Patents

Literature

78results about How to "Realize impurity removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

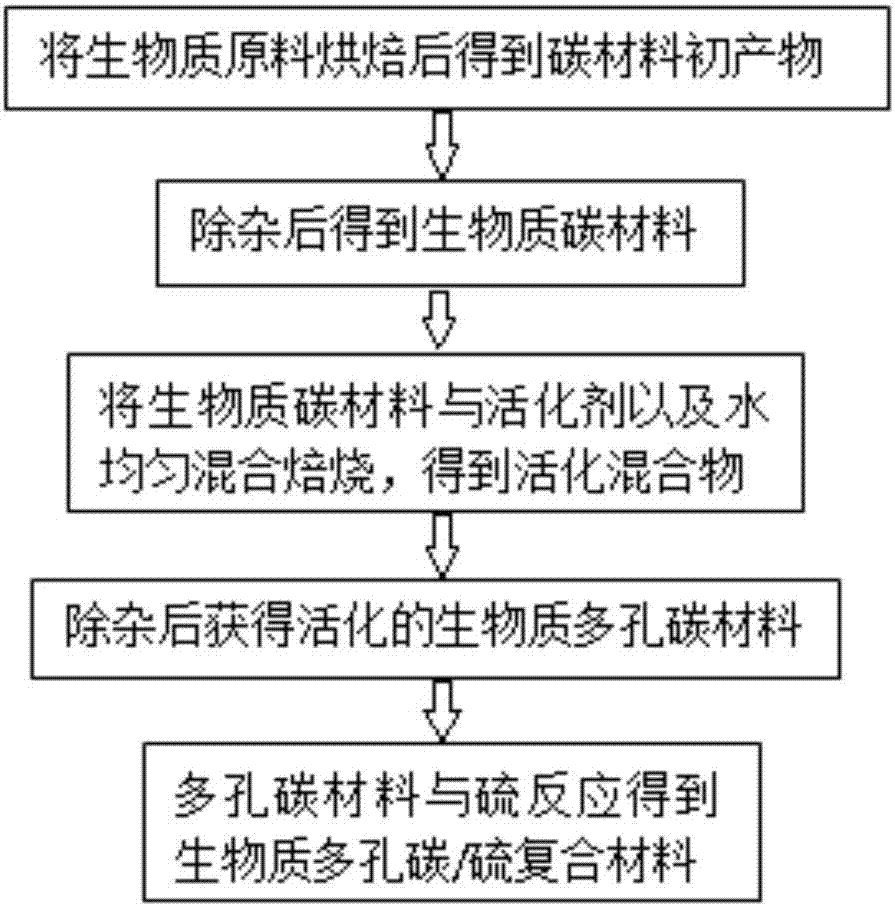

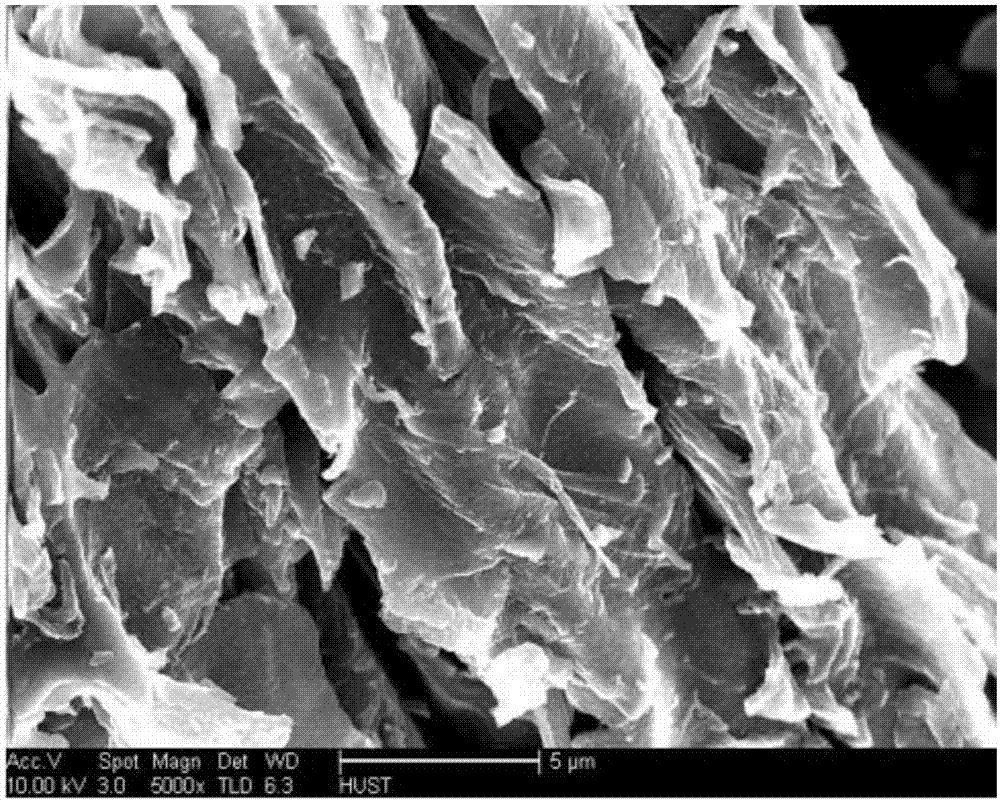

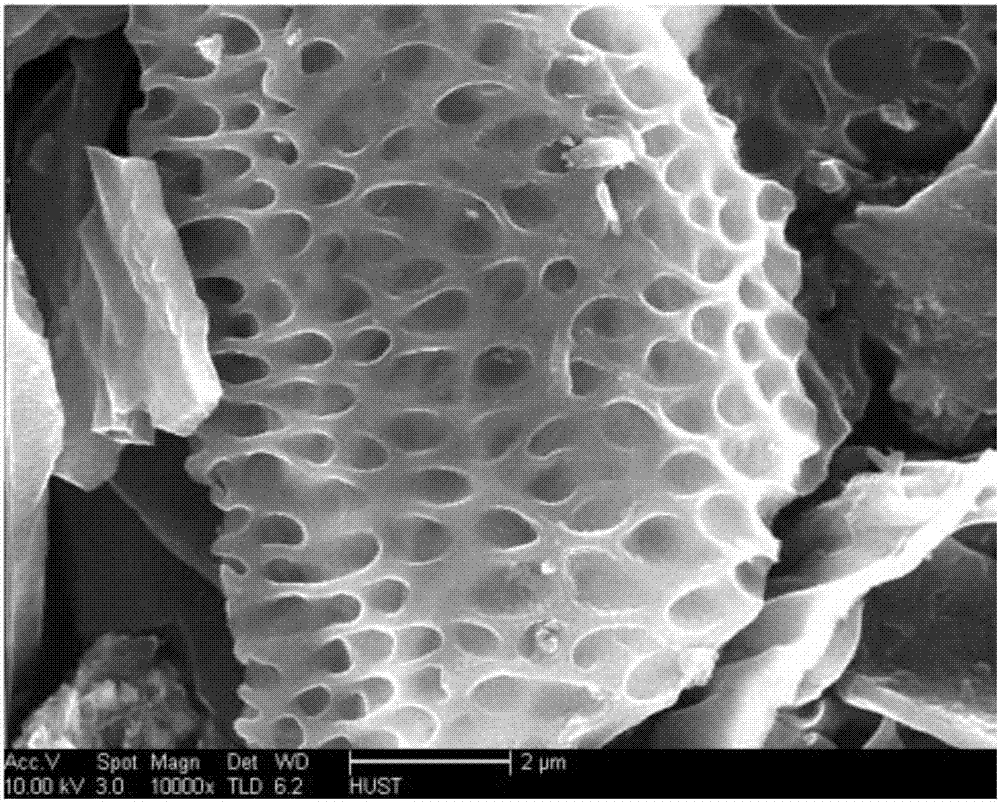

Preparation method and application of biomass-based porous carbon/sulfur composite

InactiveCN106981644AHigh value utilizationImprove cycle stabilityHybrid capacitor electrodesCell electrodesBiomass carbonPorous carbon

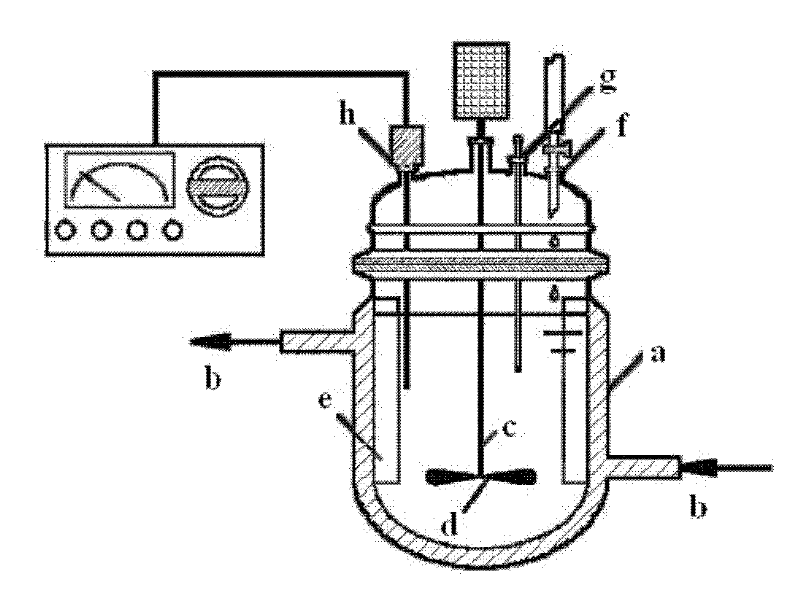

The invention belongs to the field of lithium-sulfur battery cathode materials and particularly relates to a preparation method of a preparation method of biomass-based porous carbon / sulfur composite, comprising the specific steps of S1, calcining biomass material to obtain a primary product of carbon material; S2, removing impurities from the primary product of carbon material to obtain biomass carbon material; S3, mixing well the biomass carbon material with an activator and water, and calcining to obtain activated mixture; S4, removing impurities from the mixture to obtain activated porous carbon material; S5, mixing the porous carbon material with sulfur for the purpose of reacting to obtain the porous carbon / sulfur composite. The invention also discloses application of the porous carbon / sulfur composite as a cathode material in batteries or supercapacitors. A battery prepared with the biomass carbon / sulfur composite prepared herein has high discharge capacity, good cycle stability and high coulombic efficiency, and has a promising application.

Owner:HUAZHONG UNIV OF SCI & TECH

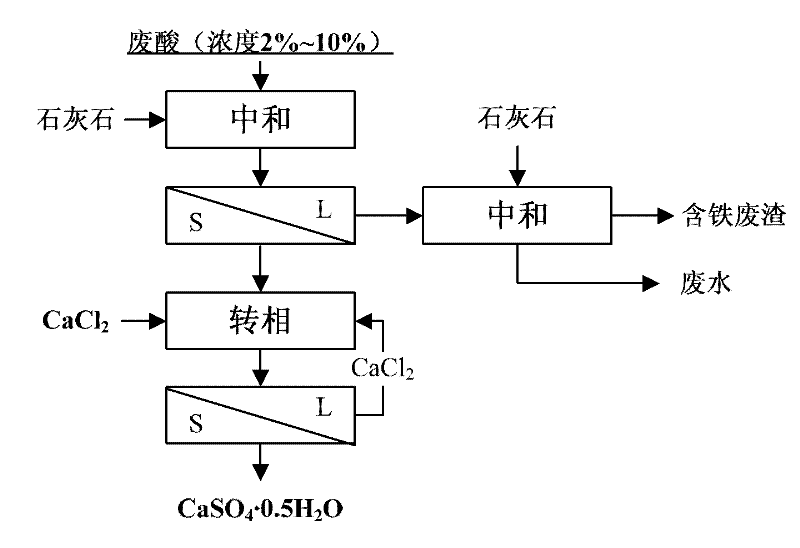

Building material and method for preparing calcium sulfate hemihydrates from titanium white waste sulfuric acid

InactiveCN102211785ANo pollution in the processEasy to operateCalcium/strontium/barium sulfatesInorganic ChemicalSulfate

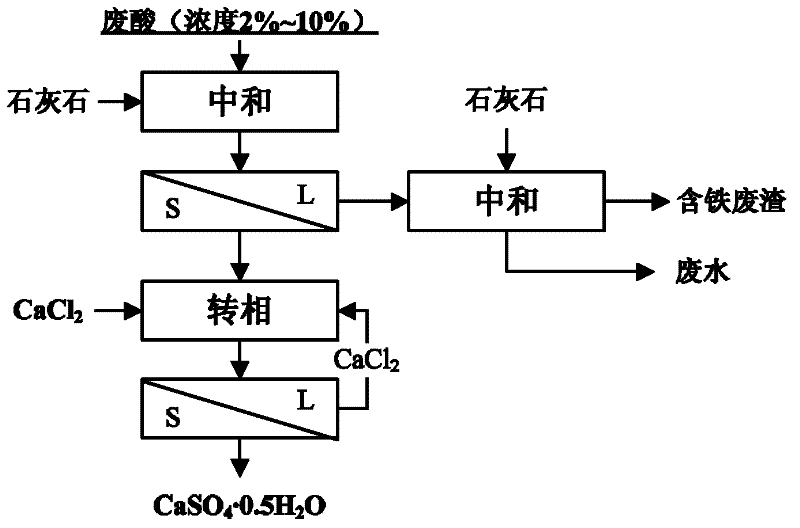

The invention relates to the field of inorganic chemical industry, and particularly relates to a building material and a method for preparing calcium sulfate hemihydrates from titanium white waste sulfuric acid. The method comprises the following steps of: 1) adding limestone or slaked lime into the titanium white waste sulfuric acid, adjusting the pH and reacting to generate precipitates of calcium sulfate in slurry; 2) performing solid-liquid separation to obtain solid of calcium sulphate dehydrate and filtrate; 3) adding calcium chloride solution into the solid of calcium sulphate dehydrate obtained in the step 2), wherein the molar ratio of the calcium chloride to the calcium sulphate dehydrate is 1:(1-2.5), adjusting the concentration of H<+>, stirring and reacting at the temperature of between 30 and 90 DEG C to separate calcium sulphate dehydrate crystal out; and 4) ageing the calcium sulphate dehydrate which is obtained in the step 3), and performing solid-liquid separation to obtain calcium sulphate dehydrate and the calcium chloride solution. The method is used for producing the calcium sulphate dehydrate for building, has good economic benefit and is environment-friendly; and the provided method has high operability and industrialization is easy to realize by the method.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Impurity removing method for vanadium contained leaching agent

ActiveCN106244828AReduce loss rateEfficient separationProcess efficiency improvementLoss rateMass ratio

The invention relates to an impurity removing method for a vanadium contained leaching agent. According to the technical scheme, potassium sulphate is added into the vanadium contained leaching agent according to the mass ratio of the potassium sulphate to aluminum in the vanadium contained leaching agent being (2.5-4.0):1, crystallization is carried out, primary solid-liquid separation is carried out, and liquid obtained after crystallization and potassium alum are obtained. A reducing agent is added into the liquid obtained after crystallization according to the ratio of the amount of total matter in the reducing agent to the amount of the Fe(III) matter in the liquid obtained after crystallization being (1.5-3.5):1, stirring is carried out, and liquid obtained after reducing is obtained. A precipitator is added into the liquid obtained after reducing according to the ratio of C2O4<2-> matter in the precipitator to the amount of iron matter in the liquid obtained after reducing being (2-15):1, stirring is carried out, secondary solid-liquid separation is carried out, and the vanadium contained leaching agent obtained after impurity removing and filter residues are obtained; the vanadium contained leaching agent obtained after impurity removing is used for the follow-up vanadium enrichment process; and the filter residues are dried, and therefore the oxalates compound by-products of iron are obtained. The impurity removing method has the beneficial effects of being good in vanadium and impurity ion separating effect, simple in process, small in reagent consumption, low in vanadium loss rate and capable of achieving resource utilization.

Owner:WUHAN UNIV OF SCI & TECH

Method for preparing manganese sulfate by utilizing manganese oxide

InactiveCN103540773AReduce the pressure of post-purificationImprove adsorption capacityPolyelectrolyteSorbent

The invention belongs to the field of processing battery materials, and particularly relates to a method for preparing manganese sulfate by utilizing manganese oxide. The preparation method comprises the steps of manganese sulfate steeping, neutralization and iron removal, and deep removal of heavy metals. As an adsorbent, MnO4<-1> in Ca(MnO4)2 and NaMnO4 in the deep removal process of heavy metals has strong adsorption effect on As, Sb and Mo ions, has strong adsorption capability on Cu, Co, Ni, Pb, Fe and other ions in the solution, deep impurity removal of the manganese sulfate solution can be realized under the secondary adsorption action of the adsorbent after the Fe, Cu, Co, Ni and Pb are removed, so that the concentrations of trace elements As, Sb and Mo are all less than or equal to 0.003ppm to obtain high-quality manganese sulfate solution, the filtering and impurity removal of the solution and precipitation of ion impurities can be accelerated by utilizing a filtering aid and a macromolecular polyelectrolyte flocculant, the preparation technology can be simplified, and the preparation process efficiency can be improved.

Owner:GUANGXI GUILIU CHEM CO LTD

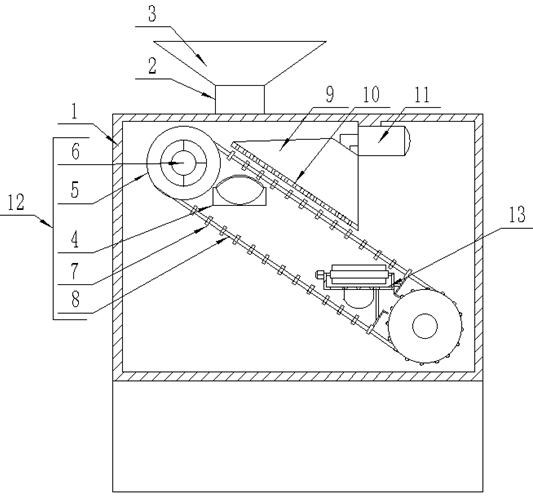

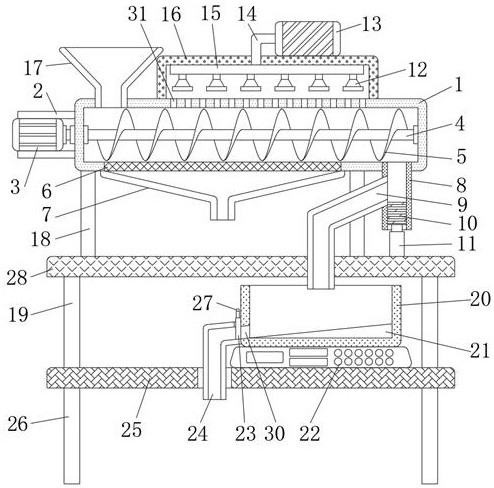

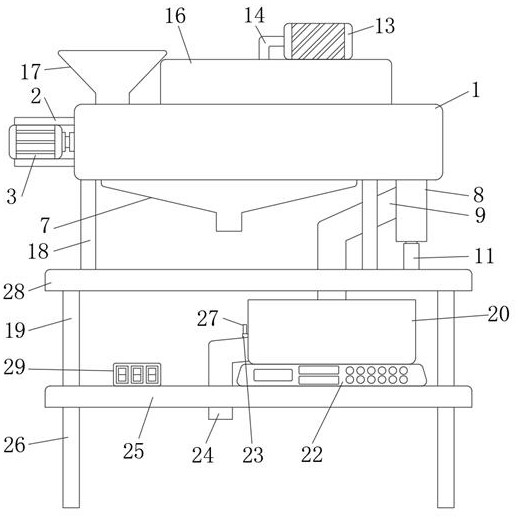

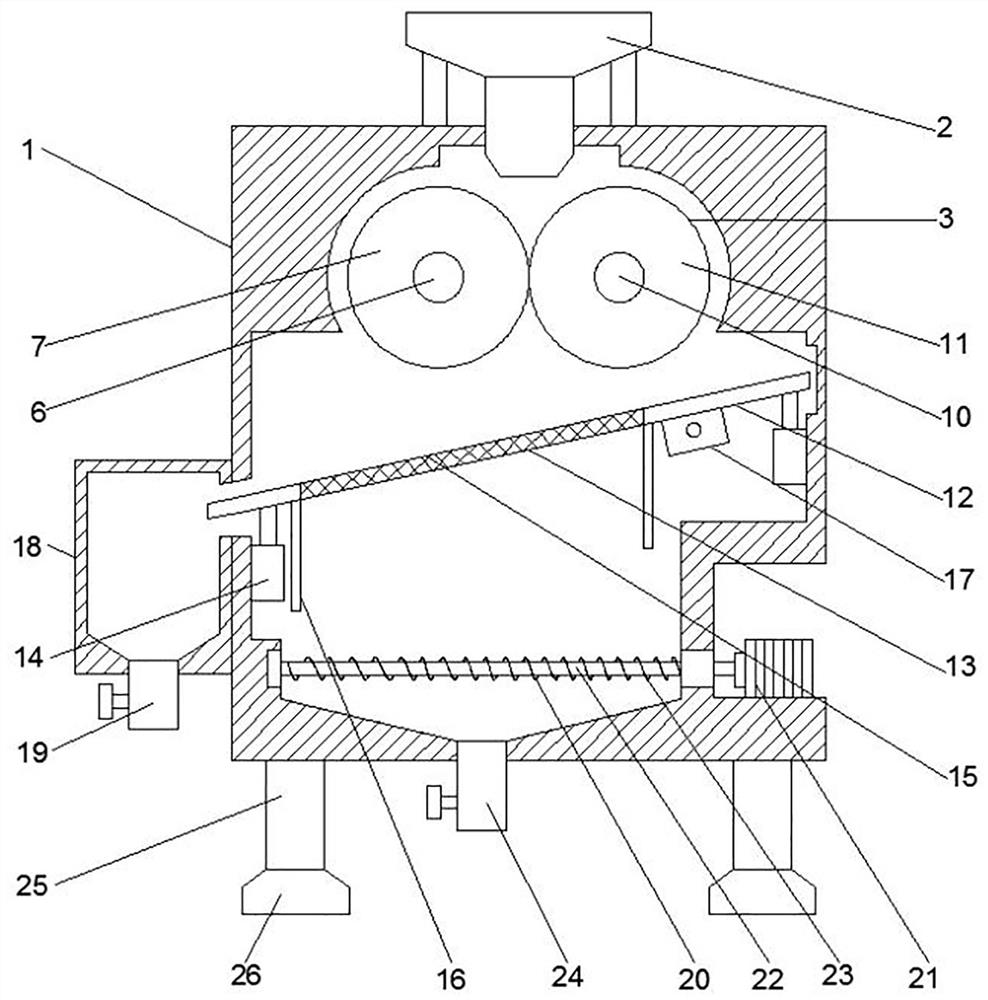

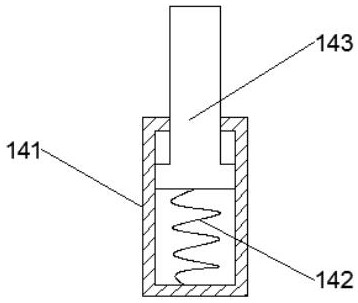

Recycled concrete aggregate machining device

InactiveCN110339995ARealize cleaning and removing impuritiesEffective classificationSievingGas current separationWater dischargeEngineering

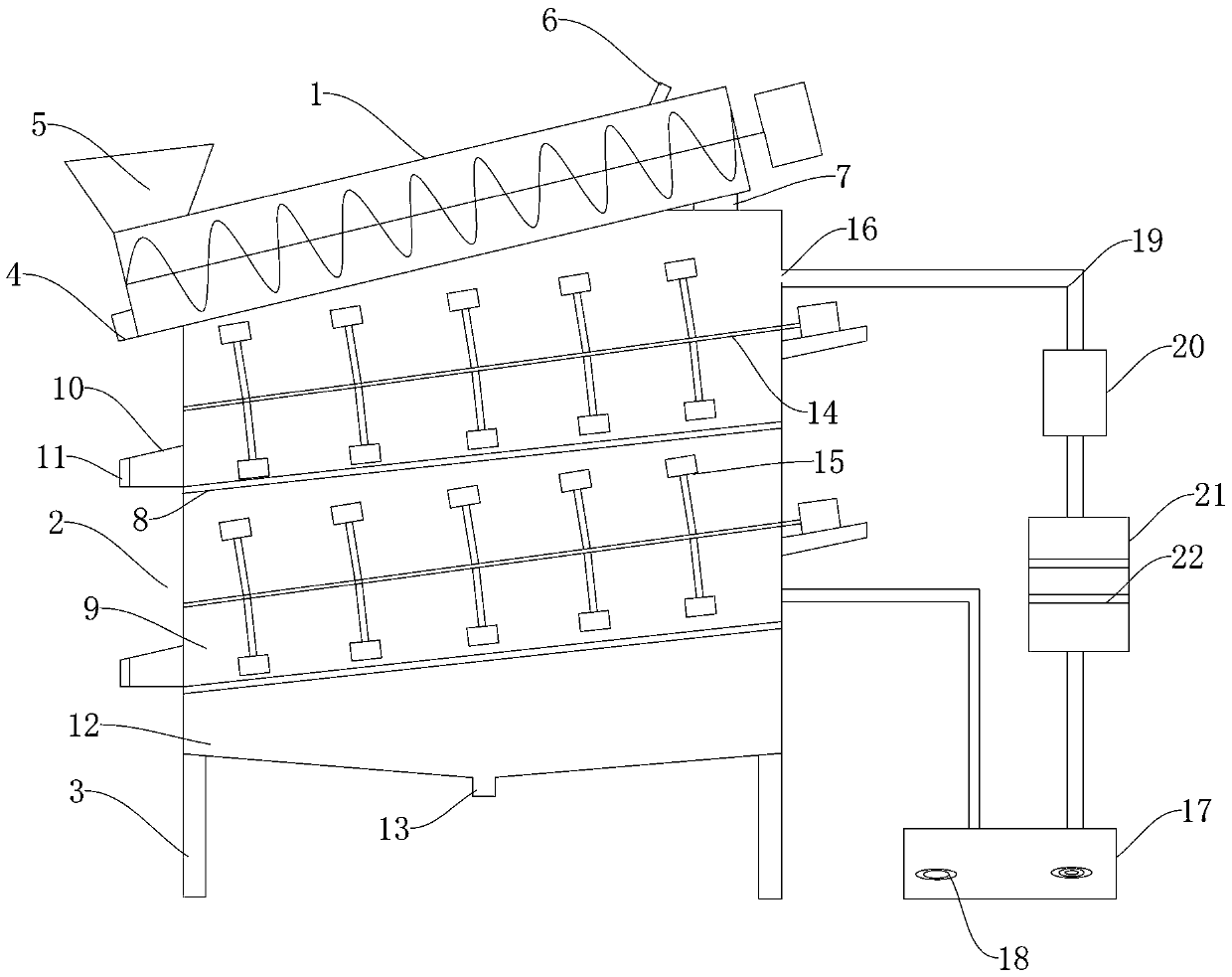

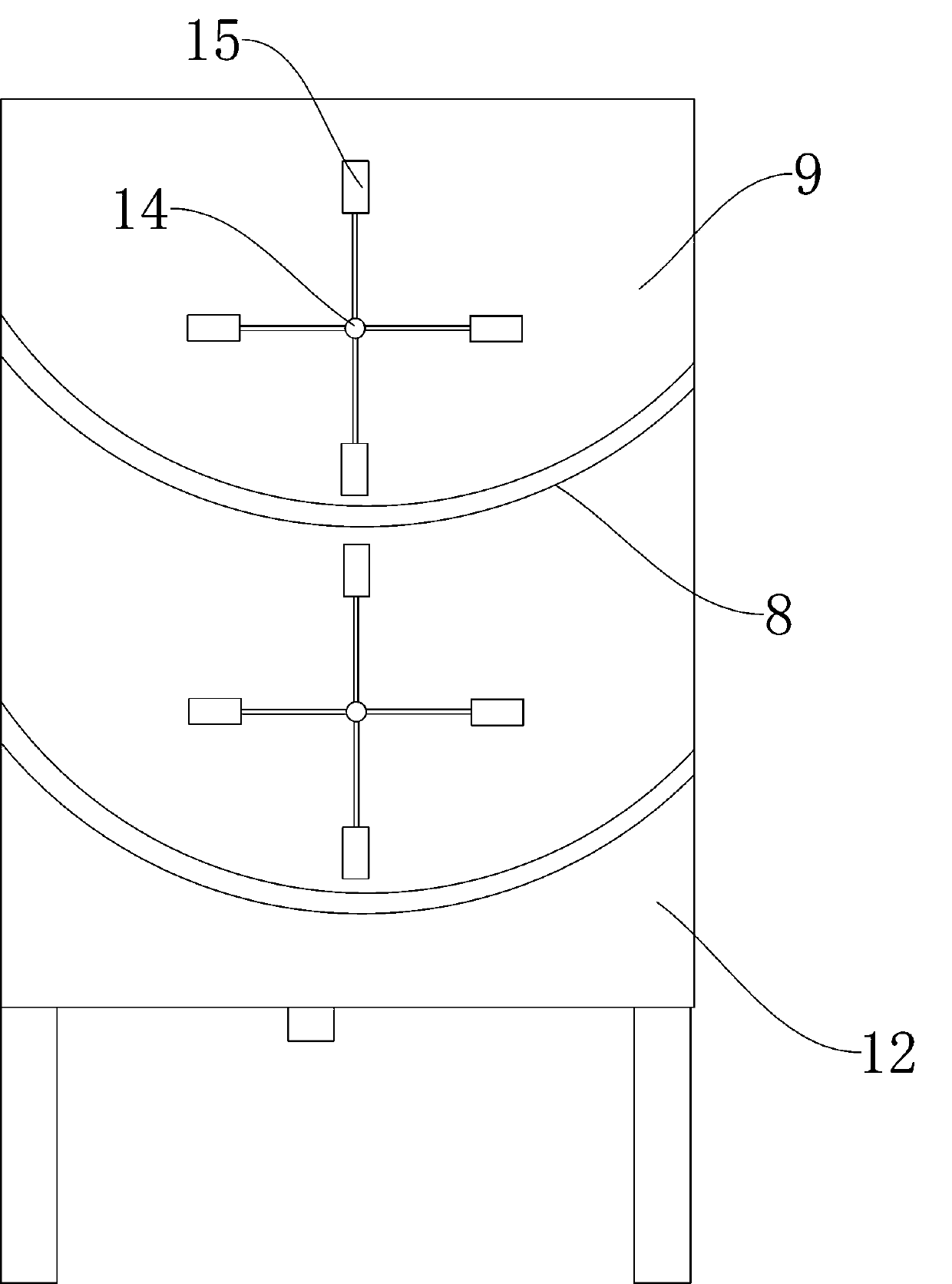

The invention provides a recycled concrete aggregate machining device. The recycled concrete aggregate machining device comprises a spiral conveyor and a screening box, wherein the spiral conveyor isobliquely arranged, the screening box is arranged below the spiral conveyor, a supporting frame is arranged at the lower end of the screening box, a material leaking port is formed in the lower end ofthe spiral conveyor, a material inlet is arranged at the position over the lower end, a water inlet is formed in the higher end of the spiral conveyor, a discharging end is arranged under the higherend of the spiral conveyor, the discharging end is in communication with the screening box, the screening box is provided with a plurality of layers of screens from top to bottom, the hole diameters of the screens are gradually reduced from top to bottom, the screening box is divided into a plurality of stirring cavities by the screens, each stirring cavity is provided with a material discharge port, the material discharge ports are provided with sealing plates, a water collecting cavity is arranged below the lowermost layer of screens, a water discharge port is formed in the water collectingcavity, stirring shafts are arranged in the stirring cavities, blades are arranged on the stirring shafts, and the stirring shafts are driven by a motor. According to the recycled concrete aggregate machining device, cleaning and impurity removal and screening of recycled concrete aggregate can be carried out at the same time, the operation is simple, the production efficiency is improved, and theenvironmental pollution is small.

Owner:湖北乾奥建设工程有限公司

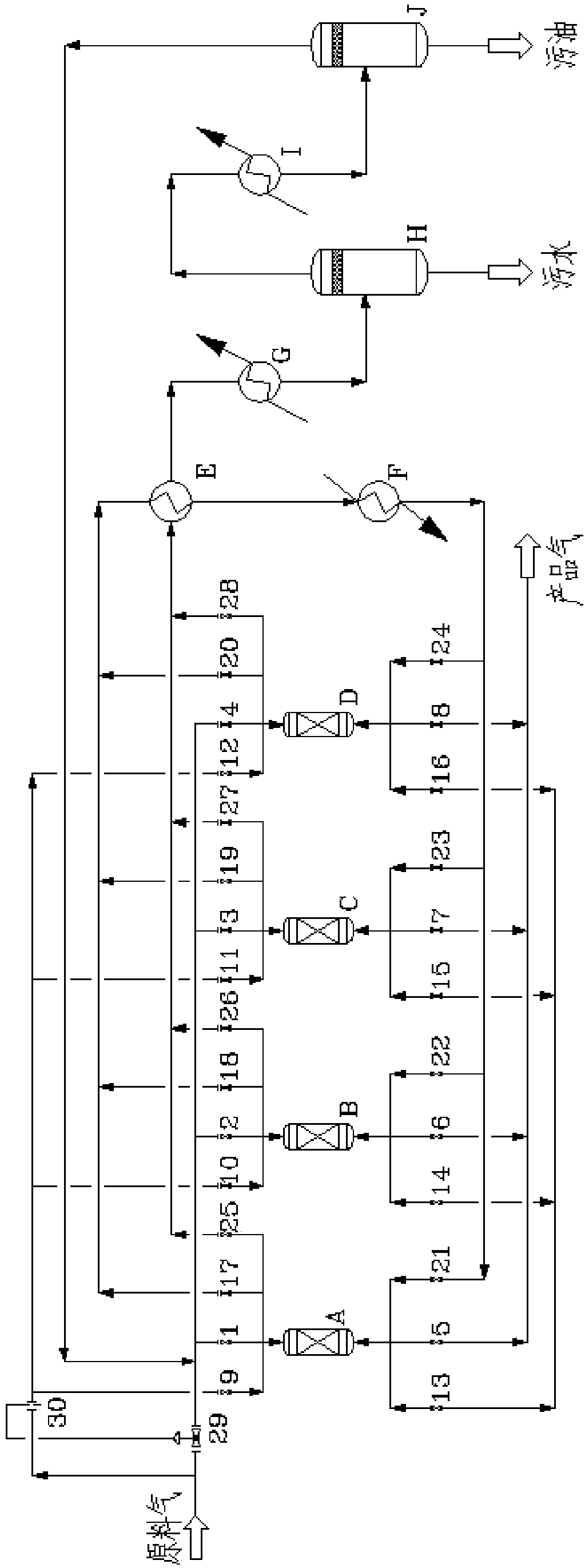

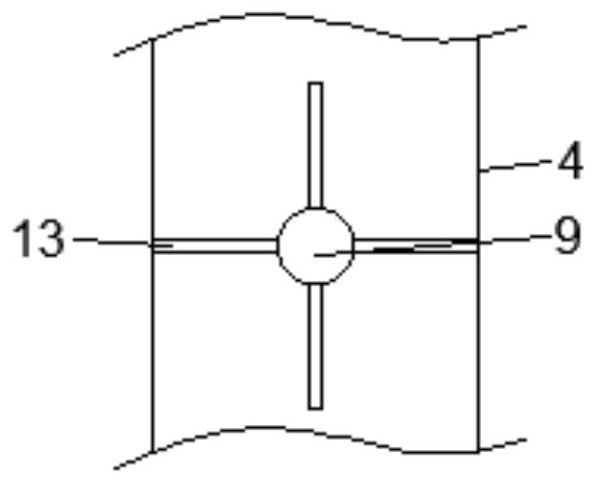

Device for dewatering and dealkylating methane-rich gas

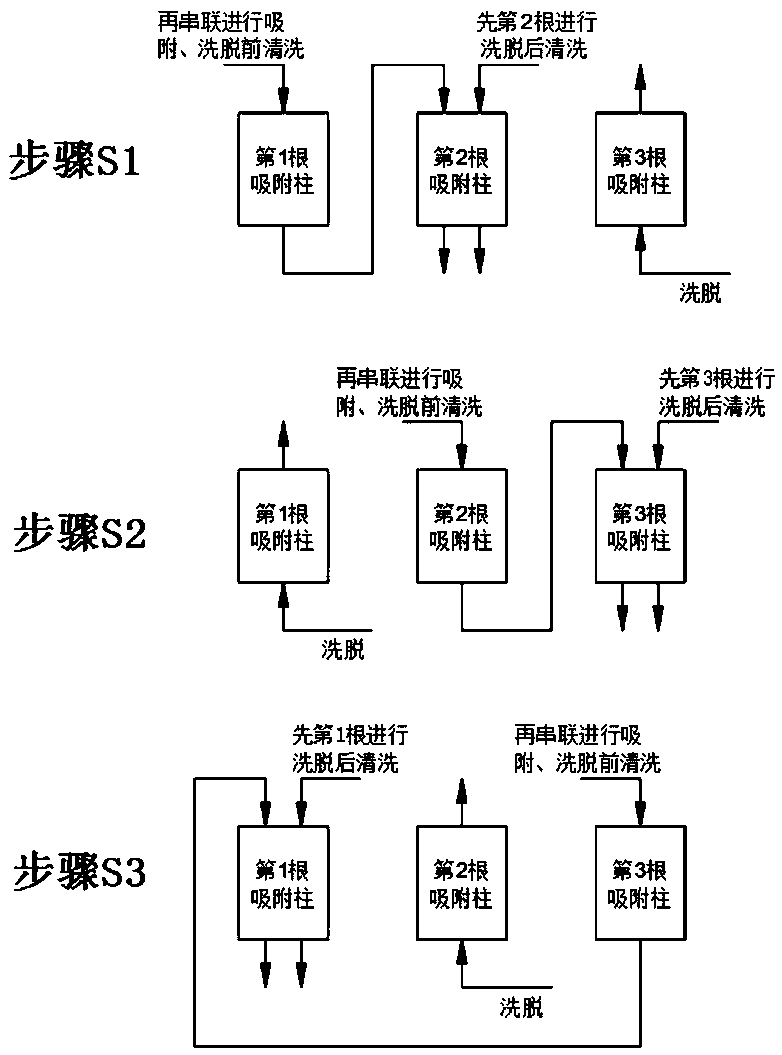

ActiveCN104368221AAchieve adsorptionRealize the heating effectGaseous fuelsDispersed particle separationProcess engineeringProduct gas

The invention provides a device for dewatering and dealkylating methane-rich gas. The device comprises a first gas feeding pipeline, a gas producing pipeline, a second gas feeding pipeline, a circulating-gas pipeline, a cooling-gas pipeline and a heat exchanger (E), wherein a first gas inlet of the heat exchanger is communicated with the cooling-gas pipeline. The device also comprises a heater (F), a heating gas pipeline, a desorbing gas pipeline, a cooler, a separator, four adsorbing towers and valves. The device provided by the invention comprises three independent gas channels, the four adsorbing towers form three gas channels and work simultaneously by controlling different valves, so that the heat is fully utilized and the energy consumption is reduced, simultaneously the operating load of the heater and the cooler is stabilized, and the operation of the whole device is stable. Therefore, the four adsorbing towers carry out different treating processes, and the heat is repeatedly utilized, so that the energy consumption is greatly saved.

Owner:SICHUAN HENGRI GAS ENG CO LTD

Tea processing machine and processing method thereof

ActiveCN112841331AImprove vibrationEasy to separatePre-extraction tea treatmentWrapper twisting/gatheringCartoning machineElectric machinery

The invention discloses a tea processing machine and a processing method thereof. The tea processing machine comprises a feeding machine box, a feeding pipe is vertically arranged on the rear portion of the upper left side of the feeding machine box, an impurity removing and guiding mechanism is arranged between the lower end of the feeding pipe and the inner side of the feeding machine box, and a rotary weighing mechanism is arranged on the rear side of the lower end of the feeding machine box; and a boxing mechanism is arranged on the lower side of the rotary weighing mechanism. A first driving motor drives a transmission wheel and a transmission rubber rope on the upper left side to rotate, and meanwhile, a high-pressure air pump is started to suck air, so that fine holes in a bottom plate of an air guide hollow body generate strong negative pressure, a suction effect is generated on tea leaves in a feeding transition box, and the tea leaves abut against the side wall of an inner ring of the transmission rubber rope; and then vibration impurity removal is conducted in the transmission process, finally, the materials are discharged to the rotary weighing mechanism, weighing is conducted through a weighing supporting plate, when the corresponding weight is reached, the materials are automatically discharged downwards, fall into a packaging barrel and then are sealed.

Owner:里森食品(广州)有限公司

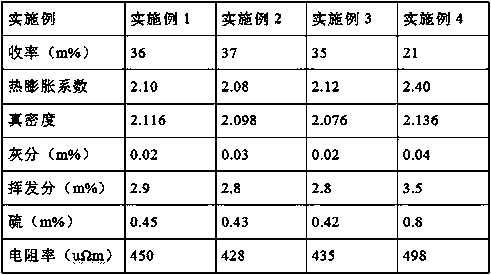

Needle-like petroleum coke and processing process thereof

ActiveCN109777460AProportion design is reasonableOptimize the preparation processTreatment with plural serial refining stagesCoking carbonaceous materialsWaxChemistry

The invention discloses needle-like petroleum coke and a processing process thereof. Raw materials of the needle-like petroleum coke include catalytic cracking clarified oil, heavy coker wax oil and cellulose. Catalytic cracking oil slurry is a heavy product at the bottom of a main fractionating column in FCC equipment, consists of unconverted hydrocarbons the boiling point of which is 383-593 DEGC, and is one of the best raw materials for preparing the needle-like petroleum coke at present, but is limited in amount, and needle-like coke prepared from the catalytic cracking oil slurry cannotmeet market demands. Our research puts emphasis on preparation of needle-like petroleum coke through co-carbonization of two different raw materials. The ratio is reasonable in design, the preparing process is optimized, so that impurity removing and purification of the catalytic cracking oil slurry can be achieved, the catalytic cracking oil slurry can be fully utilized, the yield of needle-likepetroleum coke is increased, and high-quality needle-like petroleum coke is prepared which has a wide application range and which is high in practicability.

Owner:湖南亿德新能源科技有限公司

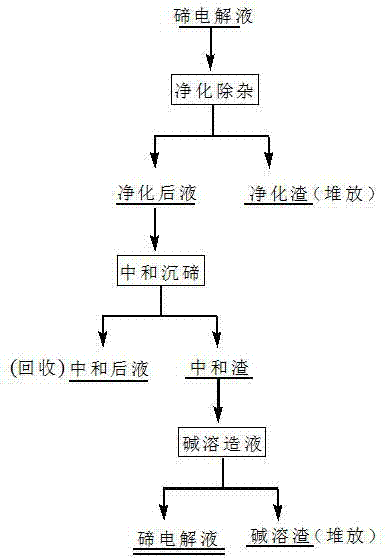

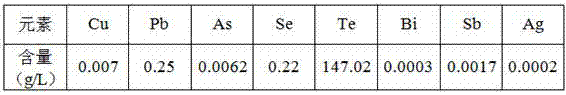

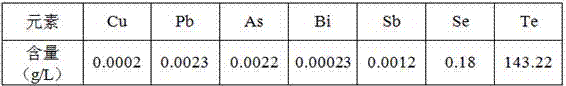

New method for removing impurities in tellurium electrolyte

InactiveCN105441970AAchieve purification effectRealize impurity removalElectrolysis componentsSolubilityFiltration

The invention relates to the technical field of metallurgy and discloses a new method for removing impurities in tellurium electrolyte. According to the method, the wet process for preparing qualified tellurium electrolyte by removing lead through purification, depositing tellurium through hydrolysis and dissolving tellurium dioxide through sodium hydroxide is adopted; after the lead is removed through sodium sulfide, a solution is subjected to neutralizing treatment through hydrochloric acid, and the pH is adjusted to 5-5.5; sodium tellurite (Na2TeO3) and sodium selenite (Na2SeO3) are hydrolyzed to generate tellurium dioxide (TeO2) and selenium dioxide (SeO2) respectively; the selenium dioxide has good solubility and can be dissolved into water and inorganic acid easily, and the tellurium dioxide has poor solubility within the pH range of 5-5.5; selenium and the tellurium are separated preliminarily; finally, tellurium dioxide is subjected to alkali dissolution and filtration to obtain the qualified tellurium electrolyte. By means of the method, purification and impurity removal of the tellurium electrolyte with high lead and selenium contents are effectively realized; the technological process is simple, the quantity and varieties of adopted raw materials are fewer, and the production cost is effectively lowered; energy consumption is less, and the recovery rate of the tellurium is high.

Owner:JINCHUAN GROUP LIMITED

Donkey-hide gelatin-tortoise shell gelatin-deer horn gelatin walnut cake and preparation method thereof

InactiveCN107440053AEffective absorptionPromote absorptionSugar food ingredientsFood ingredient functionsSesamumSugar

The invention relates to a donkey-hide gelatin-tortoise shell gelatin-deer horn gelatin walnut cake and a preparation method thereof. The donkey-hide gelatin-tortoise shell gelatin-deer horn gelatin walnut cake is prepared from the following components in parts by mass: 30 to 45 parts of donkey-hide gelatin, 5 to 7 parts of tortoise shell gelatin, 5 to 7 parts of horn deer gelatin, 35 to 40 parts of walnut kernels, 40 to 45 parts of black sesame, 45 to 50 parts of rocky sugar A, and 45 to 50 parts of yellow wine A. A preparation method of the donkey hide gelatin comprises the following steps of soaking donkey hide for 5 to 20 days under the water sealing condition; according to the mass ratio of water to donkey hide (2-6:1), adding drinking water into an extracting tank with weighed donkey hide, and heating to 100 to 120 DEG C under the sealing condition; extracting for about 15 to 20h for several times; discharging gelatin liquid, coarsely filtering the gelatin liquid, finely filtering, and concentrating under the vacuum condition; concentrating in opening type concentrating equipment, removing impurities, and adding filtered soybean oil, yellow wine and rocky sugar; continuing to stir, heating and concentrating; after concentrating, performing post-treatment, so as to obtain the donkey-hide gelatin. The invented donkey-hide gelatin-tortoise shell gelatin-deer horn gelatin walnut cake has good absorbing effect.

Owner:HUNAN DONGJIAN PHARMA CO LTD

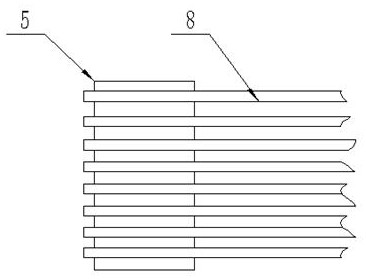

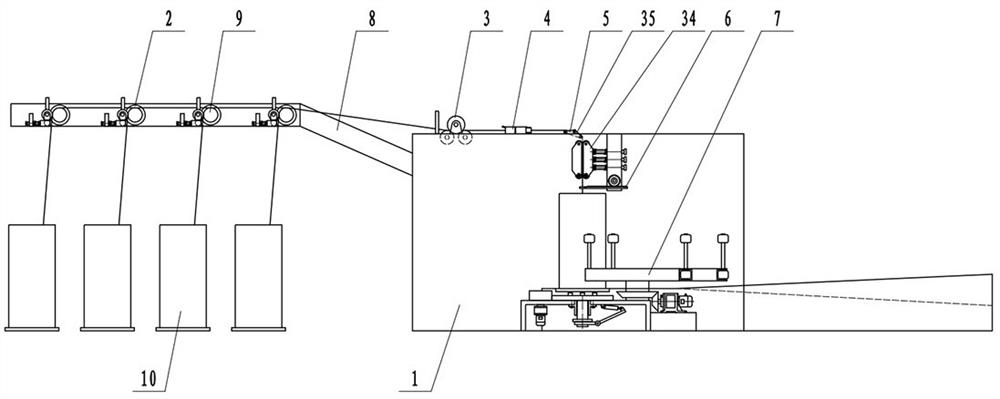

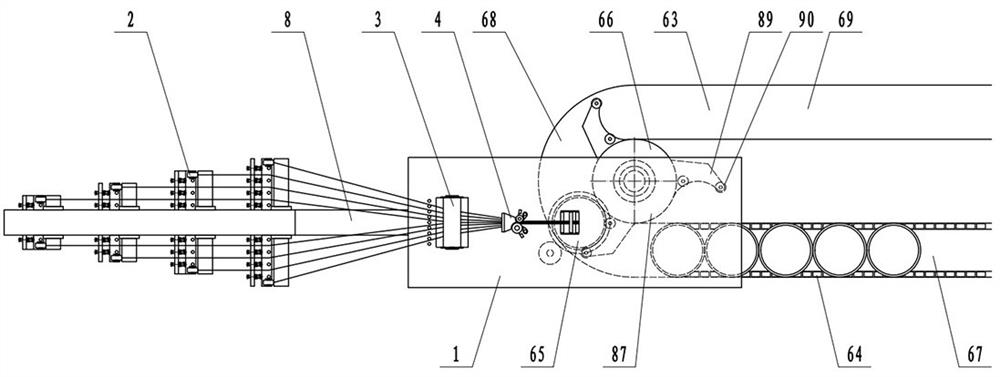

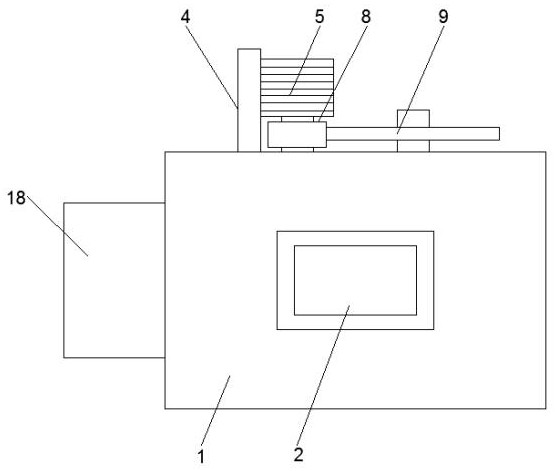

Full-automatic drawing frame

ActiveCN113403714AAvoid offsetRealize automatic can changeFibre cleaning/openingDrafting machinesBobbinElectric machinery

The invention provides a full-automatic drawing frame, and belongs to the technical field of textile machinery. The drawing frame comprises a drawing frame rack, a feeding device, a drafting device, a slivering device, a sliver pulling device, a doffing guide device and a bobbin replacing device; the sliver pulling device comprises a sliver pulling mechanism and a sliver pulling guide mechanism; the sliver pulling mechanism comprises a fixed sliver pulling assembly and a movable sliver pulling assembly; a fixed sliver pulling curtain and a movable sliver pulling curtain are both provided with gathering protruding strips which are inclined inwards; the bobbin replacing device comprises a U-shaped bobbin replacing table, a bobbin feeding roller, a bobbin rotating mechanism and a bobbin replacing mechanism; and the bobbin replacing mechanism comprises a bobbin replacing rotating disc, a bobbin replacing rotating disc supporting shaft, a bobbin replacing arc-shaped arm, a bobbin replacing pressing wheel assembly, a bobbin replacing motor, a first bobbin replacing bevel gear and a second bobbin replacing bevel gear. In the drawing process, slivers can be effectively prevented from deviating, the drawing effect is guaranteed, and automatic bobbin replacing after drawing can be achieved; and the structure is ingenious, the automation degree is high, and the drawing efficiency is greatly improved.

Owner:桐乡市建泰纺织有限公司

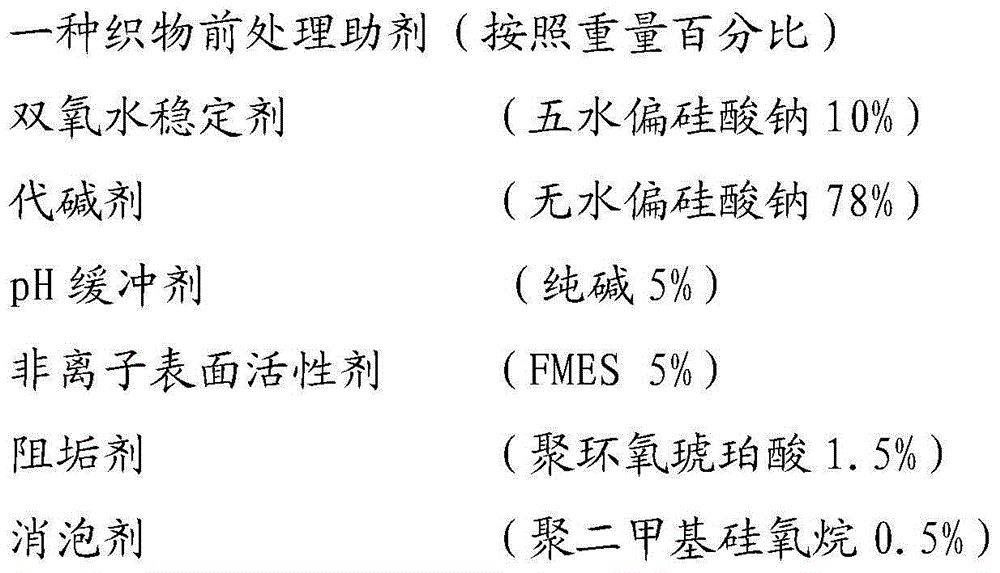

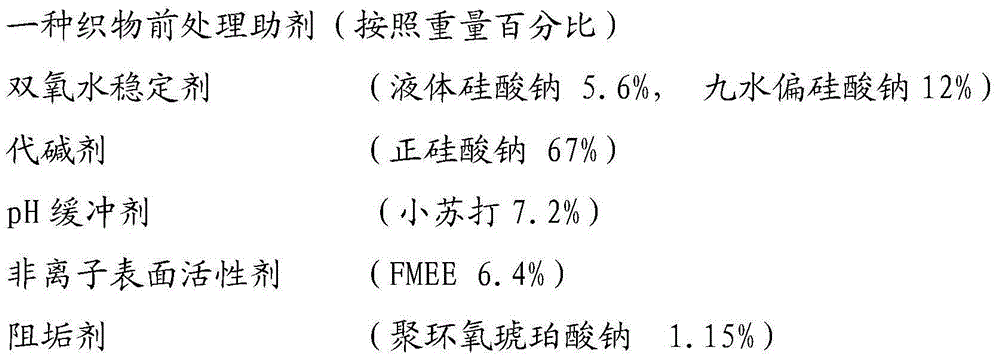

Fabric pre-treatment auxiliary

ActiveCN105155248AAchieve desizingRealize impurity removalDry-cleaning apparatus for textilesBleaching apparatusPh bufferingDecomposition

The invention belongs to the technical field of textile chemicals and relates to a fabric pre-treatment auxiliary. The fabric pre-treatment auxiliary is prepared from, by weight, 10-30% of hydrogen peroxide stabilizer, 50-78% of metabolic alcaldosis agent, 5-10% of pH buffering agent, 5-10% of nonionic surfactant, 1-2% of scale inhibitor and 0.5-1% of defoamer. The fabric pre-treatment auxiliary can be free from caustic soda flakes, provides an alkaline environment for stable hydrogen peroxide decomposition, is capable of descaling, environmentally friendly and nontoxic and guarantees that the whiteness, capillary effect and desizing rate of treated fabric meet the standards.

Owner:山东龙港硅业科技有限公司

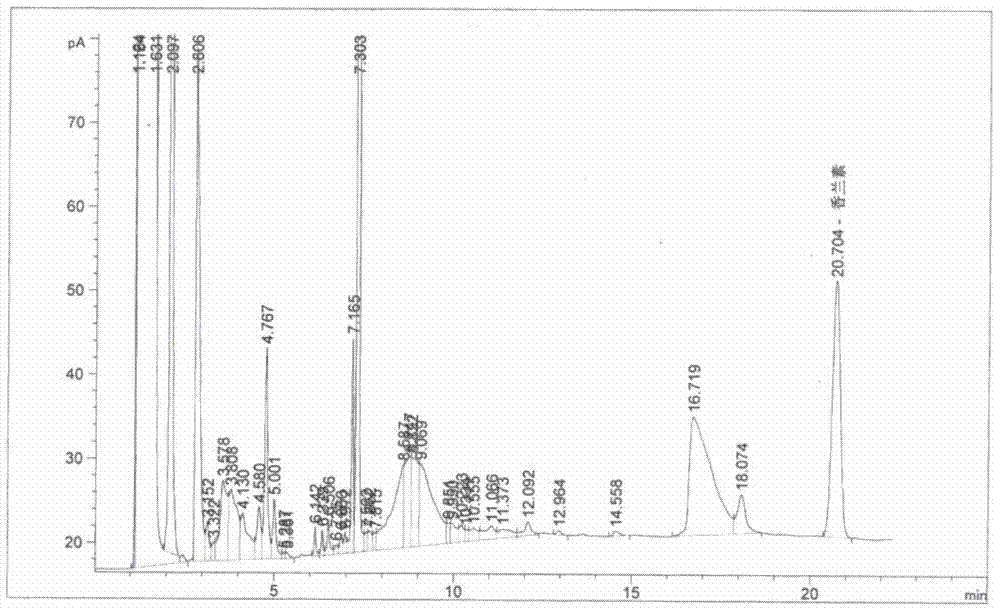

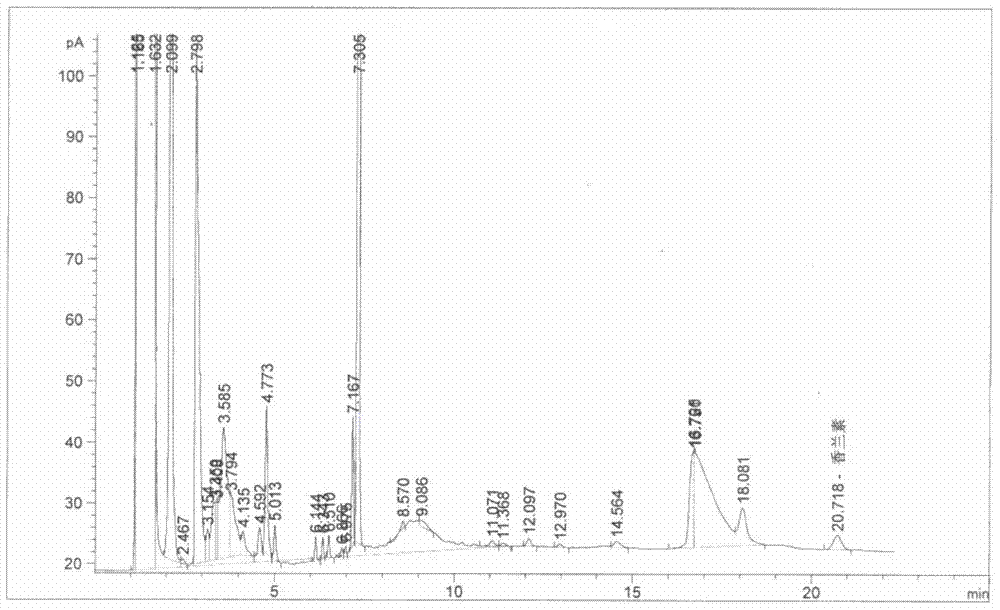

Detection method of vanillin in wine

ActiveCN103499655AFully extractedMeet the testing requirementsComponent separationAlcoholDiethyl ether

The invention discloses a detection method of vanillin in wine. The detection method of vanillin in wine comprises the following steps:1) preparing a standard liquid; 2) pretreating a sample, namely, weighing a sample of to-be-detected wine, and removing alcohol; 3) weighing the sample treated in the step 2), and extracting by adopting diethyl ether; 4) weighing the sample treated in the step 2), adding the configured standard liquid in the step 1), and extracting again by adopting diethyl ether; and 5) detecting the standard liquid prepared in the step 1), the sample treated in the step 3) and the sample treated in the step 4) by adopting a gas chromatograph. According to the detection method disclosed by the invention, the vanillin in wine can be extracted fully by a diethyl ether liquid-liquid extraction mode so as to achieve impurity removal and enrichment to conform to the detection requirement by a gas chromatographic (GC) method, and accurate quantification is realized through an external standard method by the standard sample recovery rate correcting and extracting efficiency.

Owner:浙江塔牌绍兴酒有限公司

Production method of health-care baijiu

InactiveCN108977306AHigh yieldStrong fragranceDigestive systemAntinoxious agentsActivated carbonHusk

The invention discloses a production method of health-care baijiu. The production method comprises the following steps of mixing sorghum, corns, wheat, buckwheat, polished round-grained rice and jujubes, soaking a mixture with water, mixing the soaked mixture with rice husks and bran, adding a urease-producing bacterium solution for material moisture treatment, performing retort filling for steaming, and performing discharging from the retort to obtain cooked grains; cooling the cooked grains, adding distiller's yeast for uniform stirring, adding the urease-producing bacterium solution to obtain a mixed fermented feed, performing stacking fermentation on the mixed fermented feed, and putting the mixed fermented feed after stacking fermentation into a pool for fermentation to obtain fermented grains; removing kernels of pawpaw, peaches and avocados, mixing the pawpaw, the peaches and the avocados after kernel removal with grapes, apples, fructus lycii, rhizoma dioscoreae, blueberries, olives, lotus seeds and spirulina, and performing pulping to obtain a slurry; mixing flos chrysanthemi indici, fiveleaf gynostemma herb, bulbus lilii, folium mori, folium isatidis with folium apocyni veneti, and performing extraction and concentration to obtain a leaching solution; mixing the fermented grains, the slurry and the leaching solution, and adding a fermenting enzyme for fermentation toobtain a brut; distilling the brut to obtain a base liquor; and adding activated carbon into the base liquor for adsorption, and performing freeze filtering, storage and blending to obtain the health-care baijiu.

Owner:安徽省碧绿春生物科技有限公司

Production method for multiple-grains type Baijiu

InactiveCN108949418AStrong fragranceHigh nutritional valueMicroorganism based processesAlcoholic beverage preparationBiotechnologyFiltration

The invention discloses a production method for multiple-grains type Baijiu. The production method comprises the following steps: mixing, by weight, 30-45 parts of sorghum rice, 3-8 parts of corn, 10-20 parts of wheat, 8-15 parts of buckwheat and 10-15 parts of polished round-grained rice, adding the mixture to water for immersing, then performing primary steaming and boiling, and mixing the mixture with 5-10 parts of rice husk, 2-5 parts of bran, 2-7 parts of compound fruits and 2-9 parts of common yam rhizome; performing secondary steaming and boiling after urease-producing bacteria liquid moistening material is added, adding 3-8 parts of water and taking out from a resort, cooling, add 5-8 parts of daqu, 8-12 parts of aspergillus candidus, 2-5 parts of aroma-producing yeast and uniformly stirring, performing stacking fermentation after a urease-producing bacteria liquid is added, and fermenting in a pool to obtain fermented grains materials; and adding activated carbon after distillation and performing adsorption, storing after freezing and filtration, and preparing the multiple-grains type Baijiu by blending. The production method for the multiple-grains type Baijiu has the advantages of simple process, high production efficiency and high liquor yield; and the obtained Baijiu is clear and transparent, is pure in taste, is high in quality, and is stable.

Owner:安徽省碧绿春生物科技有限公司

Circulating hot-air drying furnace

InactiveCN107940898AEnsure stabilityNot prone to looseningDrying solid materials with heatDrying gas arrangementsPulp and paper industryCentrifugal force

The invention discloses a circulating hot air drying furnace, which comprises a drying furnace shell and a rotating main shaft. A motor is installed at the center of the bottom end of the drying furnace shell, and the output rotating shaft of the motor is connected with the rotating main shaft through a coupling. One end of the rotating main shaft is equipped with an impurity collection cylinder, one end of the fixed shaft is equipped with a slider, and the inside of the drying furnace shell is equipped with a disc track, and the disc track is connected with four sliders , the top of the drying furnace shell is equipped with a hot air blower, one end of the hot air blower is connected with a hot air pipe, the hot air pipe is connected with the drying furnace shell, and the gas filter and the circulating fan are connected with a A gas pipeline, a furnace door is arranged on the surface of the drying furnace shell. In the present invention, due to the action of centrifugal force, the porous cylinder can throw the impurities in the raw materials into the impurity collection cylinder to realize the removal of impurities from the raw materials, and at the same time speed up the contact surface between the raw materials and the hot air, so as to speed up the drying efficiency of the materials.

Owner:潍坊金聖铸造材料有限公司

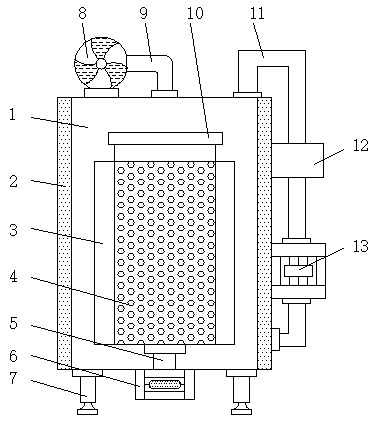

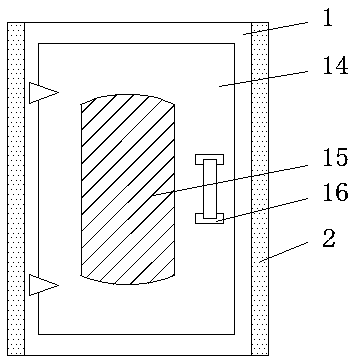

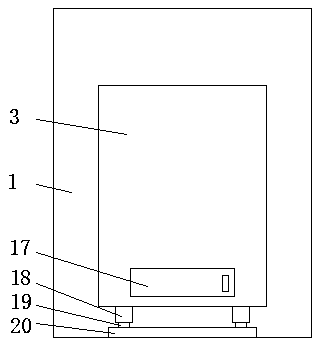

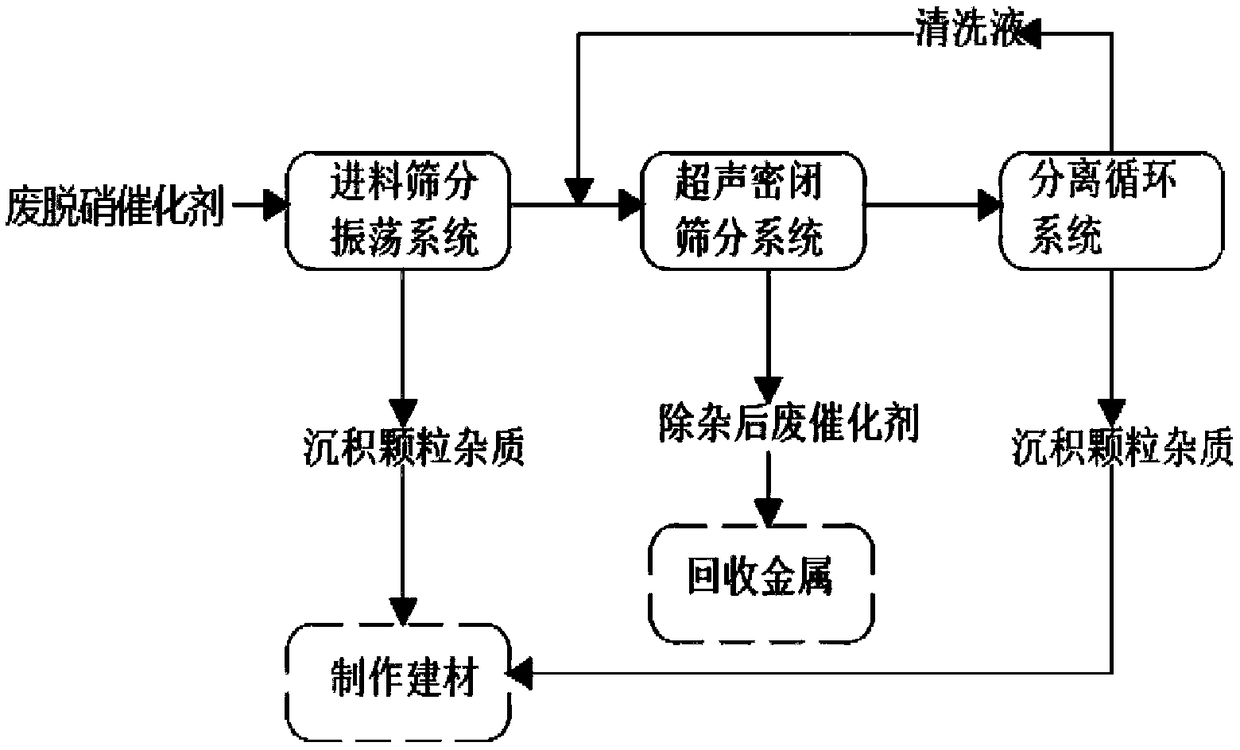

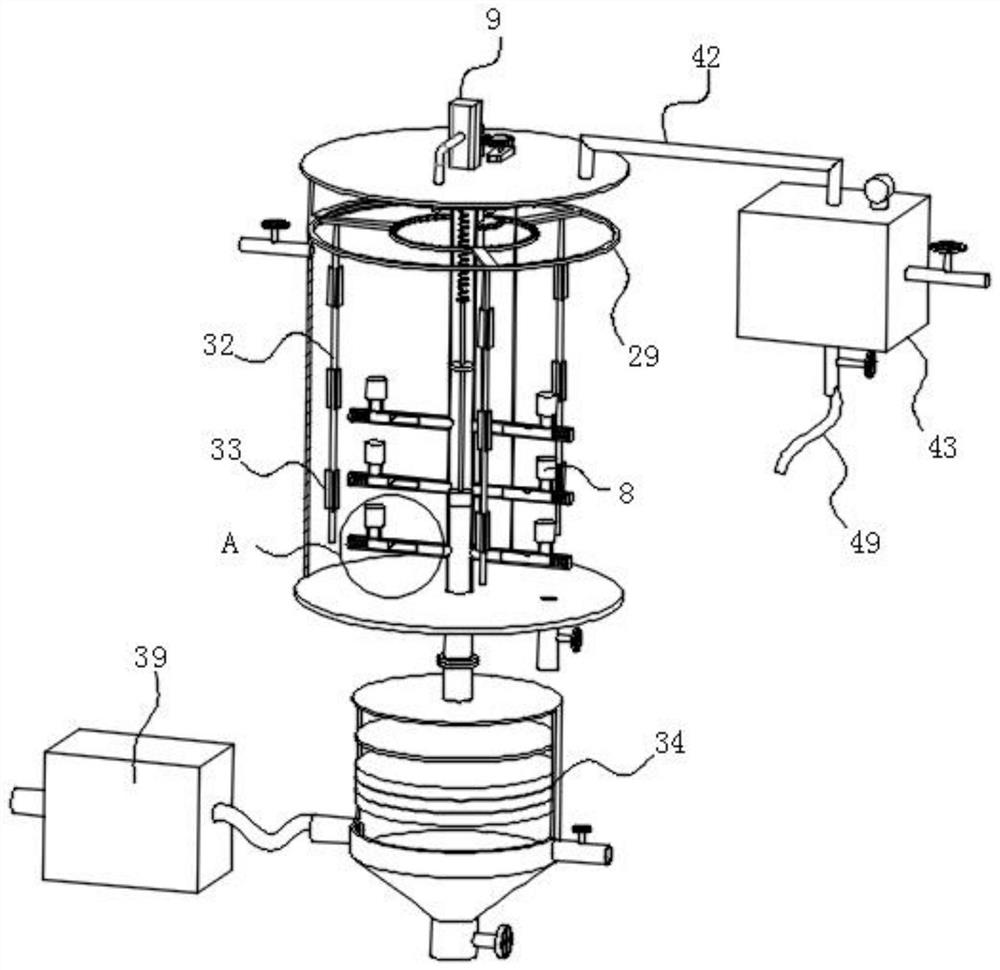

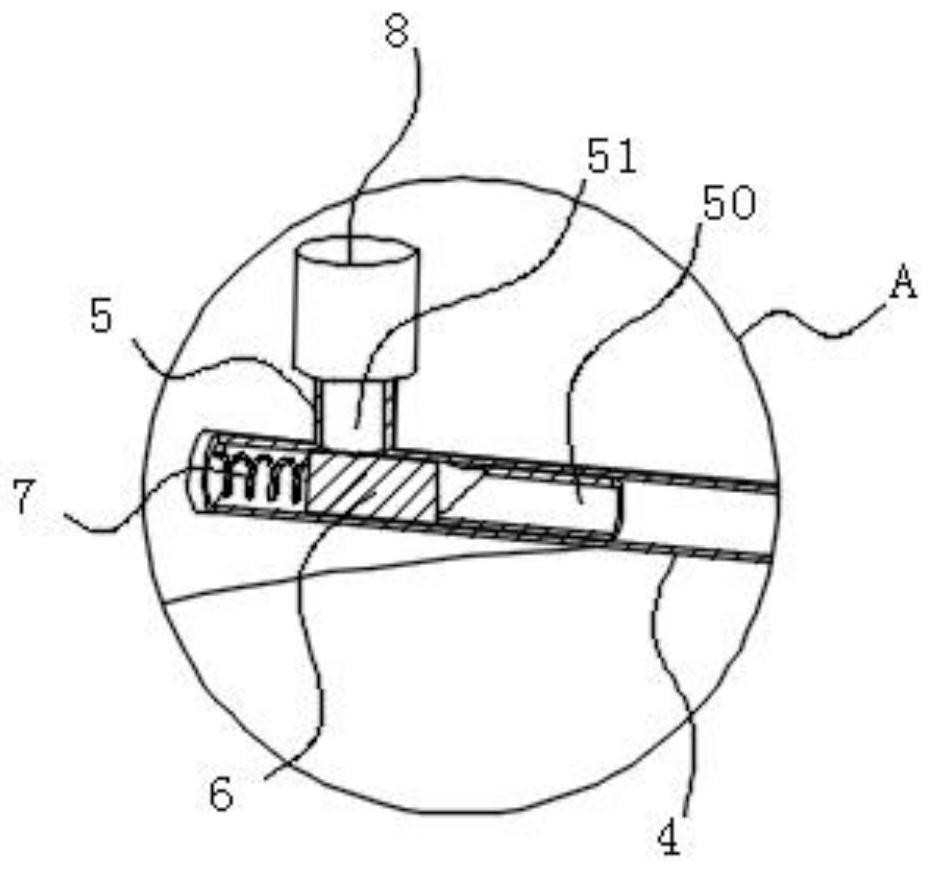

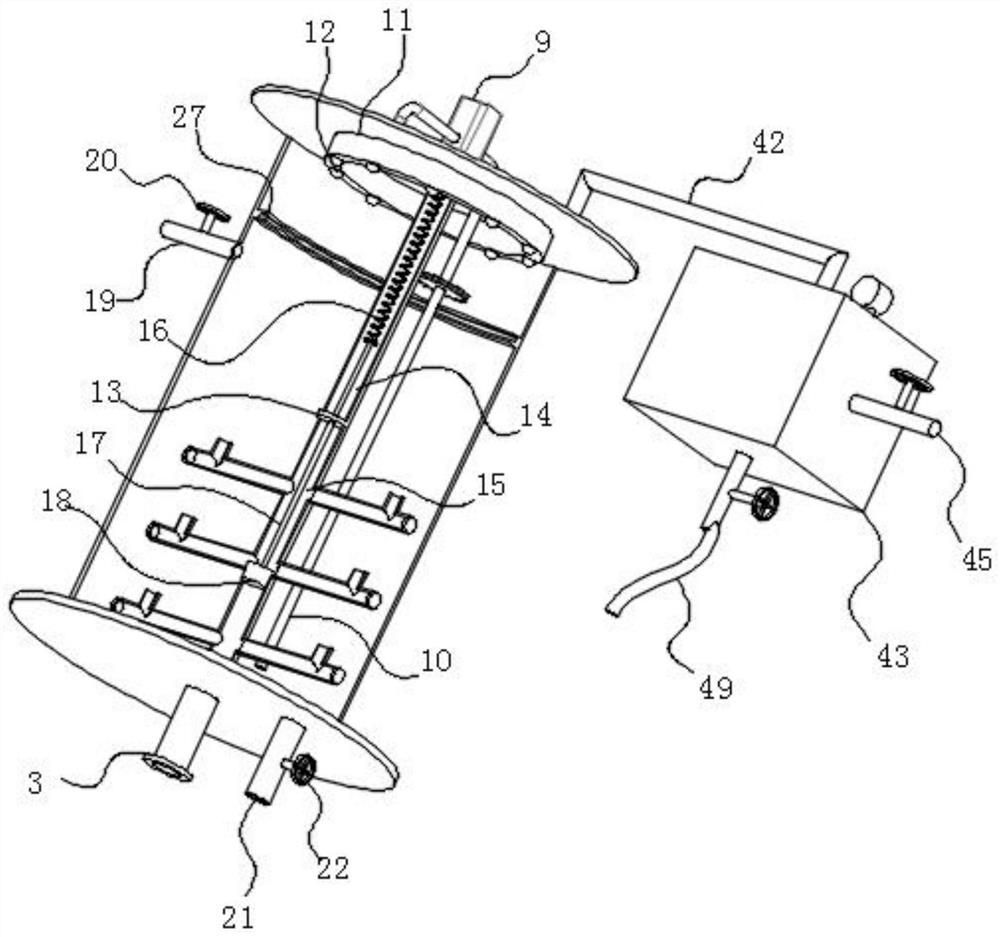

Device used for separating impurities in waste denitration catalyst and using method of device

InactiveCN109261494AEnhanced physical separation efficiencyEfficient separationSievingScreeningFly ashImpurity

The invention relates to a device used for separating impurities in a waste denitration catalyst and a using method of the device. The device comprises a feeding screening vibration system, an ultrasonic closed screening system and a separation circulation system which are connected with one another in sequence. In the technological process, the feeding screening vibration system is adopted for preliminarily separating the impurities, then the ultrasonic closed screening system is utilized for further removing soluble impurities and fly ash particles on the waste denitration catalyst, and thusthe efficiency of separating the impurities is improved; the separation circulation system is utilized for recycling cleaning liquid, and thus the impurity removal cost is reduced.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

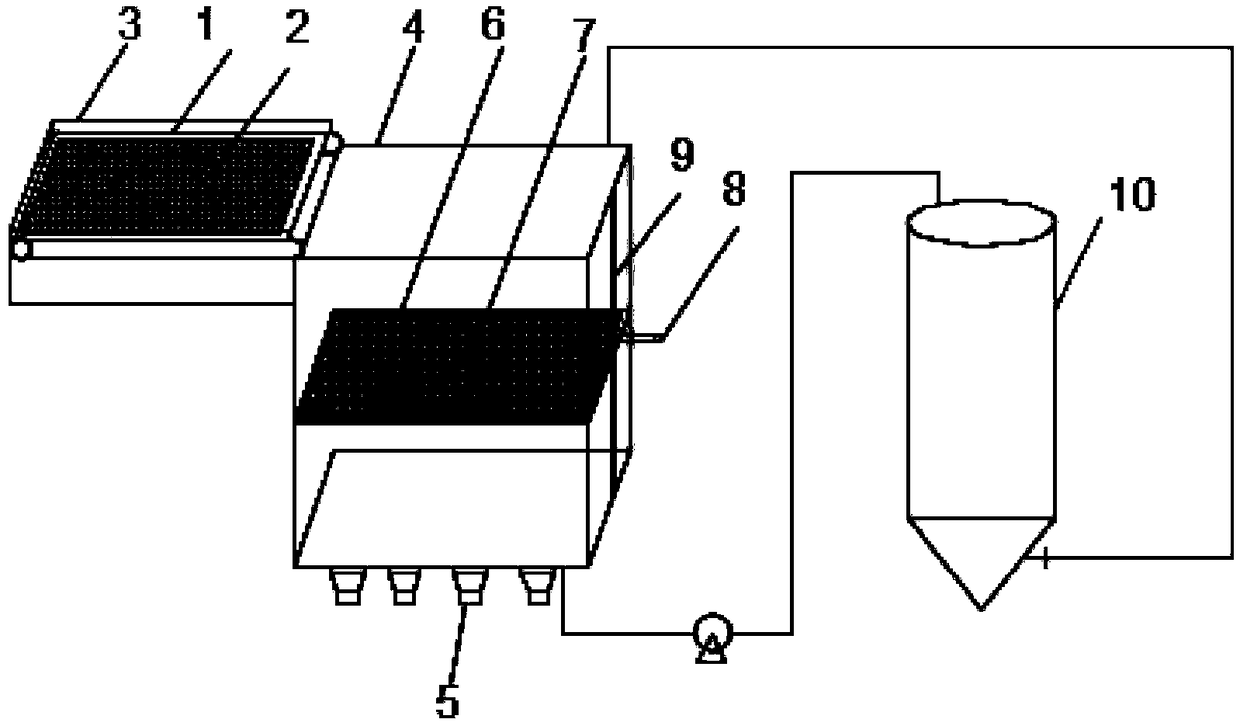

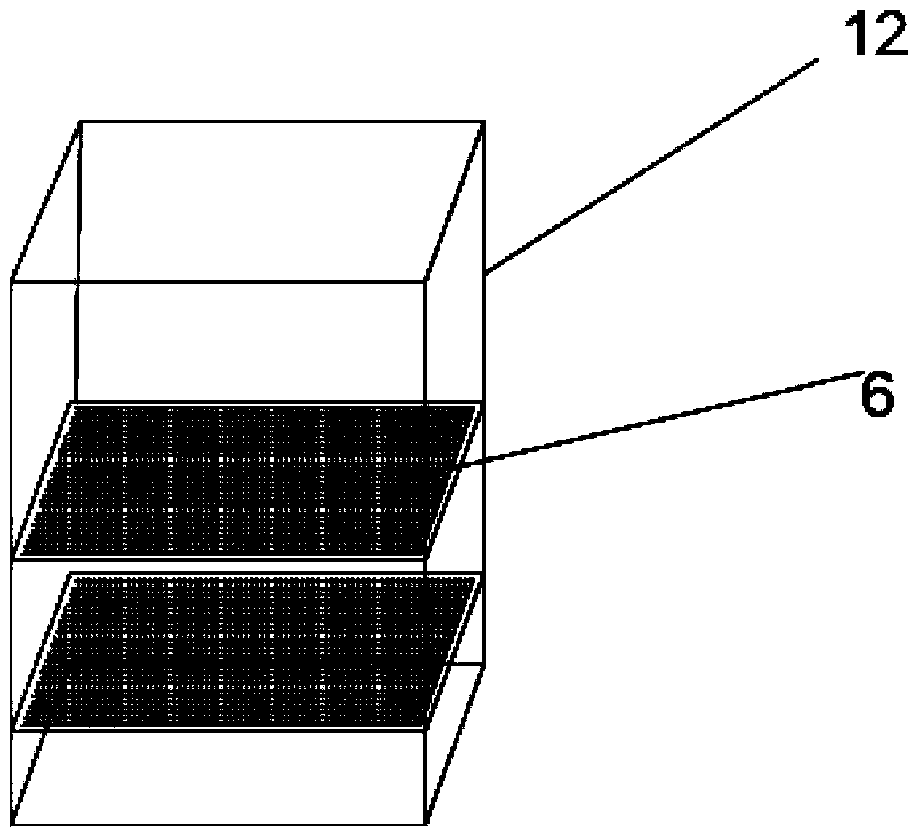

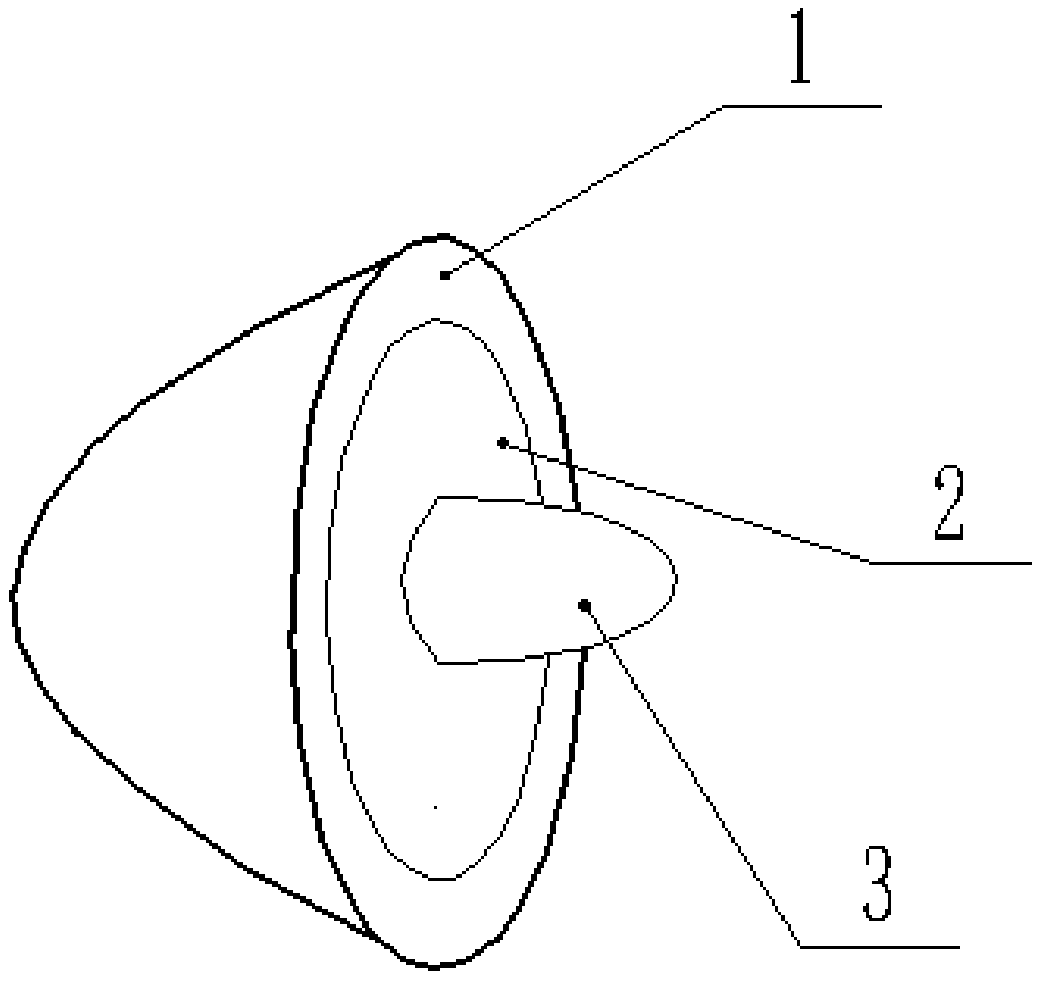

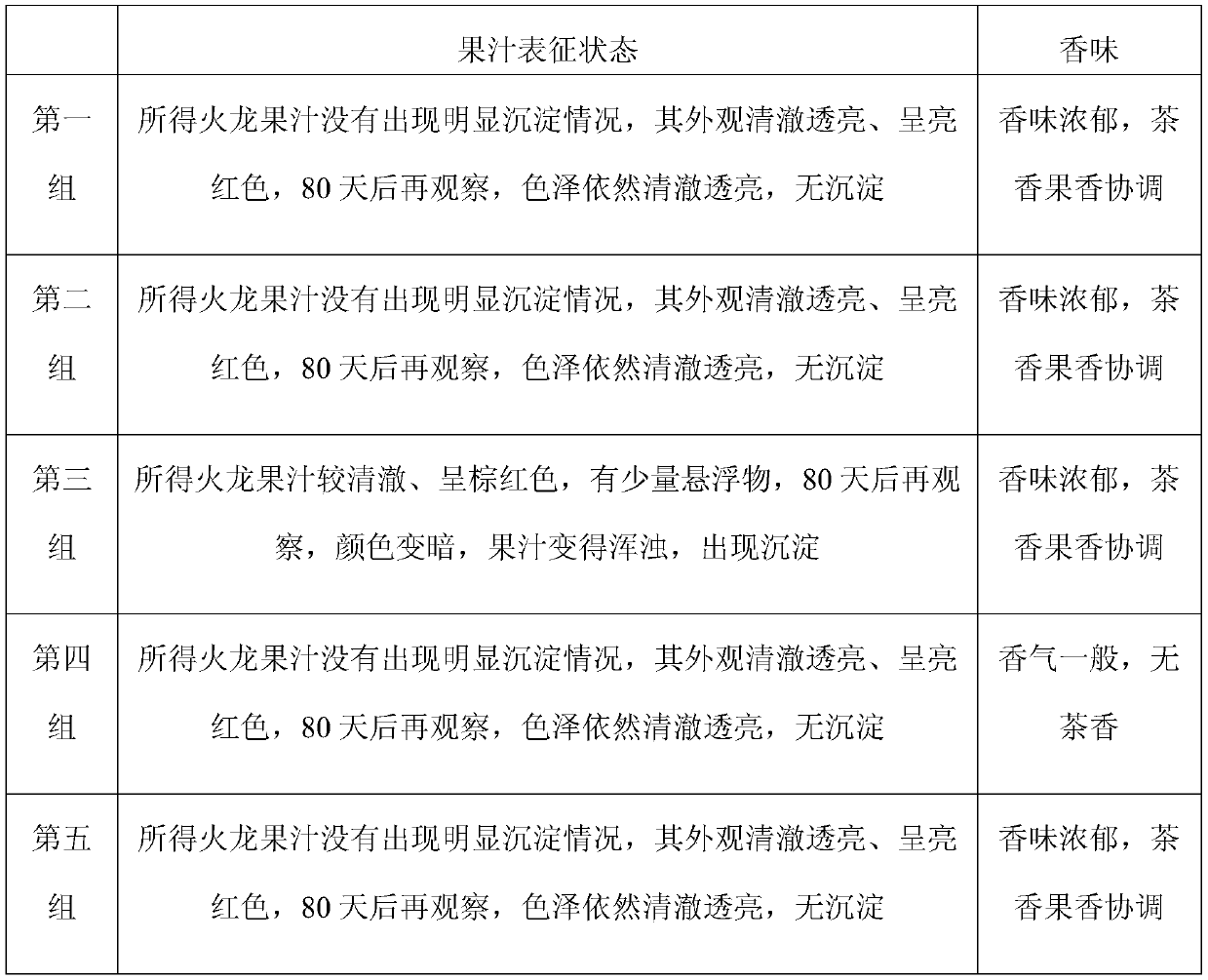

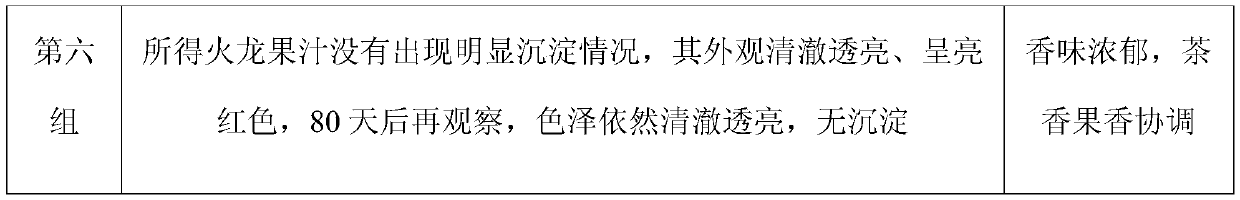

Preparation method of pitaya juice

PendingCN110881594ABright colorDelicate and refreshing tasteFood ingredient as antioxidantFood ingredient as colourBiotechnologyFruit juice

The invention, which relates to the technical field of beverage processing, provides a preparation method of pitaya juice. The preparation method of the pitaya juice comprises the following steps: (1), carrying out pitaya pretreatment; (2), carrying out peel treatment; (3) carrying out pulp treatment; (4), carrying out juice blending; (5), carrying out juice treatment; and (6), carrying out filling and sterilization. The pectin and haematochrome in peels are extracted as additives to prepare pitaya juice, so that waste is turned into wealth and the comprehensive utilization rate of pitaya is greatly increased; and the prepared pitaya juice is clear and bright in color and luster, refreshing and fine in taste, uniform and stable in juice state and harmonious and rich in aroma.

Owner:GUANGXI ZHUANG AUTONOMOUS REGION ACAD OF AGRI SCI

Quantitative packaging device for rice processing

InactiveCN112441265AReduce moistureImprove screening effectSievingScreeningAgricultural scienceAgricultural engineering

The invention discloses a quantitative packaging device for rice processing, and relates to the technical field of rice processing. The quantitative packaging device comprises a conveying cylinder, wherein two mounting seats are fixedly connected to the left side surface of the conveying cylinder, a motor is fixedly mounted between the two mounting seats, and an output shaft of the motor is fixedly connected with the left end of a rotating shaft. According to the quantitative packaging device for rice processing, through cooperation of an air heater, an air discharging pipe and a connecting pipe, a plurality of air discharging heads blow hot air, then the hot air is blown to rice through a plurality of air discharging holes, and then the rice is dried and dehumidified, so that moisture inthe rice is reduced, and the position of the rice is continuously changed in the conveying process of a spiral conveying wheel; and on one hand, the screening effect on the rice can be improved, and on the other hand, the drying effect on the rice can be improved, so that impurity removal and drying of the rice are achieved, the quality of the rice is guaranteed, storage of the rice is facilitated, and the use requirements of users are met.

Owner:常德市龙凤米业有限公司

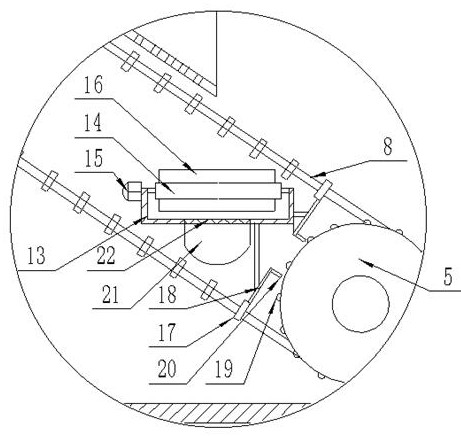

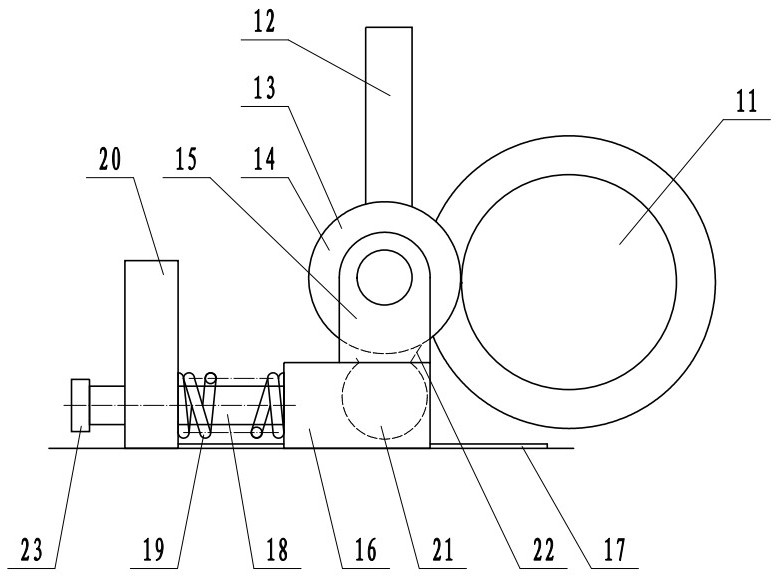

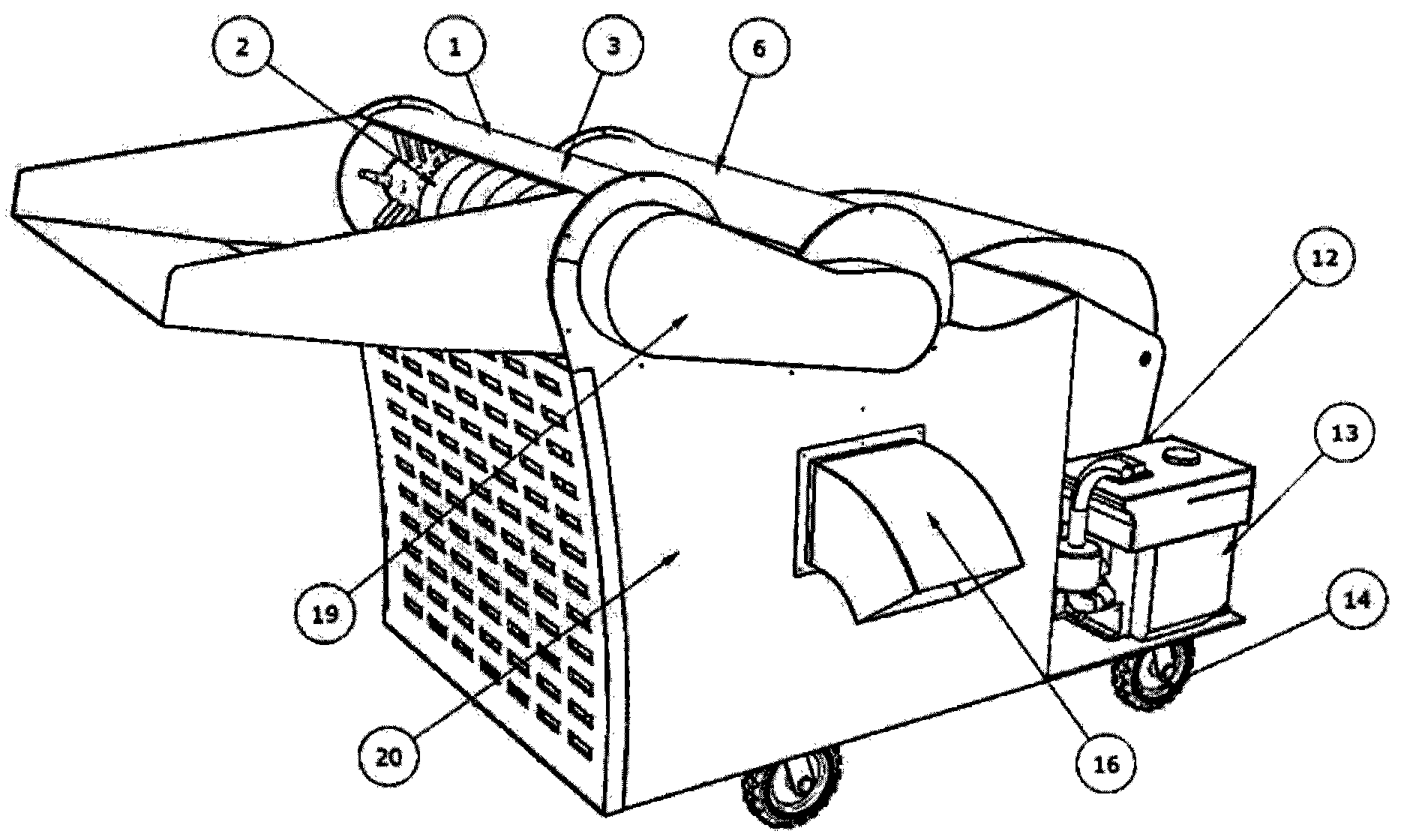

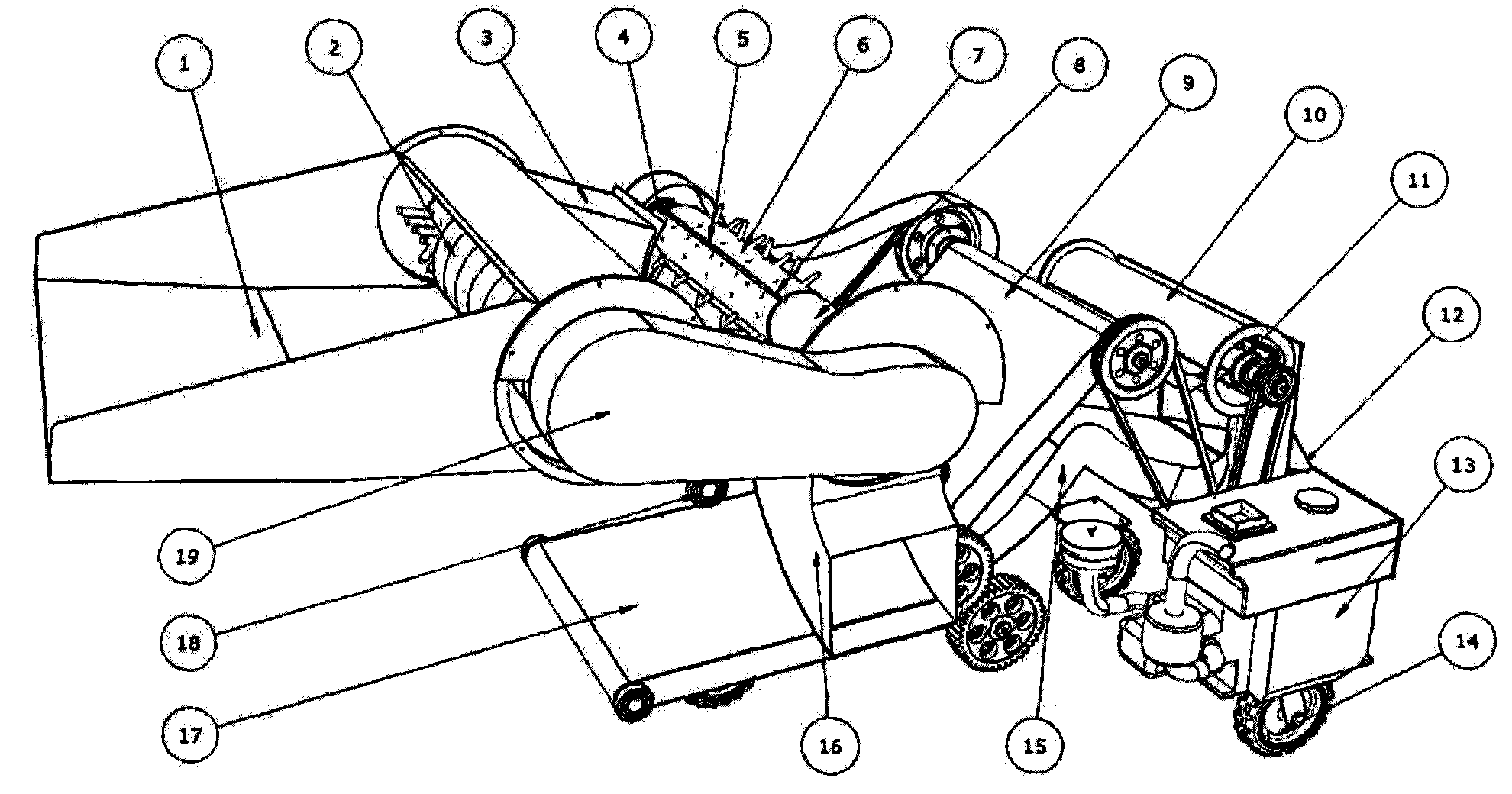

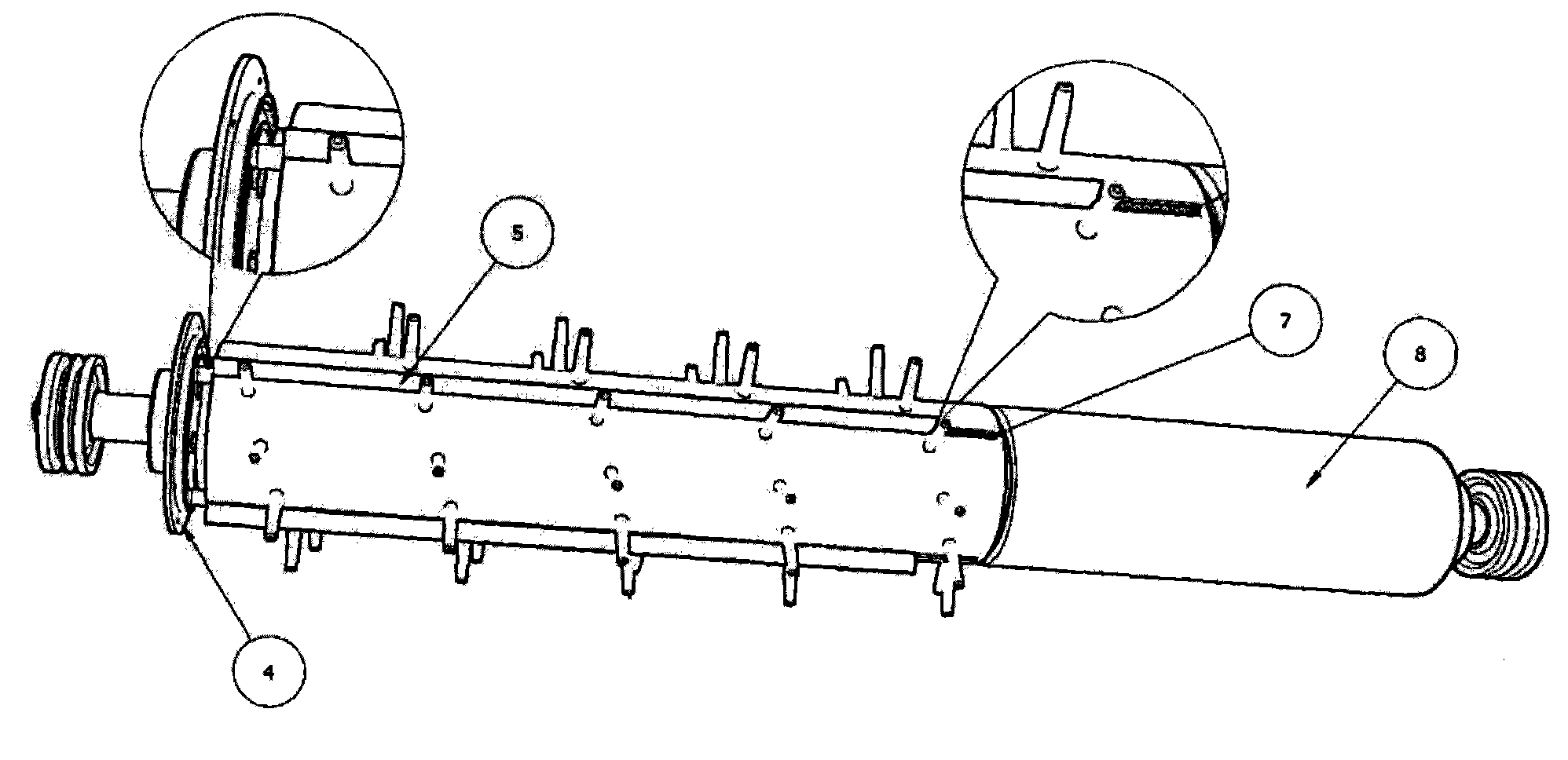

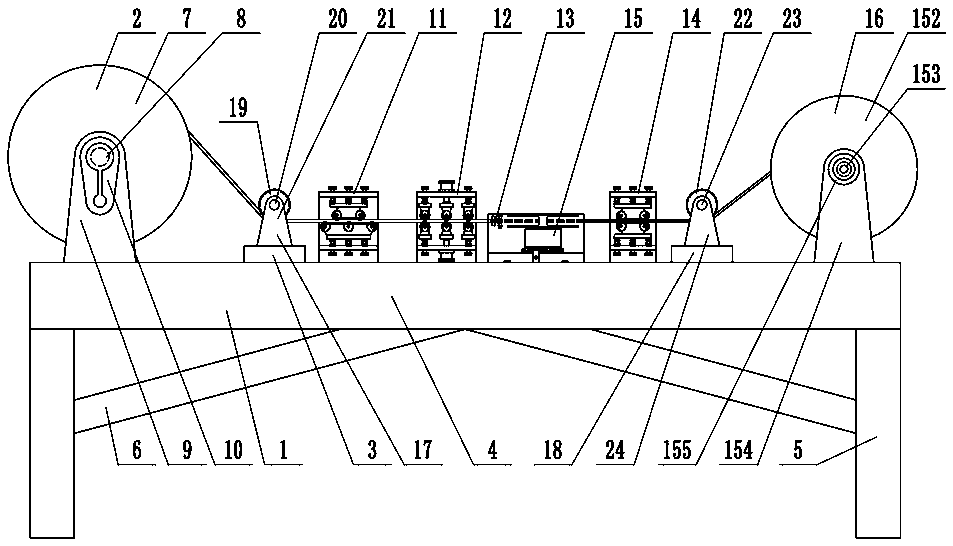

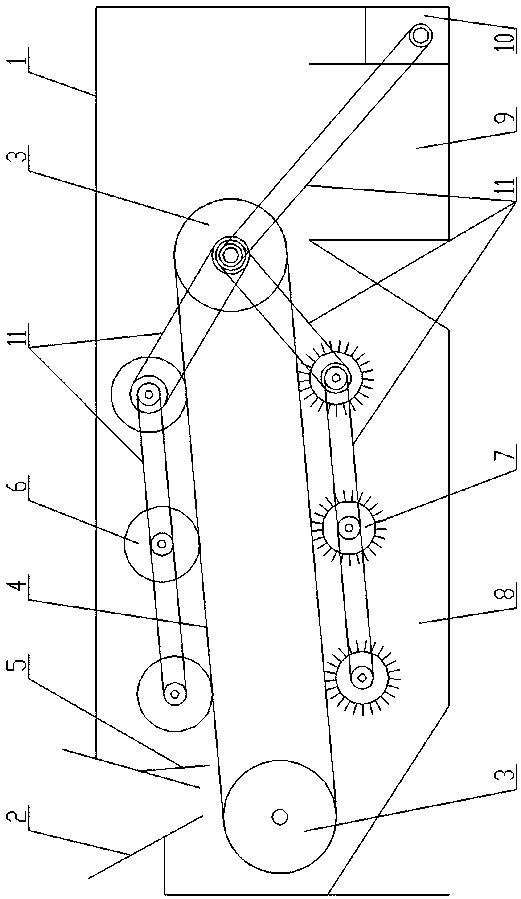

Small and medium-sized agricultural green pea pod picking machine

The invention provides a small and medium-sized agricultural green pea pod picking machine which can reduce manual work. The small and medium-sized agricultural green pea pod picking machine is composed of a machine frame (20), a feeding mechanism (2), a separation mechanism (6), a horizontal conveying belt (17), a slanting conveying belt (9), a vibrating screen (18), universal wheels (14), a fan (10) and a diesel engine (13). The feeding mechanism is provided with spiral blades, materials are fed into the feeding mechanism (2) by the axial force generated when the spiral blades rotate, seedlings and pods of the pea seedlings with pods are separated in the separation mechanism (6) under the effect of the centrifugal force, fallen pods are subject to purification through the vibrating screen (18) and the fan (10), and the seedlings are pushed out from the other end under the pushing of the axial force generated when spiral teeth rotate. The small and medium-sized agricultural green pea pod picking machine is reasonable and compact in structure, complete in functions, simple to operate, safe and reliable, can meet growth requirements of green peas in large and small areas, greatly improves the picking efficiency of green pea pods, reduces picking cost, is simple and practical, and reduces labor intensity of farmers while greatly improving production efficiency.

Owner:谢桂仁 +3

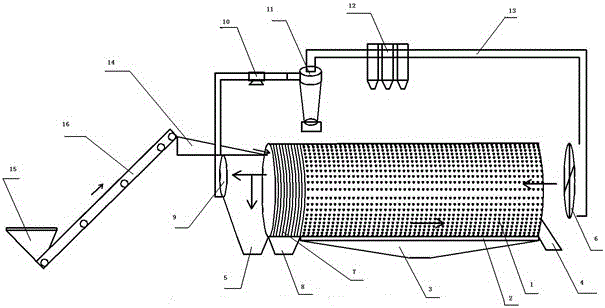

Spindle-shaped material tail removing machine

InactiveCN106584598ARealize mechanized tail removalAchieve uniformityGas current separationMetal working apparatusPulp and paper industryImpurity

The invention provides a spindle-shaped material tail removing machine which comprises a feeding mechanism, an impurity removal screening mechanism, a tail removing mechanism and a dust removal mechanism; the tail removing mechanism comprises a mesh tail removing rotary drum, a tail removing scraping plate located at the bottom of the outer side of the mesh tail removing rotary drum, and a tail receiving hopper which is connected to the bottom of the tail removing scraping plate in a supporting mode; and the tail end of the mesh tail removing rotary drum communicates with a discharging hopper. With the adoption of the spindle-shaped material tail removing machine, mechanical impurity removal, preliminary screening, tail removing and dust removal of spindle-shaped materials like radix pseudostellariae can be realized.

Owner:福建柘参生物科技研究股份有限公司 +3

Novel grain drying machine

InactiveCN111750614ADry fastUniform dischargeDrying gas arrangementsGrains dryingElectric machineryEngineering

The invention relates to the technical field of drying machines, in particular to a novel grain drying machine. The grain drying machine comprises a drying machine body, a fixing plate and a distribution and impurity removal device glidingly arranged on the left side of the fixing plate; the distribution and impurity removal device comprises a mounting plate, a vertical hopper, a horizontal hopperand a moving hopper; a No.1 rotating shaft, a No.2 rotating shaft, a No.3 rotating shaft and a No.4 rotating shaft are arranged on the side wall of the mounting plate; scattering rods are arranged atthe left part of the No.1 rotating shaft; buffering plates are arranged at the left part of the No.2 rotating shaft; a moving mechanism is arranged between the No.1 rotating shaft and the mounting plate; a No.1 motor is arranged at the right end of the No.3 rotating shaft, and a fan is arranged at the left end; a cam is arranged at the bottom end of the No.4 rotating shaft; the vertical hopper, the horizontal hopper and the moving hopper communicate with one another sequentially from top to bottom; and the vertical hopper is fixedly connected with the mounting plate through a connecting rod.According to the machine, impurities in grains can be removed, uniform discharging of the grains can be realized, quick drying of the grains is facilitated, and the practicability and the working efficiency of the machine are improved.

Owner:合肥麦稻之星机械有限公司

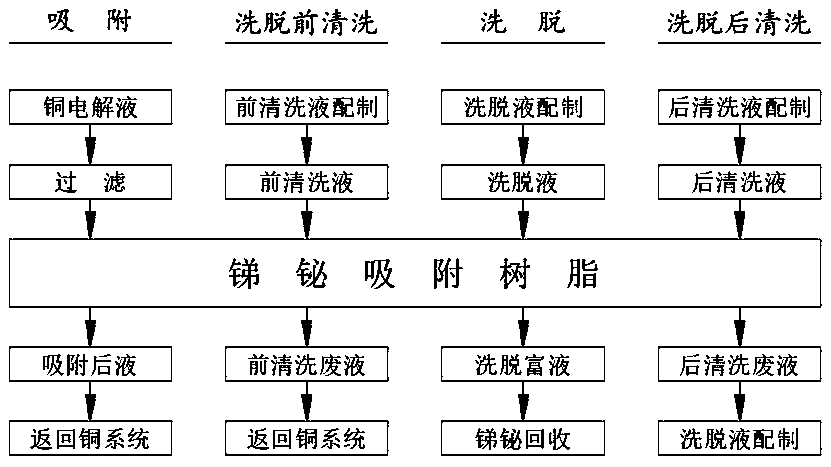

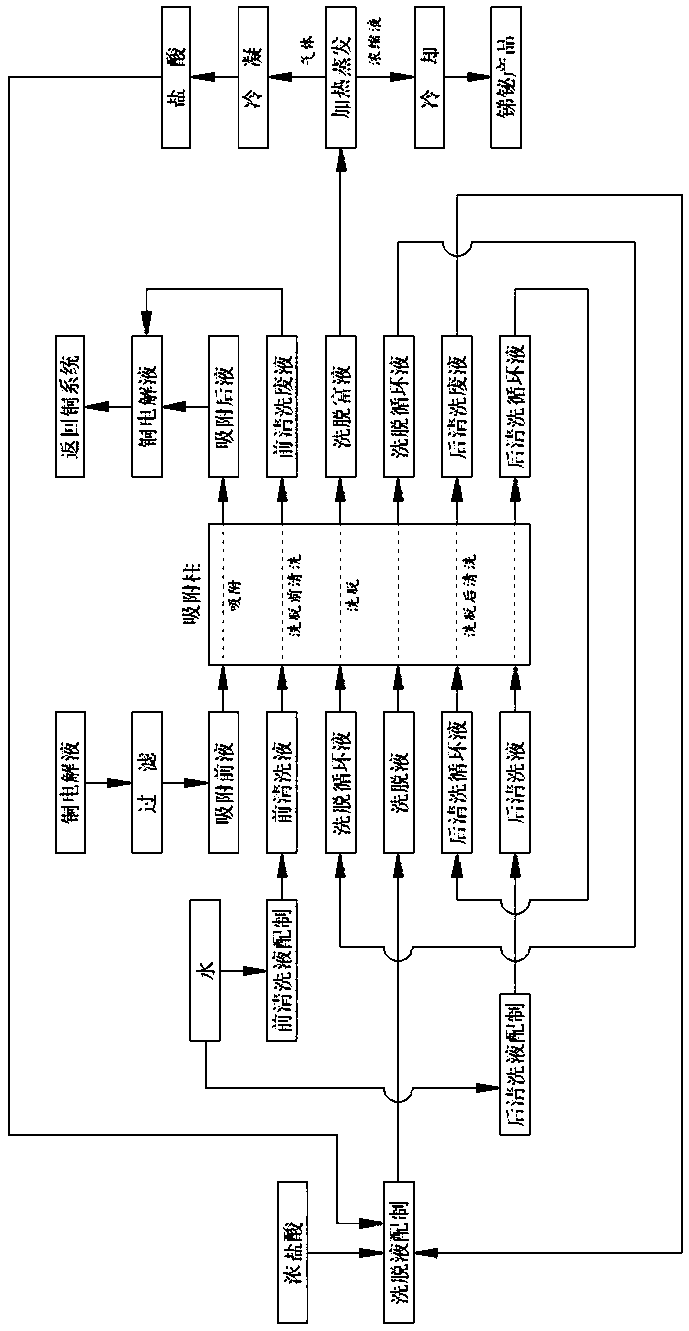

Antimony and bismuth recovery method

ActiveCN109055742AEfficient recyclingRealize impurity removalProcess efficiency improvementRecovery methodElution

The invention discloses an antimony and bismuth recovery method; and the method adopts an antimony and bismuth common elution process or an antimony or bismuth single elution process to elute antimonyand bismuth contained solution. The antimony and bismuth recovery method adopts the antimony and bismuth common elution process to treat the antimony and bismuth contained solution to realize antimony and bismuth recovery, and adopts the antimony or bismuth single elution process to treat the antimony and bismuth contained solution to realize single recovery of antimony and bismuth; and the two elution processes do not influence other components in the antimony and bismuth contained solution, and can synchronously realize decontamination of the antimony and bismuth contained solution. The method has the advantages of simple process, easy operation, low recovery cost, low waste liquid generation quantity, greenness and environmental protection, can effectively recover antimony and bismuthin the antimony and bismuth contained solution, achieves higher use value and application prospect, is suitable for large-scale recovery of antimony and bismuth, and facilitates industrial treatment.

Owner:CHANGSHA HASKY ENVIRONMENTAL PROTECTION TECH DEV CO LTD

Deerhorn glue walnut cake, and preparation method thereof

InactiveCN107397185AQuick breakdownPromote absorptionFood extractionFood ingredient as mouthfeel improving agentSUGAR/WATERRefrigeration

The invention relates to a deerhorn glue walnut cake, and a preparation method thereof. The deerhorn glue walnut cake is prepared from, by mass, 45 to 55 parts of deerhorn glue, 35 to 40 parts of walnut kernel, 40 to 45 parts of black sesame, 45 to 50 parts of rock sugar A, 45 to 50 parts of yellow rice wine A. Deerhorn glue is prepared via following steps: deer horn is smashed and fermented, and is heated to 105 to 120 DEG C at sealing conditions; stirring extraction is carried out for 15 to 20h, an obtained extract is subjected to crude filtering and fine filtering, and is subjected to concentrating in an opening-type equipment, wherein the contact area of an obtained glue solution with the air, concentrating temperature, and water content are controlled, when water content reaches a certain value, appropriate amounts of soybean oil, yellow rice wine, and rock sugar water are added; concentrating is carried out continuously, obtained glue is collected, is delivered into a container, and is subjected to refrigeration, airing, and drying so as to obtain deerhorn glue. The deerhorn glue walnut cake is reasonable in formula design, and is convenient for absorption.

Owner:HUNAN DONGJIAN PHARMA CO LTD

Purifying and discharging device for flue gas desulfurization and denitrification

InactiveCN114534472ARealize the cooling effectRealize impurity removalGas treatmentDispersed particle filtrationThreaded pipeFlue gas

The invention discloses a purification and emission device for flue gas desulfurization and denitrification, and relates to the technical field of waste gas treatment. The device comprises a filter assembly and a purification box body, a threaded pipe penetrates through the peripheral side surface of the branch pipe; sliding rods are in sliding fit with the inner walls of the branch pipes; the input end of the infusion pump is rotationally matched with a connecting pipe; an annular liquid storage box is fixedly mounted at the top in the purification box body; atomizing nozzles are distributed on the bottom face of the annular liquid storage box in a circumferential array mode. Flue gas subjected to cooling and impurity removal is introduced into a flue gas header pipe and then enters all branch pipes to extrude a sliding rod, so that an L-shaped gas inlet groove communicates with a threaded pipe, the flue gas enters a sodium hydroxide solution in a purification box, a driving motor is started to drive a connecting pipe to rotate, and therefore a stirring assembly is driven to rotate to stir absorption liquid; the purpose of uniformly mixing the absorption liquid is achieved; clO2 is introduced into the top in the purification box body through the gas inlet pipe, NO is oxidized into NO2 by ClO2, then NO2 is reduced into N2 by using a Na2SO3 aqueous solution, and desulfurization and denitrification are synchronously carried out.

Owner:汪宣坤

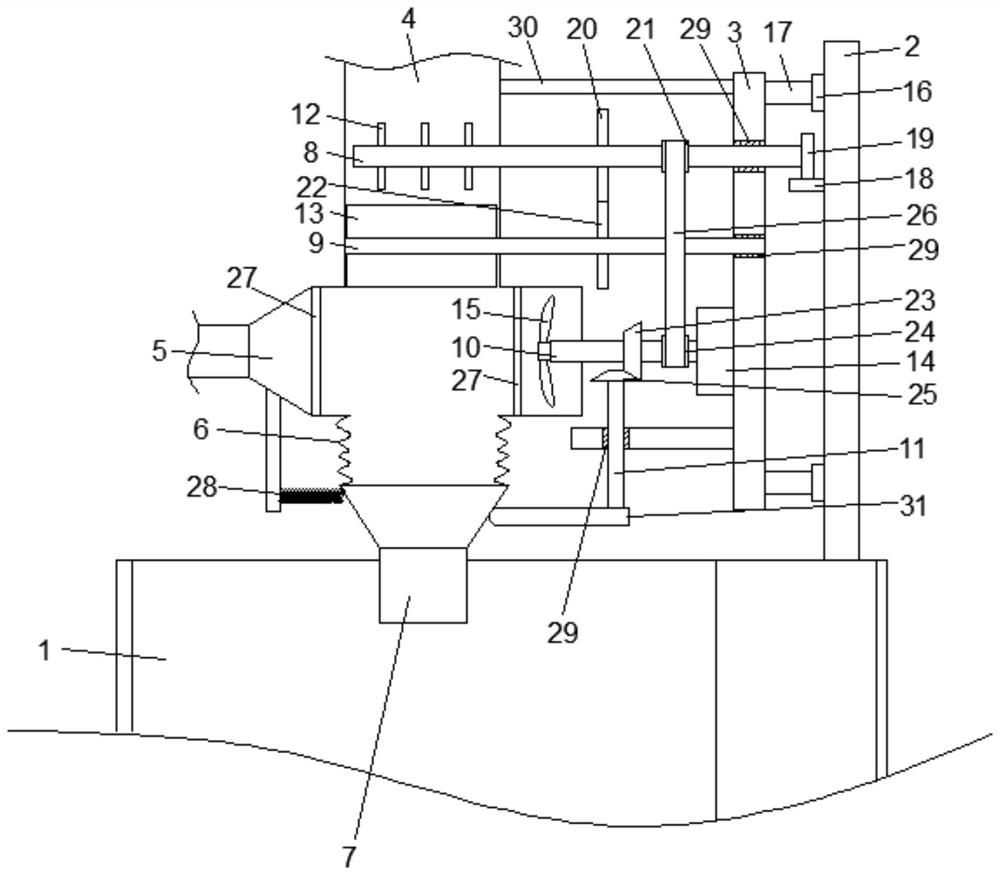

Efficient feed production line

ActiveCN113455680AEasy to produceFacilitates flexible productionConveyorsFeeding-stuffProduction lineProcess engineering

The invention provides an efficient feed production line. The production line comprises an automobile incoming material conveying and impurity removing mechanism, a cake meal conveying and impurity removing mechanism and a powder conveying and impurity removing mechanism, and the discharging end of the automobile incoming material conveying and impurity removing mechanism and the discharging end of the cake meal conveying and impurity removing mechanism are both connected with a feeding port of a crushing mechanism; discharging ports of the crushing mechanism and the powder conveying and impurity removing mechanism are connected with a feeding port of a batching bin through a first distributor, a discharging port of the batching bin is connected with a mixing machine, a small material feeding port is formed in the mixing machine, the mixing machine is connected with a mixing elevator, the mixing elevator is sequentially connected with a semi-finished product bin, a granulator, a cooler, a seventh bucket elevator, a classifying screen and a finished product bin in the feed conveying direction, and a waste material articulated chute is arranged between the classifying screen and the granulator. According to the automatic feed production line, automatic transfer of materials among all procedures is achieved, manual participation is not needed, the materials are prevented from being polluted, loss is small, efficiency is high, the production line is suitable for processing of various feeds, and flexible production of the feeds is facilitated.

Owner:河南广安生物科技股份有限公司

Impurity separation and screening device for producing carbon black

PendingCN111974489AImprove product qualityAvoid material wasteGrain treatmentsCarbon blackGrinding mill

The invention provides an impurity separation and screening device for producing carbon black. The impurity separation and screening device comprises a box body, a feeding hopper is arranged in the middle of the upper end of the box body, and a grinding mechanism, a screening mechanism and an impurity separation mechanism are arranged on the lower part of the feeding hopper and in the box body from top to bottom in sequence. A material entering the box body is grinded by the grinding mechanism, then screened by the screening mechanism, subjected to impurity removal through the impurity separation mechanism, and discharged from the bottom of the box body. The impurity separation and screening device is provided with the screening mechanism and the impurity separation mechanism, and the screening mechanism and the impurity separation mechanism interact with each other to adsorb and clean metal impurities in the material while the material is screened, so that impurity removal during screening is achieved, and the product quality is improved.

Owner:嘉峪关大友嘉能精碳科技股份有限公司

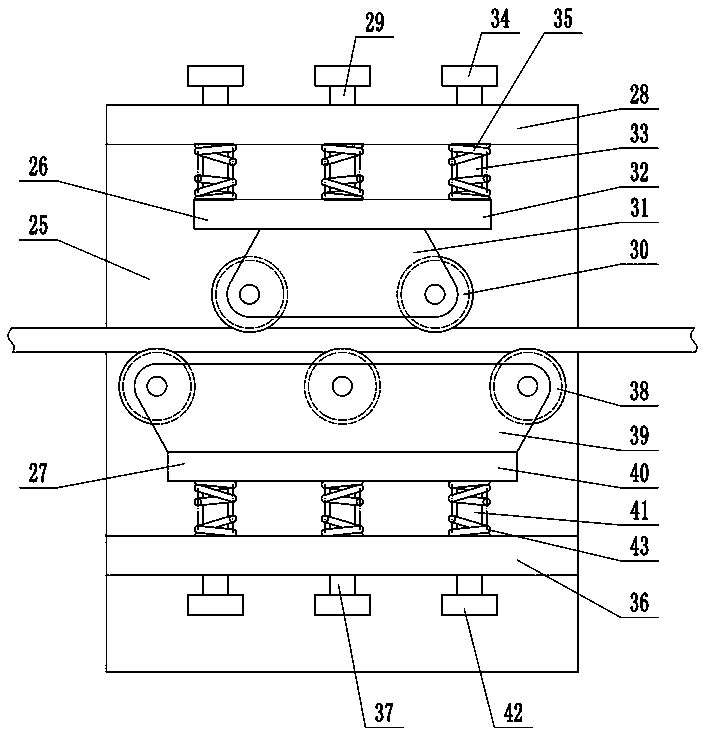

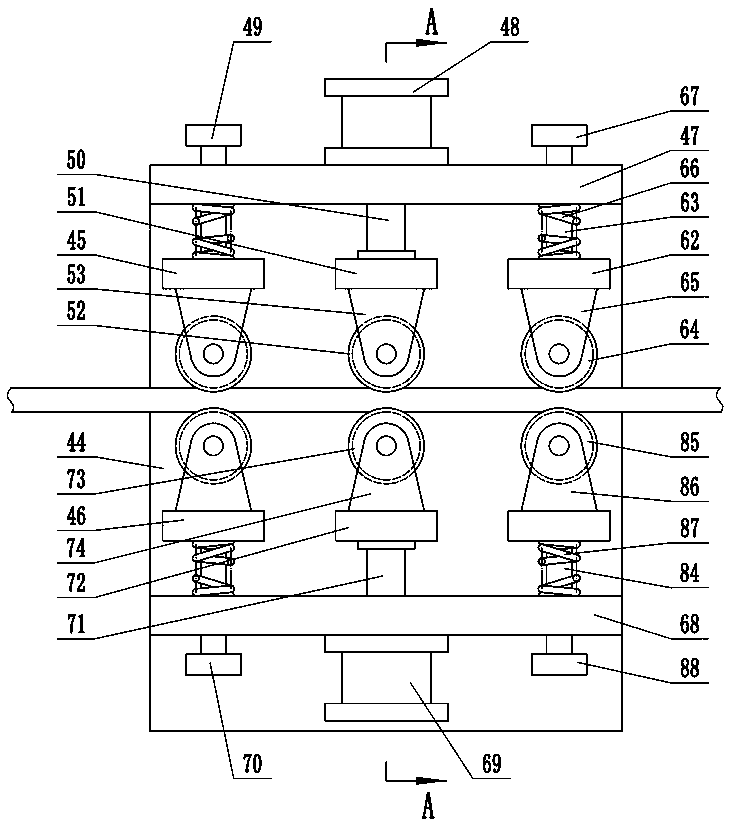

Wire stripping machine

ActiveCN111477416AGood for continuous cuttingGuaranteed continuityBasic electric elementsElectronic waste recyclingPower cableElectrical conductor

The invention provides a wire stripping machine, and belongs to the technical field of power cables. The wire stripping machine comprises a wire stripping rack, a wire withdrawing device, a guiding device, a straightening device, a wire cutting device, a wire stripping device, an impurity removing device, an insulating protection layer recycling device and a metal conductor recycling device, wherein the straightening device comprises an upper straightening mechanism and a lower straightening mechanism, the upper wire cutting mechanism and the lower wire cutting mechanism of the wire cutting device are symmetrically arranged on a wire cutting bracket up and down, the wire stripping device comprises a front wire stripping mechanism and a rear wire stripping mechanism, and the upper impurityremoving mechanism and the lower impurity removing mechanism of the impurity removing device are symmetrically arranged on an impurity removing bracket up and down. According to the invention, the assembled disc-type wire cutting knife is adopted, so that continuous cutting of an insulating protective layer is facilitated, knife breaking is effectively avoided, and the continuity of wire strippingis ensured; and the insulating protection layer recycling device and the metal conductor recycling device are arranged, so that synchronous classified recovery of a plastic protective layer and a metal conductor can be realized, and continuous wire stripping is ensured.

Owner:嘉兴市平安电气工程有限公司

Preparation method for inulin

ActiveCN111057166ARealize impurity removalAchieve decolorizationChromatographic separationActivated carbon

The invention discloses a preparation method for inulin, and belongs to the technical field of natural extract extraction and refining. The preparation method comprises six steps of pretreatment, extraction, flocculation, filtration, concentration and separation. According to the method, the equipment utilization rate is increased, activated carbon is added into a crude extract in the flocculationprocess, meanwhile, the impurity removal, decoloration and debitterizing processes of an extract are achieved, the production steps are simplified, the energy consumption is reduced, the step of desalting by using ion exchange resin before chromatographic separation is omitted, and the problem of treatment of resin regenerated sewage is effectively solved.

Owner:CHENGUANG BIOTECH GRP CO LTD

Adhesive impurity removing device for cleaning oats

The invention relates to an adhesive impurity removing device for cleaning oats. The device comprises a shell; a feed hopper is arranged at the top of the shell; a conveying belt is arranged in the shell; a material scraping plate is arranged above the conveying belt; materials are distributed on the conveying belt in an equal-thickness layer through contact of a bottom edge of the material scraping plate and the materials; a layer of cotton material is adhered to a surface of the conveying belt; a plurality of rubber rollers are arranged above the conveying belt; a plurality of brush rollersare arranged below the conveying belt; and an outer peripheral surface of each rubber roller is pressed on the upper surface of the conveying belt. Impurities in the materials are adhered to the uppersurface of the conveying belt by extrusion of the rubber rollers and cooperation of the cotton material, so that oat grains in the materials slide off one side of the conveying belt along a conveyingdirection, and the impurities are conveyed to a lower surface of the conveying belt. The impurities fall off from the lower surface of the conveying belt when the brush rollers rotate to brush the lower surface of the conveying belt. An impurity collecting box and a grain collecting box are arranged on a bottom surface of the shell; and a motor for driving belt pulleys, the rubber rollers and thebrush rollers to synchronously rotate is also arranged on the bottom surface of the shell.

Owner:HENAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com