Method and apparatus for recovering metal from electric furnace dust

A technology of dust recovery and electric furnace, applied in separation methods, chemical instruments and methods, furnaces, etc., can solve the problems of semi-melt discharge, insufficient reduction of iron components, increase heating temperature, etc., and achieve high-efficiency metal recovery and operation The effect of long-term stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

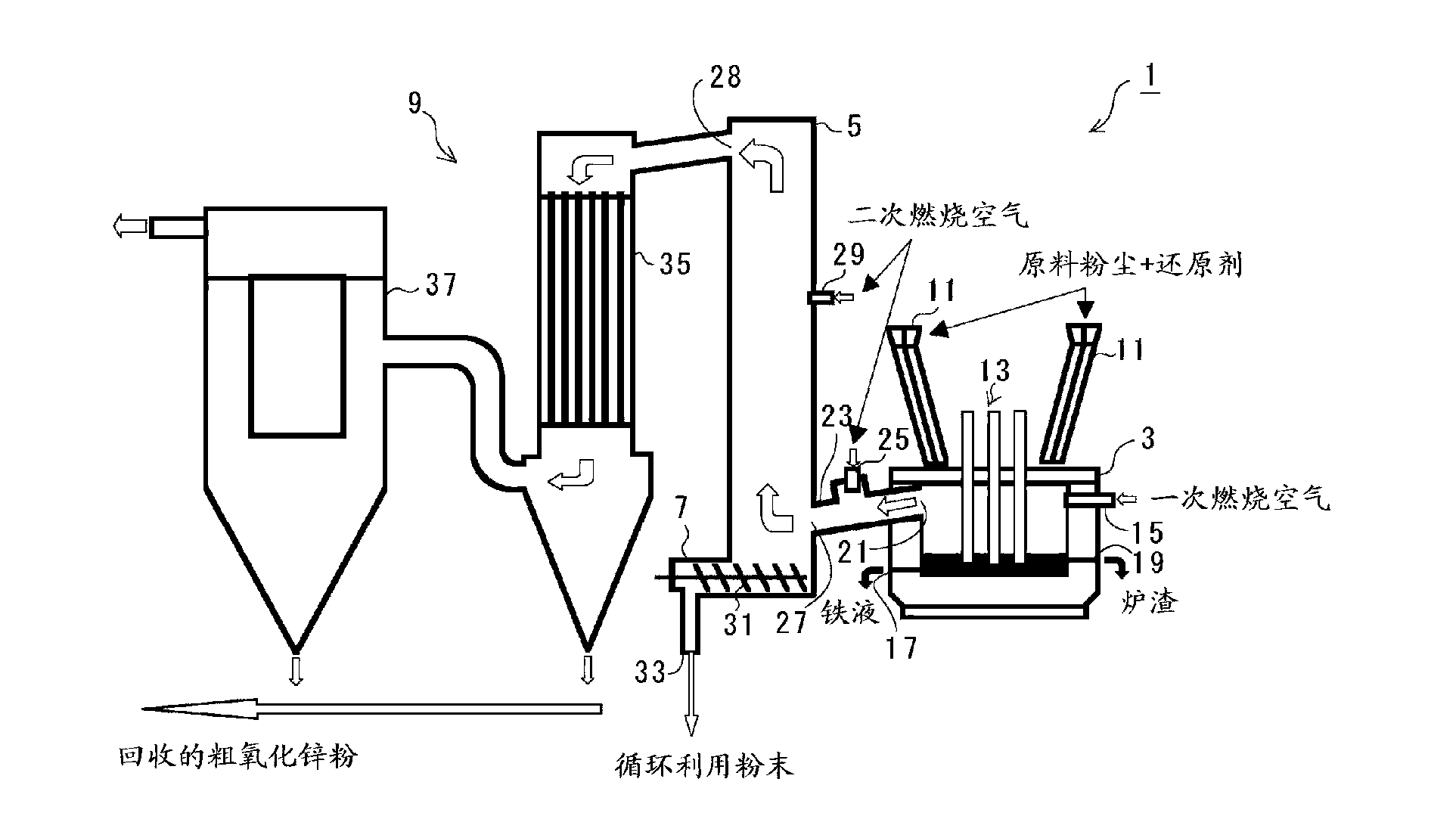

[0100] Shown below figure 1 Specific basic specifications of the device for recovering metal from electric furnace dust according to the first embodiment.

[0101] Rated electric furnace dust handling capacity: 5 tons / hour

[0102] ·Inner diameter of furnace: 4mφ

[0103] ·Power capacity: 12MVA

[0104] ·Size of secondary combustion chamber: inner diameter 2.5mφ×height 9m

[0105] Dimensions of multi-tube gas cooler: tube diameter 0.3mφ×length 7m×12 pieces

[0106] The gas volume and temperature at the outlet of the secondary combustion chamber: 6500Nm 3 / h×720℃

[0107] ·Outlet gas volume and temperature of multi-tube gas cooler: 6500Nm 3 / h×390℃

[0108] ·Bag filter inlet gas volume and temperature: 15000Nm 3 / h×180℃

[0109] ·Metal recovery capacity: 1.25 tons / hour

[0110] ·Coarse zinc oxide recovery: 2.0 tons / hour

[0111] ·ZnO in crude zinc oxide: 65~73%

[0112] ·Continuous operation time: 3 to 5 days

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com