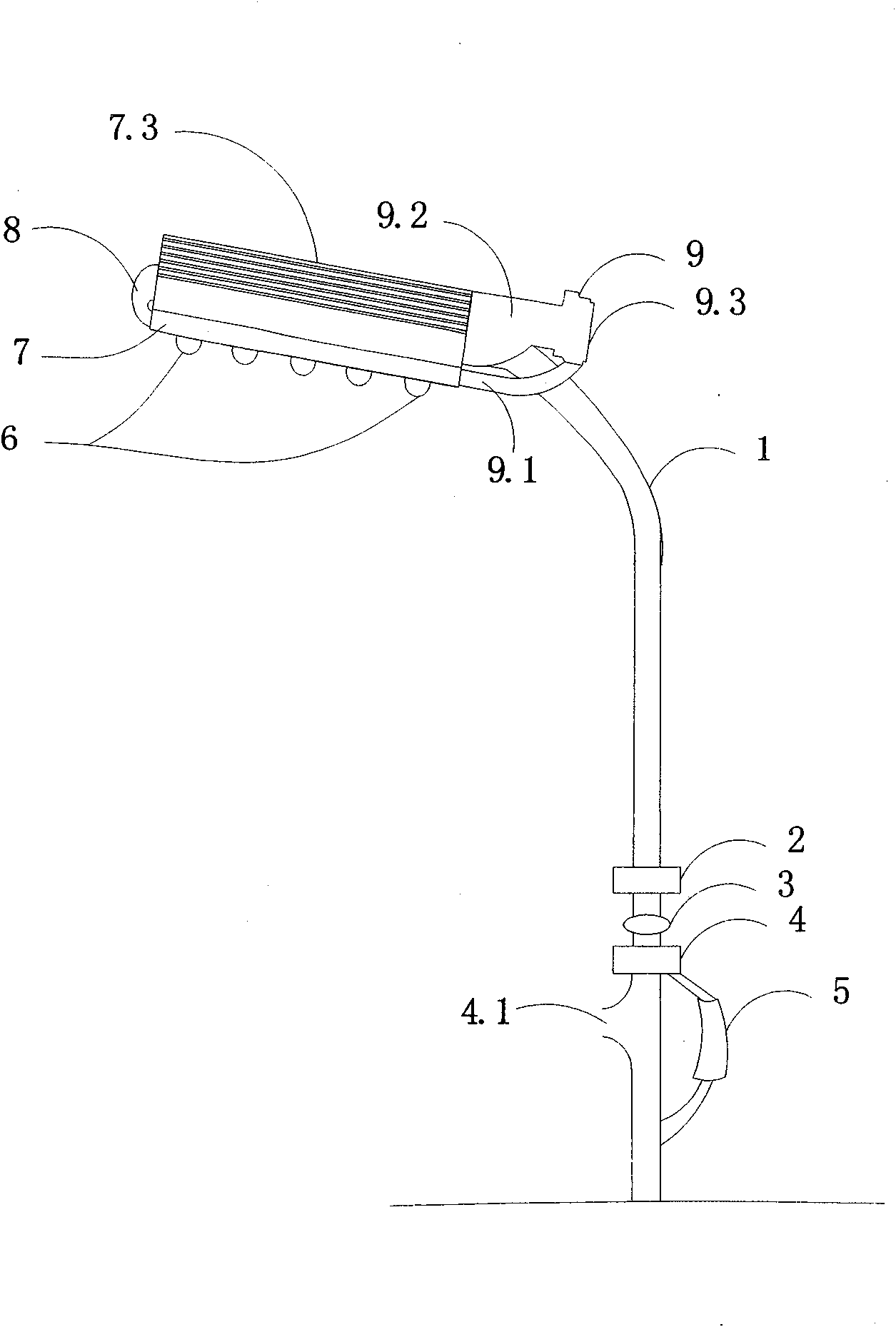

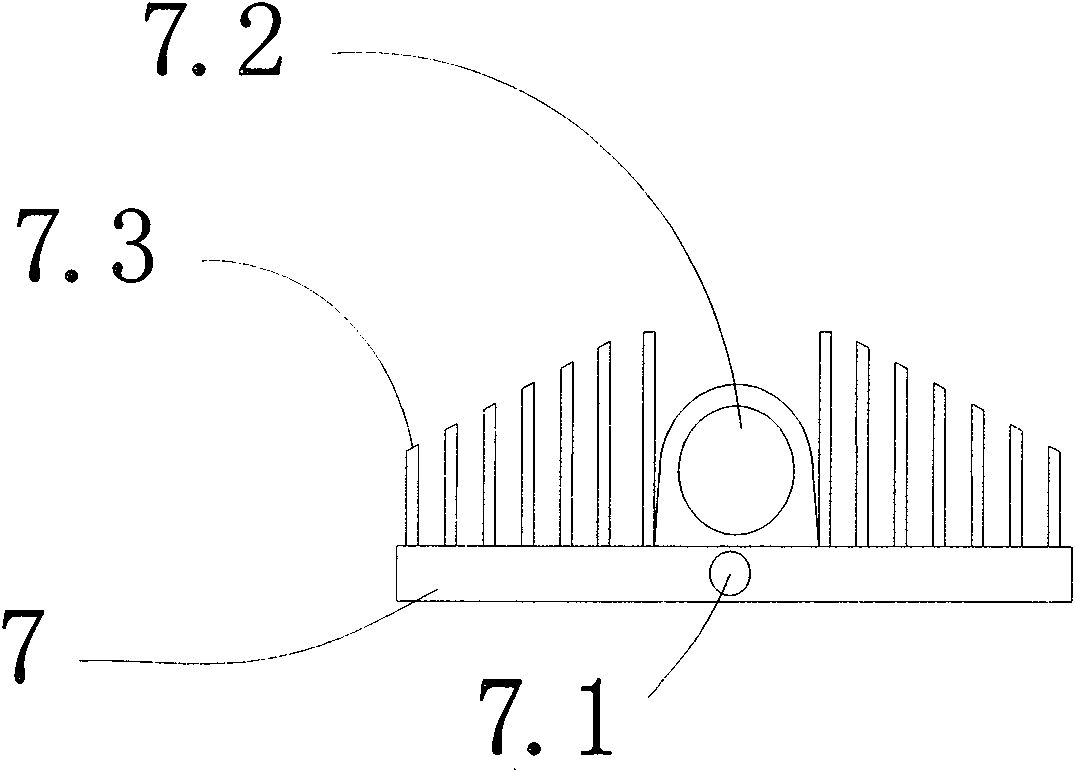

Maintenance-free active heat radiating system of LED (Light Emitting Diode) lamp

ActiveCN102109156AImprove ventilation efficiencyEffective filteringLighting heating/cooling arrangementsAir filterEngineering

The invention discloses a maintenance-free active heat radiating system applied to an LED (Light Emitting Diode) lamp, and the system provided by the invention has the advantage of good heat radiating effect and basically does not have dust. In the maintenance-free active heat radiating system disclosed by the invention, a cyclone accelerator, an air filter, a cyclone dust shunt and a dust collector are arranged at the lower end of a hollow lamp post; the air inlet of the cyclone dust shunt is connected with outside air; after the air passes through the rotary channel of the cyclone dust shunt, large-grain dust is deposited into the dust collector by vrtue of a rotary acceleration; then, the clean air enters the middle channel of the cyclone dust shunt and is blown into the air filter and the cyclone accelerator; a heat radiator is arranged on an LED lighting assembly at the upper end of the lamp post; a through hole is drilled on the heat radiator; a fixed pipe and a heat radiating sheet are arranged at the upper face of the heat radiator; after the air supplied by the cyclone accelerator at the lower end in the lamp post enters the fixed pipe connected with the lamp post from an inner hole at the upper end of the lamp post, the air passes through the through hole through a vent pipe arranged at the other end of the fixed pipe and is blown into the air inlet of an air increaser through the other end of the through hole; and the air outlet of the air increaser is aligned with the heat radiating sheet to blow the air. The maintenance-free active heat radiating system disclosed by the invention has the advantage of good heat radiating effect and basically does not have dust.

Owner:盐城博思维信息科技有限公司

Electric de-dusting purifying device for phosphorus-making furnace gas

InactiveCN102527179ASolve the problem of difficult ash discharge operationReduce productionCombination devicesVapor condensationEnvironmental resistancePhosphate

Owner:JIANGXI UNIV OF SCI & TECH +2

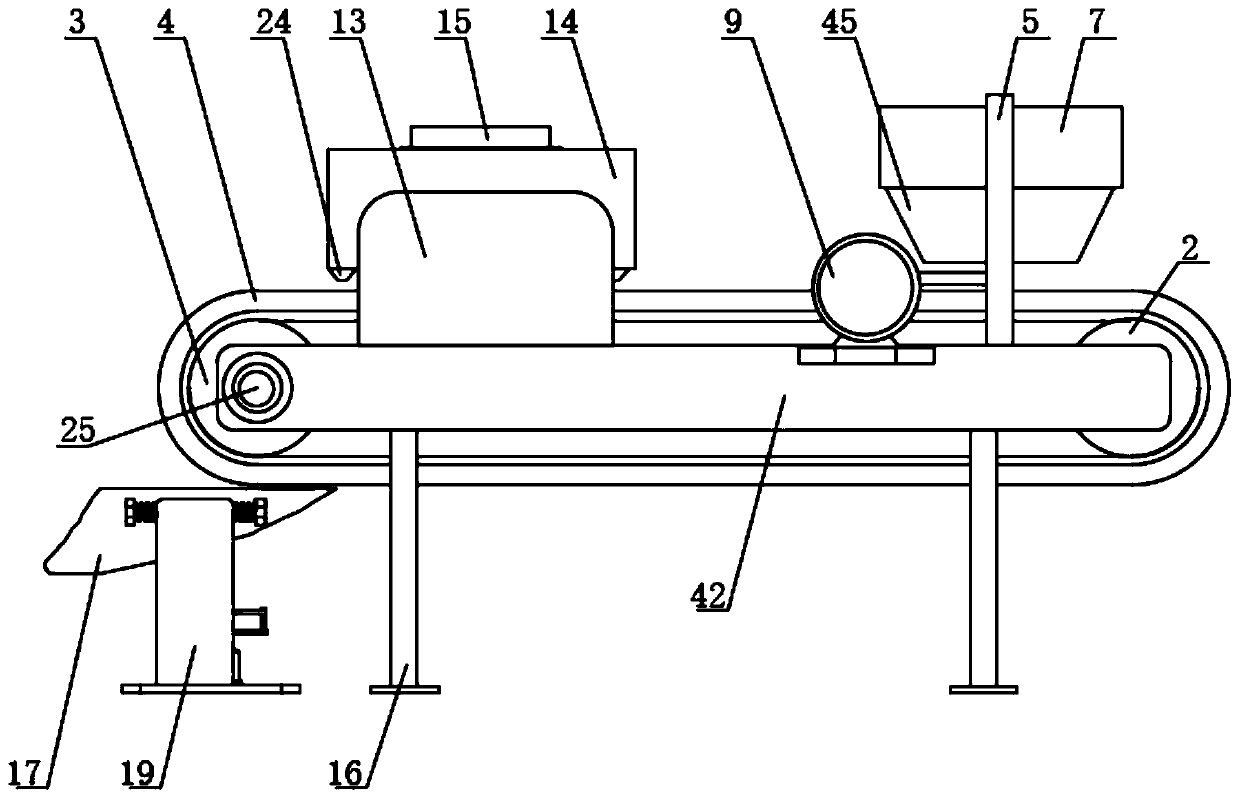

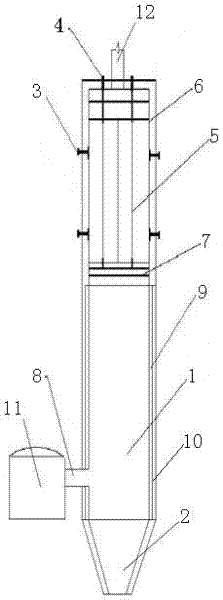

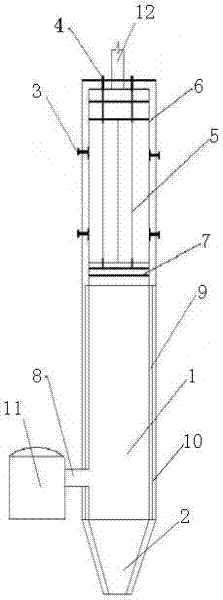

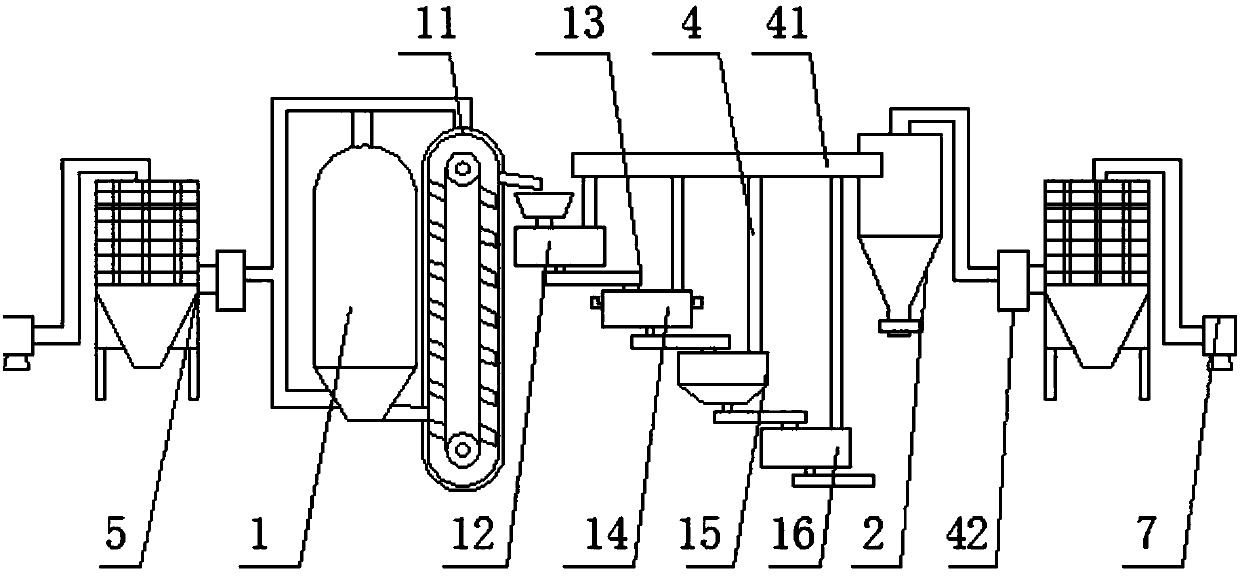

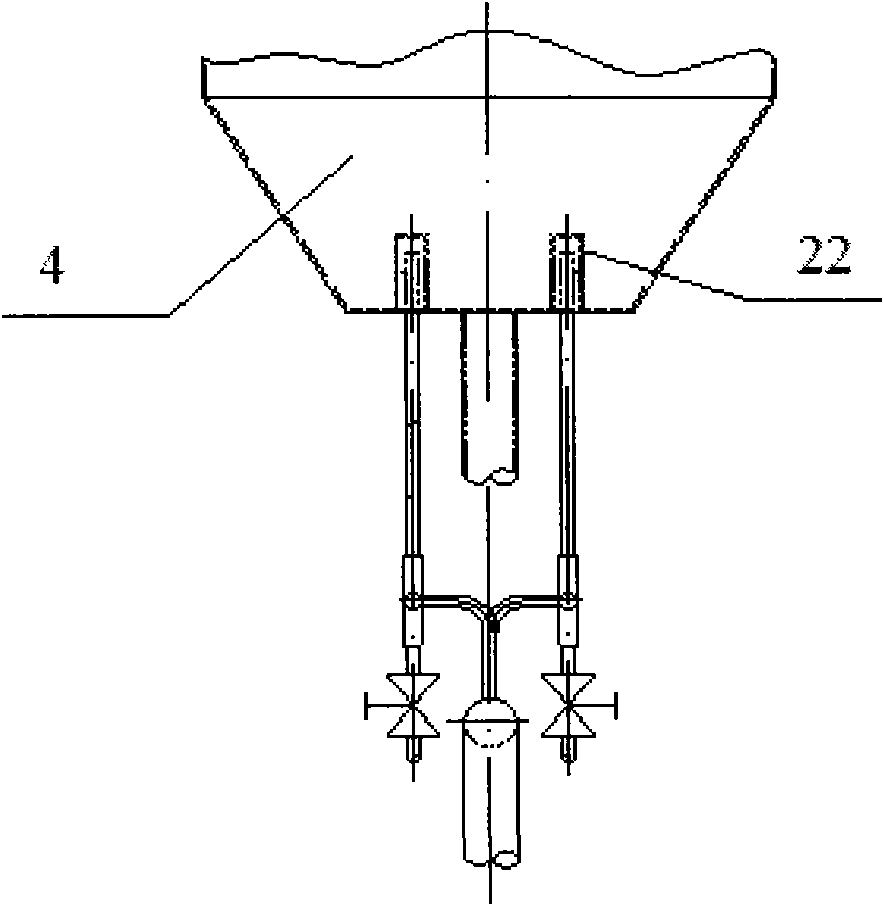

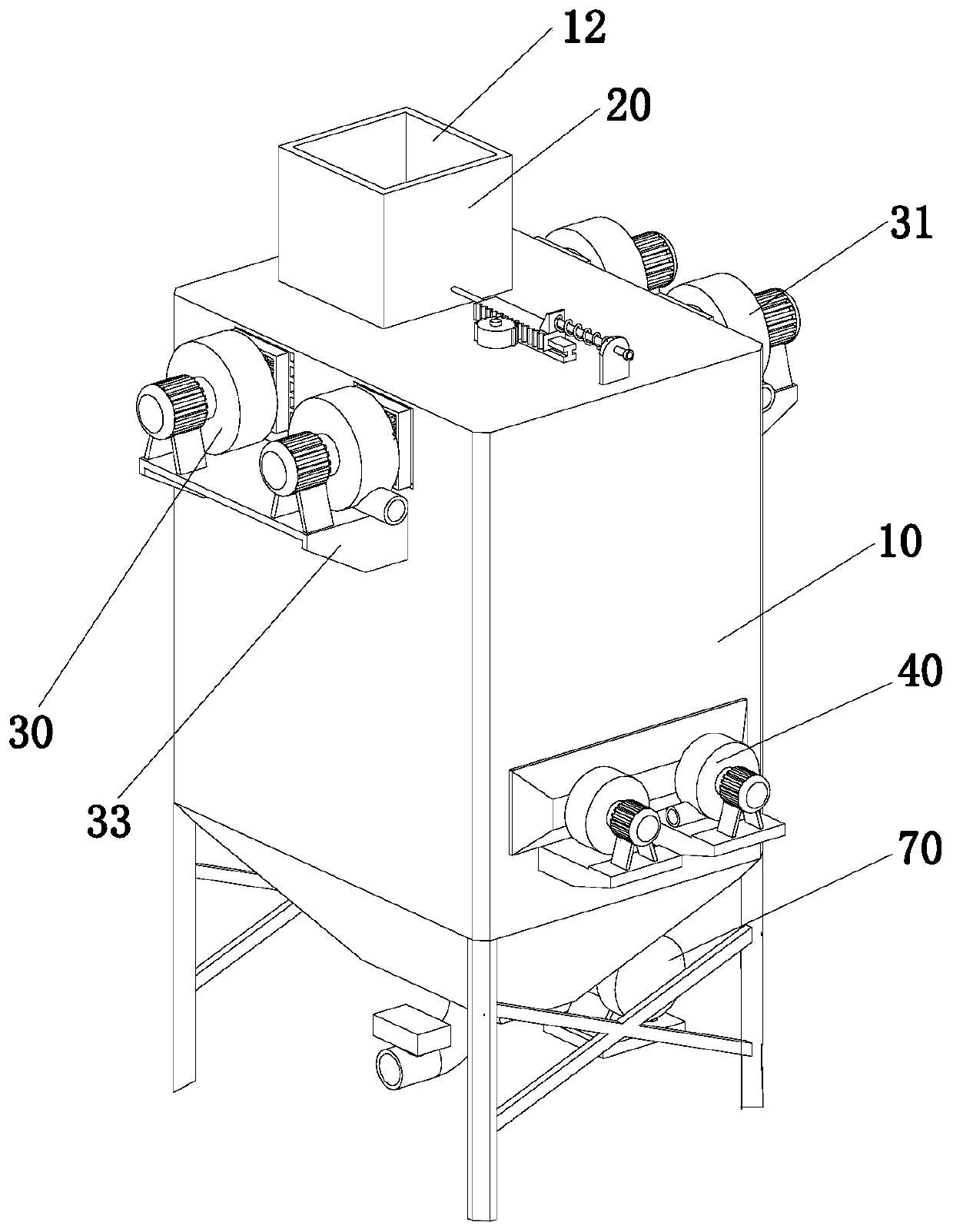

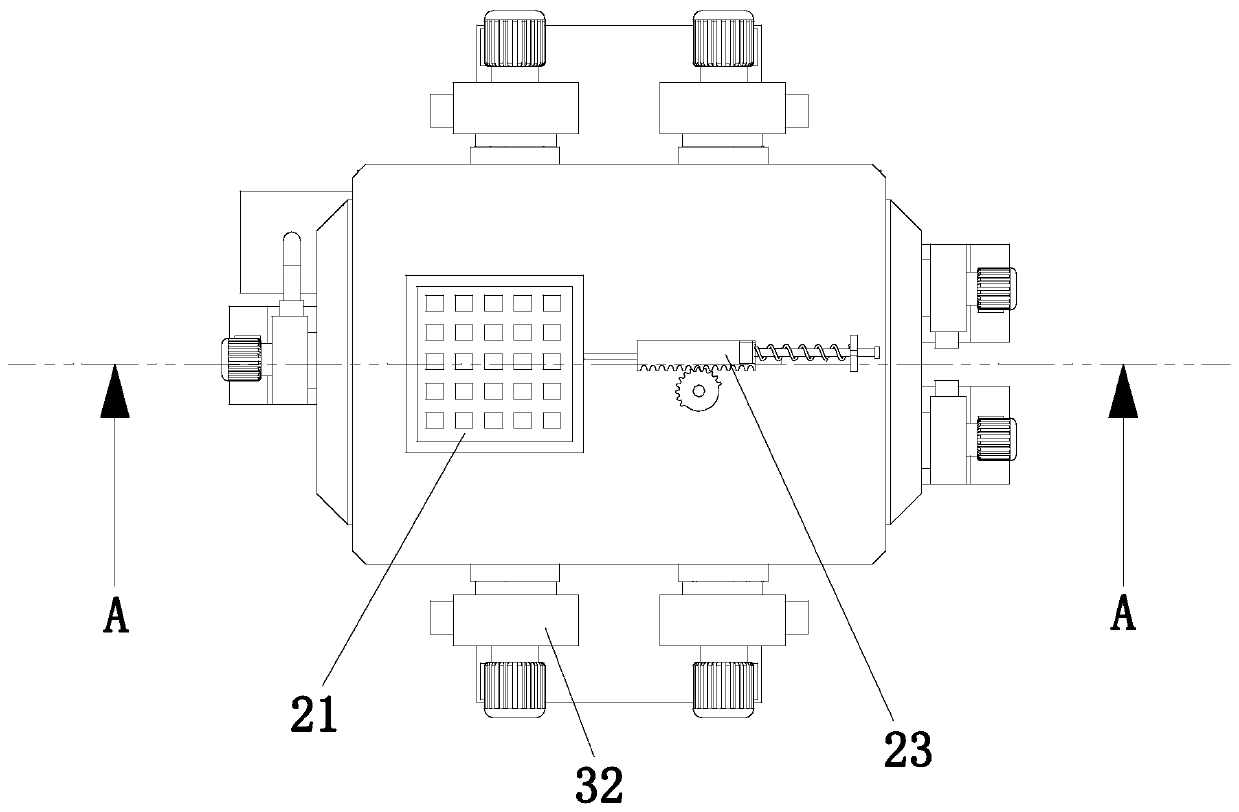

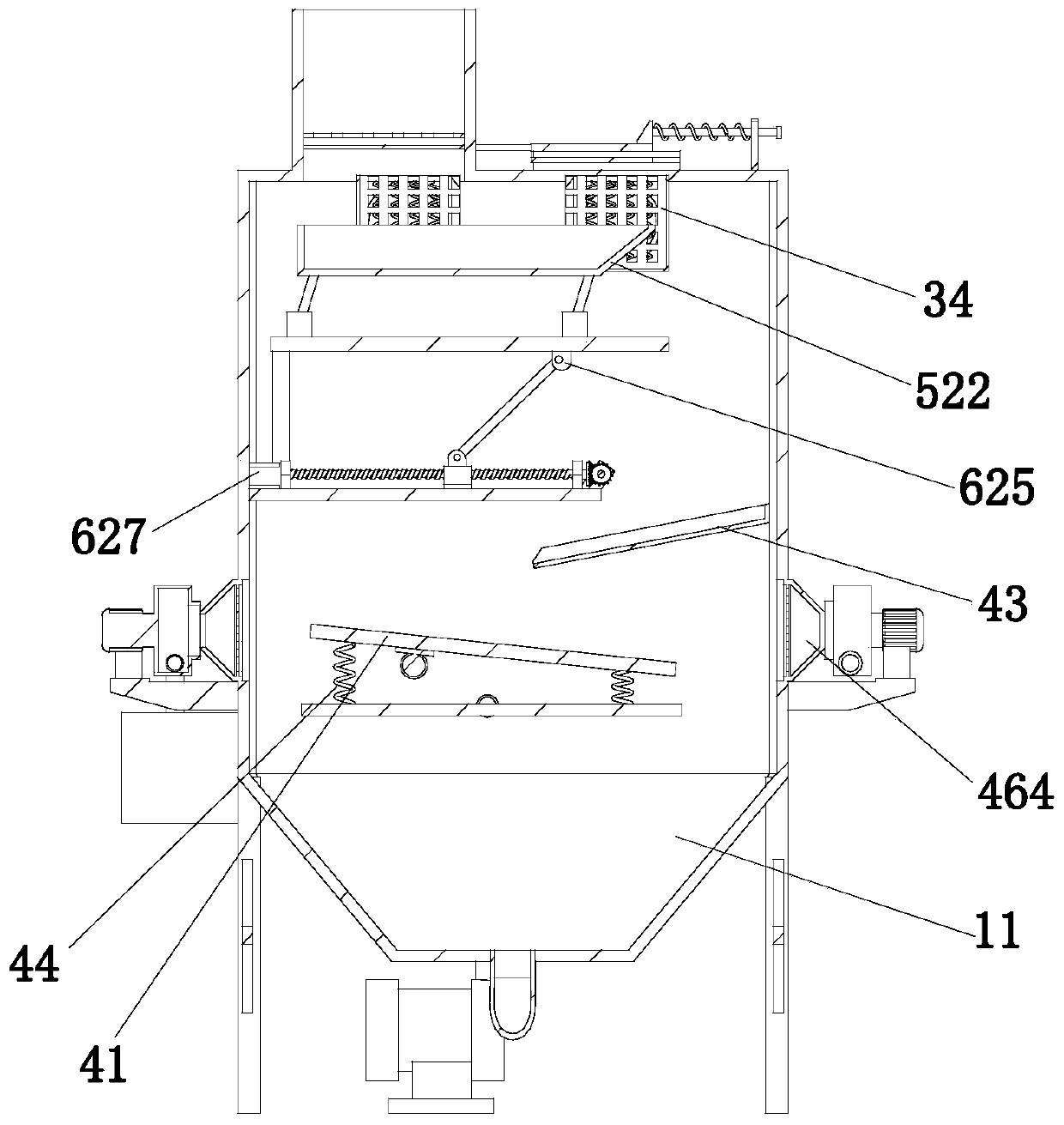

Negative pressure dust-removing system for grain dust

PendingCN107596840AImprove efficiencyConvenience guaranteedCombination devicesEngineeringBucket elevator

The invention discloses a negative pressure dust-removing system for grain dust. The negative pressure dust-removing system comprises a grain cabin, wherein a bucket elevator is fixedly connected withan outlet on the lower surface of the grain cabin; a crushing device is fixedly connected with the outlet on the rear side of the upper surface of the bucket elevator; a vibration screen device is fixedly connected with the outlet of the crushing device through a conveying device; a buffering cabin is fixedly connected with the outlet of the vibration screen device through the conveying device; apackaging device is fixedly connected with the outlet of the buffering cabin through the conveying device; an exhaust pipe is fixedly connected with the upper surfaces of the crushing device, the vibration screen device, the buffering cabin and the packaging device; a connecting pipe is fixedly connected with the upper surface of the exhaust pipe; a cyclone dust removal device is fixedly connected with the outlet of the connecting pipe; and an explosion-proof valve is fixedly connected with the outlet of the cyclone dust removal device through the pipeline. The negative pressure dust-removingsystem for grain dust is capable of greatly promoting the use convenience and safety, promoting the dust collection effect and guaranteeing the working efficiency.

Owner:安徽祥源科技股份有限公司

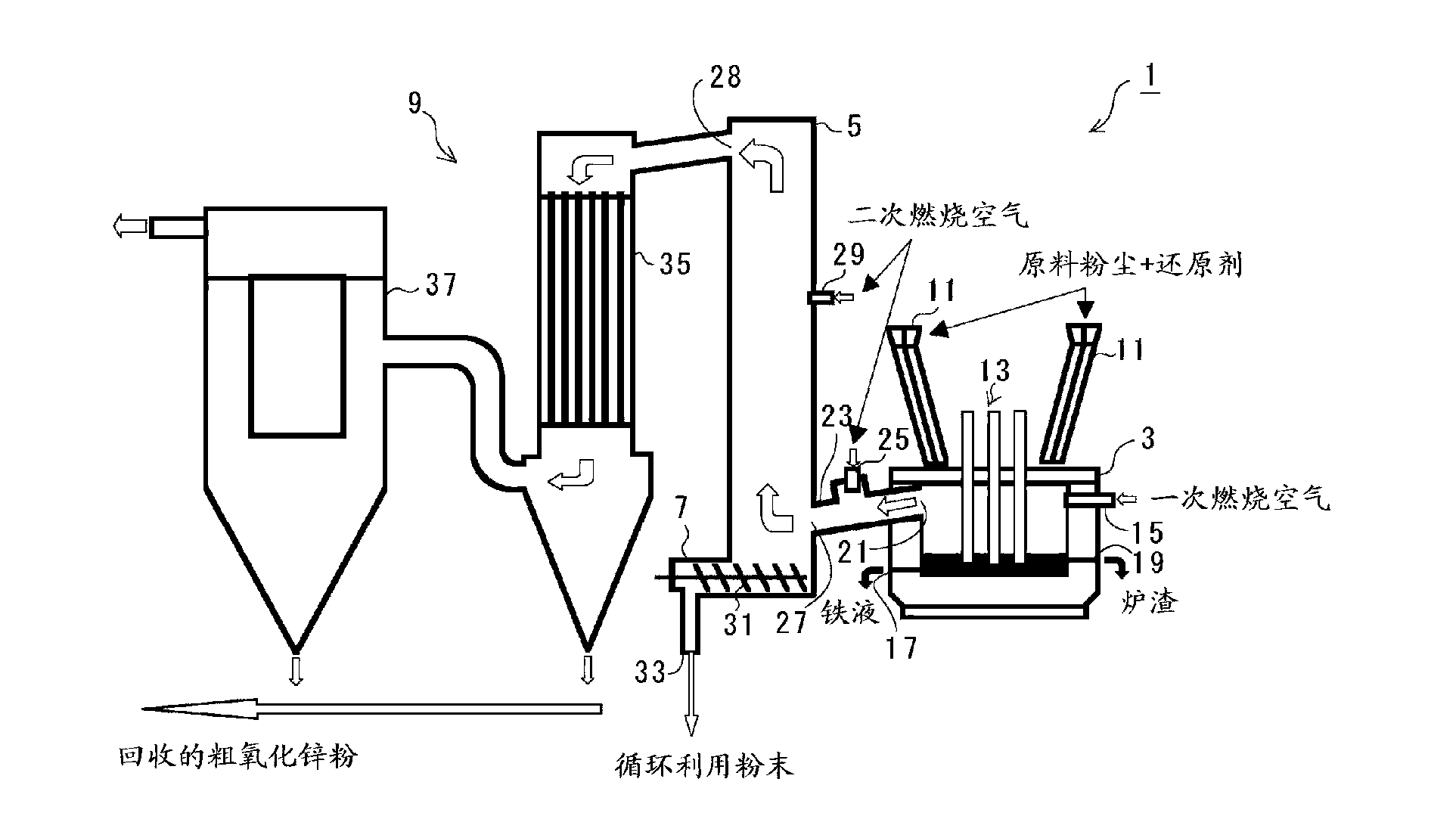

Method and apparatus for recovering metal from electric furnace dust

InactiveCN103069023AEfficient recyclingEasy to operateDispersed particle separationProcess efficiency improvementCombustion chamberZinc

Obtained are a method and an apparatus for recovering a metal from electric furnace dust, which are capable of recovering the metal with high efficiency without causing problems such as occlusion of the apparatus. An apparatus (1) for recovering a metal from electric furnace dust of the present invention, which recovers molten iron and zinc oxide by melting and reducing electric furnace dust, which contains not less than 12% by mass of a chlorine content and a zinc content in total, mainly by electrical energy. The apparatus (1) for recovering a metal from electric furnace dust comprises: a melting / reduction furnace (3); a secondary combustion chamber (5) in which the exhaust gas from the melting / reduction furnace (3) is caused to form an upward flow at an ascending rate of 0.5-2.0 m / s (inclusive); a coarse-grained dust recovery device (7) for recovering coarse-grained dust that settles in the lower part of the secondary combustion chamber (5); and a fine dust recovery device (9) which is disposed on the exhaust gas exit side of the secondary combustion chamber (5) for the purpose of recovering fine dust.

Owner:JP STEEL PLANTECH

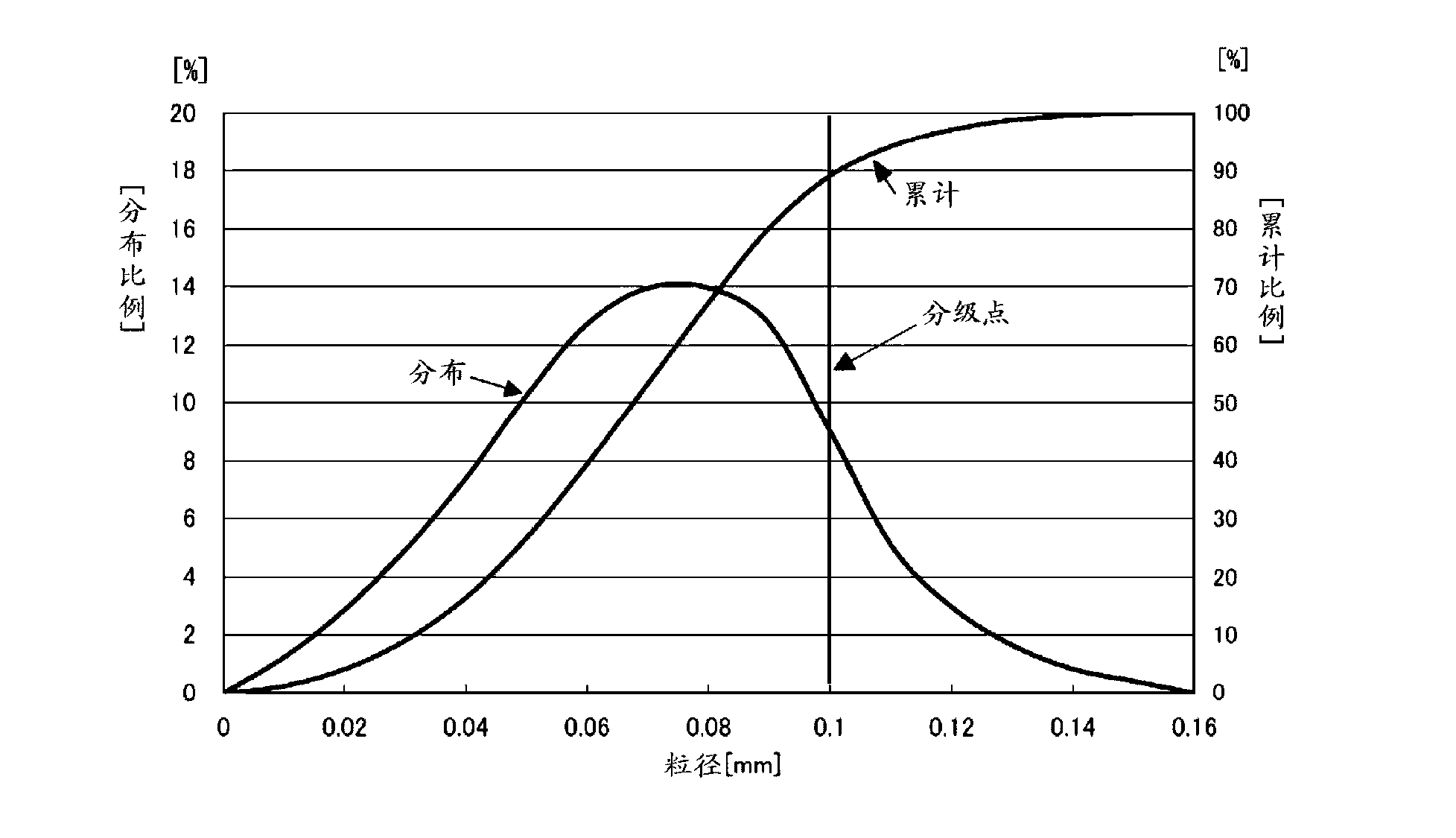

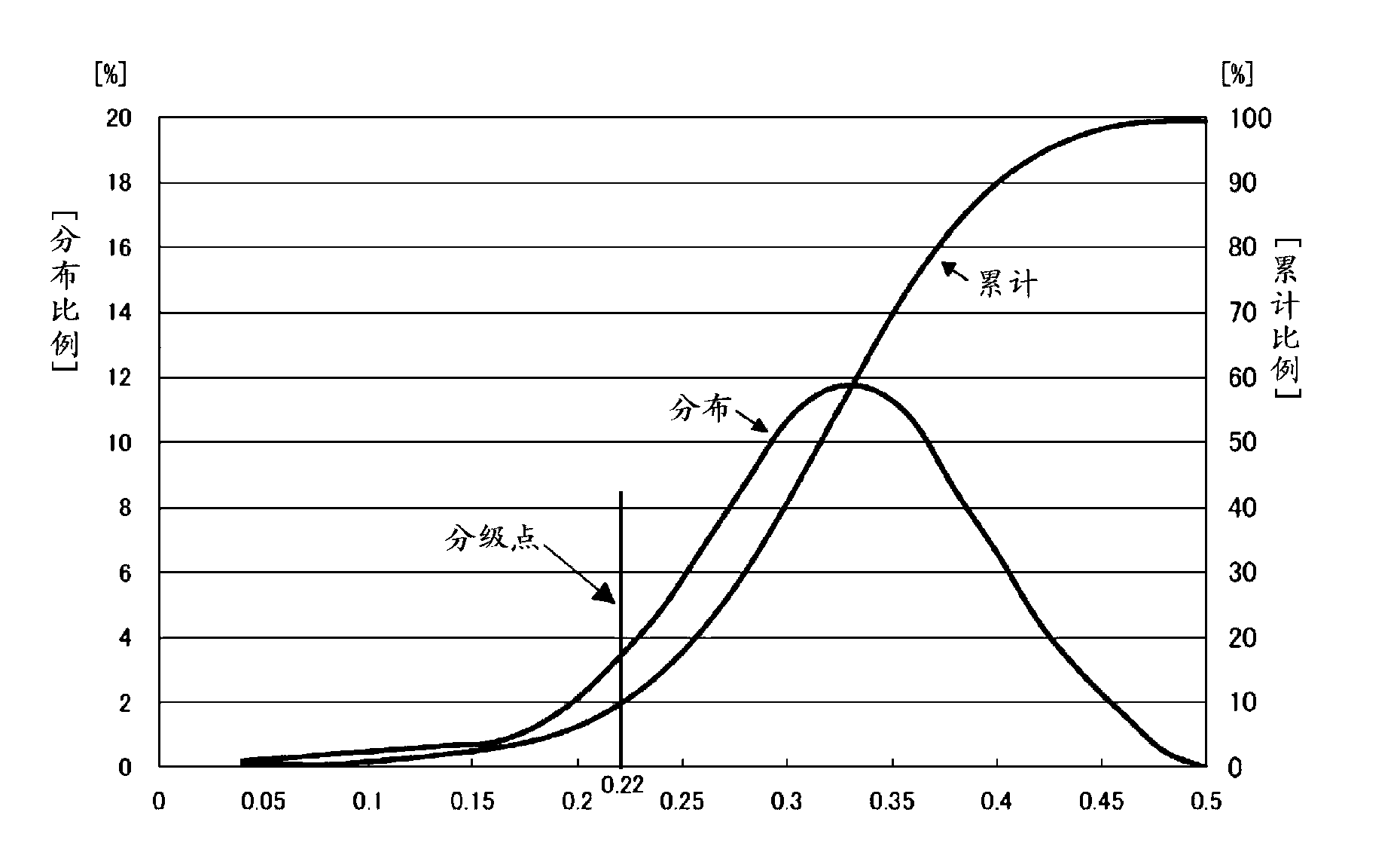

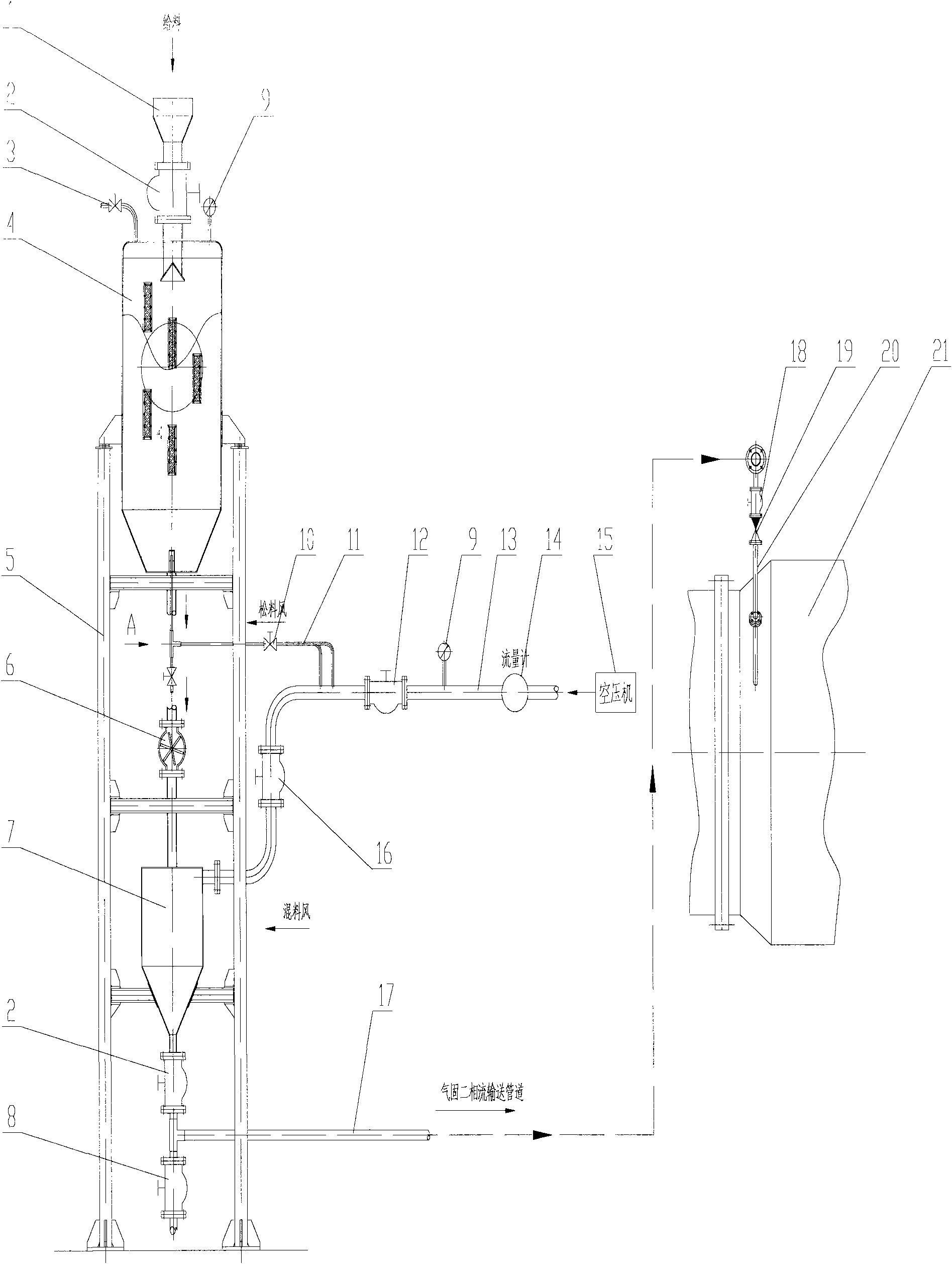

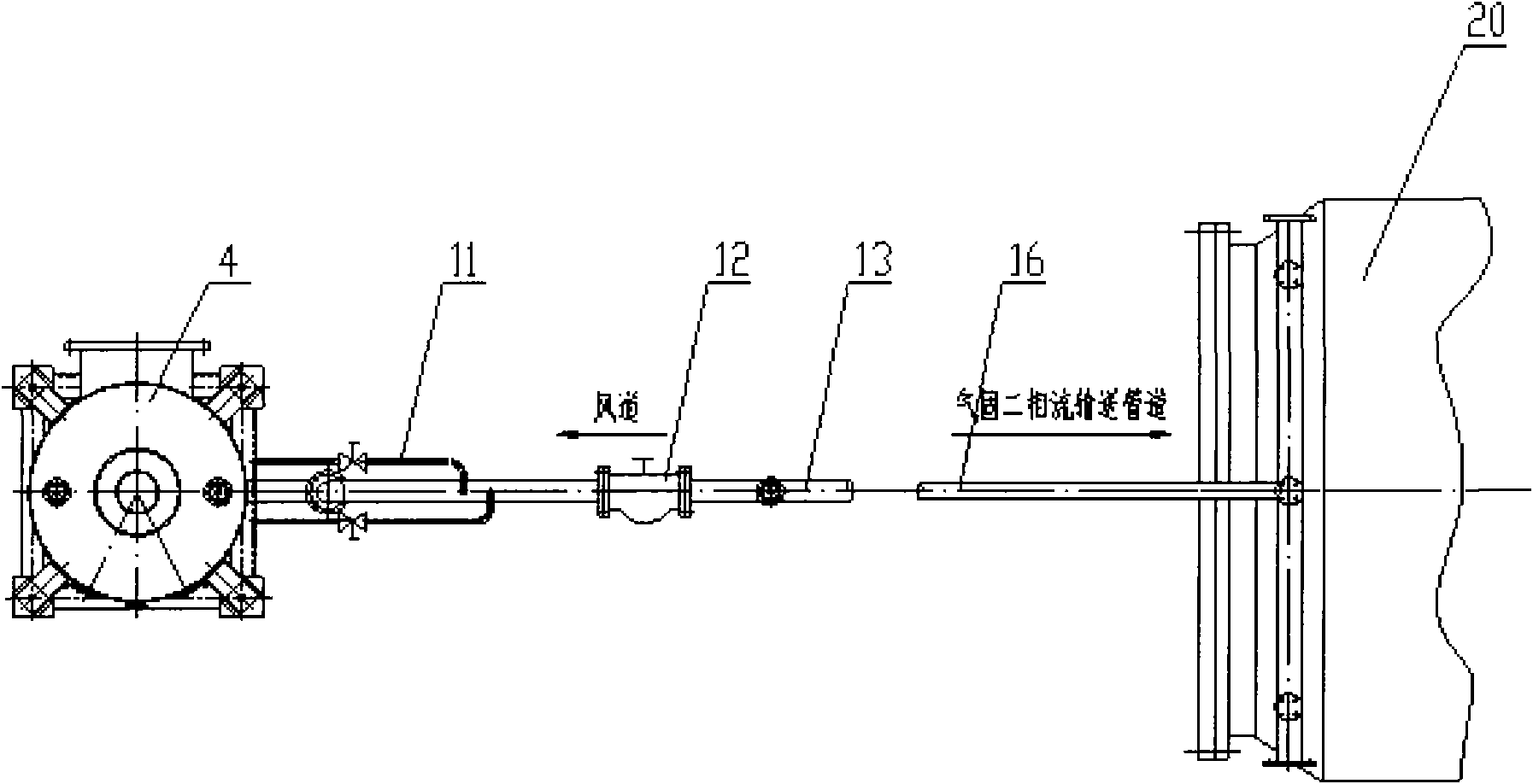

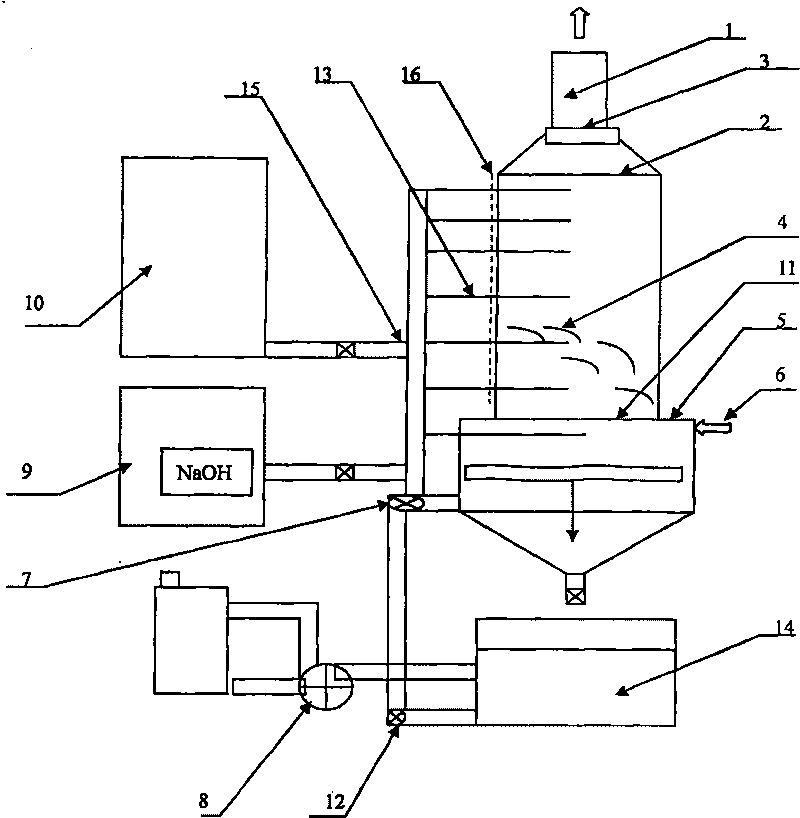

Fluidized grain dust removing system

ActiveCN101634456ASimple preparation processImprove controllabilitySolid removalEngineeringAir compressor

The invention provides a fluidized grain dust removing system which comprises a charging hopper, a material storage pot, a screwed feeder and a material even mixing pot which are sequentially connected from the top down and fixed on a steel bracket, wherein a cylinder body of the material storage pot is divided into an upper part and a lower part, the upper part is cylindrical, and the lower part is of an inverted cone shape; an upper sealing head of the material storage pot is connected with an outlet of the charging hopper through a pipeline, and a lower sealing head of the material storage pot is connected with an inlet of the screwed feeder through a pipeline; an outlet of the screwed feeder is connected with the top of the material even mixing pot; the upper part of the material even mixing pot is cylindrical, while the lower part is of the inverted cone shape; the top end of material even mixing pot is connected with one end of a main air pipe, while the other end of the main air pipe is connected with an air compressor, and a material loosing air pipe is also led out from the main air pipe; and the bottom end of the material even mixing pot is connected with one end of a material conveying pipeline, while the other end of the material conveying pipeline is connected with a front smoke box of a boiler. The system can mix fine sand with air so as to enable the fine sand to be fluidized and has simple manufacturing process, strong controllability, high safety, good stability, ideal dust removing effect as well as convenient use and maintenance.

Owner:BEIJING HANGHUA ENERGY SAVING ENVIRONMENTAL PROTECTION TECH CO LTD

Method for treating calcination fume and vanadium-deposition waste water in vanadium extracting production

InactiveCN101716457ADispersed particle separationWaste water treatment from metallurgical processEvaporationPollution

The invention provides a method for treating calcination fume and vanadium-deposition waste water in vanadium extracting production, which comprises the following four steps: wet dust removal, alkaline process dechlorination, crystallization by evaporation and ammonia desulfurization. The four steps are realized by utilizing a compound purification tower, thereby solving the problems that the prior vanadium extracting technology often treats the calcination fume by direct discharge or simple treating facilities, can only catch large-grain dust, and can not effectively absorb chlorine, chlorine hydride, sulfur dioxide and other noxious gases so as to cause serious pollution, the exhaust gas can not be discharged according to the standard, and the vanadium-deposition waste water can not be treated.

Owner:HUBEI YUNXI LONGCHANG VANADIUM

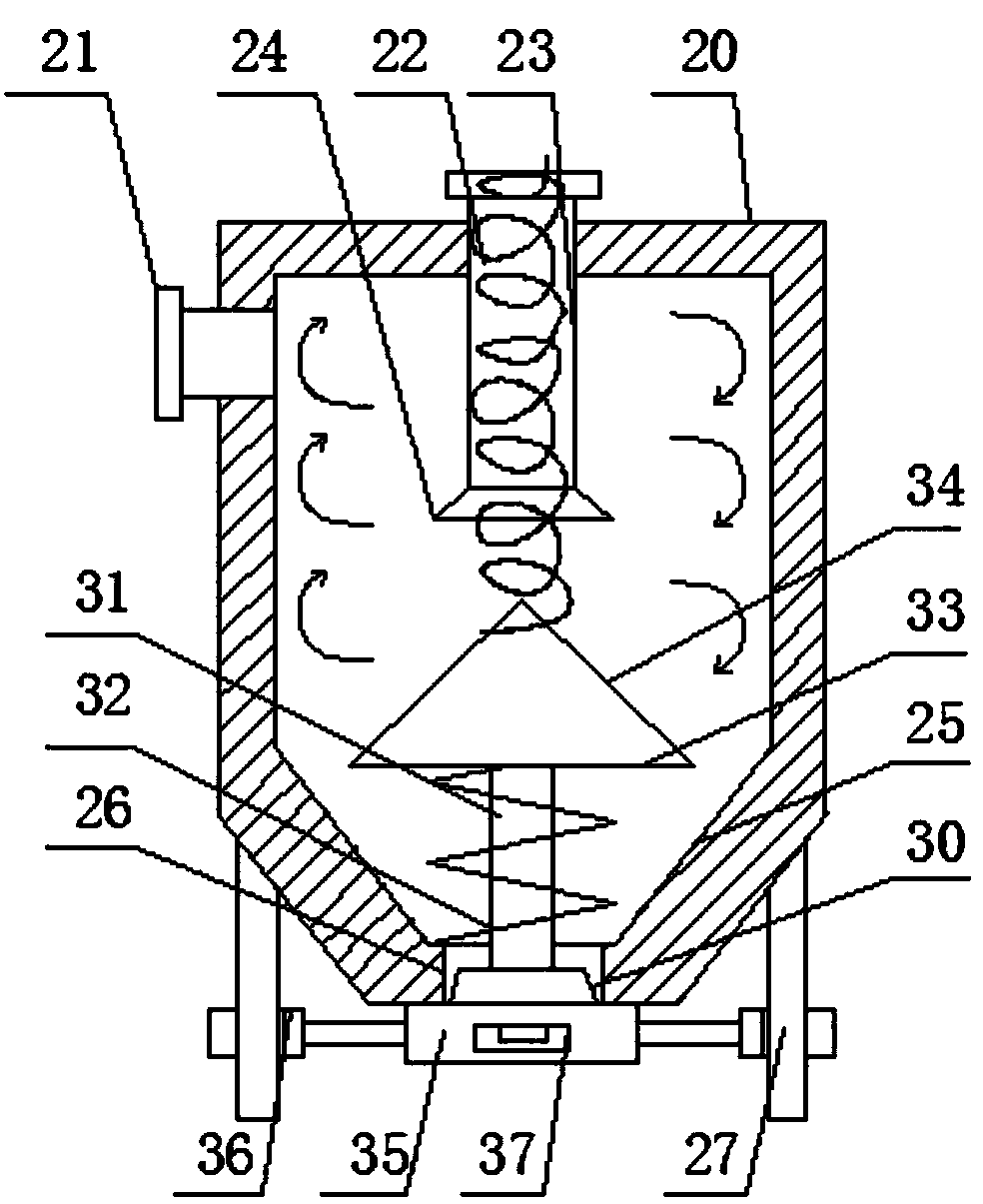

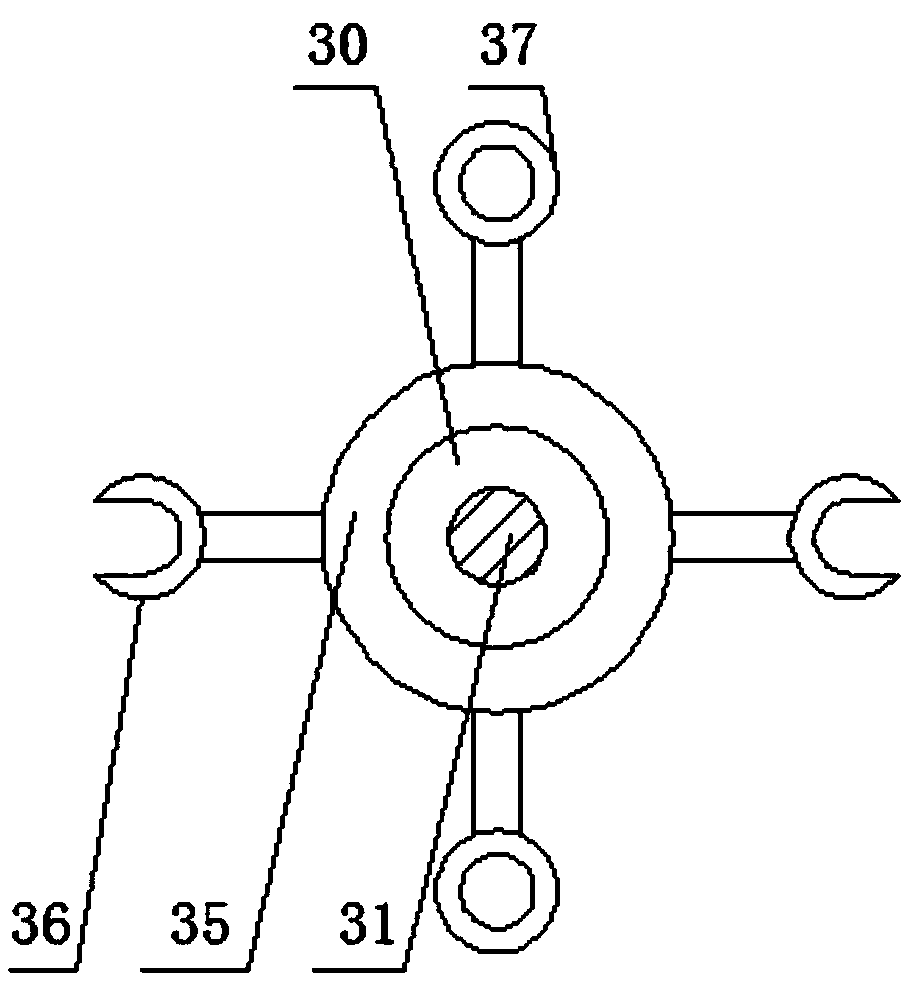

Grain selecting device

InactiveCN107138411AImprove cleanlinessSave manpower and material resourcesGas current separationDrive motorGrain dust

The invention discloses a grain selection device, comprising a device body, a feed inlet and an ash outlet are respectively provided on the top and side walls of the device body, a feed channel is provided on the top inner wall of the device body, and The feed channel is located directly below the feed inlet, and a drive motor is fixedly installed in the side wall of the device body away from the ash outlet, and the output shaft of the drive motor is connected to one end of the first rotating shaft, and the other end of the first rotating shaft is One end is connected with a fan blade, a first gear is installed in the middle of the first rotating shaft, a bearing is fixedly installed on the inner wall of the bottom plate of the device body, a second rotating shaft is fixedly installed on the inner ring of the bearing, and the top of the second rotating shaft A second gear is installed. In the present invention, the dust and larger grain stones in the grain are removed through mechanical automation, which saves manpower and material resources, effectively improves the cleanliness of the grain, and facilitates the next step of processing. The device has a simple structure and novel design, and is worth popularizing.

Owner:JIANGSU HAIDA FOOD

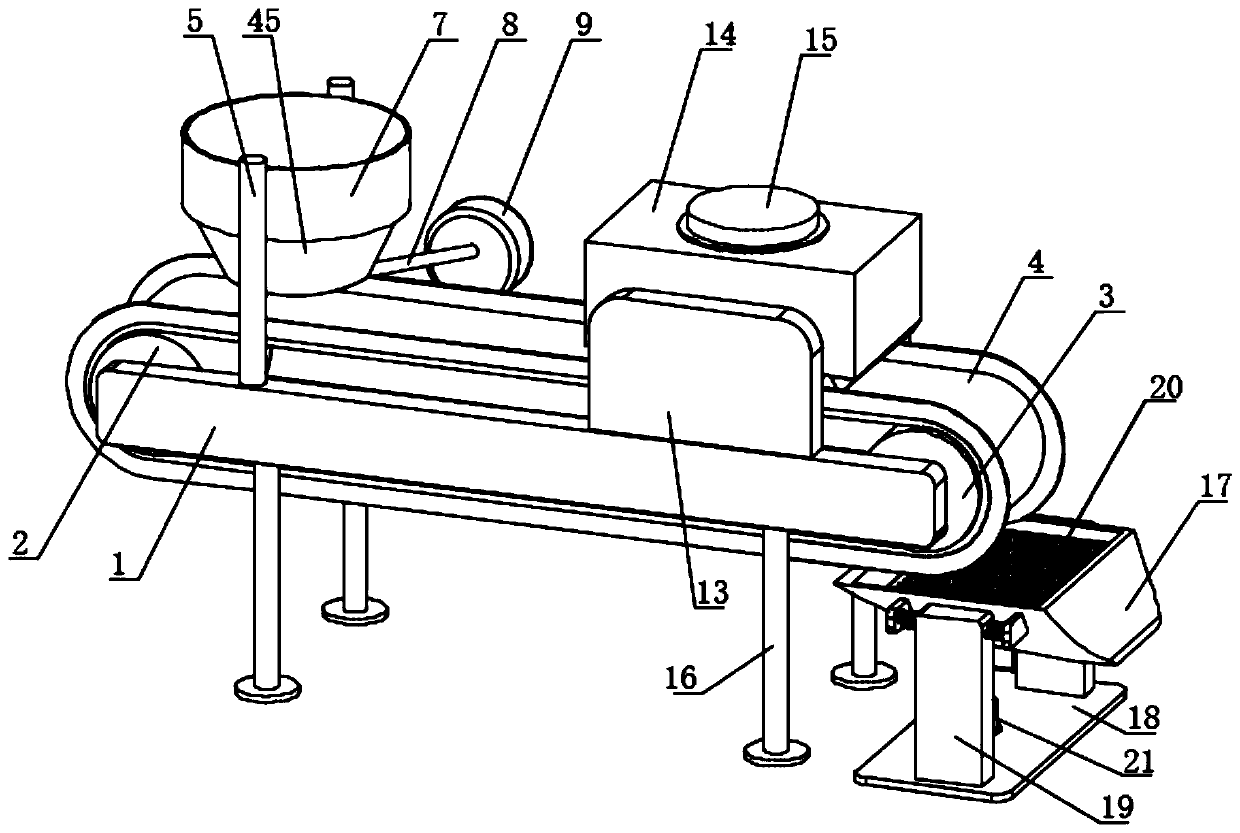

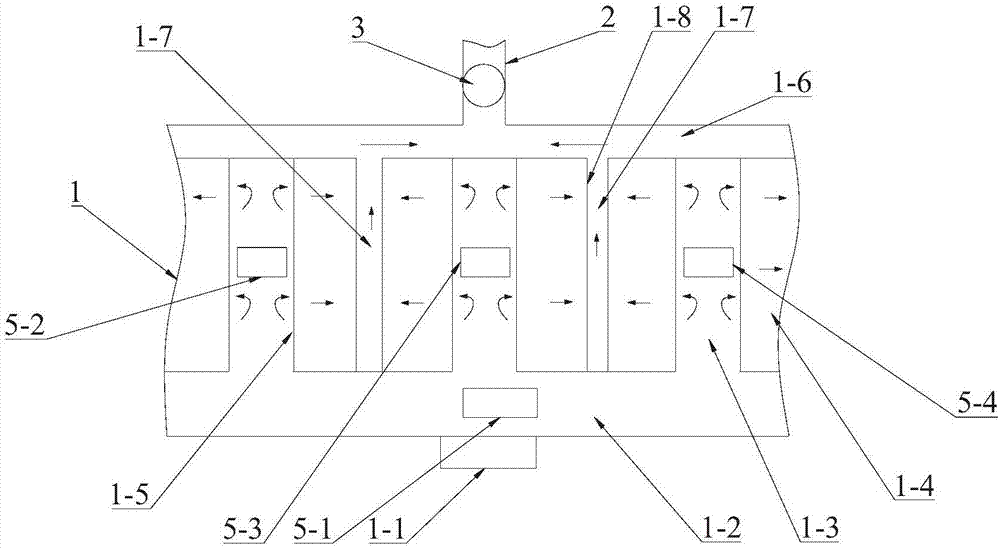

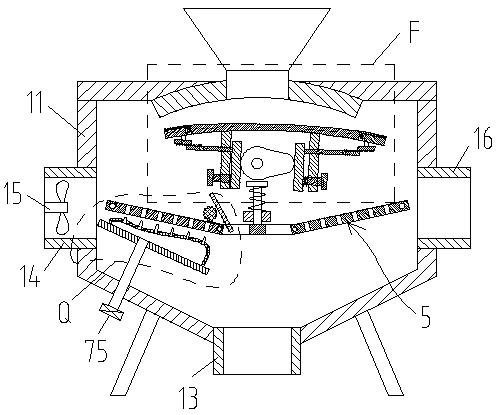

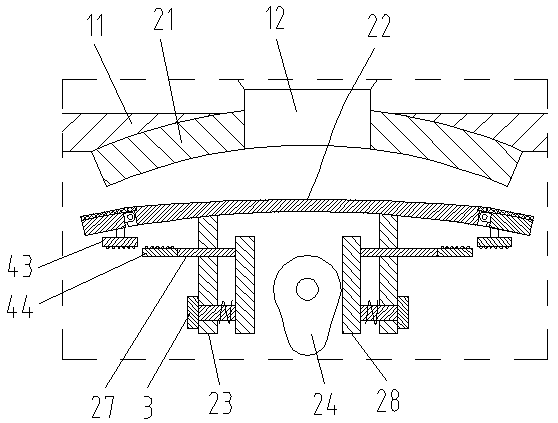

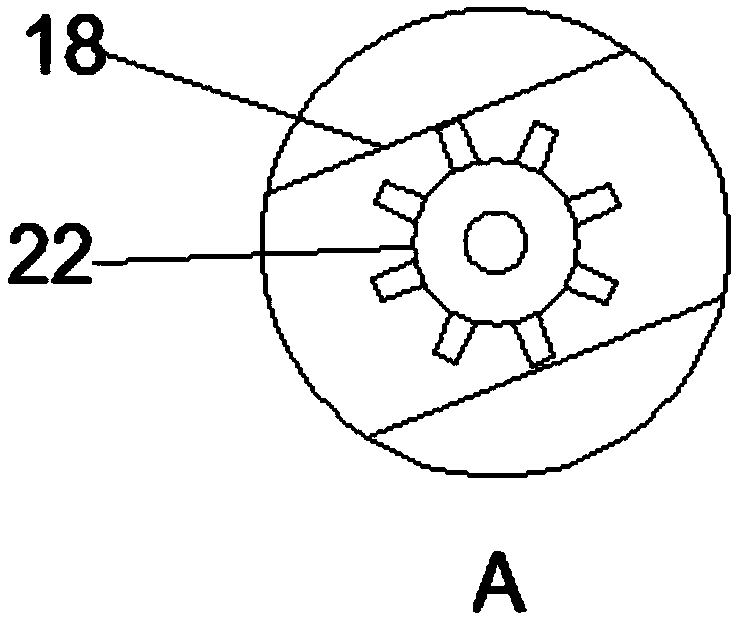

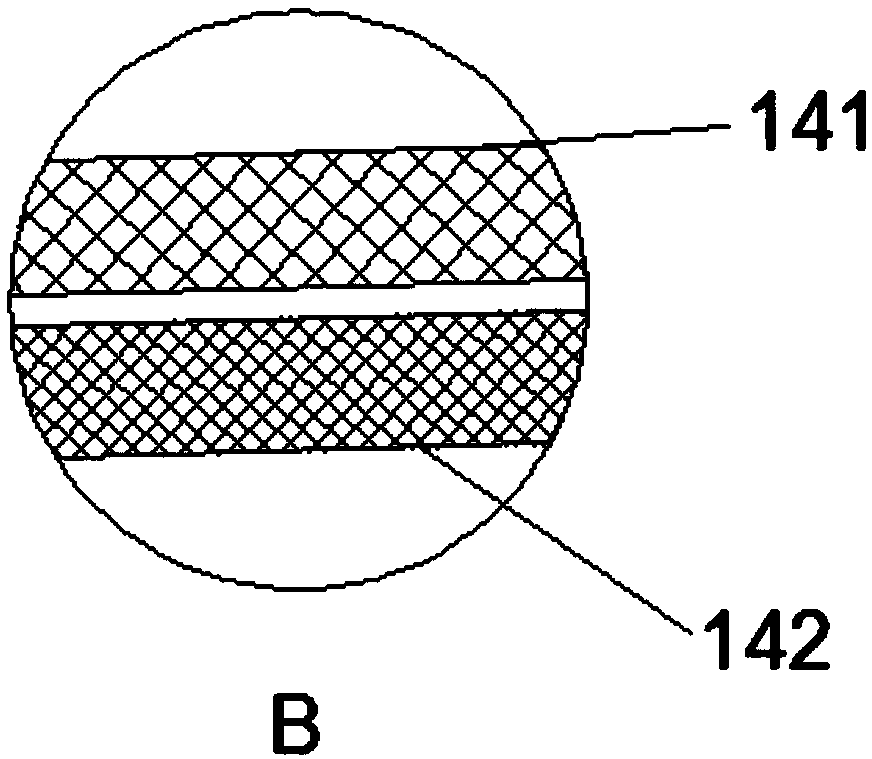

Combined type mobile grain dust remover

InactiveCN106215590AImprove adsorption capacityGuaranteed separation efficiencyCombination devicesCyclonic separationEngineering

The invention belongs to the technical field of environment-friendly equipment and especially relates to a combined type mobile grain dust remover. The combined type mobile grain dust remover comprises a cyclone body, a grain filtering bed and a dust collecting hopper and is characterized in that the dust collecting hopper is arranged under the cyclone body; the grain filtering bed is arranged on the inner side of the cyclone body; an inner filter screen and an outer filter screen are respectively arranged on the two sides of the grain filtering bed; the outer filter screen is located between the cyclone body and the grain filtering bed; an air inlet is arranged above the cyclone body; an air outlet is arranged above the grain filtering bed; a separating screen is arranged above the dust collecting hopper; one side of the separating screen is higher than the other side; the lower side of the separating screen extends out of the dust collecting hopper and is communicated with a storage box; the storage box is communicated with the top of the grain filtering bed through a filter material conveying pipeline. The combined type mobile grain dust remover has the beneficial effects that the two principles of cyclone separation dust removal and grain filtering dust removal are combined with each other, a secondary separating function is realized in one device, the problem of low dust removing efficiency of the grain dust remover is solved and the occupied area is small.

Owner:TIANJIN MAOBIN MACHINERY EQUIP

Cold storage cavern device for grain dust removal and freshness preservation

InactiveCN110553453AAvoid undriedEasy to operateLighting and heating apparatusStationary refrigeration devicesGrain storageEngineering

The invention discloses a cold storage cavern device for grain dust removal and freshness preservation, and belongs to the field of grain storage devices. The device comprises a storage cabinet, a quantitative feeding mechanism, a grain drying mechanism and a dust removal mechanism, wherein the grain drying mechanism and the dust removal mechanism are arranged inside the storage cabinet, a refrigerating chamber is arranged at the lower section inside the storage cabinet, a feeding box is arranged at the top of the storage cabinet, the grain drying mechanism comprises a drying assembly, a material turning assembly and a pouring assembly, the material turning assembly comprises a supporting table, a material turning component and a material turning box, the material turning box is provided with a vent hole, and the material turning box is provided with a material discharging nozzle. According to the device, by means of the dust removal mechanism, the dust removal operation can be carriedout on grains on a vibration plate and a material guide slide way, by means of the grain drying mechanism, the material turning operation can be carried out on the grains, and the situation that thegrains are not dried locally is avoided, and by means of the pouring assembly, the grains can be poured so as to enable the grains to fall onto the material guide slide way.

Owner:惠州市安谷农业开发有限公司

Drum type grain drying machine

InactiveCN107178977ADry evenlyImprove cleanlinessGas current separationDrying machines with non-progressive movementsEngineeringMechanical engineering

The invention discloses a drum type grain dryer, which comprises a main body bracket, a clamping plate is embedded in the main body bracket, a fixing rod is sleeved in the clamping plate, and the outer wall of the fixing rod is connected with a dryer through a connecting rod. Dry pipe, a motor is arranged above the main body bracket, and one end of the motor is connected to a driving gear plate through a linkage shaft, the top of the driving gear plate meshes with the large gear plate on the drum, and the inner wall of the drum is welded with a material transfer sheet, A discharge port is provided under the other end of the drum. In the present invention, the device is equipped with a fan under the discharge port, so that the device can blow away the dust and shells in the grains and separate them from the grains during unloading, so that the cleanliness of the grains is higher. The device installs the drying pipe inside the drum through the fixed rod, which can make the device dry the grains more efficiently, and can make the device dry the grains more uniformly, increasing the practicability of the device .

Owner:CHENGDU YANXINGGUO TECH CO LTD

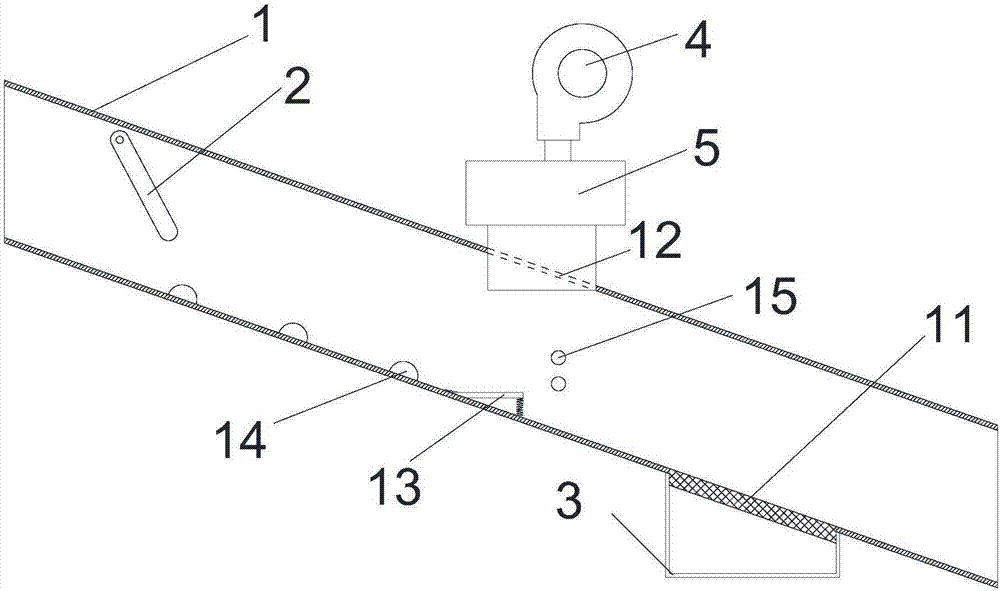

Grain conveying equipment

InactiveCN107470149AReduce impurityImprove suction effectSievingGas current separationMechanical engineeringTime-Consuming

The invention provides a grain conveying equipment, which includes a conveying pipeline, a material regulating plate, a storage box, a fan and a filter device; A filter screen is installed in the lower part. The filter screen and the material adjustment plate are located on opposite sides of the conveying pipe. The sundries storage box is installed under the conveying pipe corresponding to the position of the filter screen. Between the material adjustment plates, the air inlet pipe of the fan is connected to the ash outlet, and the pipeline connecting the fan to the ash outlet passes through the filter device; a lifting plate is installed under the corresponding ash outlet in the conveying pipe, and the lifting plate is close to one end of the material adjustment plate The conveying pipe can be rotatably connected, and one end of the lifting plate away from the material adjusting plate is connected to the conveying pipe through an elastic piece. The invention effectively saves time and economical investment in grain dust removal.

Owner:望江西圩米业有限公司

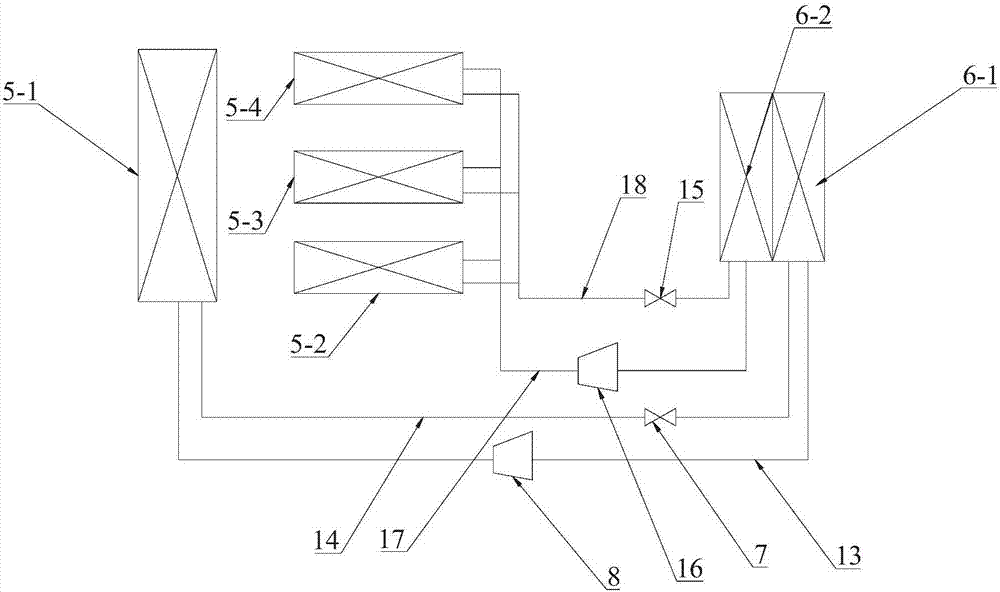

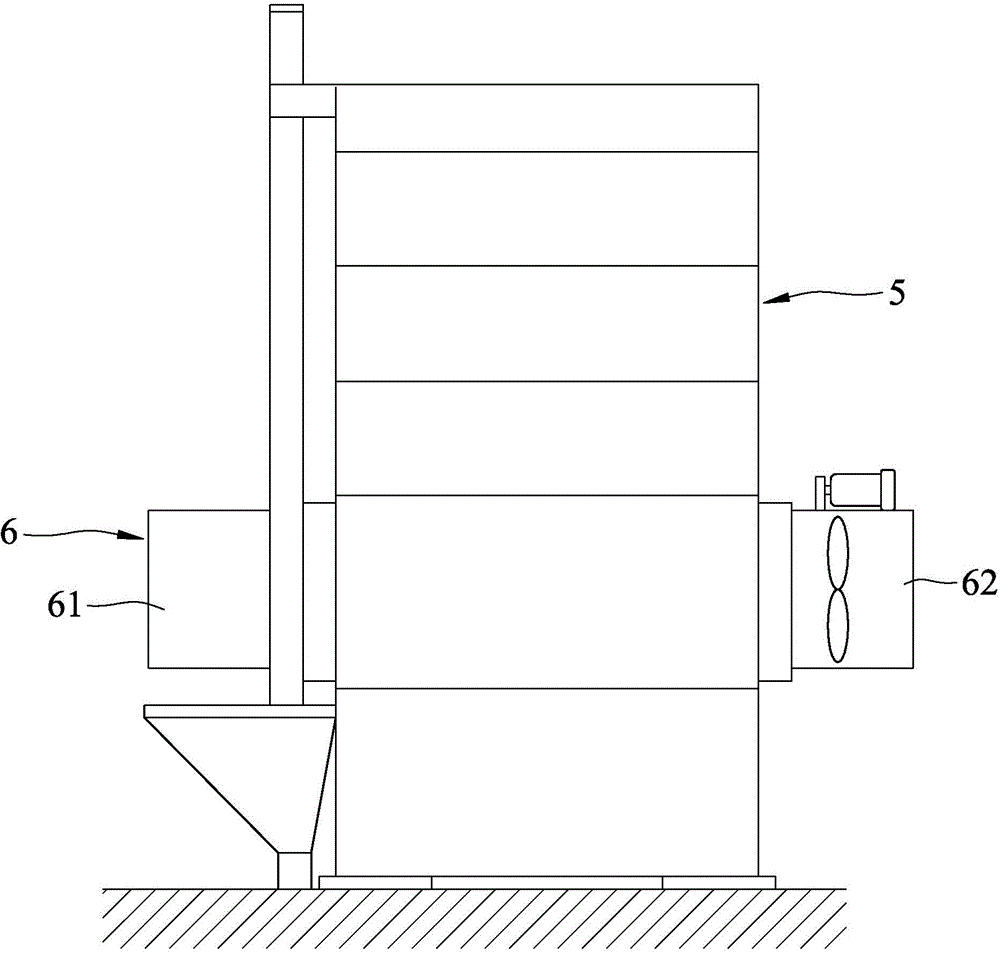

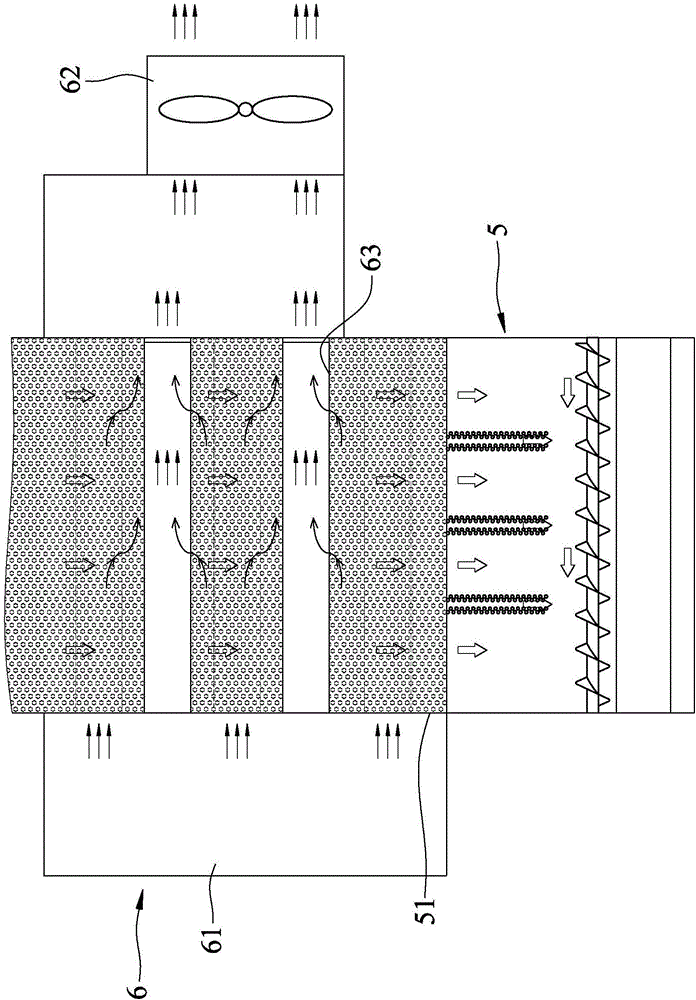

Novel grain drying device

PendingCN107144124AIncrease temperatureImprove drying efficiencyFood processingClimate change adaptationEngineeringTower

The invention discloses a novel grain drying device. The device comprises a drying tower (1), a heat pump used for providing hot air for the drying tower (1) and a dust collection chamber (4) which is communicated with the drying tower (1) through a dust discharging pipe (2) and used for collecting grain dust. A blower (3) is arranged between the inlet end of the dust discharging pipe (2) and the drying tower (1), and a condenser (5) of the heat pump is arranged in a hot air inlet cavity (1-2) of the drying tower (1). Through the novel grain drying device, the drying efficiency of the drying tower (1) can be improved, the energy is saved, and the floor space of equipment can also be saved.

Owner:苏州市农业机械有限公司

Grain particle sieving device

InactiveCN110694908AFunctionalCompact structureSievingGas current separationElectric machineCylinder block

The invention discloses a grain particle sieving device which includes a turntable and a screening box located above the turntable. A protruding wave slideway is arranged on the outer side surface ofthe turntable, a sliding block matched with the wave slideway is arranged inside the wave slideway, a piston matched with the inner wall of a cylinder is arranged inside a fixed cylinder, one side ofthe piston is fixedly connected with the sliding block through a connecting rod, air inlet holes and air outlet holes are formed in the upper end and the lower end of the fixed cylinder, and the air outlet holes communicate with the inner part of the screening box through air outlet pipes. The turntable can give a circumferential force to the screening box to complete sieving of grain, while the grain is sieved, dust of the grain can be removed through the arrangement of the wave slideway and the fixed cylinder as well as air inlet pipes and the air outlet pipes, and the functions are practical; and the screening function and the grain dust removing function can be realized by sharing one rotating motor for driving, and the structure is compact and simple.

Owner:浏阳市浏阳河米业有限责任公司

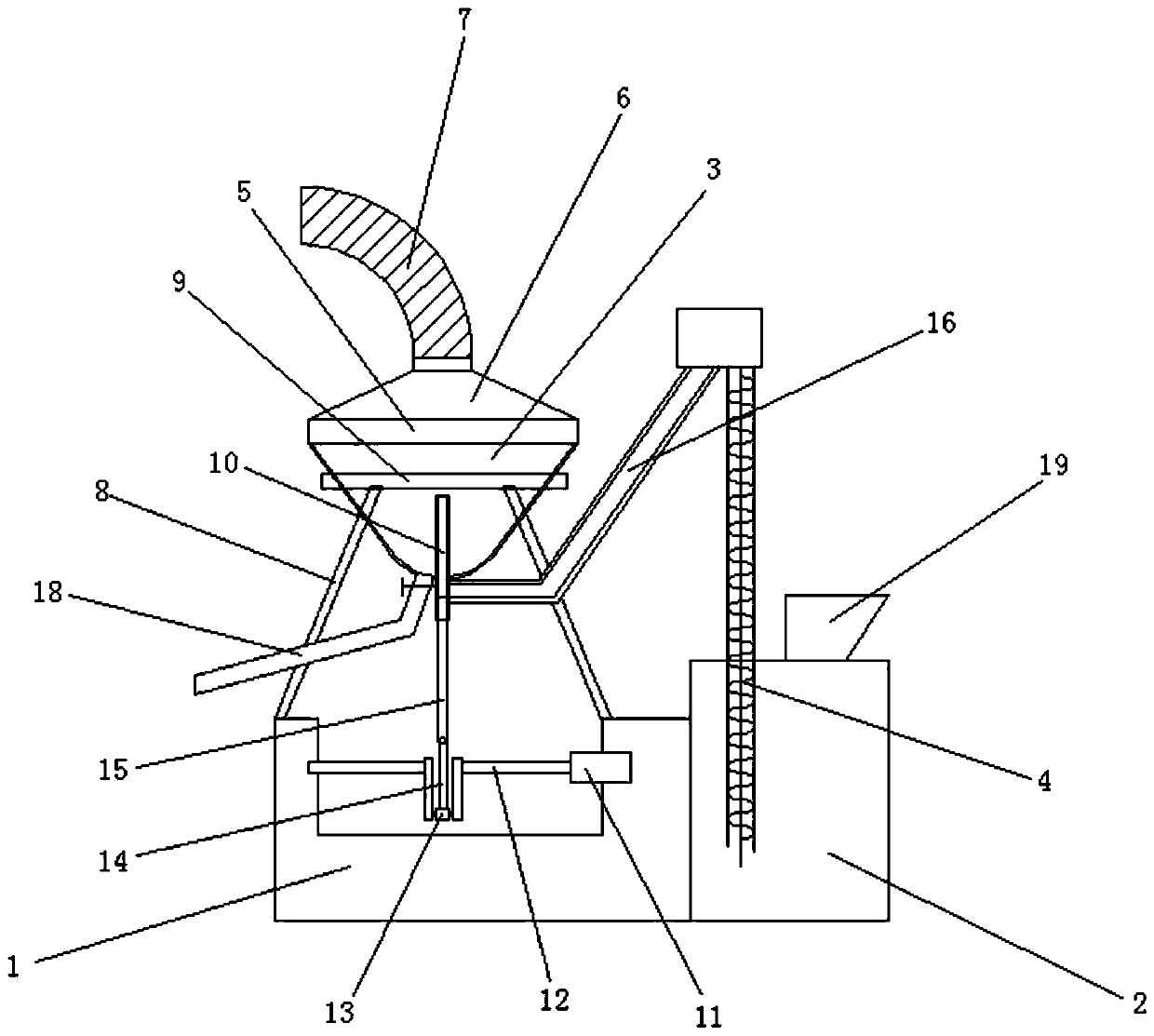

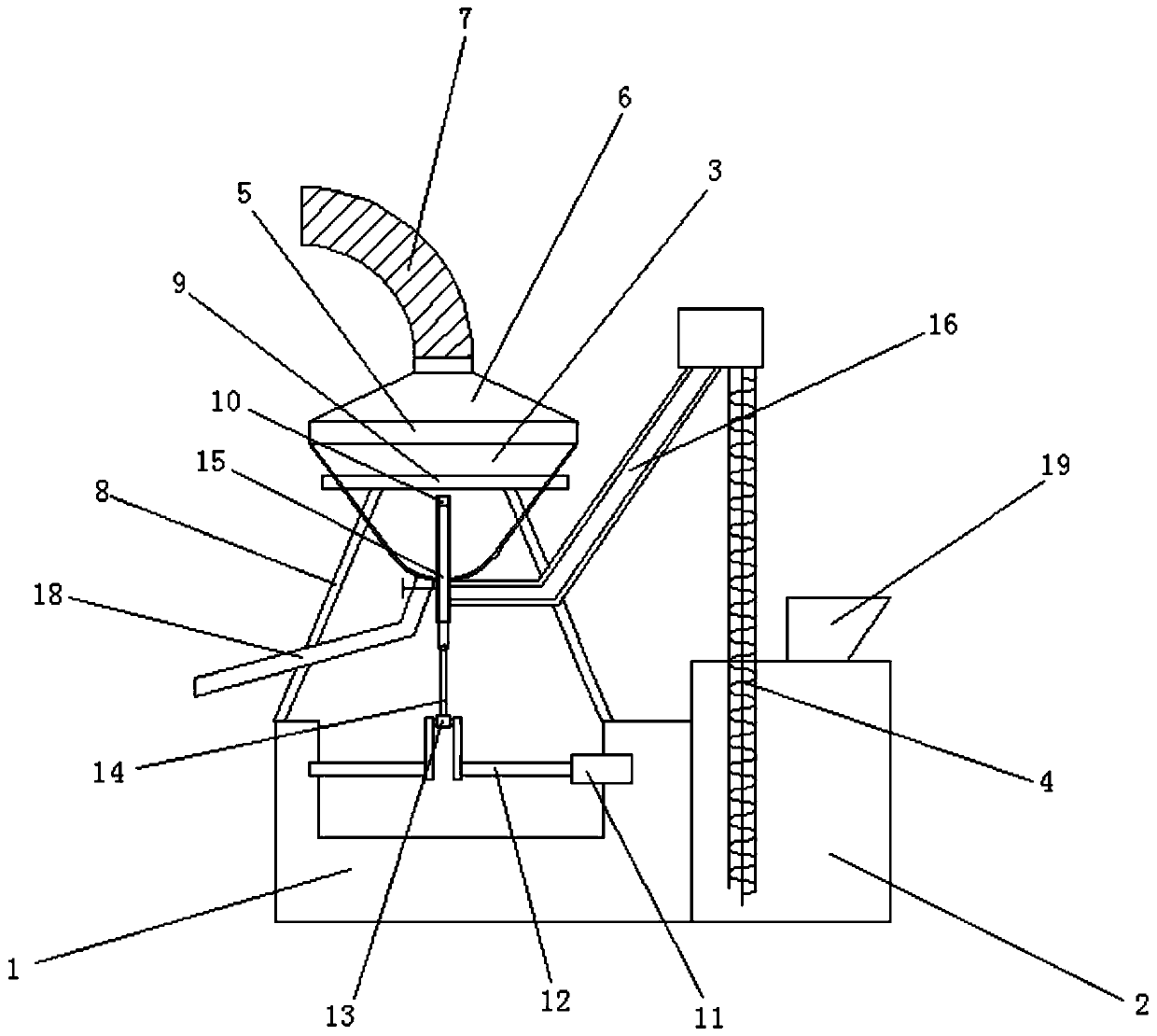

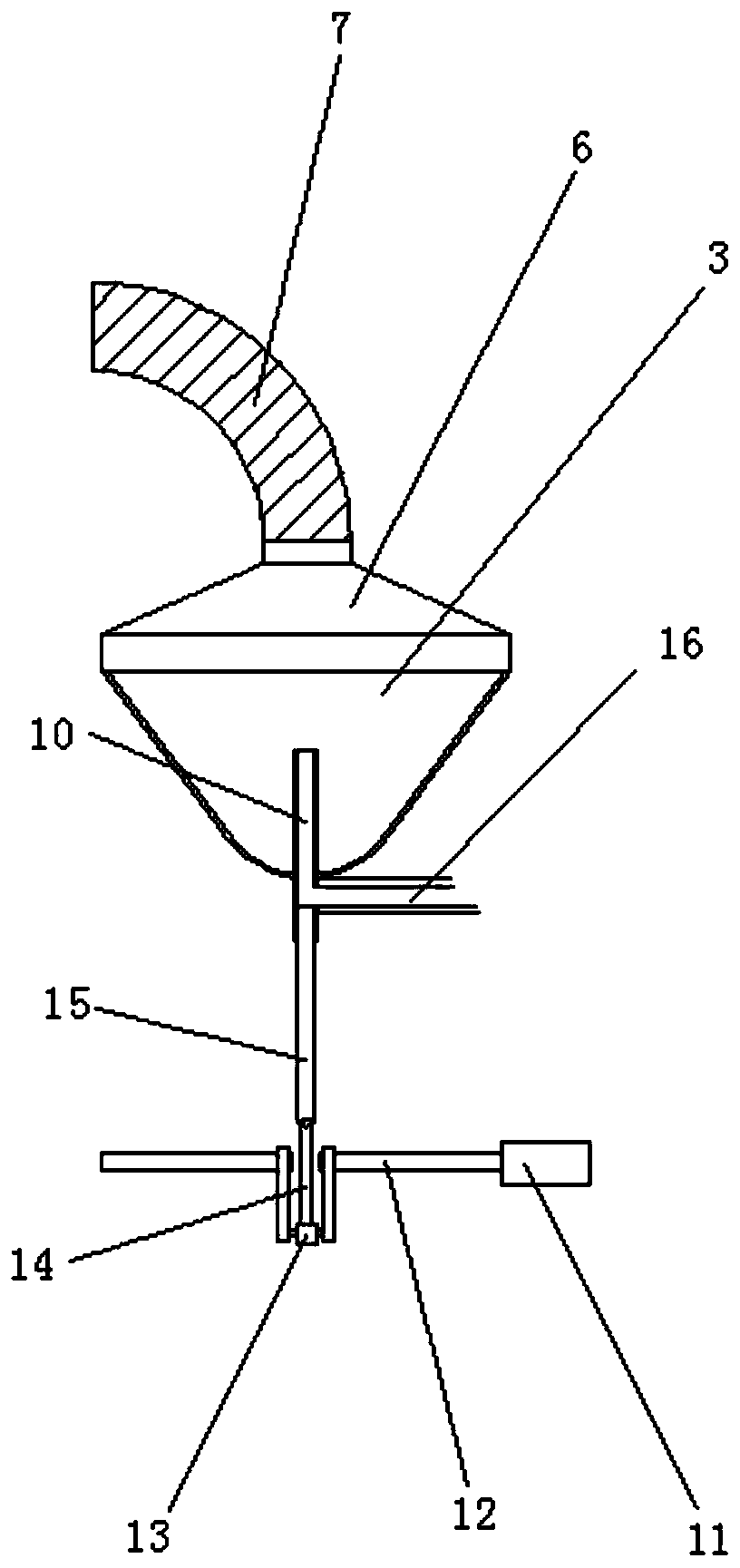

Gushing type circulating grain dust removing device

The invention relates to the field of grain processing, and discloses a gushing type circulating grain dust removing device which comprises a base. The bottom of the base is fixedly provided with a crankshaft rotating rod mechanism, the top of the base is rotatably hinged to an ejector rod, the top of the left side of a storage bin is fixedly provided with an elevator, the top of a dust removal hopper is fixedly provided with a negative pressure fan, the bottom of the dust removal hopper is fixedly connected with a grain spraying pipe, the tops of two sides of the base are provided with the dust removal hopper through supports and installation rings, a guide pipe is fixedly connected between the top of the elevator and the right side of the lower part of the grain spraying pipe, the guidepipe communicates with the grain spraying pipe, the ejector rod is movably sleeved with the bottom of the grain spraying pipe, and the left side of the bottom of the dust removal hopper is fixedly provided with a discharge pipe. The effect of controlling feeding can be achieved, grains are driven to be fluffy and uniformly distributed in the dust removal hopper in a gushing manner, dust and grainscan be separated easily, the function of circularly and repeatedly removing dust is achieved, and the dust removal effect is enhanced.

Owner:ANHUI JIESHOUSHI YUNLONG FOOD MACHINE ENG

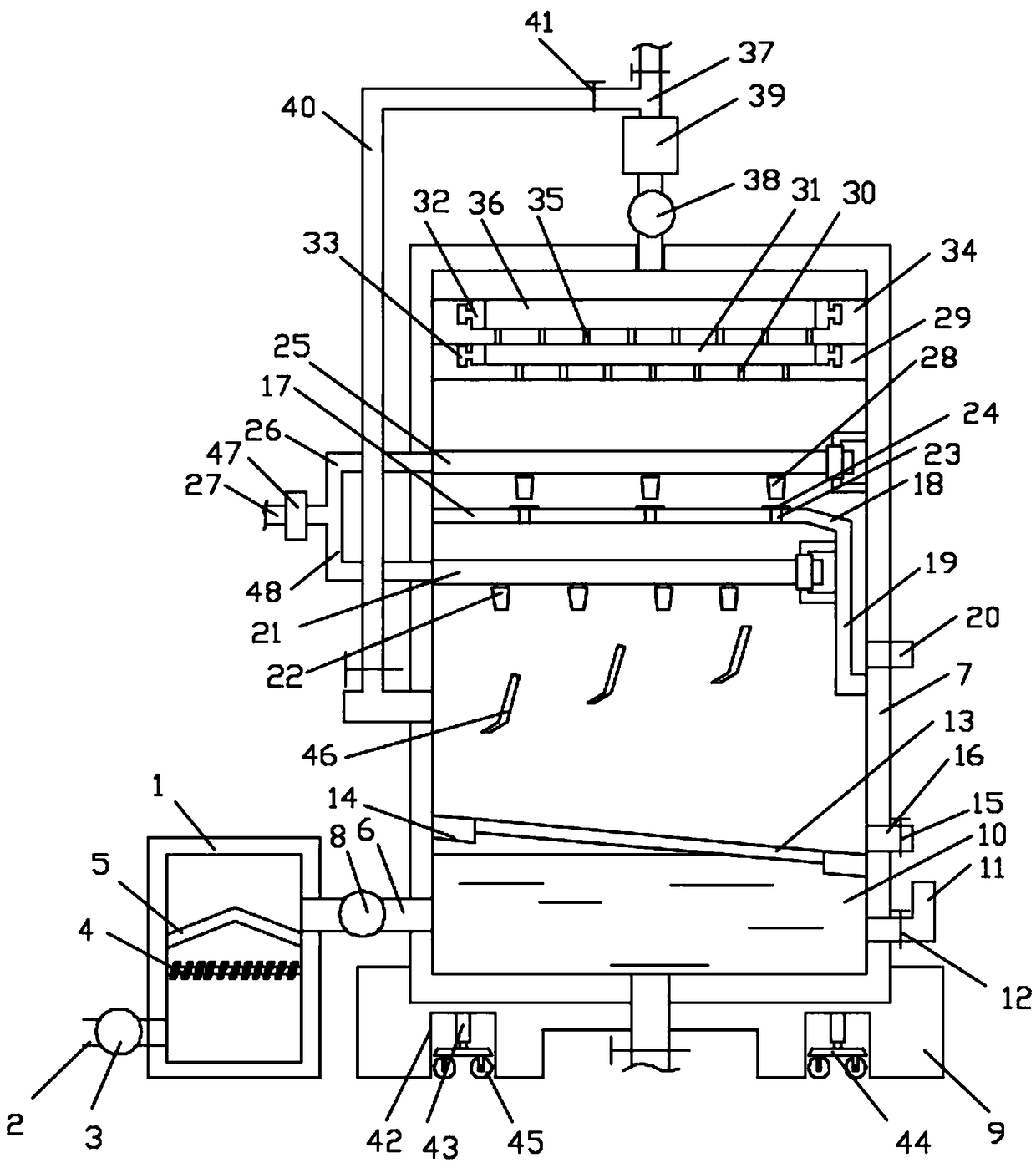

Grain drying machine with dust-collecting device

InactiveCN106338194AComplete dischargeEnhance the effect of dust removalDrying gas arrangementsEngineeringAir blower

A grain drying machine with a dust-collecting device comprises a shell, a hot air dust-collecting unit and a main dust-collecting unit, wherein the shell defines a hollow accommodation chamber and comprises a partition plate used for partitioning the hollow accommodation chamber into a drying space and a grain collecting space; the partition plate is provided with a plurality of openings for grains to fall into the grain collecting space from the drying space; the hot air dust-collecting unit comprises a hot-air blower, an exhaust fan and an air flue group; the hot-air blower is arranged on one side of the shell; the exhaust fan is arranged on the other side of the shell; the air flue group communicates with the hot-air blower, the exhaust fan and the drying space; and the main dust-collecting unit comprises a dust-collecting pipe for communicating the grain collecting space with the exhaust fan. By the exhausting and absorbing force of the exhaust fan, grain dust in the hollow accommodation chamber can be discharged by the exhaust fan through the air flue group and the dust-collecting pipe.

Owner:SUNCUE

Delicious artificial five-cereal rice and preparation method thereof

The invention discloses delicious artificial five-cereal rice. The delicious artificial five-cereal rice consists of the following raw materials in parts by weight: 30-40 parts of black bean powder, 25-35 parts of broad bean powder, 30-35 parts of pea powder, 15-20 parts of sesame seed powder, 15-20 parts of oat powder, 7-9 parts of tomato juice, 4-6 parts of duck soup, 6-8 parts of black funguses, 4-5 parts of bamboo funguses, 3-4 parts of rice wine, 1-2 parts of pine bark, 0.8-1.2 parts of aristolochiae mollissimae, 1.3-1.6 parts of longstamen onion bulbs, an appropriate quantity of composite mineral substances, an appropriate amount of starch, an appropriate amount of table salt and an appropriate amount of water. The artificial rice disclosed by the invention has two layers of envelopes, so that the artificial rice is not liable to deform and crack when being soaked and cooked, and the appearance of rice granules is well maintained; varied coarse food grains, such as grain dust, are used as main materials, so that the artificial rice contains more cellulose and hemicellulose, can stimulate the functions of the stomach and the intestines, and prevents constipation. The duck soup and the bamboo funguses are added, so that finished products are rich in nutrient elements, and the taste of the finished products is delicious.

Owner:ANHUI FUNING RICE IND CO LTD

Grain dust removing device

InactiveCN110947622AWon't clogImprove circulation efficiencyGas current separationCleaning processes and apparatusThermodynamicsElectric machine

The invention discloses a grain dust removing device which comprises a box body. An air inlet pipe is fixedly connected to one side of the box body. A draught fan is fixedly connected in the air inletpipe, and an air outlet pipe is fixedly connected to the other side of the box body. A first arc plate is fixedly connected to the top of the interior of the box body, and a second arc plate is connected in the box body in a sliding manner. A material falling channel is formed between the first arc plate and the second ac plate. Two vertical plates are fixedly connected to the bottom of the second arc plate, and a drive motor is fixedly connected to the outer portion of the box body. A main shaft of the drive motor stretches in the box body and is fixedly connected with a cam at the end head,and the cam is located between the two vertical plates. The grain dust removing device has the beneficial effects that by means of the grain dust removing device, the cam rotates to act on the vertical plates so that the second arc plate can swing around an arc track in the box body in a reciprocating manner, grains passing through the material falling channel are guided through the second arc plate and fall in a scattered manner, flowing airflow is improved for sufficiently separating dust among the grains, and the separation efficiency is high.

Owner:陆凯

Exhaust gas treatment device

InactiveCN109011987AGuaranteed reliabilityCombination devicesIncinerator apparatusAtmospheric airGas passing

The invention discloses an exhaust gas treatment device, comprising an exhaust gas pretreatment tank body, wherein an air inlet pipe is connected with the lower end of the left side wall of the exhaust gas pretreatment tank body; a first air suction pump body is connected with the air inlet pipe; and an electric heating pipe is horizontally arranged between and connected with the middle portions of the left and right inner side walls of the exhaust gas pretreatment tank body. Exhaust gas is pretreated by the exhaust gas pretreatment tank body; since the electric heating pipe is arranged insidethe exhaust gas pretreatment tank body, combustible pollutants in the exhaust gas can be burned off; a pretreatment filter screen filters out large-grain dust; then the gas is introduced into a waterfiltration chamber in an exhaust gas centralized treatment tank through an exhaust gas guiding pipe so as to realize filtering of the gas with clear water; then the gas moves upwards, successively passes through a first atomization nozzle and a second atomization nozzle for spraying and purification twice, then passes through a first purification layer and a second purification layer for purification twice and is then discharged; and before the gas is discharged into the air, an exhaust gas detector is arranged for detection of the gas, and the gas is discharged only when the gas reaches thestandard, so the reliability of exhaust gas purification is ensured.

Owner:合肥名华教育科技有限公司

Grain dust removal device

InactiveCN109382319AImprove filtering effectSpeed up filteringSievingGas current separationImpellerFiltration

The invention discloses a grain dust removal device. The grain dust removal device comprises a screening box, wherein the top right corner of the screening box is provided with a feed port, the innerportion of a fan case is provided with a fan, the inner portion of the screening box is provided with a filter plate, the upper surface of the filter plate is provided with a baffle, the lower surfaceof the filter plate is provided with a first dust falling groove, the left end of the first dust falling groove is connected with a second dust falling groove, the upper surface of the left end of ascreening plate is provided with a limiting rope, the inner portion of a motor box is provided with a motor, the shaft portion of the motor is connected with a half gear, the half gear is meshed witha tooth discharging plate, the grain slides off from the filter plate, a part of the dust is fed into the first dust falling groove through the action of the filter plate, and then passes through thesecond dust falling groove, so that the part of the dust finally falls into a first dust collection box for unified treatment. In order to control the falling speed of the grain, the surface of the filter plate is provided with a plurality of impellers, and the rotation of the impellers is driven through sliding-down of the grain, so that the descending speed slows down, thereby being capable of performing filtration better.

Owner:安徽粮友机械科技有限公司

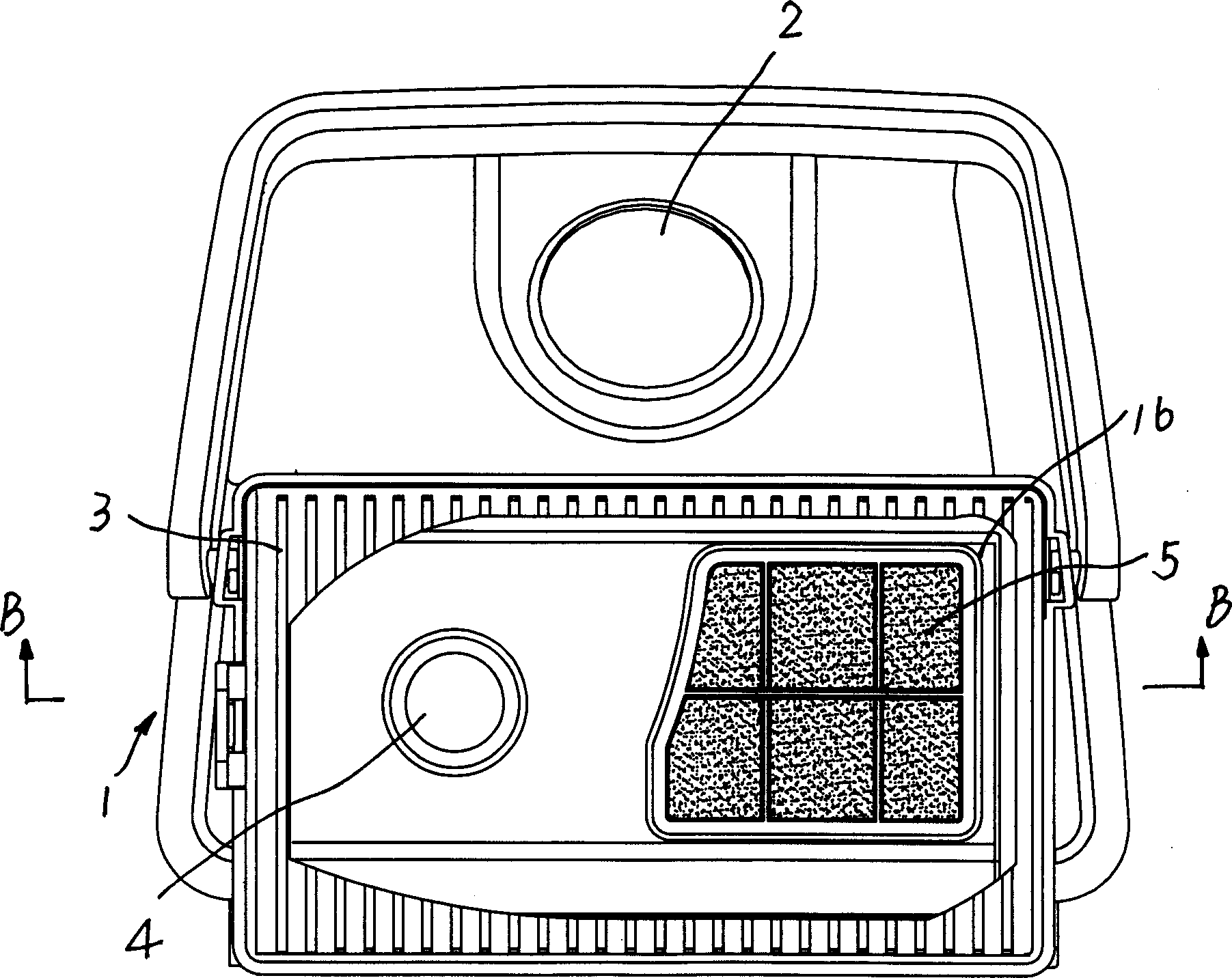

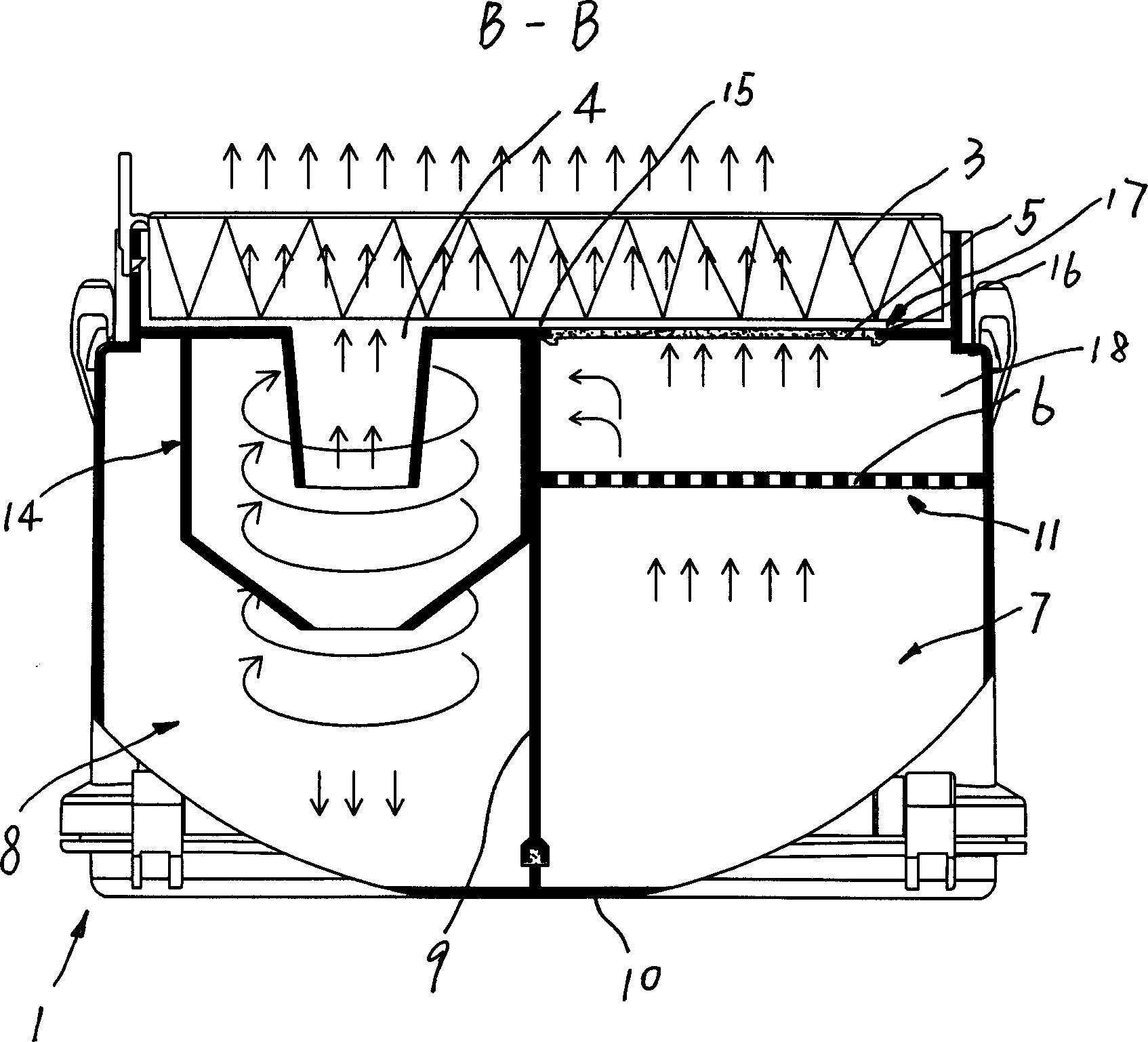

Dust separator of vacuum cleaner

InactiveCN1748631AImprove dust filtration efficiencyIncrease total air flowSuction filtersCycloneCyclonic separation

Owner:卞庄

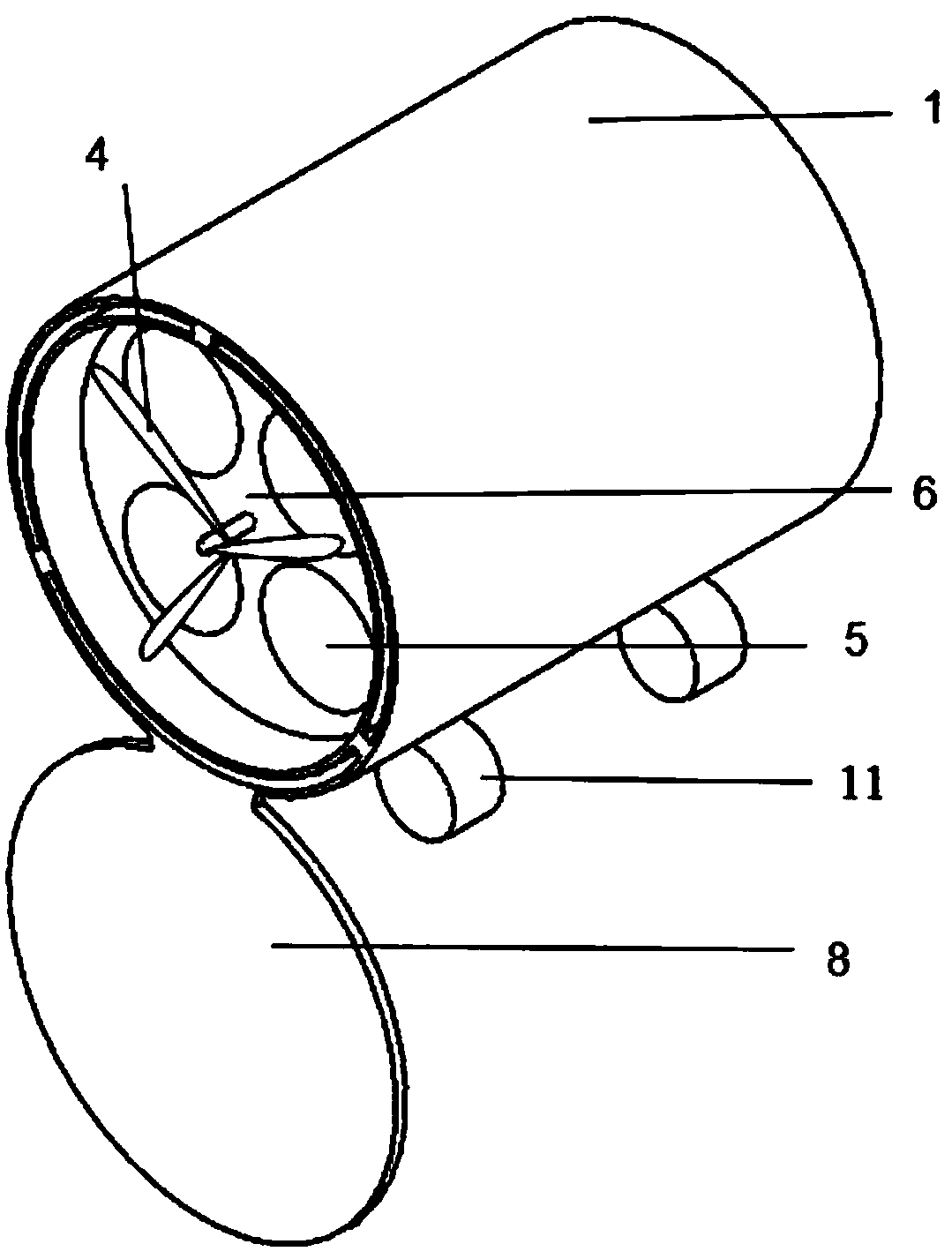

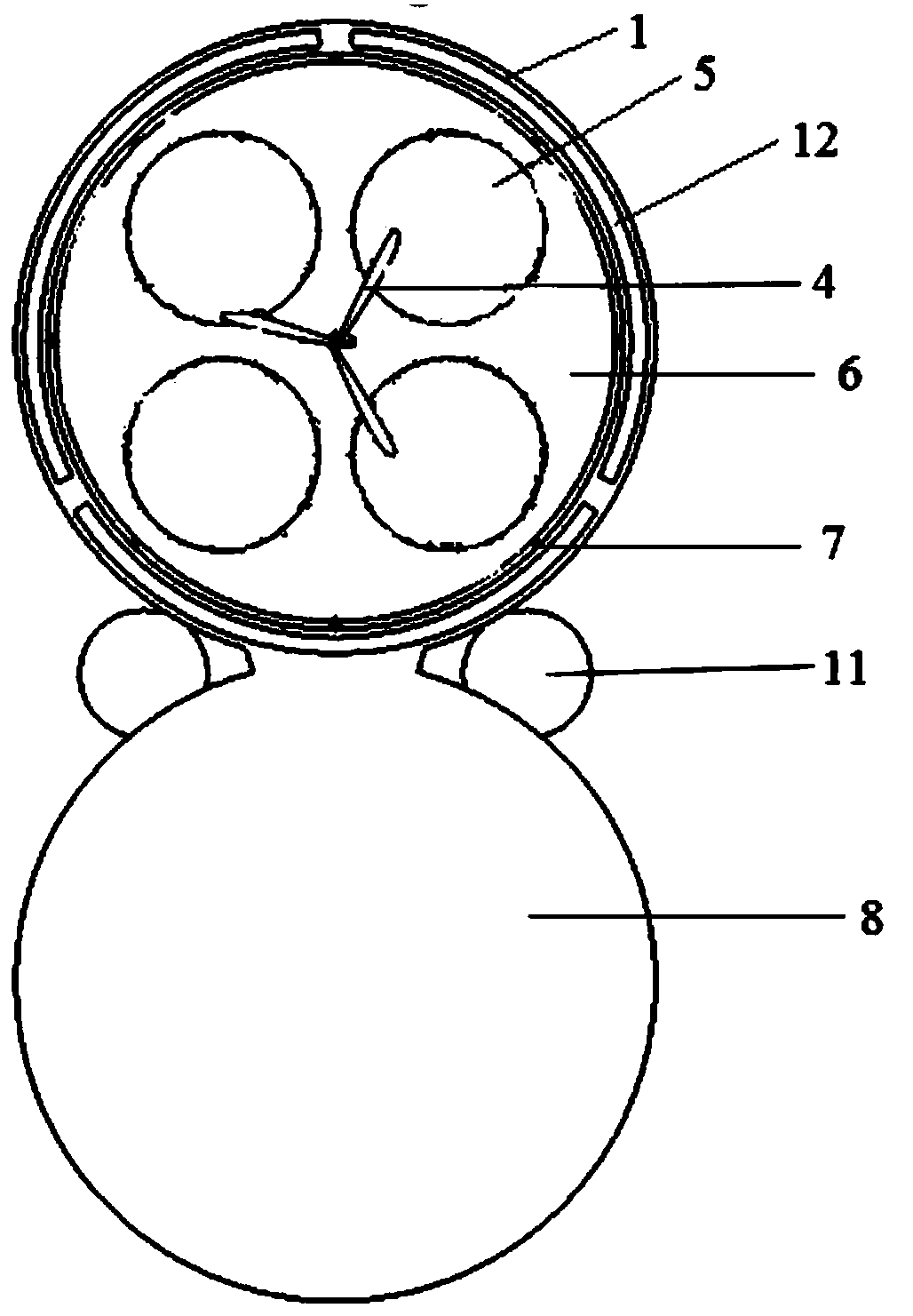

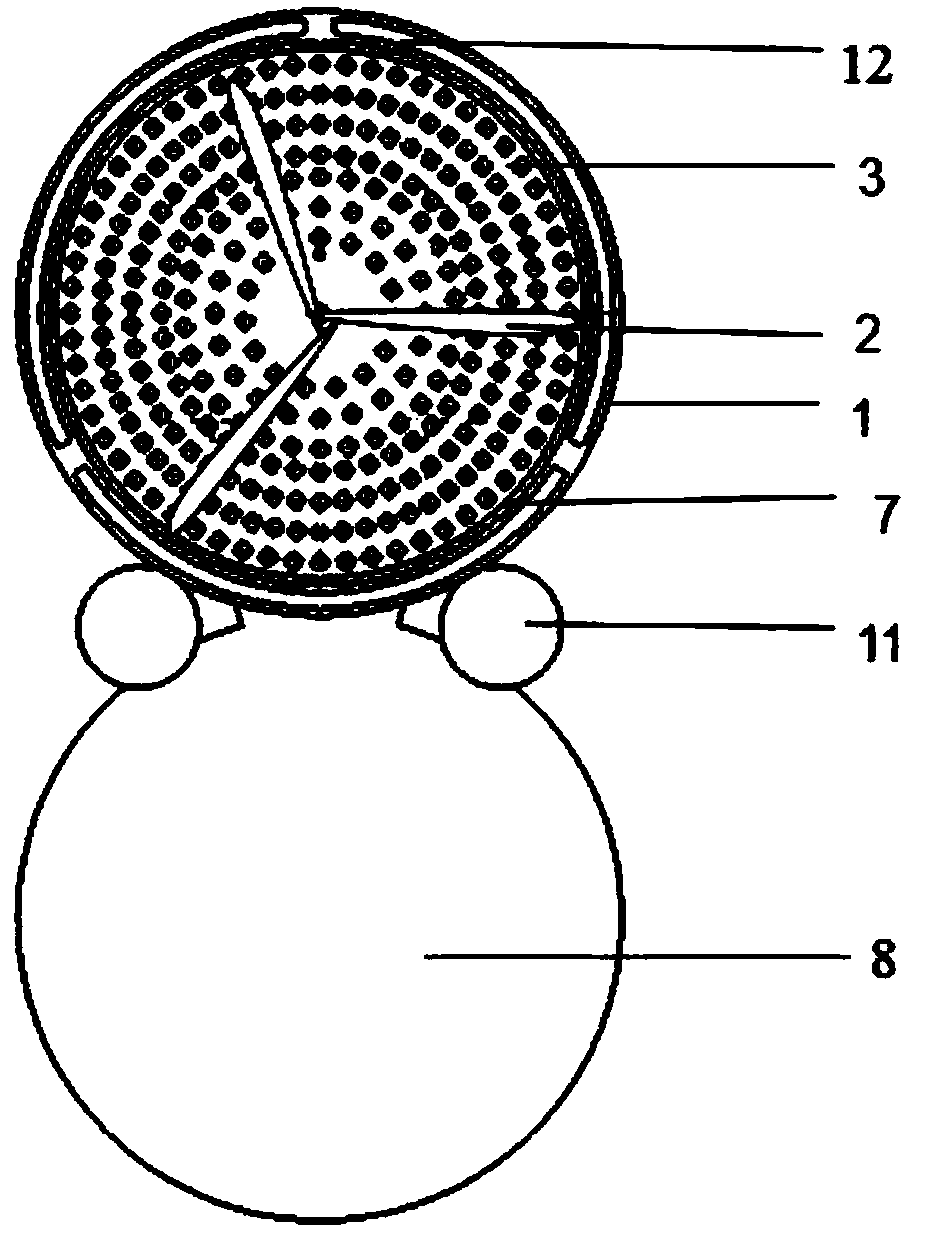

Food sorting and drying machine

PendingCN109539732ASpeed up water evaporationSpeed up the air flowDrying gas arrangementsDrying chambers/containersAir velocityMicrometer

The invention discloses a food sorting and drying machine. The machine comprises a cylindrical shell, an active blade, a filter net, a passive blade, a left wheel type roller with multiple food placing tubes, two cylindrical roller bearings and a first sealing cover; the food placing tubes are used for containing various foods; the active blade is used for pumping dried to-be-purified air into thefood placing tubes of the left wheel type roller; the filter net is used for filtering and collecting grain dust which is 0.5 micrometer or above and bacteria in to-be-purified air, and the dried purified air is obtained; the passive blade is used for rotating according to flowing dried purified air and then driving the left wheel type roller to rotate, the air velocity of the food surface is increased, and water evaporation of the food is accelerated; multiple wind circulation systems are used for conveying wet purified air reflected through the first sealing cover to an atmosphere; comparedwith traditional air drying, the air drying efficiency is improved, and green safe air drying is achieved.

Owner:DALIAN OCEAN UNIV

Grain dust and impurity removing system

InactiveCN107931126ARealize impurity removalAchieve FeaturedSievingGas current separationConvulsionReciprocating motion

The invention discloses a grain dust removal and impurity removal system, which includes a linear reciprocating push mechanism, a screening mechanism and an optimal collection device. The linear reciprocating push mechanism is an incomplete gear transmission mechanism. The machine and the dust filter bag, the linear reciprocating push mechanism drives the sieve plate to move, the impurities in the grain are captured and deposited by the exhaust fan and the dust filter bag, and the grain after the impurity removal is further separated and collected by the air flow in the optimal collection device. The beneficial effect of adopting the present invention is that the grains pass through the screening mechanism and the optimal collection device successively to realize the impurity removal and selection of the grains, and the device system is simple and effective and easy to maintain.

Owner:重庆智恒科技咨询有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com