Method for treating calcination fume and vanadium-deposition waste water in vanadium extracting production

A technology for vanadium precipitation wastewater and a treatment method, which is applied in the field of comprehensive treatment and can solve the problems of large pollution, inability to effectively absorb harmful chlorine gas, and inability to treat vanadium precipitation wastewater.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

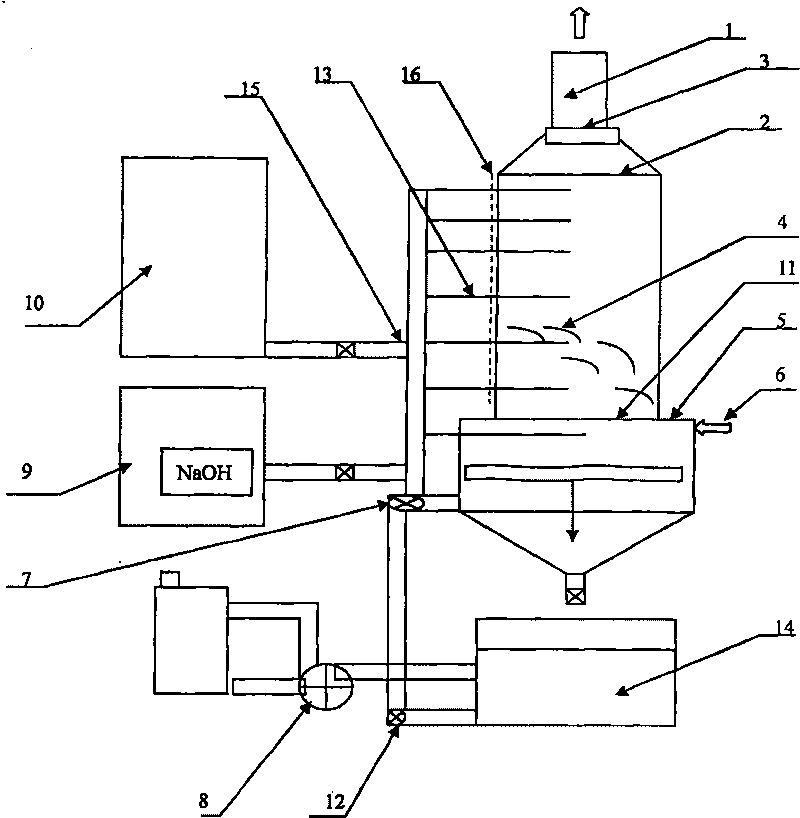

[0015] The treatment method of roasting flue gas and vanadium precipitation wastewater in the production of vanadium extraction includes 4 steps of wet dust removal, alkali dechlorination, evaporative crystallization, and ammonia desulfurization. These 4 steps use a composite purification tower (such as figure 1 ) to realize, the composite purification tower includes the gas outlet chimney 1, the upper tower body 2, the gas-liquid separator 3, the spiral guide plate 4, the lower tower body 5, the air inlet 6, the spray device 7 and 12, the vacuum suction filter The device 8, the lye tank 9, and the vanadium precipitation waste water tank 10 are characterized in that: the gas outlet chimney 1 is welded on the upper tower body 2; the upper part of the upper tower body 2 is a cone, and the lower part is a cylinder, and the inside of the cone is riveted with gas and liquid Separator 3, the middle and lower part of the cylinder is welded with spiral deflector 4; the upper tower body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com