Grain selecting device

A technology for grain and movable installation, which is used in solid separation, separation of solids from solids by air flow, chemical instruments and methods, etc., can solve the problems of insufficient grain cleanliness, incomplete impurity removal, waste of manpower and material resources, etc., and saves money. Manpower and material resources, simple structure, and the effect of improving cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

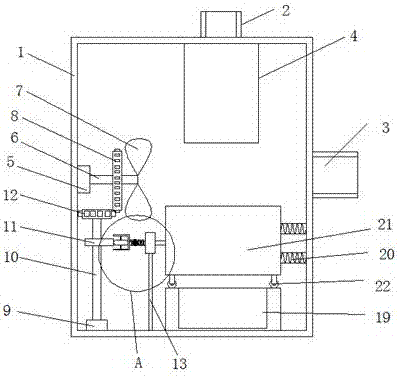

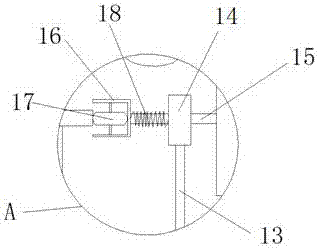

[0017] refer to Figure 1-2 , a grain selection device, comprising a device body 1, the device body 1 is a stainless steel alloy structure, the top and side walls of the device body 1 are respectively provided with a feed inlet 2 and an ash outlet 3, and the top inner wall of the device body 1 is provided with There is a feed channel 4, and the feed channel 4 is located directly below the feed port 2, and the drive motor 5 is fixedly installed in the side wall of the device body 1 away from the ash outlet 3, and the output shaft of the drive motor 5 is connected to the first rotating shaft 6 The other end of the first rotating shaft 6 is connected with a fan blade 7,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com