Dust separator of vacuum cleaner

A dust separation and vacuum cleaner technology, applied in suction filters and other directions, can solve the problems of heavy separation burden on downstream separators, poor cyclone separation effect, and large airflow flow, so as to improve the cyclone separation effect, reduce airflow, and improve dust filtering efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

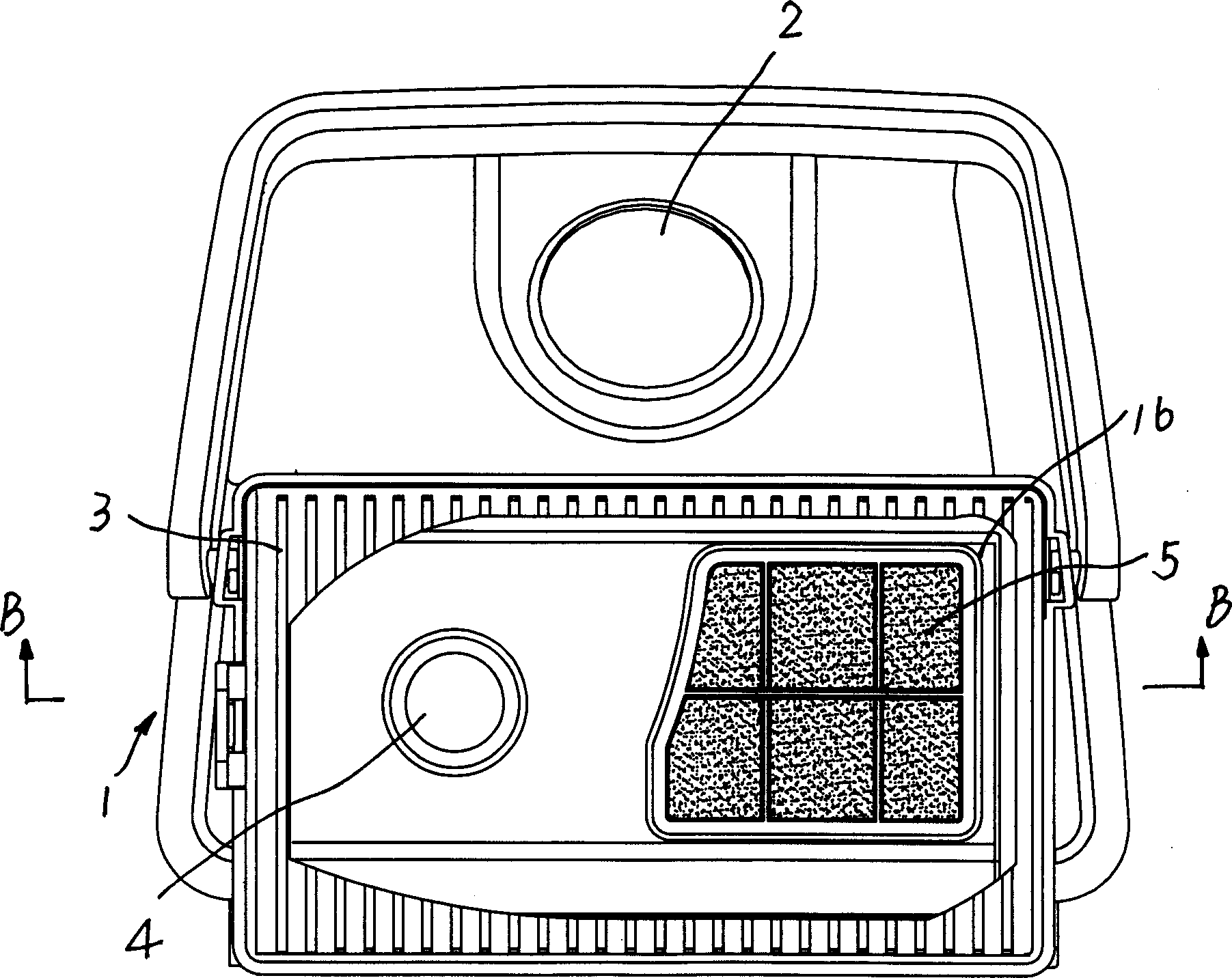

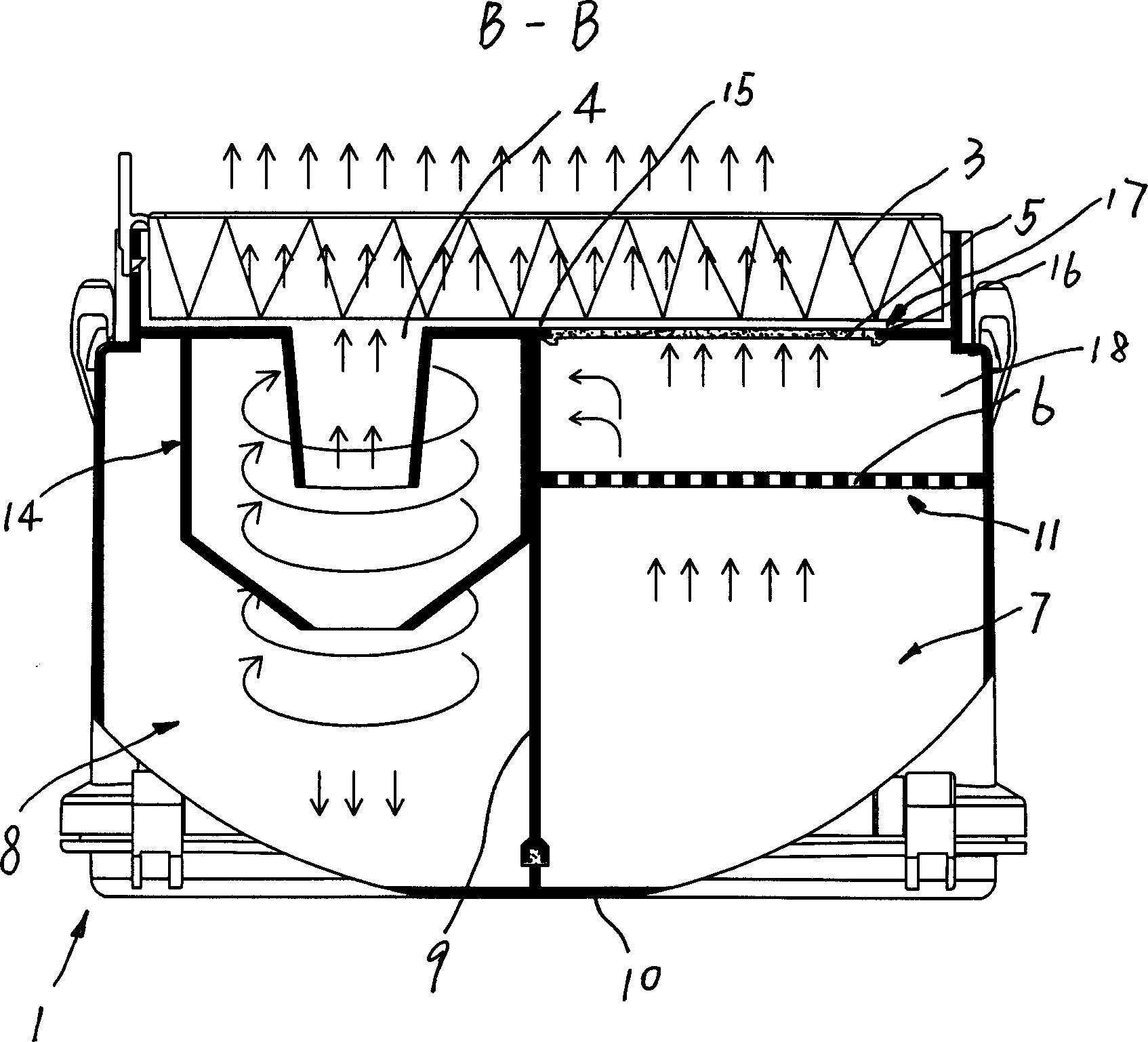

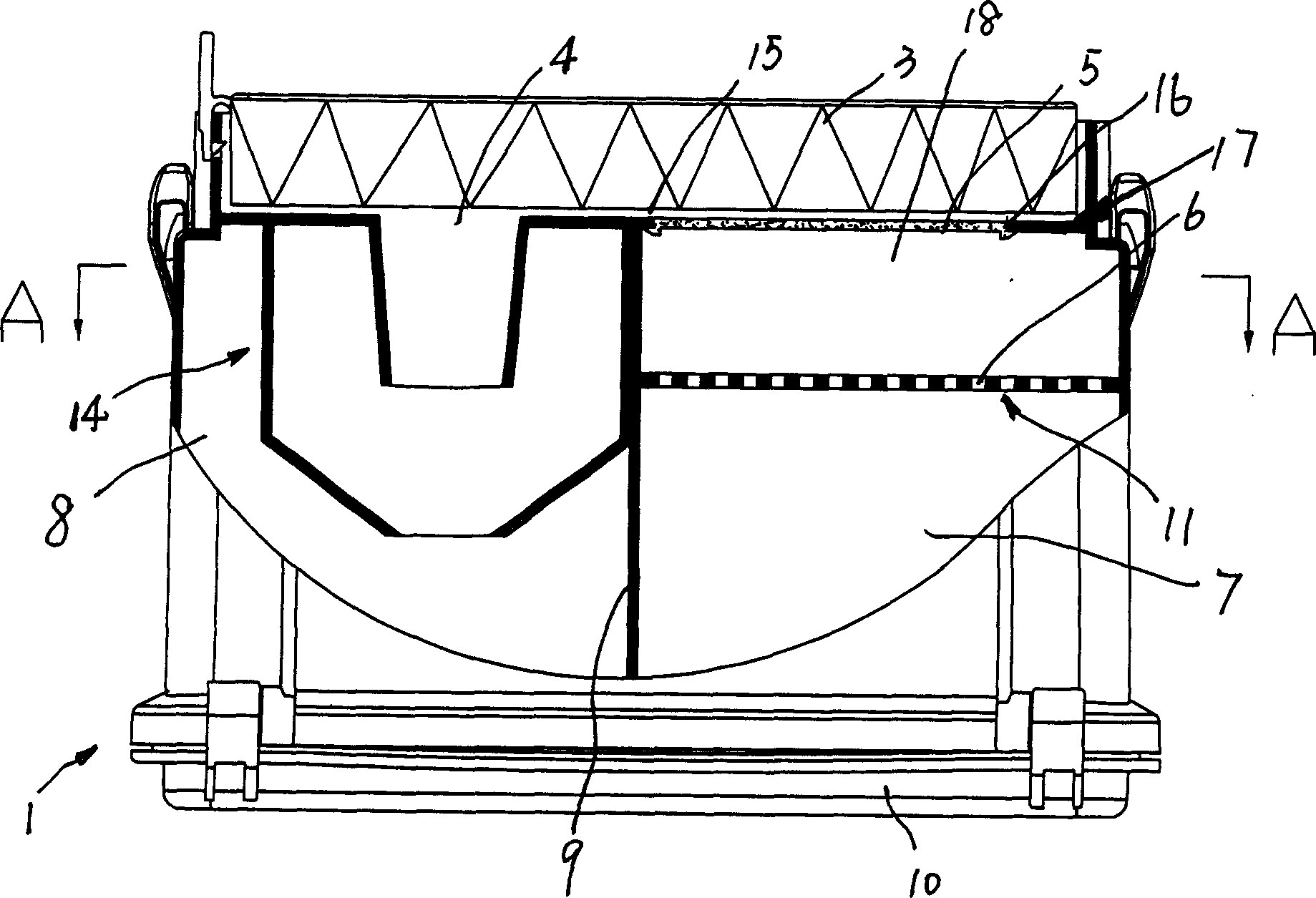

[0014] See attached figure 1 - attached Figure 5 , a dust separation device on a vacuum cleaner, which includes a first separator 17, a cyclone separator 14 located on the side of the first separator 17, and the first separator 17 includes an upstream dust chamber 7 and an air flow The distribution chamber 18, the upstream dust chamber 7 and the airflow distribution chamber 18 are separated by a mesh plate 11 with a plurality of mesh holes 6, the upstream dust chamber 7 has a dust wind inlet 2, and the The airflow distribution chamber 18 has a first airflow outlet 13 and a second airflow outlet 16, the second airflow outlet 16 is provided with a first filter 5, and the cyclone separator 14 has a cyclone inlet 12 and a cyclone outlet 4. The first air outlet 13 communicates with the cyclone inlet 12 , and the second air outlet 16 and the cyclone outlet 4 directly lead to the air outlet channel 15 .

[0015] The second filter 3 is arranged on the air outlet channel 15 .

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com