Adhesive impurity removing device for cleaning oats

An oatmeal cleaning technology, which is applied in the direction of cleaning devices, transportation and packaging, conveyor objects, etc., can solve the problems of grain loss, complicated impurity removal, low impurity removal rate, etc., and achieve the effect of uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

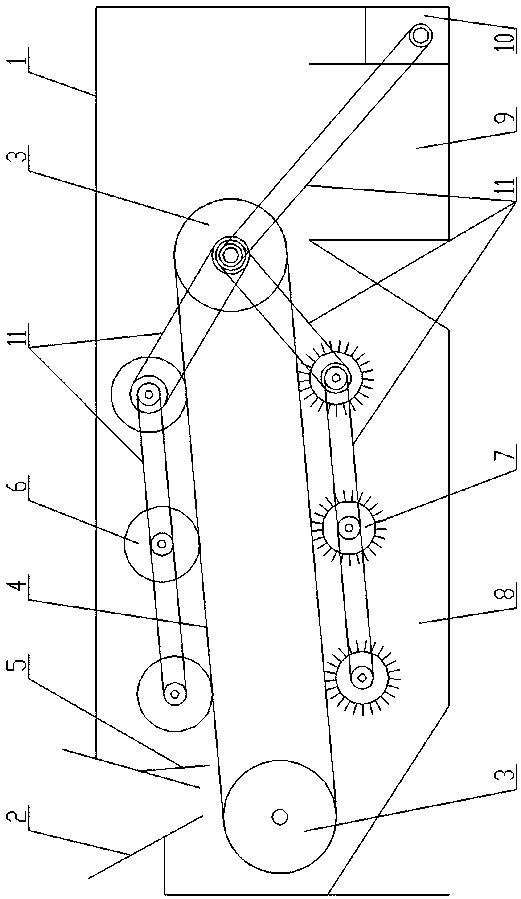

[0014] Referring to the accompanying drawings, the specific implementation is as follows:

[0015] An adhesive type impurity removal device for cleaning oats, comprising a housing 1, a feed hopper 2 is installed on the top of the housing 1, and two pulleys 3 are provided in the housing 1 for receiving the bottom of the feed hopper 2 Conveyor belt 4 for falling materials, above the conveyor belt 4 is provided with a scraper 5, the scraper 5 is located on the side of the feed hopper 2 along the conveying direction of the conveyor belt 4, and contacts the material through the bottom edge of the scraper 5 The material is distributed on the conveyor belt 4 to form layers of equal thickness.

[0016] The surface of the conveyor belt 4 is attached with a layer of cotton material, and the top of the conveyor belt 4 is provided with a plurality of rubber rollers 6. There are a plurality of brush rollers 7, the axes of the rubber roller 6 and the brush roller 7 are all parallel to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com