Antimony and bismuth recovery method

A technology for recovering antimony-bismuth and antimony-bismuth, which is applied in the field of recycling antimony-bismuth, can solve the problems of difficult EDTA wastewater treatment, limited number of cycles, and high cost of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

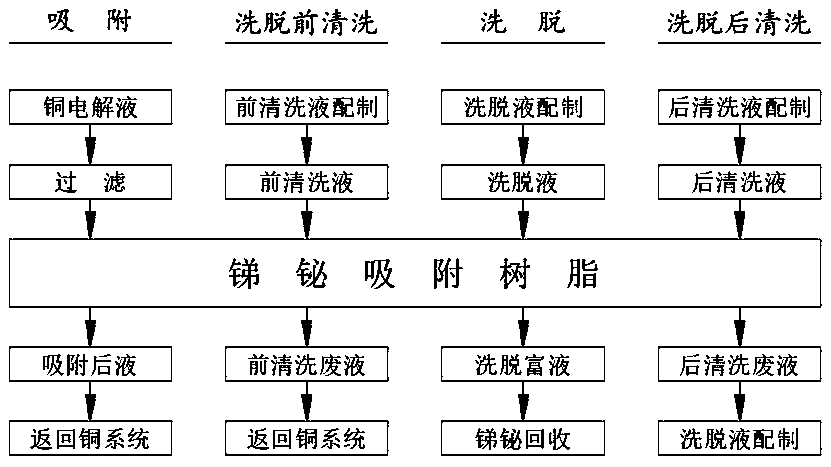

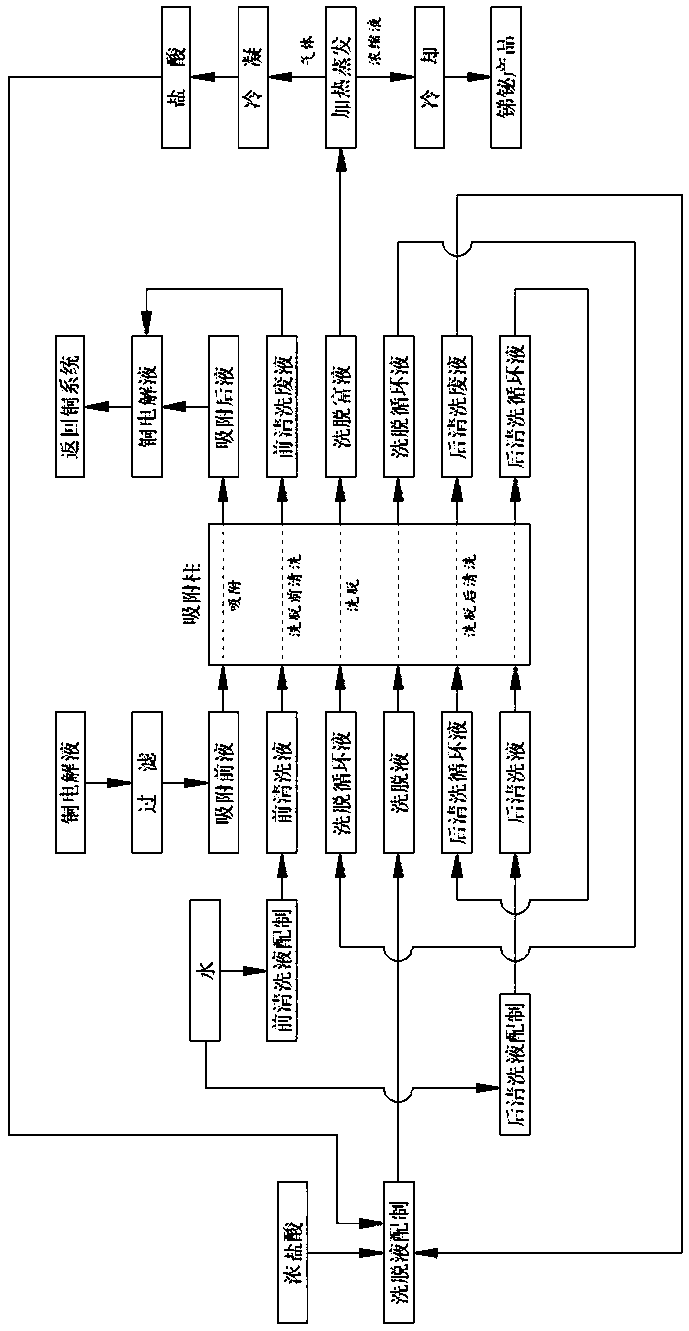

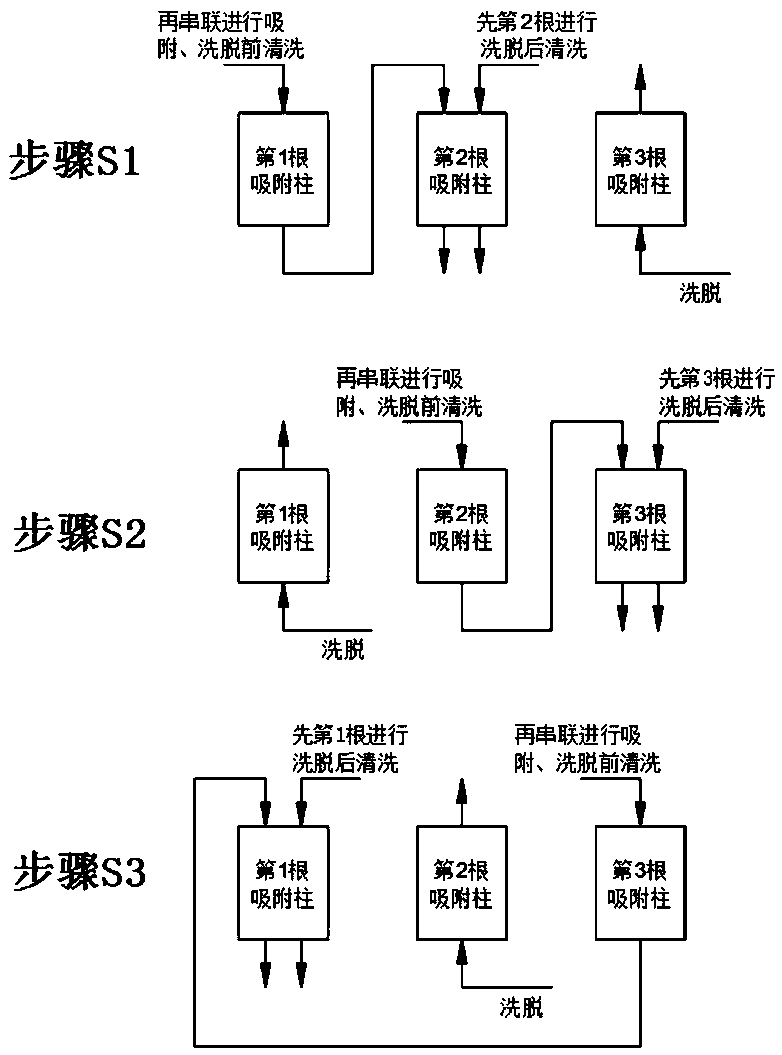

[0071] A method for reclaiming antimony-bismuth, adopting antimony-bismuth co-elution process, such as figure 1 and figure 2 Shown, this antimony-bismuth co-elution process comprises the following steps:

[0072] (1) Taking the copper electrolyte of a copper smelter as a solution containing antimony and bismuth, its composition and concentration of each composition are shown in Table 1.

[0073]

[0074] Filter the above-mentioned copper electrolyte through a filter membrane with a filtration precision (that is, the pore size of the filter membrane) of 1 μm, and then pass the filtered copper electrolyte through 200 mL of antimony-bismuth adsorption resin (phosphoramidate chelate) at a speed of 10 BV / h Resin), using the antimony-bismuth adsorption resin to adsorb the antimony and bismuth in the copper electrolyte until the antimony-bismuth adsorption resin reaches adsorption saturation. The adsorbed liquid produced during the adsorption process was used to return to the c...

Embodiment 2

[0096] A method for reclaiming antimony and bismuth, adopting a separate elution process of antimony and bismuth, such as figure 1 and Figure 4 Shown, this antimony bismuth separate elution process comprises the following steps:

[0097] (1) Taking the copper electrolyte of a copper smelter as a solution containing antimony and bismuth, its composition and concentration of each composition are shown in Table 1. The copper electrolyte in Example 1 is filtered through a filter membrane with a filtration accuracy of 1 μm, and then the filtered copper electrolyte is passed through 200 mL of antimony-bismuth adsorption resin (phosphoric acid amino acid chelating resin) at a speed of 10 BV / h, using The antimony-bismuth adsorption resin adsorbs the antimony and bismuth in the copper electrolyte until the antimony-bismuth adsorption resin reaches adsorption saturation. The antimony-bismuth post-adsorption liquid generated during the adsorption process is used to return to the coppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com