Grain dust removing equipment and use method thereof

A dust removal equipment and grain technology, which is applied in grain drying, lighting and heating equipment, chemical instruments and methods, etc., can solve the problems of increasing labor intensity of workers, time-consuming and laborious, and low dust removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

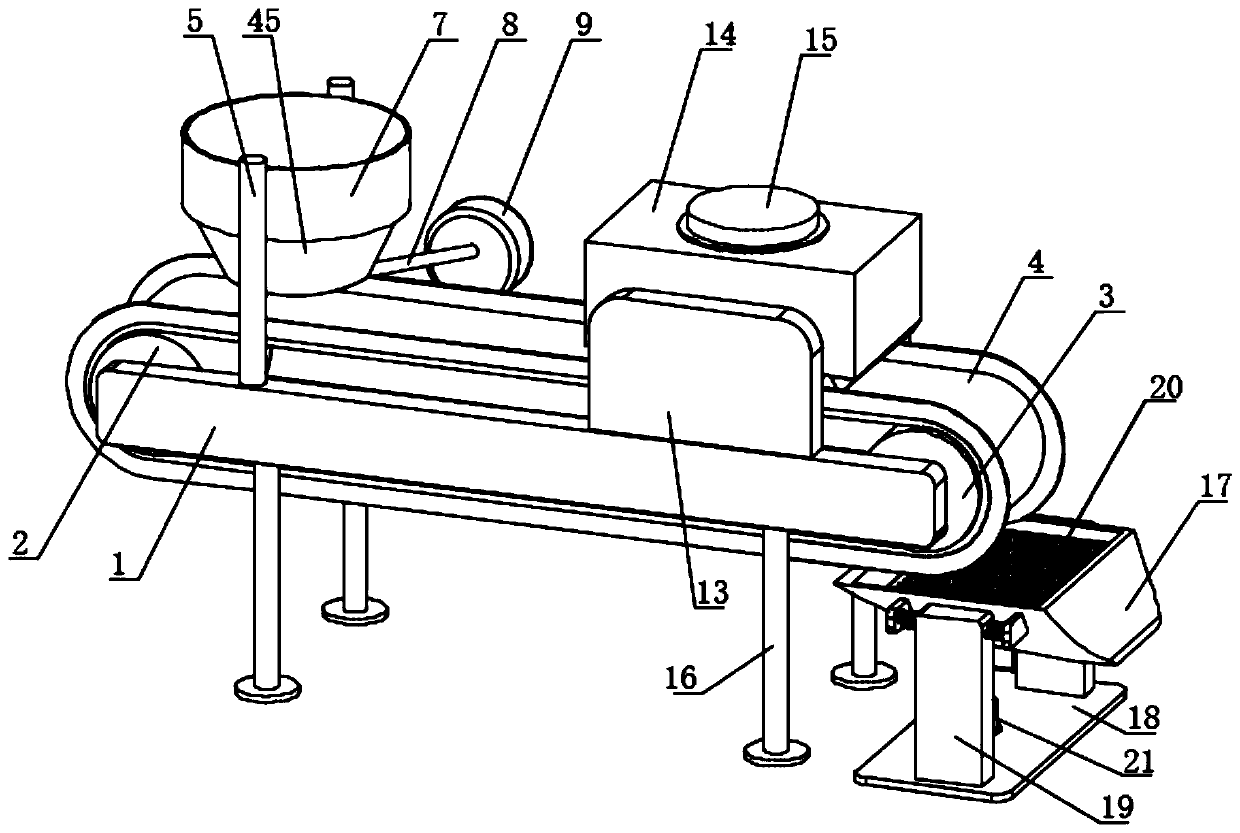

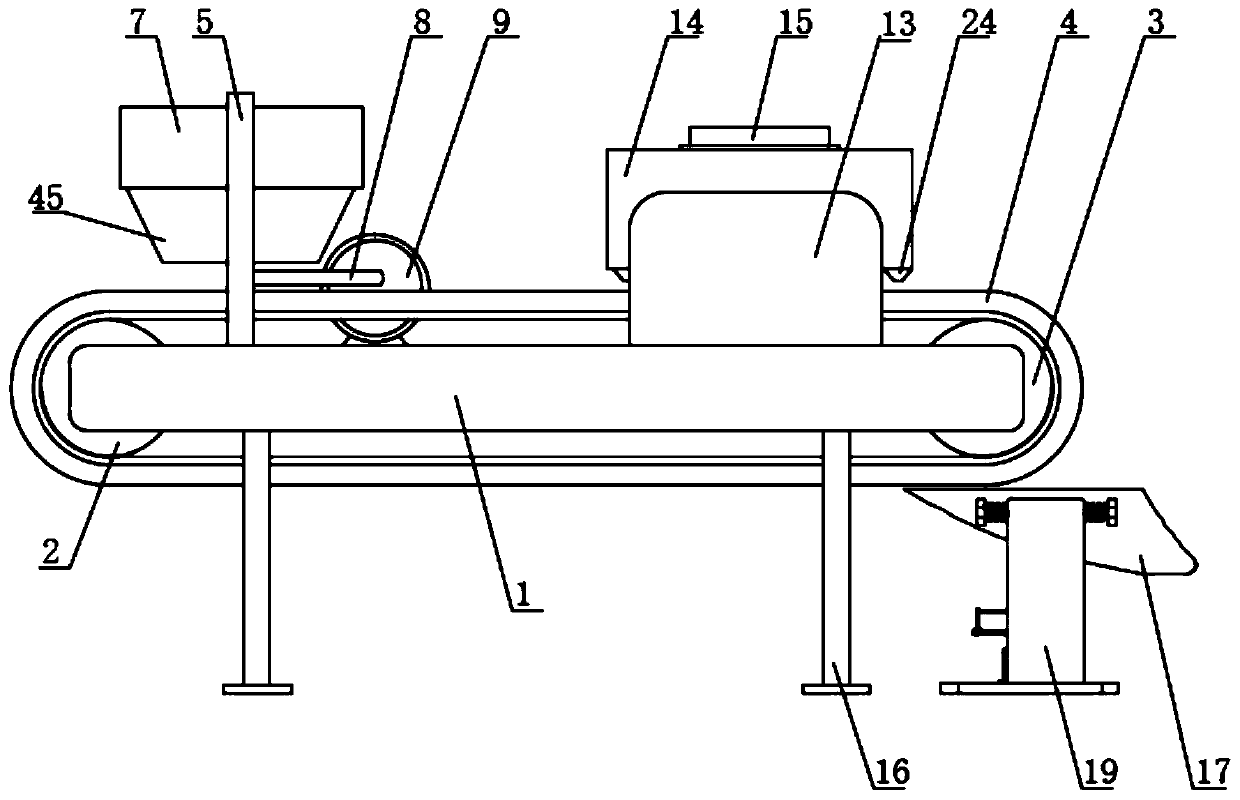

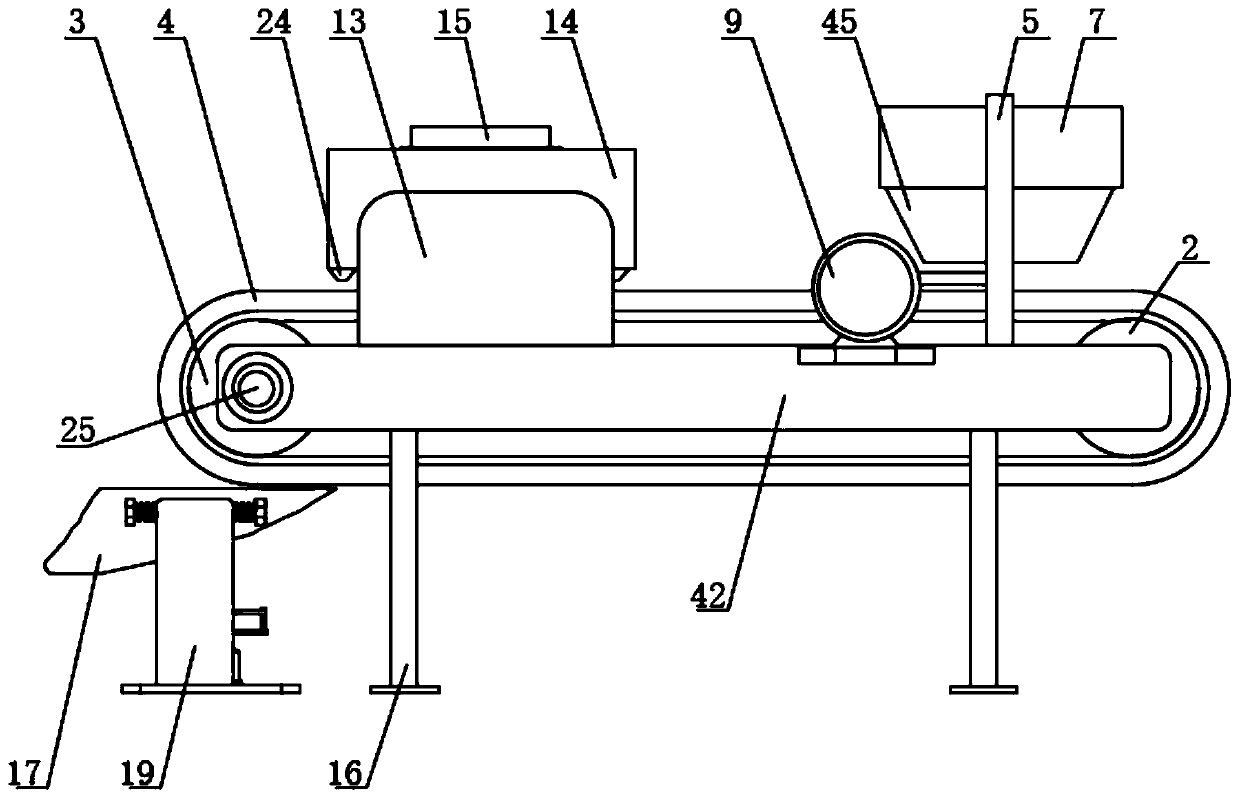

[0051] Example one: such as Figure 1-18 As shown, a grain dust removal equipment includes a first side plate 1 and a second side plate 42. The first side plate 1 is located on one side of the second side plate 42 and the first side plate 1 and the second side plate 42 are close to each other The first roller 2 and the second roller 3 are rotatably connected to one side of the second side plate 42. A driving motor 25 is fixedly installed on one side of the second side plate 42. The roller 3 is connected by a coupling. The outer wall of the first roller 2 and the outer wall of the second roller 3 are connected with the same sidewall conveyor 4, the top side of the first side plate 1 and the second side plate The top side of the 42 is fixedly installed with a vertical rod 5, and the top of the two vertical rods 5 close to each other is welded with the same discharge box 7. The discharge box 7 is located directly above the sidewall conveyor 4, and the discharge box A circular hol...

Embodiment 2

[0067] Embodiment two: such as Figure 19 with 20 As shown, there is a grain dust removal equipment. The difference between this embodiment and the first embodiment is that: the top of the first side plate 1 and the top of the second side plate 42 are fixedly installed with a plurality of mounting rods 11 arranged at equal intervals. The rod 11 is located between the vertical rod 5 and the vertical plate 13. The tops of the two mounting rods 11 are welded with the same horizontal plate 10, and the bottom of the horizontal plate 10 is fixedly installed with a scraper 12, and the bottom of the scraper 12 extends to the rib for conveying In the belt 4, the bottom of the scraper 12 is fixedly installed with a plurality of arc-shaped teeth 26 arranged at equal intervals. The arc-shaped teeth 26 are located in the rib conveyor belt 4, and the bottom of the arc-shaped teeth 26 is between the top of the rib conveyor belt 4. The spacing between the two scrapers 12 is 5-15mm. The arc teet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com